#16 WildCard

This week I tried Wood Milling

Assignment

- Design and produce something with a digital process: Wood Milling

(incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. - Other processes

Outcomes

What did I do this week: Wood Milling

Requirements

Process: 3D Wood Milling

Requirements:

- To cut out the wood while milling. Set up optimal paths for this purpose.

- Smooth finish

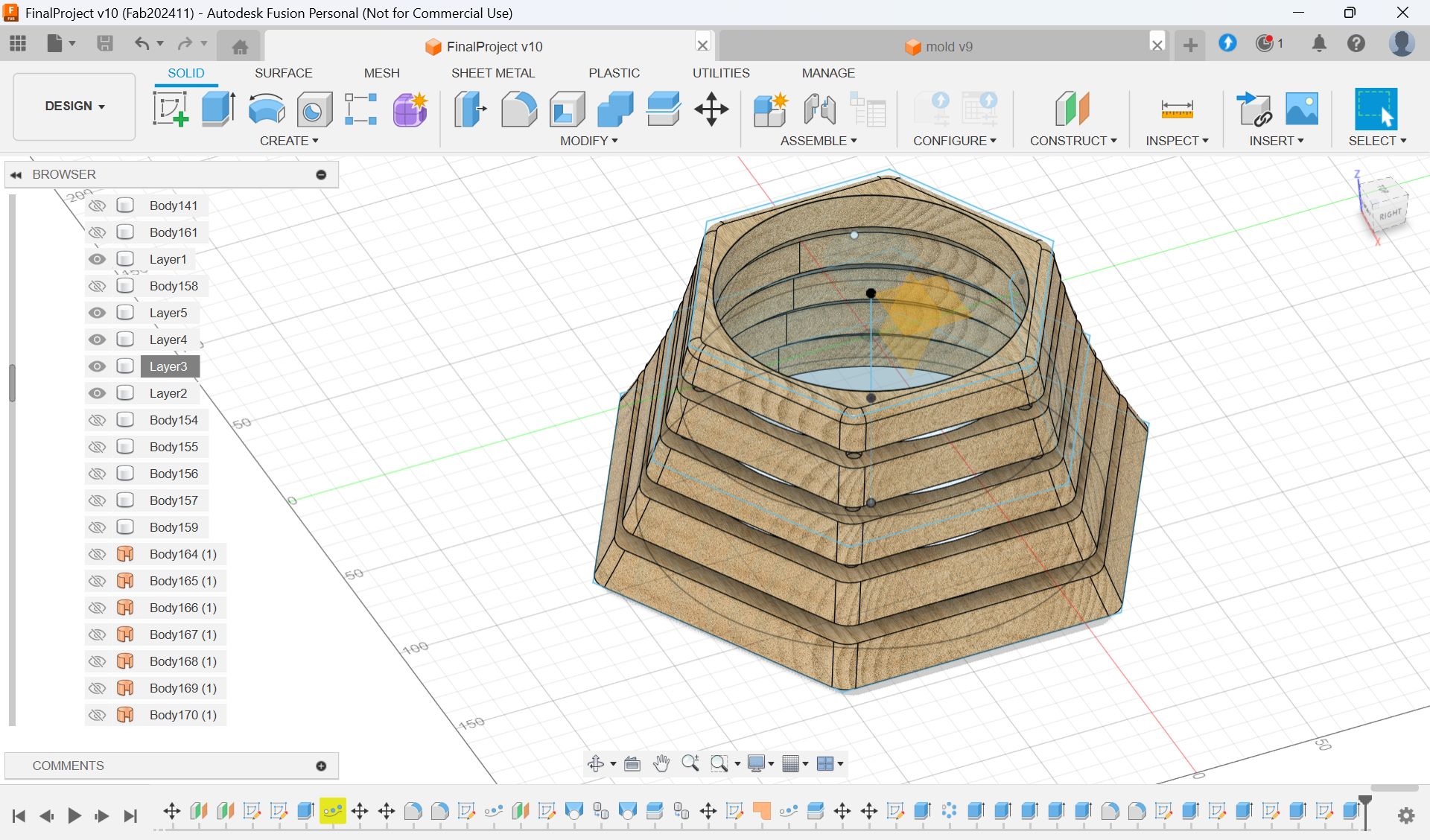

Design (Fusion)

Design requirement: to cut a smooth finished block out from a single piece of wood.

Initially, I was going to make a box shape and cut it out from a block of wood,

However,

- It would be a waste to dig out the entire center parts of wood (= unusable later)

- Digging takes too much time

- It is difficult to find a large block of wood

For these reasons, I modified the design to combine several wooden boards.

In addition, due to the problems of heat exhaust and image projection of the projector,

we considered a method that would have a good design but also leave a gap between

the projector and the projector.

As a result, the following design was obtained.

As for the parts connecting these trees, I tried to use CNC machining at first, but it

was too thin to cut out, so I decided to use laser cutting.

*Design of the connection part

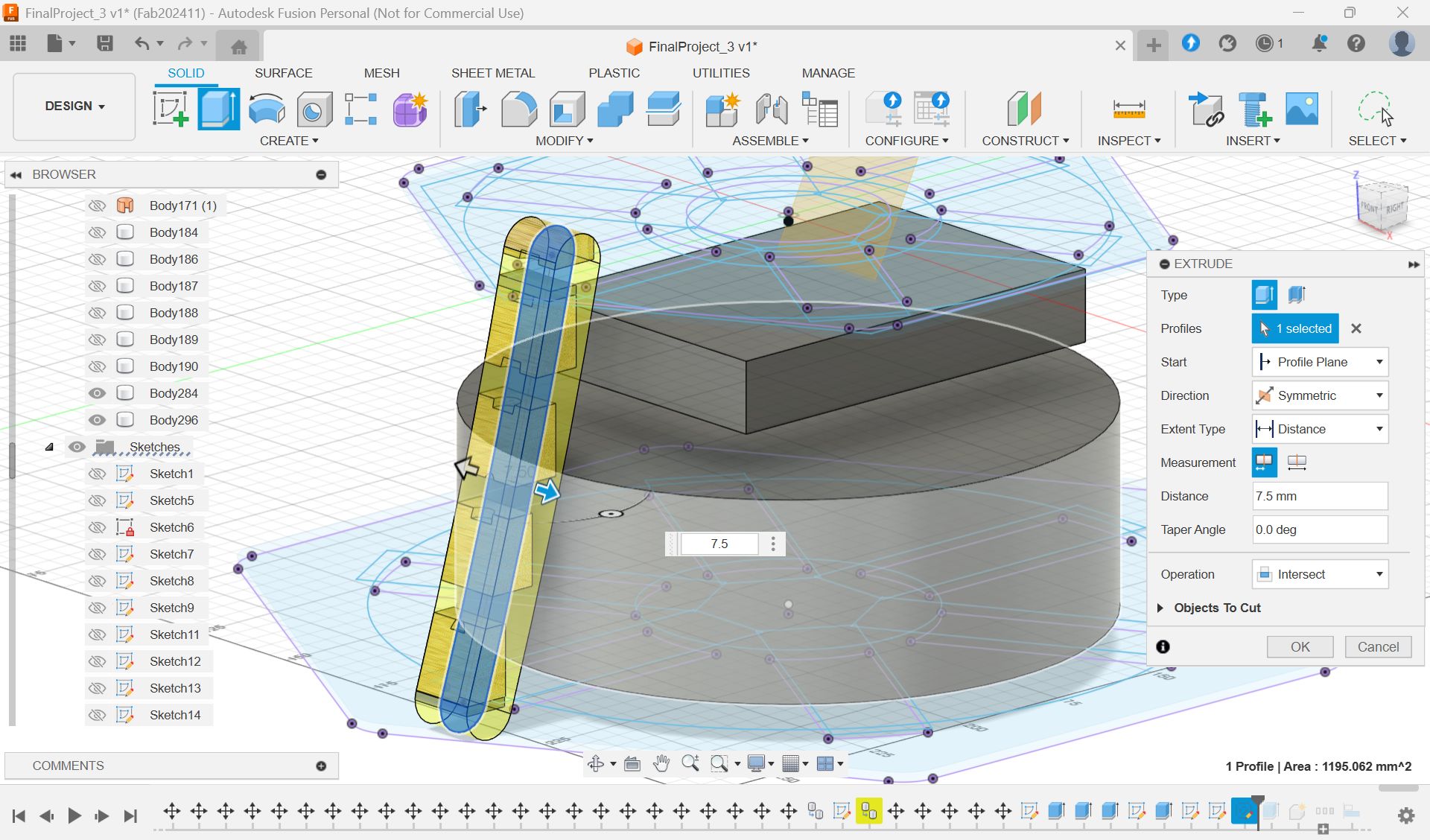

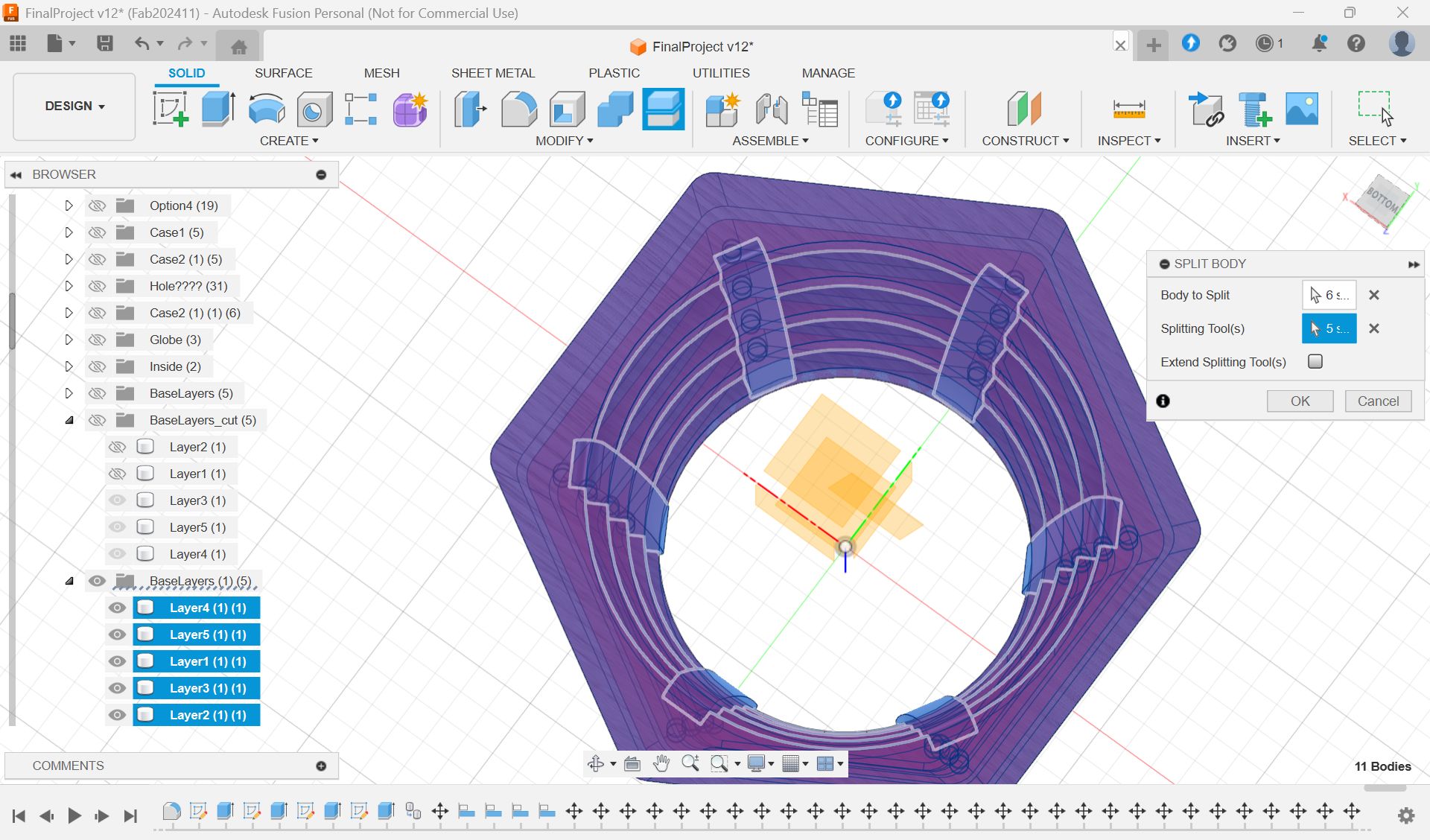

Tool Path

Path requirement: Set up a tool path to cut out a block from a piece of wood while

cutting it.

In this process, I had the most difficulty in finding the best way to create the tool

path suitable for the above.

Since I needed to cut out the tree, not just dig it out, I spent a lot of time trying

to figure out how it should be set up.

Fusion or VCarve?

I couldn't find documentation to do both milling and cropping, so I went back and forth

between the two softwares to find a way to set it up successfully. As a result, I

used VCarve to set up the settings.

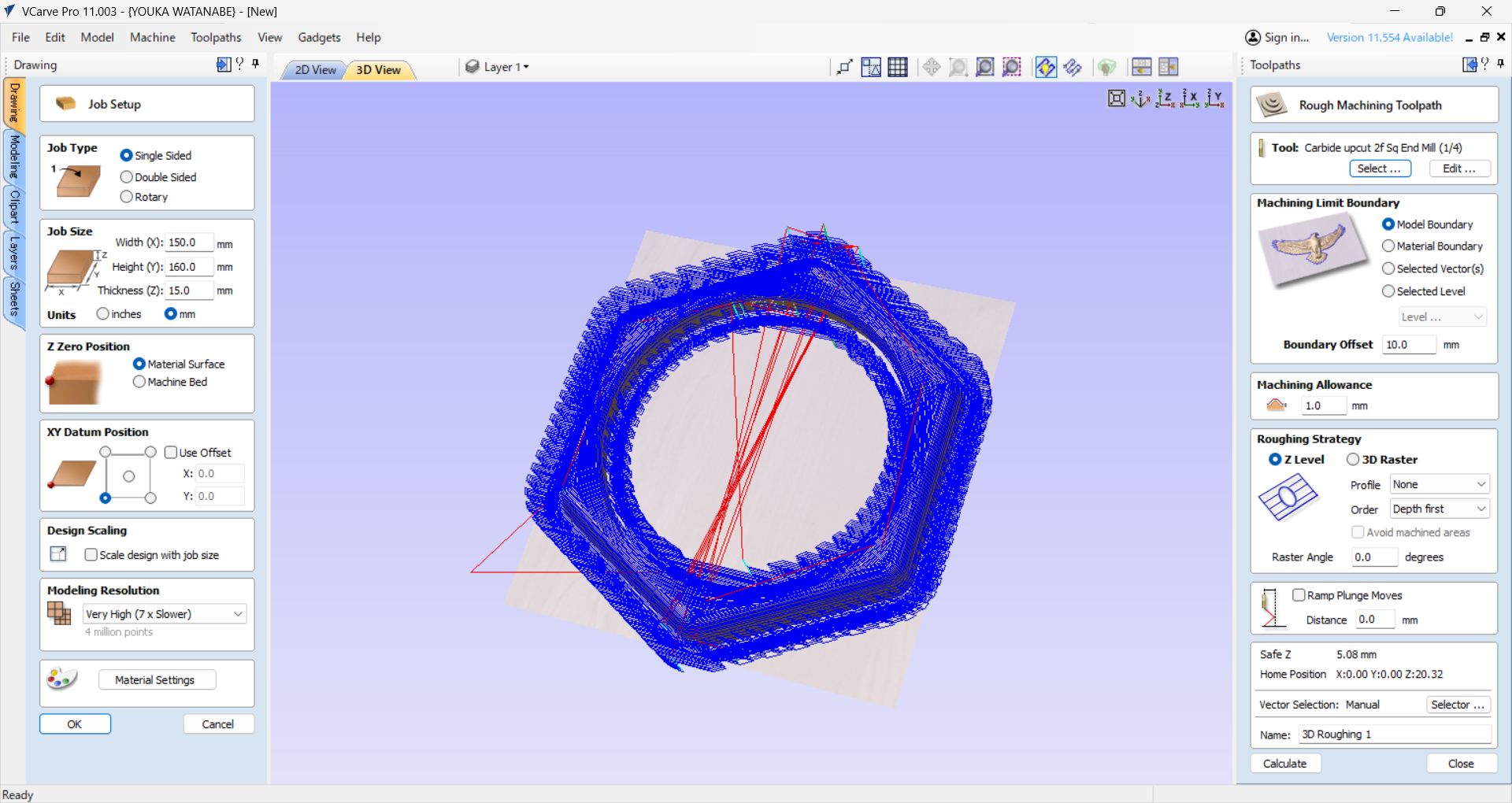

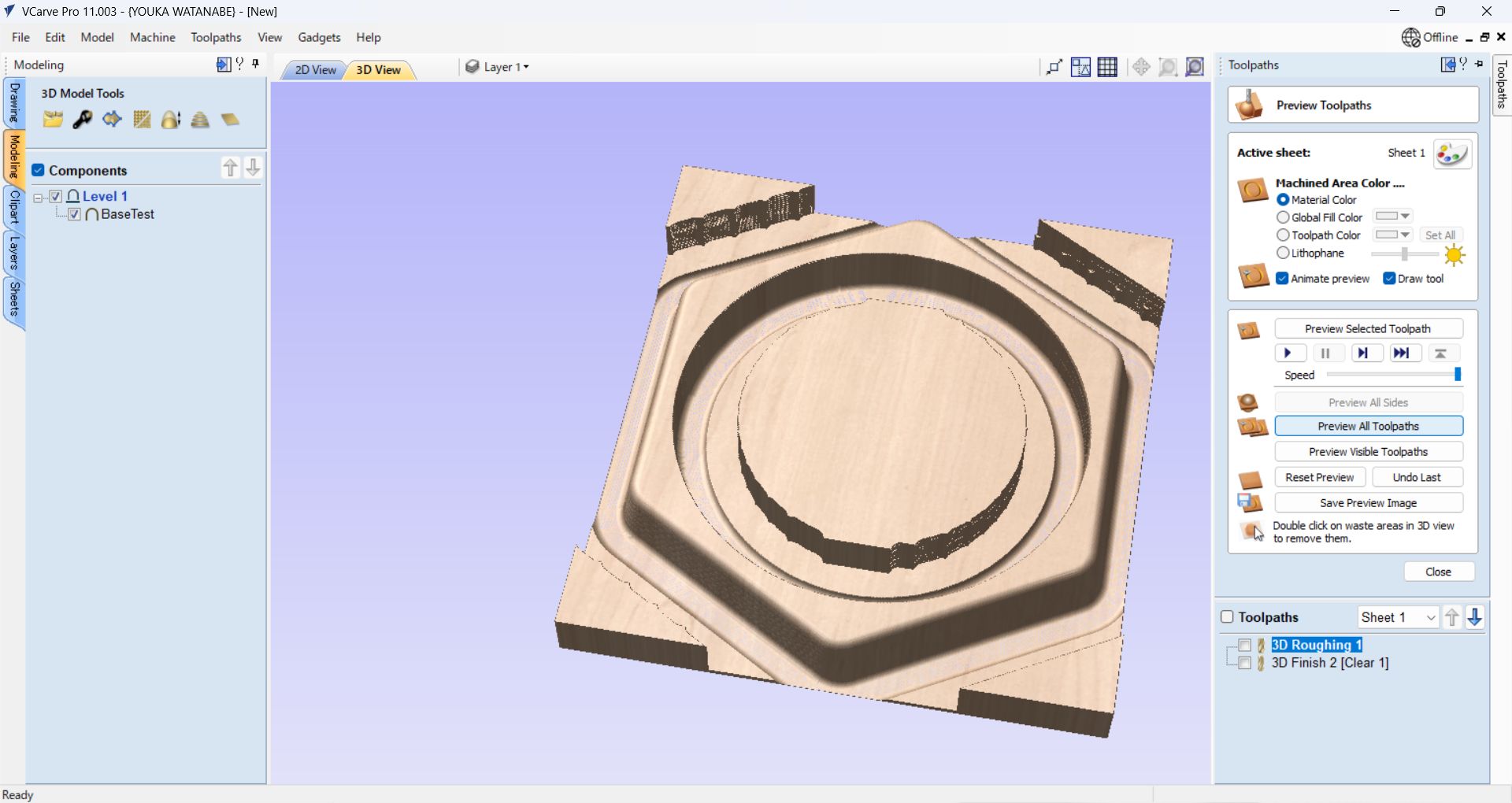

Settings in VCarve

Toolpath:

3D roughing for rough cut

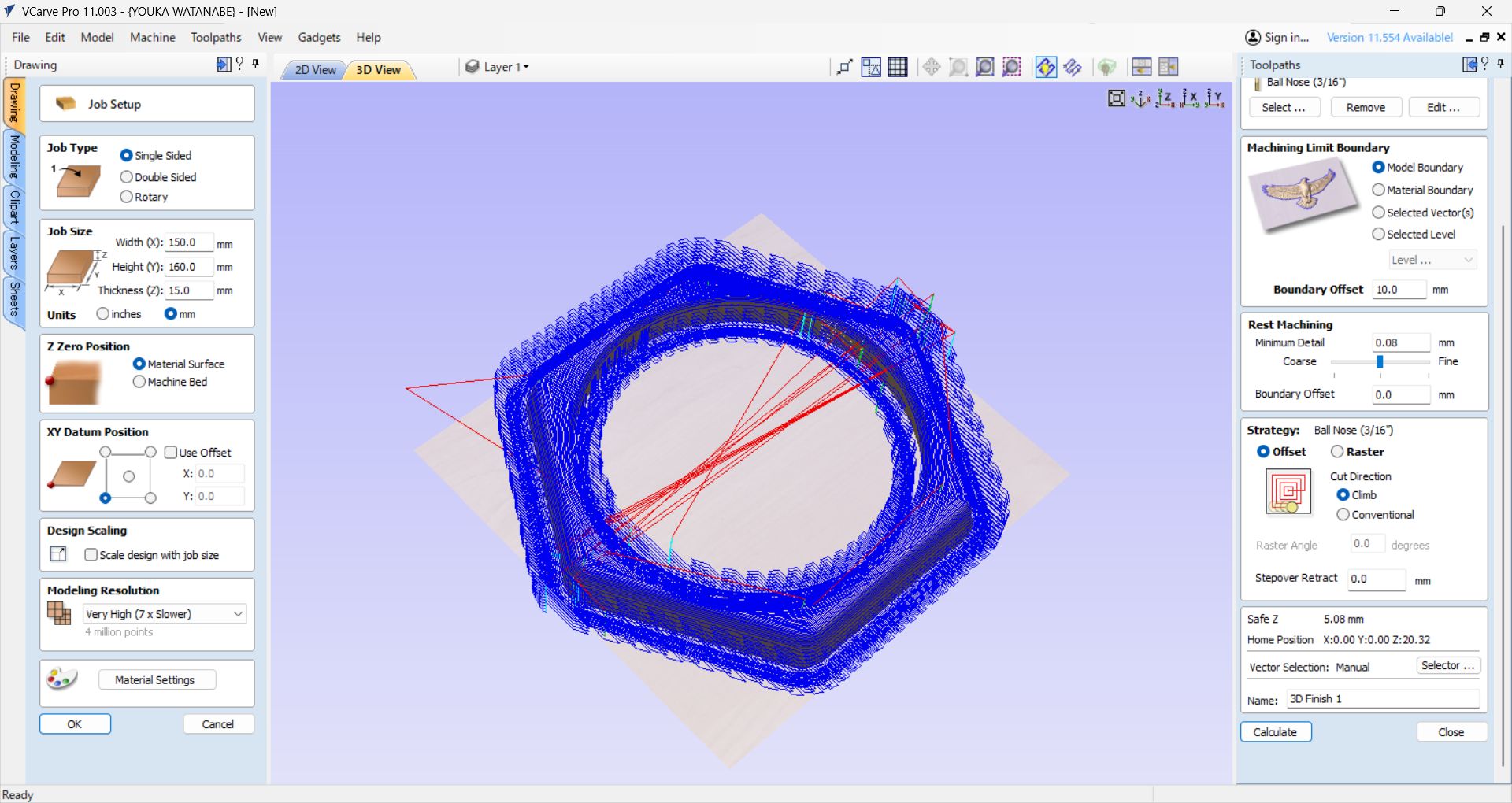

3D Finishing for finish cut

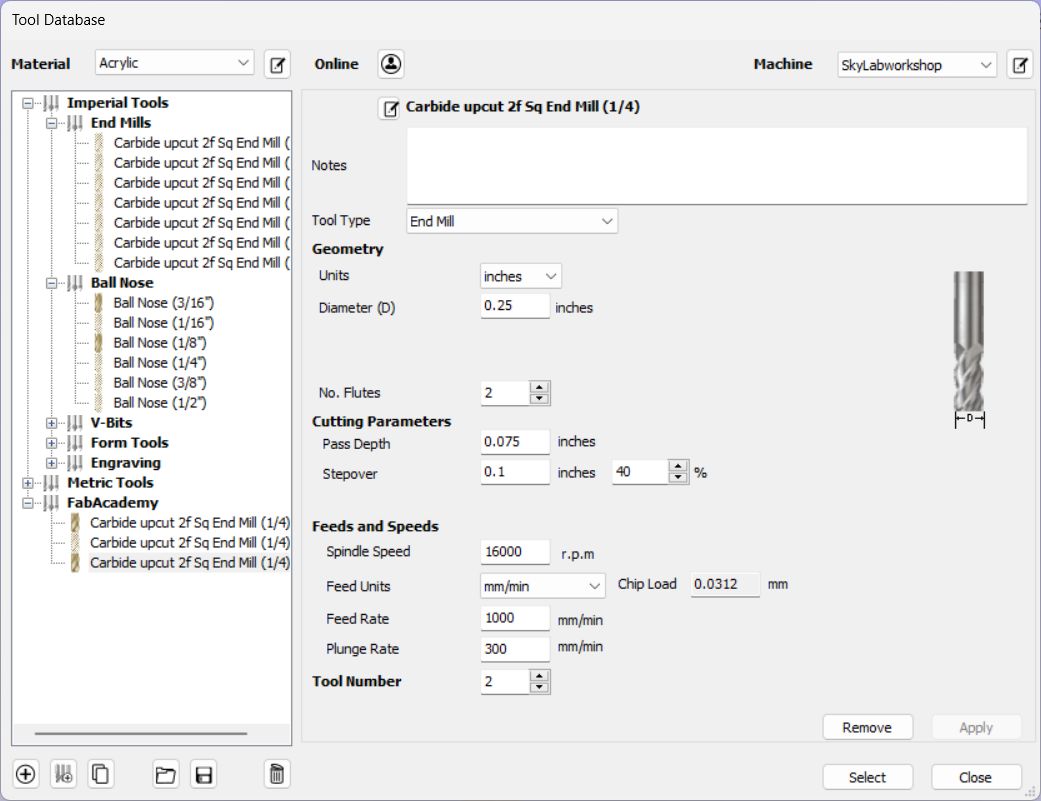

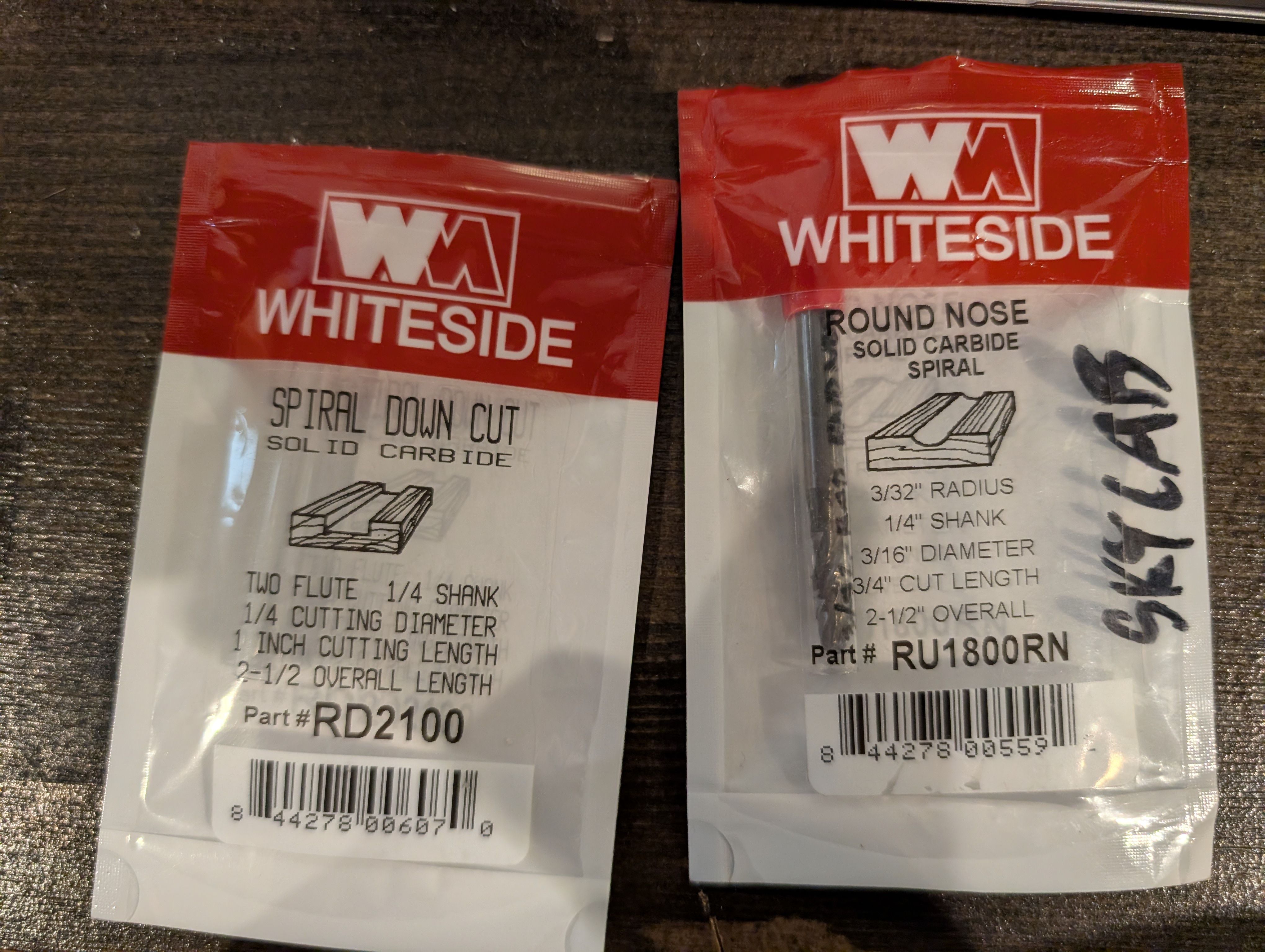

Tool:

Roughing:

Spiral Down Cut 2 Flute, 1/4 shank, 1/4 cutting diameter

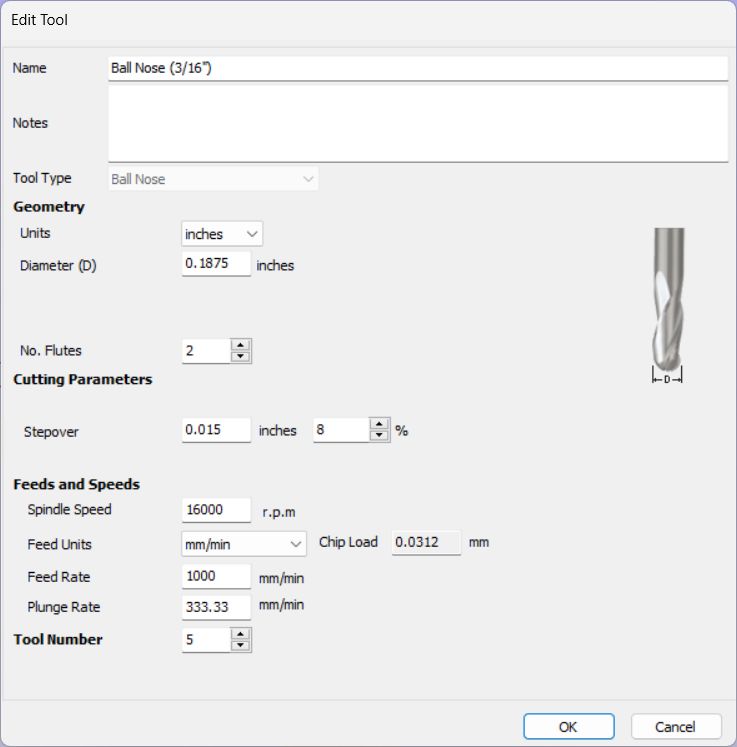

Finishing:

Round Nose , 3/32 radius, 1/4 shank, 3/16 diameter

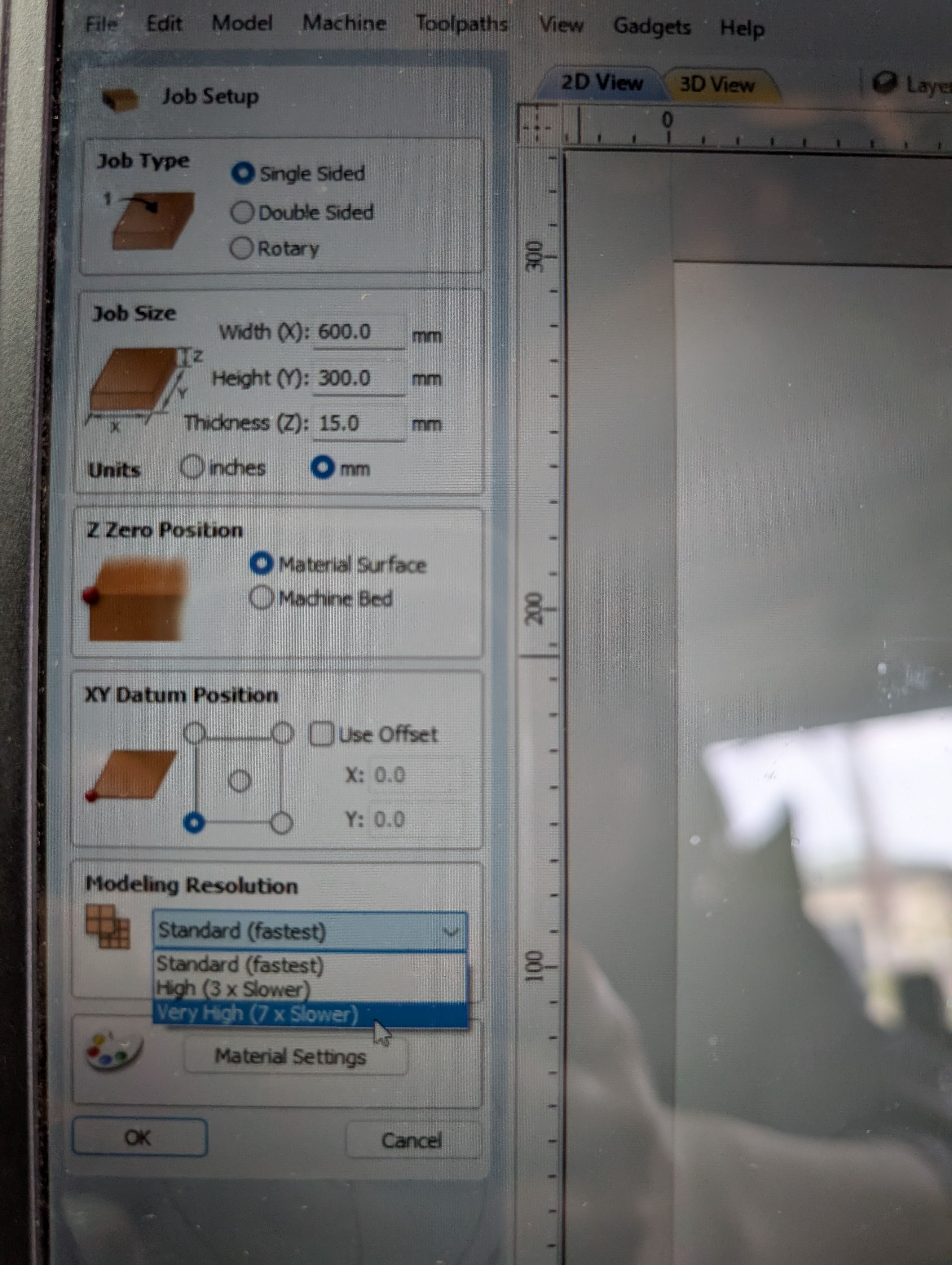

Job Setup

Single sided Job size: set same as material size

Offset X,Y = 0,0

Modeling Resolution: Very High

Material Settings: Canadian Maple

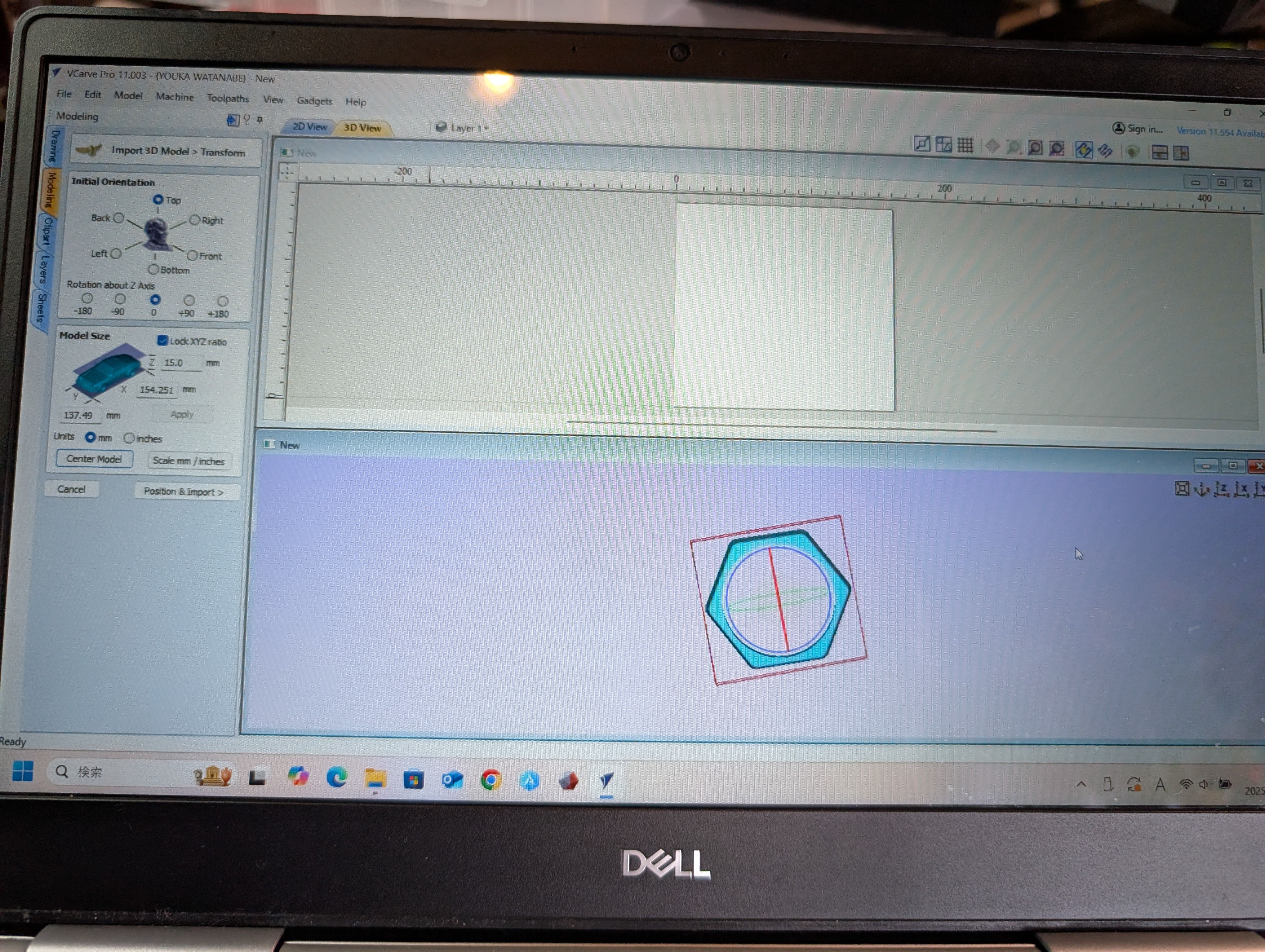

Import 3D Model from "Import 3D model" menu in "Modeling" tab

Center model

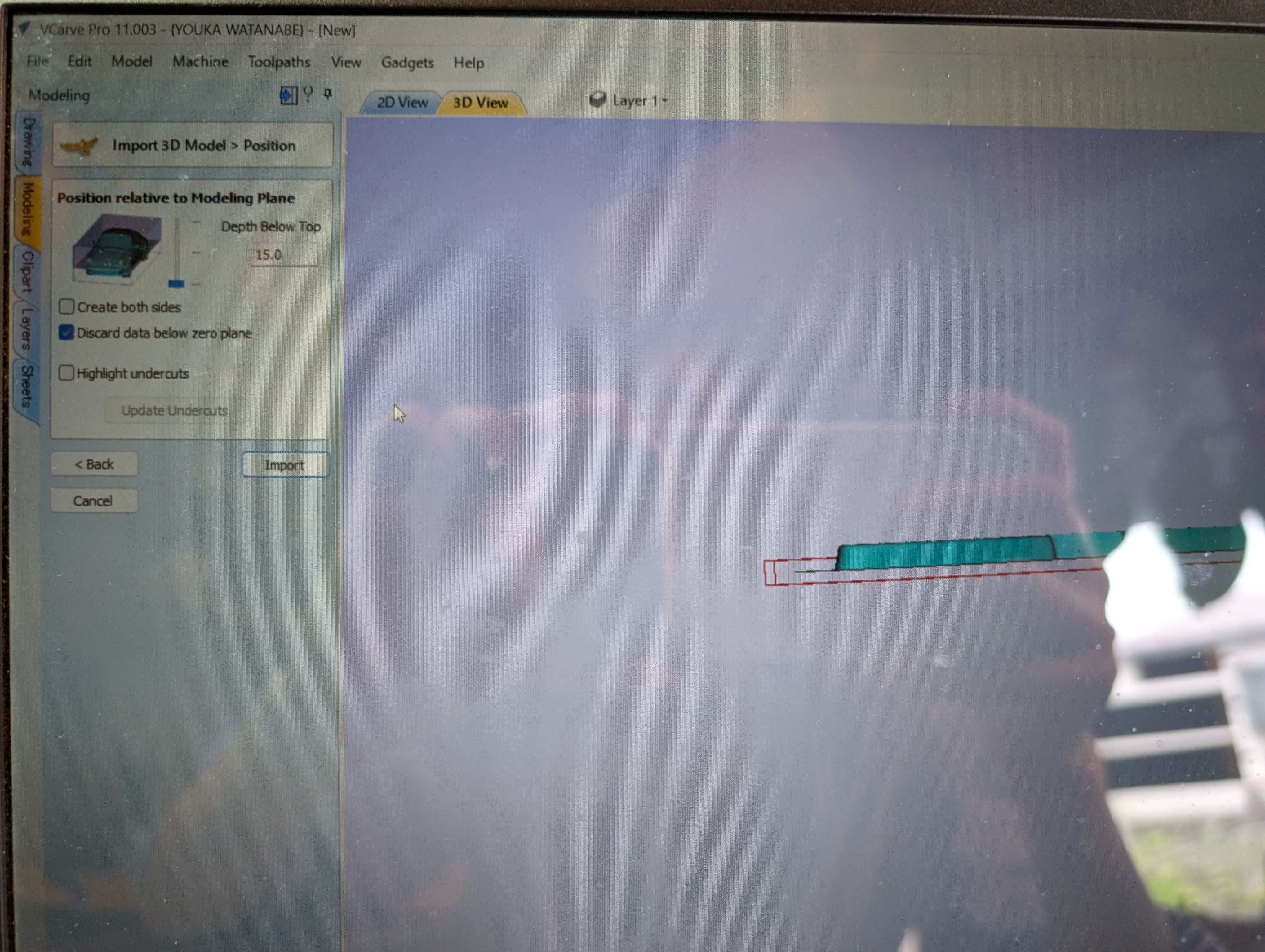

Position relative to modeling Plane - Depth Below Top: same as material thickness(since

this is not double sided design)

Setting for Roughing tool

Setting for Finishing tool

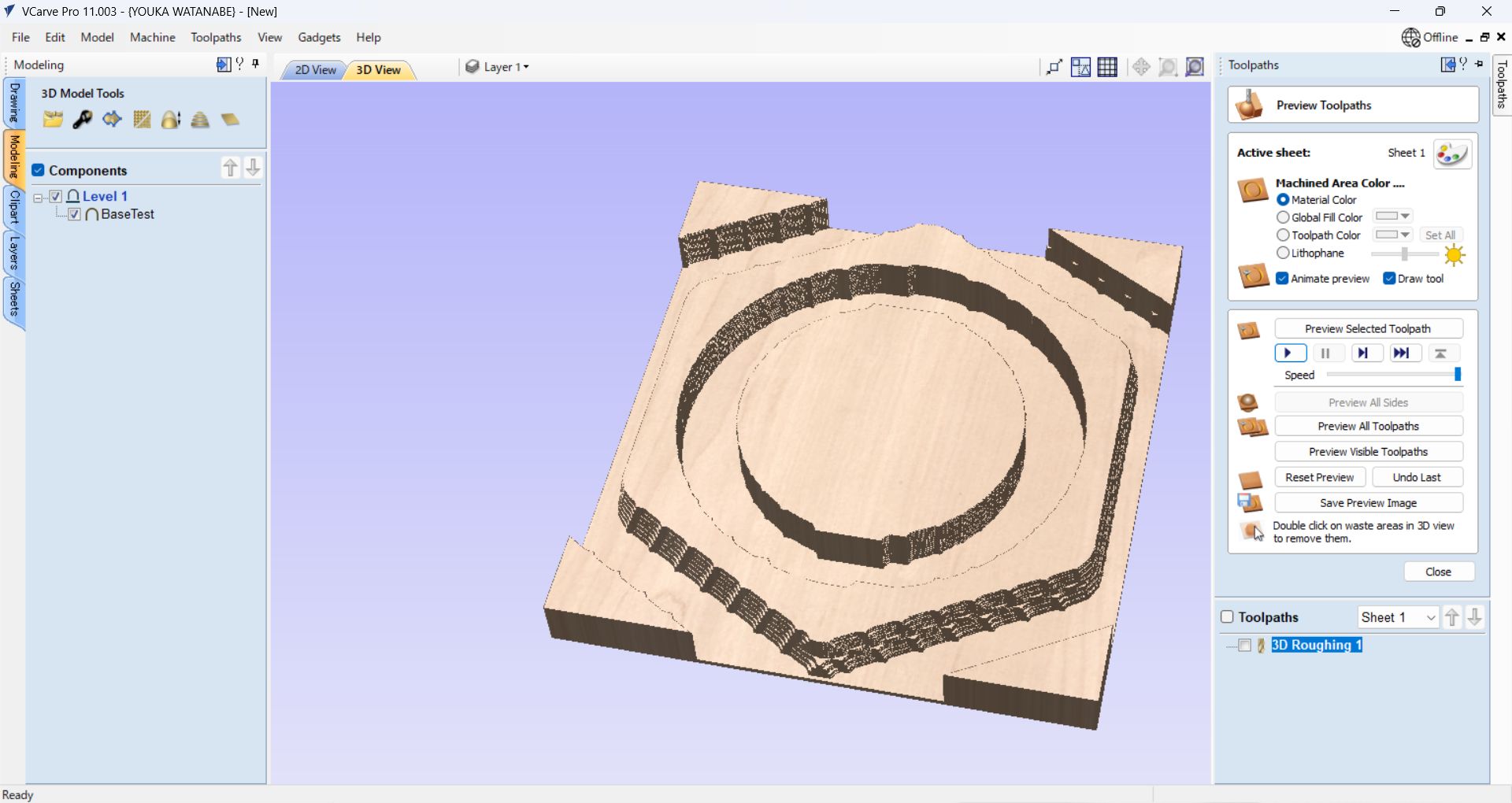

Roughing path setting

Machining Limit Boundary: Same as above.

Model Boundary, Boundary offset: 10.0mm(Bigger than tool diameter(6.5mm))

Finishing path setting

Machining Limit Boundary: Model Boundary, Boundary offset: 10.0mm(Bigger than tool

diameter(6.5mm))

Model Boundary, Boundary offset: 10.0mm(Bigger than tool diameter(6.5mm))

Strategy: Offset, Cut Direction: Climb

At first, when I set the Model Boundary, an error occurred when generating toolpaths.

The error was resolved by using Material Boundary, but Material Boundary has many

milling parts, which is wasteful and time-consuming.

As a solution, I set a Boundary Offset of the tool width (∔α) in the Model Boundary and

was able to cut successfully.

CNC

As with Machining, the following steps are used in OpenBuild for cutting.

After RoughCut is finished, it is necessary to replace the tool for Finishing.

The XY axis is not changed, but only the Z axis is reset (as in SRM). It is necessary

to set z-axis correctly (see below) since it cause CNC may or may not cut out the

wood.

Safety (Protect Eyes and wear mask)

In some cases, it is necessary to fix the part to be cut with screws.

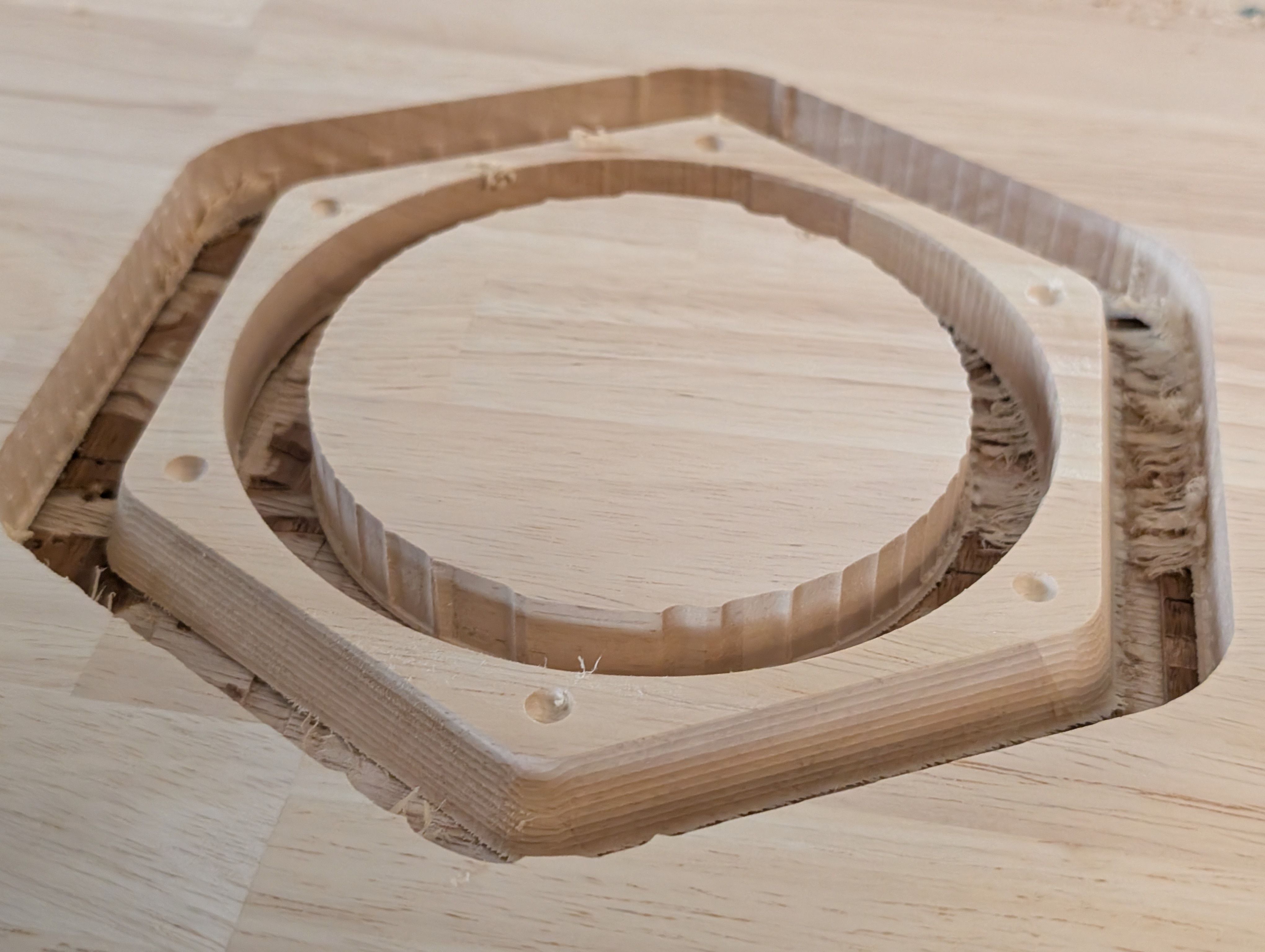

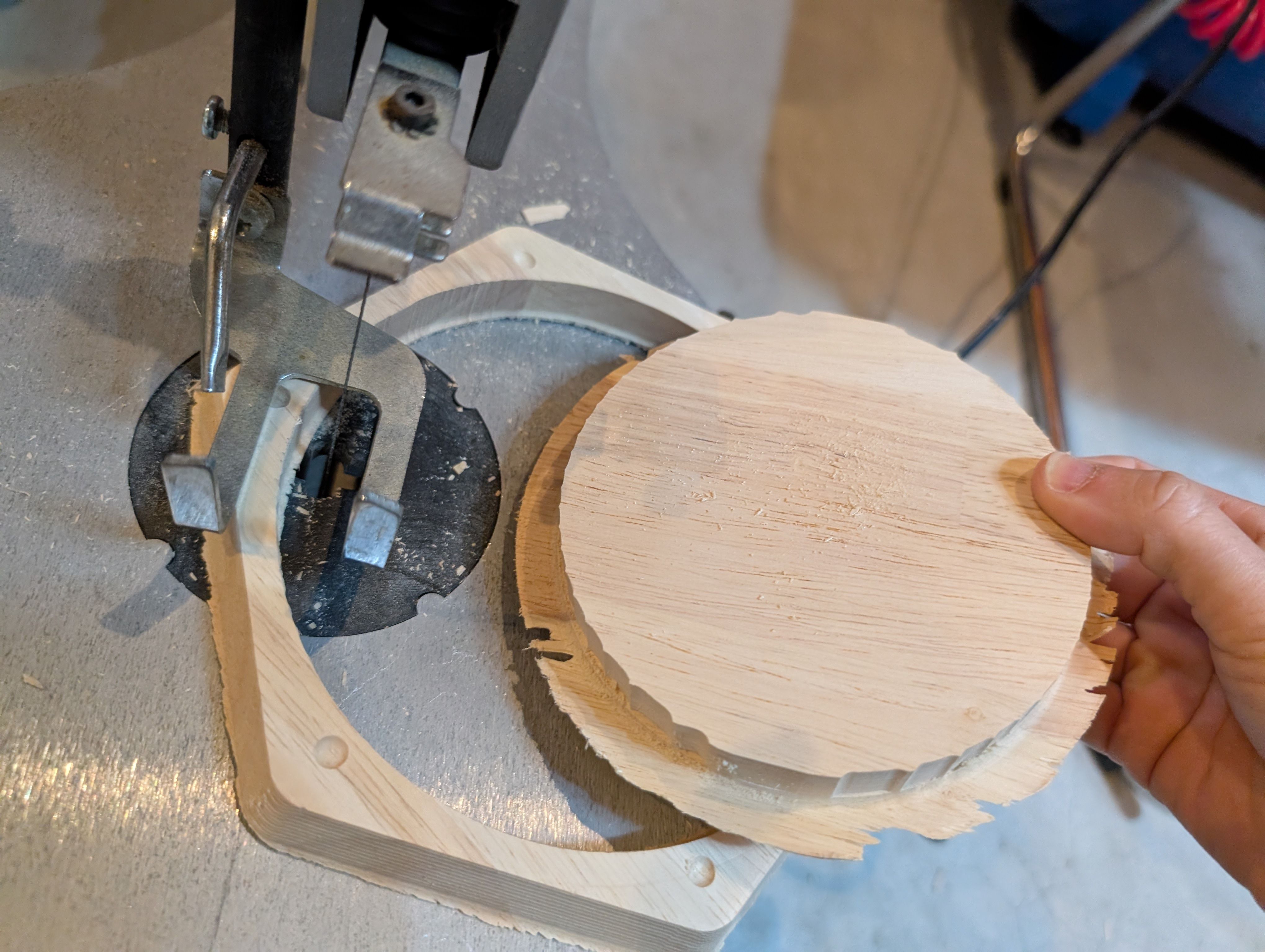

Finishing

Requirement: Smooth Finishing

At the time of scraping, the surface was generally finished smooth.

However, some of the bottom surface remained and was not separated from the wood,

resulting in a process of cutting and sanding the remaining parts with a thread saw.

(If the Z-axis is not set correctly, it may or may not be able to be cut.)

Result of assembly

References

https://docs.vectric.com/docs/V12.0/Aspire/JPN/Help/form/Orientate

3D Model Flat/index.html

https://www.autodesk.com/jp/support/technical/article/caas/sfdcarticles/sfdcarticles/JPN/Unable-to-open-a-file-after-crash-in-Fusion-360.html

https://www.autodesk.com/jp/support/technical/article/caas/sfdcarticles/sfdcarticles/JPN/Converting-Fusion-360-to-DWG-or-DXF.html

https://www.vectric.com/support/tutorials/vcarve-pro/?playlist=getting-started-with-vectric-software&video=how-to-import-and-machine-a-3d-model

https://www.youtube.com/watch?v=cORavE0W3fo

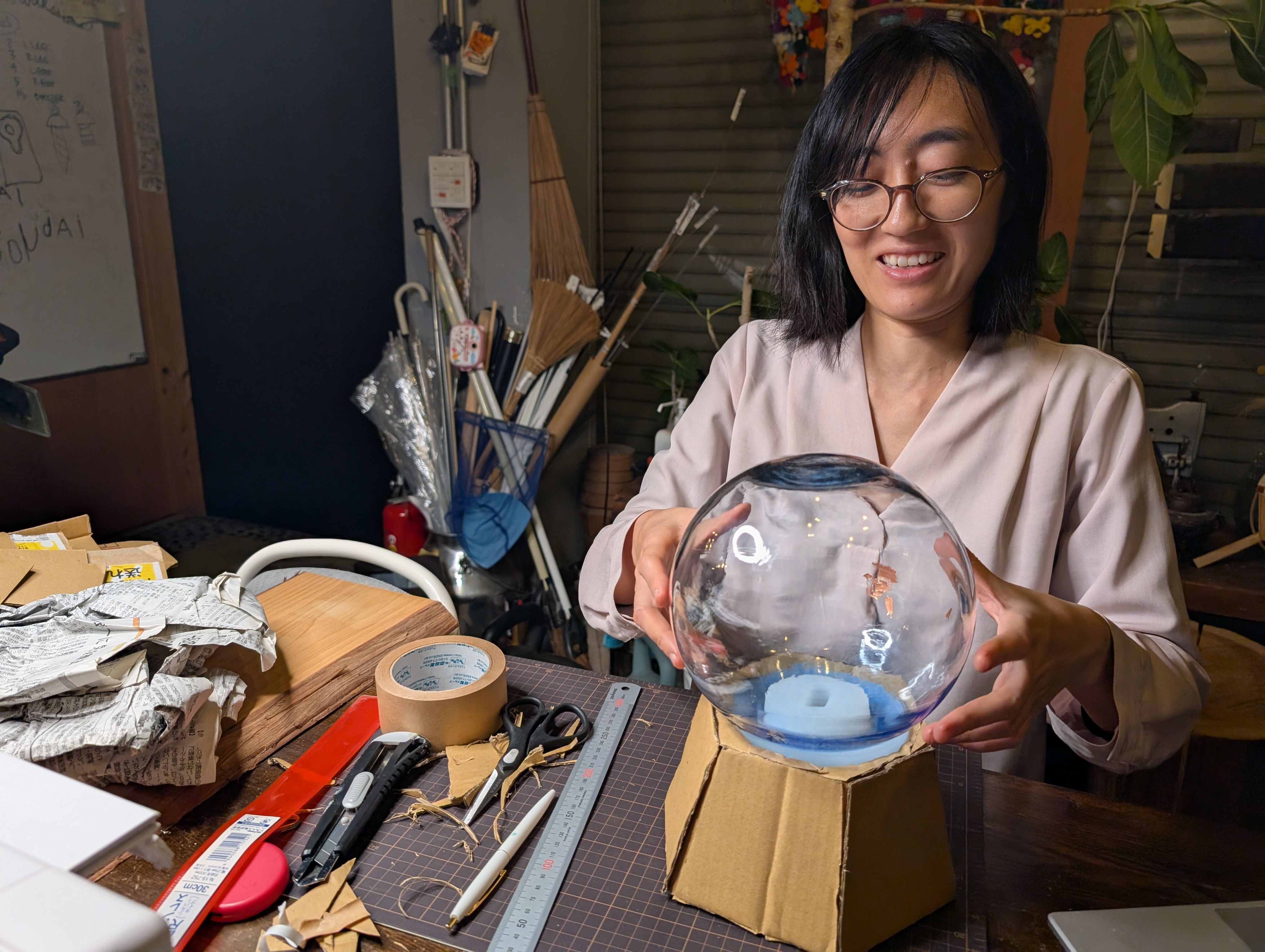

Extra: Other processes that have been implemented and are not part of the current assignment

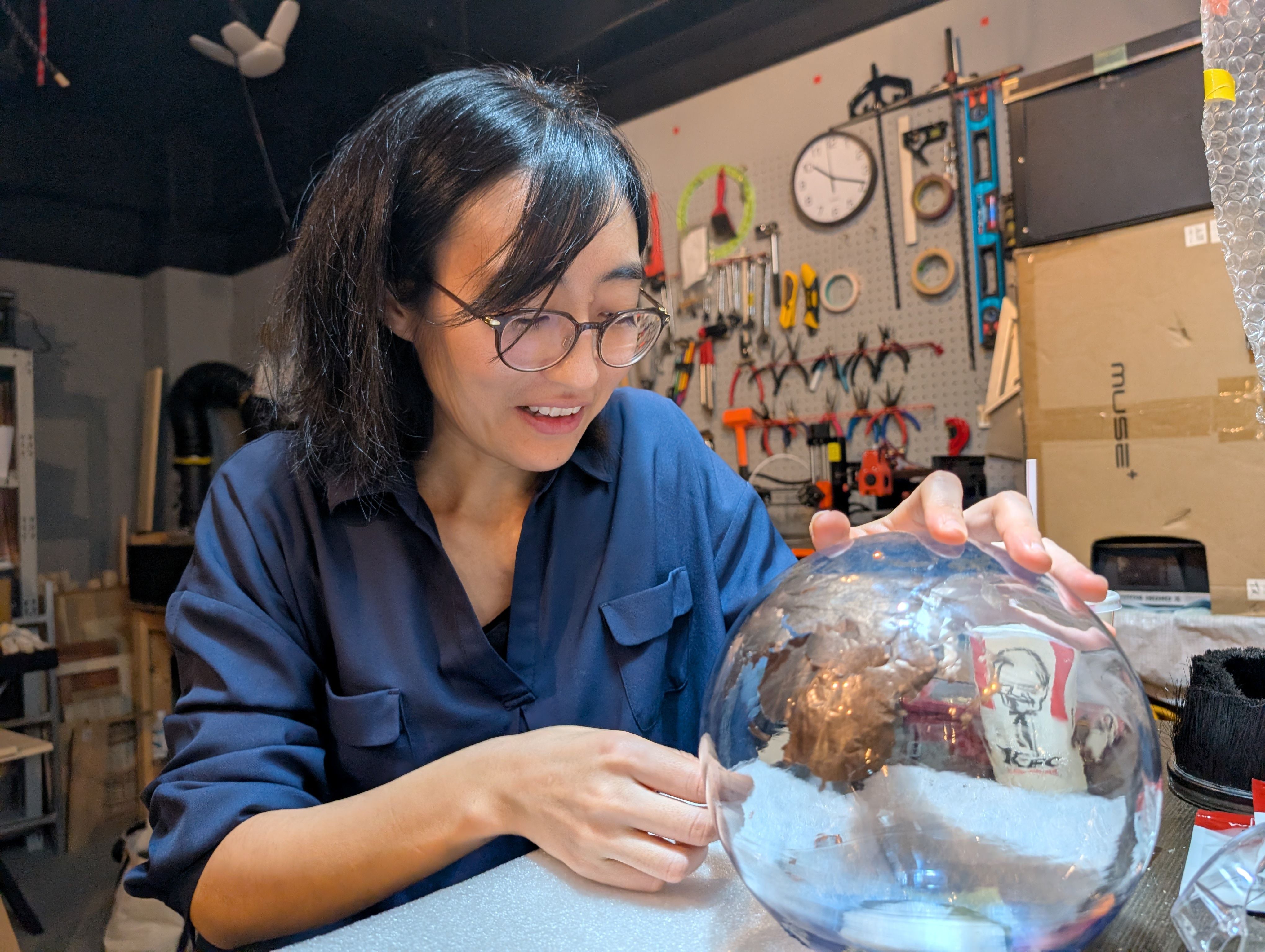

Glassblowing

(Visit to a floating ball production studio in Hokkaido, Japan)

The ball is rotated on a mold and breathed into the mold.

In this case, an existing mold was used for the sphere, but various shapes are possible

by creating a digital mold.

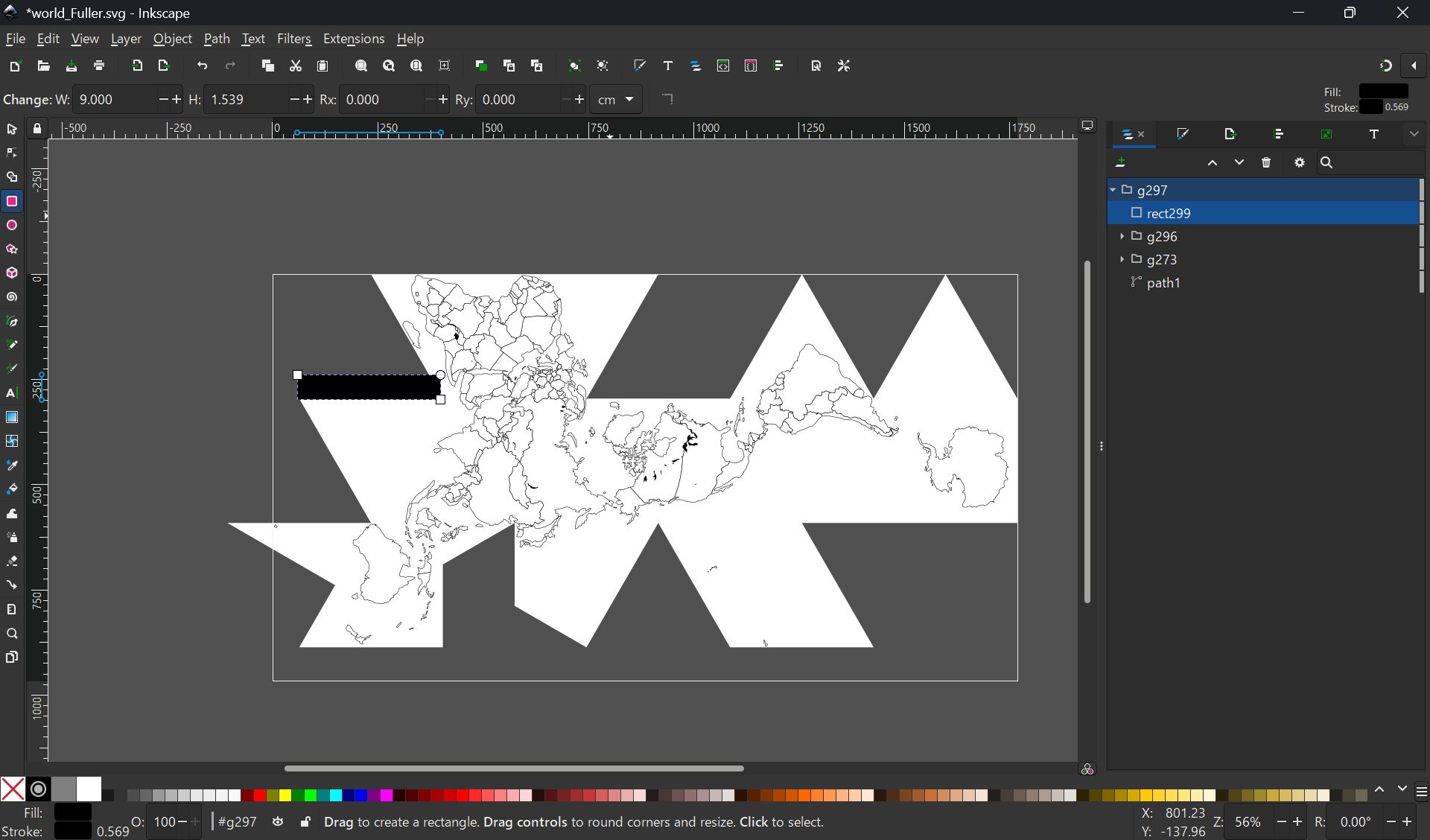

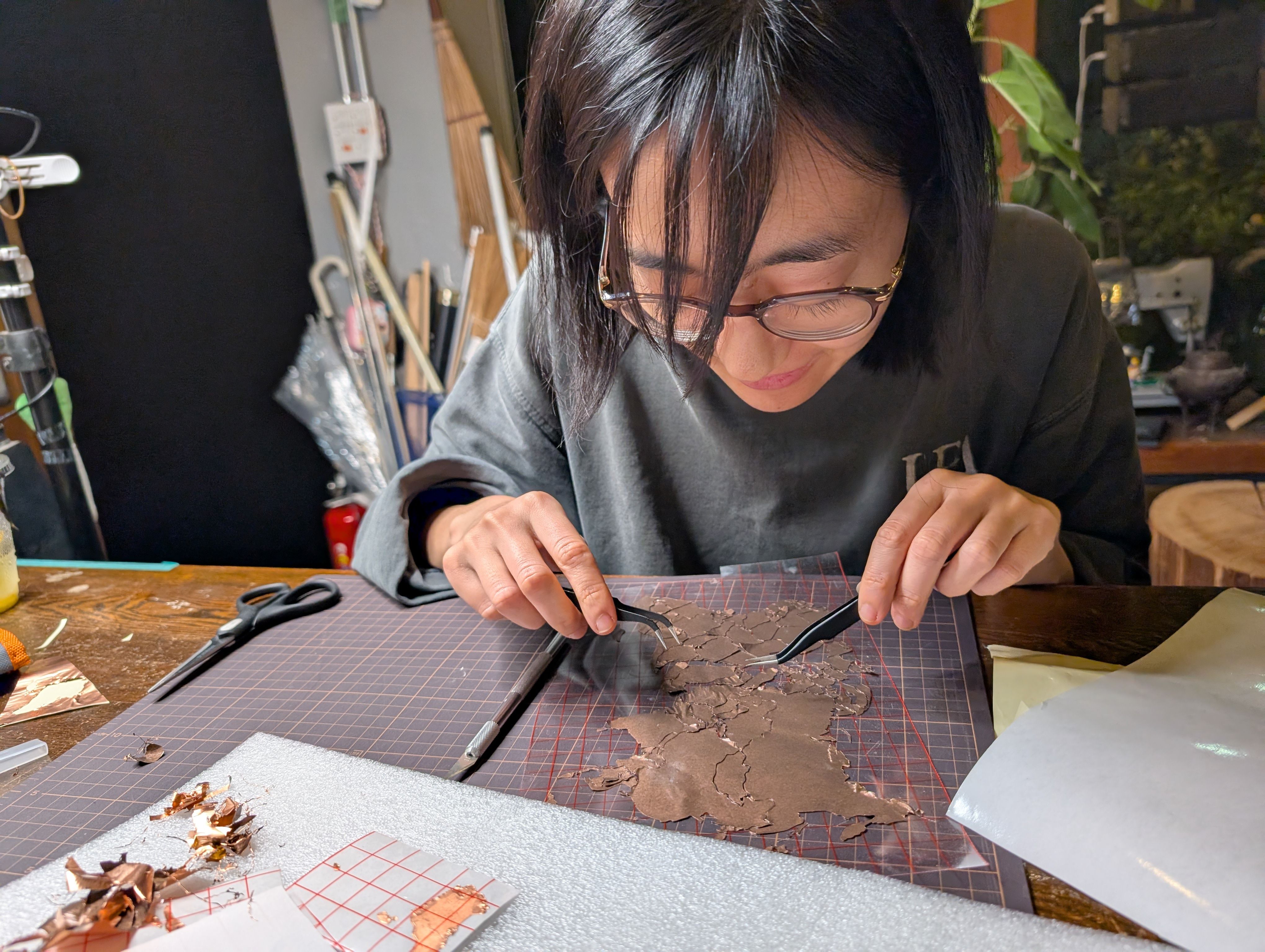

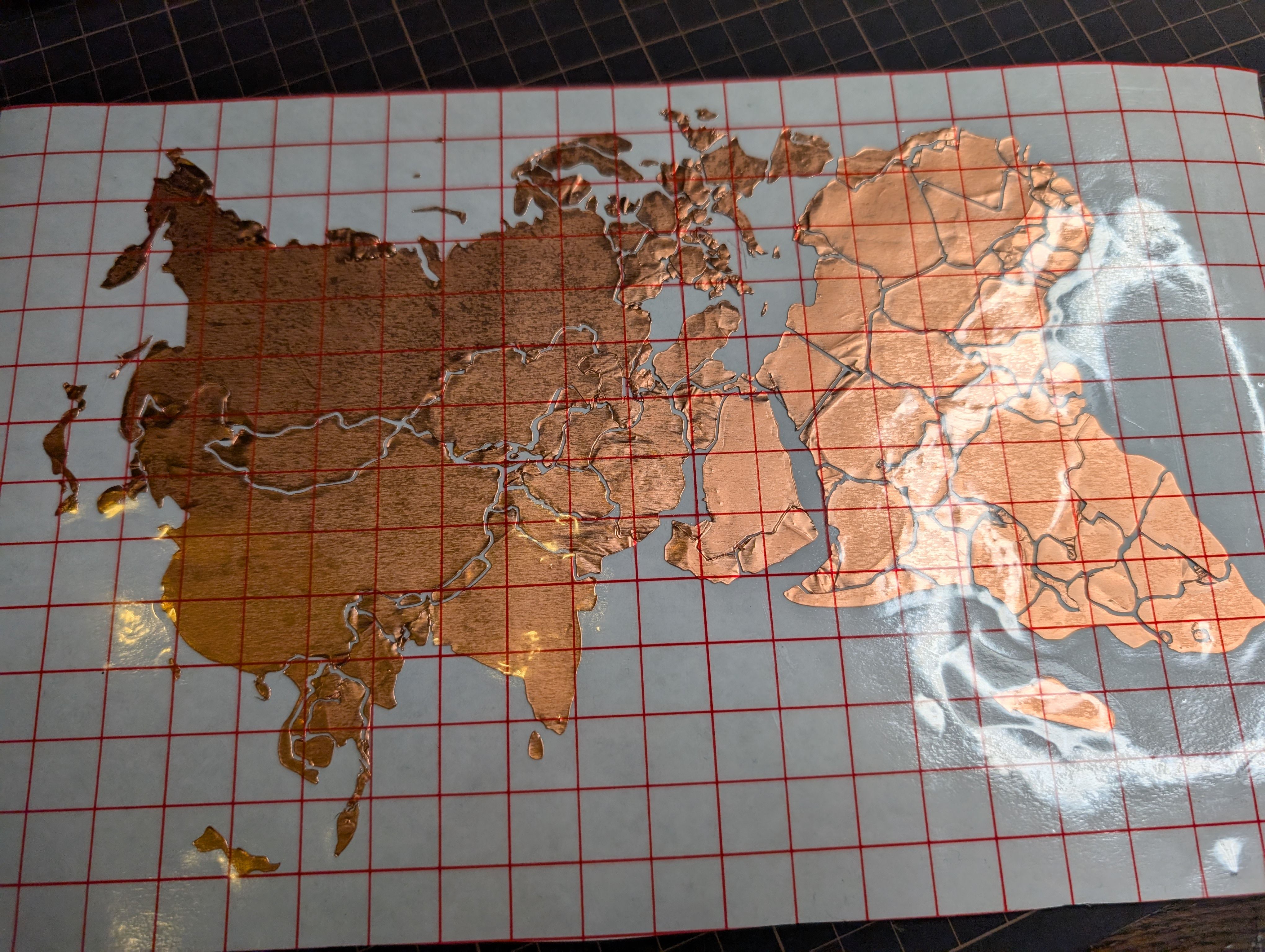

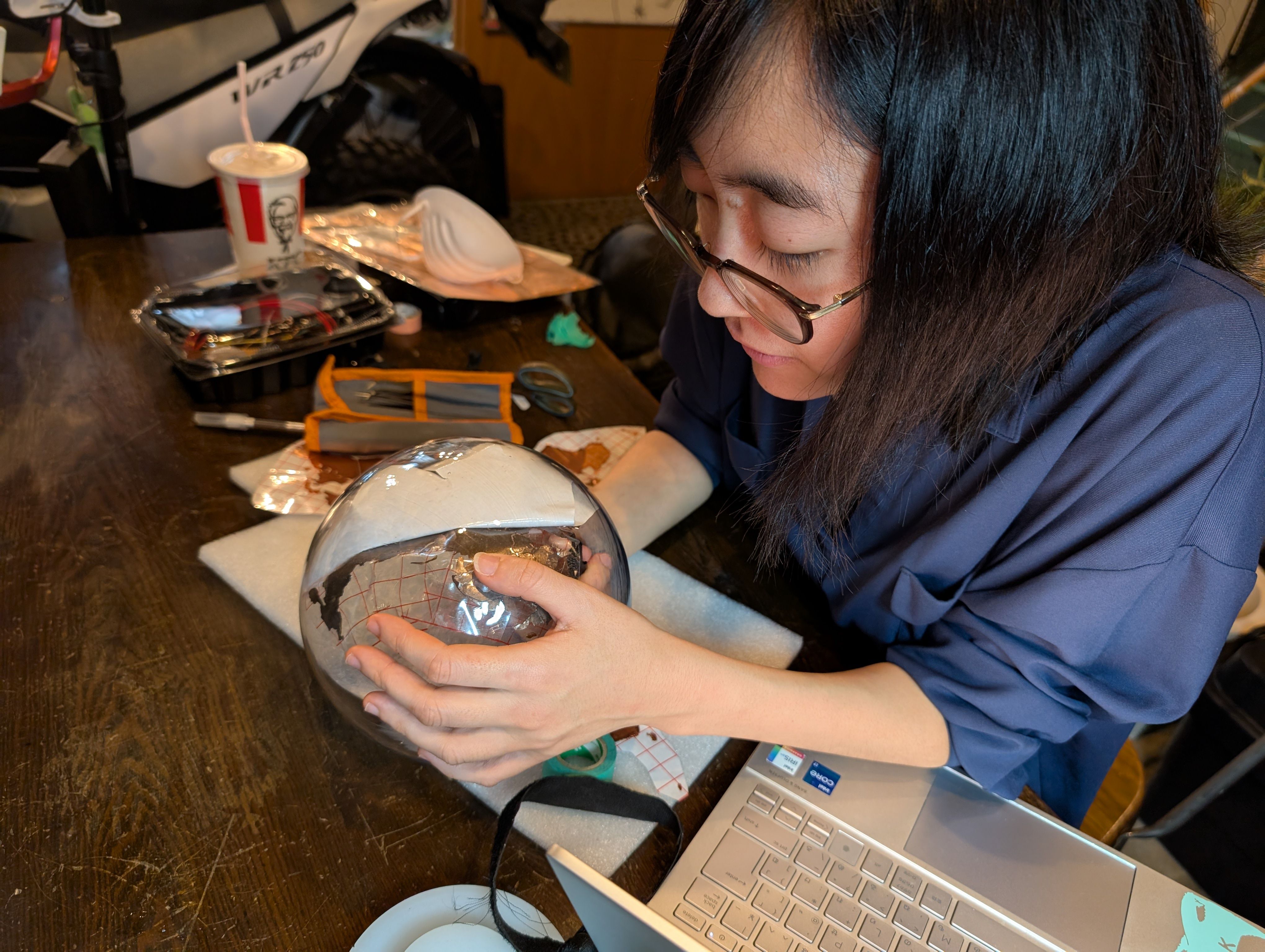

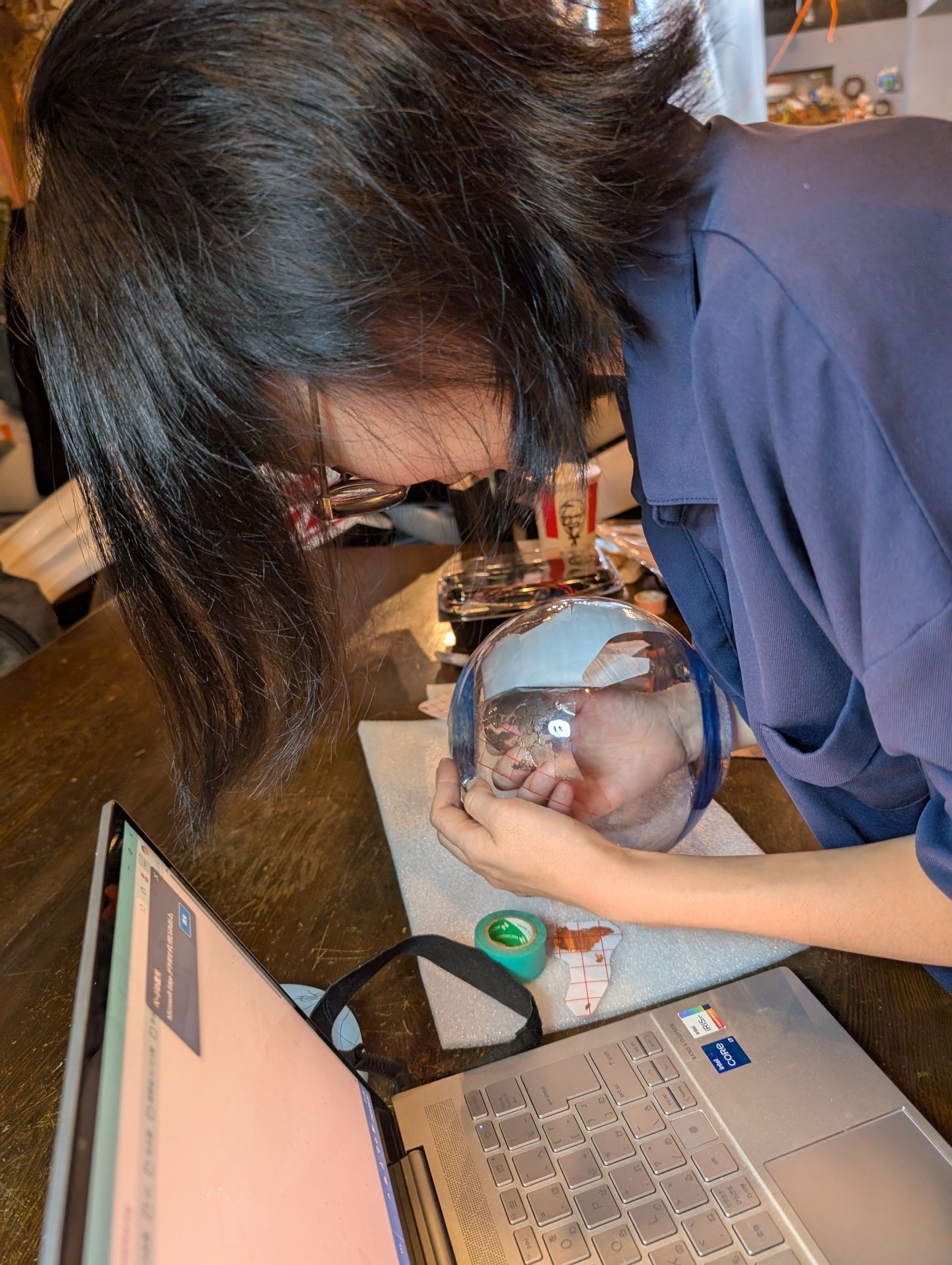

Copper Sheet Vinyl Cut

Copper sheet is cut into the shape of a country. Fixed to the inner surface of the

glass.

I wanted to map the globe while maintaining the relative positions of the countries, so

I searched for a map projection that would suit this.

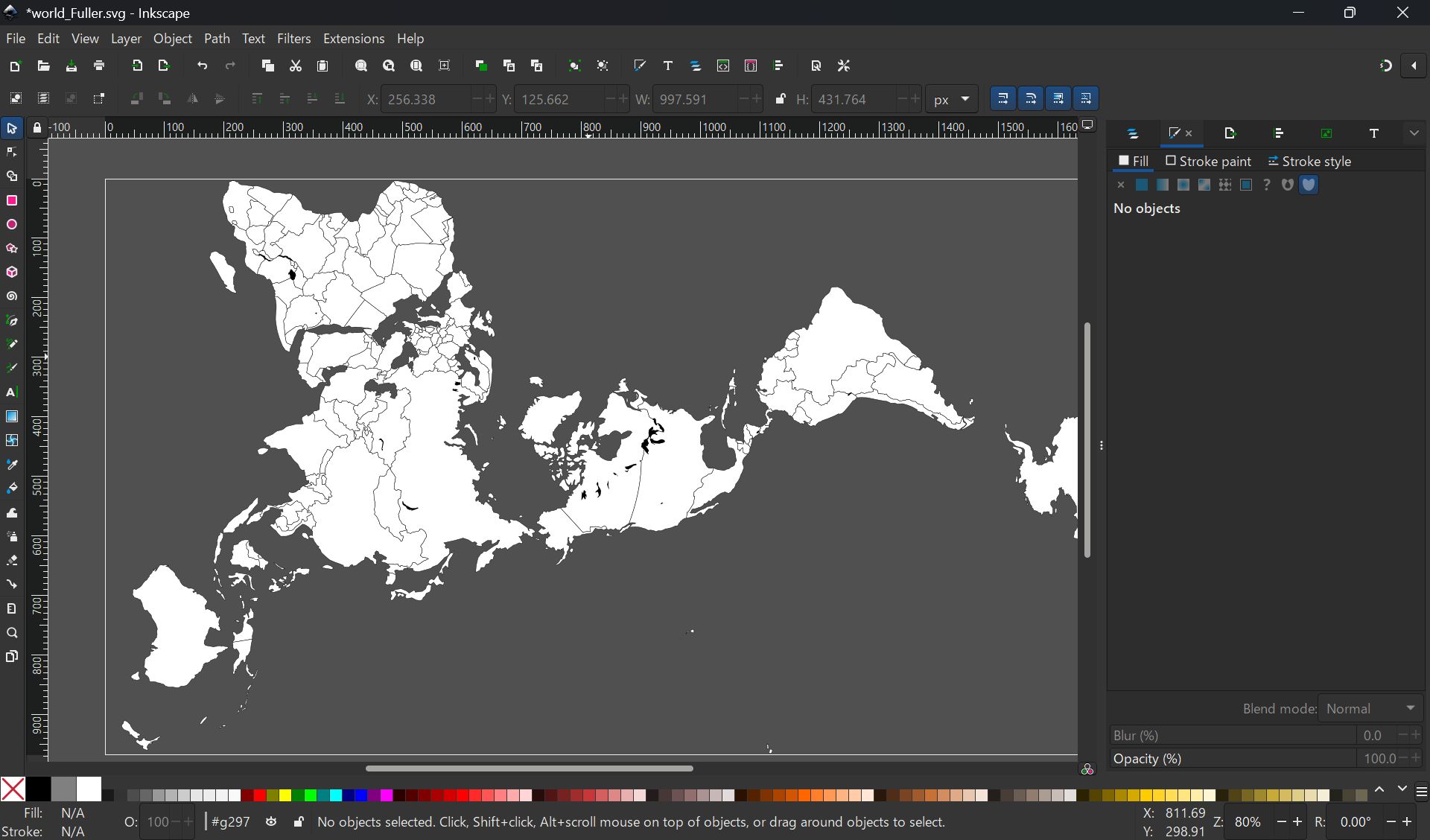

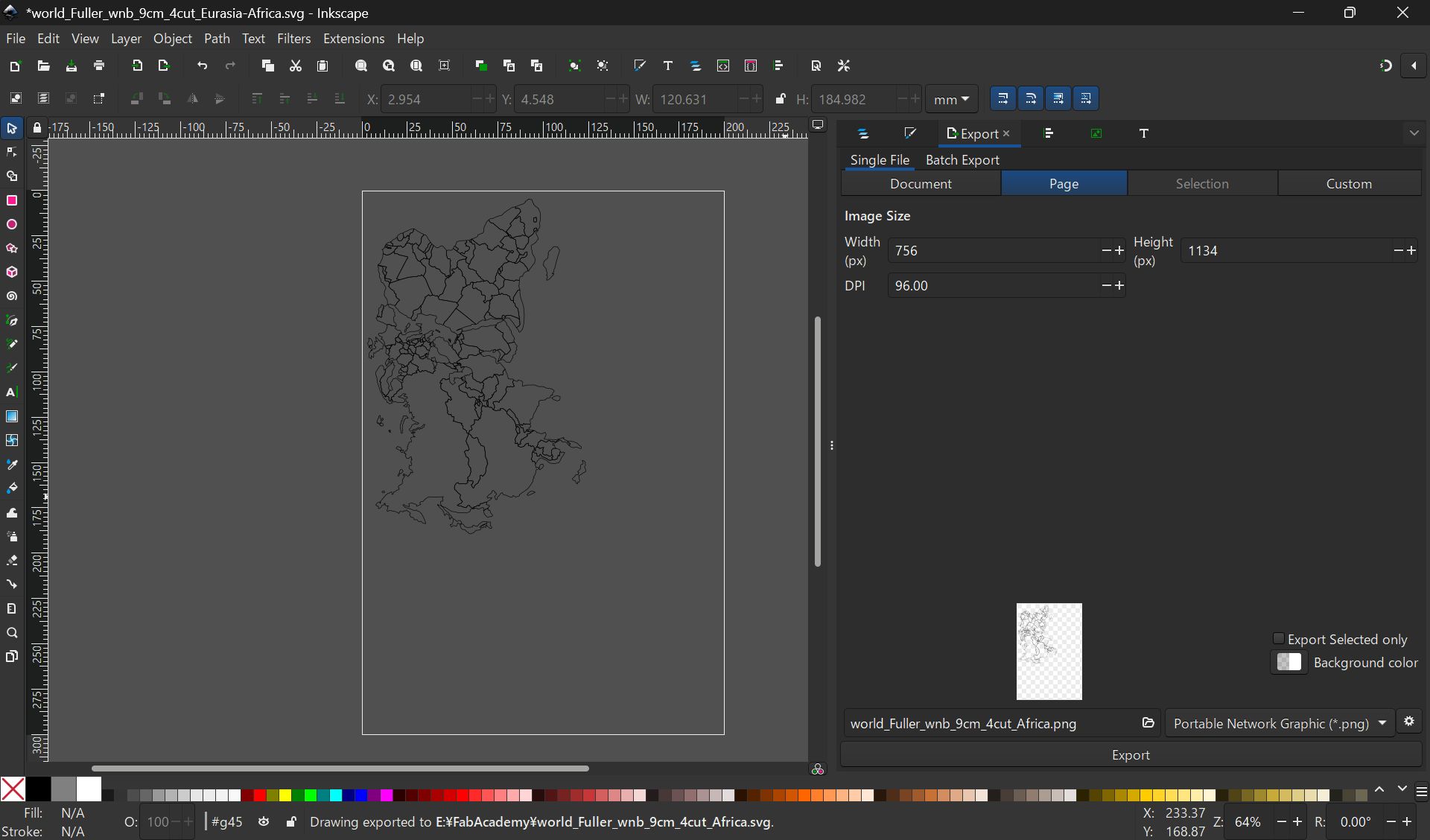

I used the map data from Wikipedia and adjusted in size with Inkscape:

File:Blank_world_map_Dymaxion_projection.svg

Export the map symmetrically with PNG (to be pasted from the inside of the sphere)

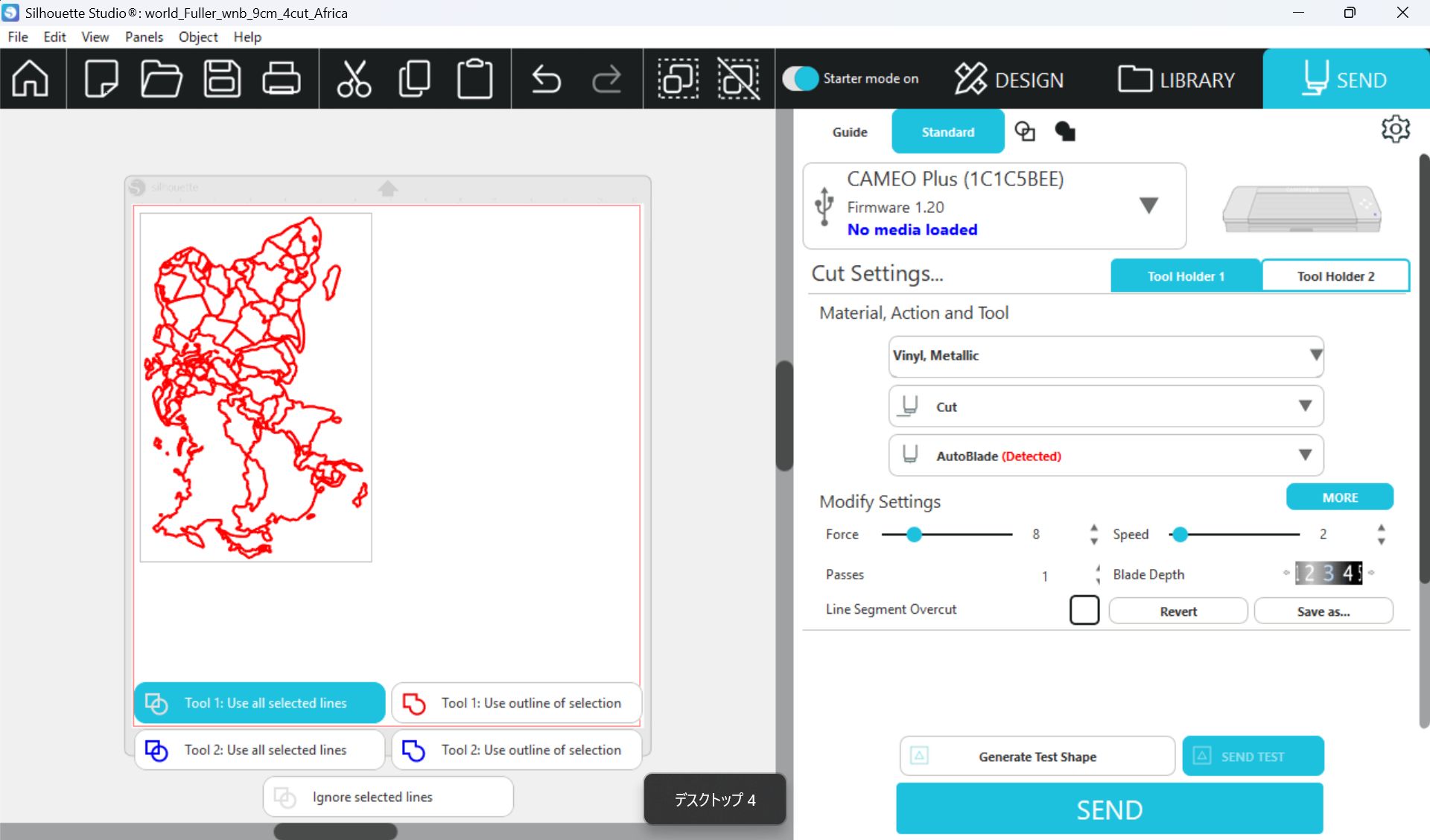

Used Silhouette Studio

Setting

Force: 8, Speed:2, Passes:1, Bade Depth: 5

*If the pressure or depth is too strong, the copper will float up, so it is important

to use the right amount of Force and Depth.

Point

- How to fix the copper foil on the inner surface of the spherical glass. At first, I tried to fix the copper foil on the glass using an application sheet while maintaining the exact position of the countries, but it was difficult to fix the sheet on the glass, especially on the long horizontal Eurasian continent, and the sheet kept coming off. Since the fixation was weak, spray glue was used.

- Connection of copper wire from MCU6(soldering) Since it was difficult to solder inside the sphere, solder was fixed separately in the form of copper foil tape. It was successfully fixed in a country with a large area, but it was difficult to keep it fixed in a country too small.

I also put a frosted glass-like sheet on the outside.

Outcomes

- crv files for VCarve

- tap files for OpenBuild

- ai file for side support parts Laser cut

- svg file for world map vinyl cut

I could try wood milling and found setting for tool path