Negative mold casting

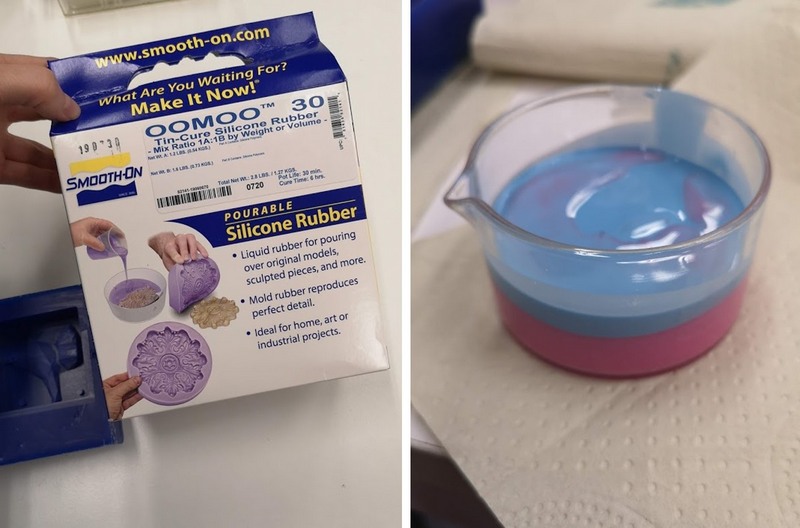

I planned to cast the candle in the mold, therefore my choice was the OOMOO 30:

- 1:1 by volume mix ratio (no scale necessary)

- Vacuum degassing is not necessary

- 6-hour cure time

The process is quite simple. I just mixed part A and part B by volume ratior 1:1 withouе even using the scales.

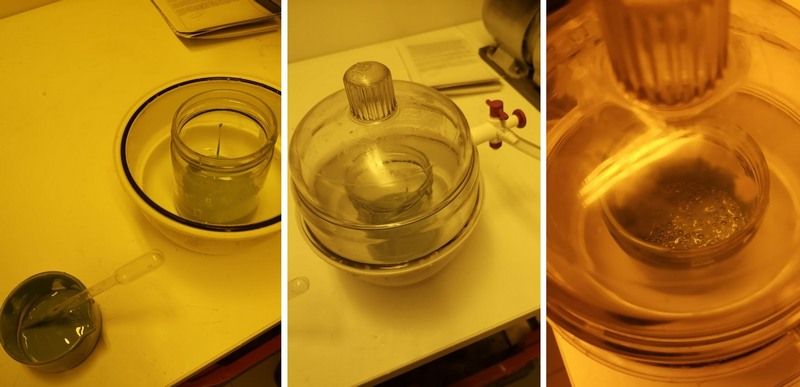

Though the Vaccum degassing is not neccessary according to the instructions, I used degassing for about 2 mins, when most of the bubbles apppeared on the surface.

Then I carefully poured the mixture in to the mold and left for curing for 6 hours. Negative mold then was easily removed from wax positive mold. Surface was perfect - detailed print of the was mold without any bubbles.

Casting

Final and the most exciting step: casting. For casting I used couple of small candles. I removed the aluminium case and melted candles on a water bath. Thread from the candle I used for my own candle by inserting it in the upper hole of the mold. Wax cured in about 1 hour and the candle was ready.

Since the scale of the candle was quite small the pleasure was fast.

I'LL BE BACK.

FILES:

Reflection

Casting is a lot of fun! Next time I would definietly go for more complicated model to cast, there is a unlimited room for creativity. I would like to cast something from metal.