#13 Molding and Casting

This week I learned how to make mold and cast the shape.

Assignment

Group assignment

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

- Compare printing vs milling molds

Individual assignment

Outcomes

What did I do this week: 1. Group Assignment

The group assignment page - week13

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

- Compare printing vs milling molds

We compared five different materials.

For details, please see the group page: The group assignment page - week13

What did I do this week: 2. Individual assignment

Design a mold around the process you'll be using, produce it with a smooth surface finish that does not show the production process, and use it to cast parts

Since I use the glass globe for Final Project, I thought it is nice to have a support parts with soft

material for the glass.

*My first plan was float the globe, but it seems no time to do it for 1st spiral…So this new part is

needed.

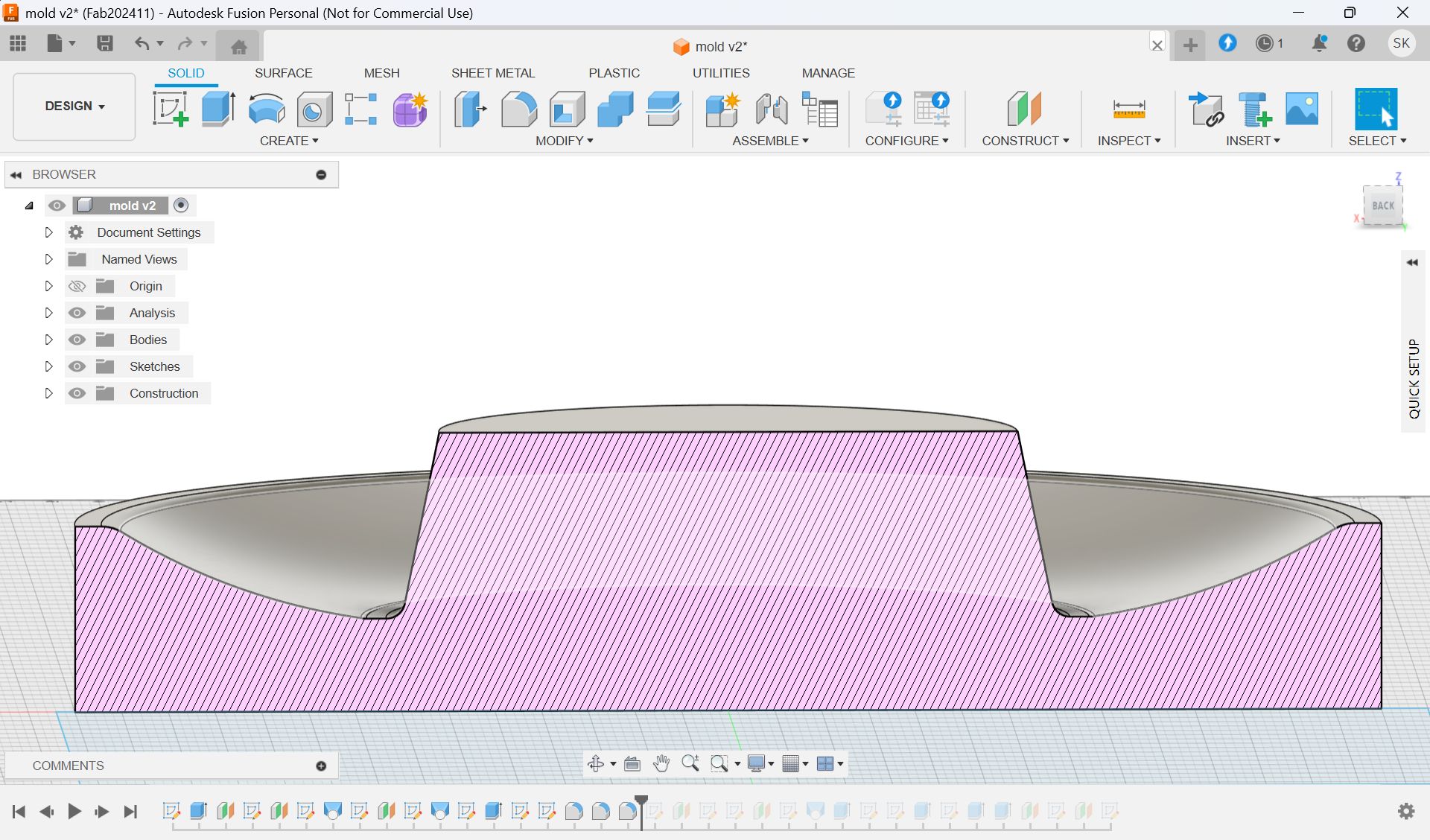

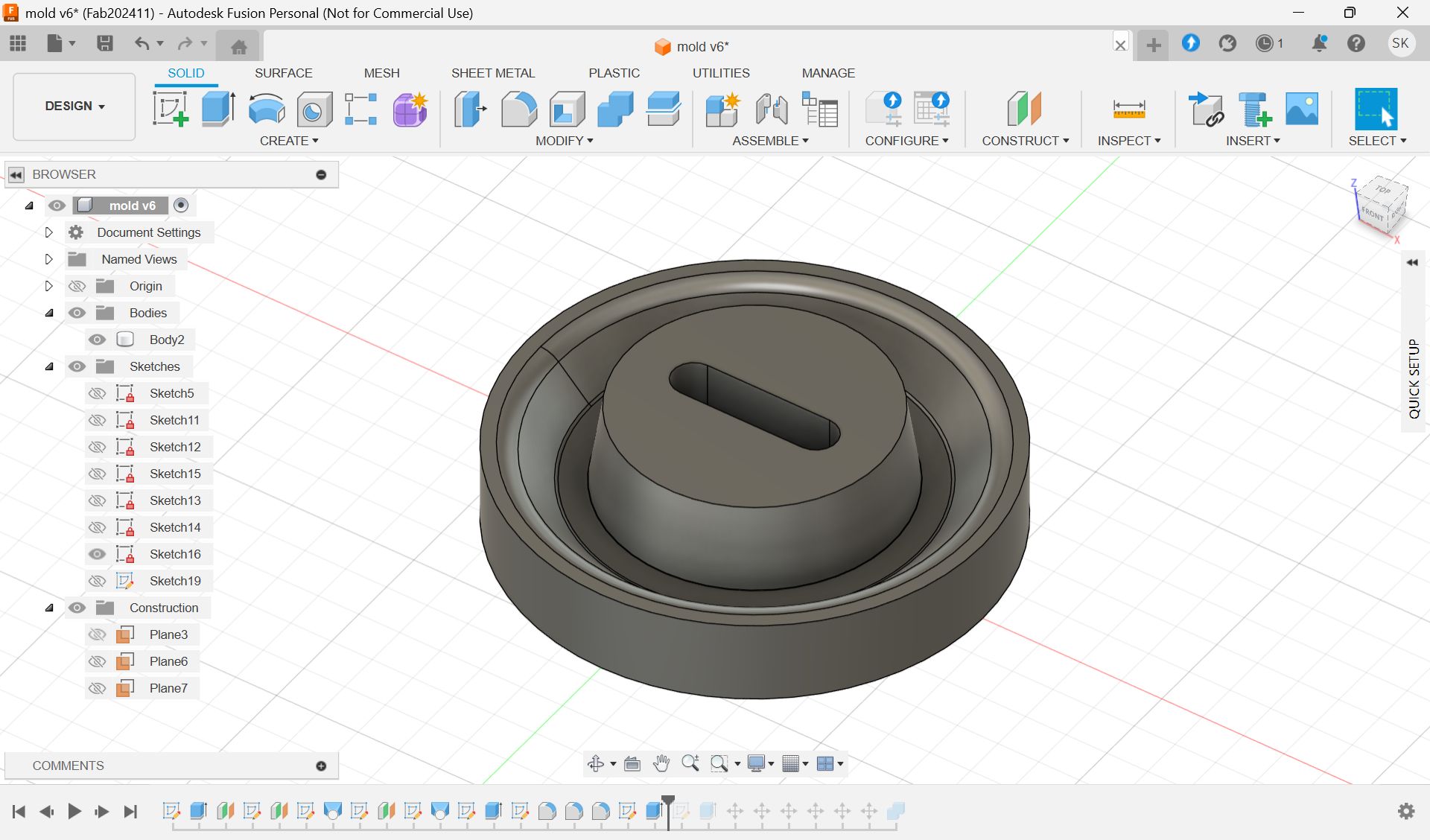

1.Test model

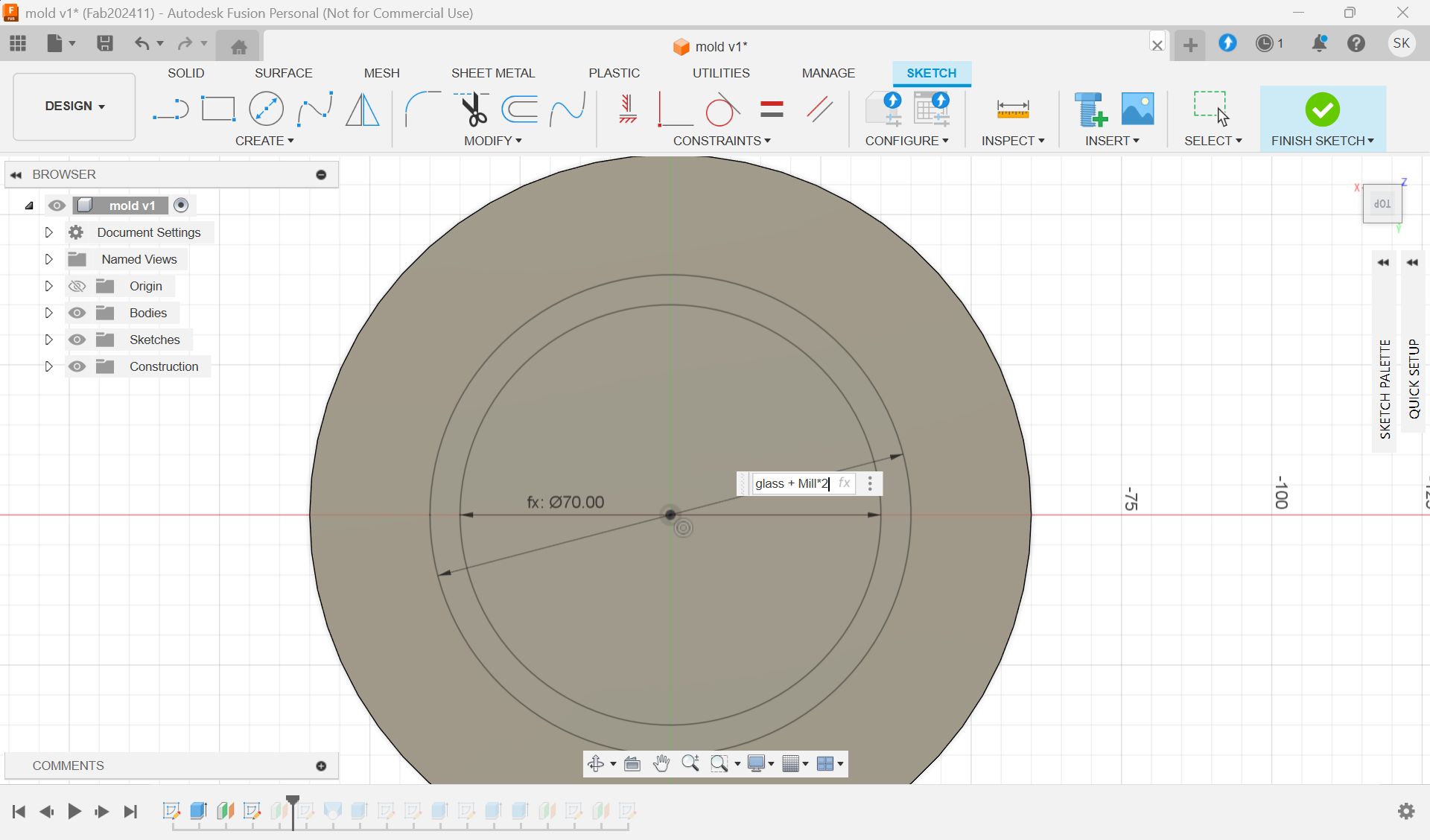

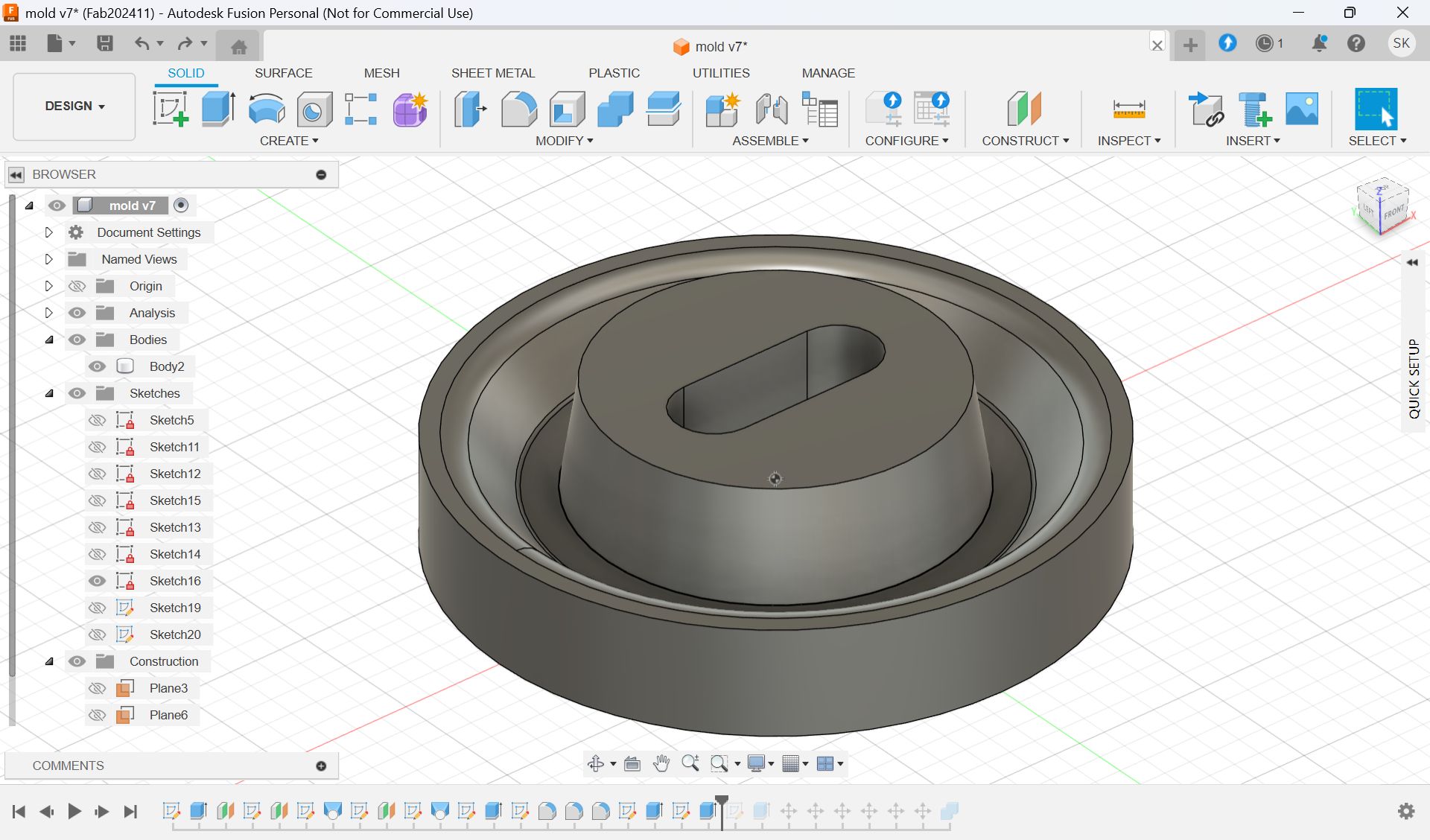

Modeling - Fusion

It was my first time to do casting, so I made a small test piece first.

I made the curve surface with the site below:

https://forums.autodesk.com/t5/fusion-ri-ben-yu/ping-mianni-duisurukubomi-dinpuru/td-p/7121074

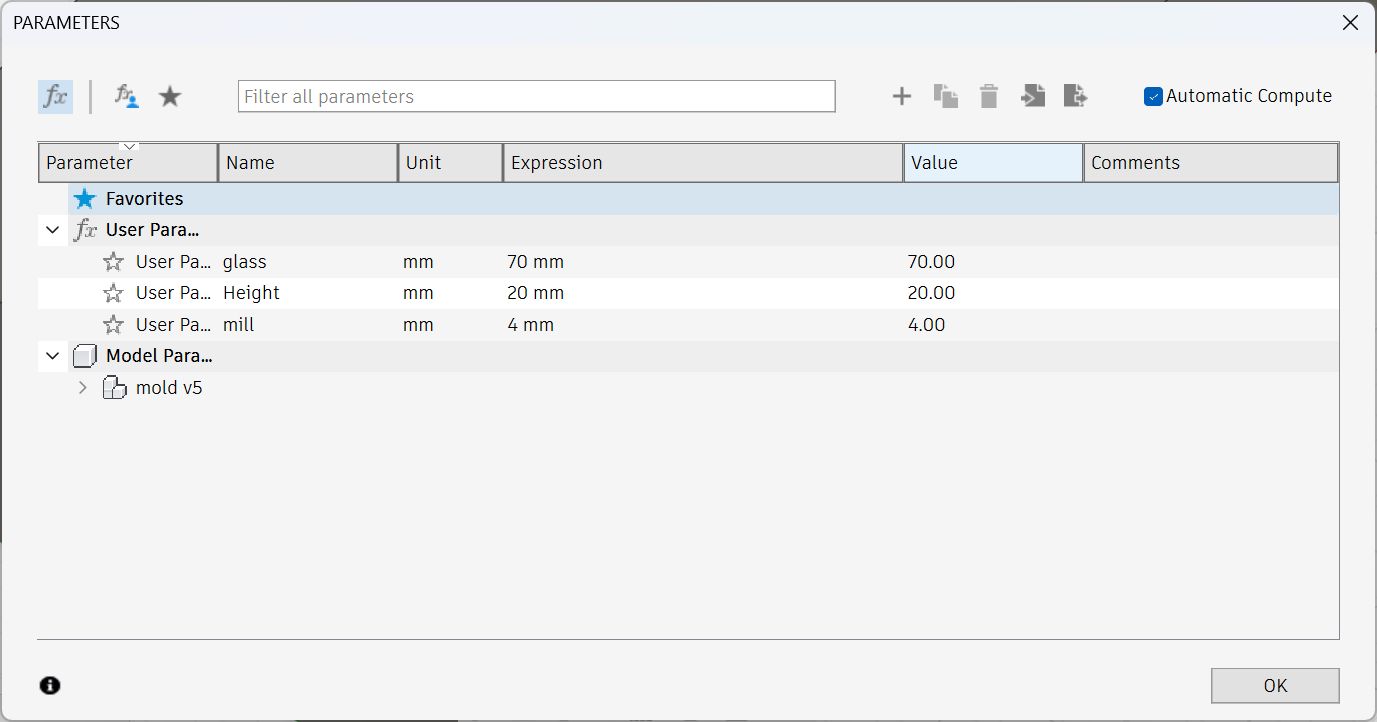

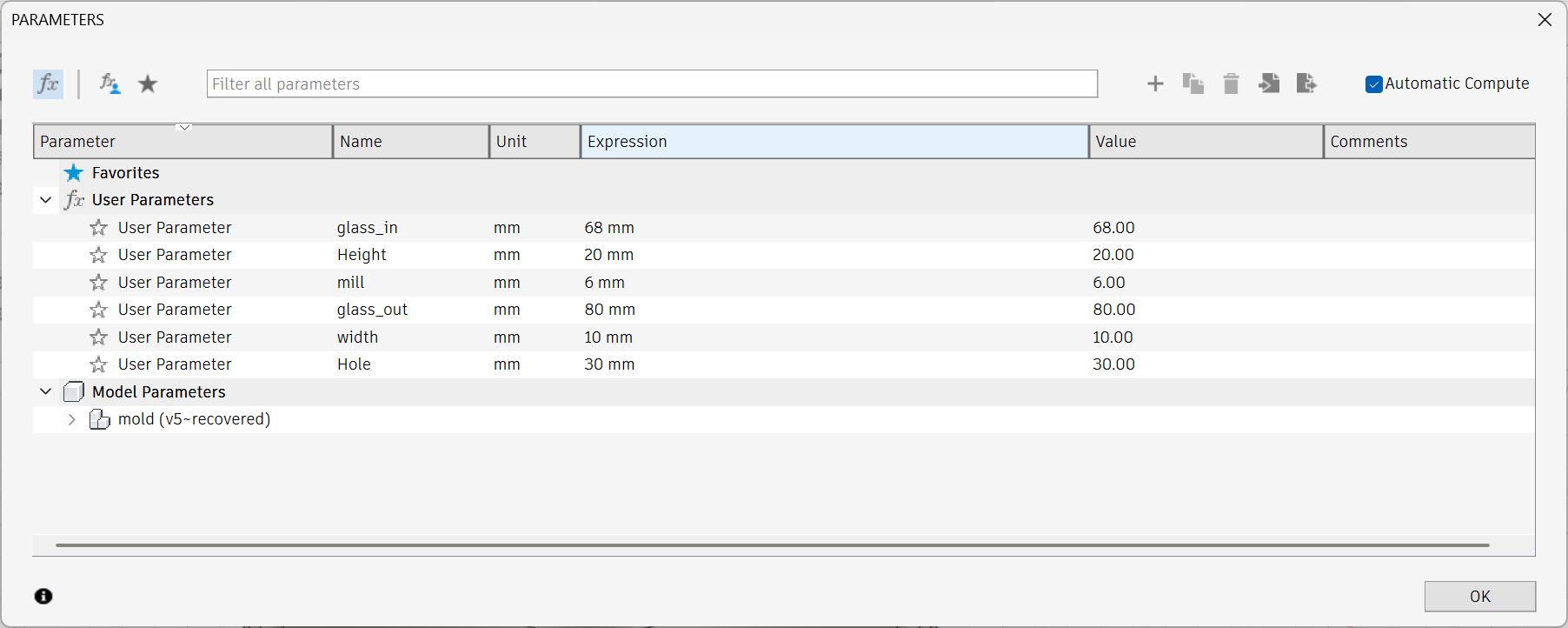

Parameter for test model

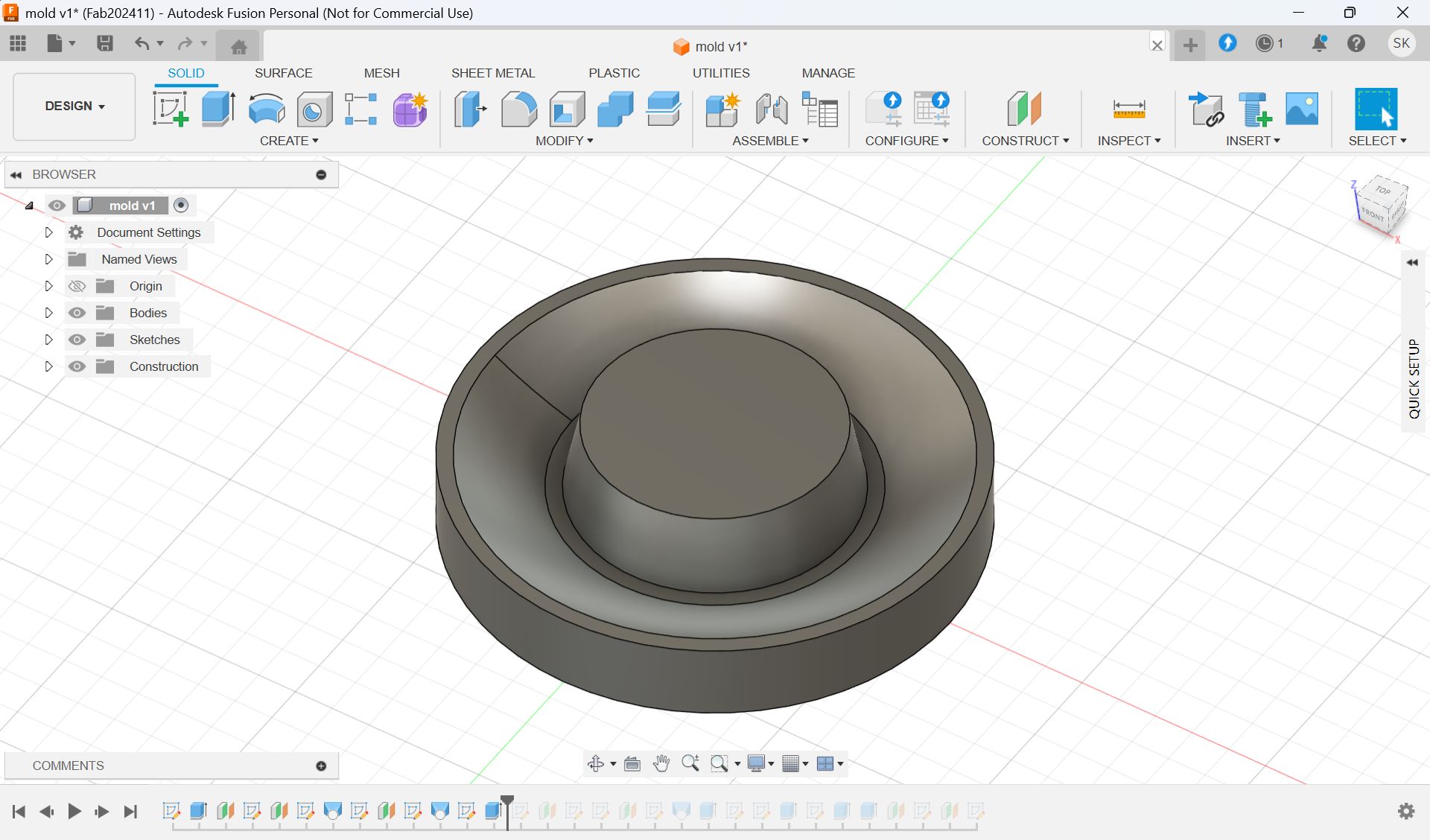

Made a model

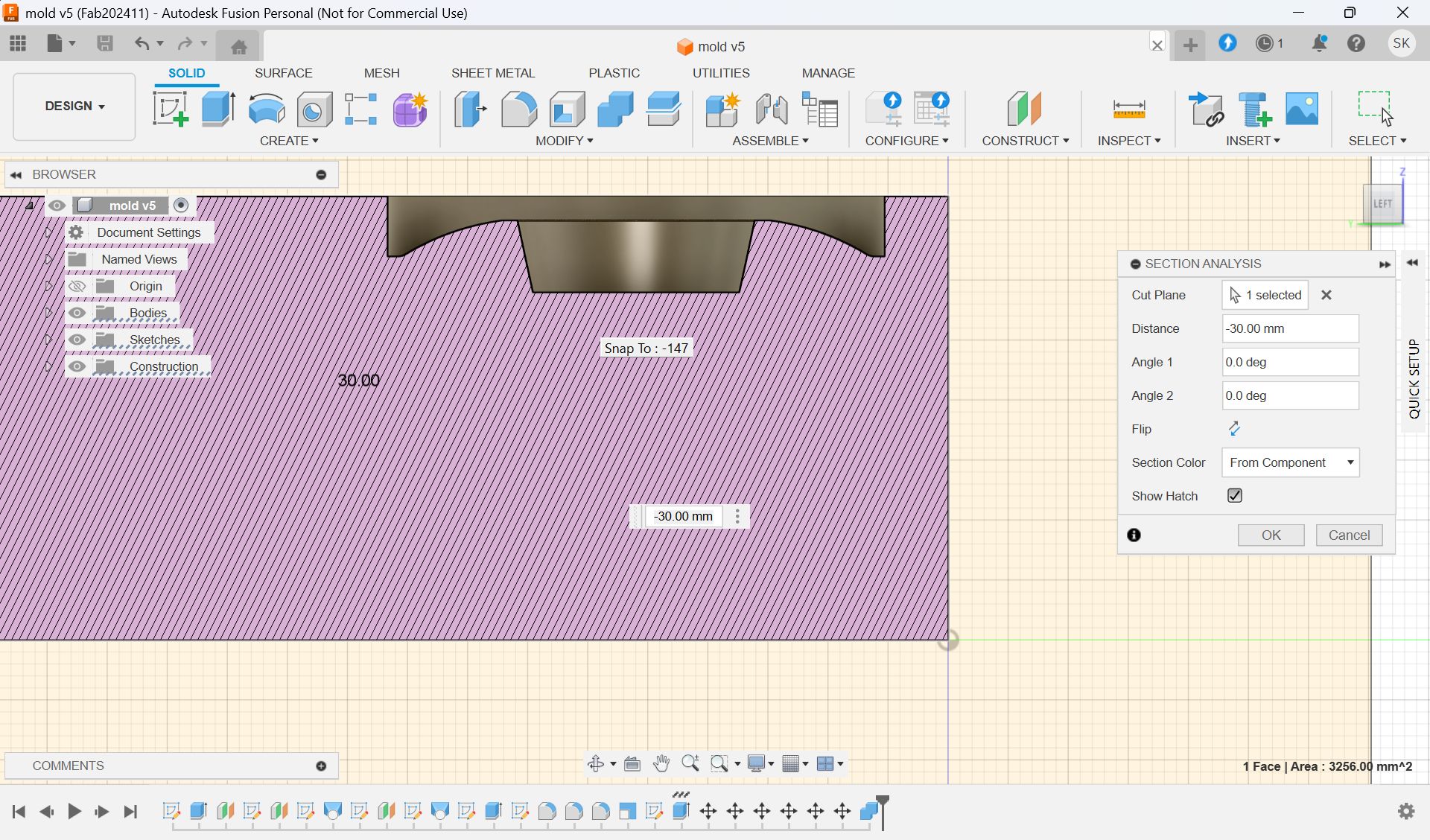

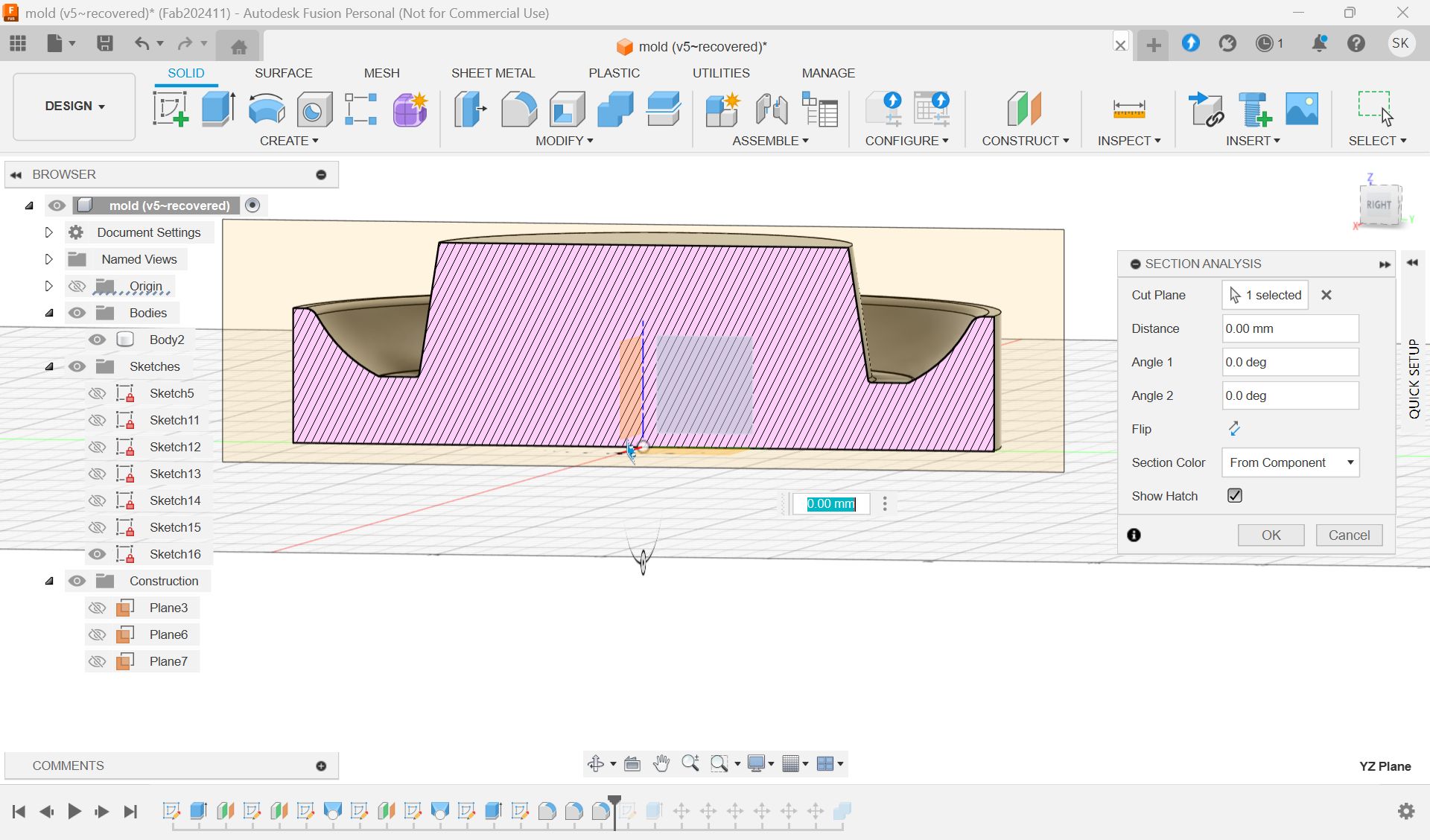

Check the cross section

This time, for testing purposes, I set it to 0.35x.

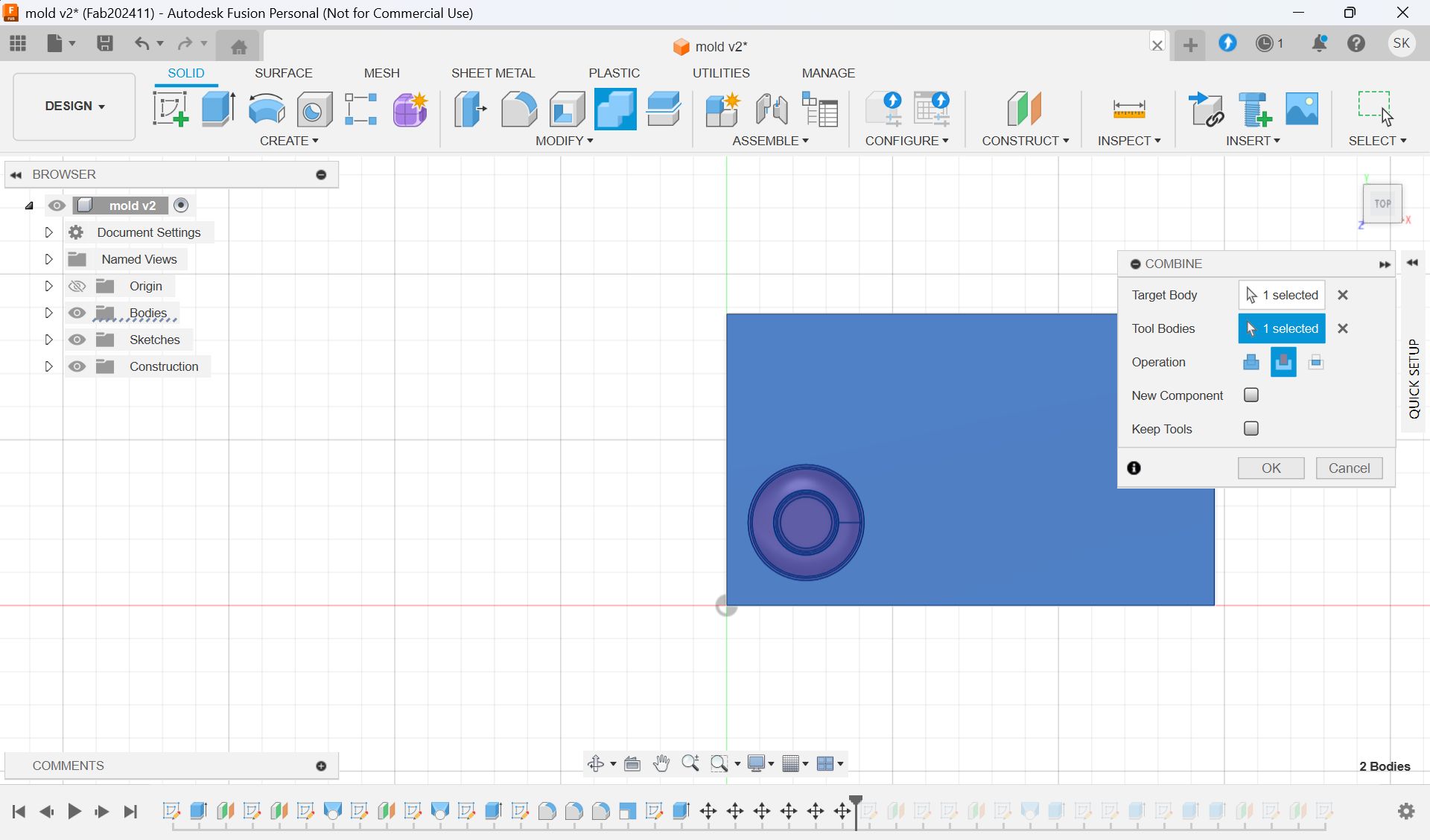

To make a mold, create a box with the size of the wax and select Combine → Cut.

Check the cross section to see if the mill can pass through without any problems.

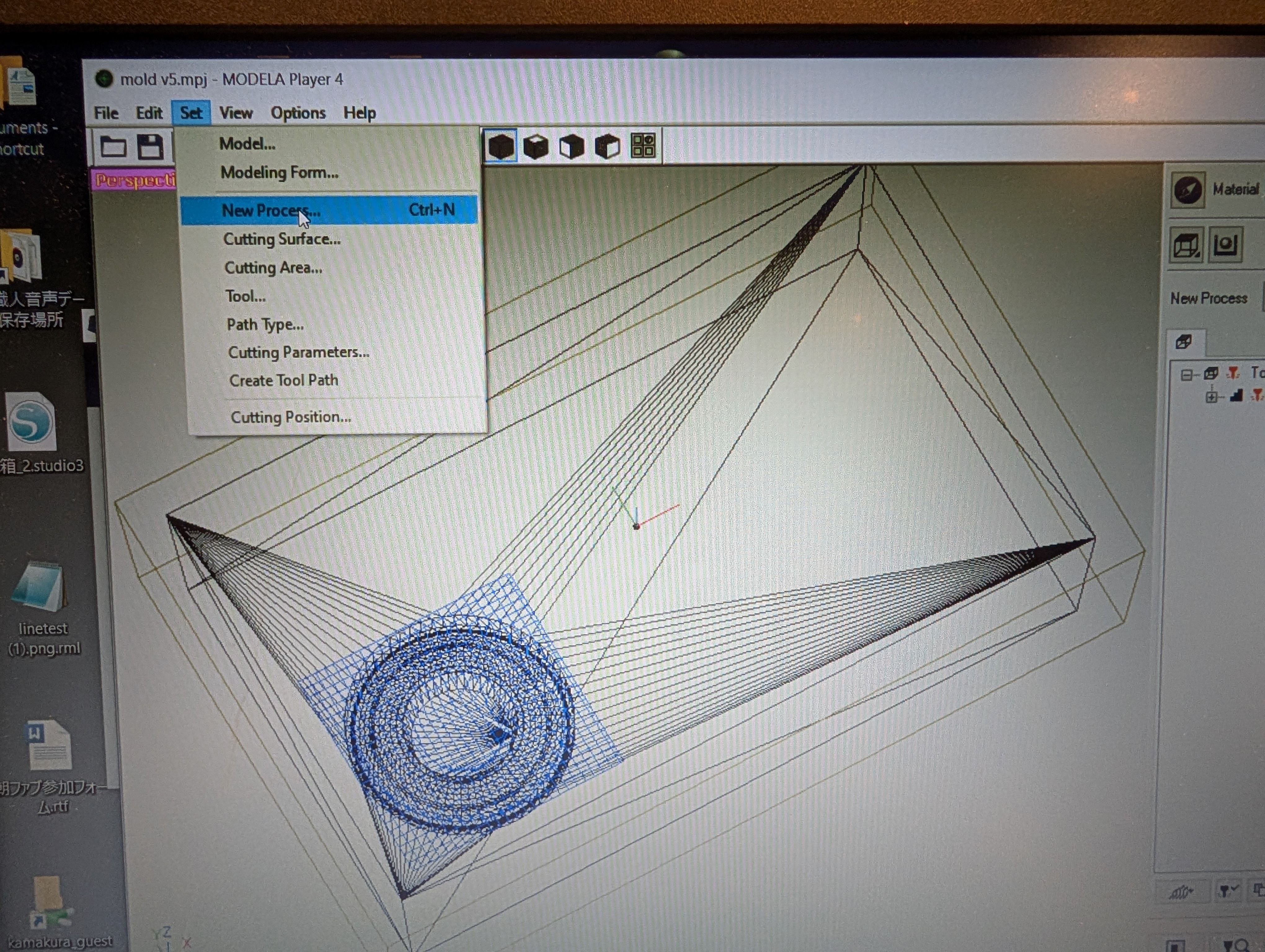

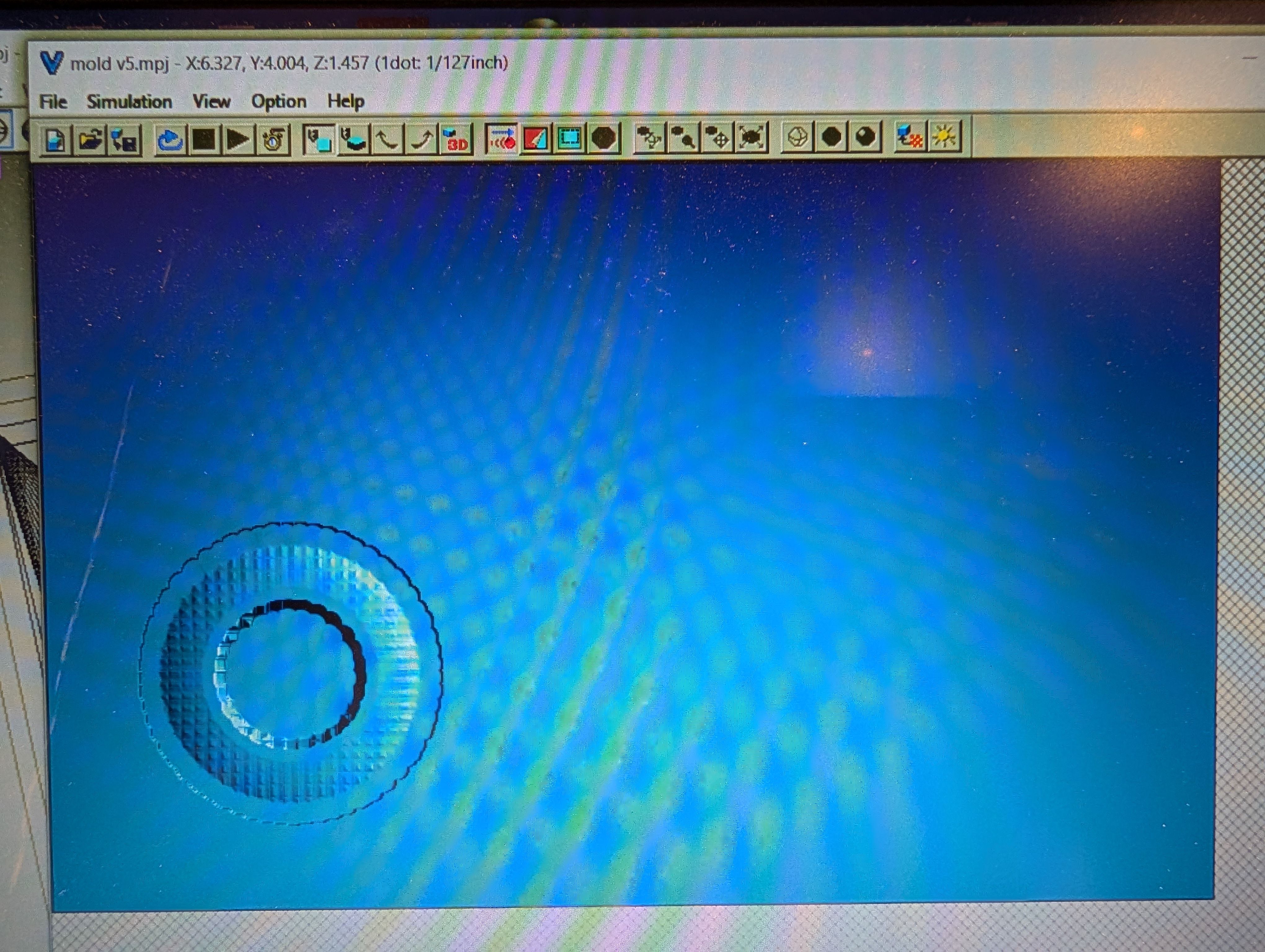

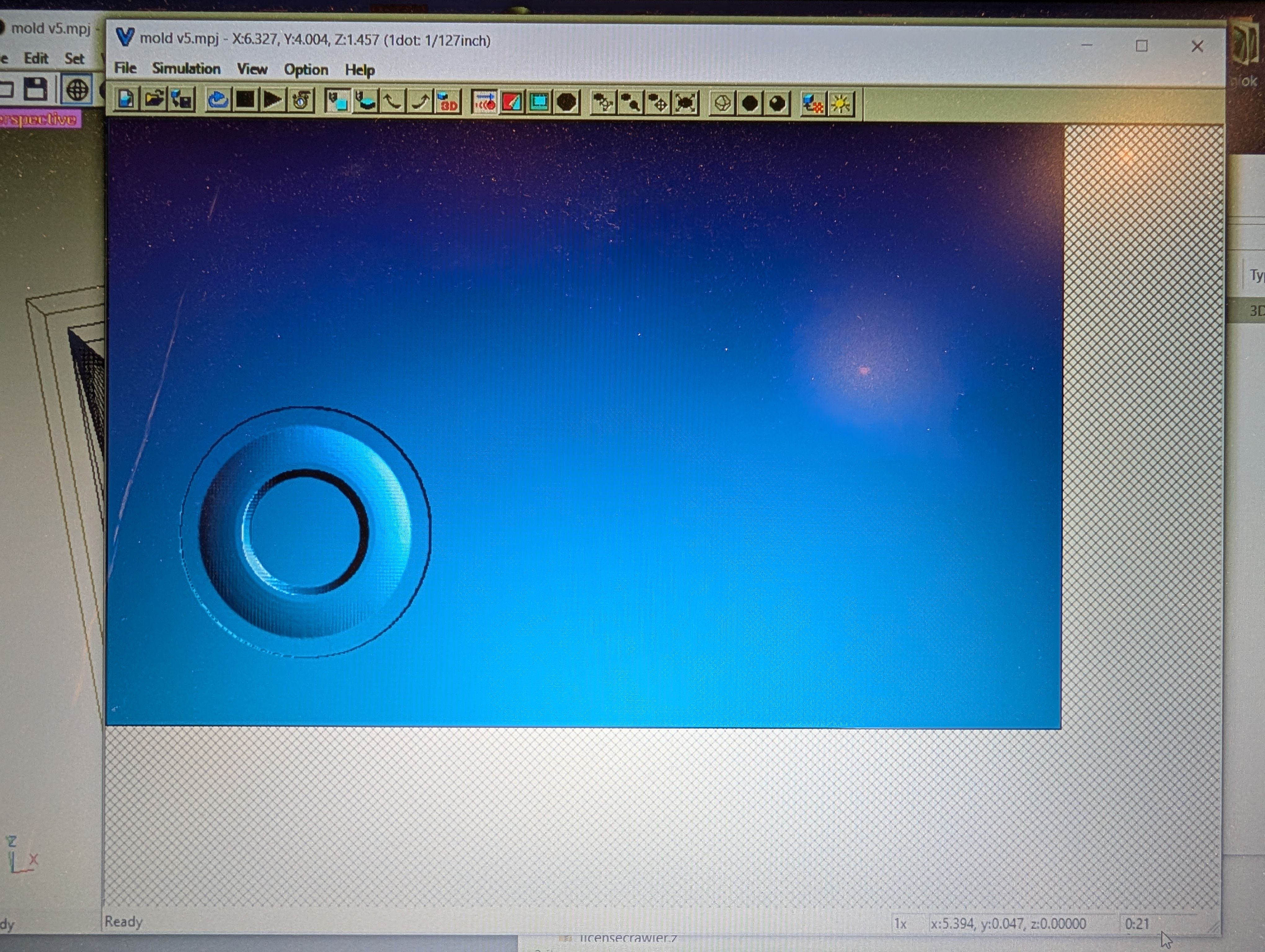

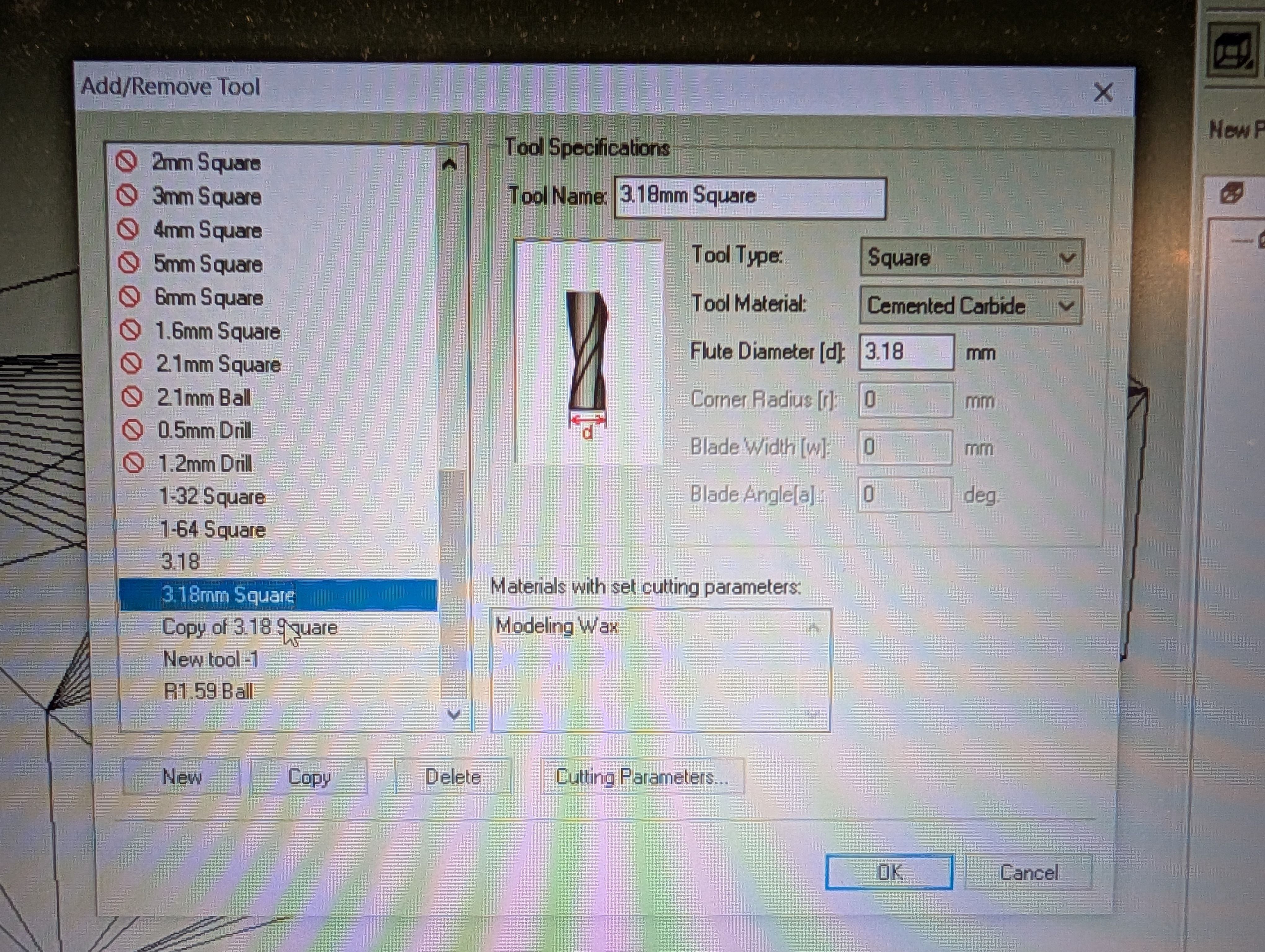

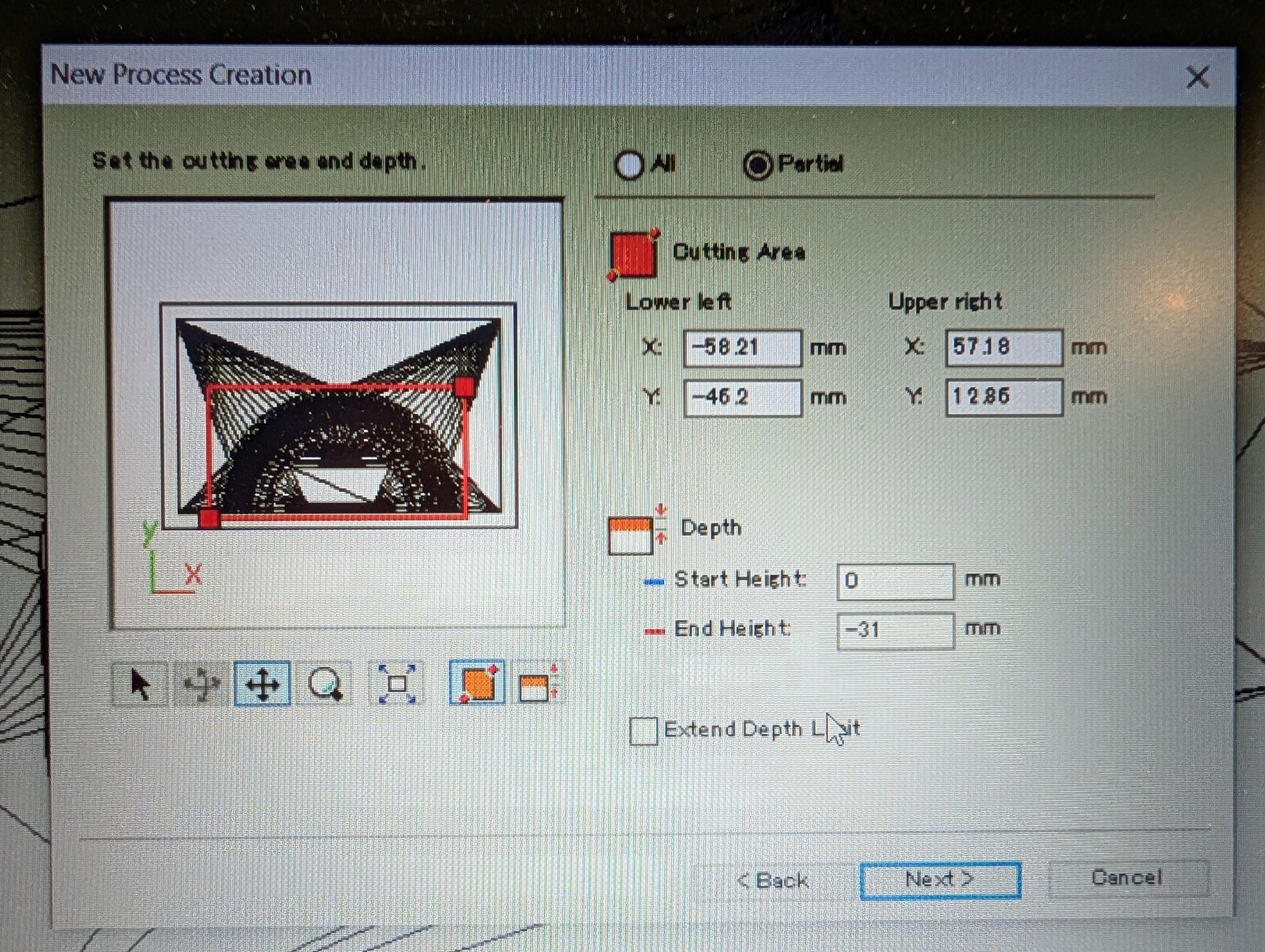

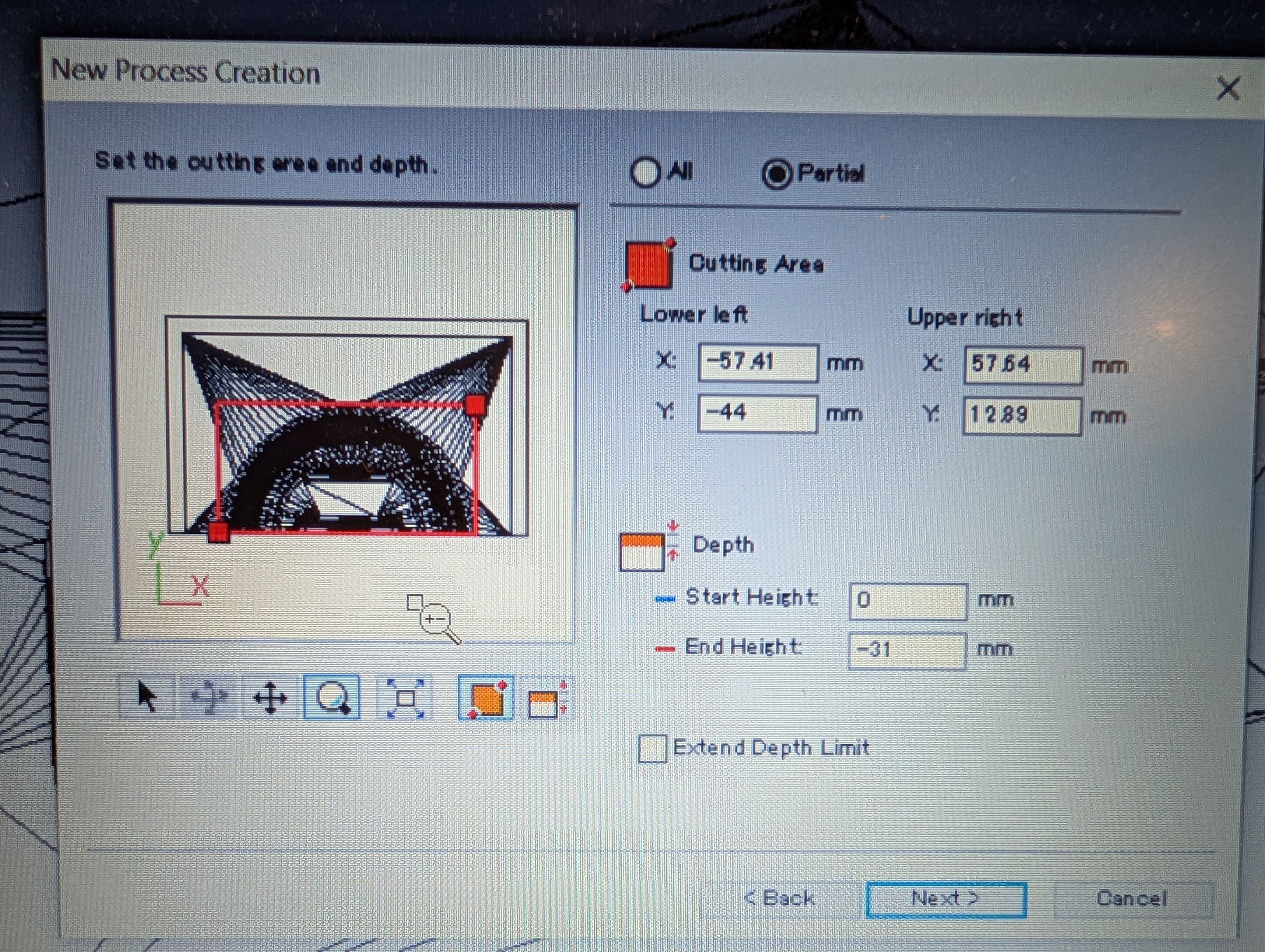

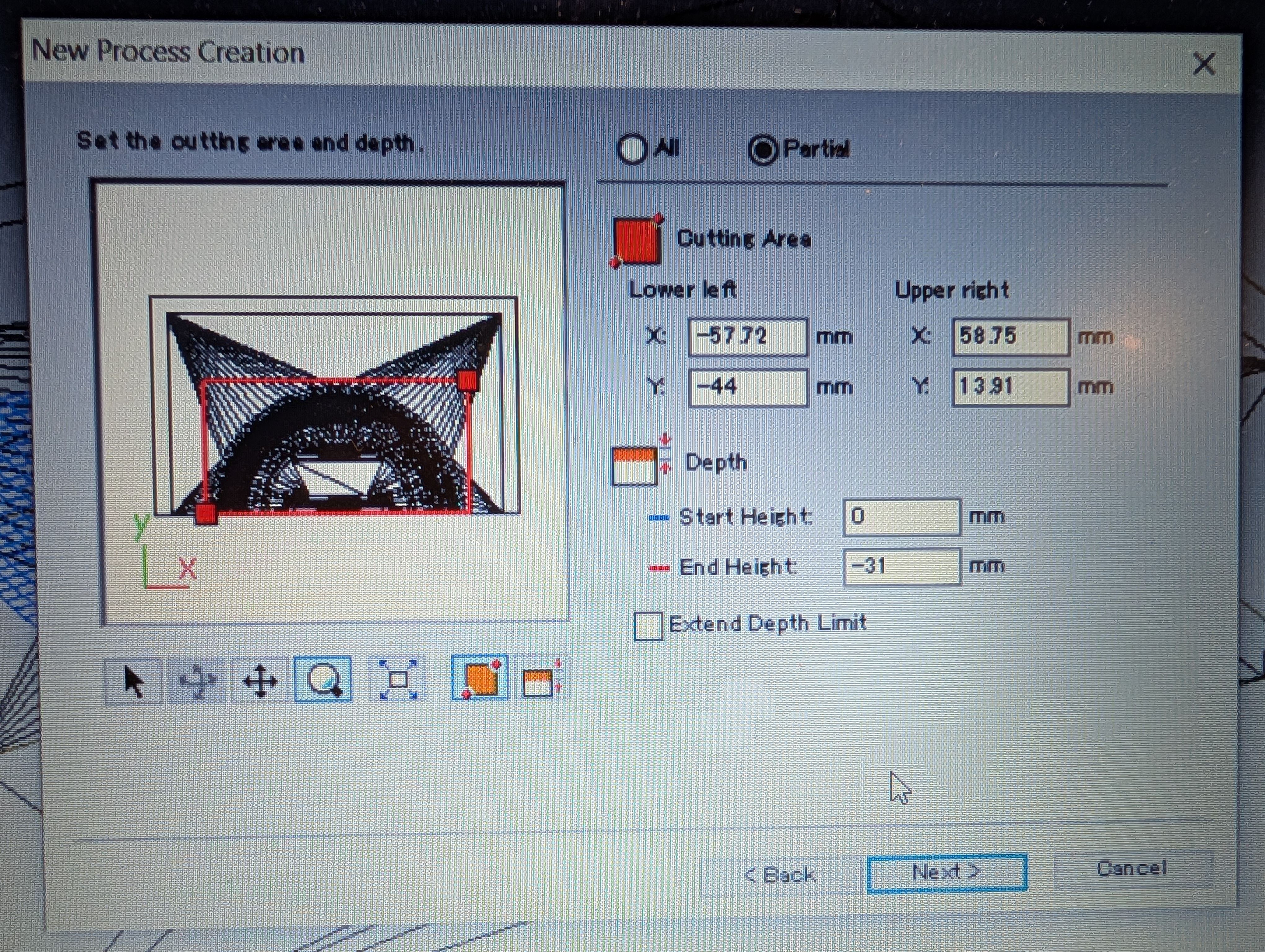

CutPass - Modela

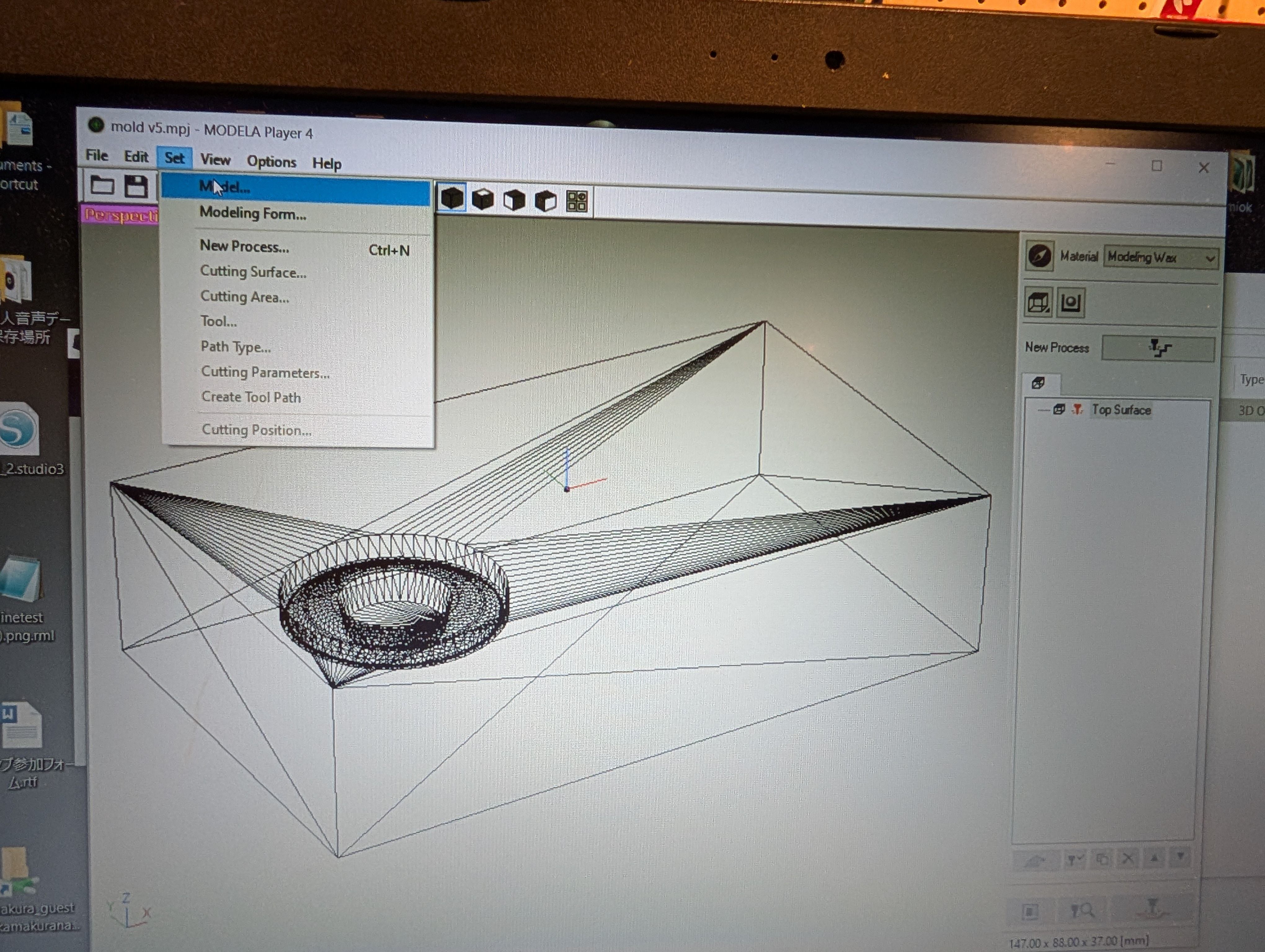

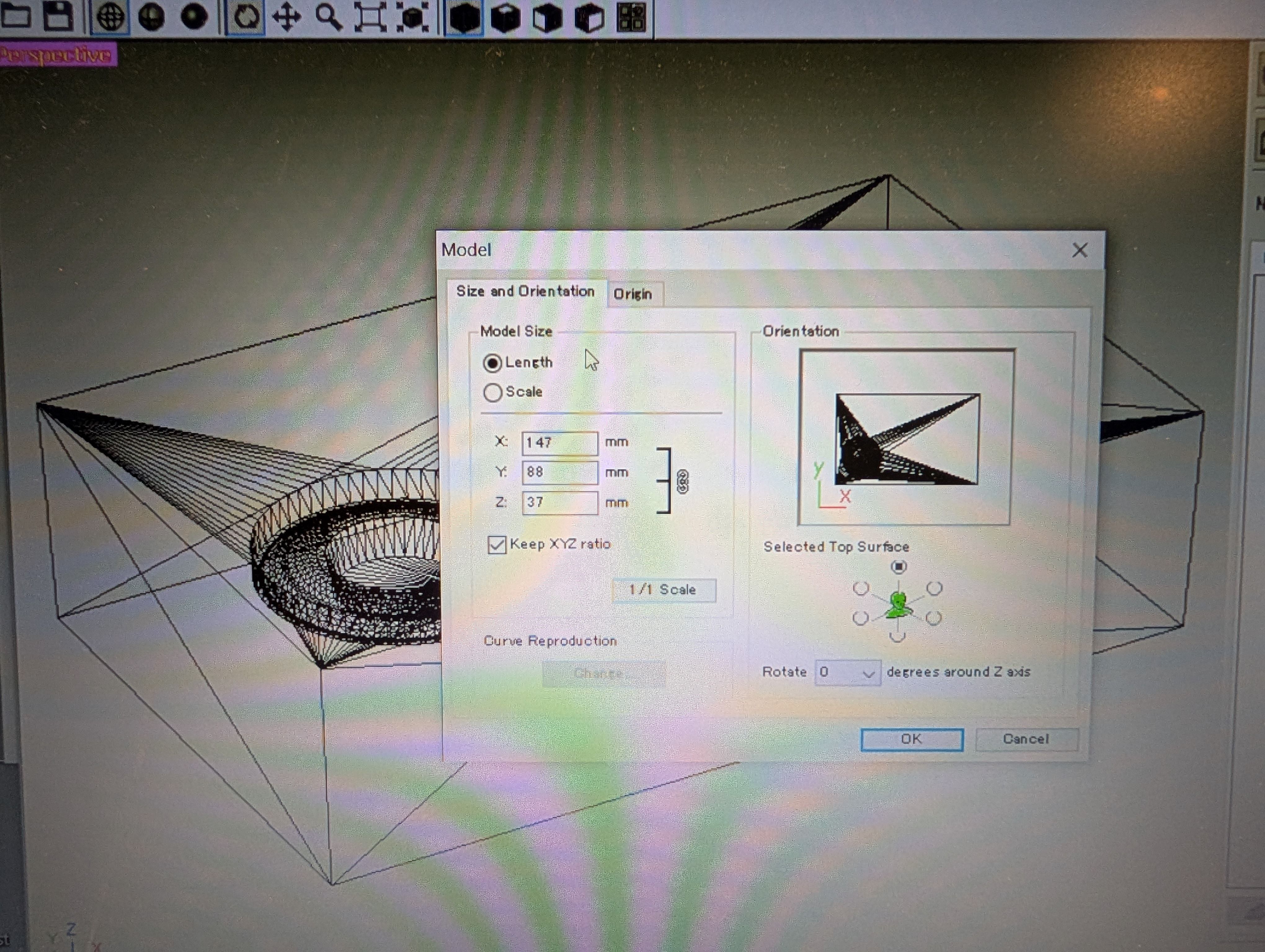

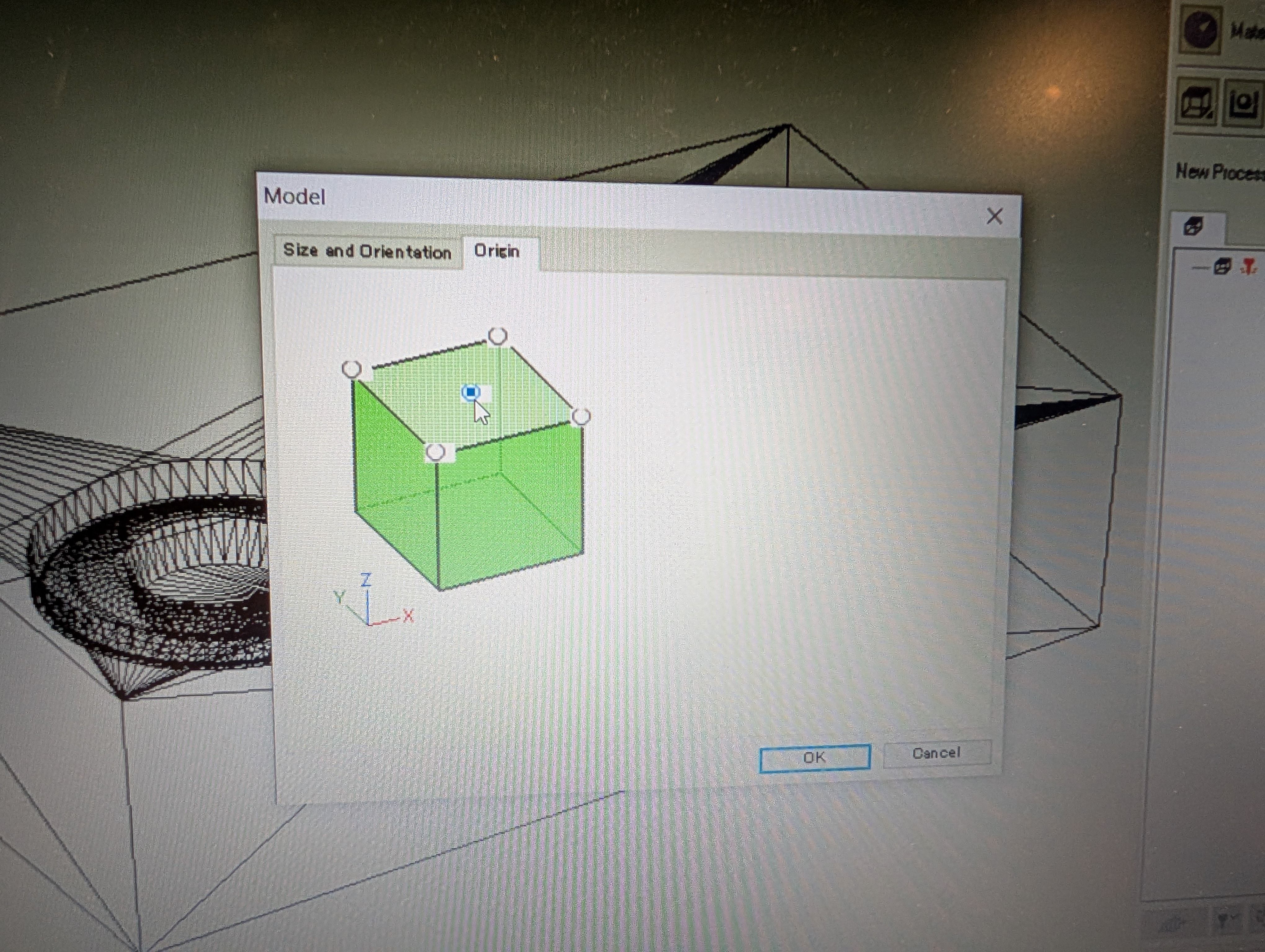

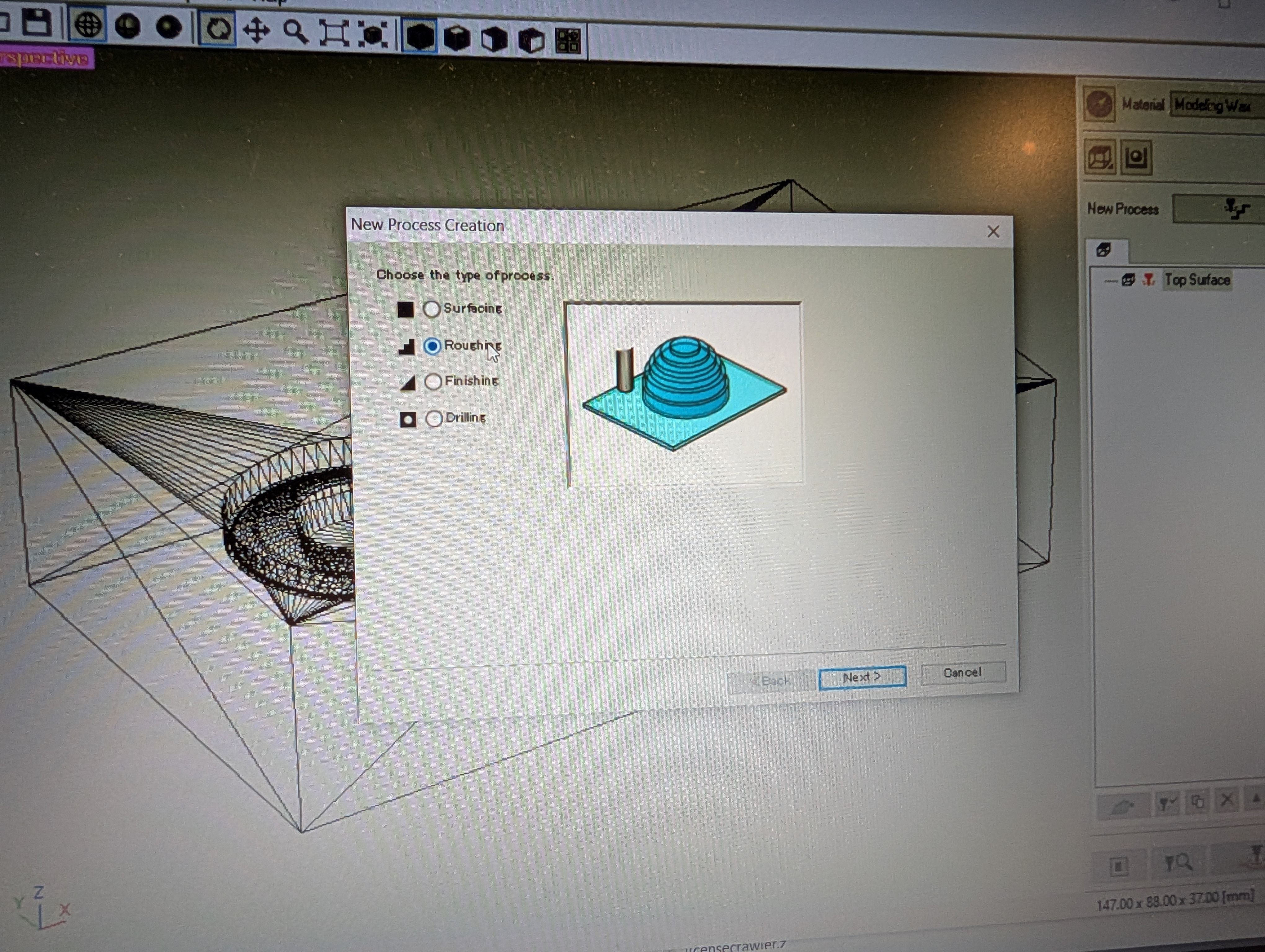

Modela

Open file, choose “Model” menu and confirm the orientation. And Origin

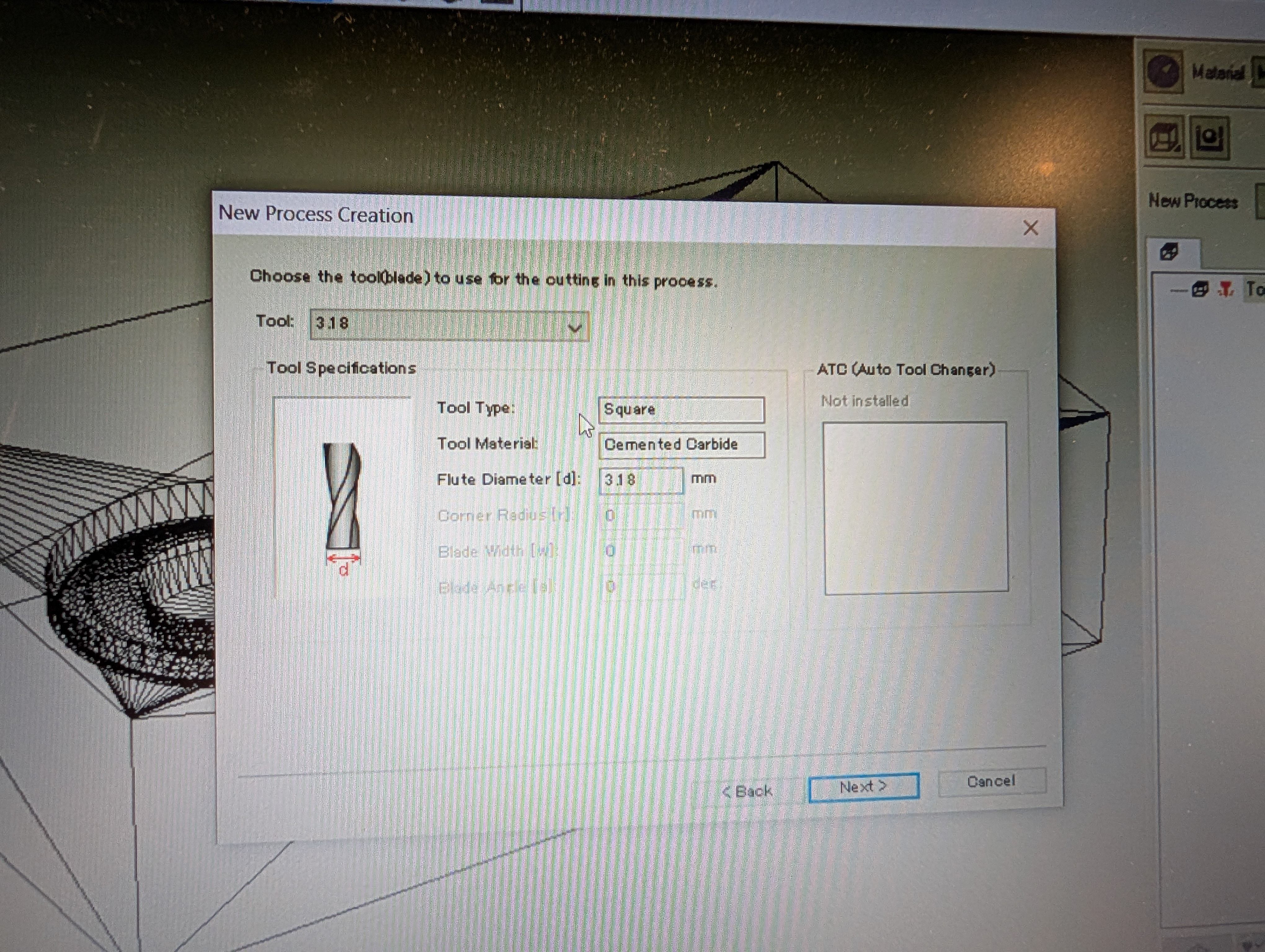

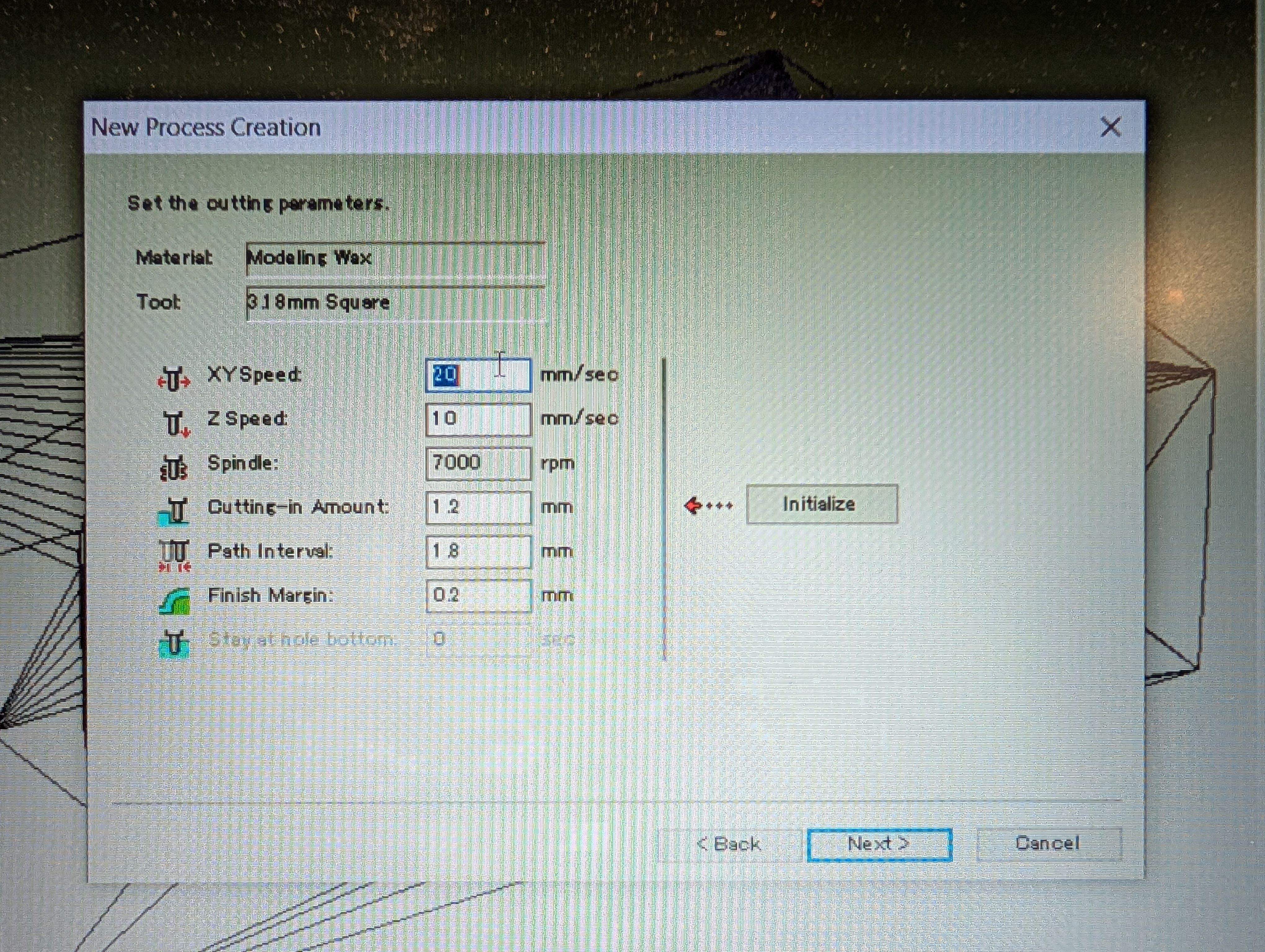

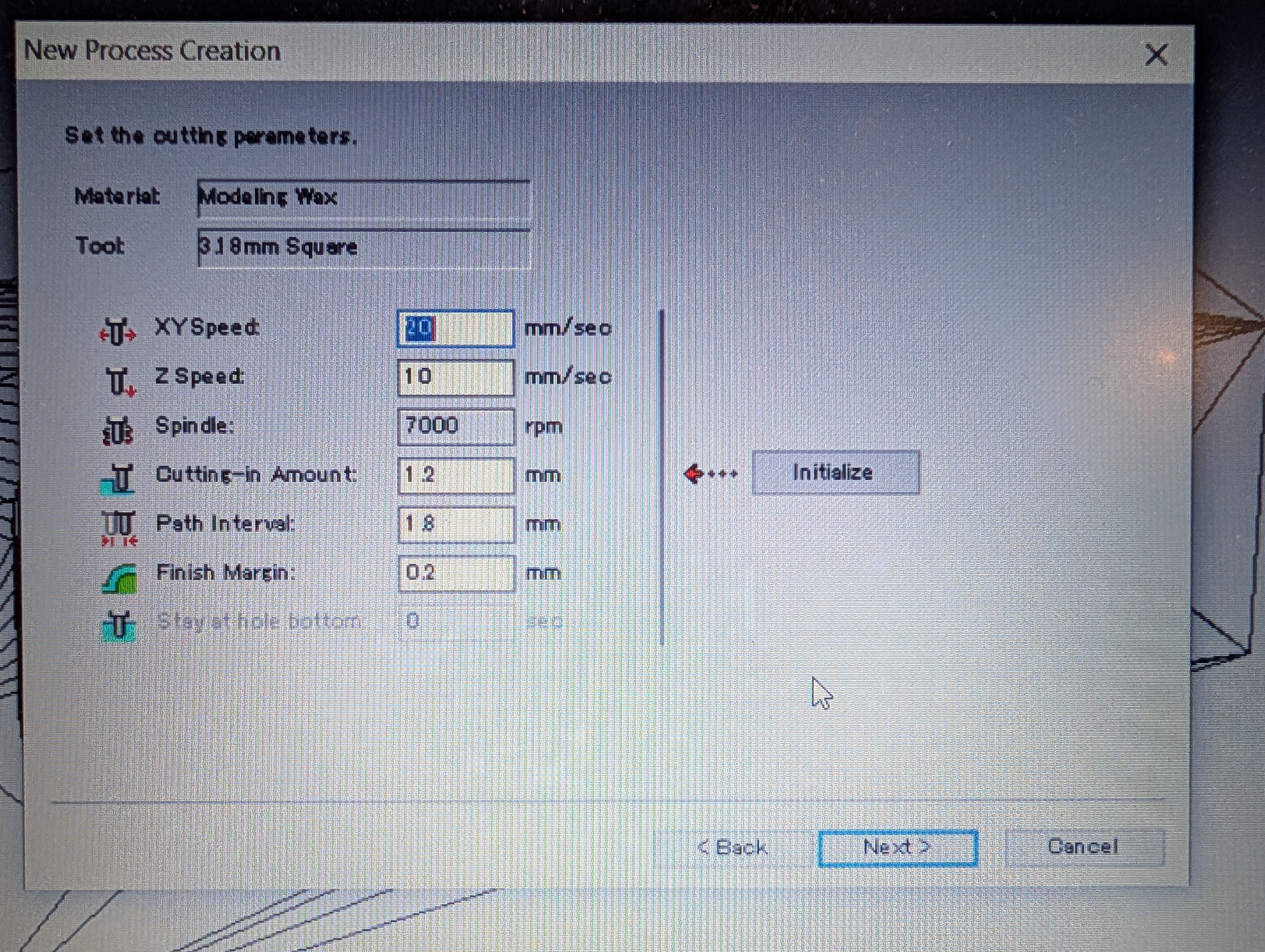

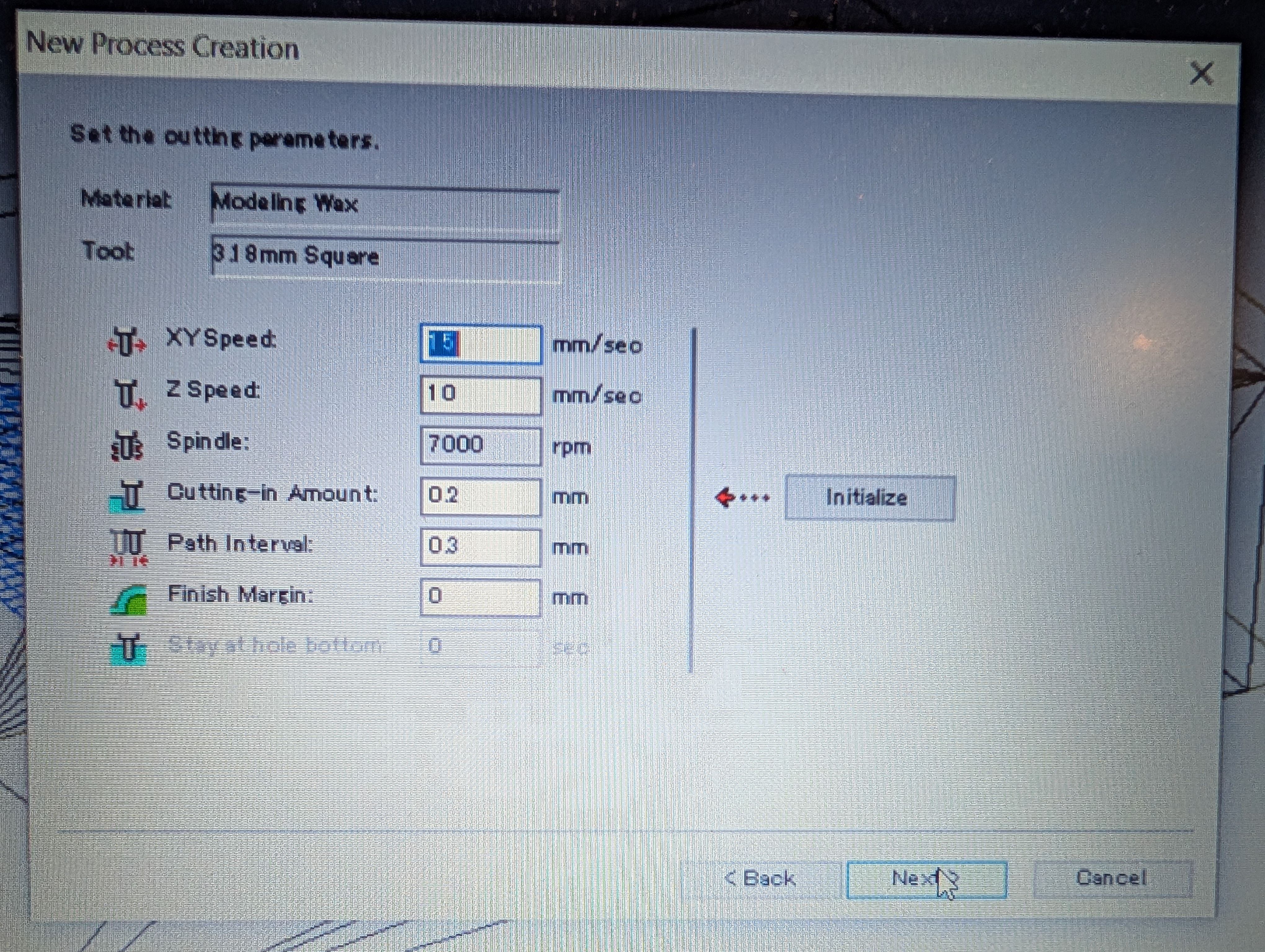

Setting for Roughing

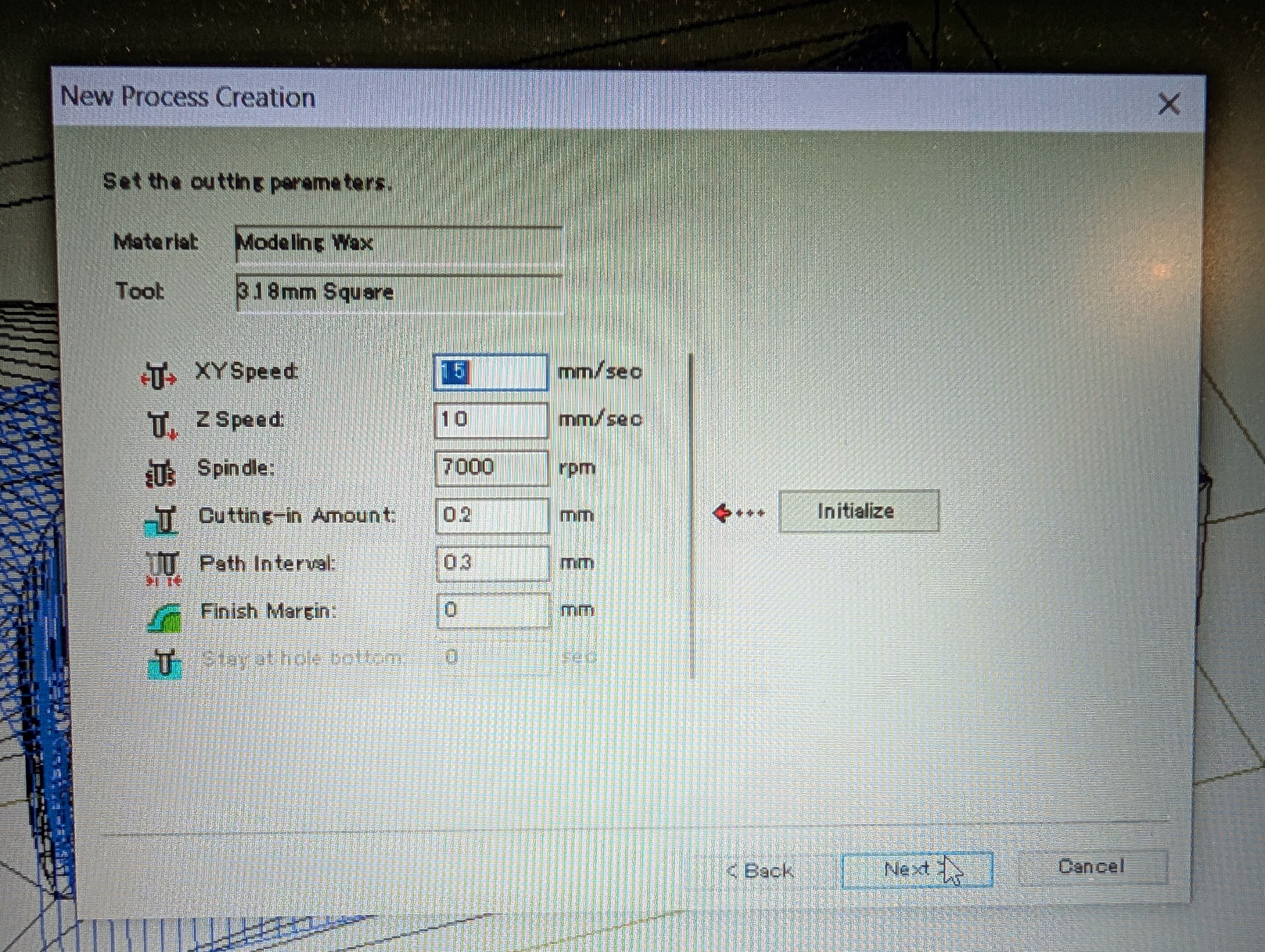

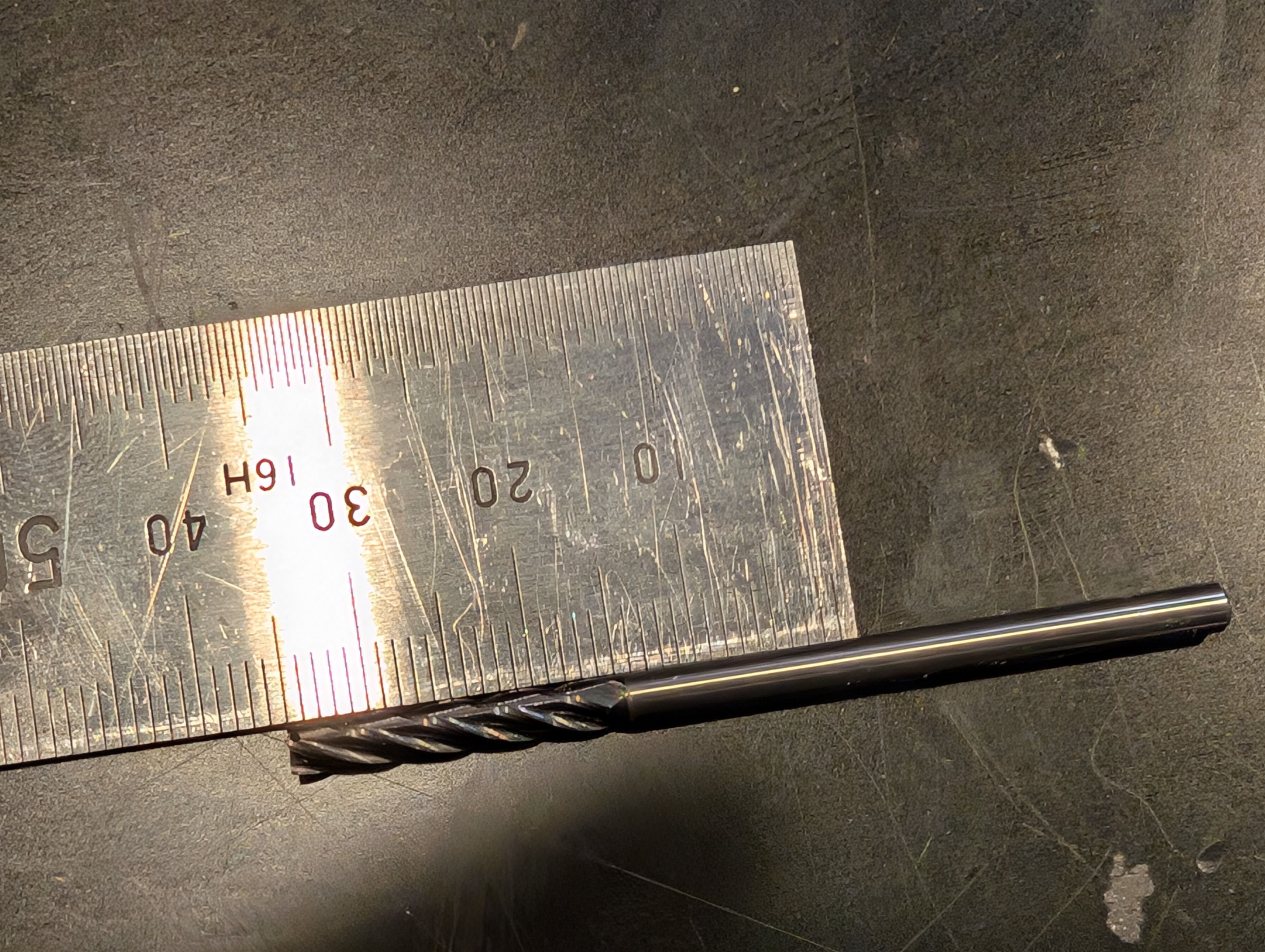

Tool(blade): 3.18 mm square mill

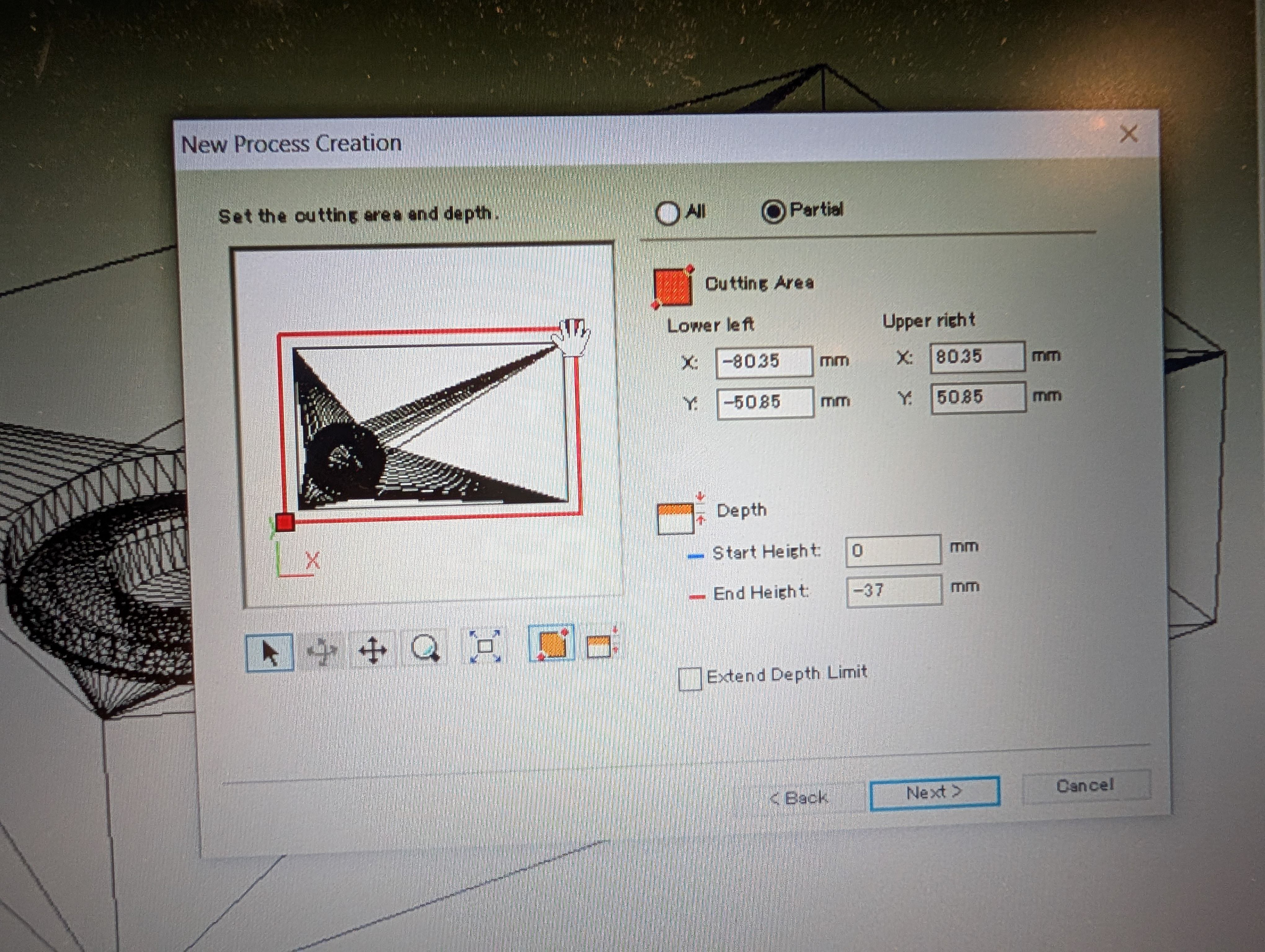

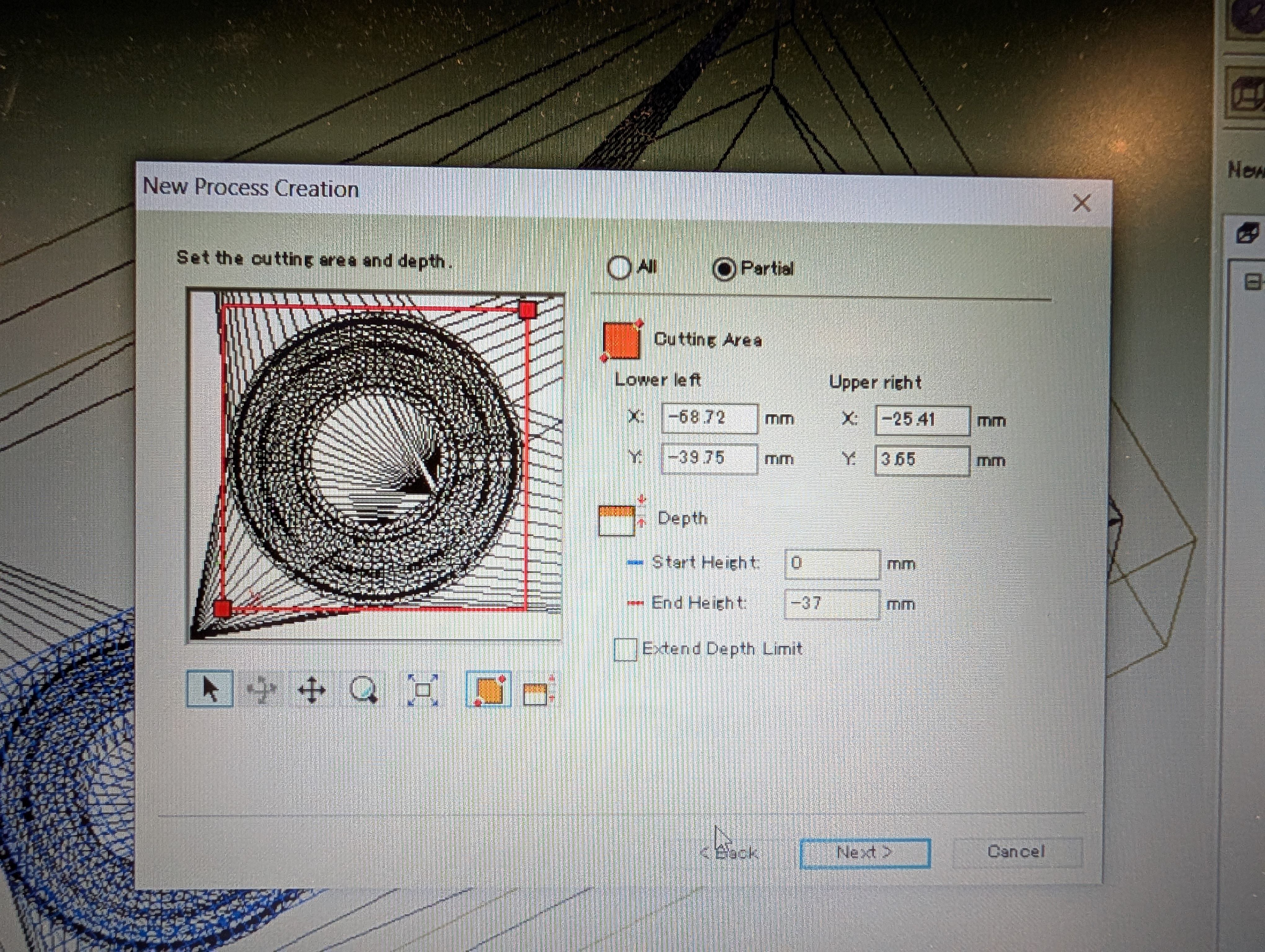

Set cutting area and shorten the cutting time

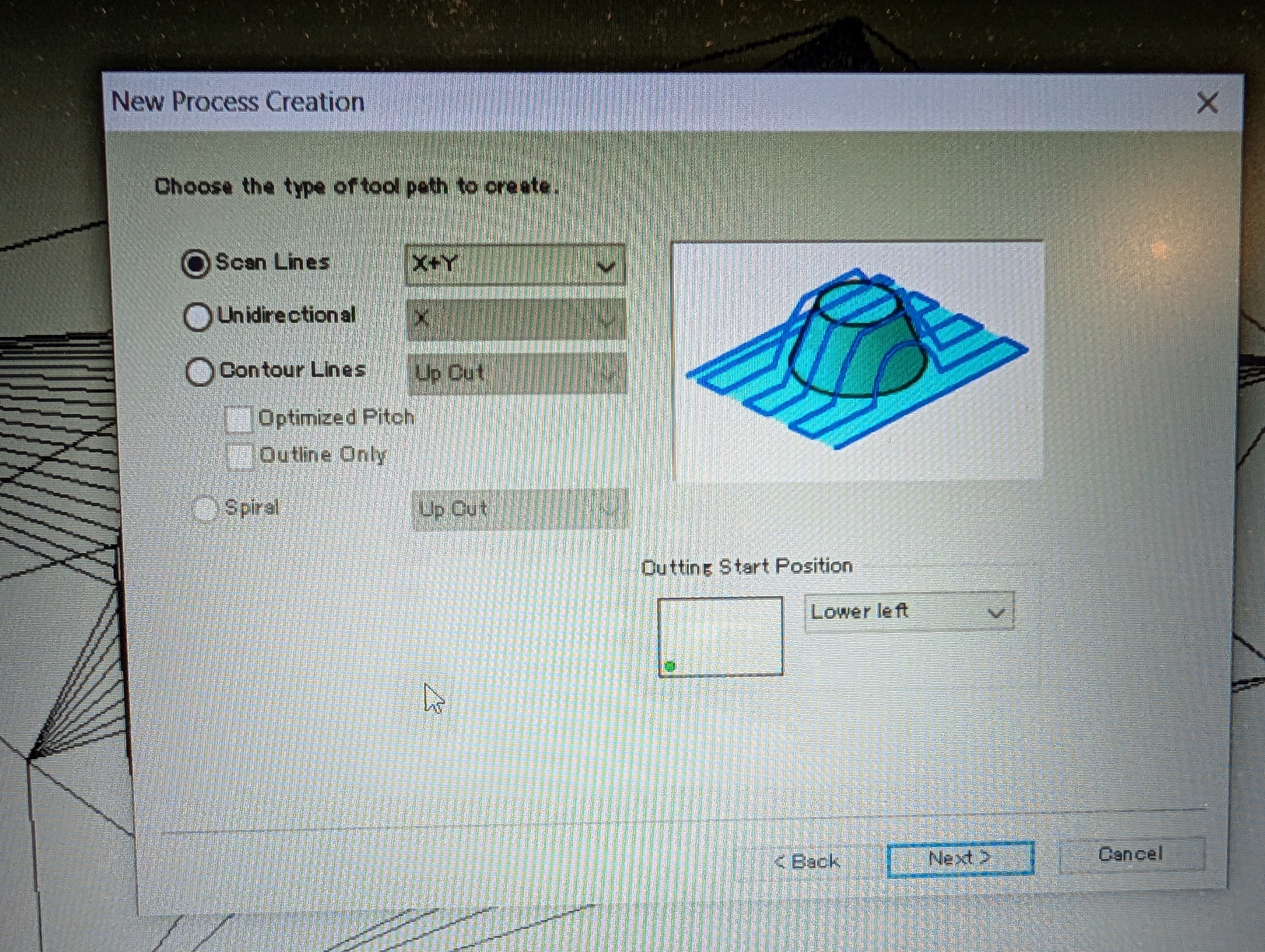

Scan Lines X+Y

XY Speed : 20mm/sec

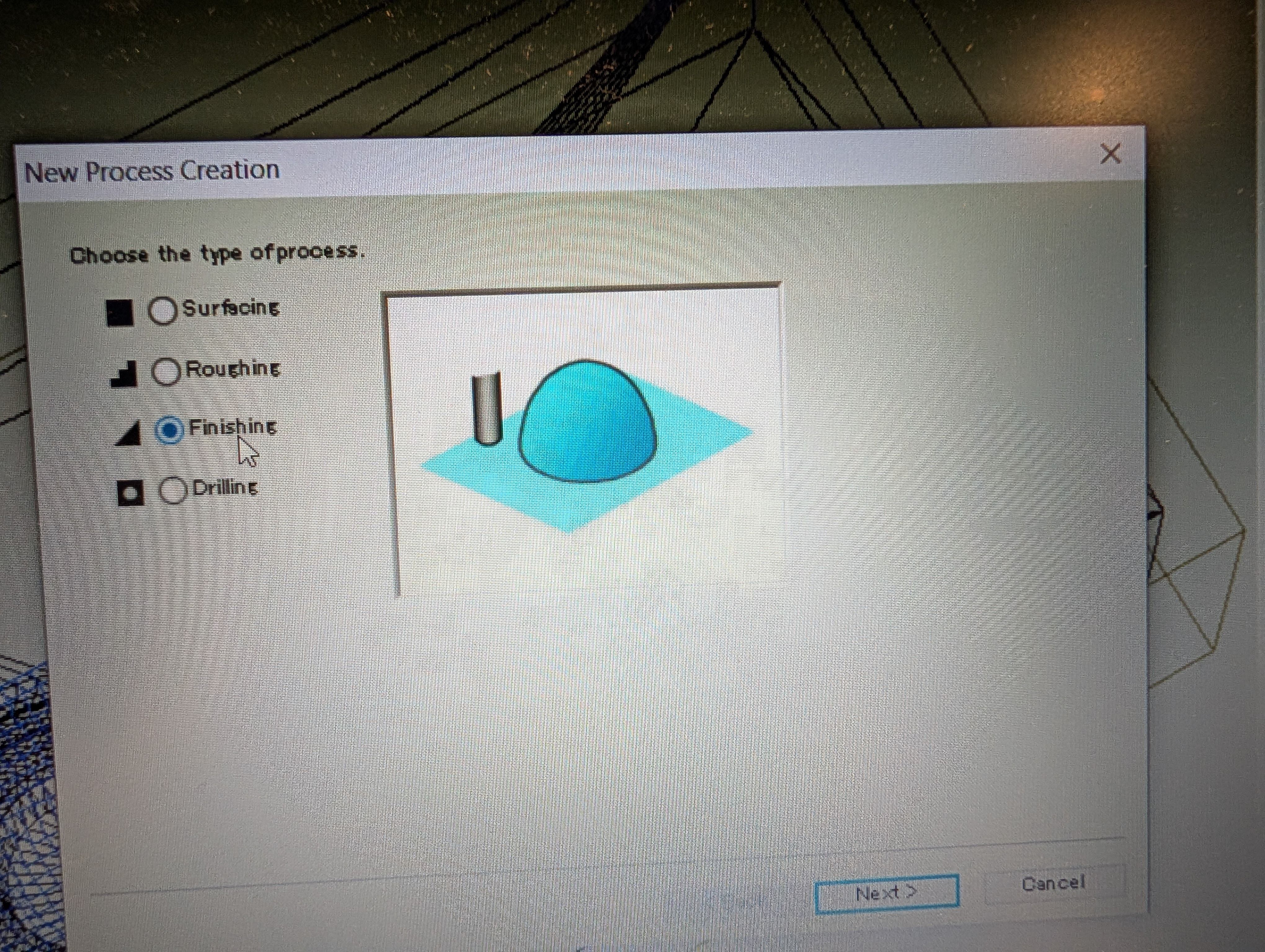

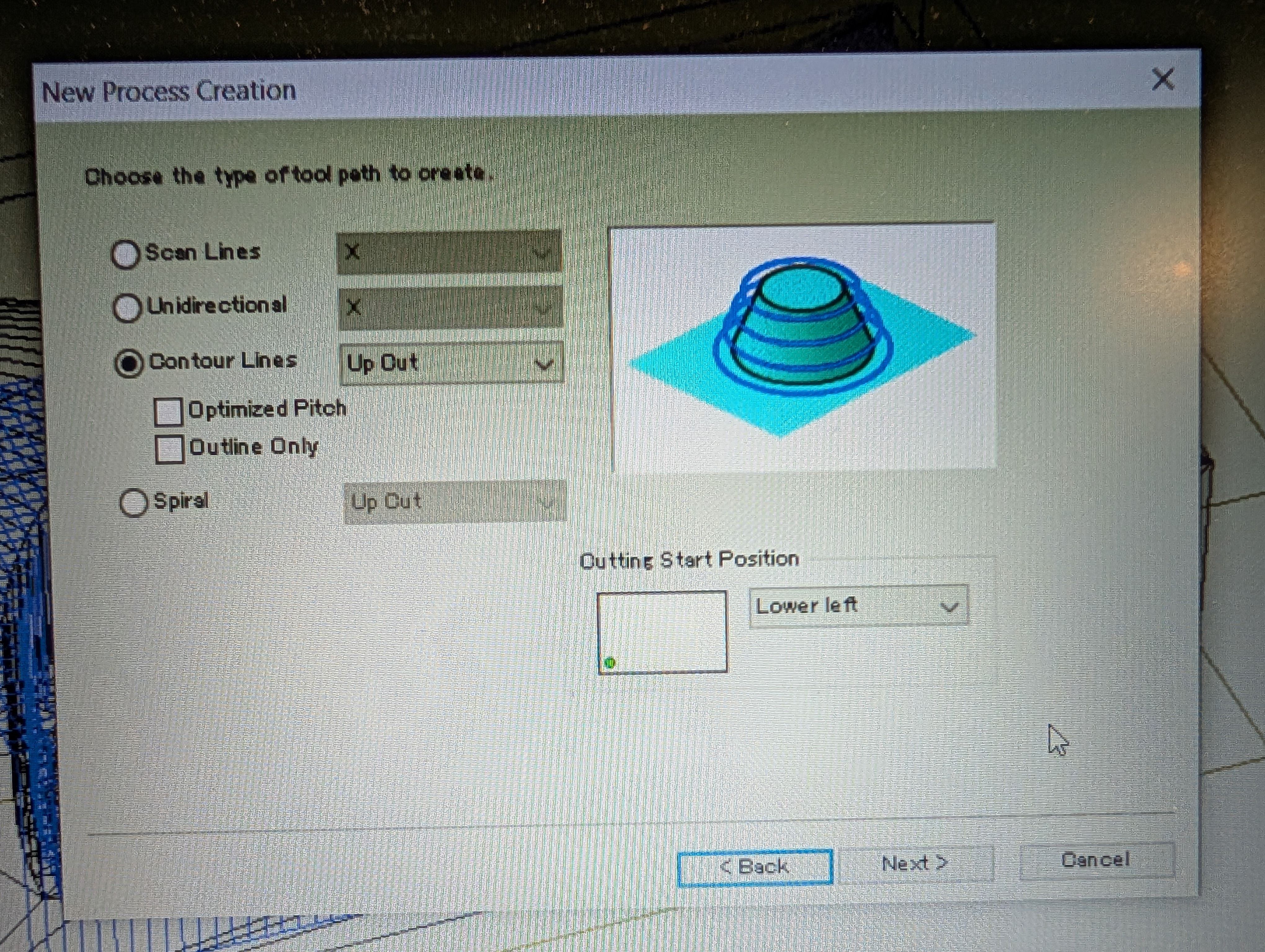

Setting for finishing

Use same tool

Contour Lines Up Out

XY Speed : 15mm/sec

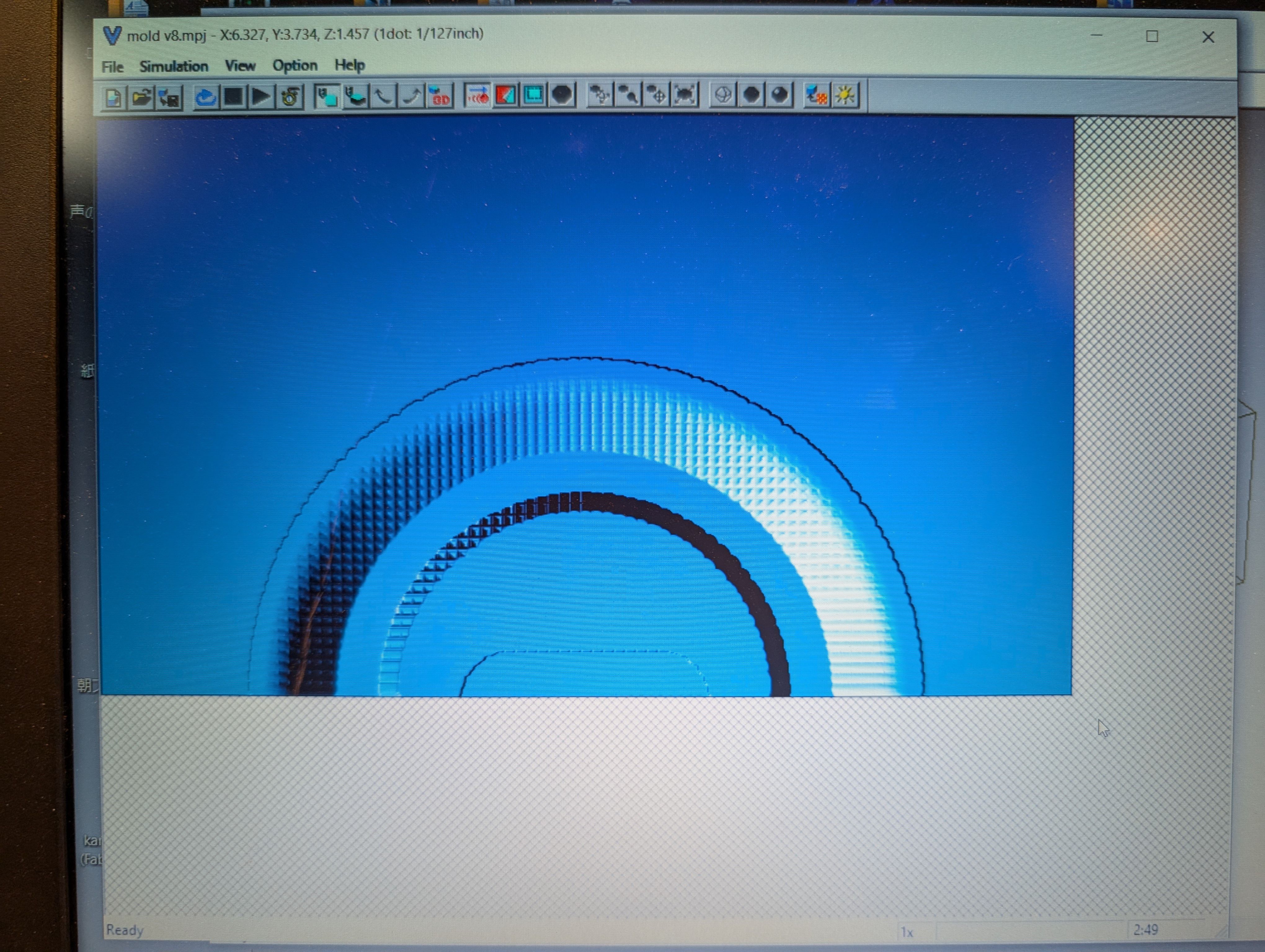

Check time from “Preview Cutting” menu

Time for roughing: 0h12m

Time for finishing: 0h21m

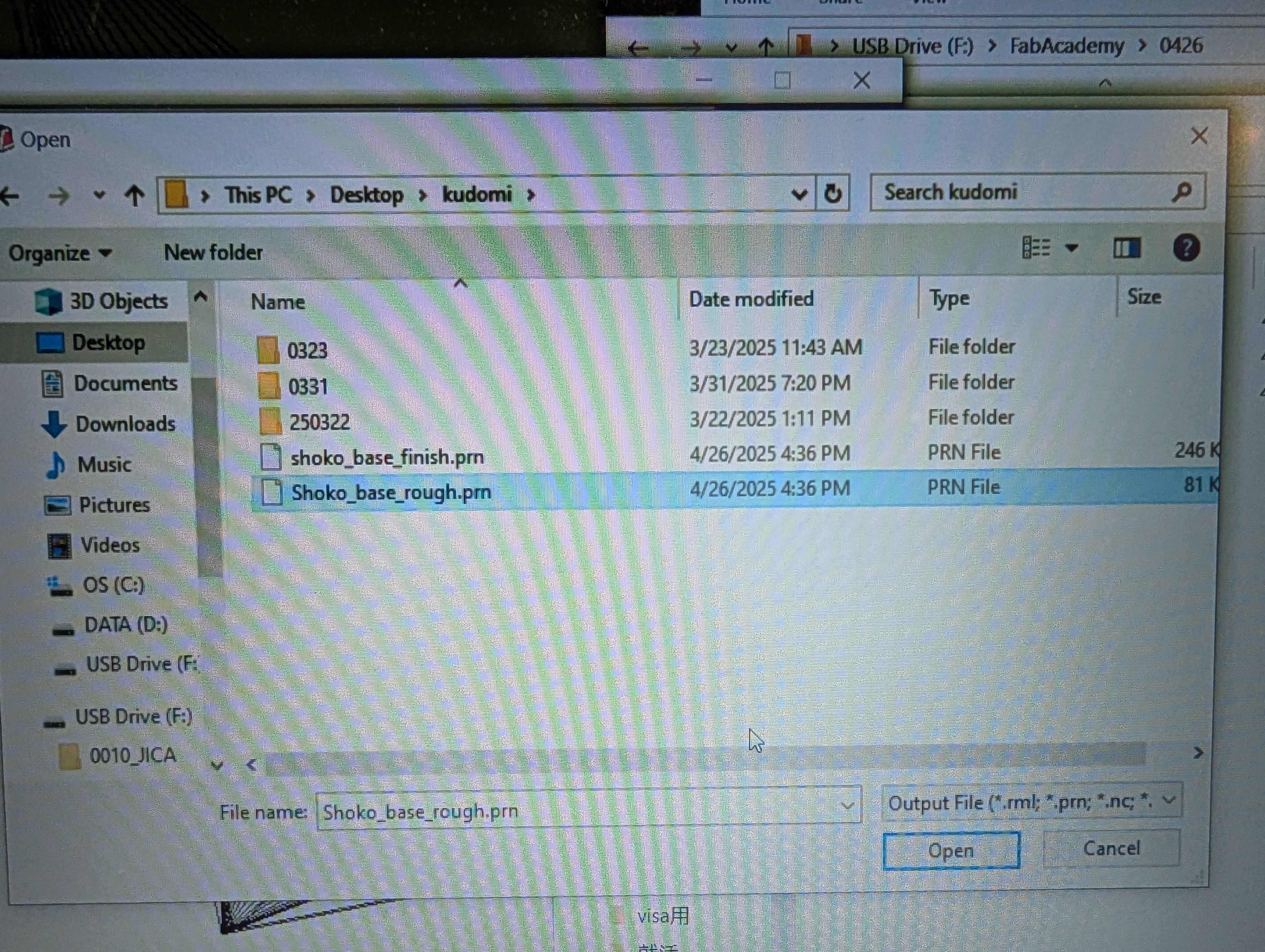

Output path file from “Cut” menu on right bottom

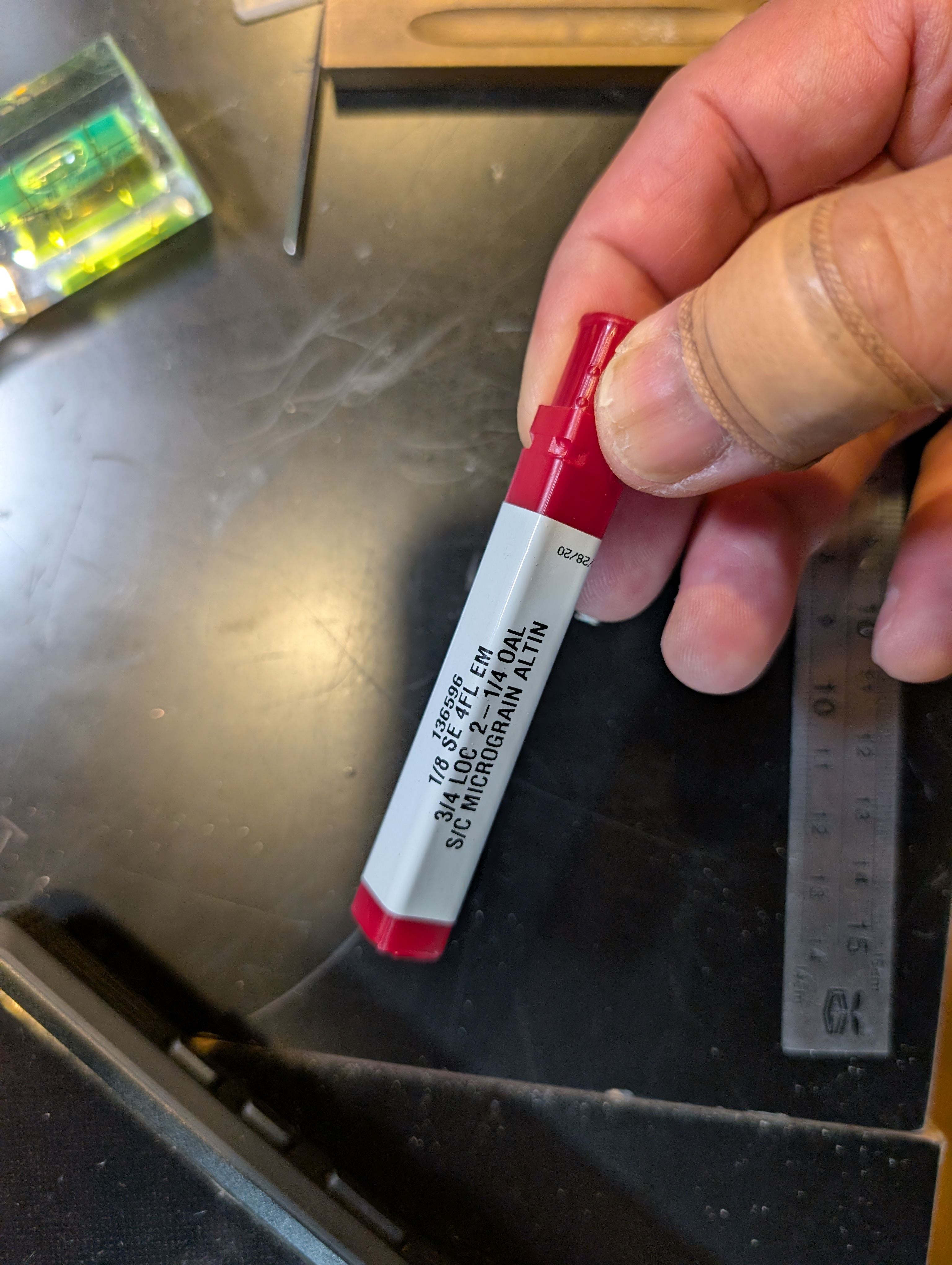

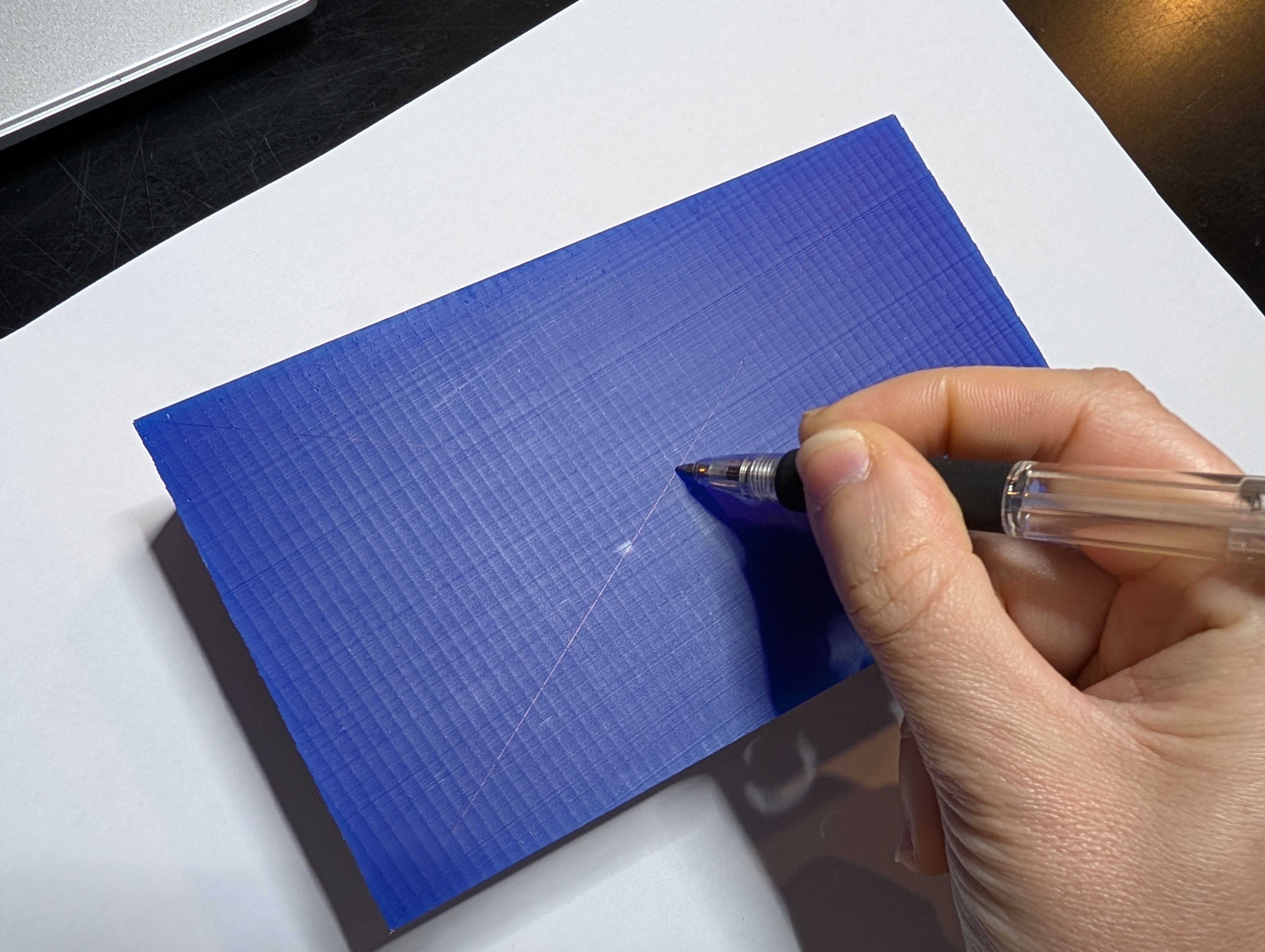

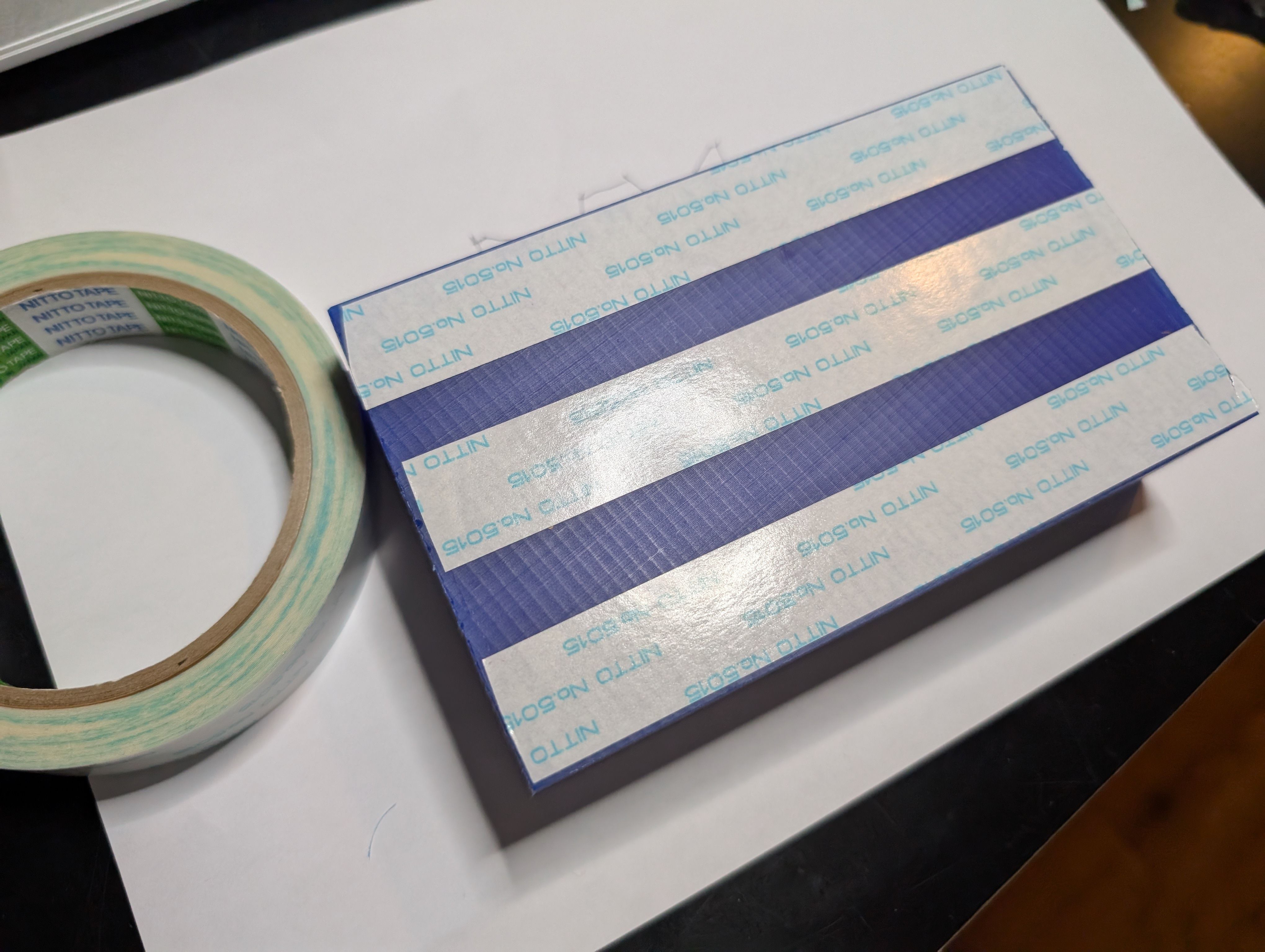

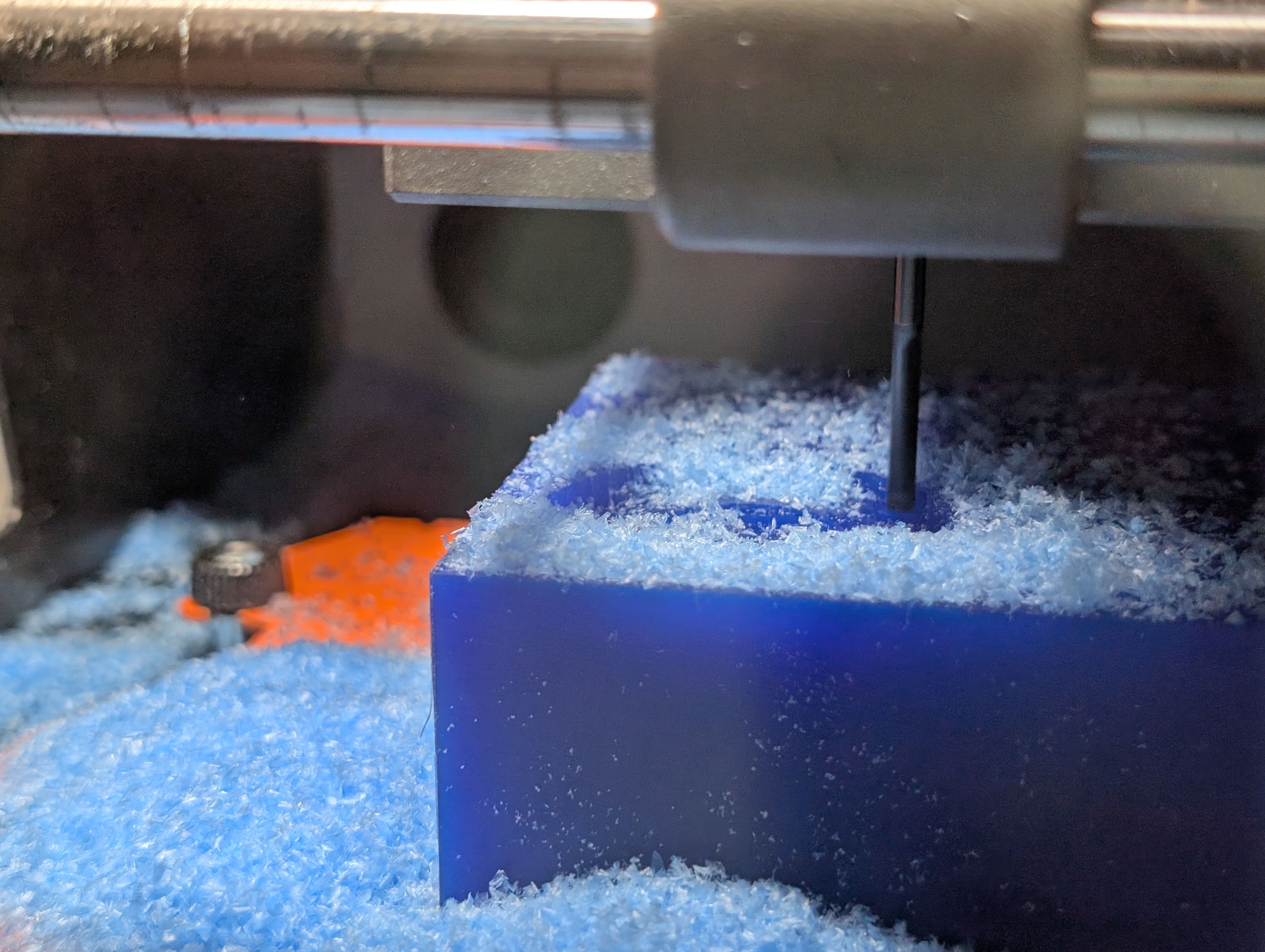

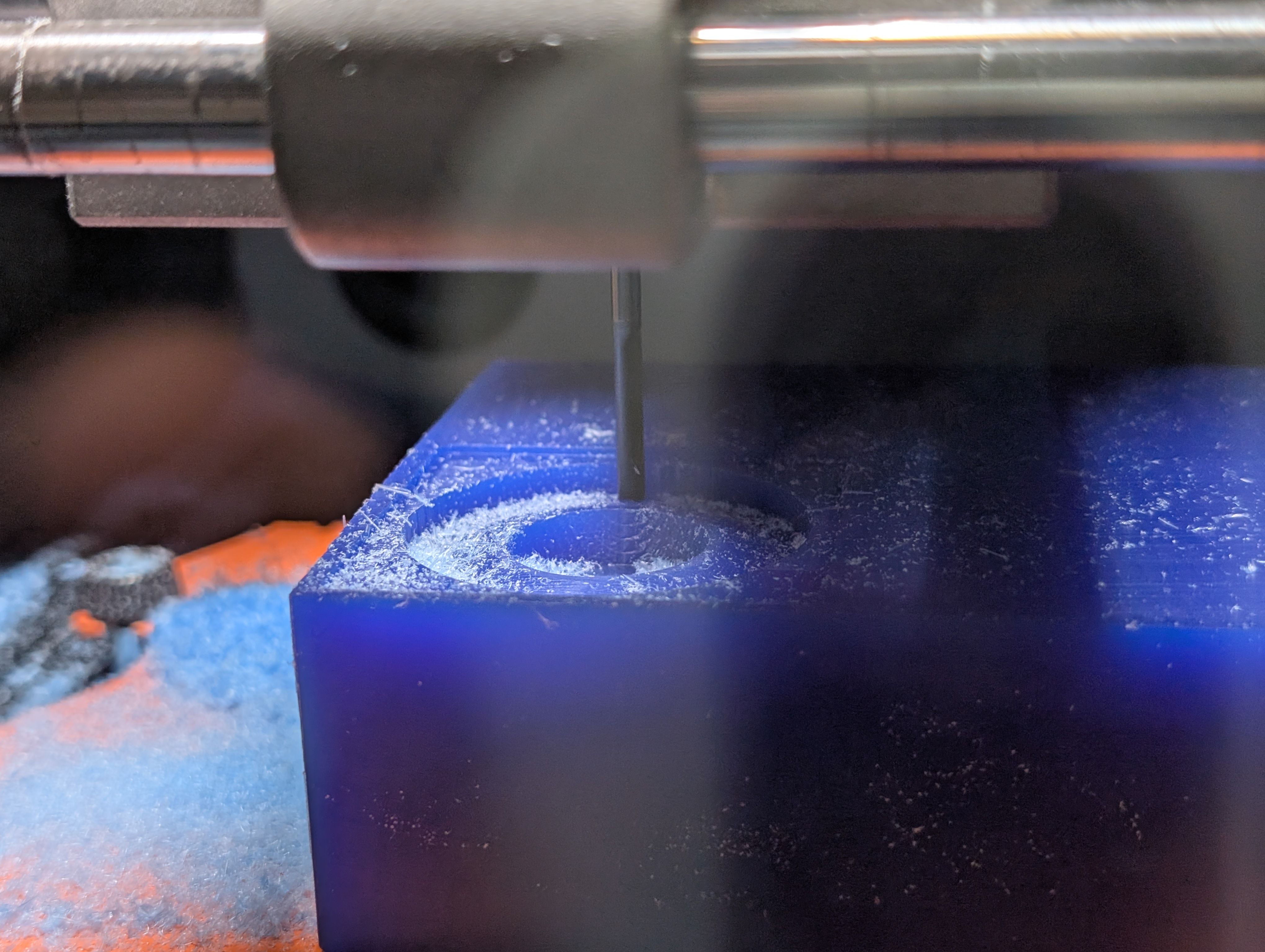

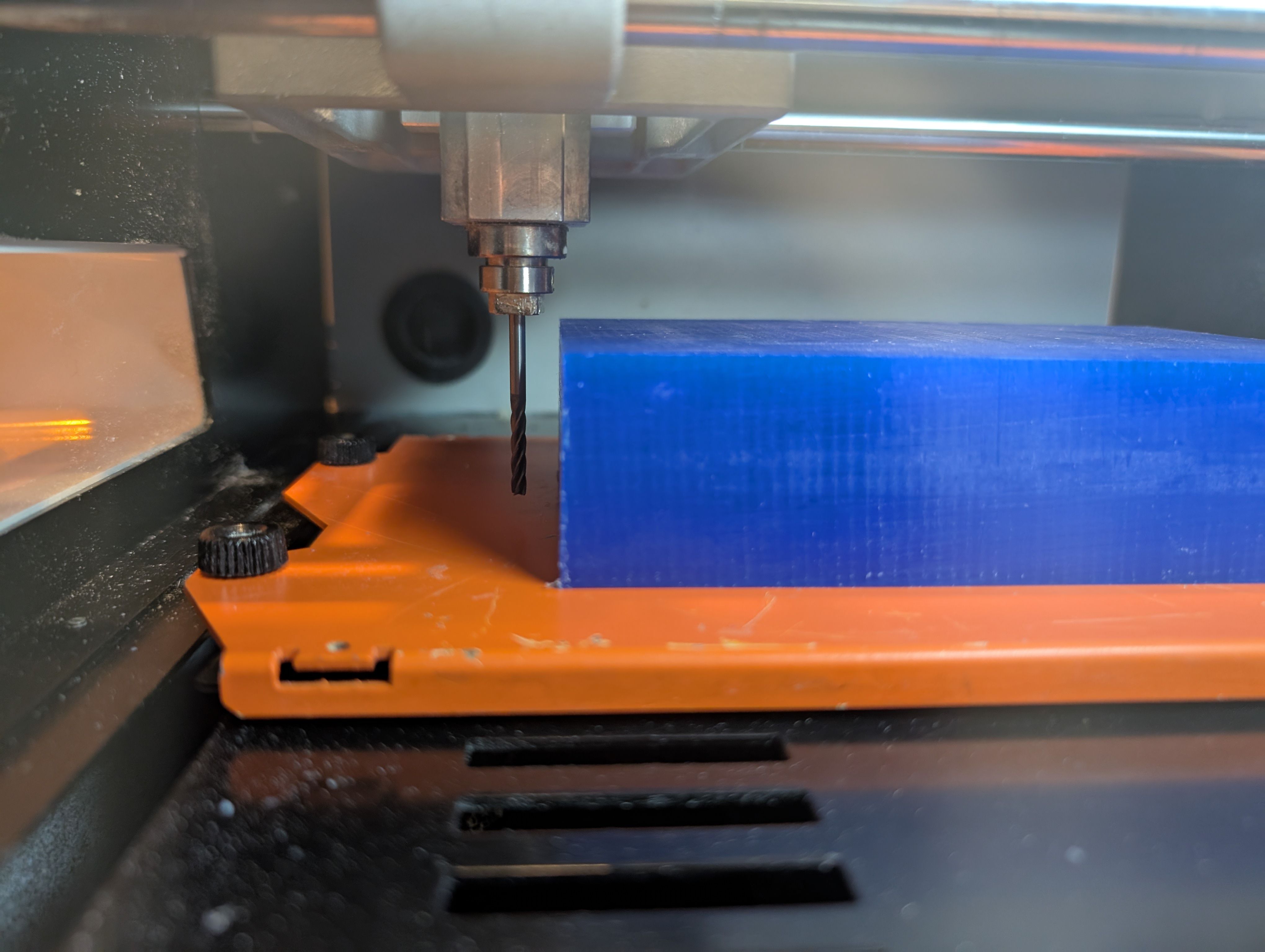

Milling

Tool: 1/8 SE 4FL EM

Apply double-sided tape to the backside.

Make a mark in the center of the wax.

Fix the wax so that it is parallel to the base of the machine. (Use a ruler, etc.)

Set the XY origin in the center of the wax.

Set the Z origin on the top of the wax. (Use a piece of paper to lower the Z axis until it stops

moving.)

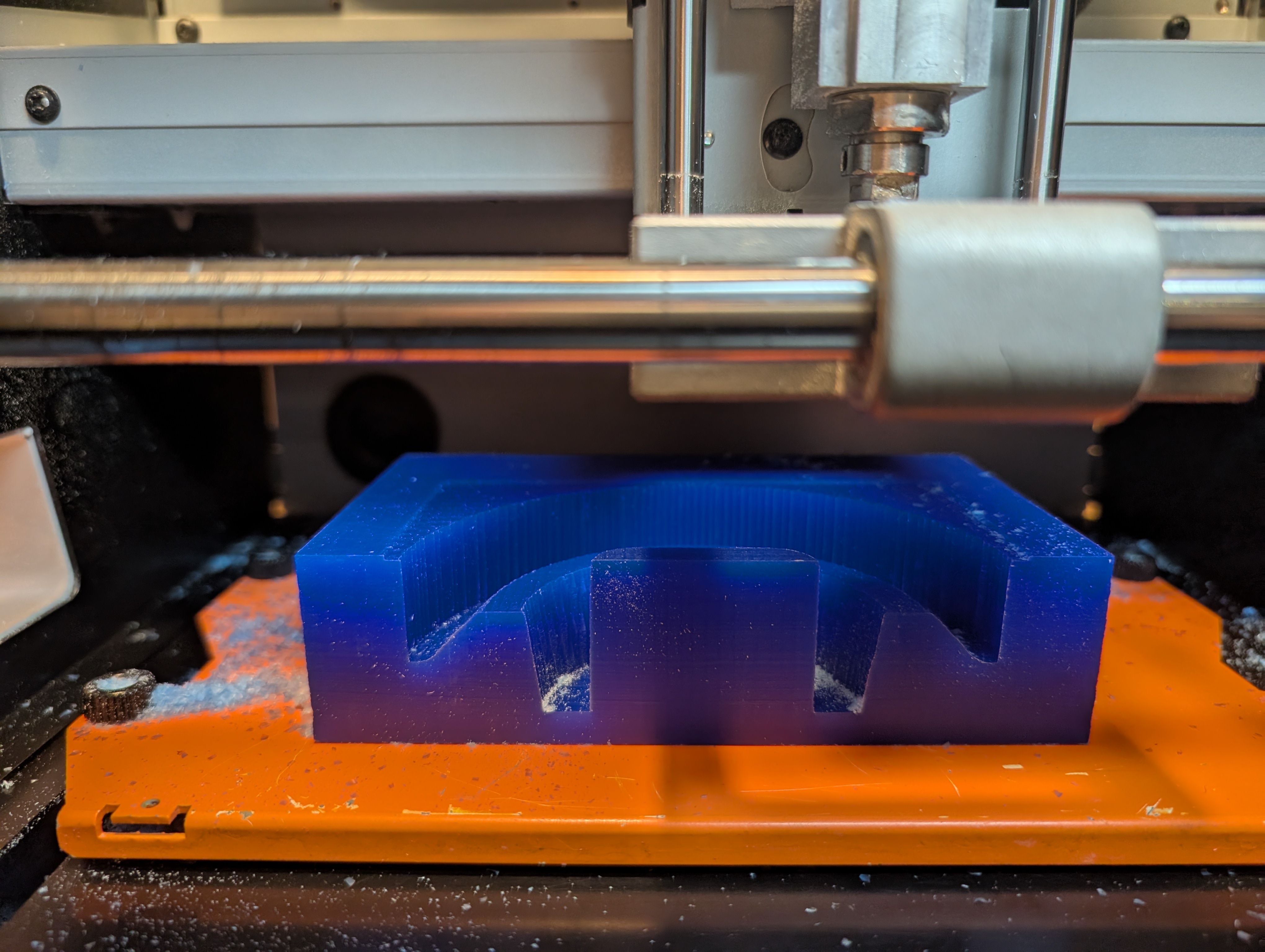

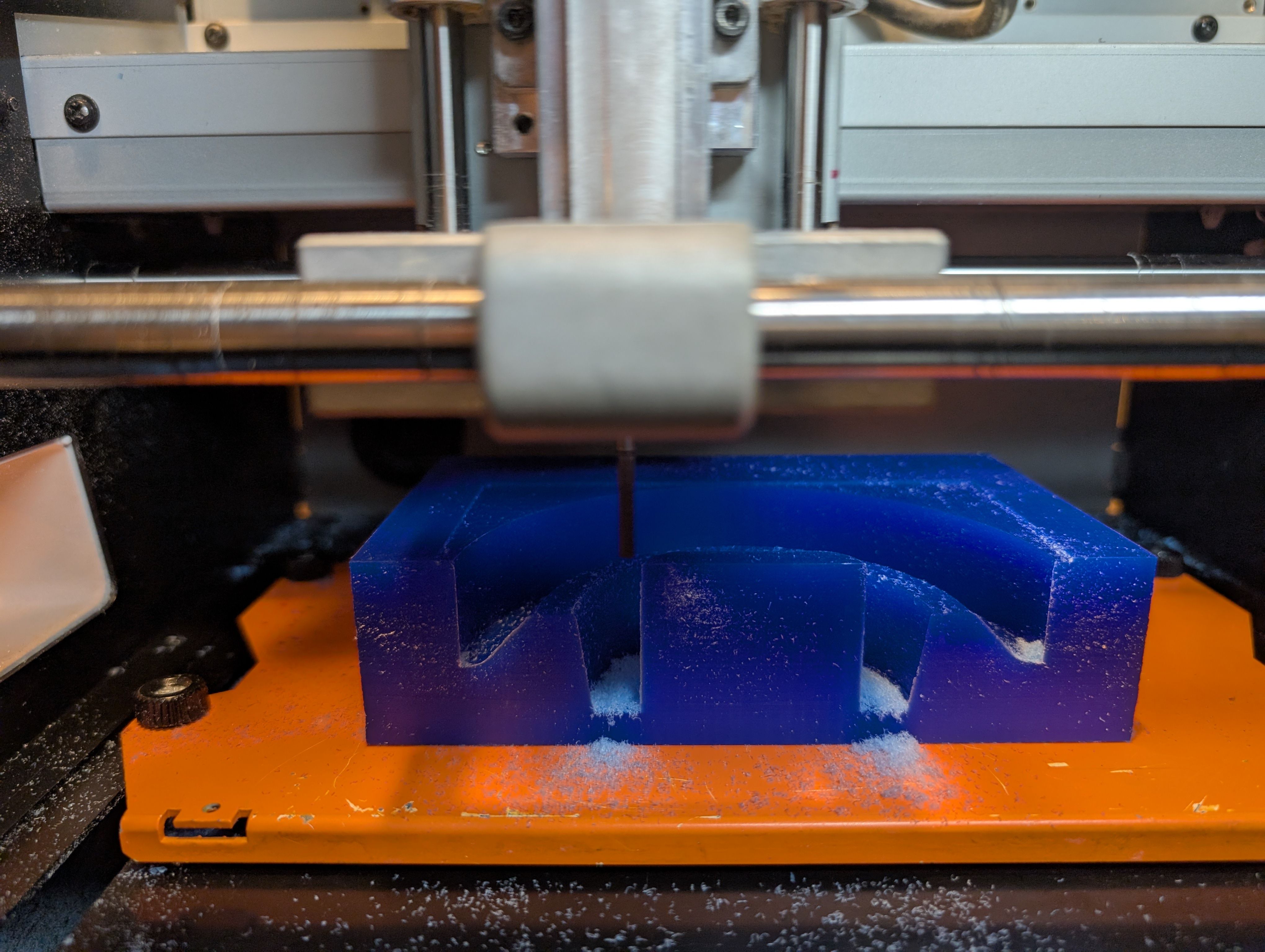

Roughing

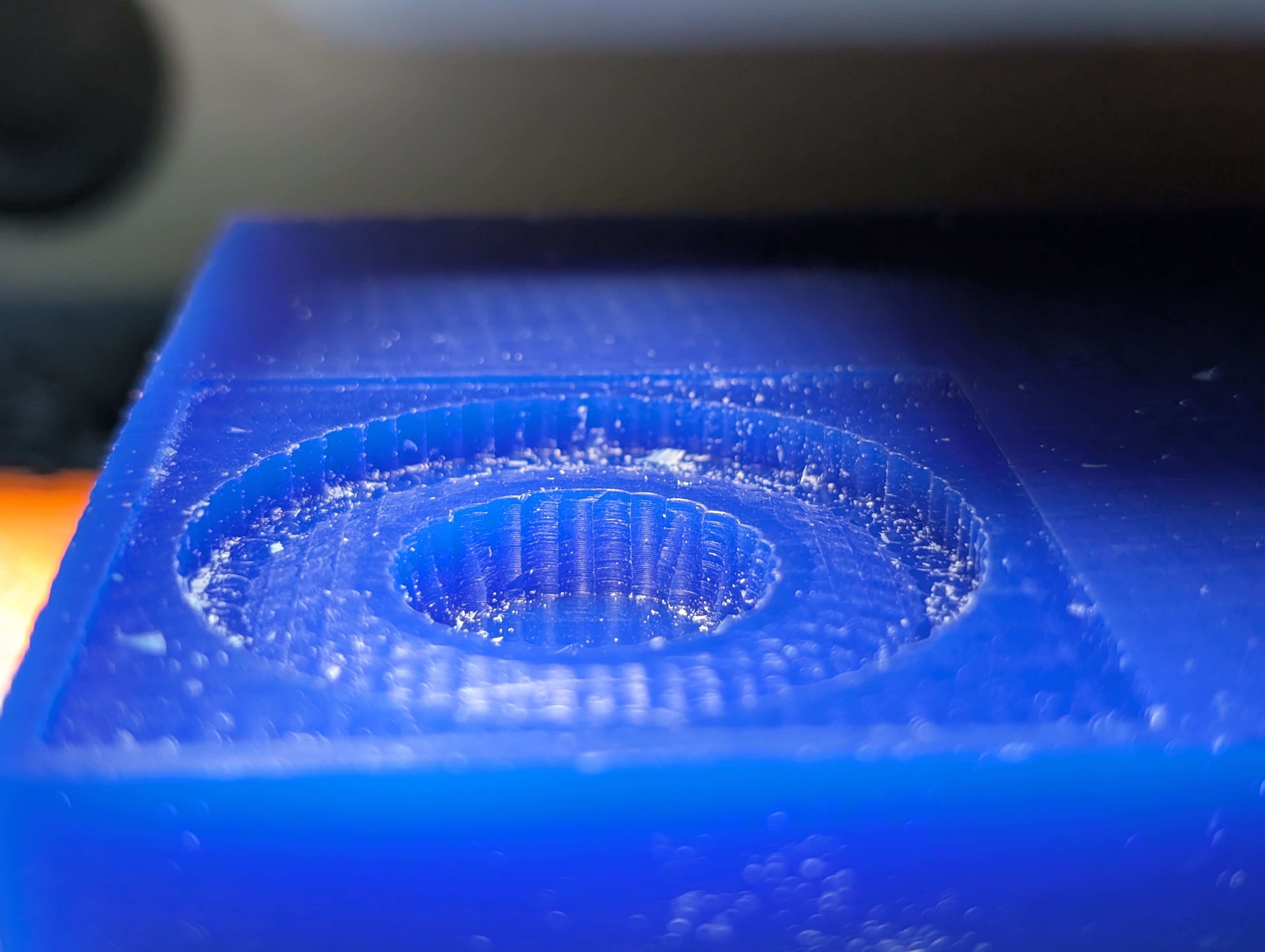

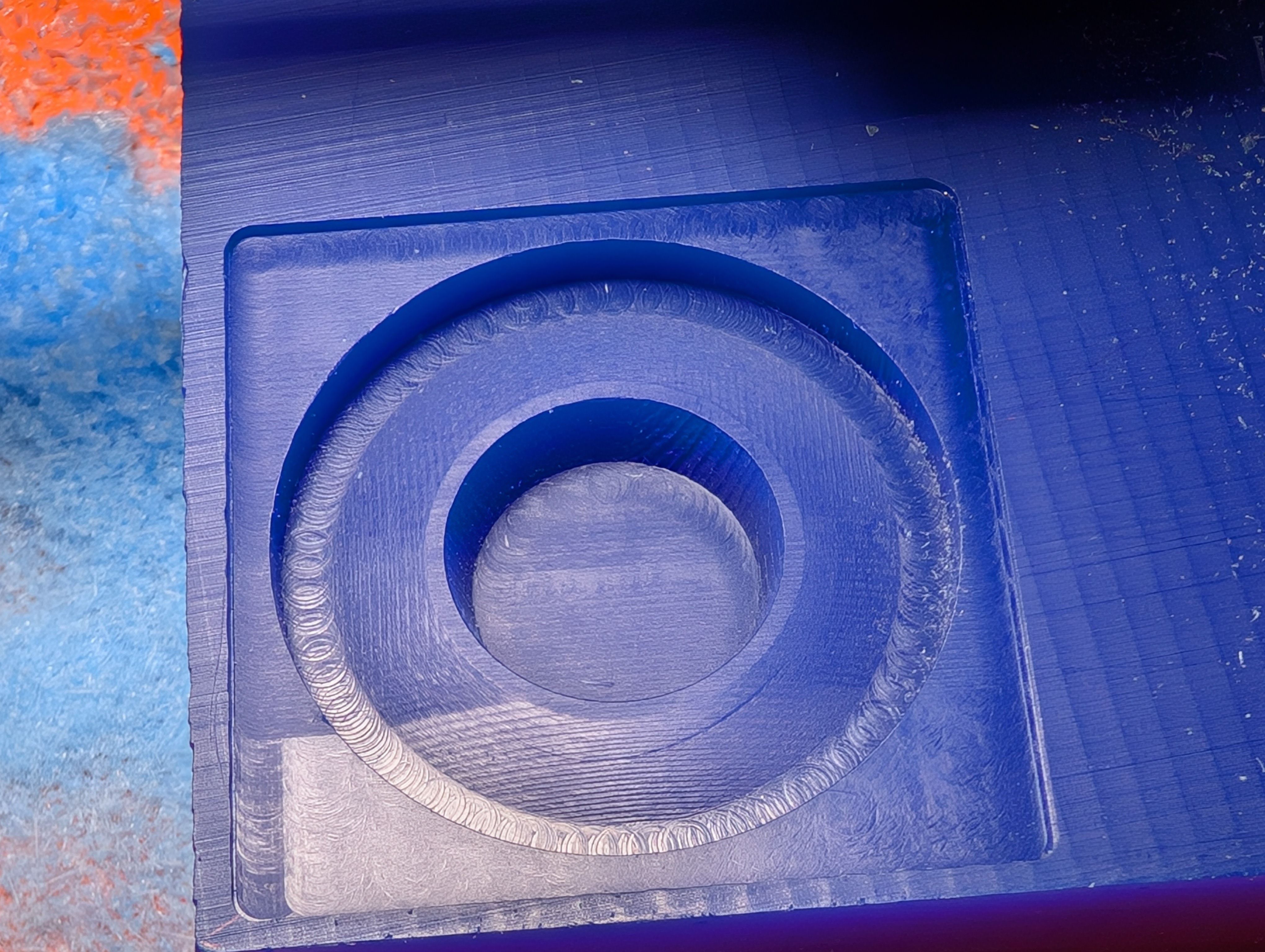

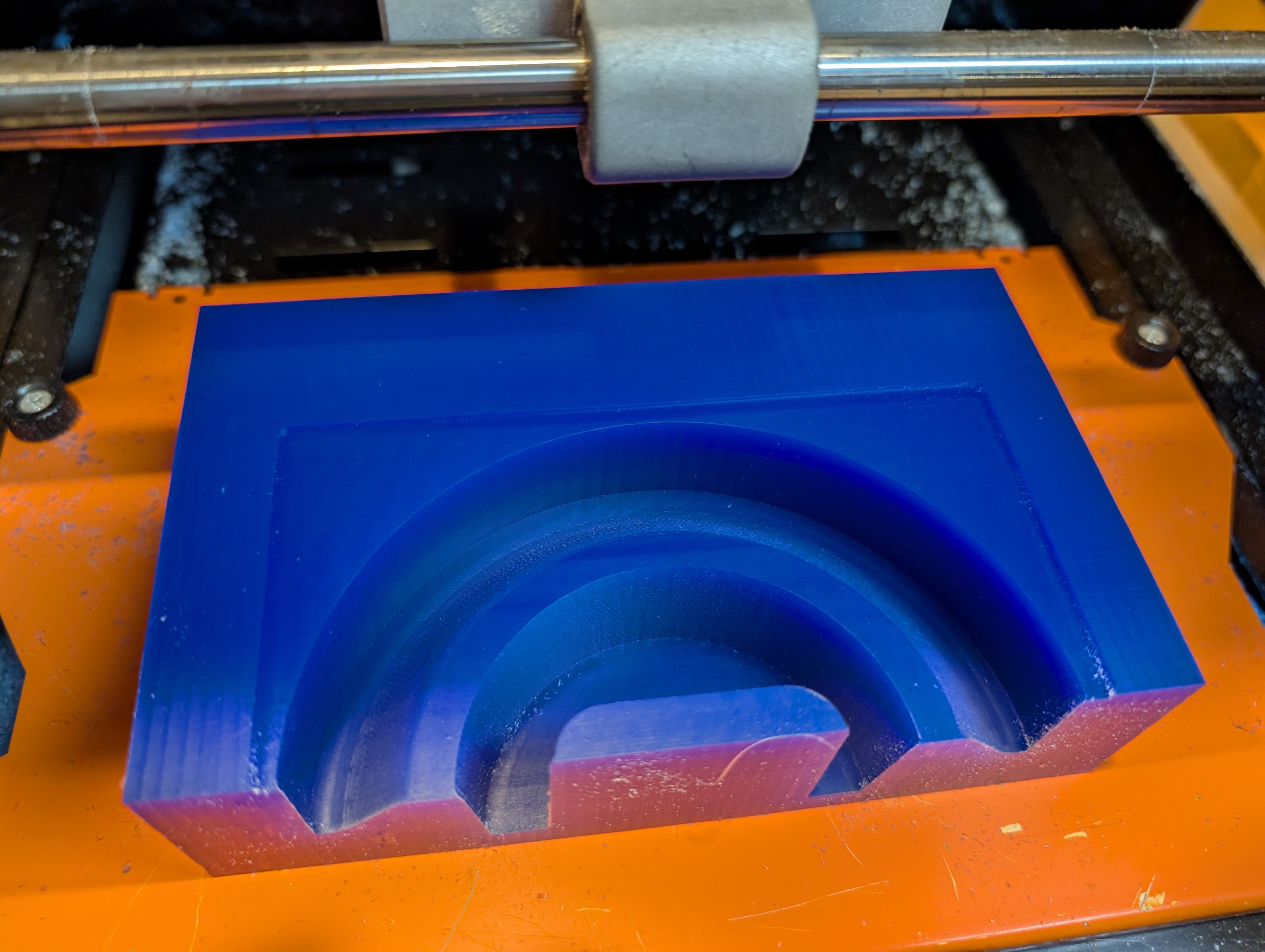

Finishing

Since it seems still rough, I added finishing path with

Scan Lines X+Y

XY Speed : 20mm/sec

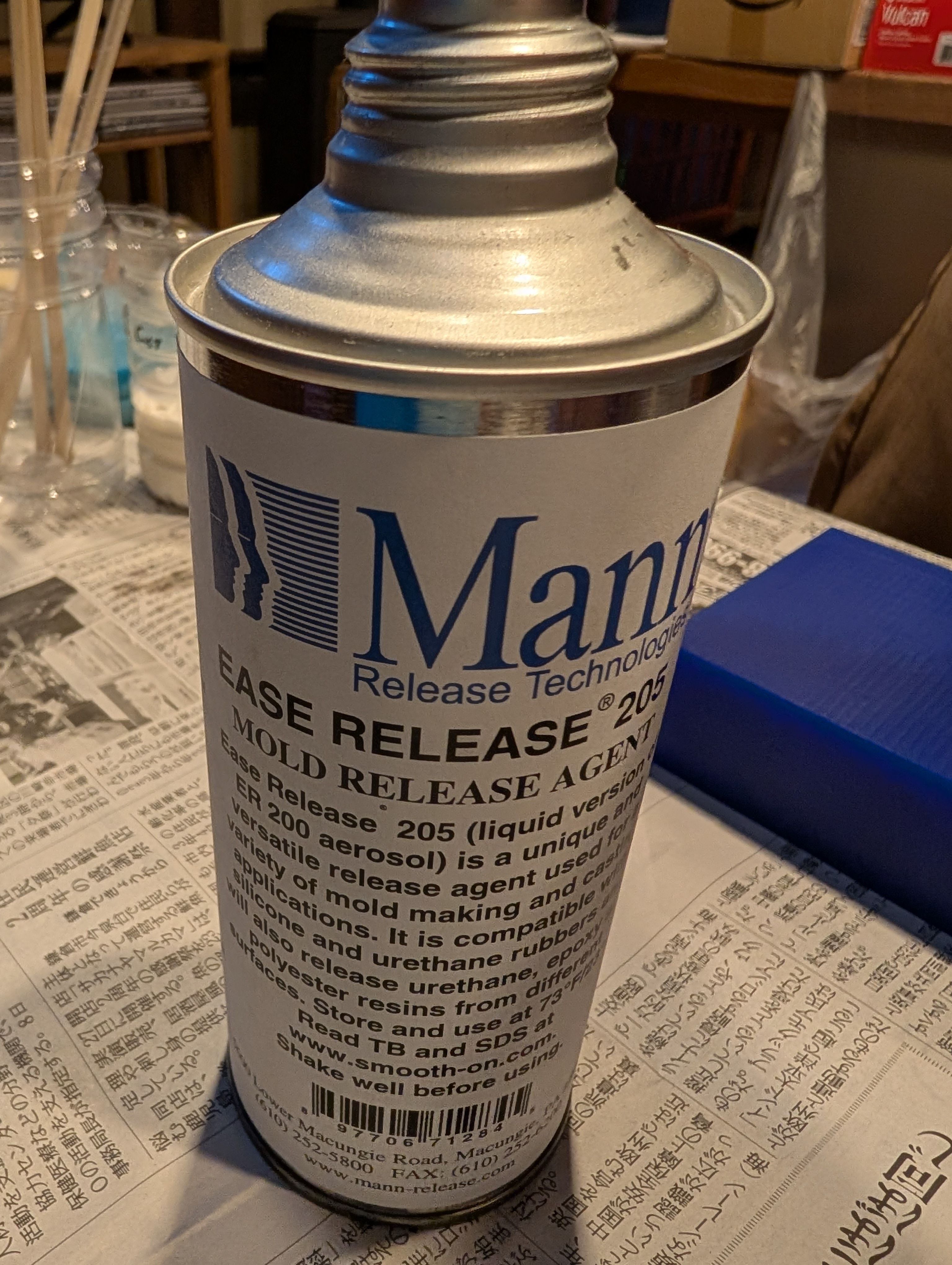

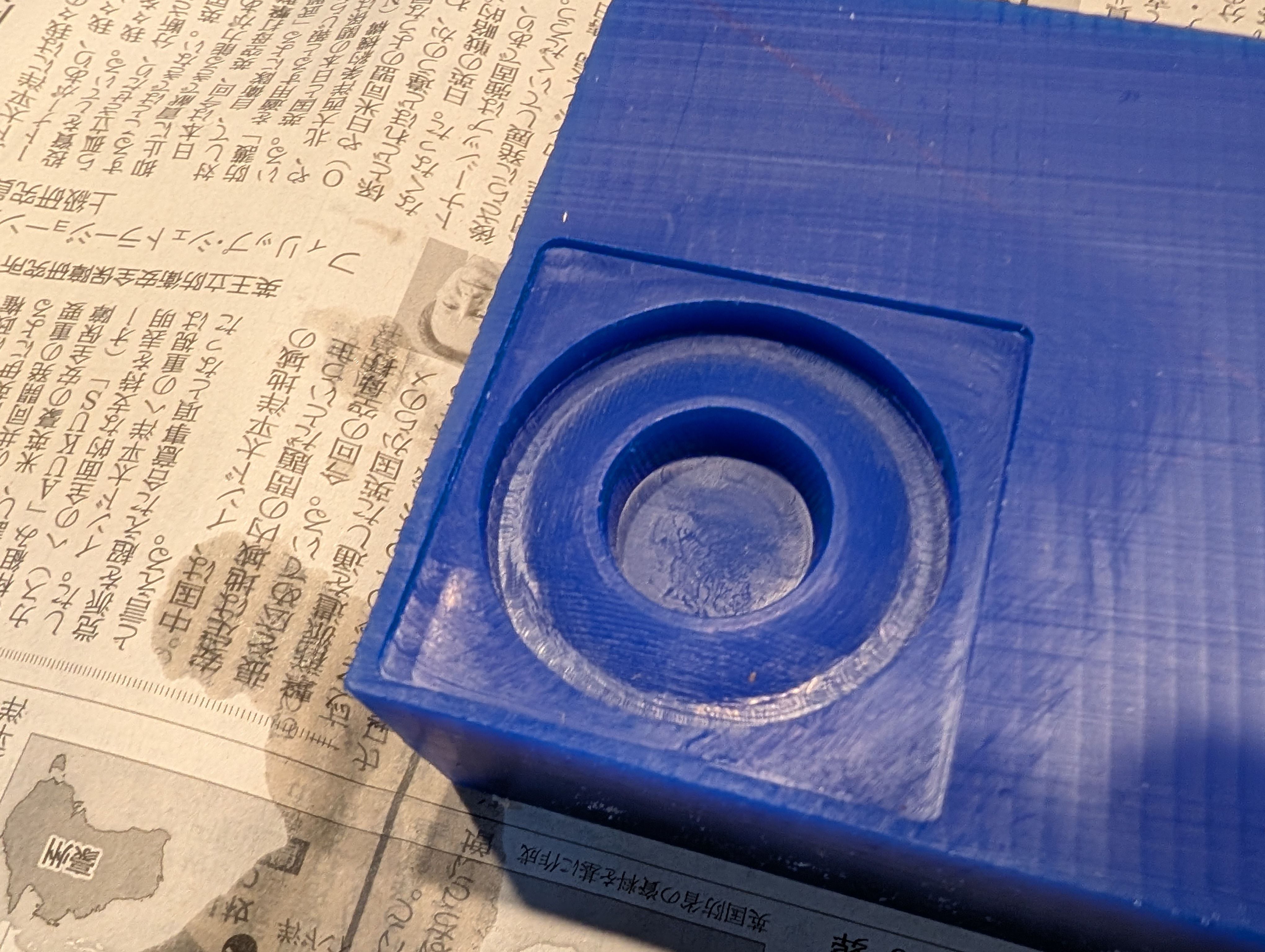

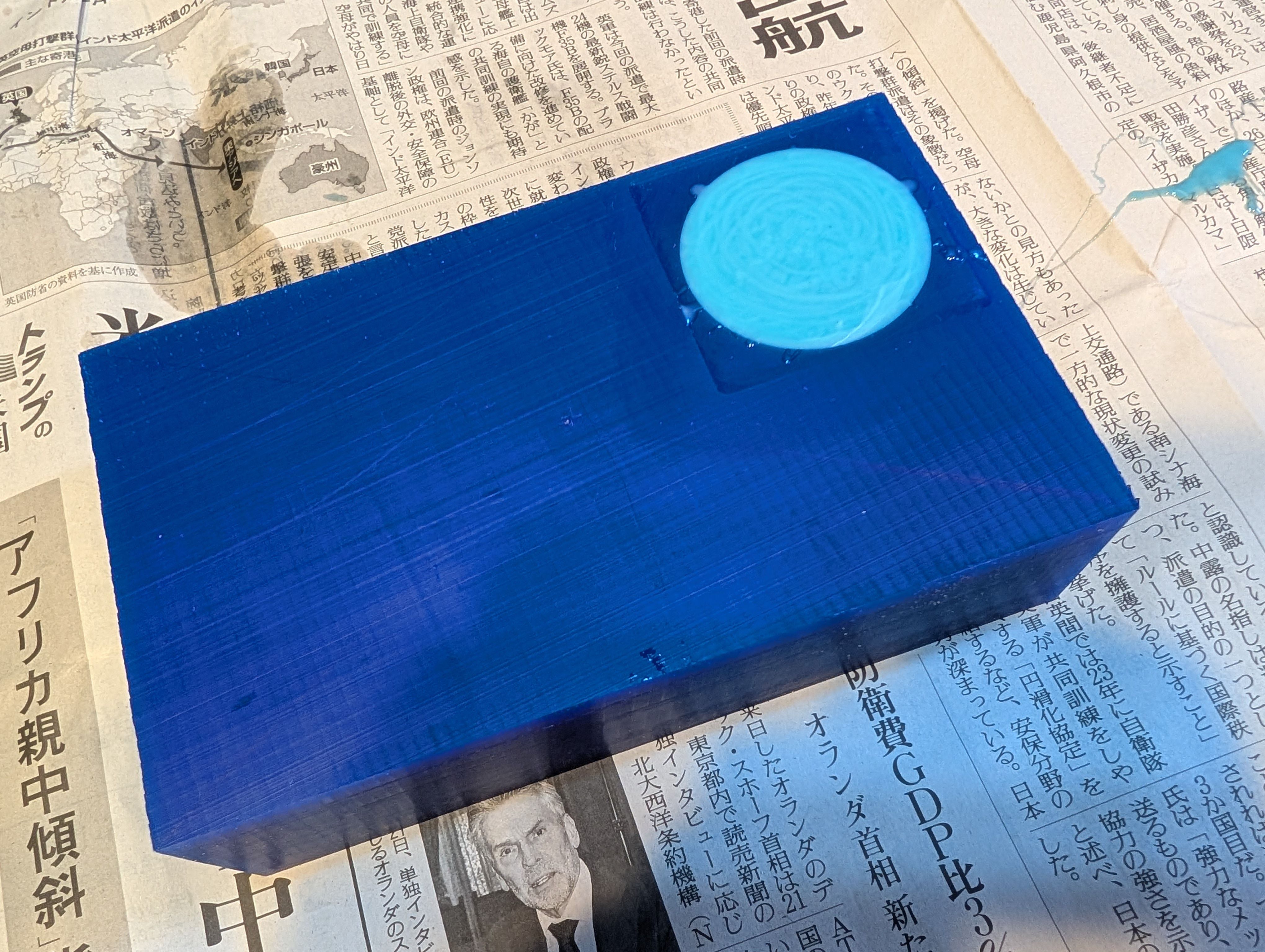

Casting

Use ease release as release agent

Use moldstar 16 fast for casting - mix A and B = 1:1

I keep it for 1 night

I could cast it successfully!

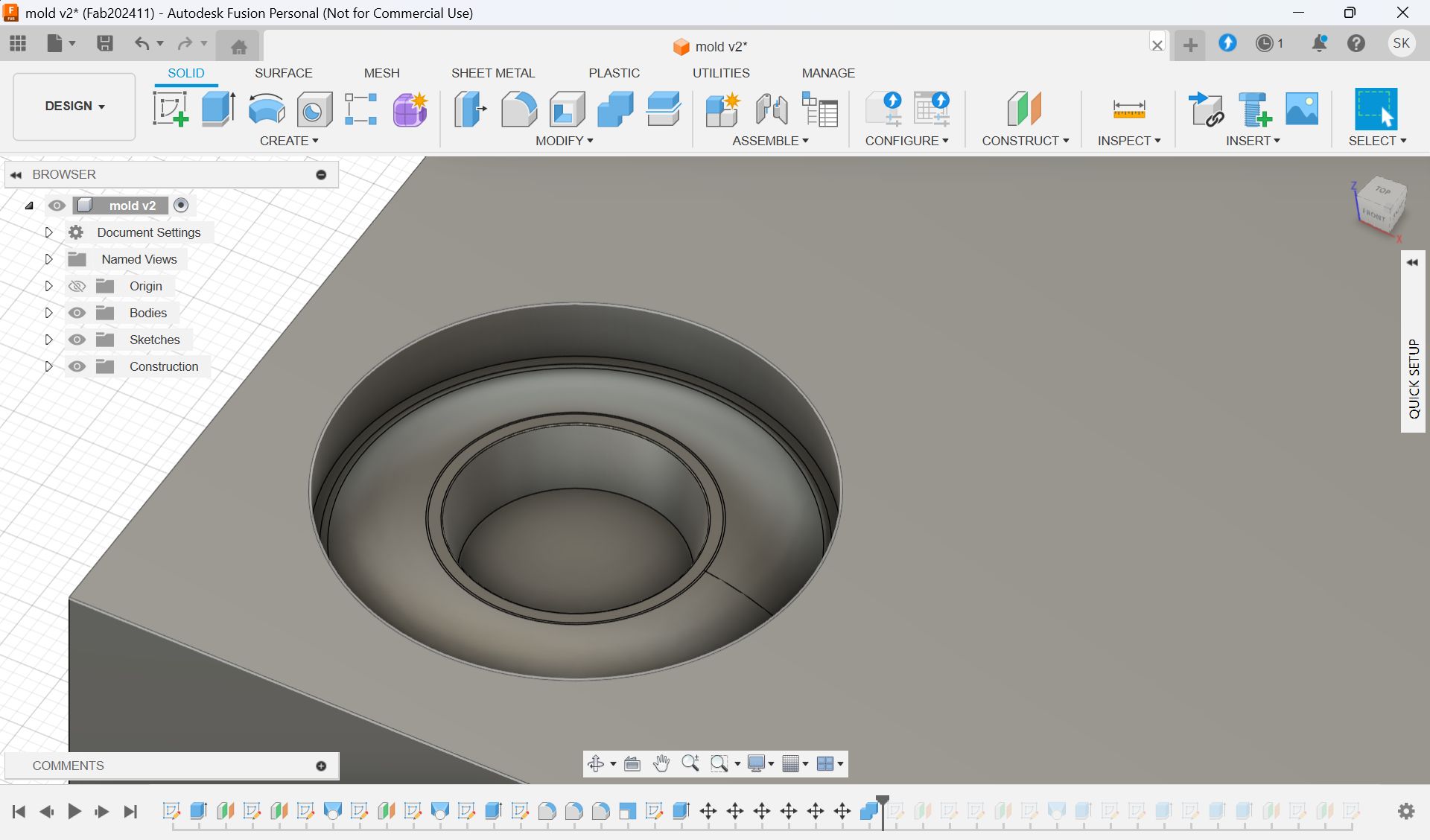

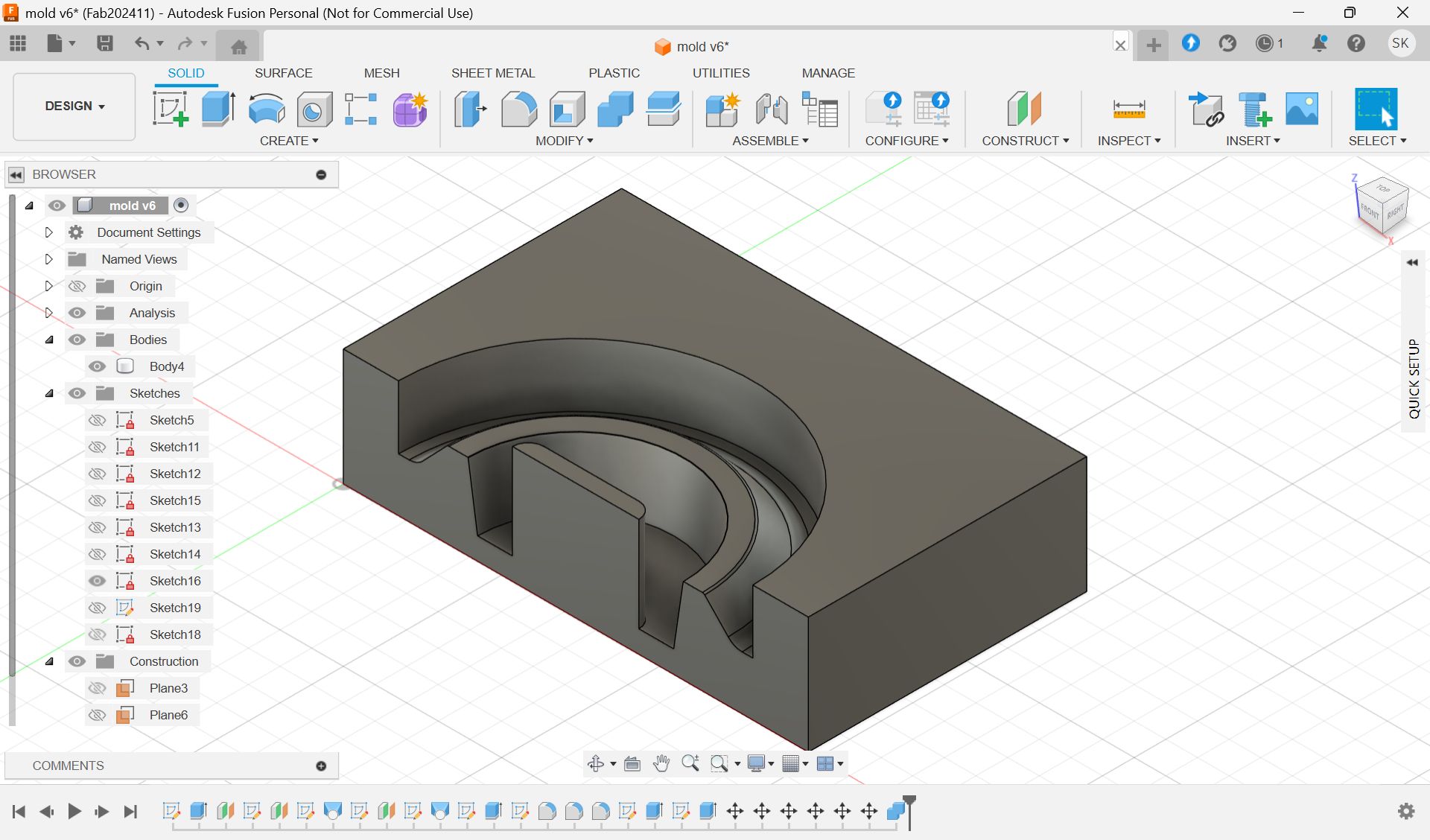

2. Final Model

Modeling - Fusion

From the test model, I adjusted the parameters.

I scaled the glass and decide the number

Parameter for final model

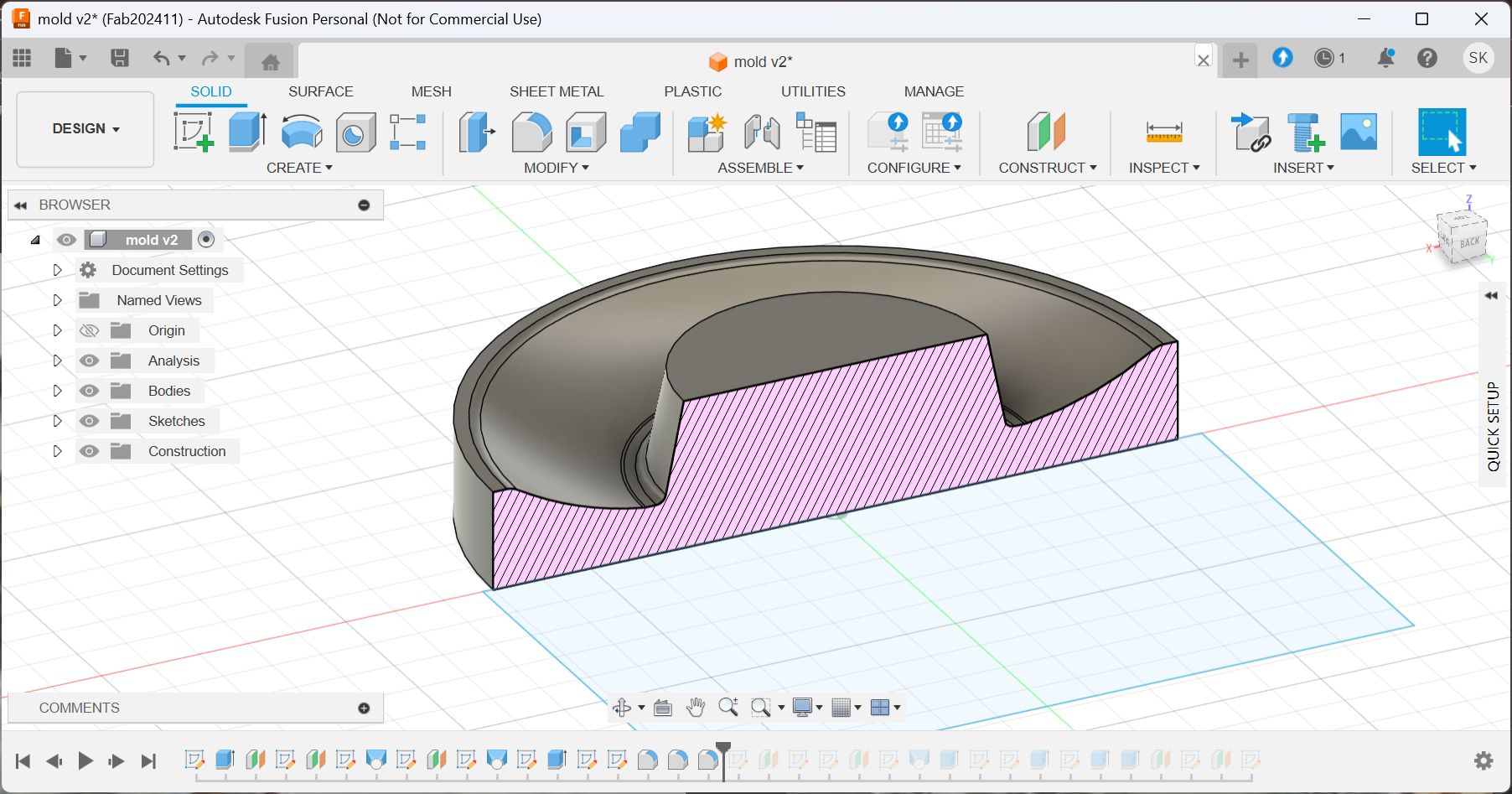

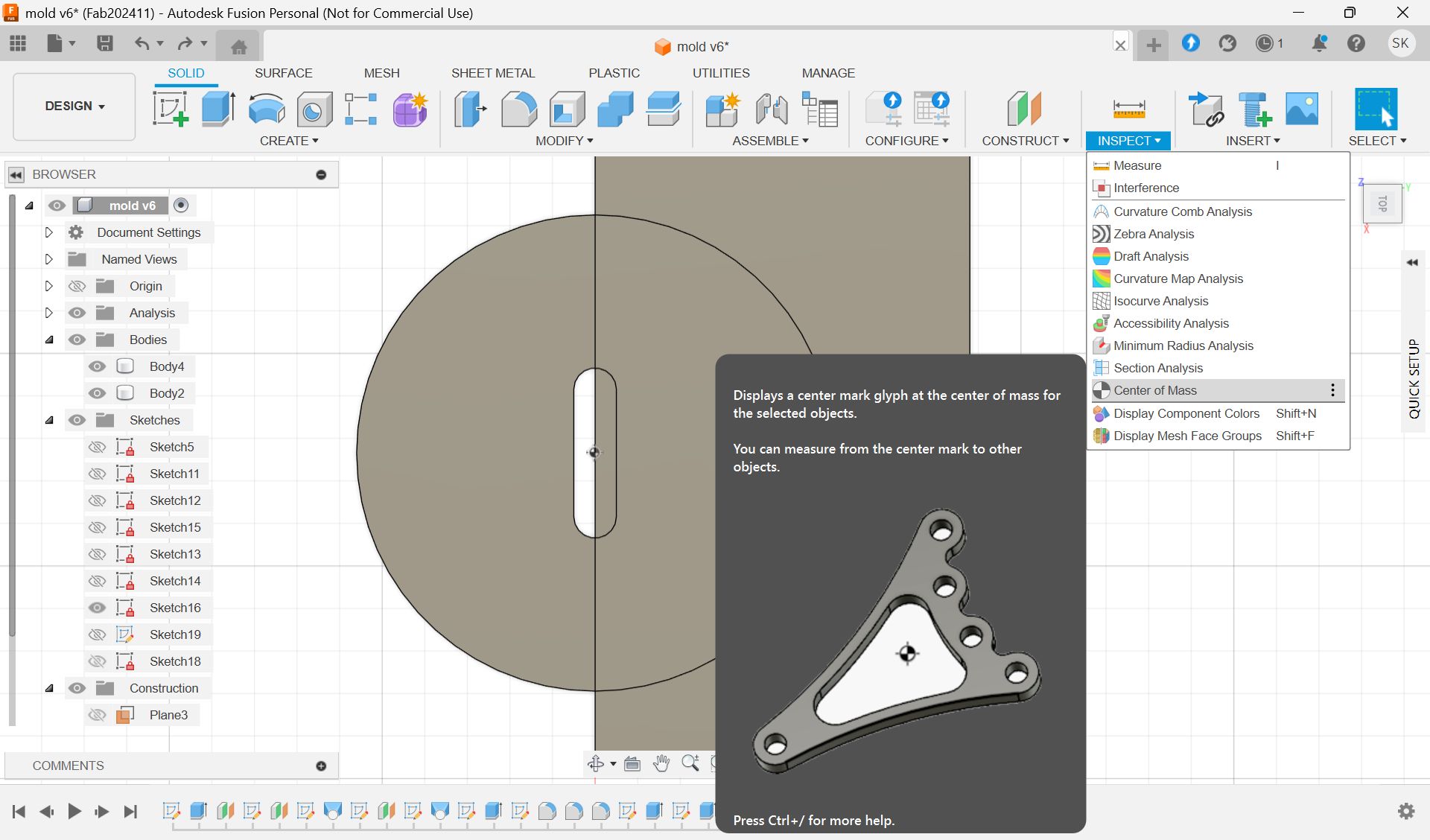

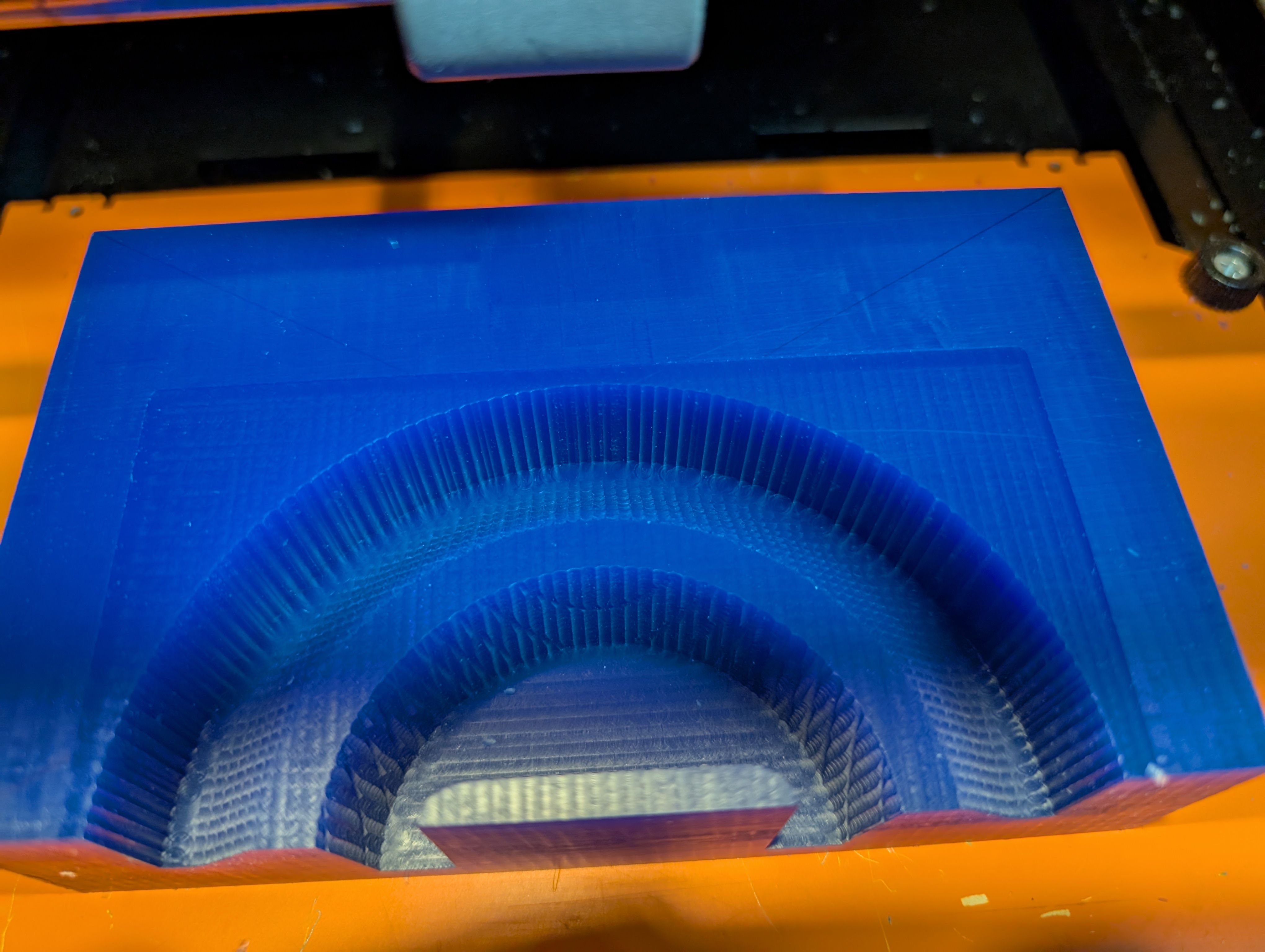

Check the cross section

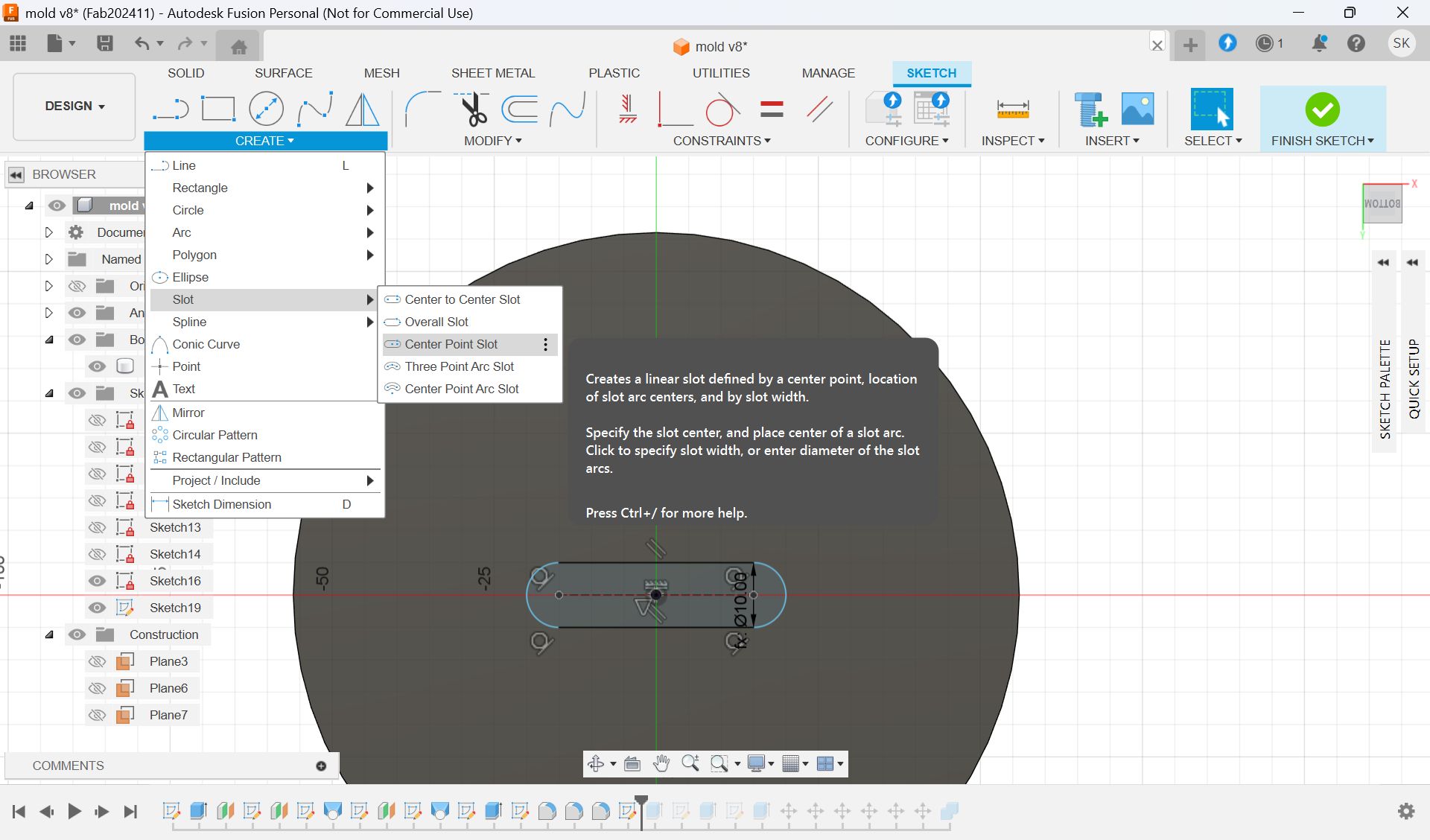

I wanted to add a hole for cables.

Add hole with “Slot“ form Sketch menu and extrude it.

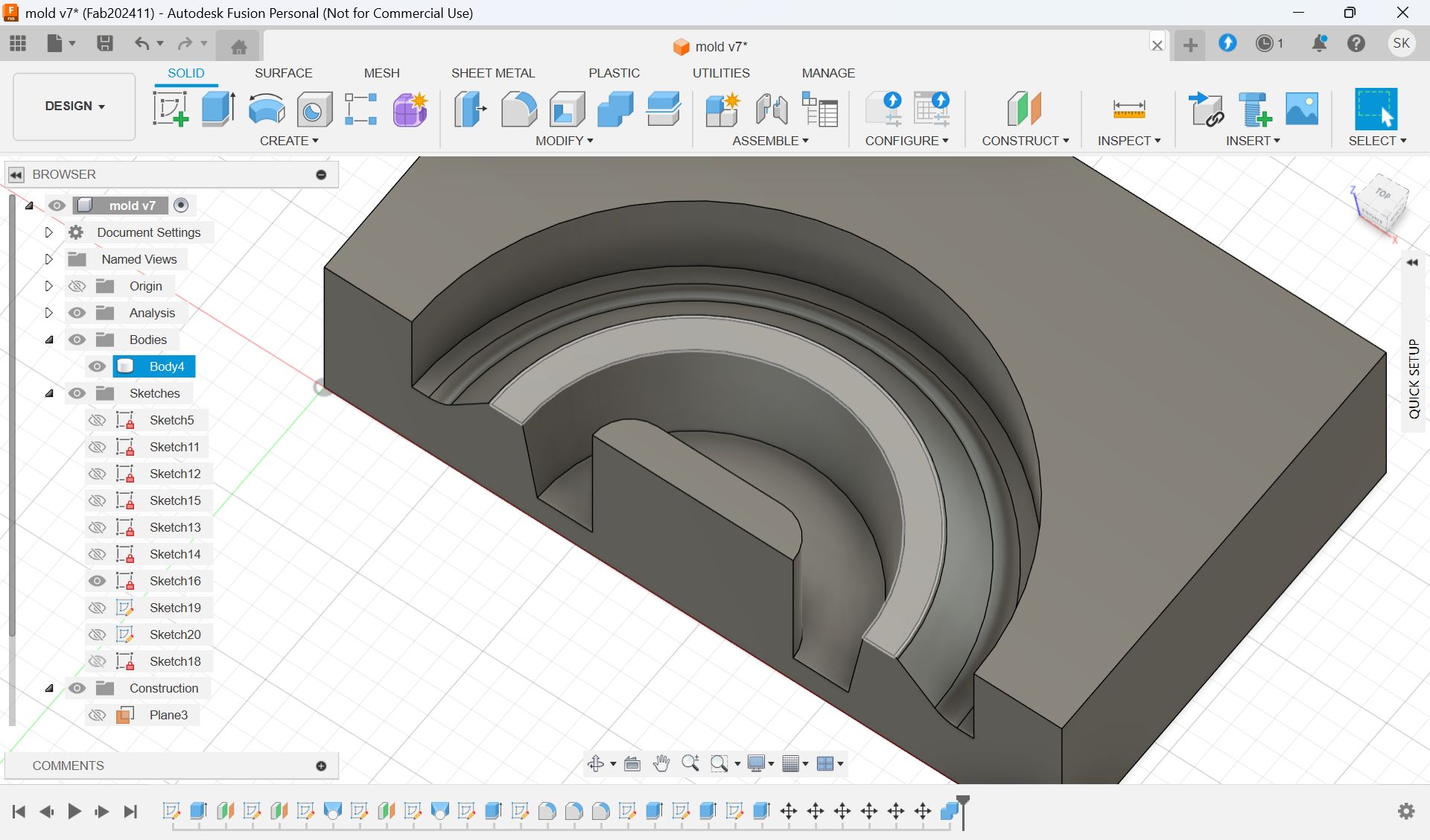

Since the wax is smaller than the model size, I made the half cut mold.

To make it divided in the center, use the “Center of mass”.

This is the final model for 1st half.

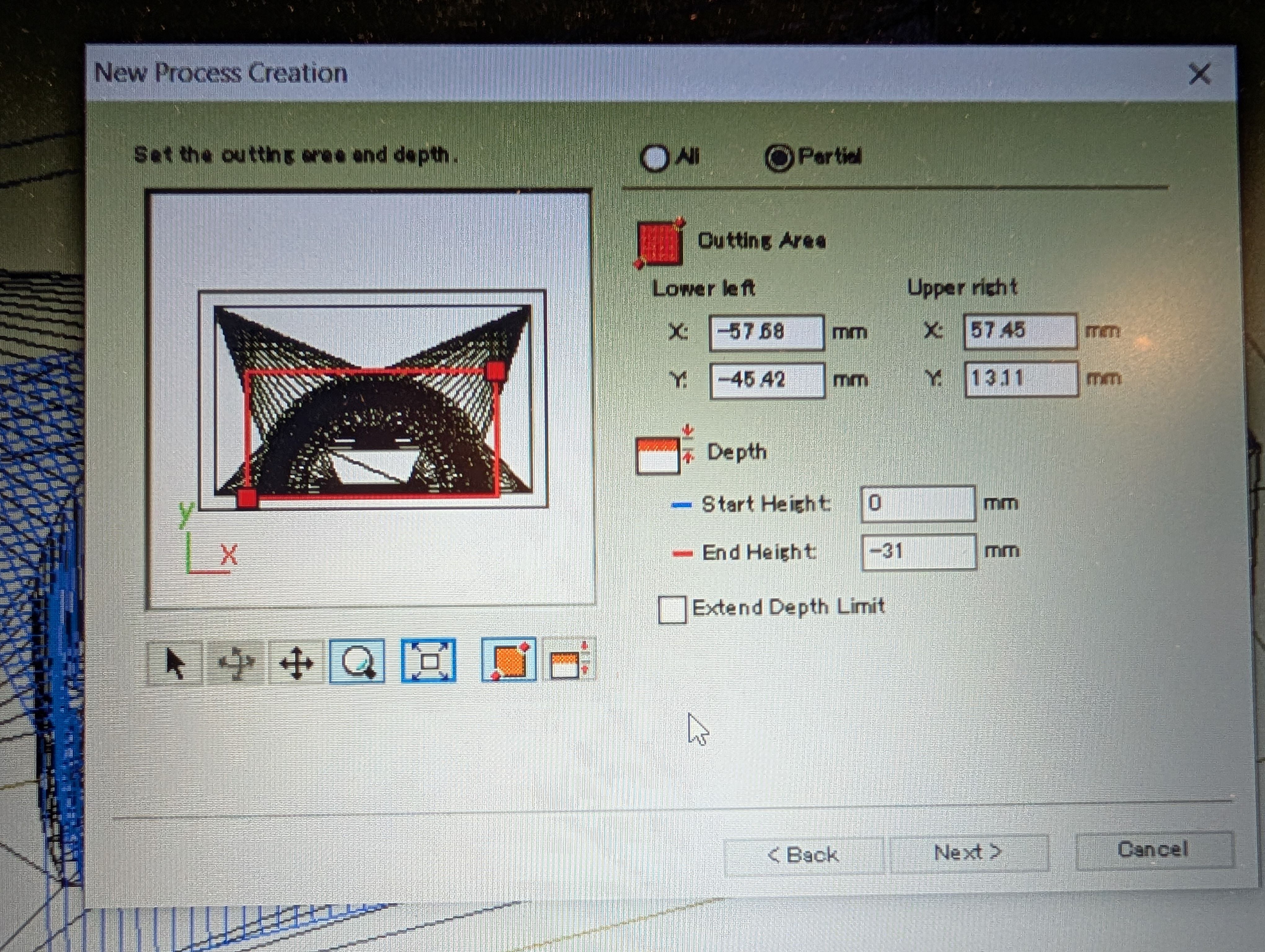

Path

This time I alse chosed 3.18 square mill.

Setting for roughing

Scan Lines = X + Y

XY speed = 20 mm/sec

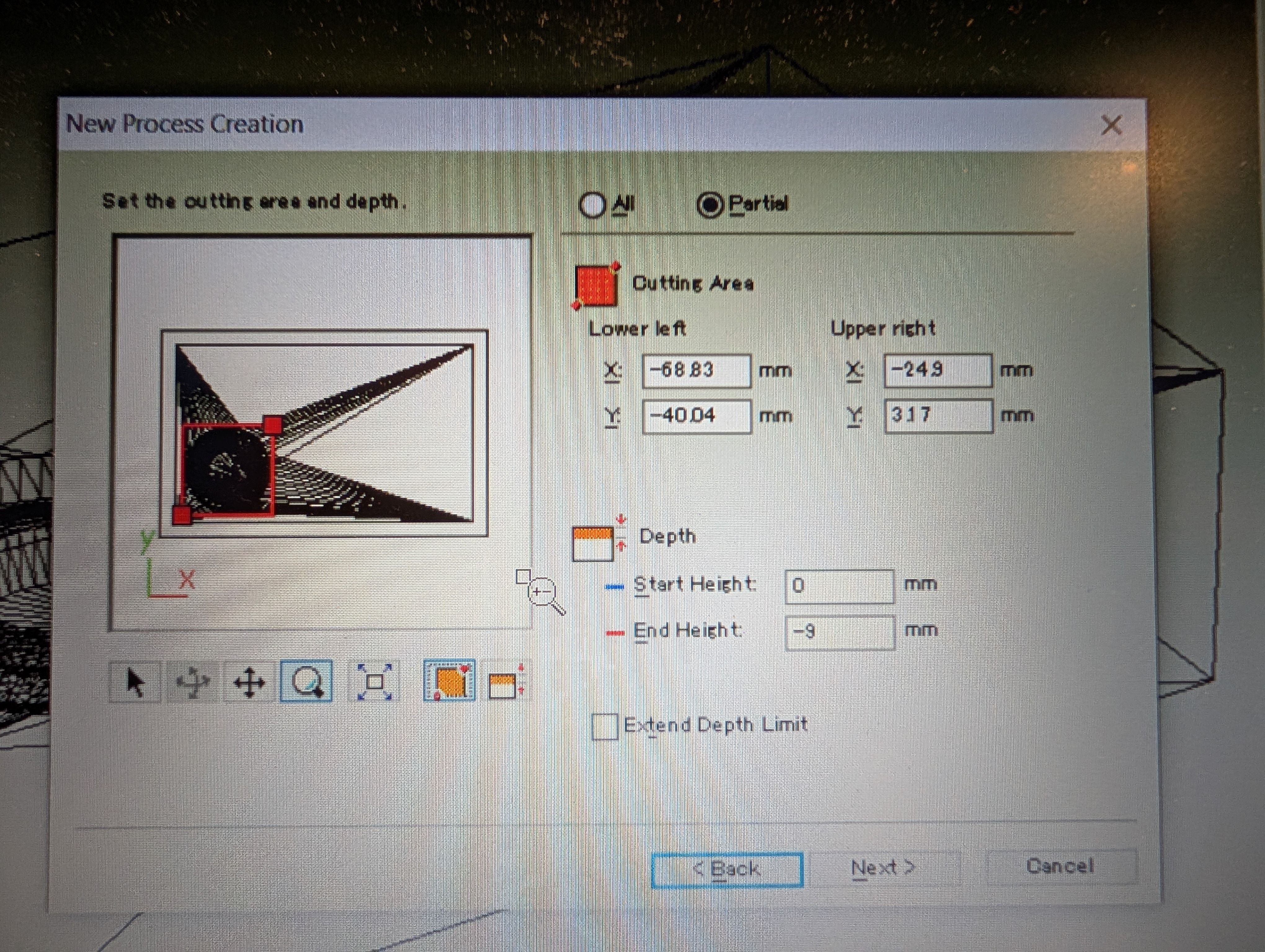

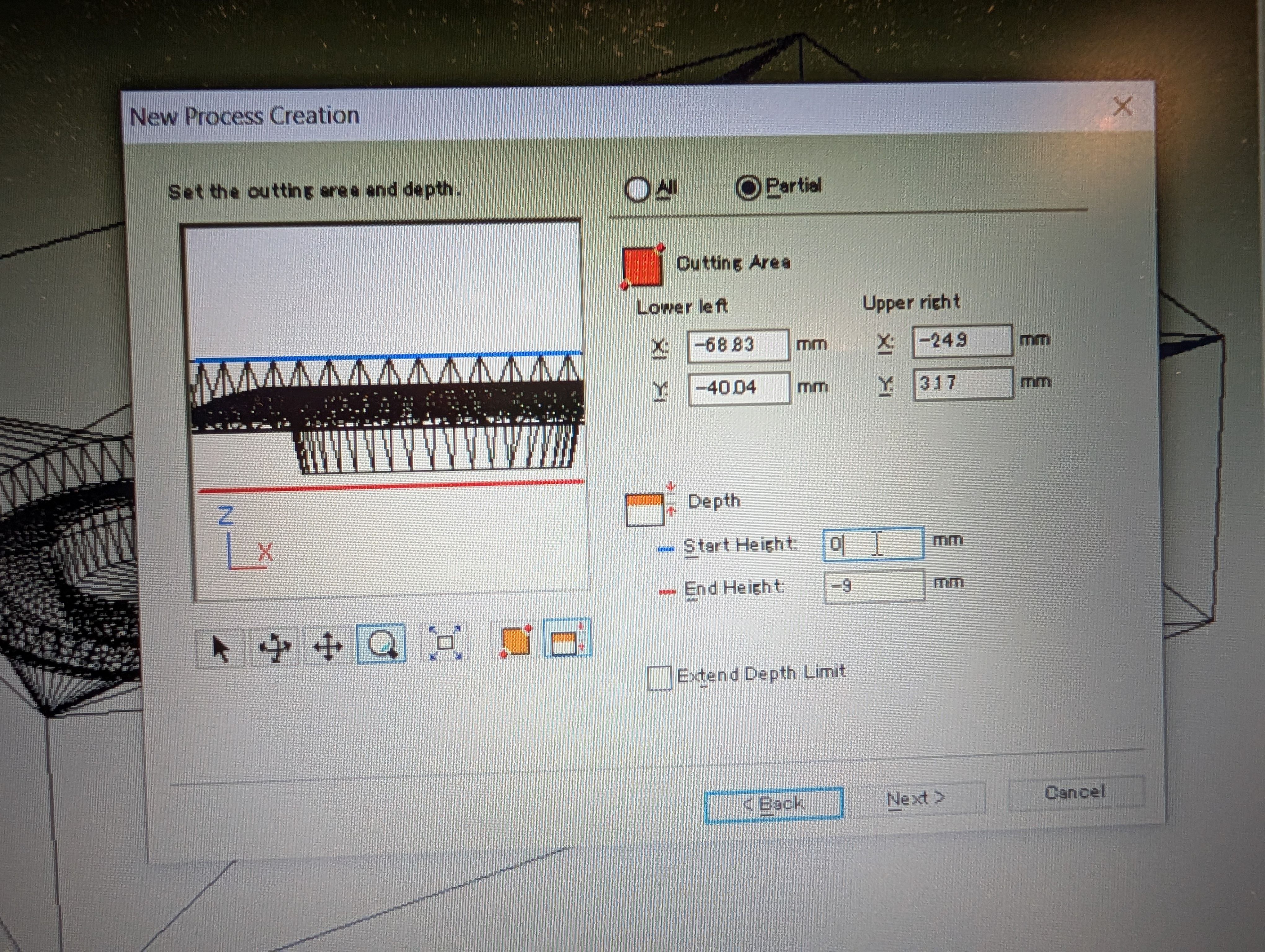

Setting for Finishing

Contour Lines : Up out

XY speed = 15 mm/sec

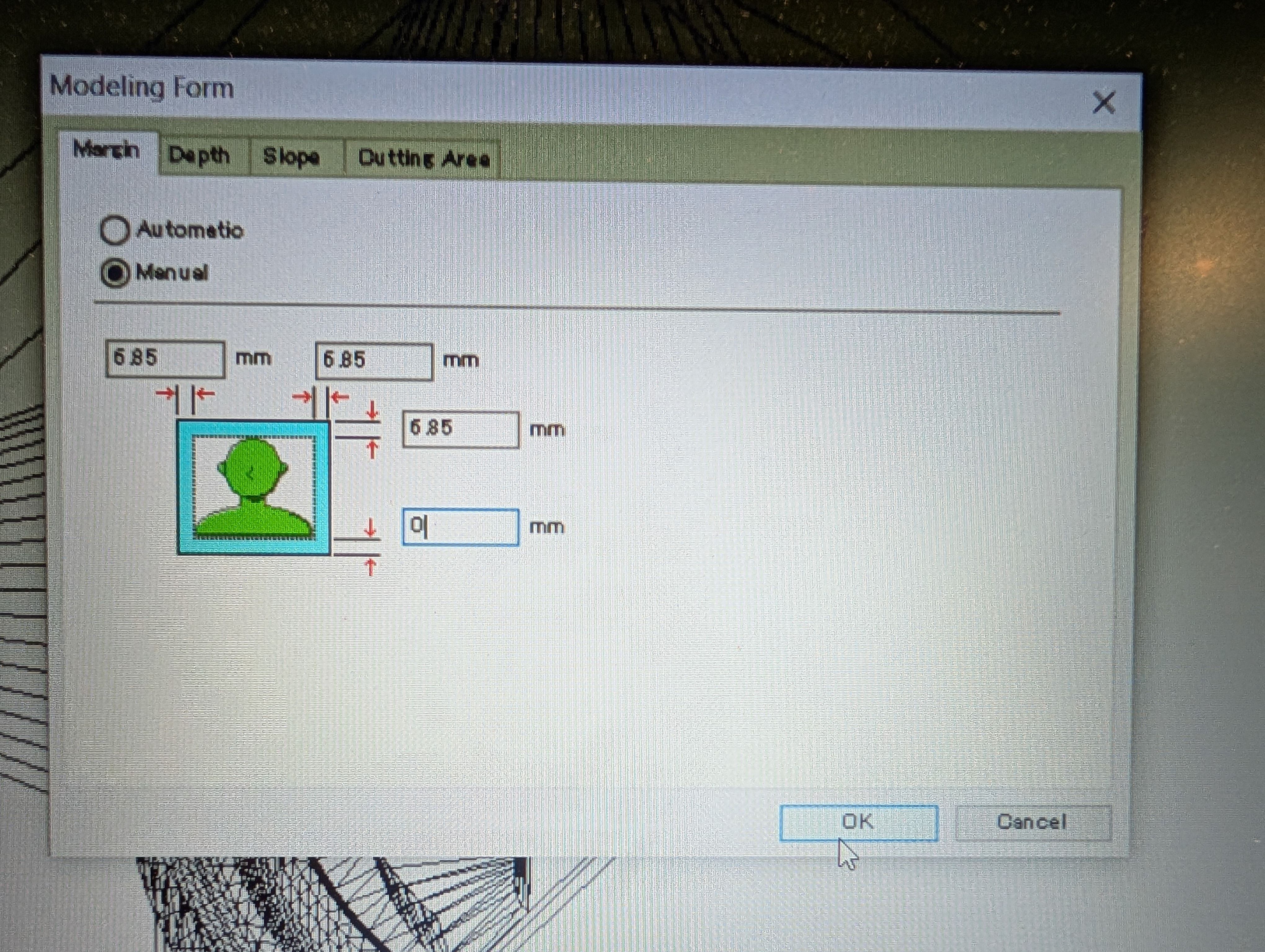

To will without leaving any edges, I have to delete margin.

I set margin bottom = 0mm from Modeling Form menu.

Check time from “Preview Cutting” menu

Time for roughing: 2h53m

Time for finishing: 1h37m

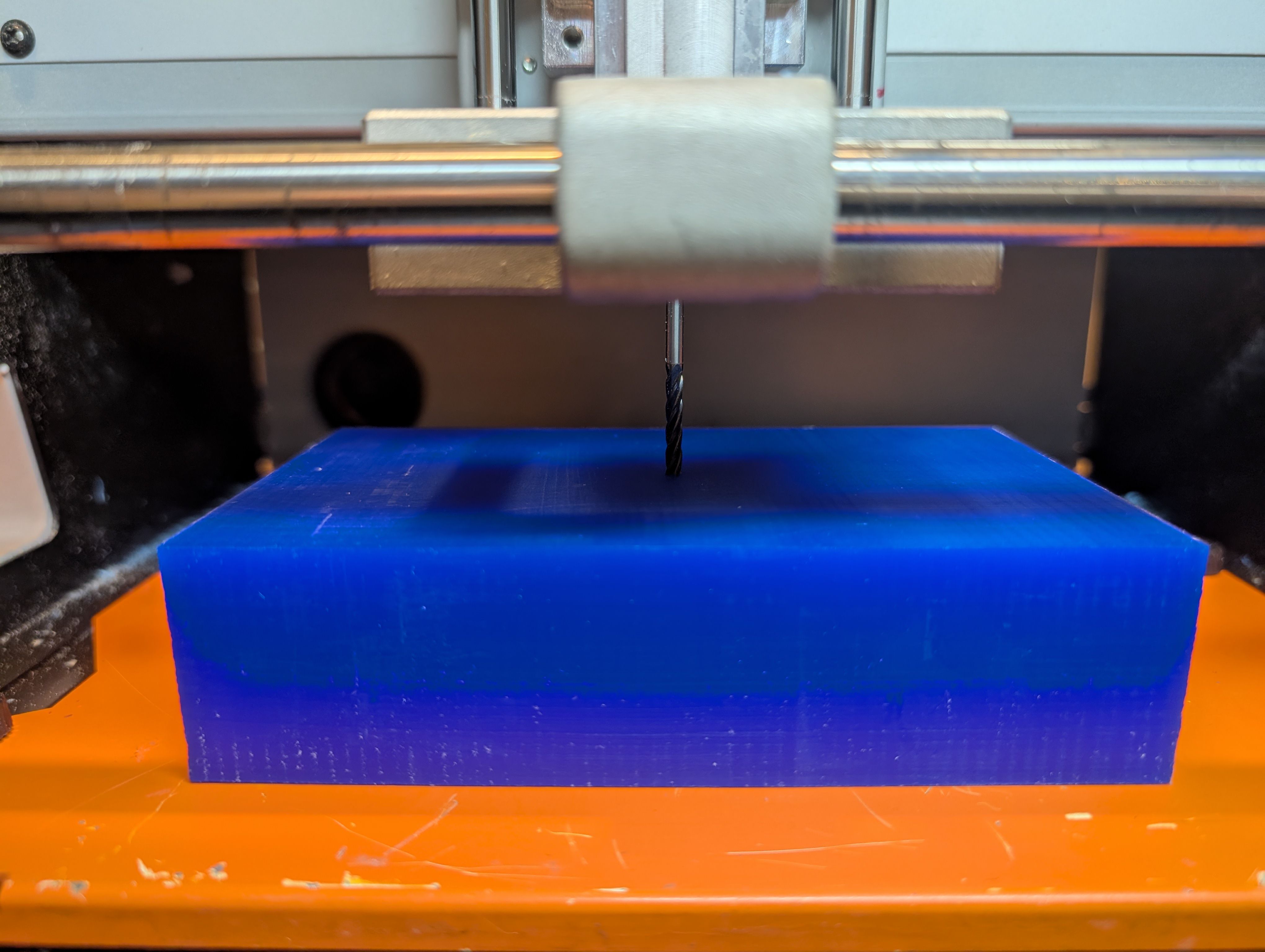

To set tool, I have to check the depth of workspace, and height of wax, and calculate

depth of workspace : 31mm

(depth of design: 30mm)

height of wax: 37mm

→tool length should be between 31-37

Tool I used: 3.18 inch 2FL LONG

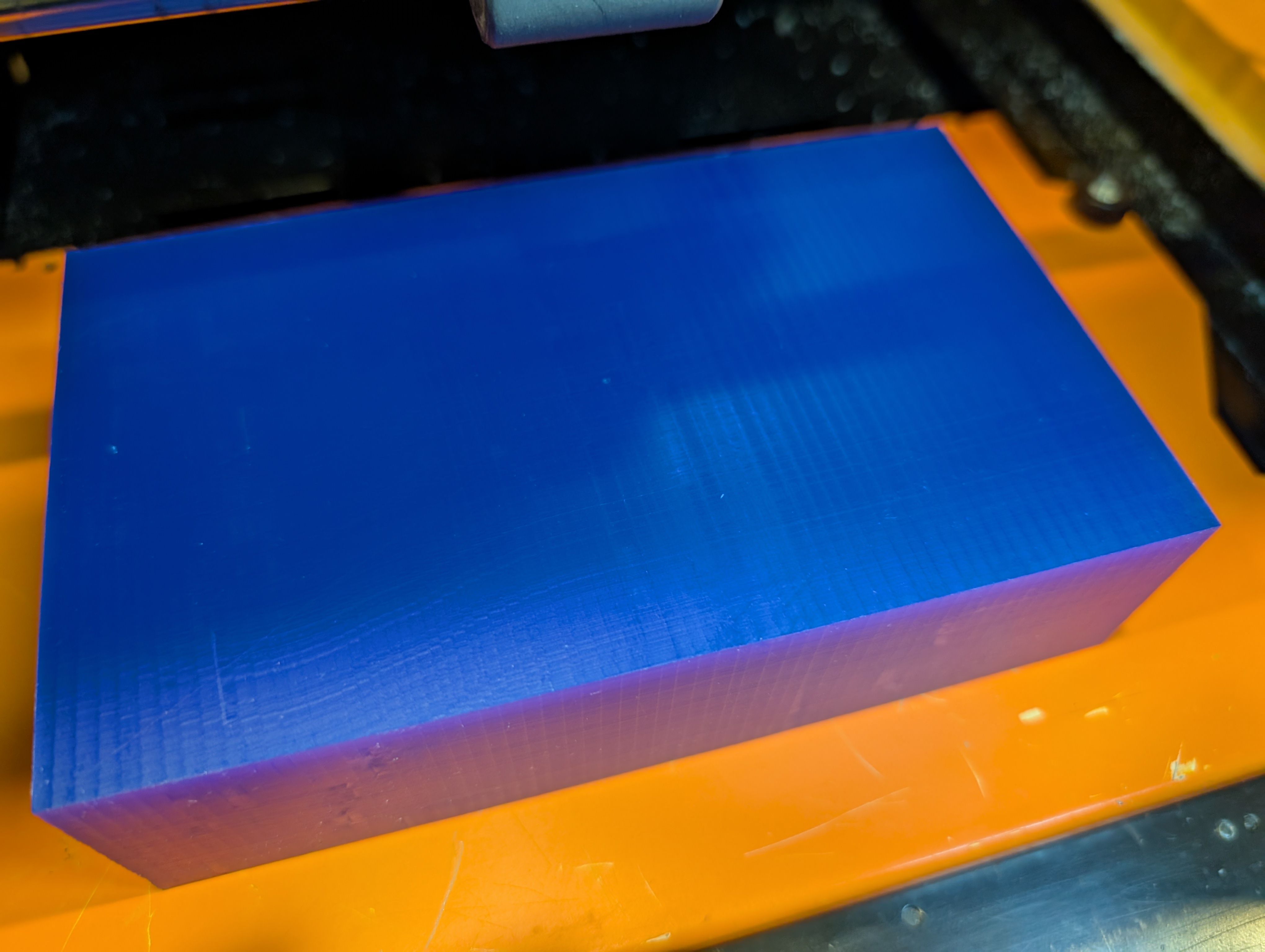

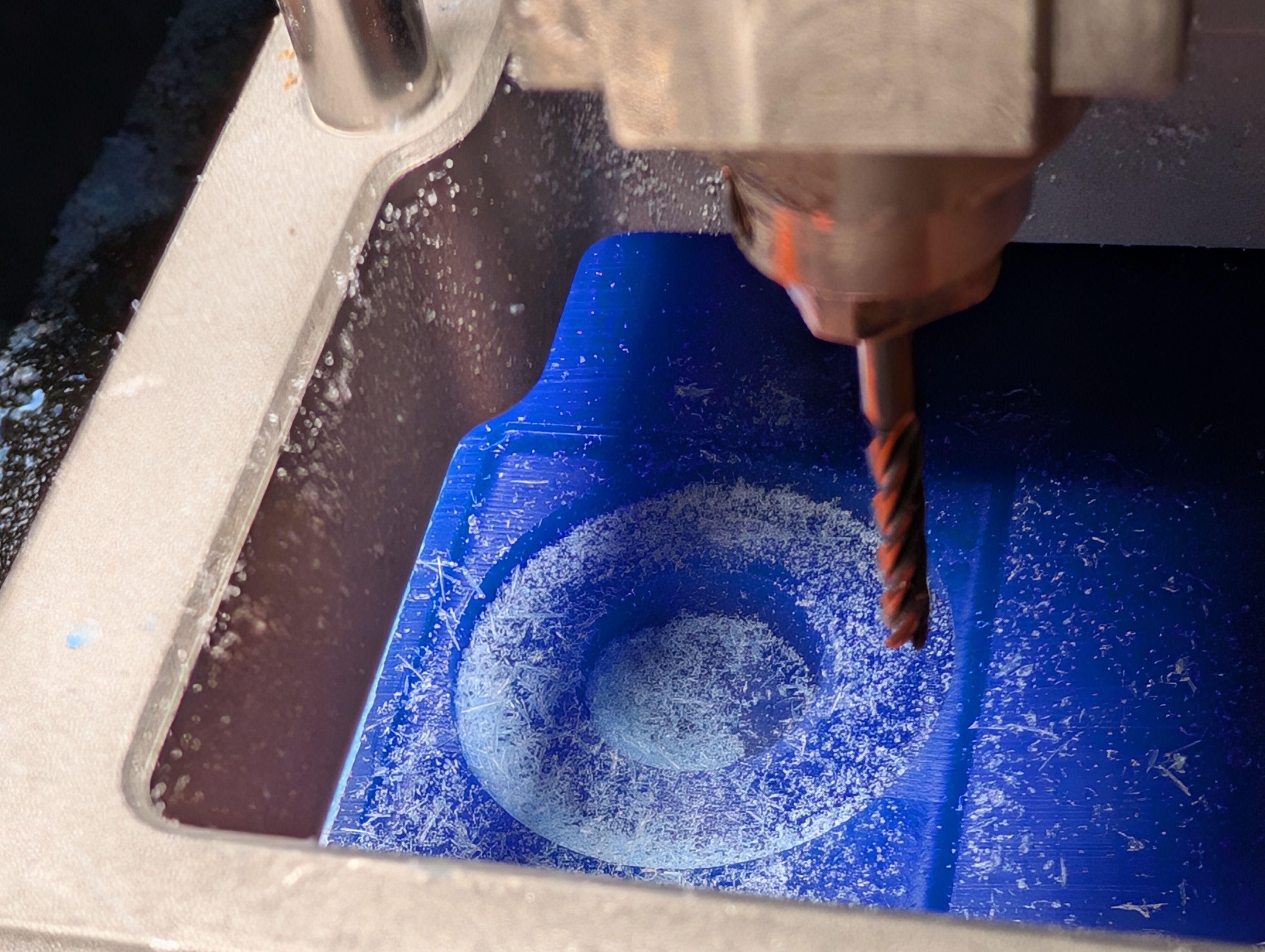

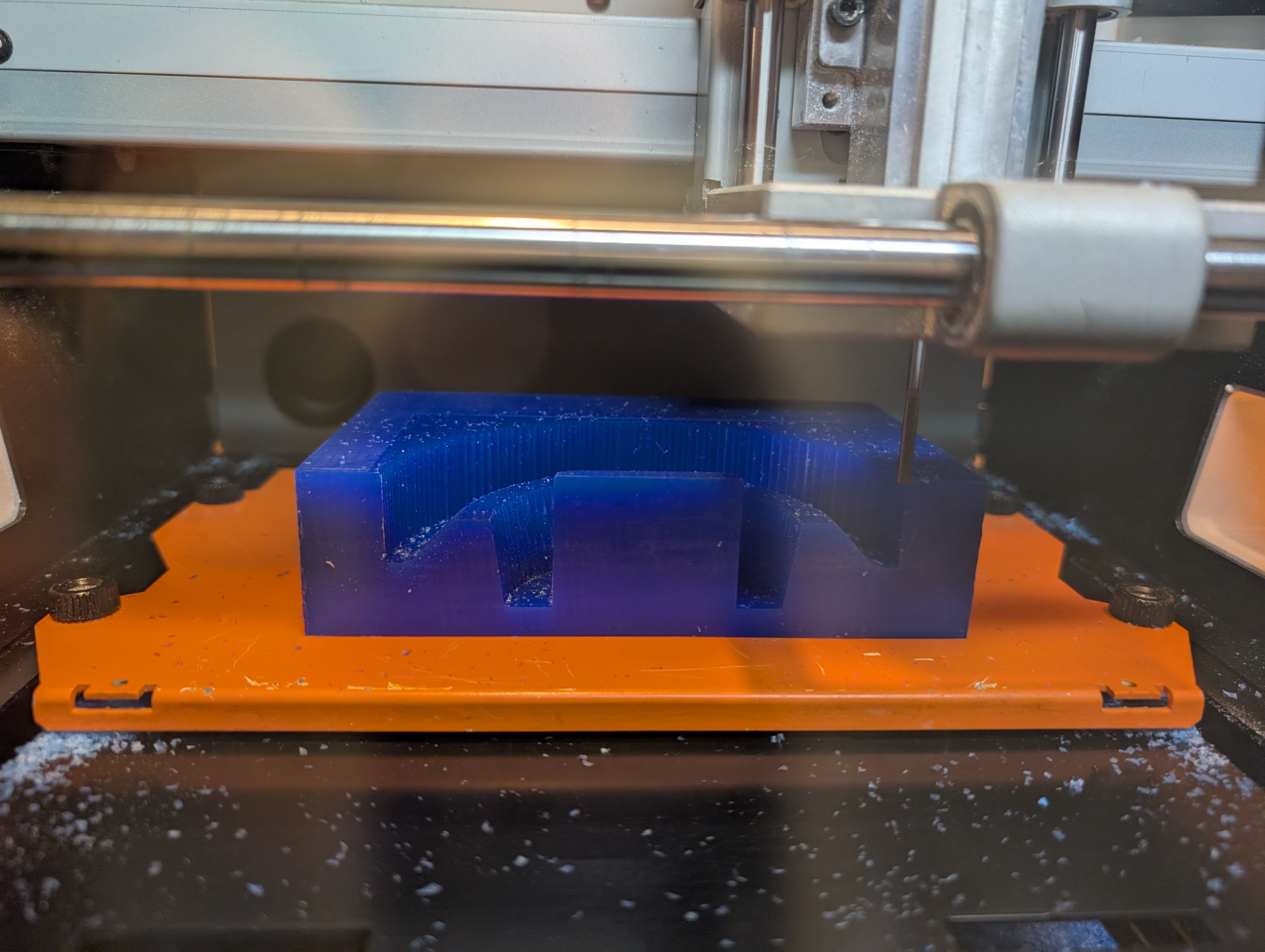

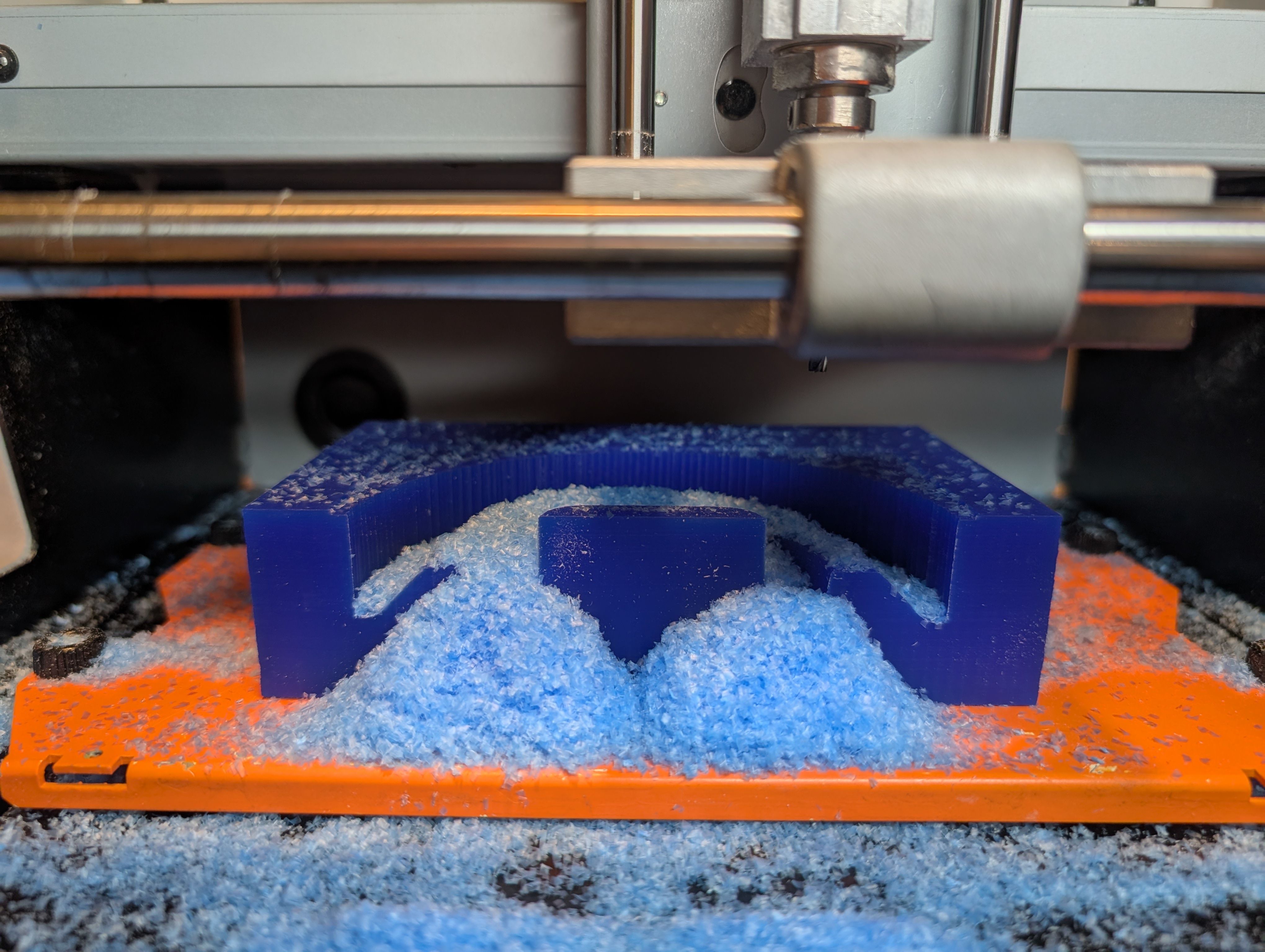

Start cutting.

Roughing goes well.

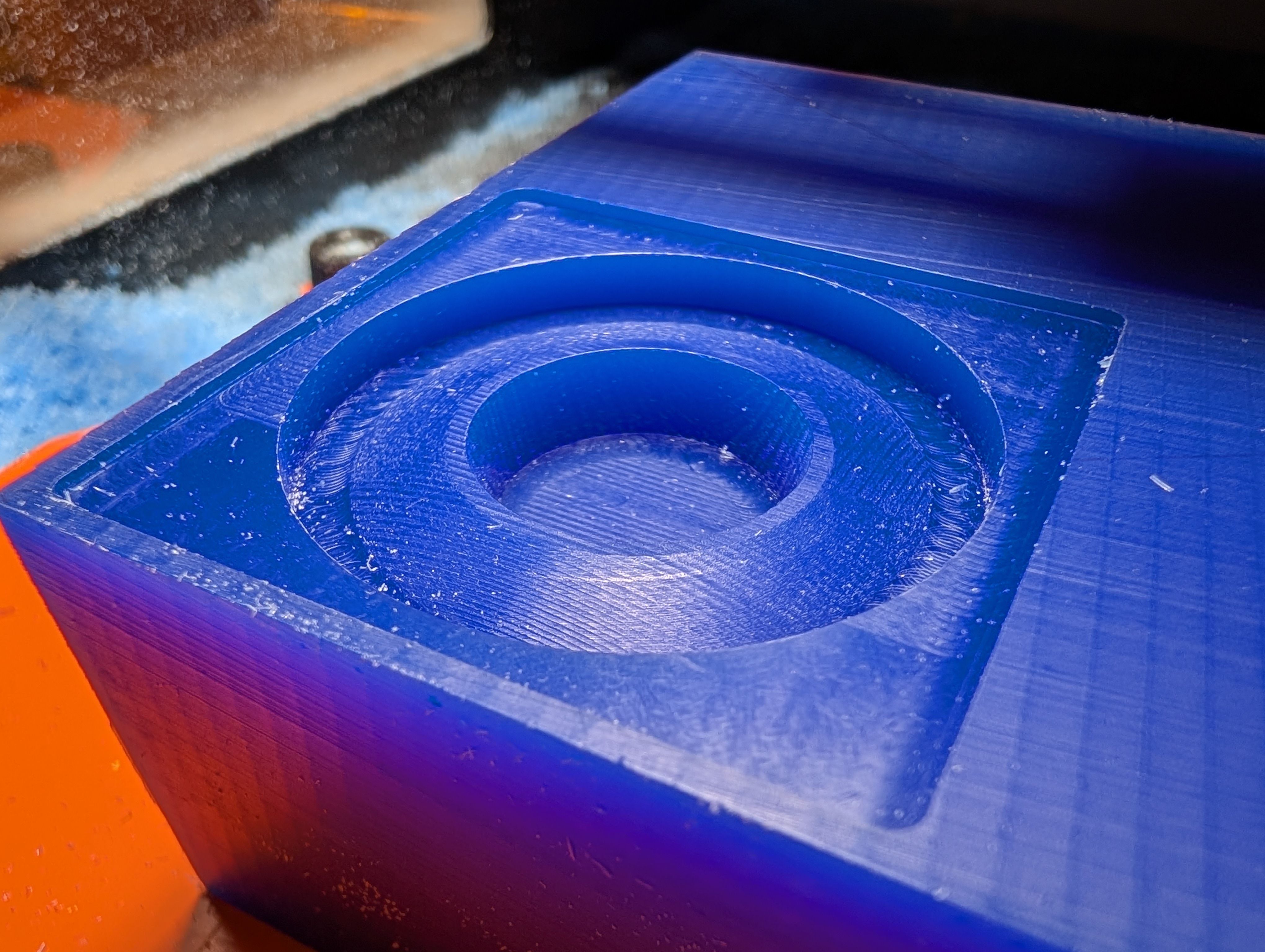

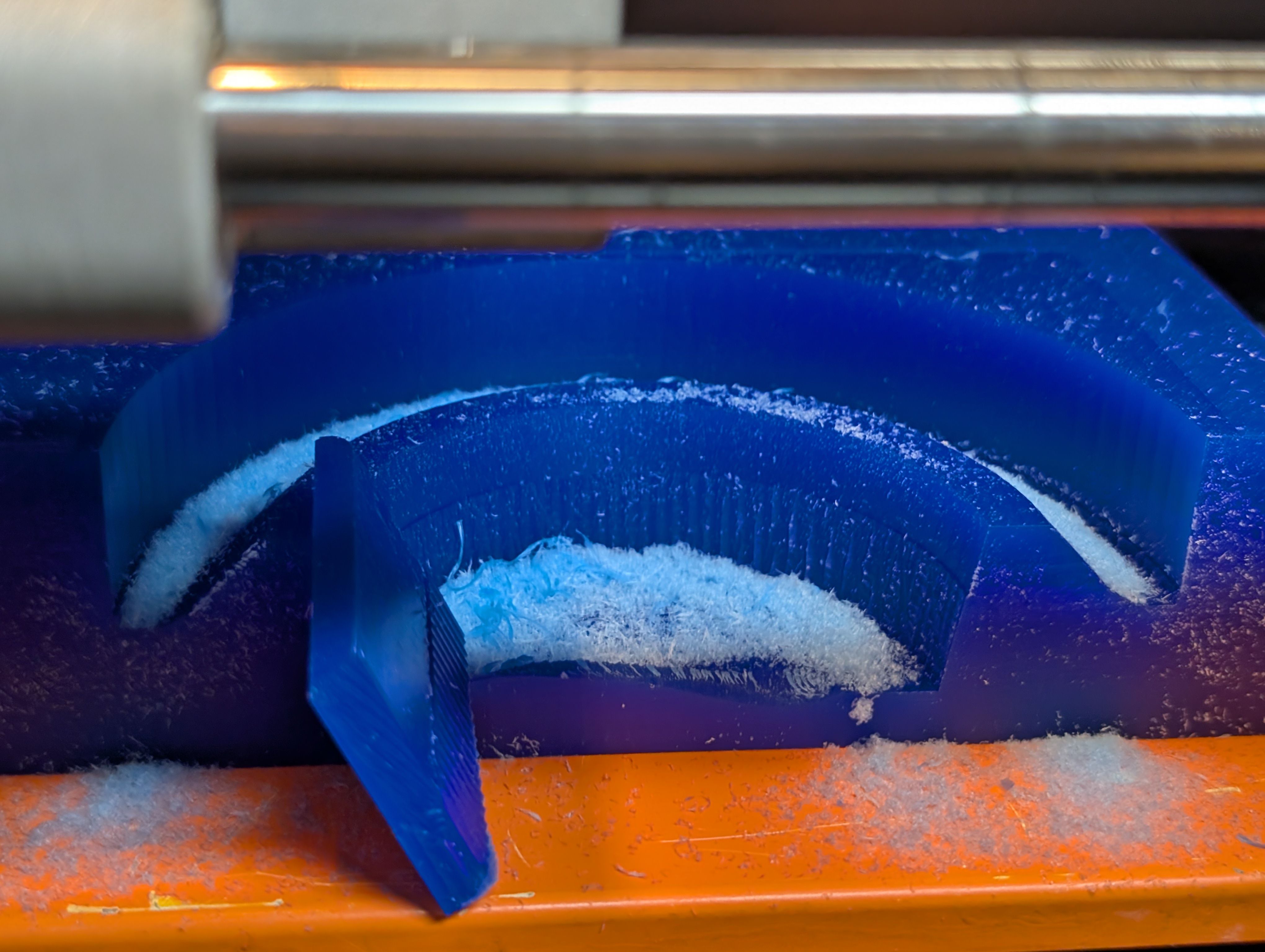

Finishing

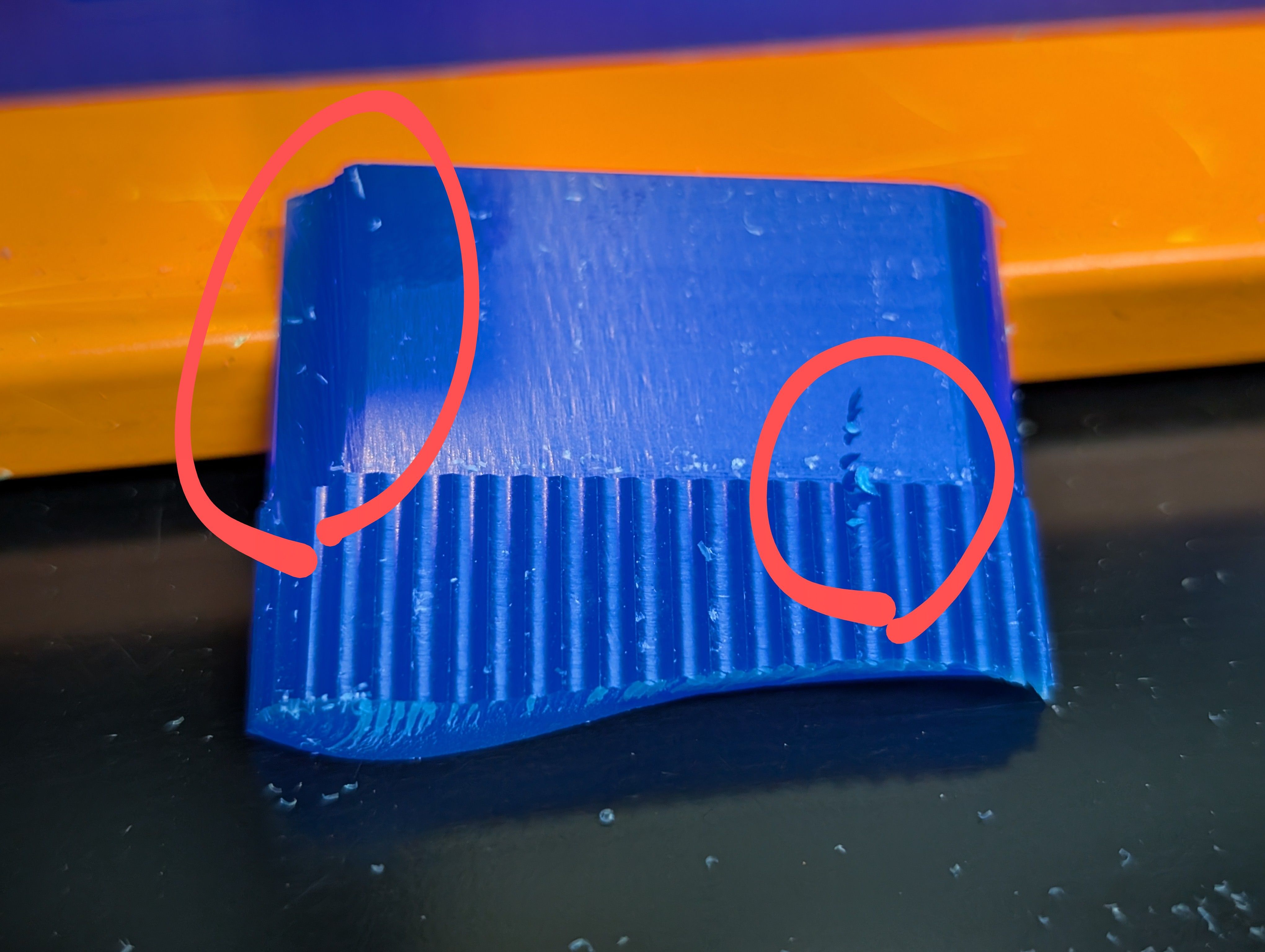

However, while finishing, the wall broken…(for make hole)

It seems the width is too thin.

Since the mill blades go in from the same direction every time, I think too much pressure was being

applied in that direction only.

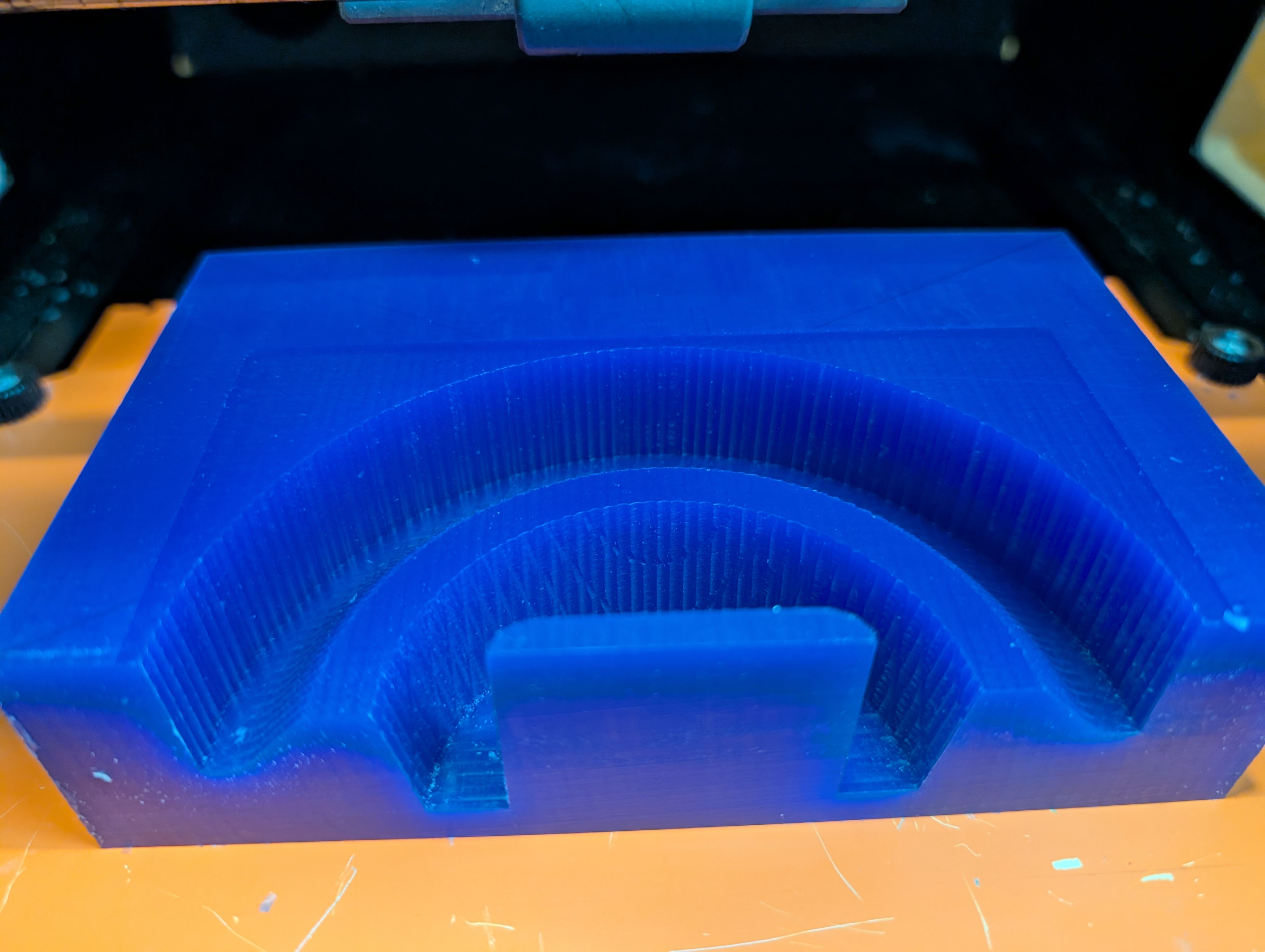

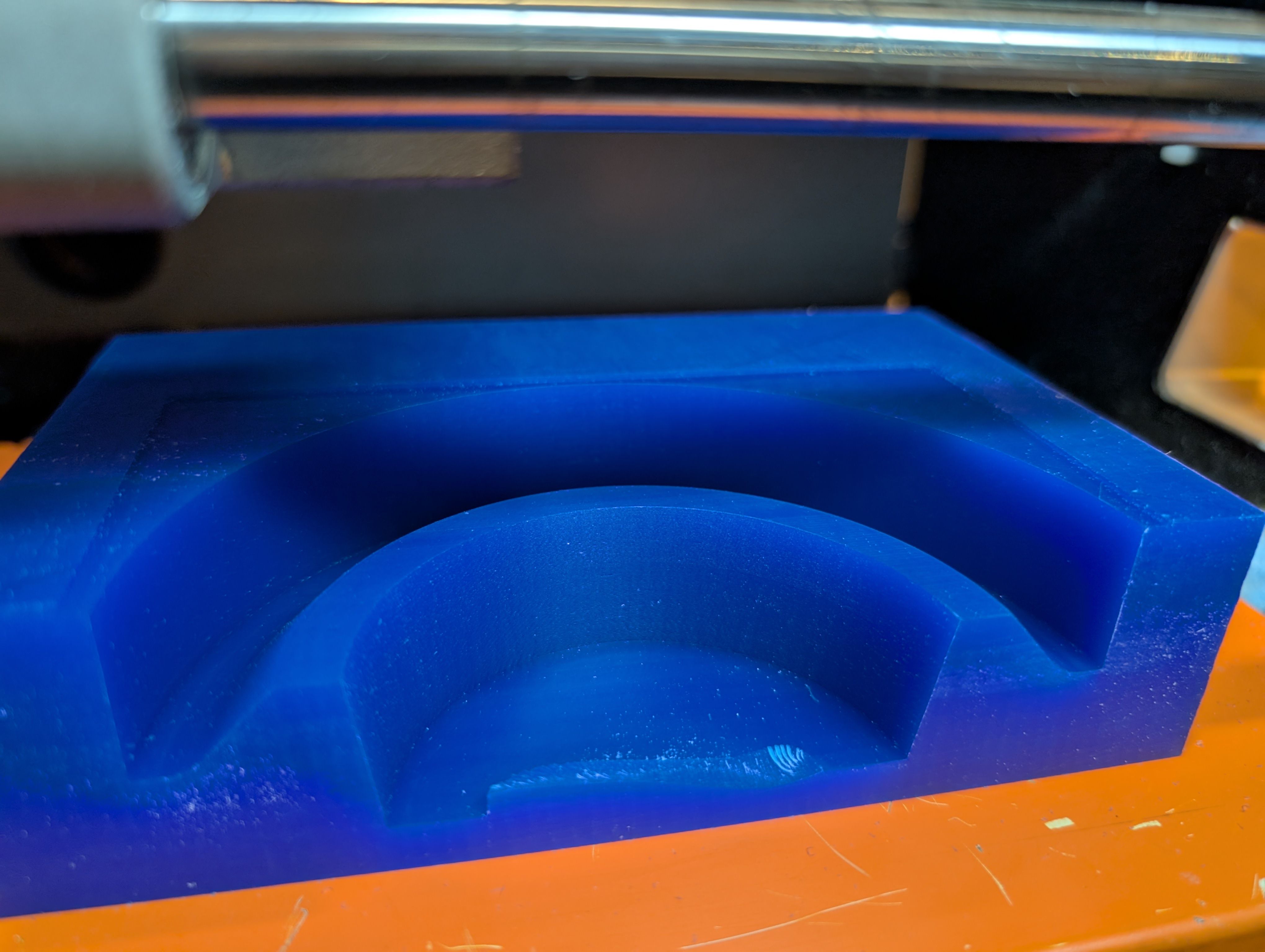

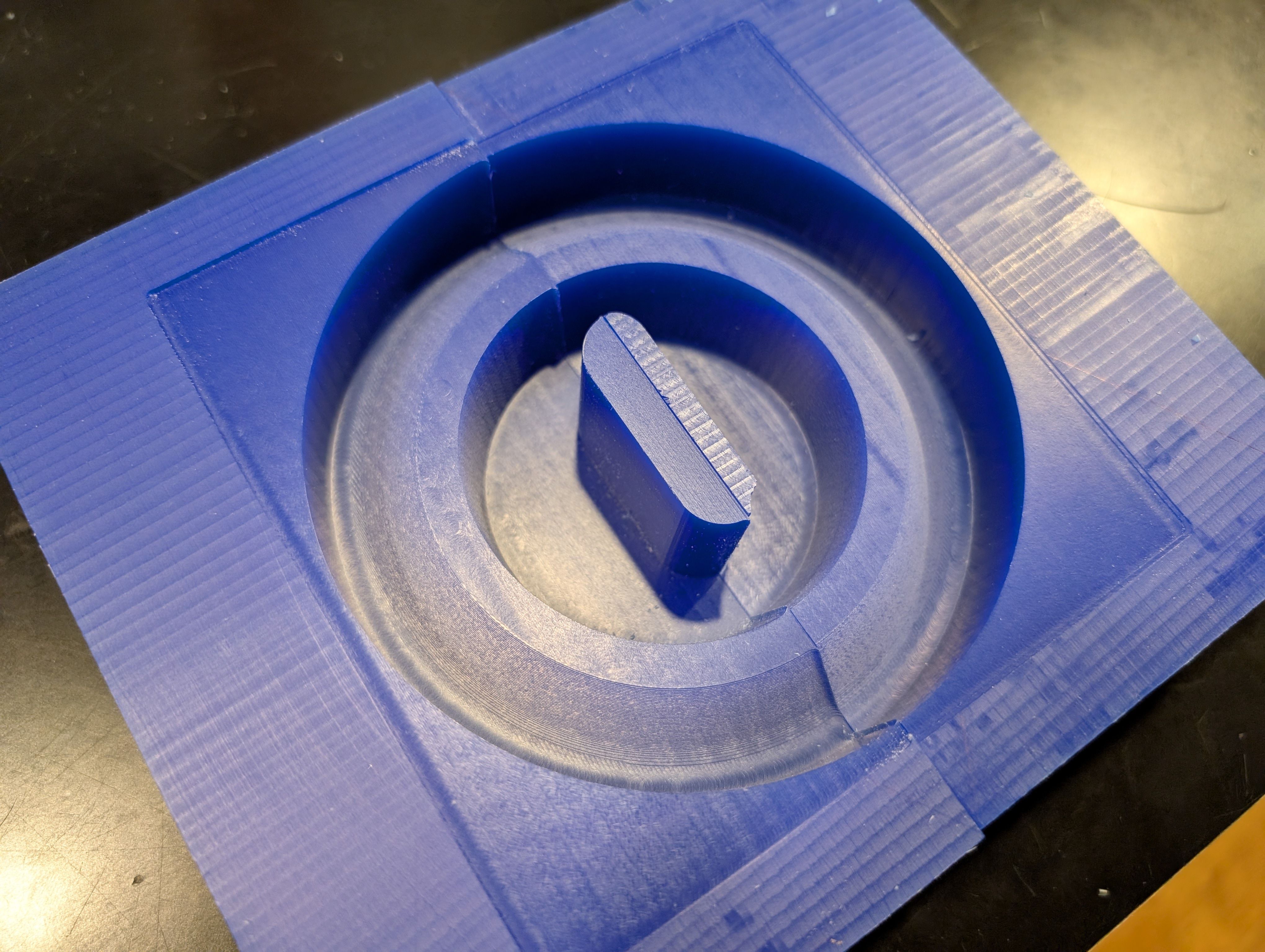

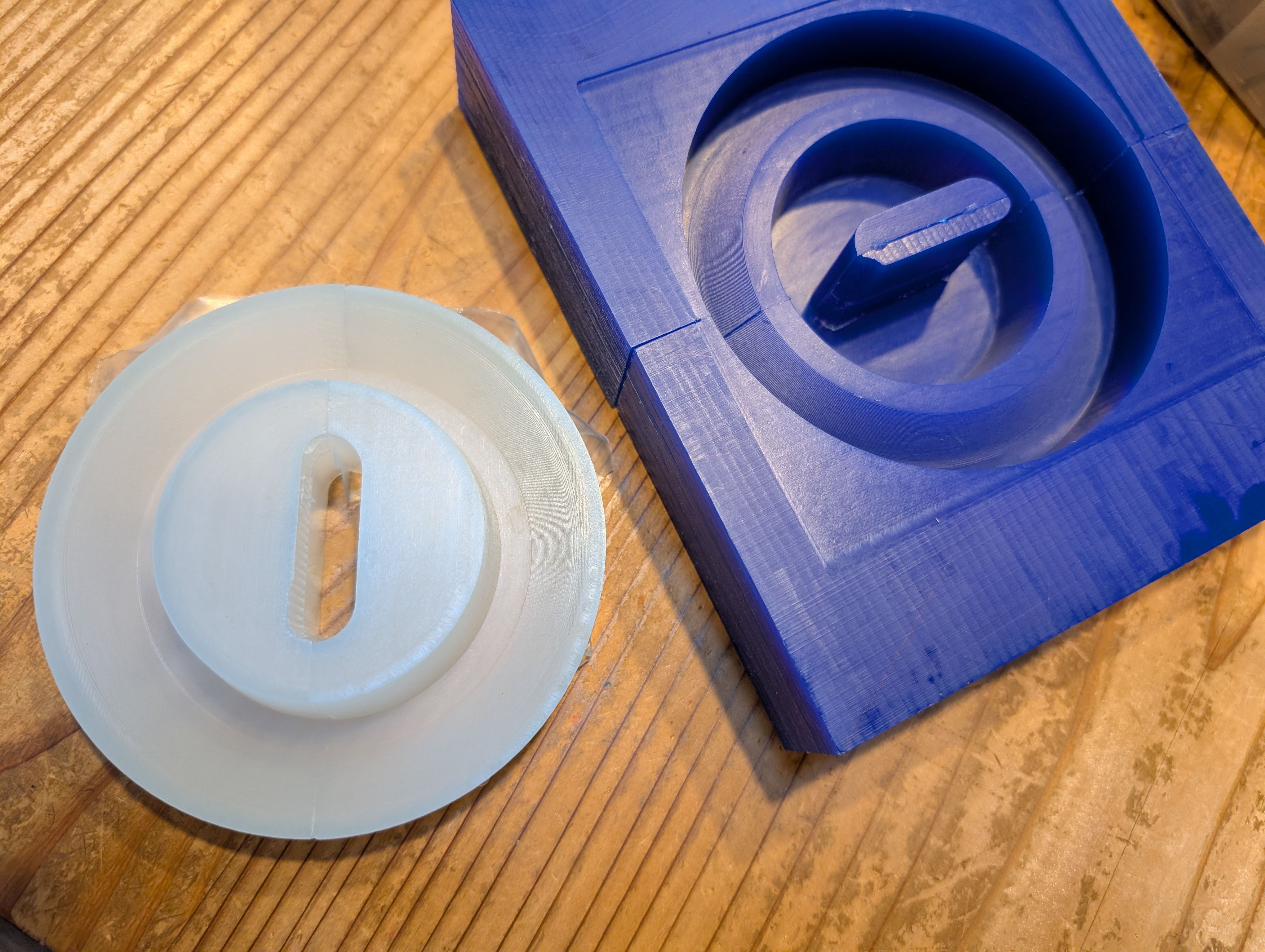

Result for 1st half mold

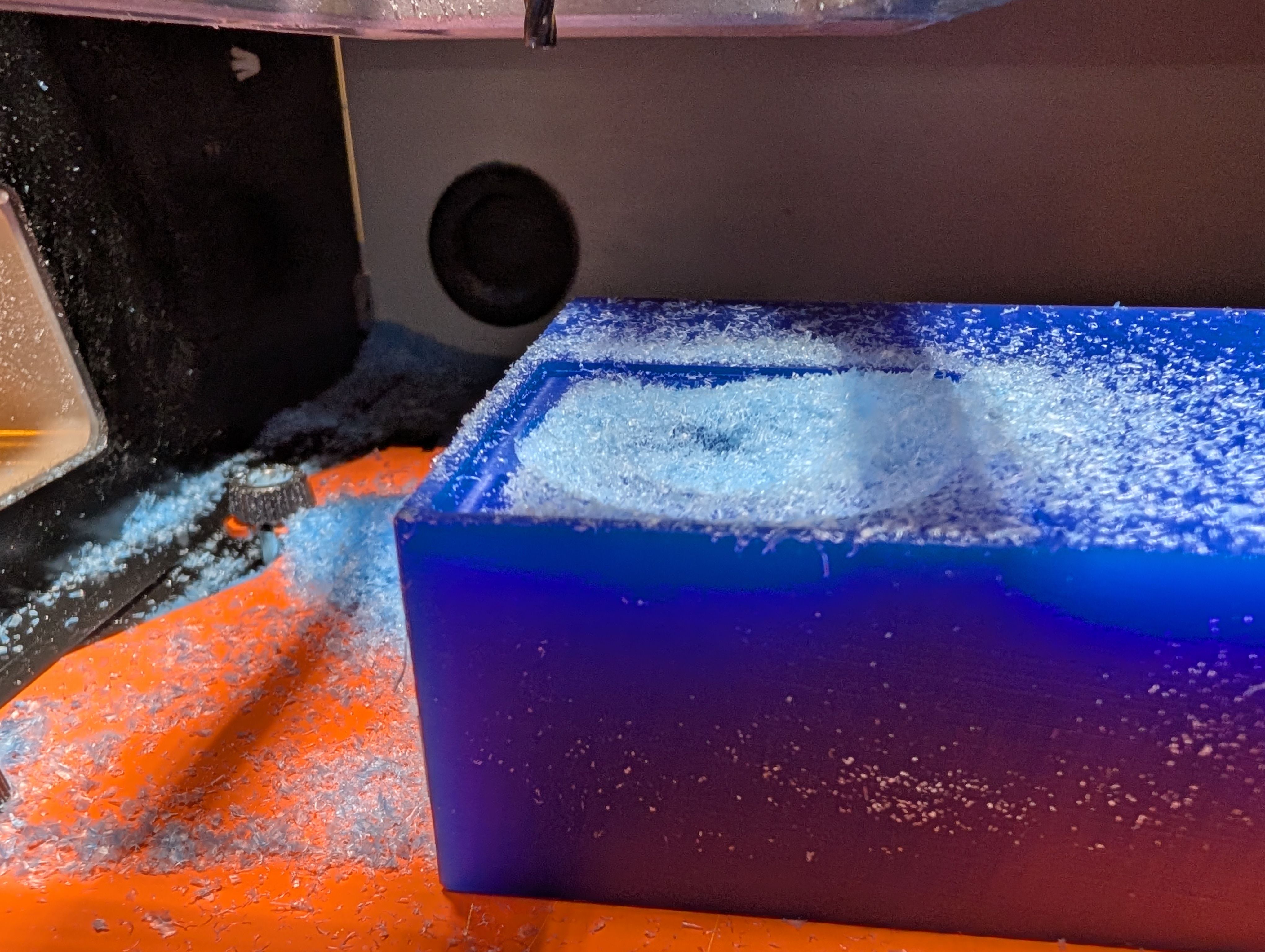

Make 2nd half mold

After 1st half mold, since the hole is too thin to cut out, I made the hole bigger and made 2nd half

mold.

Setting for roughing

Setting for finishing

Time for roughing: 2h49m

Time for finishing: 1h36m

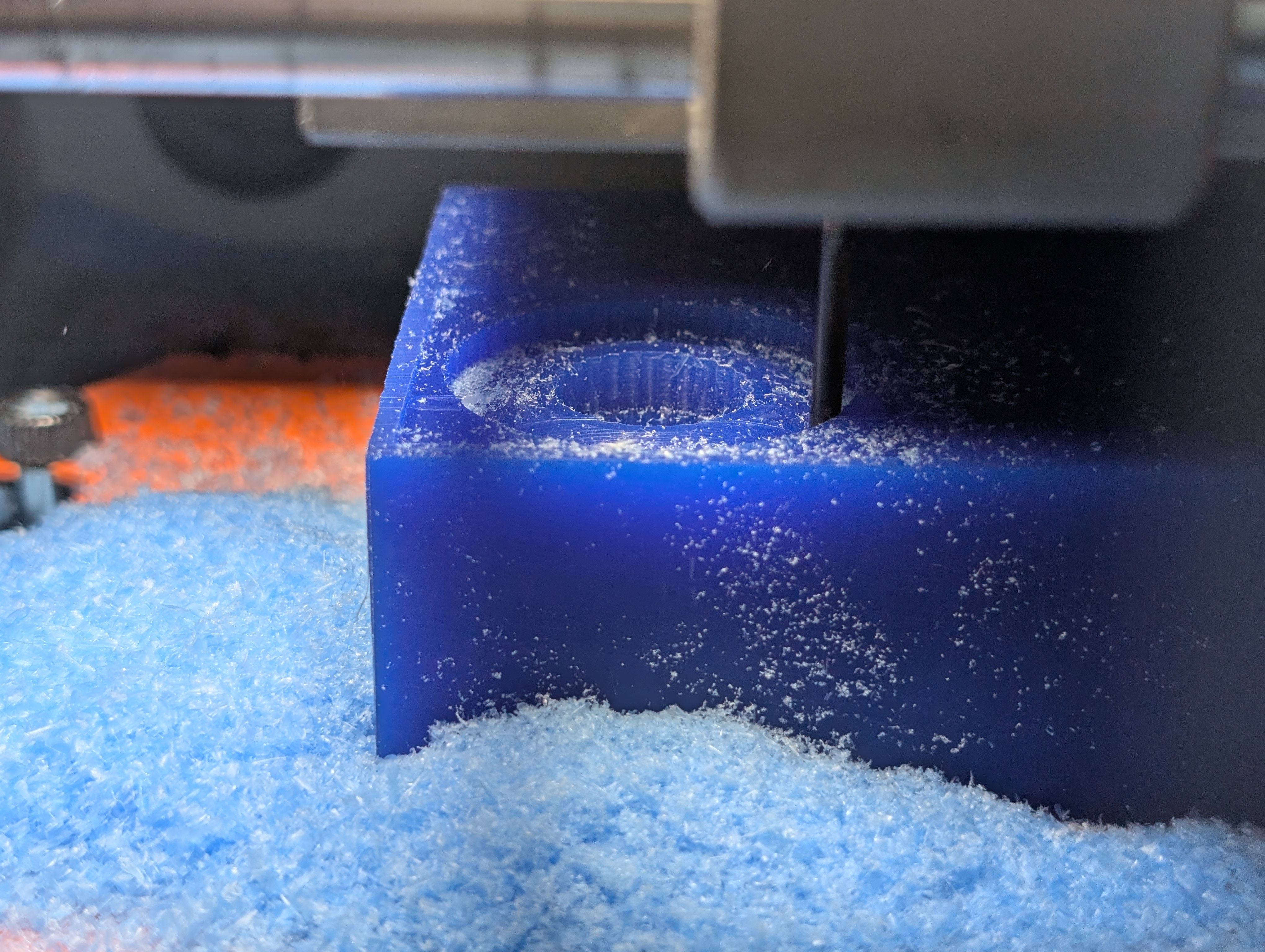

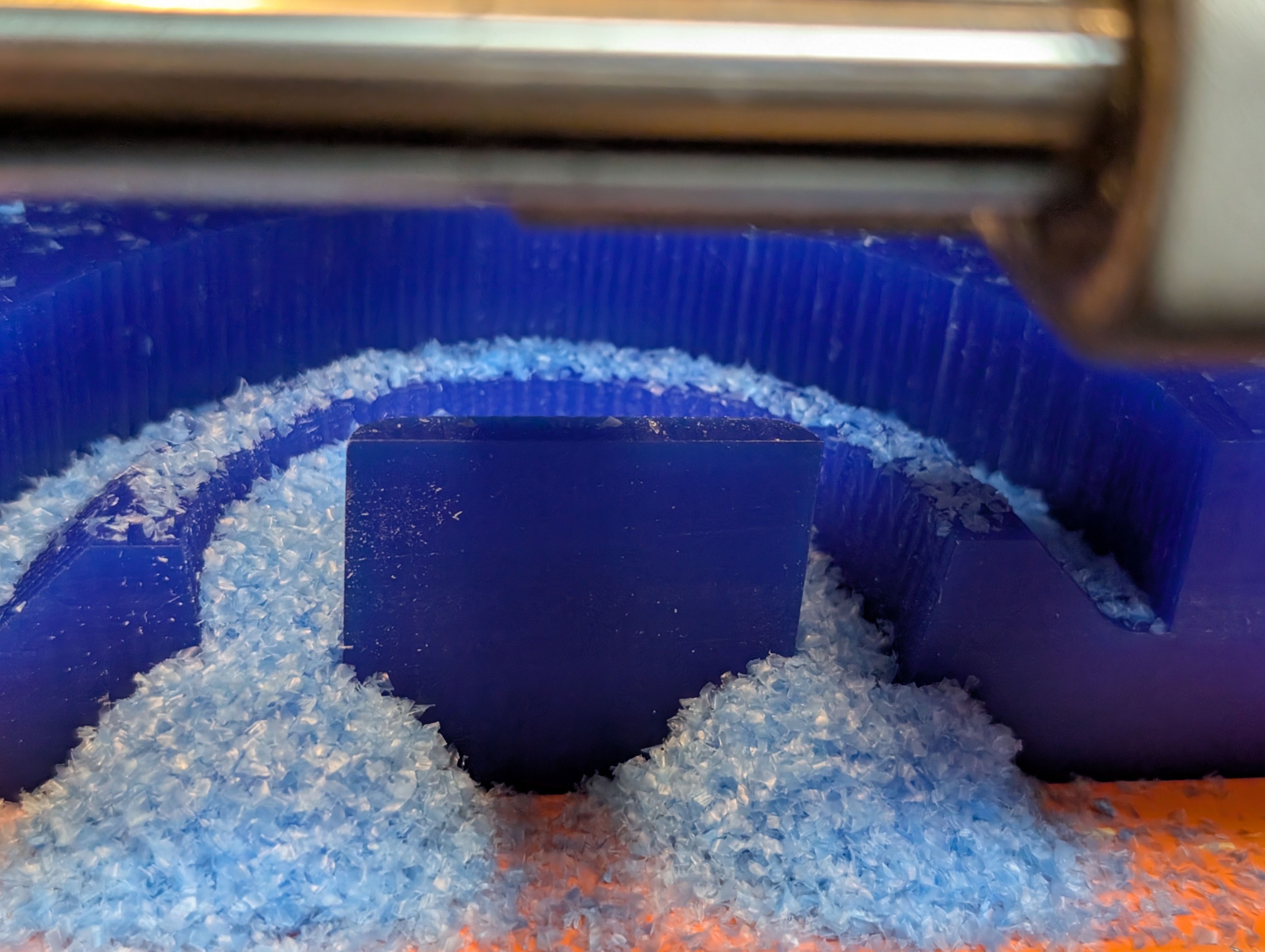

Roughing

Finishing

*A large amount of waste was generated

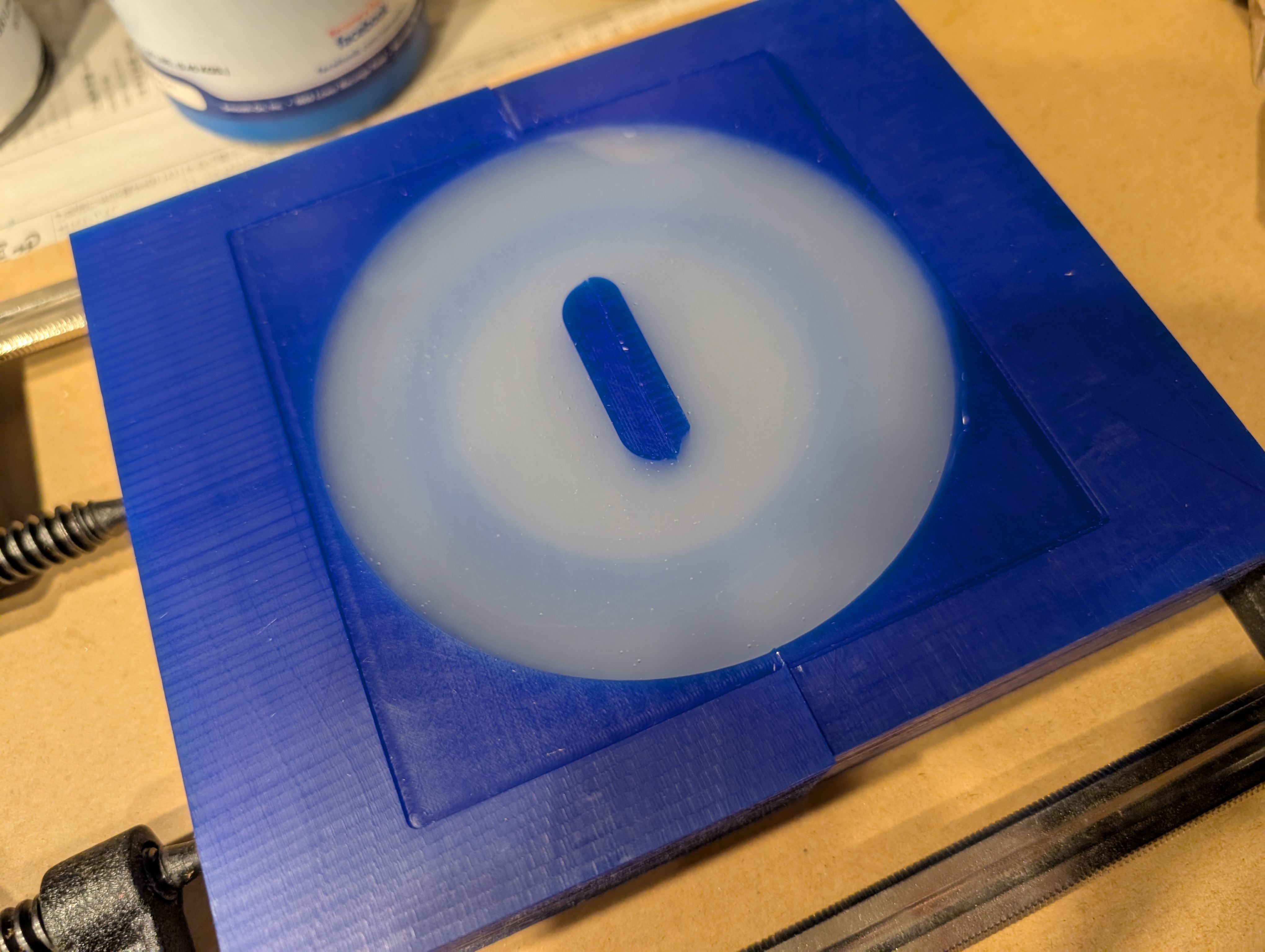

It fits nicely

The broken part was fixed with glue.

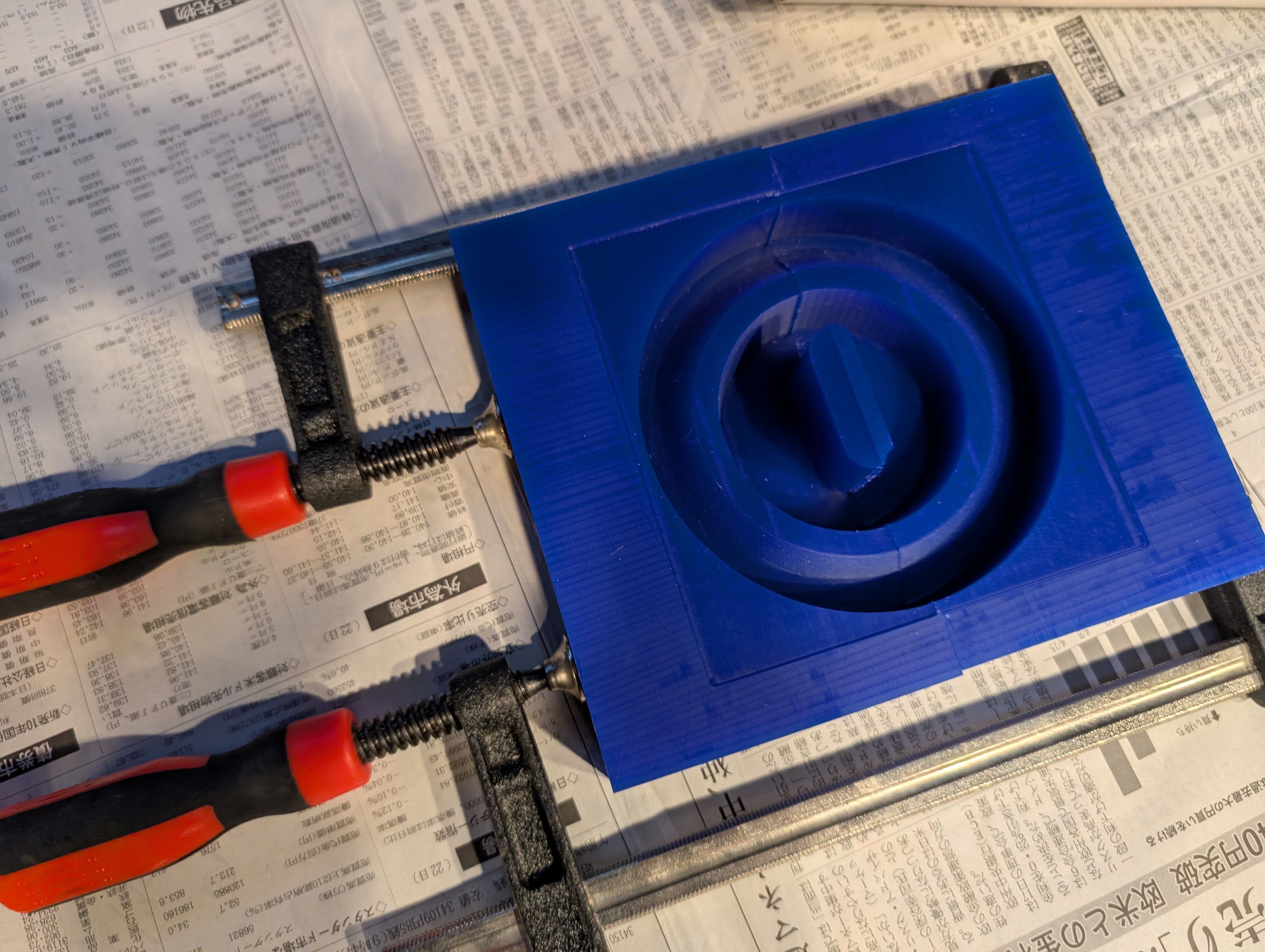

The 2 parts were also fixed together with glue and clamp.

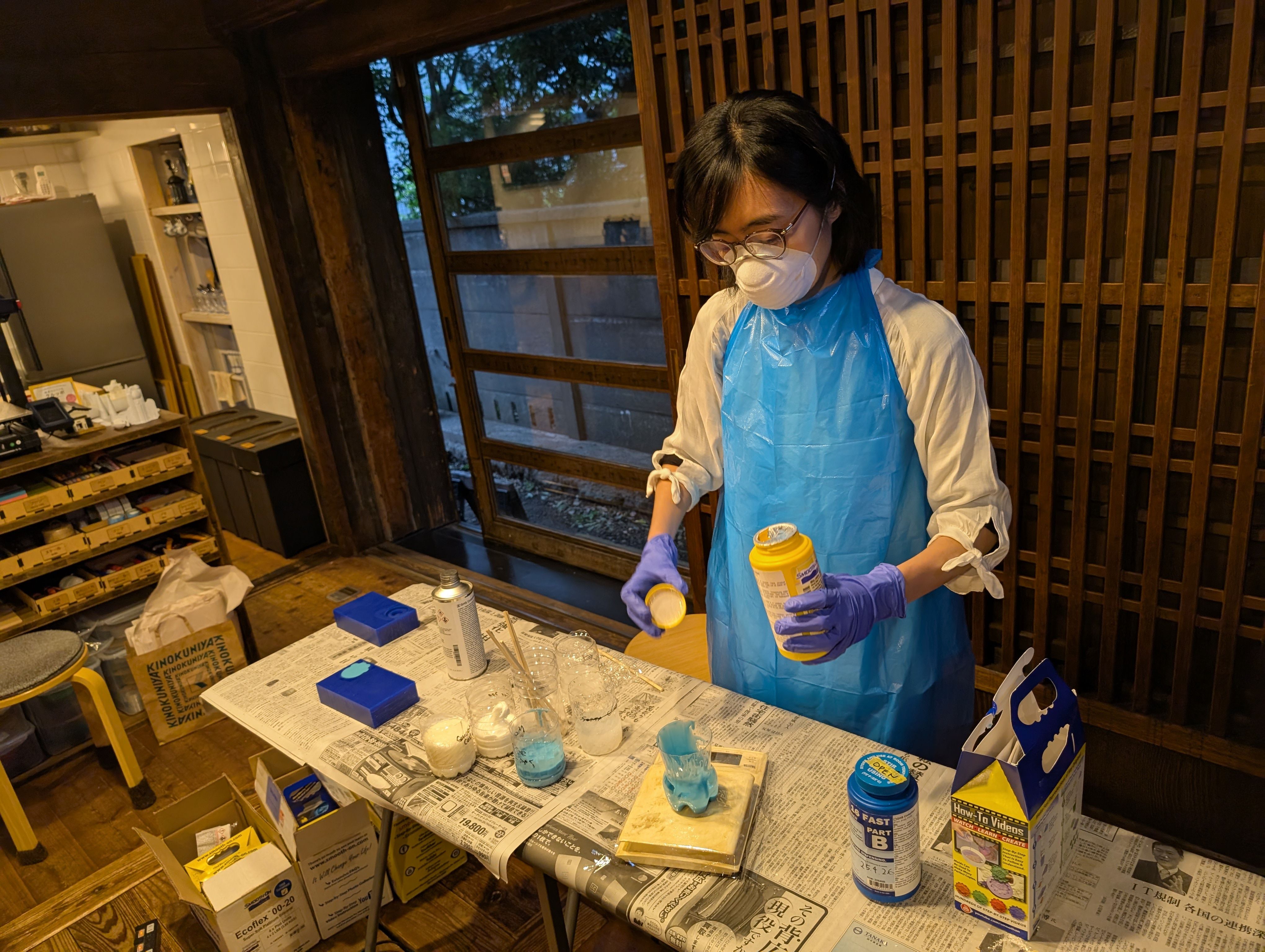

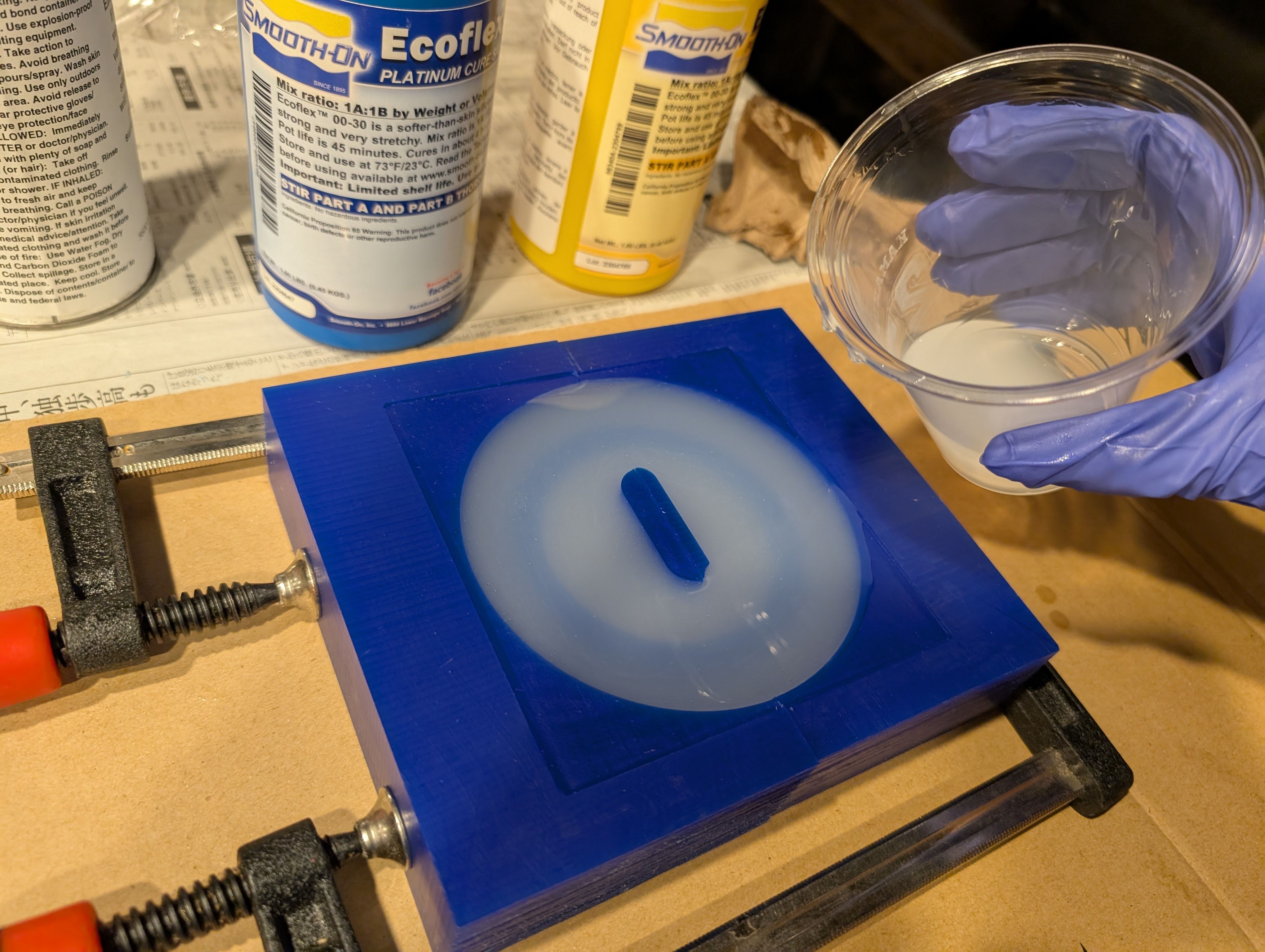

Casting

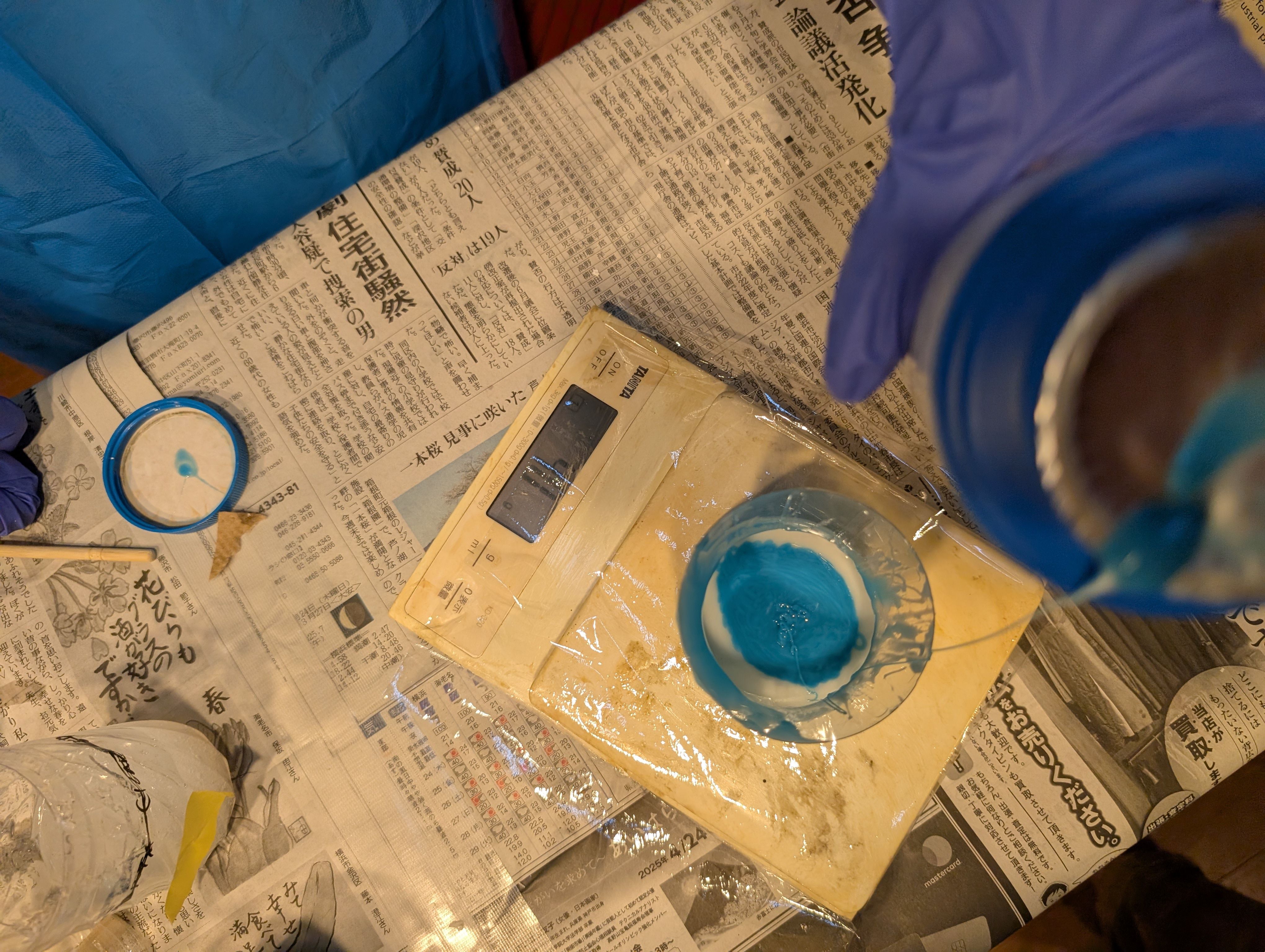

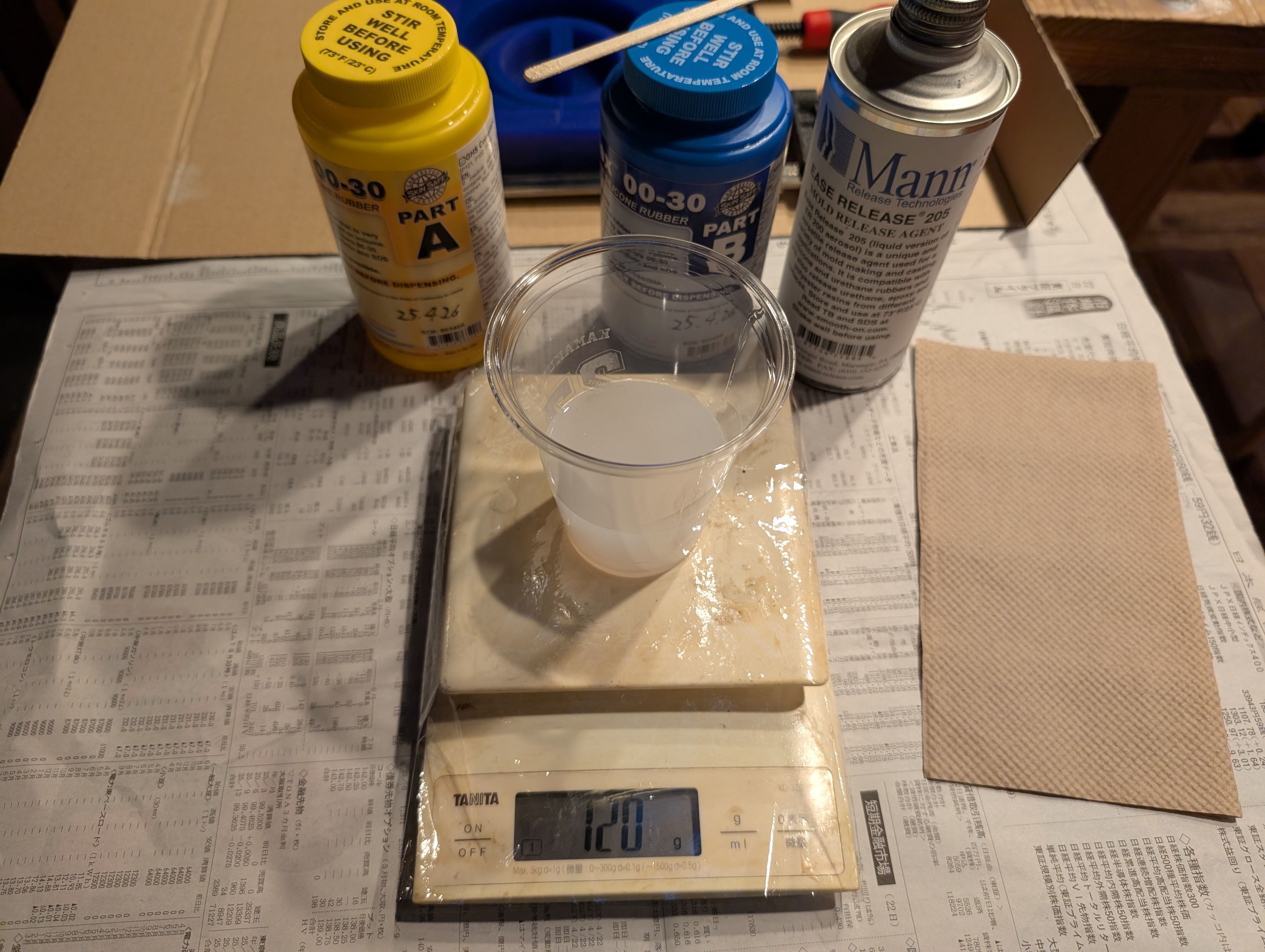

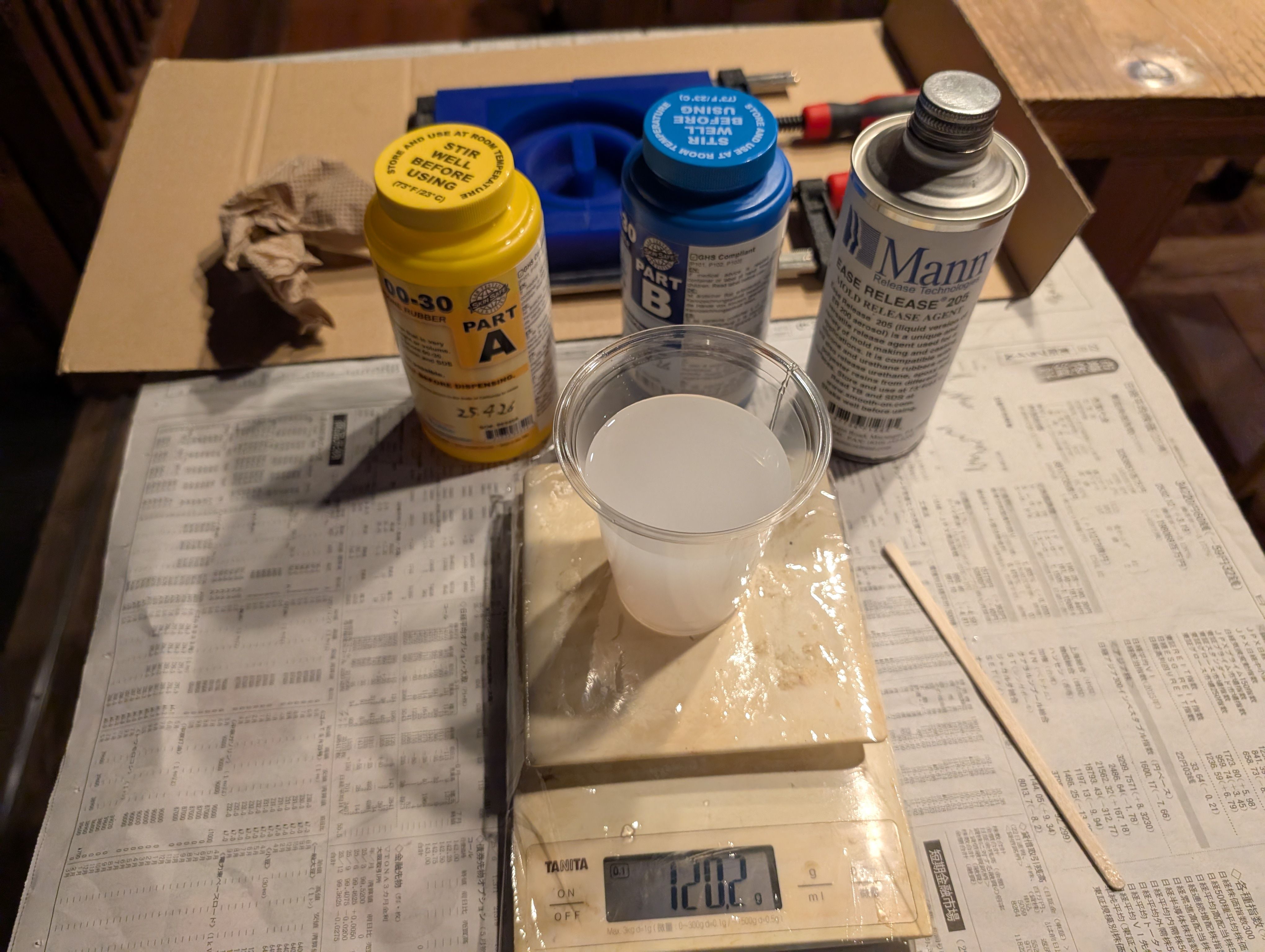

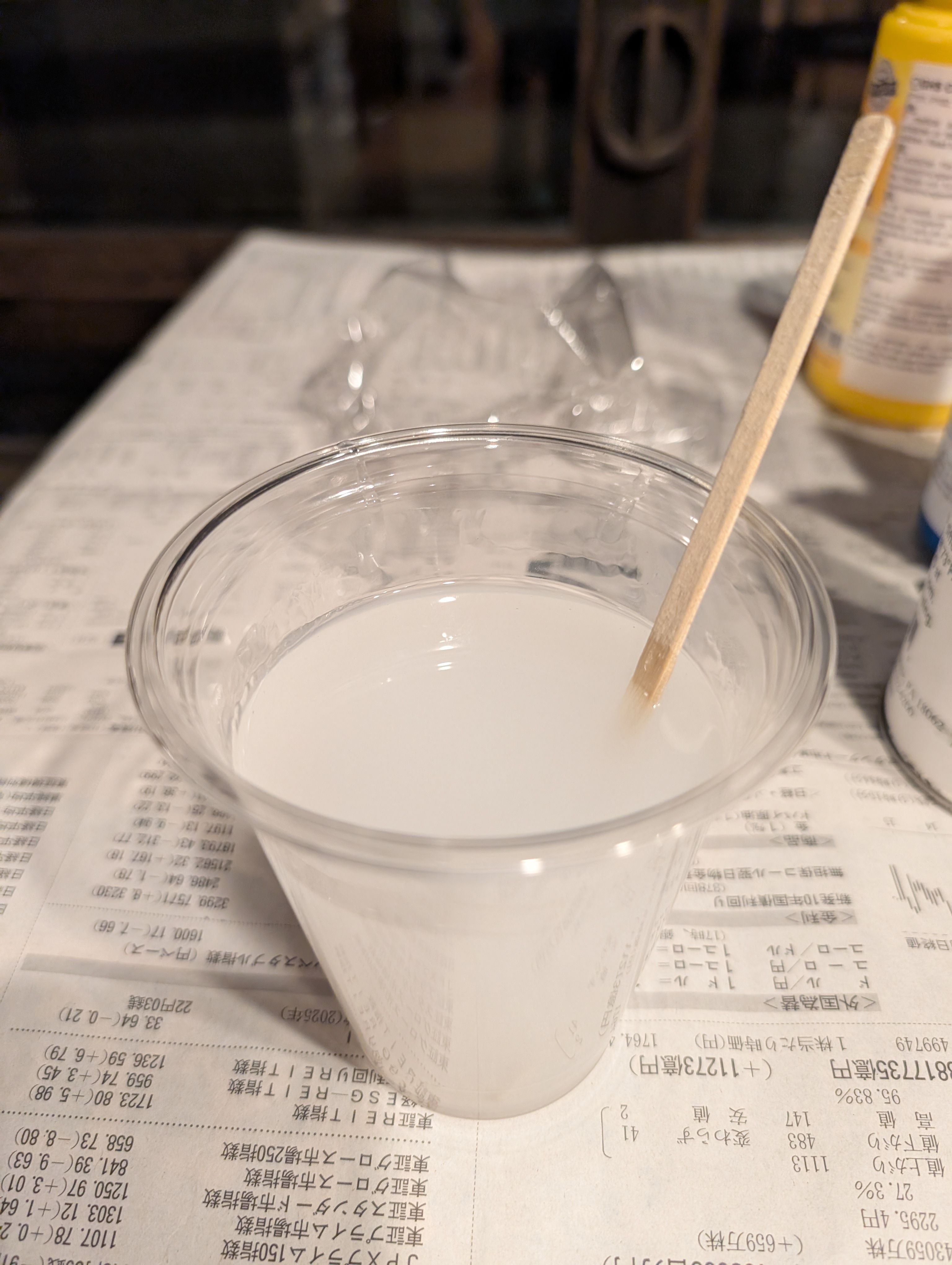

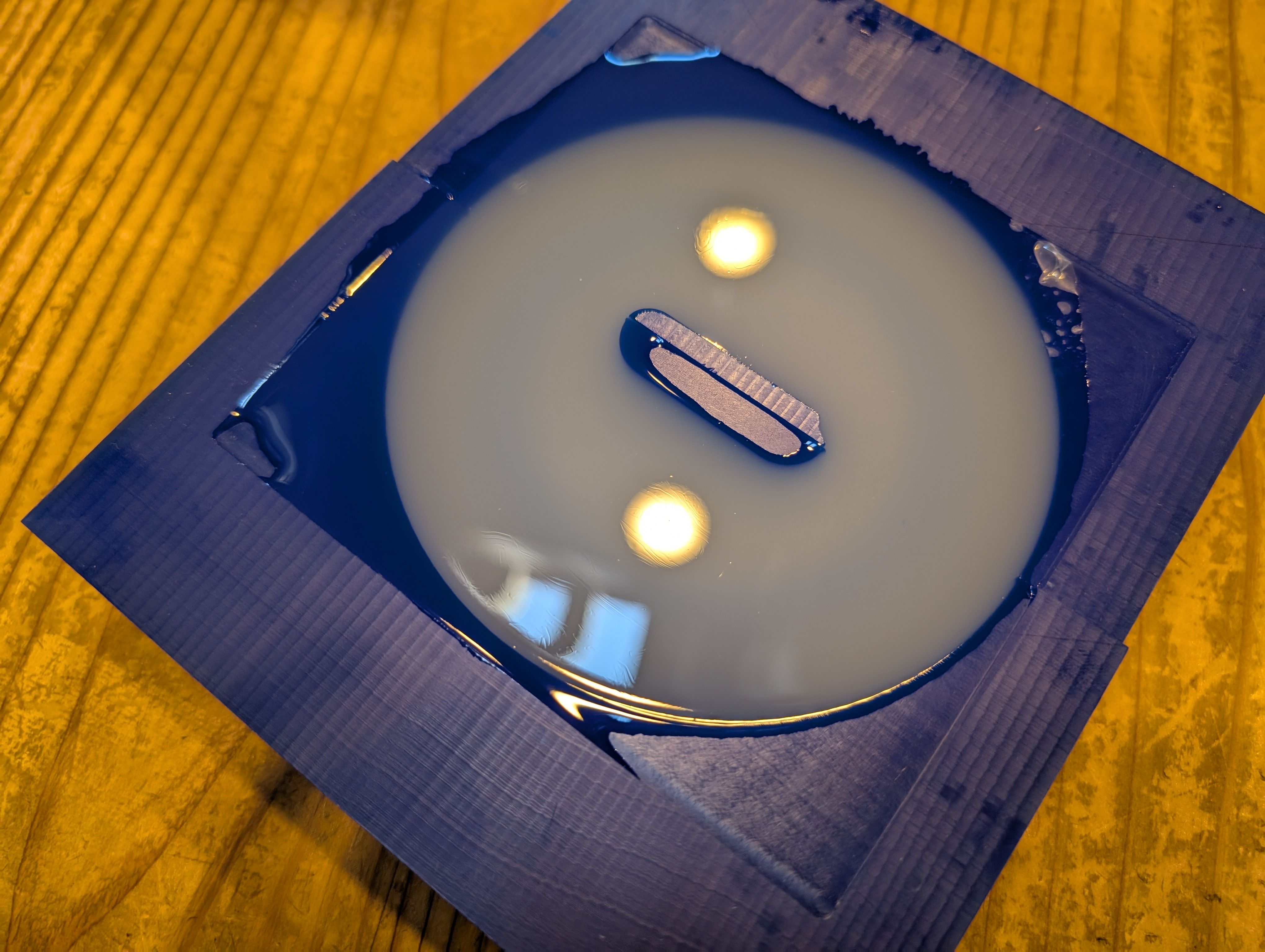

I used Ecoflex 00-30. Part A : Part B = 1 : 1 = 120g : 120g

Mix them well and put to the mold

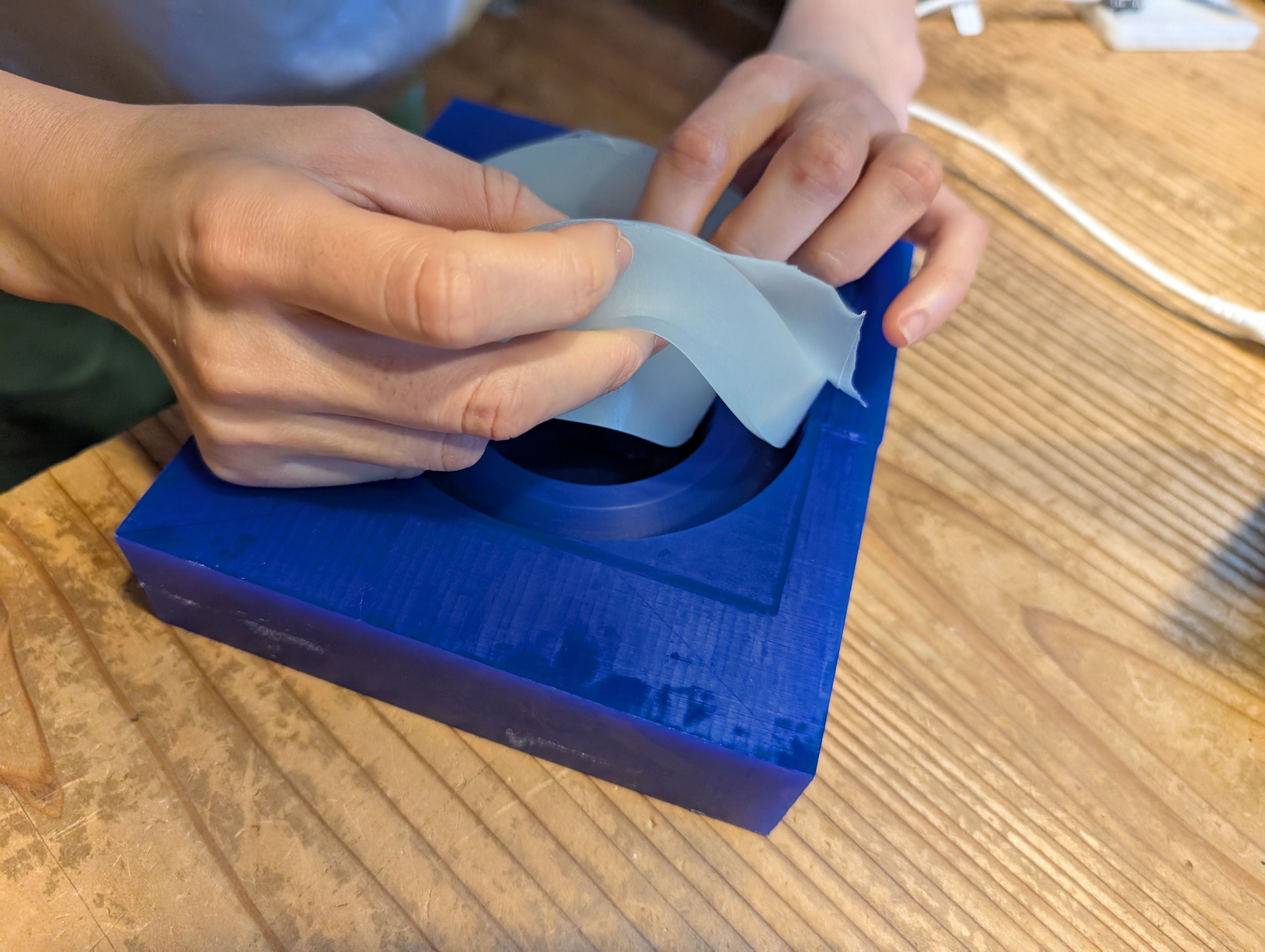

Result

It fit well with the glass!

Outcomes

- f3d for test

- stl for test

- f3d for final

- stl for final model side1

- stl for final model side2(wider hole)

This week I could tried molding and casting with machining for the first time, and could made a part for FP.

Remaining issues - things to check

***