- Week 1 : Project Management

- Week 2 : Computer-aided

- Week 3 : Computer Controlled Cutting

- Week 4 : Embedded Programming

- Week 5 :3D Scanning and Printing

- Week 6 : Electronic Design

- Week 7 : Computer Controlled Machining

- Week 8 : Electronics Production

- Week 9 : Input Devices

- Week 10 : Output Devices

- Week 11 : Networking and Communication

- Week 12 : Mechanical Design and Machine Design

- Week 13 : Midterm Review

- Week 14 : Molding and Casting

- Week 15 : Interface and Application Programming

- Week 16 : System Integeration

- Week 17 : Wildcard Week

- Week 18 : Applications and Implications, Project Development

- Week 19 : Invention, Intellectual property and Income

- Week 20 : FInal Project Requirements

Week 18 : Applications and Implications, Project Development

Objectives of the Week

Scope of the Project

Line Bot is an autonomous line-following robot designed to detect and follow a black path on a white surface using an infrared sensor array. The robot integrates custom electronics, embedded programming, and a laser-cut acrylic structure to create a reliable and efficient educational platform. The goal is to demonstrate real-time motor control and sensor integration using a compact and well-structured system.

Project Plan

Tasks Completed

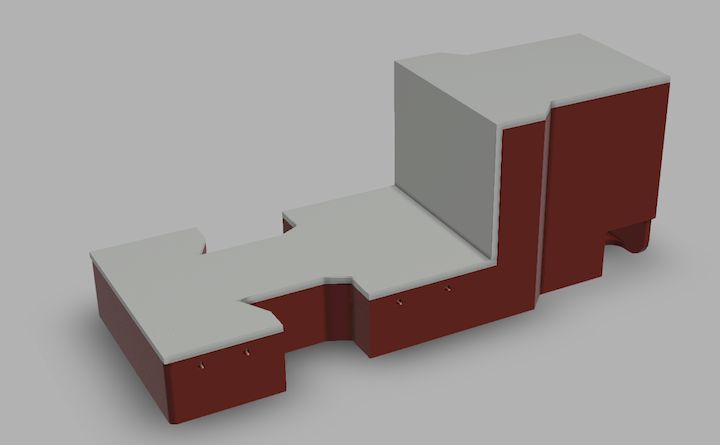

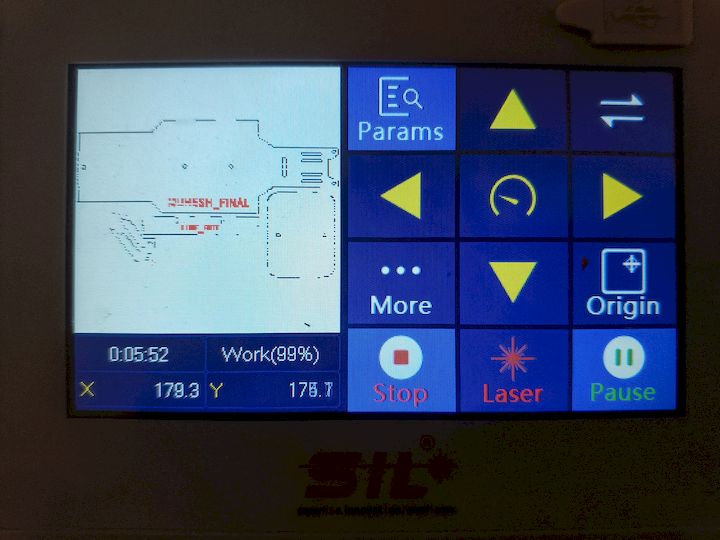

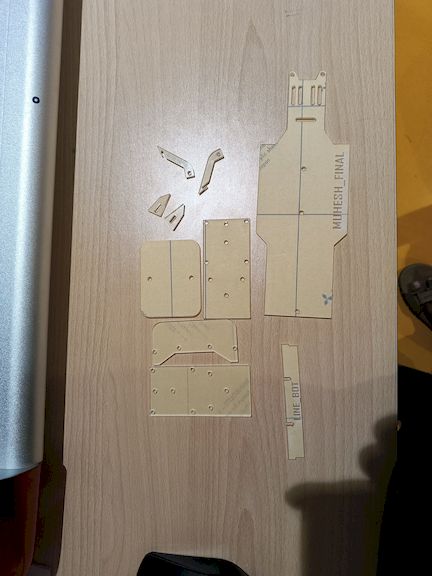

- Designed and laser-cut the acrylic chassis for the bot.

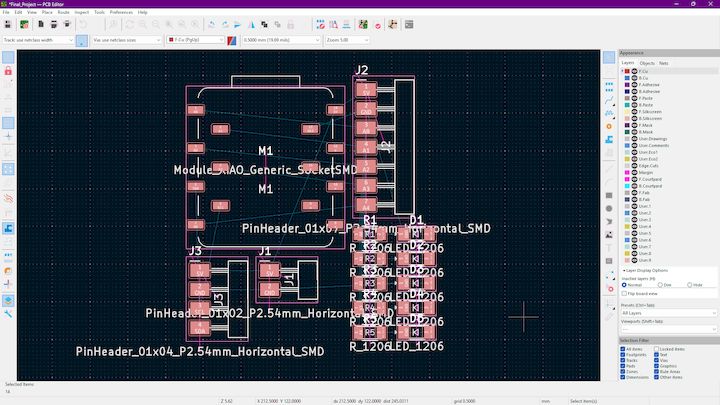

- Developed and fabricated a custom PCB for motor and sensor connections.

- Integrated XIAO ESP32-C3 with L298N motor driver and IR sensor array.

- Programmed line-following logic with PWM-based motor control.

- Tested the bot for basic navigation and response accuracy.

Tasks Remaining

- Final testing under different lighting conditions and path types.

- Optimize movement for smoother turns and straight-line stability.

- Finalize OLED display for status updates and debugging information.

- Prepare documentation, video presentation, and evaluation material.

Bill of Materials (BOM)

| # | Item | Description | Qty | Unit Cost (₹) | Total (₹) |

|---|---|---|---|---|---|

| 1 | XIAO ESP32-C3 | Microcontroller Unit | 1 | 5.50 | 5.50 |

| 2 | Fabricated PCBs | Motor + Sensor Interface | 2 | 2.00 | 4.00 |

| 3 | Header Pins & Wires | Male/Female, Solder Wires | 1 set | 1.00 | 1.00 |

| 4 | BO Motors + Wheels | Plastic Gear Motors with Wheels | 2 sets | 2.50 | 5.00 |

| 5 | L298N Motor Driver | Dual H-Bridge Driver | 2 | 2.00 | 4.00 |

| 6 | Connector Wires + JST | 2/7-pin Wires and Terminals | 2 sets | 1.00 | 2.00 |

| 7 | OLED Display | 0.96" I2C Monochrome | 1 | 3.00 | 3.00 |

| 8 | 5-Line Sensor Array | IR Line Detection Module | 1 | 4.00 | 4.00 |

| 9 | Acrylic Sheet | 100x100 mm Chassis Base | 1 | 1.50 | 1.50 |

| 10 | Line Marker Tape | Black Tape for Path | 1 roll | 0.50 | 0.50 |

Total Estimated Cost: ₹30.50 (~$37)

Project Summary

Line Bot is a fully integrated, line-following robot that combines sensing, actuation, and embedded control in a small form factor. The bot uses an ESP32-C3 to interpret signals from a 5-line IR sensor array and adjust motor speeds via an L298N motor driver using PWM. A laser-cut acrylic chassis houses the electronics and mechanical parts. An OLED display provides real-time sensor feedback and status display. All systems are powered by a battery pack and connected via JST headers for easy maintenance.

System Capabilities

What Will It Do?

- Follow a predefined black path on a white background using IR sensors.

- Adjust motor speeds based on real-time sensor input to stay on track.

- Display system and sensor status on an onboard OLED display.

- Operate wirelessly with efficient battery management.

Who Has Done What Beforehand?

Line-following robots have been widely implemented in both academic and hobbyist contexts. I reviewed projects from Fab Academy archives and YouTube tutorials to understand effective sensor layouts, motor driving techniques, and PID control. My approach focuses on integrating a compact ESP32-based solution with custom PCBs and display modules for enhanced feedback.

What Will You Design?

- Custom PCB for sensor and motor integration.

- Chassis design using 2D CAD for laser cutting.

- Firmware for reading sensor data and executing motor logic.

Final Structure

Laser Cutting Process

Materials, Sources, and Cost

What Materials and Components Will Be Used?

- ESP32-C3, IR sensor array, L298N motor driver

- BO motors, OLED display, JST connectors

- Laser-cut acrylic chassis and basic hardware

Where Will They Come From?

Components were sourced from Robu.in, local hardware shops, and the Fab Lab inventory. PCB fabrication and laser cutting were done in the Fab Lab.

How Much Will They Cost?

Total estimated cost is ₹30.50 (~$37), including electronics and fabrication materials.

Processes Used

- 2D CAD and laser cutting (acrylic chassis)

- PCB design using KiCad and in-house milling

- Embedded programming with Arduino framework

- Soldering and system assembly

- Testing and debugging for sensor accuracy and motor response

Evaluation Criteria

- Bot must follow the path accurately with minimal drift

- OLED should display real-time updates

- All files and documentation are original and complete

- System must demonstrate modular and repairable design

Open Questions and Learnings

What Questions Need to Be Answered?

- Can line-following be improved using PID tuning?

- How does lighting or surface quality affect sensor performance?

- Is the system expandable for obstacle avoidance or wireless control?

What Has Worked?

- IR sensor array accurately detects line edges

- ESP32 PWM control delivers responsive motor behavior

- OLED provides helpful debugging information

What Hasn’t?

- Initial chassis balance issues affected stability

- Sensor jitter under poor lighting required filtering

What Will Happen When?

- Final field testing: Within 2 days

- Documentation and video editing: This weekend

- Final presentation and submission: Before the project deadline

What Have You Learned?

- How to integrate electronics, mechanics, and software effectively

- Importance of system-level debugging and early testing

- Hands-on knowledge of ESP32, PWM, IR sensors, and embedded systems

- How to plan and manage a full project lifecycle in a Fab Lab context