Computer Controlled Machining

This week we are working on computer controlled machining, to make large objects.

The weekly assignment was to create something big, preferably with no fasteners or glue!

CNC Milling Explained

Computer controlled milling is a process by which we use a computer to control machinery, in this case for subtractive fabrication, in which we take away or cut through material.

The machine we used () has a large working area of several square meters,

Group Assignment

You can find the group assignment here

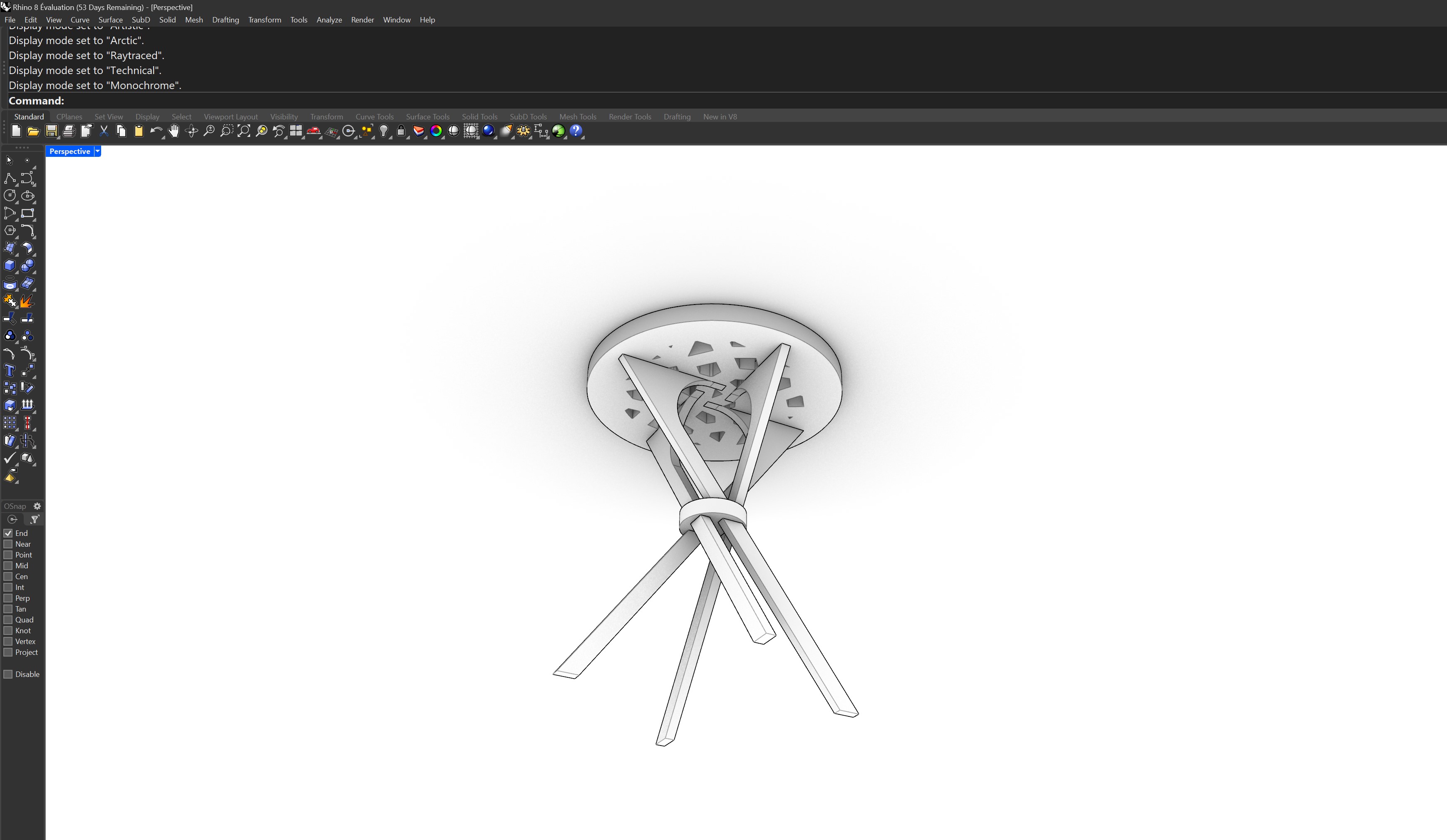

Stool Design

You can find the Grasshopper file for the stool here!

Starting this week, I already knew what I wanted to make, a pair of stools for my balcony so I could sit and drink coffee.

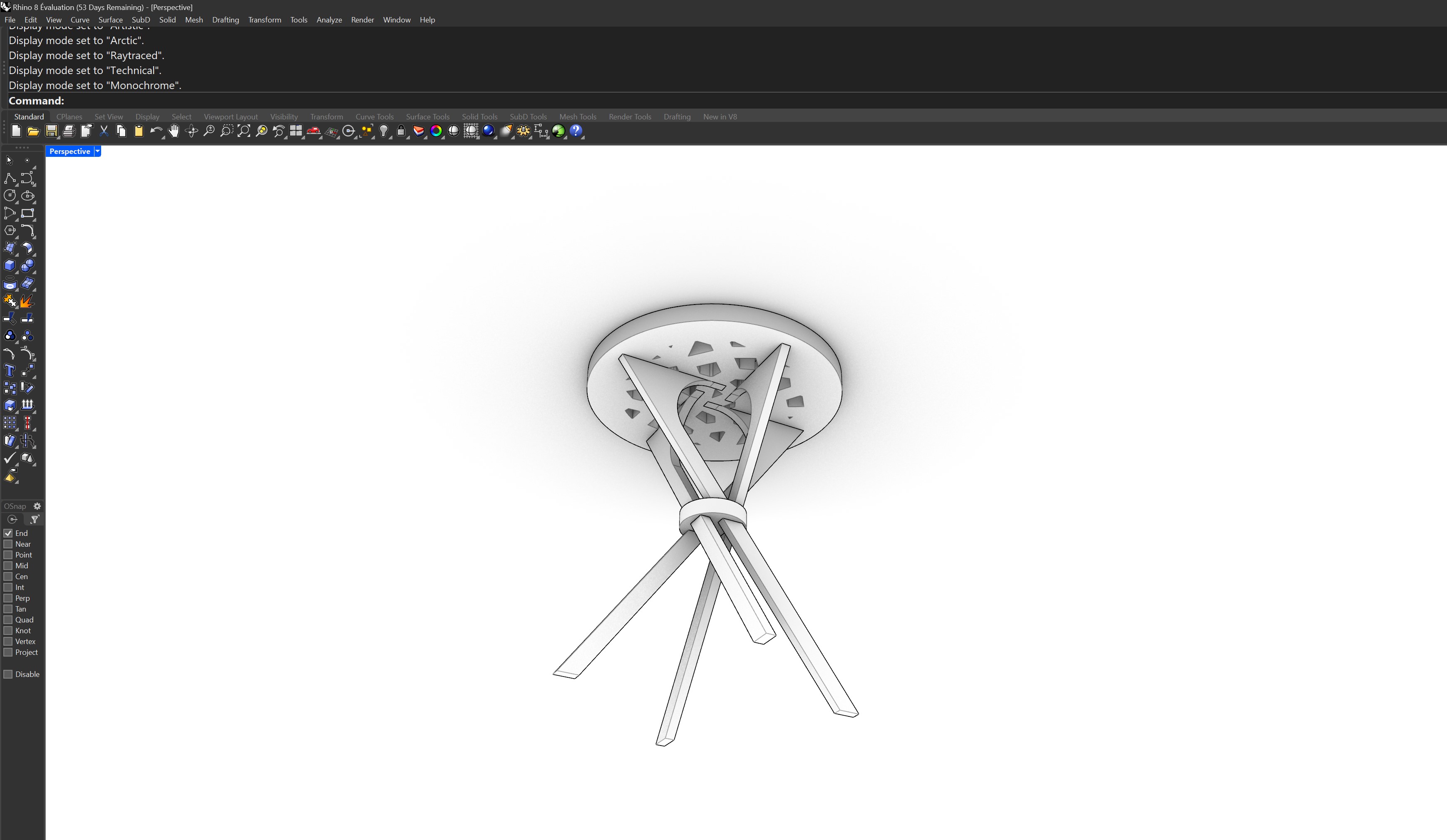

I started by modelling the stool in Grasshopper.

After that I laser cut a miniature version in order to test my design.

After that I laser cut a miniature version in order to test my design.

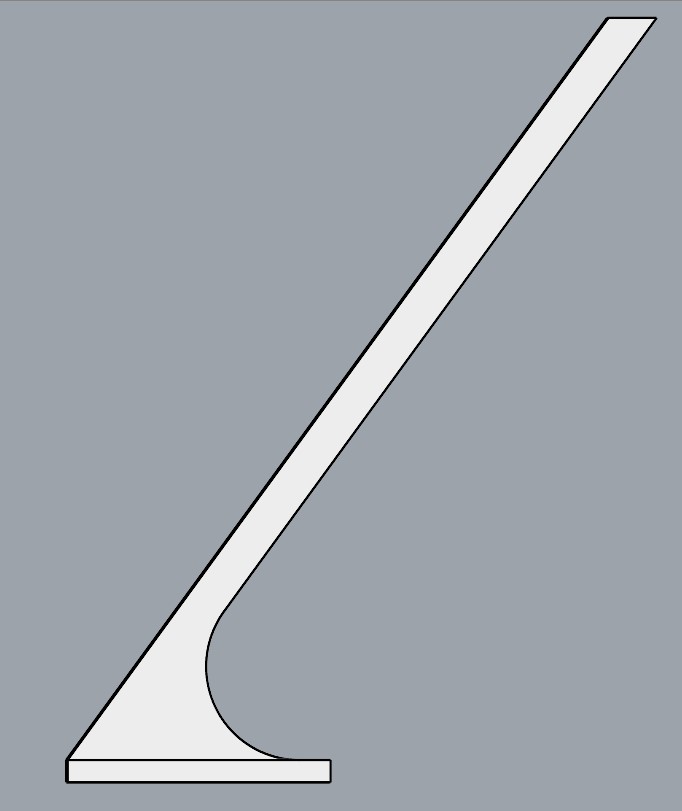

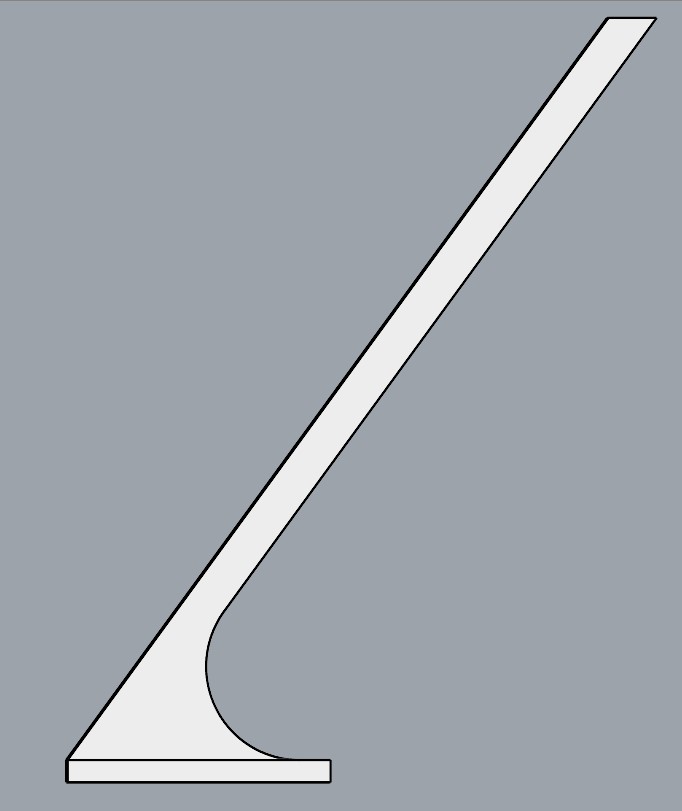

I noticed in the laser cut version that the legs were definitely too weak to support weight.

I decided to change the legs to add some extra support as well as a 3D printed ring in order to further support the legs.

I noticed in the laser cut version that the legs were definitely too weak to support weight.

I decided to change the legs to add some extra support as well as a 3D printed ring in order to further support the legs.

Once the modelling was done, I started preparing the files for milling and got to the actual cutting!

Once the modelling was done, I started preparing the files for milling and got to the actual cutting!

RhinoCAM prep

My friend Susanna helped me greatly for this part!

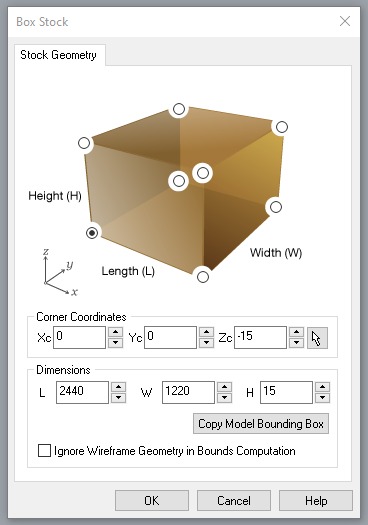

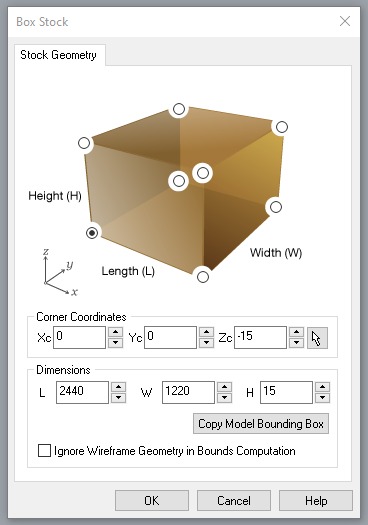

In order to prepare the RhinoCAM settings, I first had to set up the dimensions of my piece of wood.

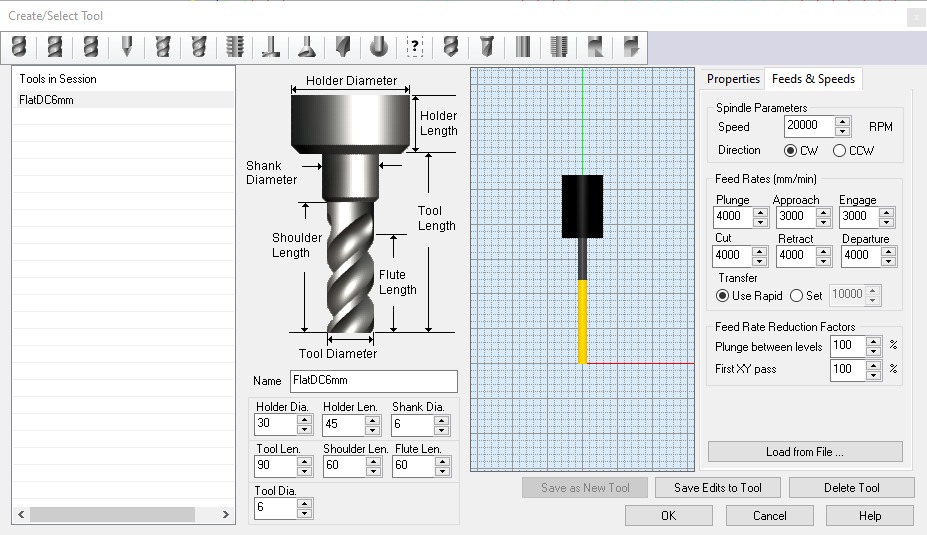

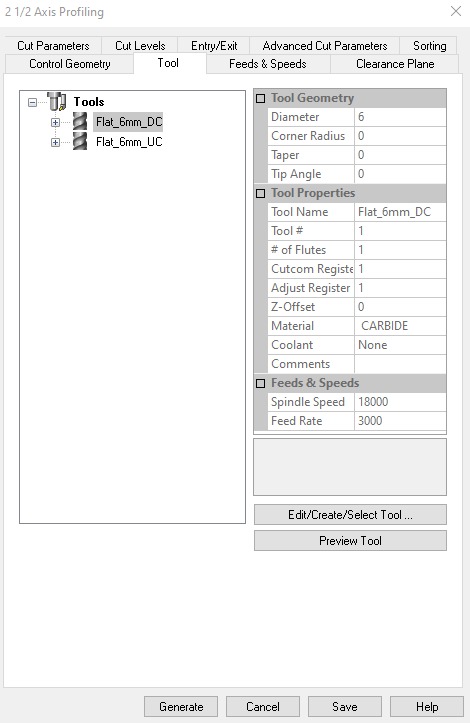

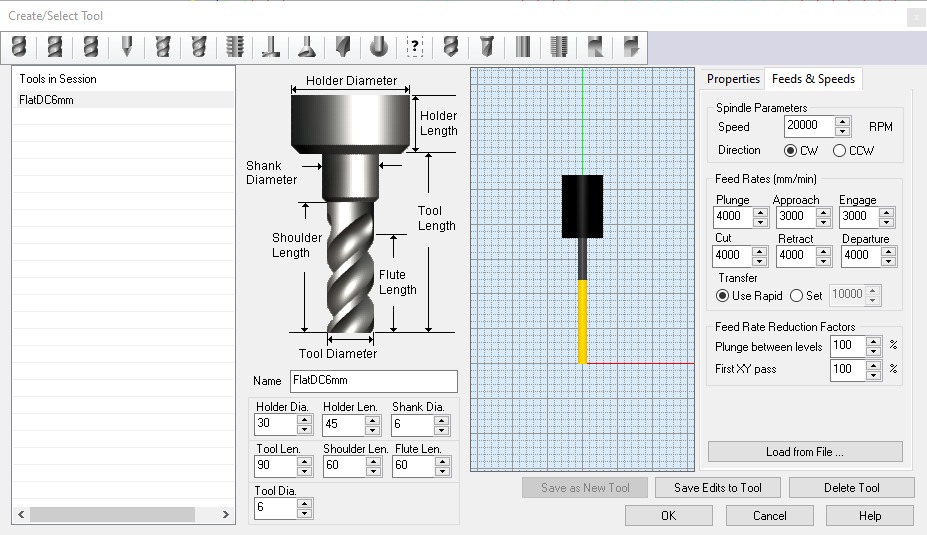

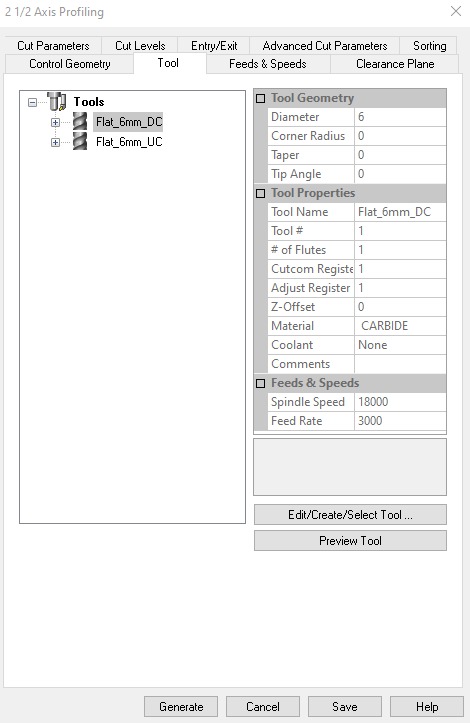

I then was able to set up the milling tools for the job.

I then was able to set up the milling tools for the job.

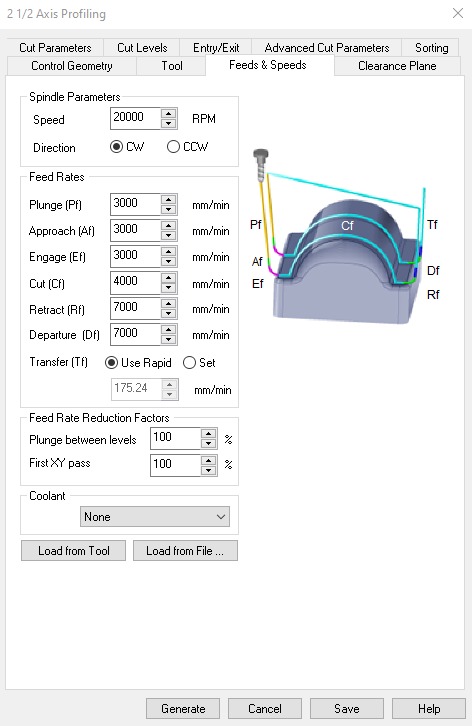

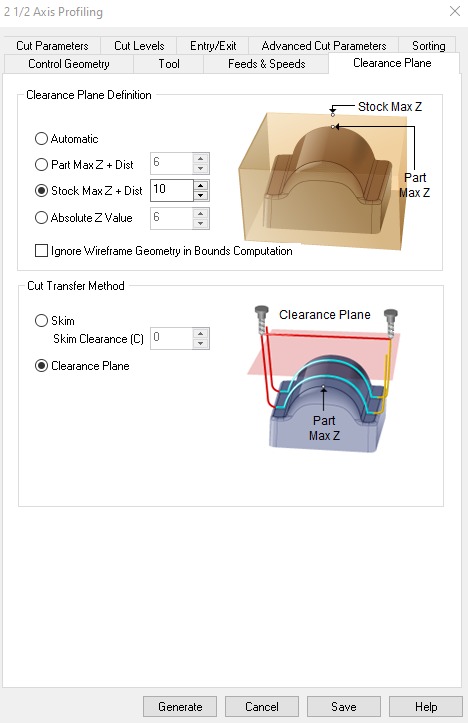

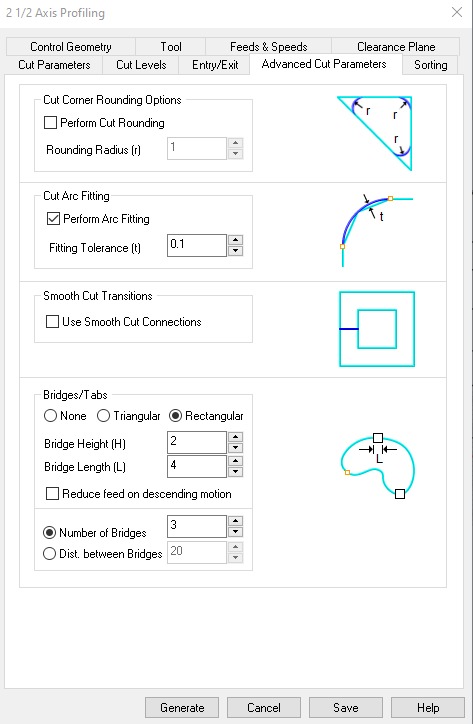

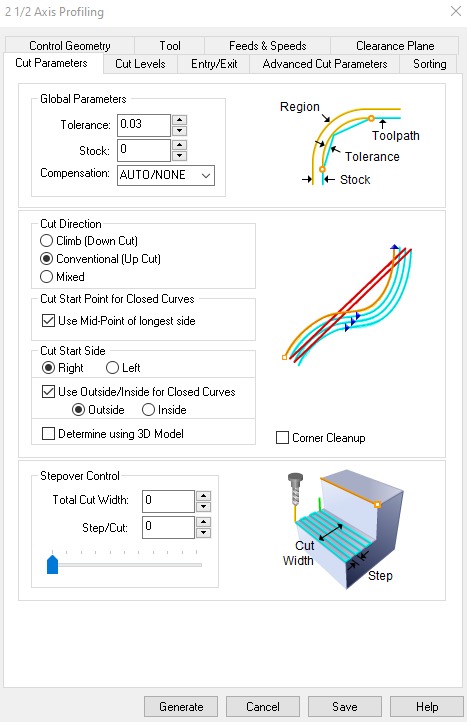

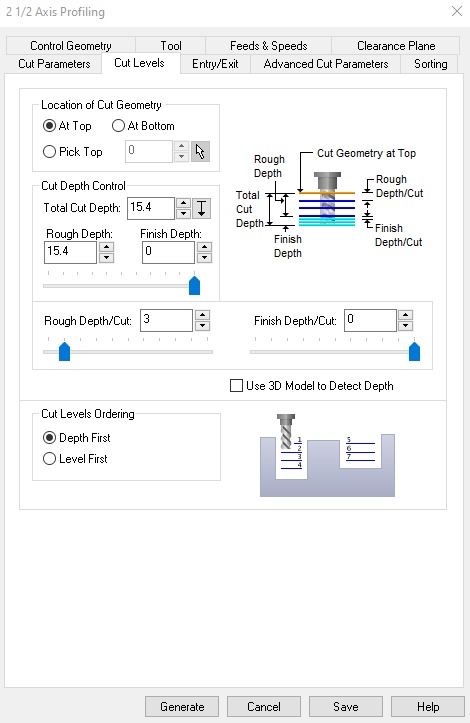

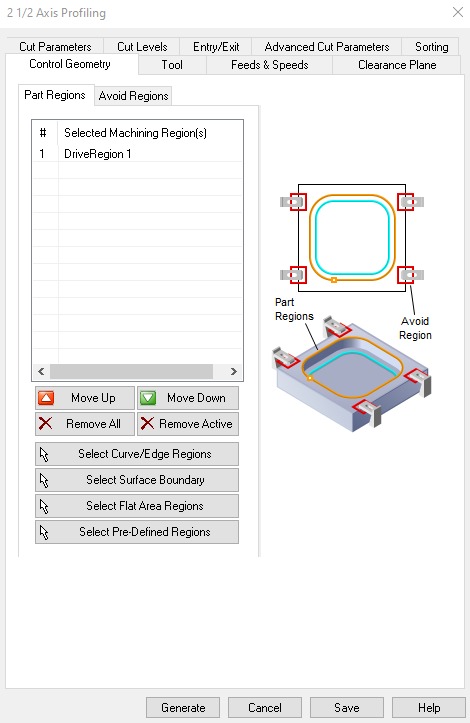

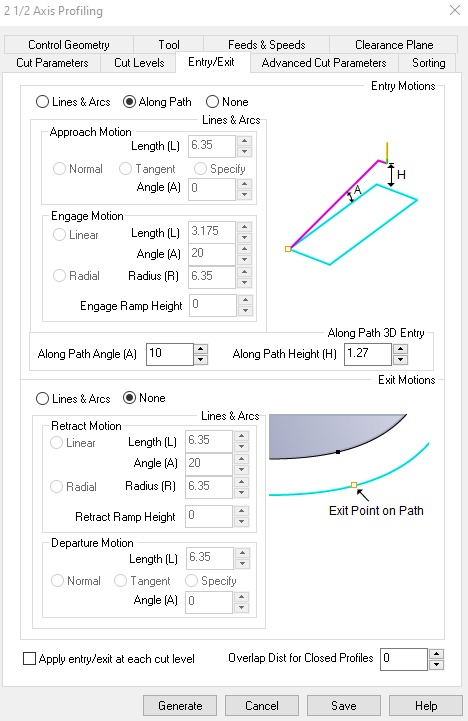

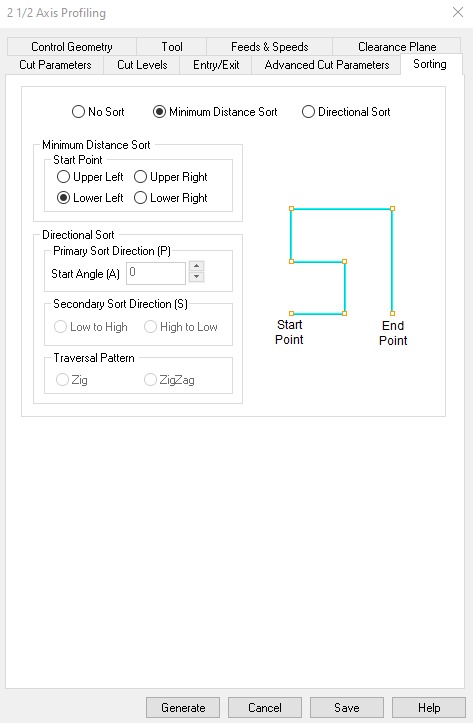

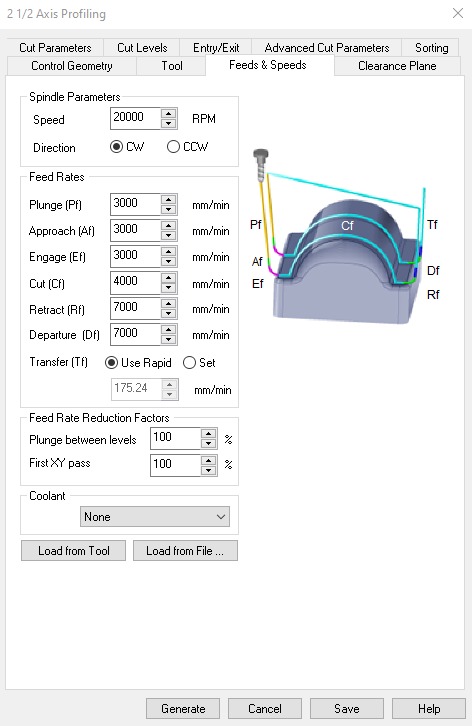

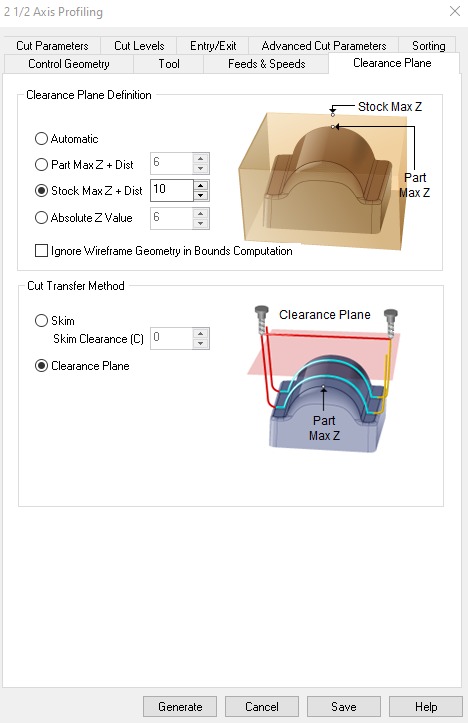

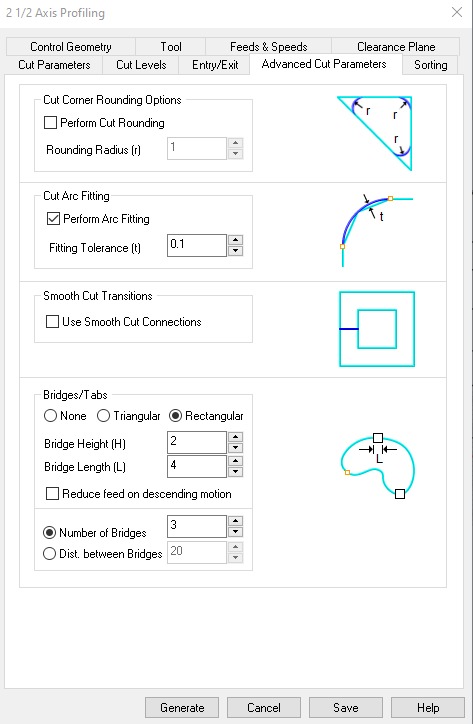

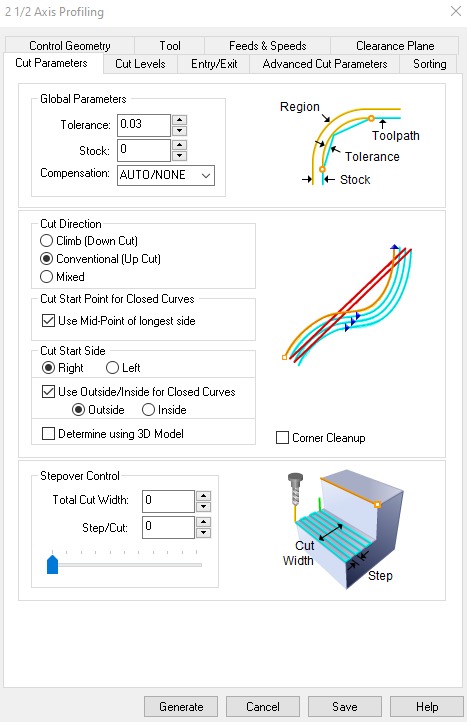

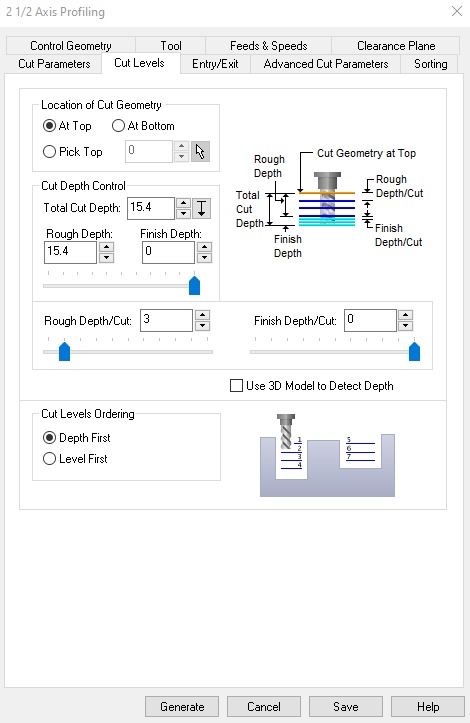

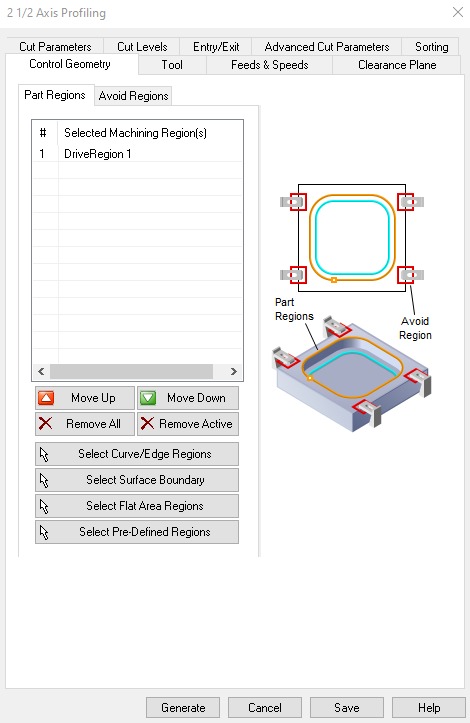

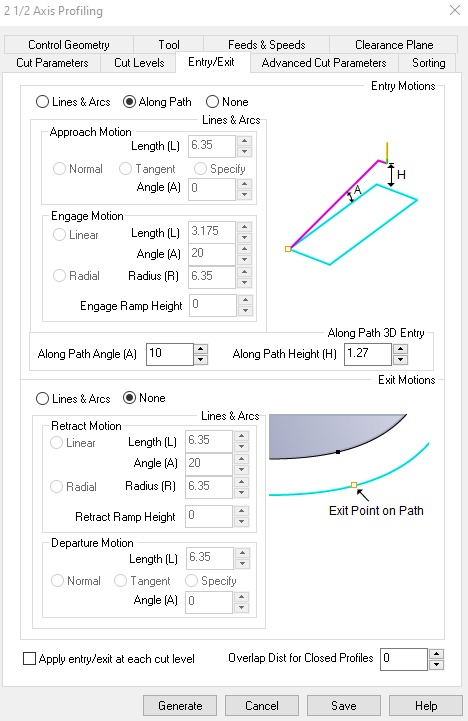

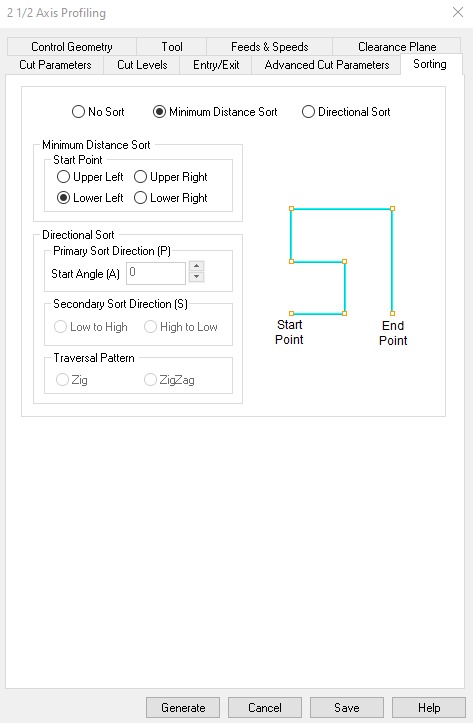

Profiling came next, which was checked over by instructor Adai!

A lot of settings are mostly left on default, but some are changed.

Profiling came next, which was checked over by instructor Adai!

A lot of settings are mostly left on default, but some are changed.

For pocketing, I used most of the default settings, but changed the cut levels to 5mm.

For pocketing, I used most of the default settings, but changed the cut levels to 5mm.

Cutting

You can find the 2D file with RhinoCAM settings here!

The .nc instruction sets for telling the machine what to do is here for drilling the screw holes and here for the stool cut.

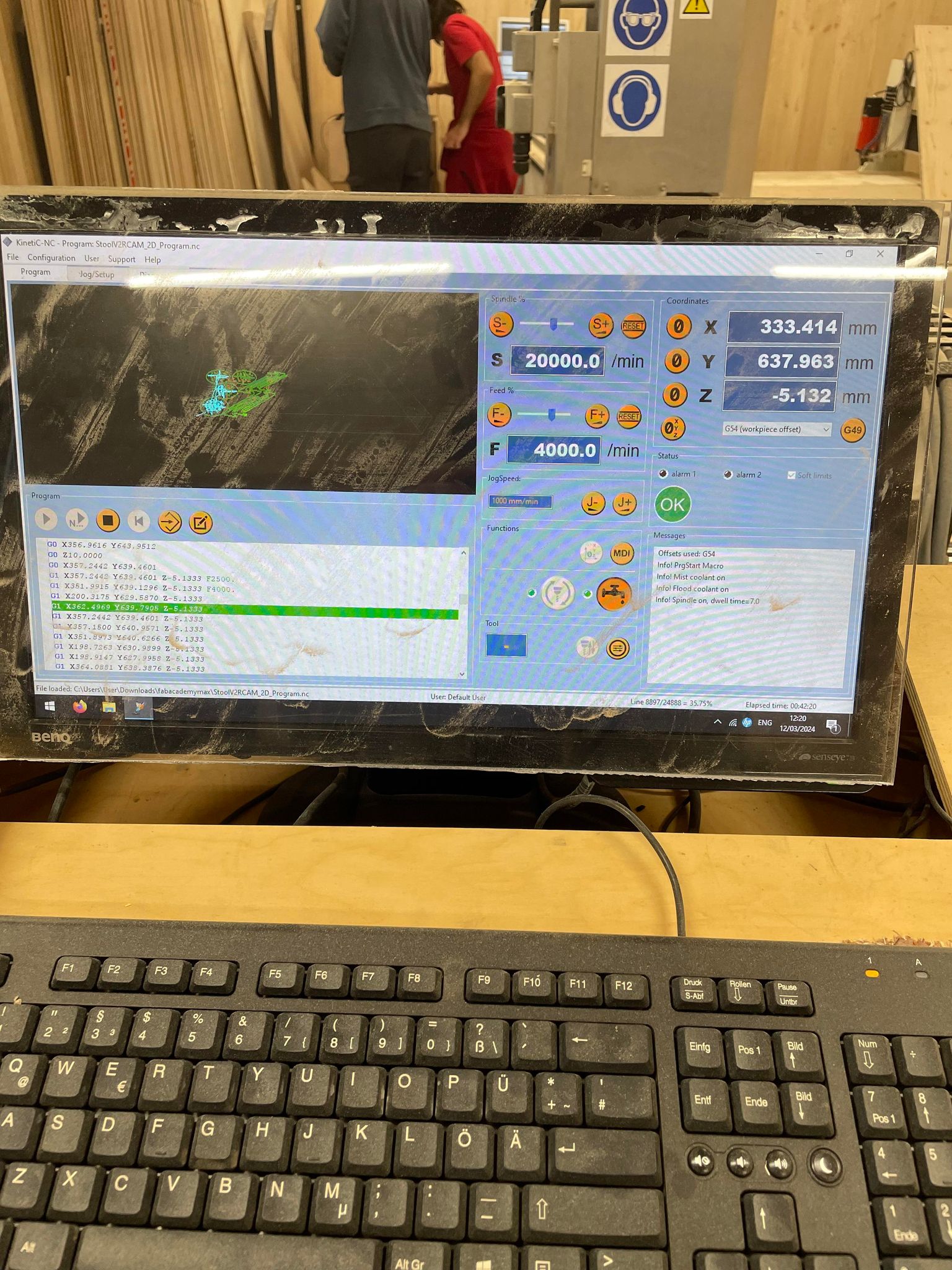

I first sent the drilling file to the machine after positioning my board, and drilled in screws to hold the board down.

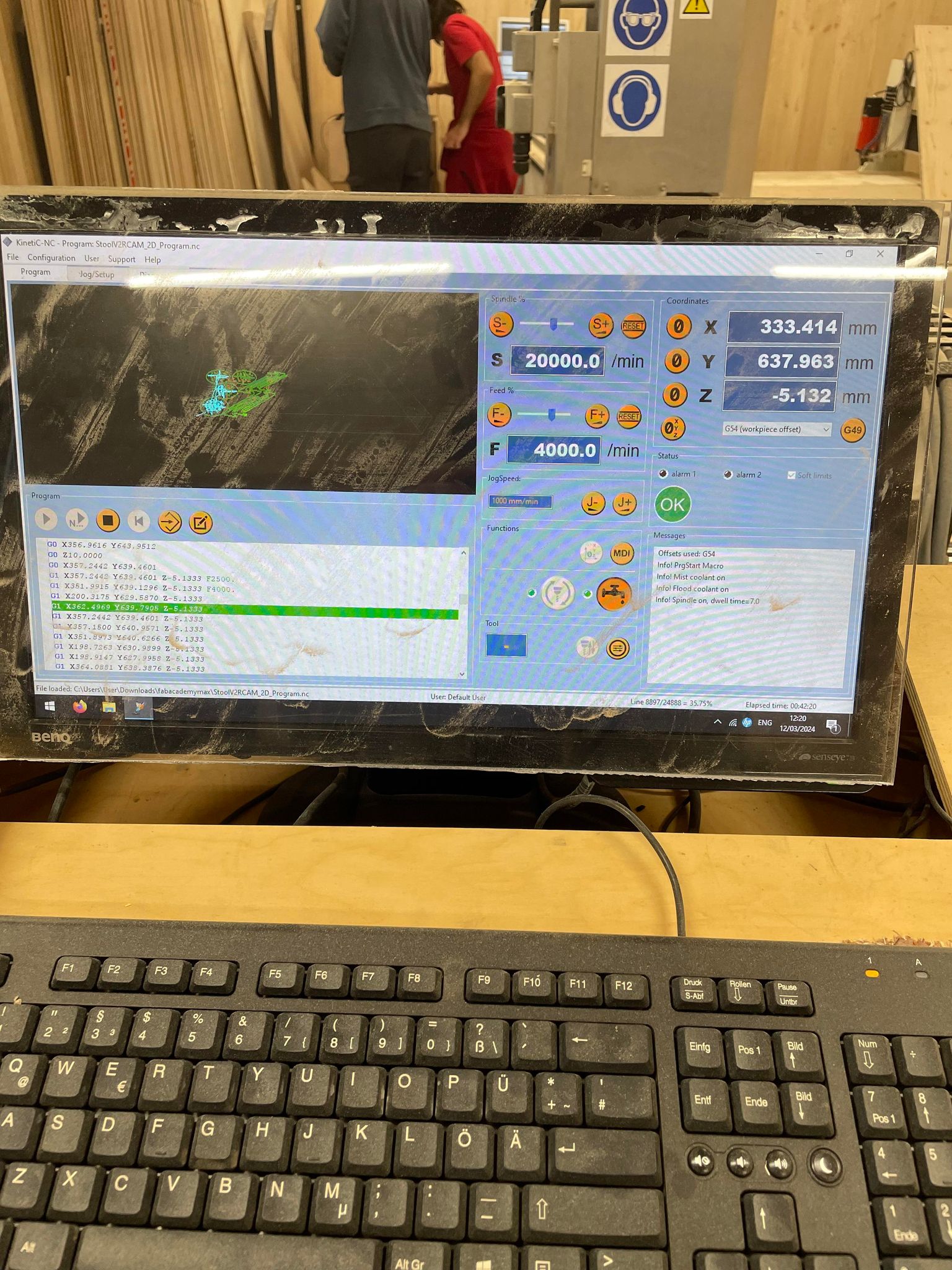

I was then able to send the second file and start the cuts!

I was then able to send the second file and start the cuts!

Once finished, the stool needed to be sanded and the legs had to be trimmed a bit to fit into the top holes.

Once finished, the stool needed to be sanded and the legs had to be trimmed a bit to fit into the top holes.

Once sanded and trimmed, everything fit nicely.

Once sanded and trimmed, everything fit nicely.

The issue came when I then tried to sit on it...

The issue came when I then tried to sit on it...

I renamed the second stool into a coffee table so I would not try to sit on it anymore and here is the hero shot!

All this was done without using glue or fasteners!

I renamed the second stool into a coffee table so I would not try to sit on it anymore and here is the hero shot!

All this was done without using glue or fasteners!

Going further

I am still in need of stools for my balcony, so once the use of the CNC machines has gone down a bit, I will redesign and re-cut the legs, making them straight and thicker to withstand more weight.

After that I laser cut a miniature version in order to test my design.

After that I laser cut a miniature version in order to test my design.

I noticed in the laser cut version that the legs were definitely too weak to support weight.

I decided to change the legs to add some extra support as well as a 3D printed ring in order to further support the legs.

I noticed in the laser cut version that the legs were definitely too weak to support weight.

I decided to change the legs to add some extra support as well as a 3D printed ring in order to further support the legs.

Once the modelling was done, I started preparing the files for milling and got to the actual cutting!

Once the modelling was done, I started preparing the files for milling and got to the actual cutting!

I then was able to set up the milling tools for the job.

I then was able to set up the milling tools for the job.

Profiling came next, which was checked over by instructor Adai!

A lot of settings are mostly left on default, but some are changed.

Profiling came next, which was checked over by instructor Adai!

A lot of settings are mostly left on default, but some are changed.

For pocketing, I used most of the default settings, but changed the cut levels to 5mm.

For pocketing, I used most of the default settings, but changed the cut levels to 5mm.

I was then able to send the second file and start the cuts!

I was then able to send the second file and start the cuts!

Once finished, the stool needed to be sanded and the legs had to be trimmed a bit to fit into the top holes.

Once finished, the stool needed to be sanded and the legs had to be trimmed a bit to fit into the top holes.

Once sanded and trimmed, everything fit nicely.

Once sanded and trimmed, everything fit nicely.

The issue came when I then tried to sit on it...

The issue came when I then tried to sit on it...

I renamed the second stool into a coffee table so I would not try to sit on it anymore and here is the hero shot!

All this was done without using glue or fasteners!

I renamed the second stool into a coffee table so I would not try to sit on it anymore and here is the hero shot!

All this was done without using glue or fasteners!