19. Project development¶

- Complete your final project tracking your progress.

QUESTIONS¶

What tasks have been completed, and what tasks remain?¶

The design of the PLA printed pieces has been tested and completed, everything is millimetrically calculated to fit together, it is ready to join with the MDF and acrylic pieces.

I still need to modify the MDF pieces to the exact size to be cut, for example, from 20mm to 19.90mm, the change is so minimal that it seems unnecessary, but it is really very important because this makes the pieces fit and adjust as needed without using any kind of glue.

Everything is made from press fit, it is like a giant lego that has pieces of 3 materials for the structure, housing a system of motors, rack and pinion.

What has worked? what hasn’t?¶

The sockets have worked well of the pieces that are already printed in PLA filament, what still does not work is the plate because I still need to program to get the whole project to work.

What questions need to be resolved?¶

3D design with measurements and correct tolerance for assembly of parts, varies according to the material and position in which it will be placed: 50% , 3D parts are ready, just need to adjust the MDF and Acrylic parts.

Mechanism operation with motors and rack and pinion: 50% It is designed but the MDF parts need to be adjusted so that everything fits perfectly and can work.

Plate design and programming: It is in 50%, I have designed it but I need to program it.

What will happen when?¶

Once the final adjustments are completed, I will be able to use it and take it anywhere I want to display products or work.

What have you learned?¶

-

Work under the 3d printer workspace measurements and keep in mind how many millimeters the openings should vary depending on the position of the part to be printed.

-

Working in spiral is something I learned during the Fab Academy, as it is the most appropriate way to be able to complete projects and improve them each time, instead of trying to do something too big that you can’t finish on time.

-

To design and program boards, as well as the correct use of the programs and machines involved.

This diploma course has helped me develop multiple skills, as well as learn from mistakes and how to fix them. Sharing with a community that can learn from my experiences and I from theirs. One of the best things I learned is not to give up, to structure ideas better, to organize and to see a world of possibilities and possible applications thanks to the maker community.

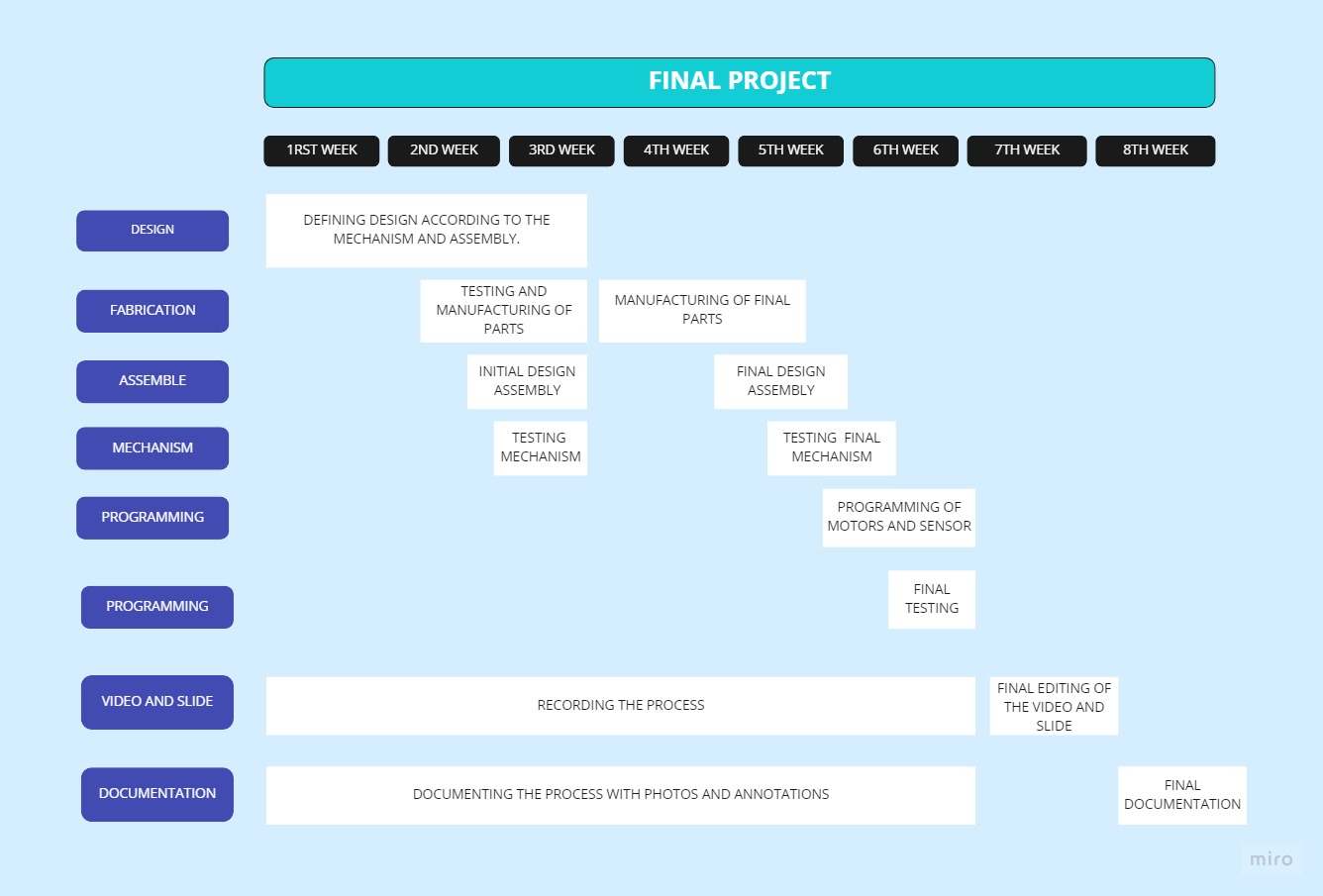

Due to restrictions because of Covid 19, I did not have access to the lab for quite some time and only recently I was able to have access, so I put the amount of time in weeks, as the time it takes me for each part of the process: