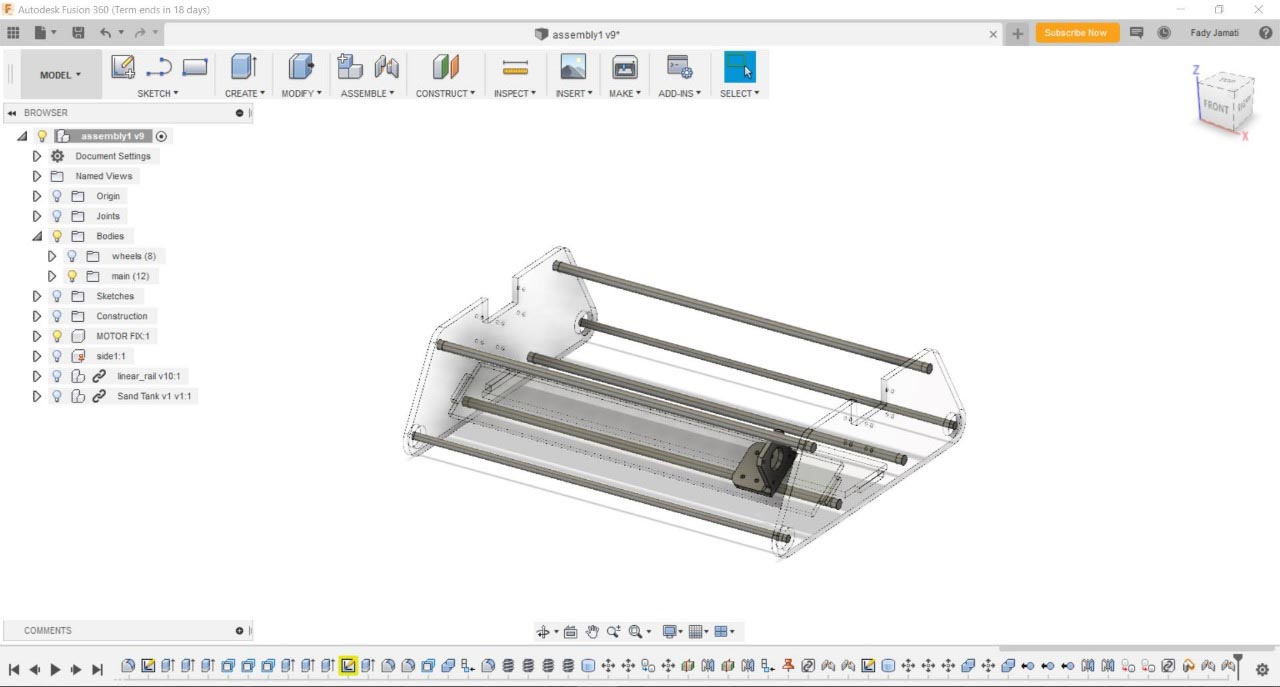

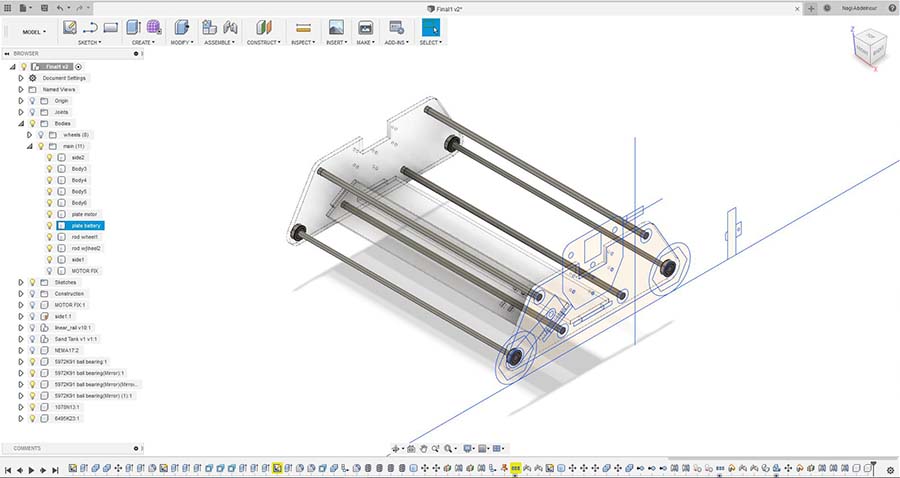

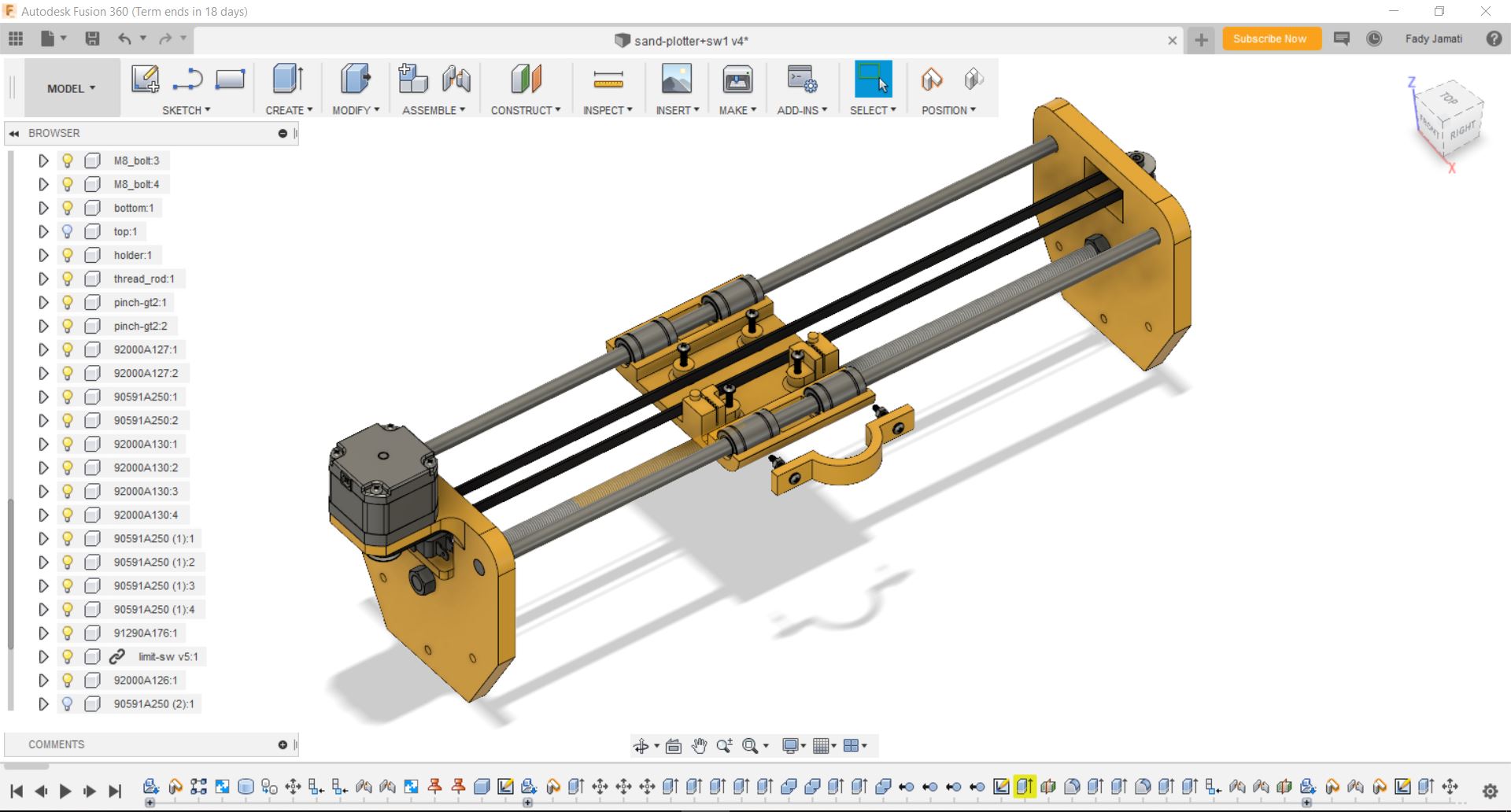

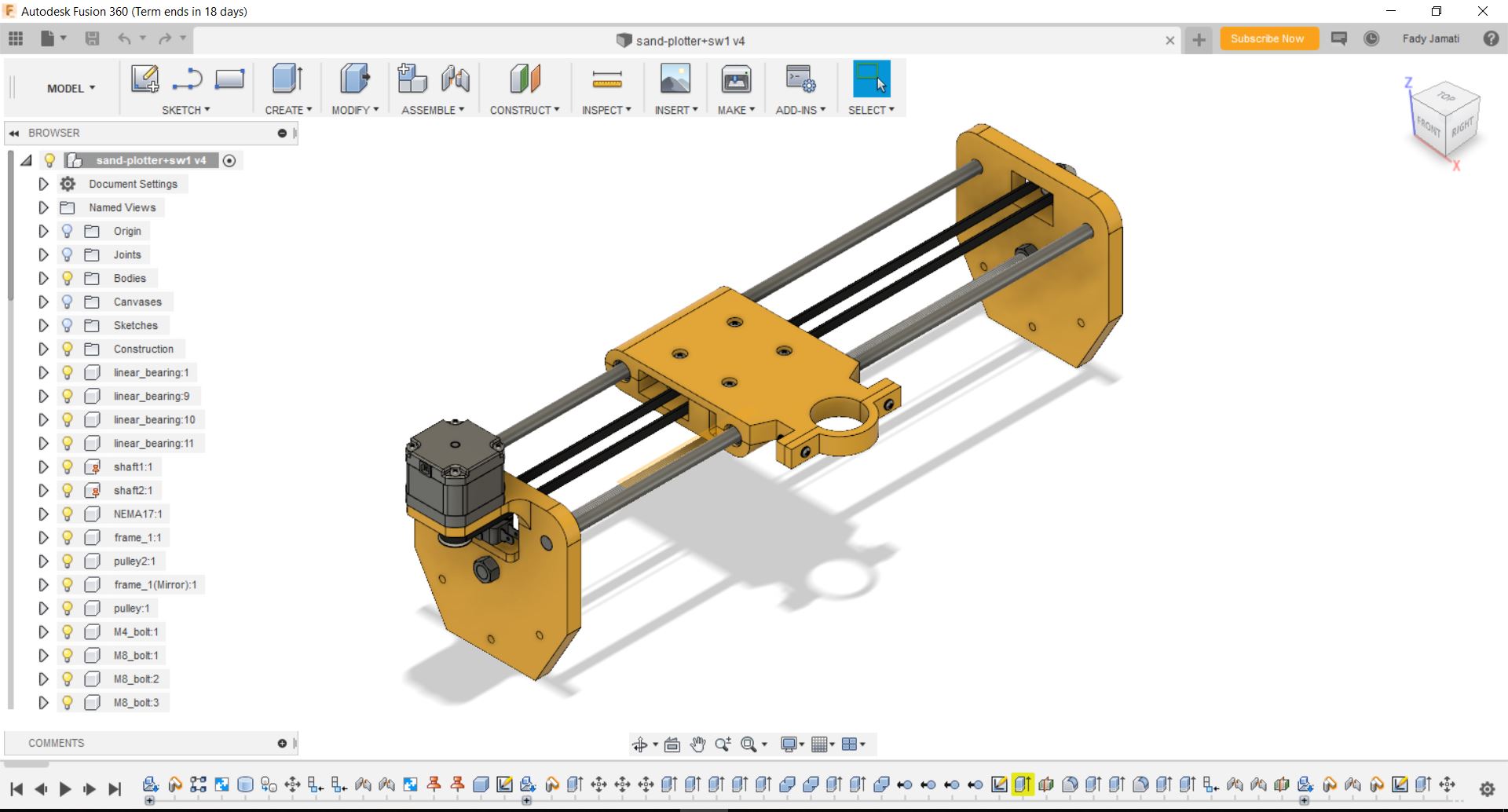

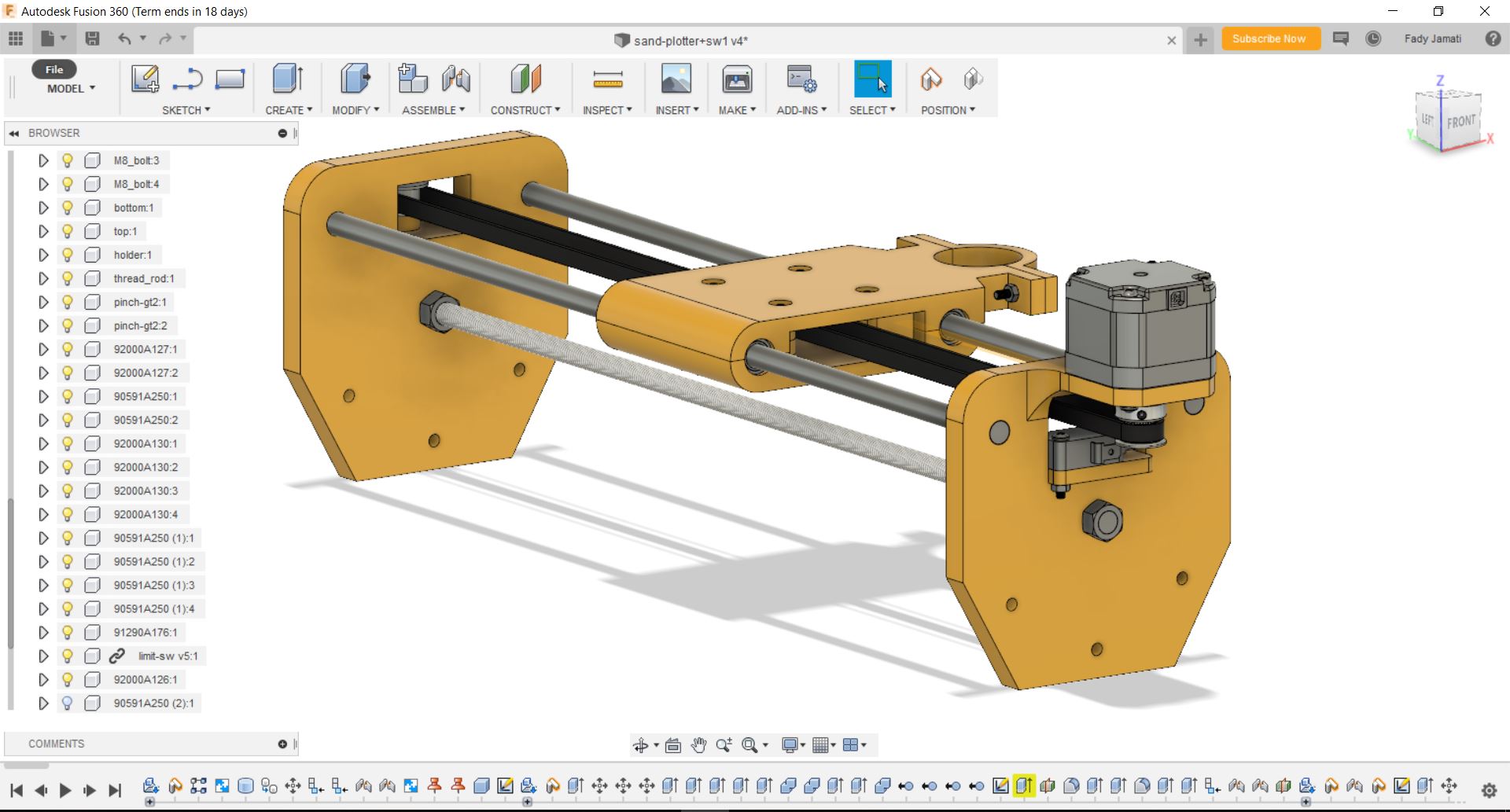

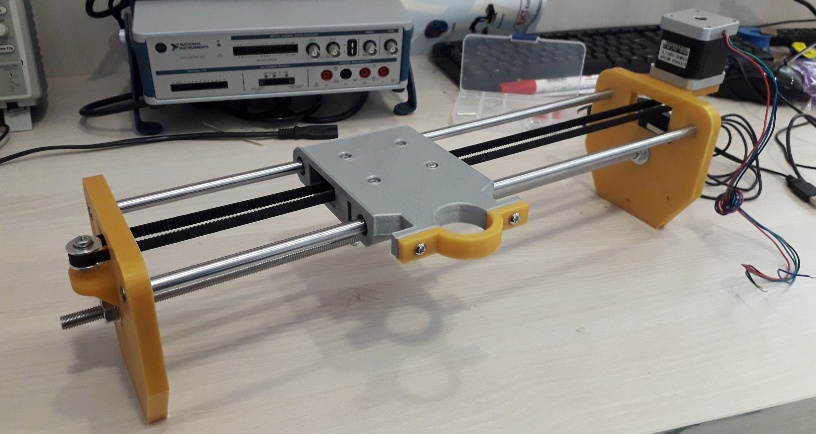

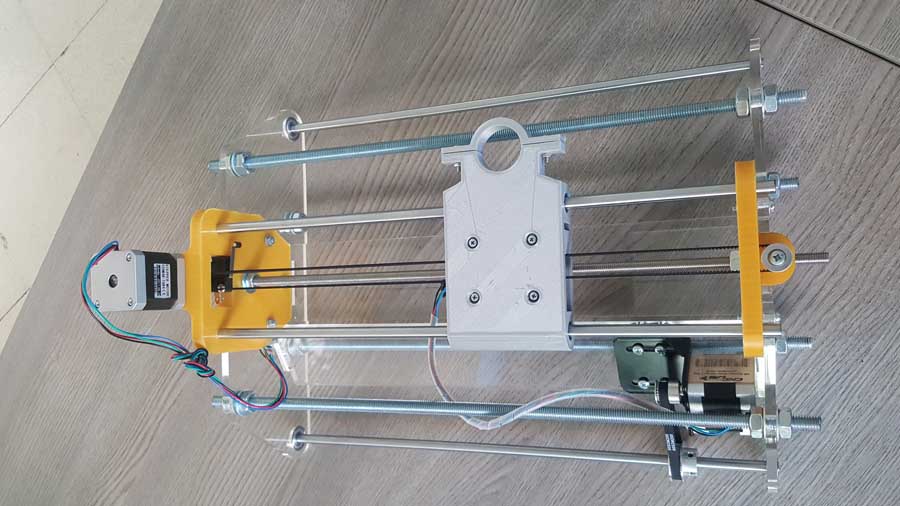

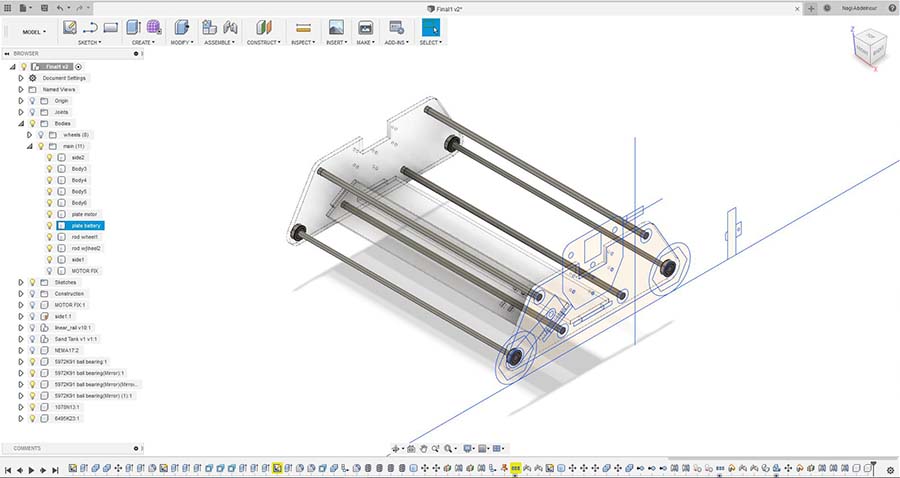

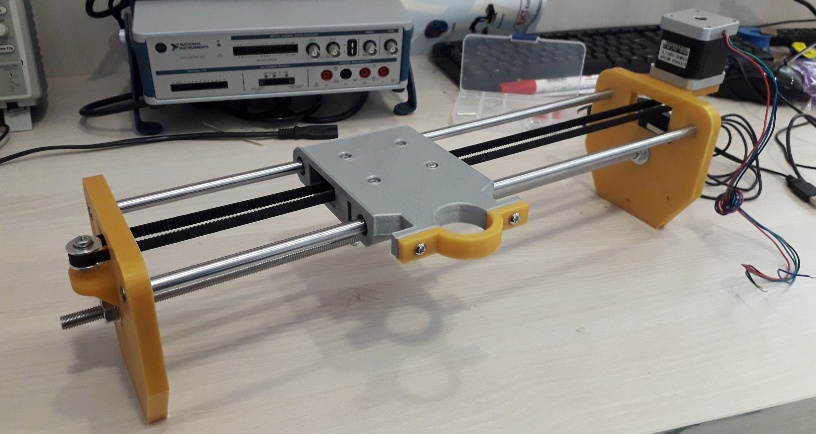

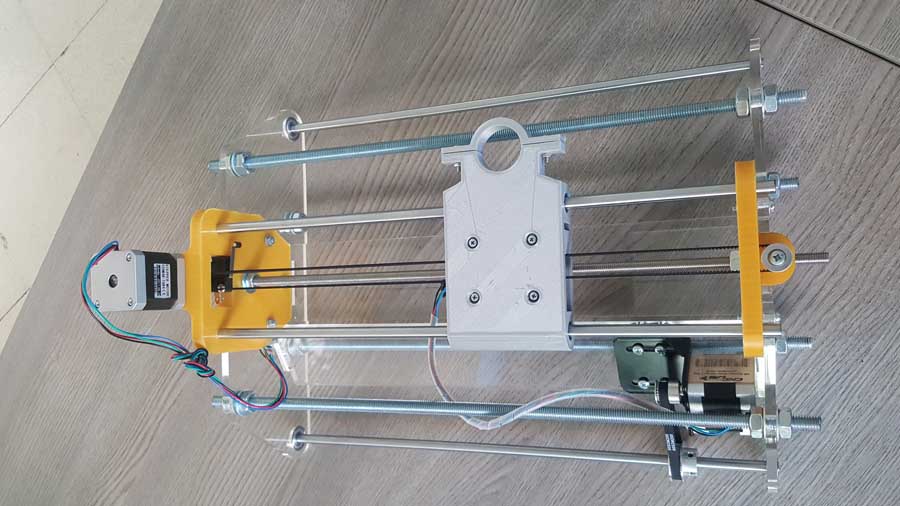

X and Y Axis Assembly:

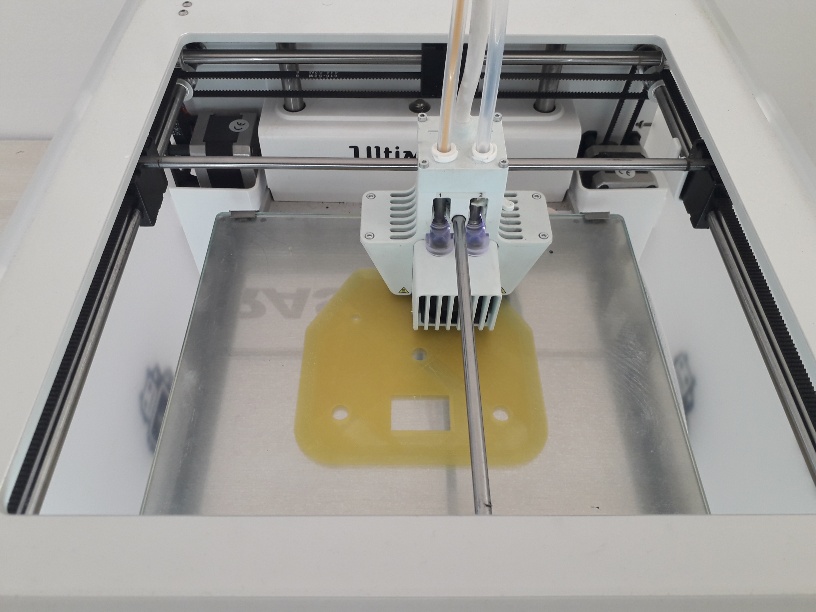

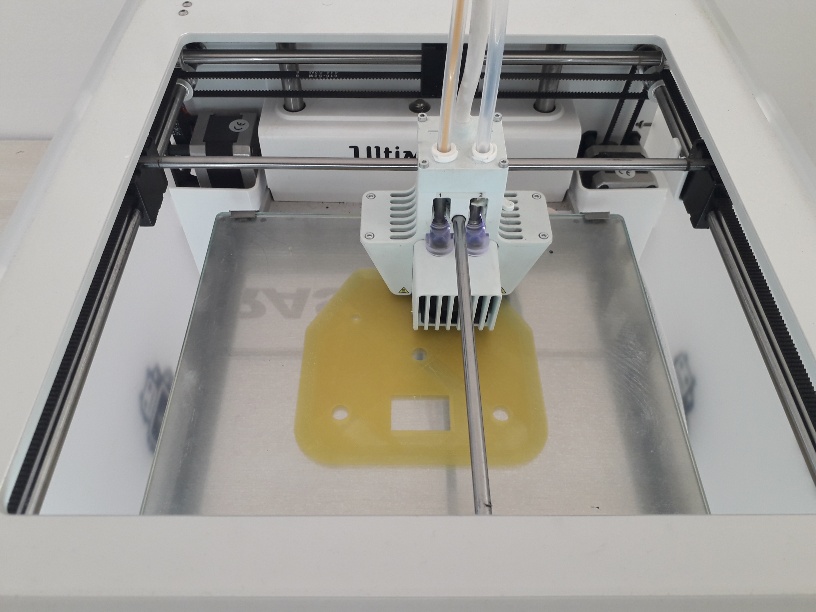

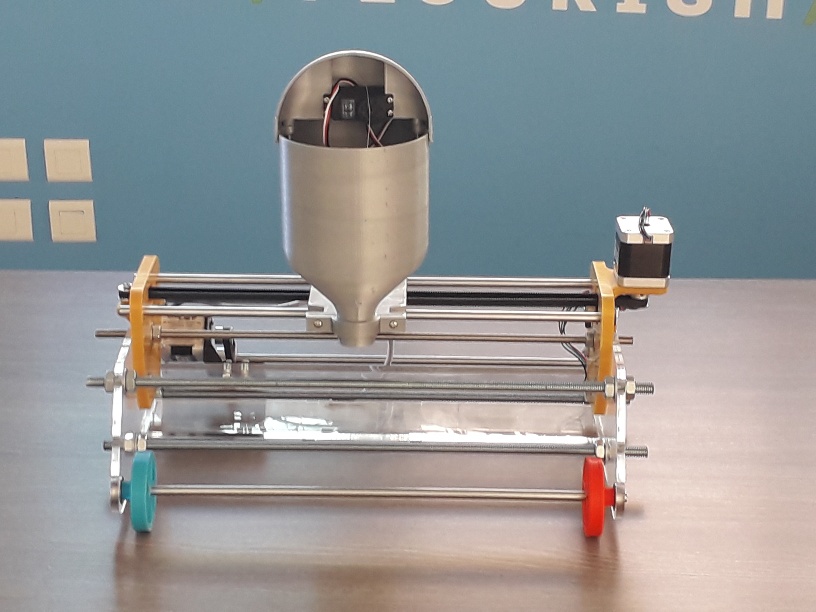

After brainstorming and discussing about several design ideas and sketches, I manufactured a first prototype to see its functionality according to our need.

During the fifteen session dated on April 30 2019, I was introduced to the different principles, materials and accessories that can be used in a Mechanical Design.

The group assignment is to:

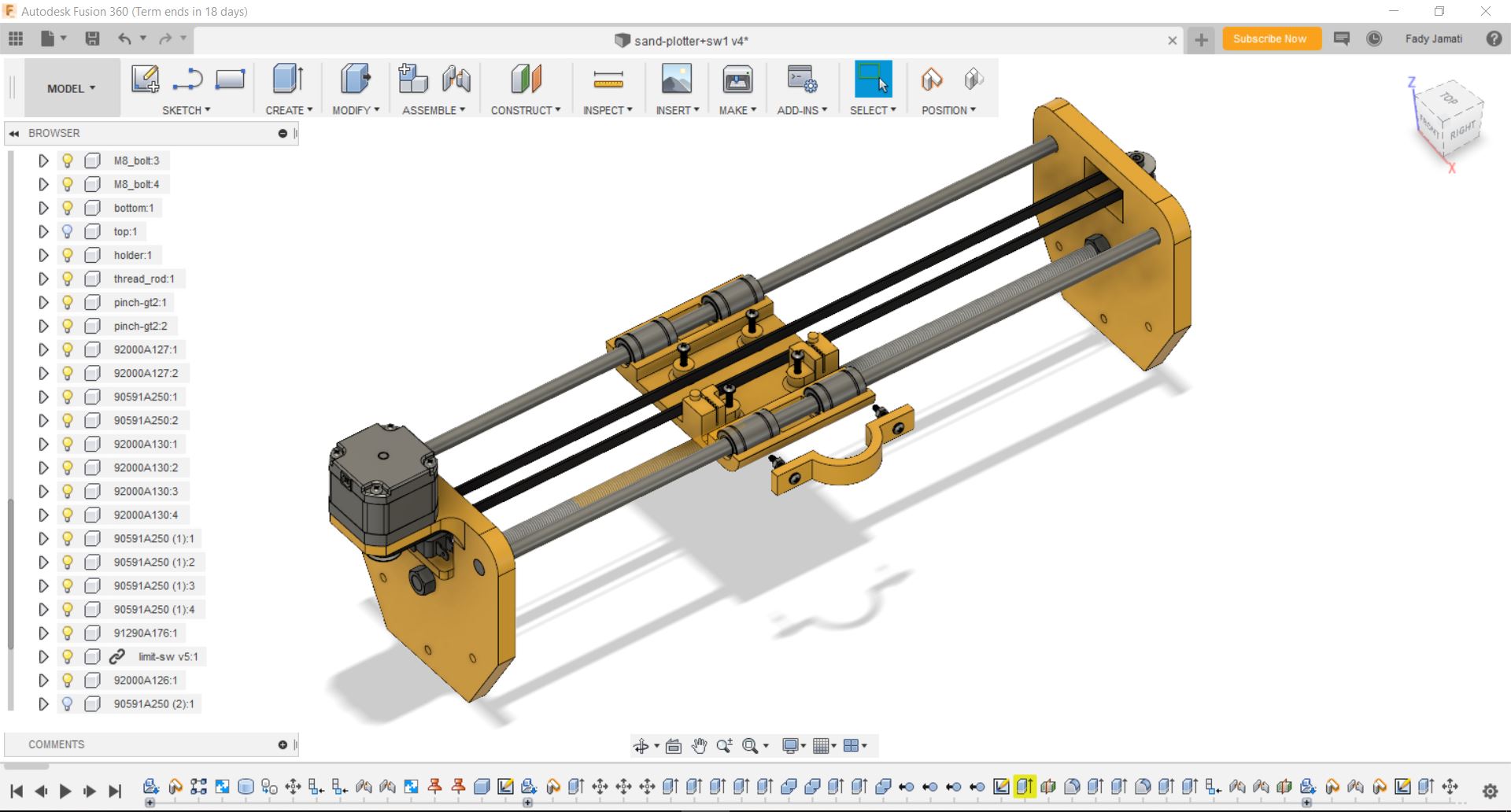

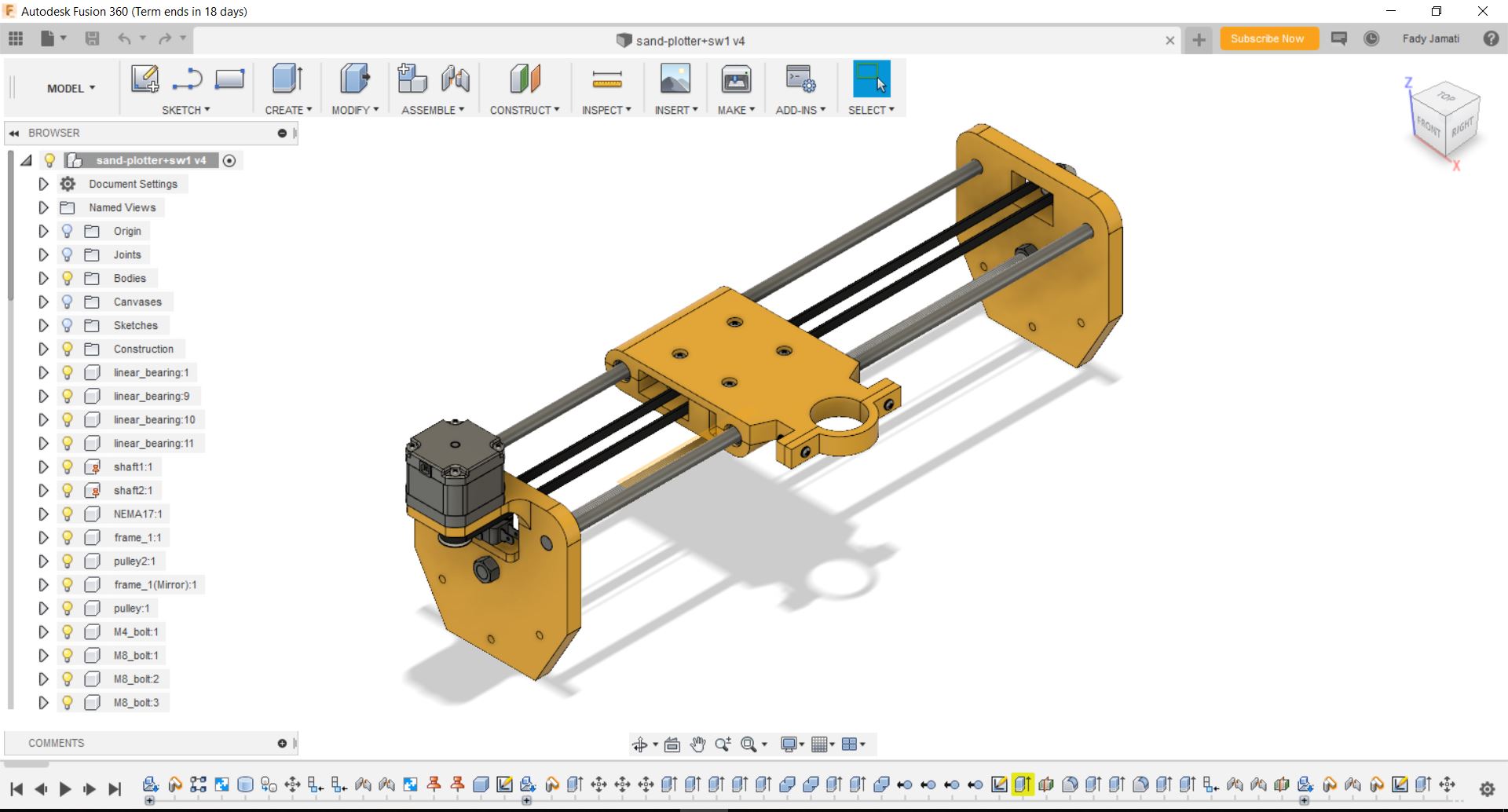

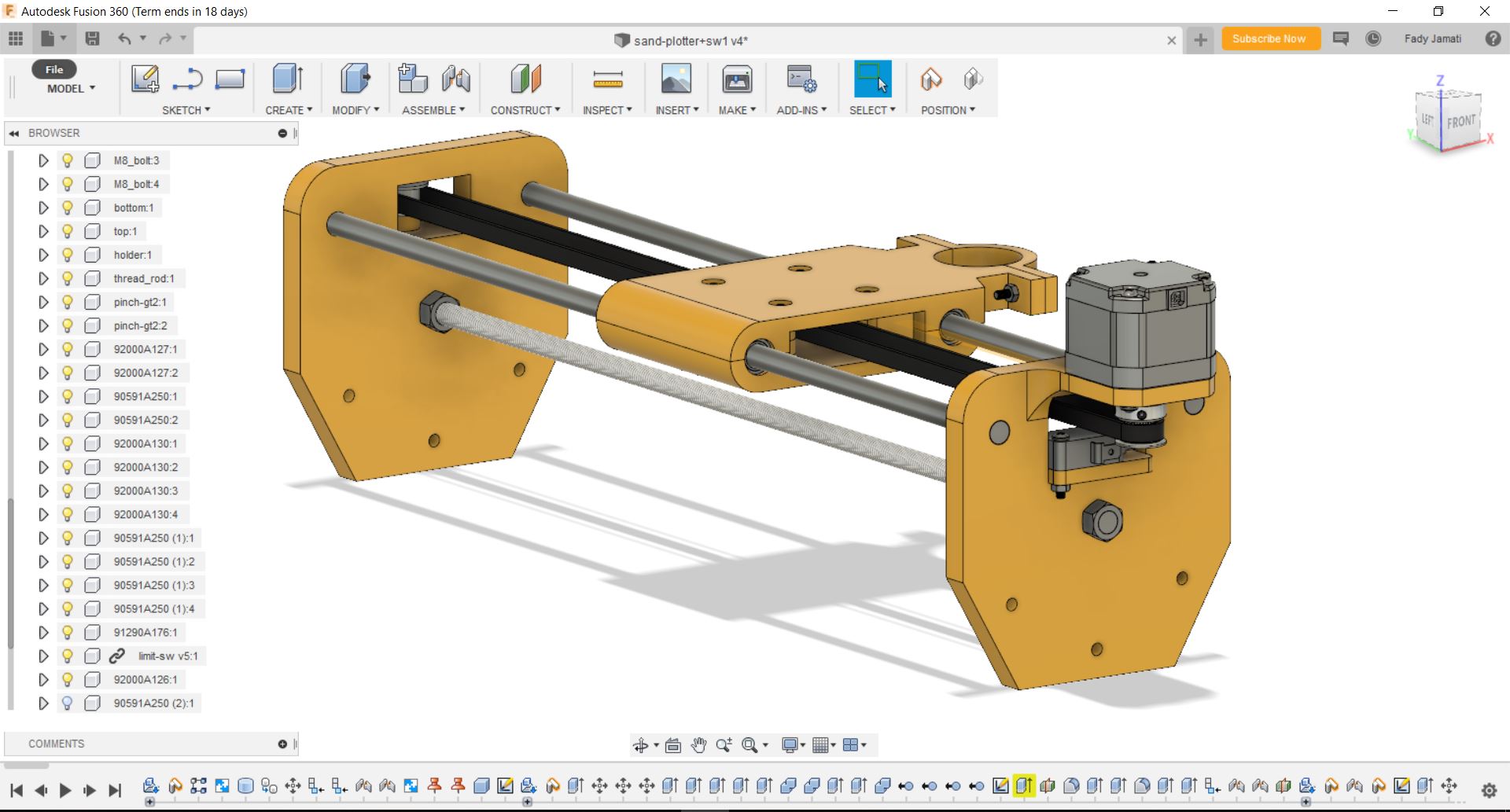

After brainstorming with the group members, we decided to design, manufacture, automate a Sand Plotter that will draw figures with sand in a street, in a floor or any other flat surfaces limited to 40cm in width and unlimited in length.

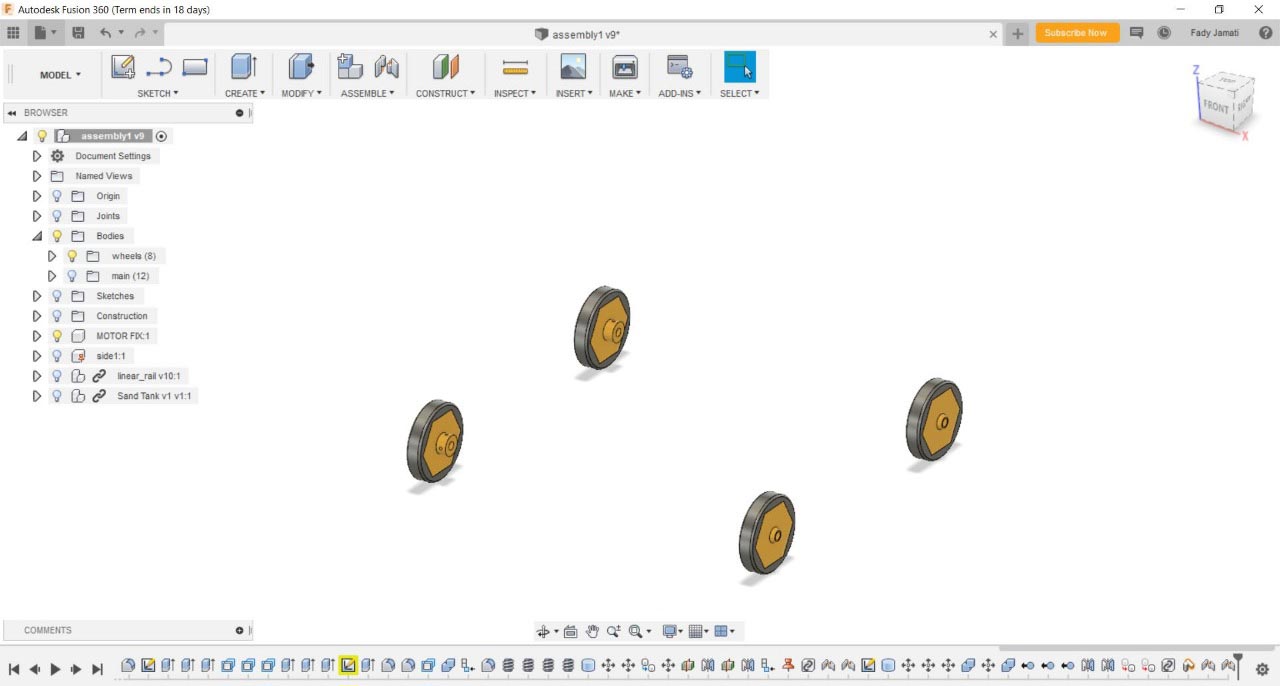

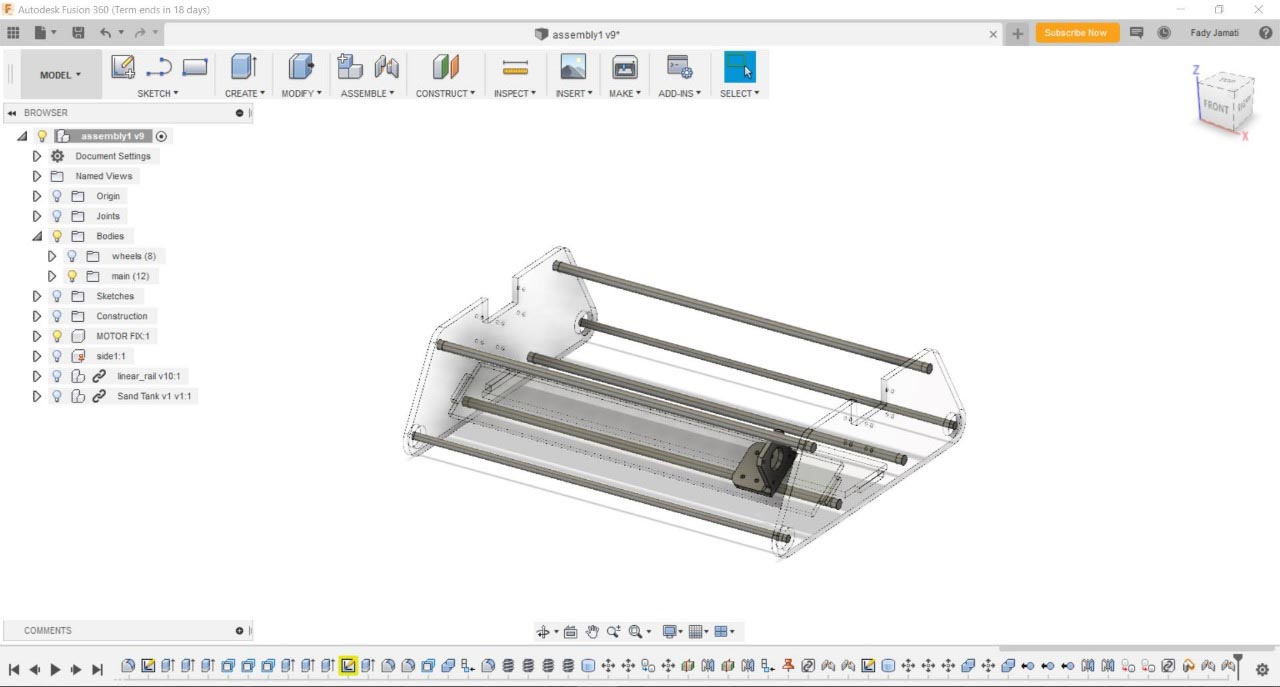

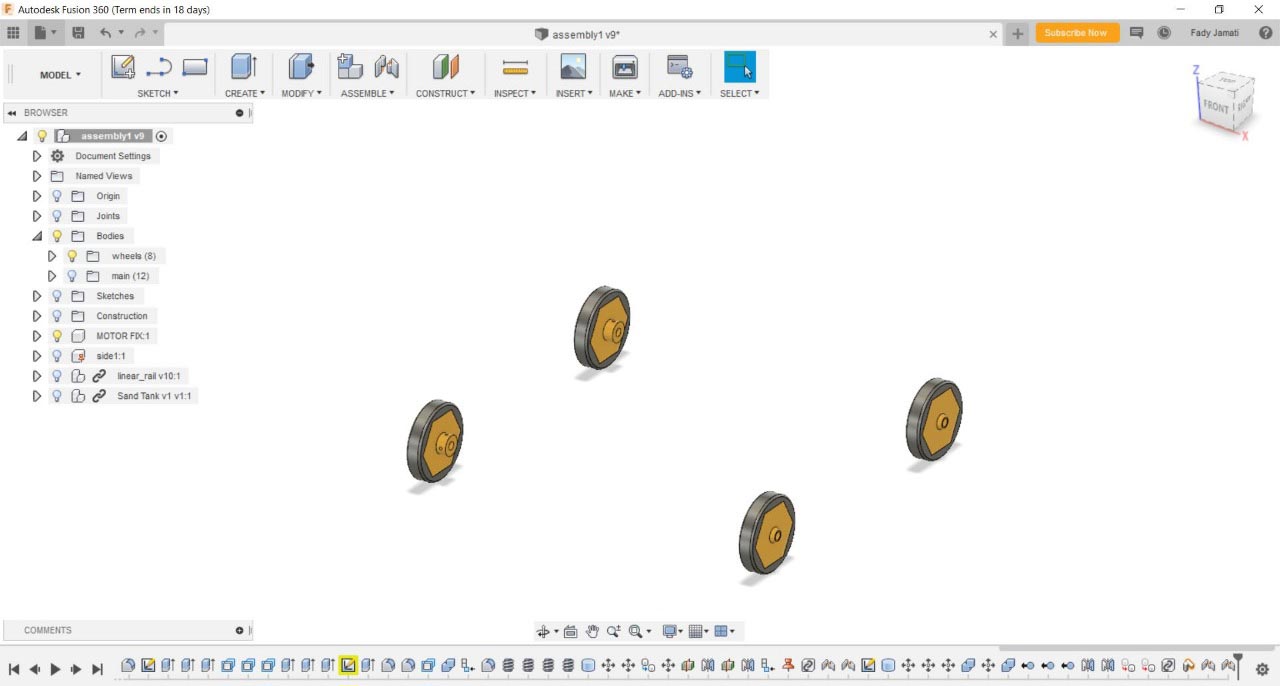

In terms of "Y" axis size, we were limited to 40cm as mentioned before due to the available rod length, the "X" axis is unlimited because it's on the machine wheels.

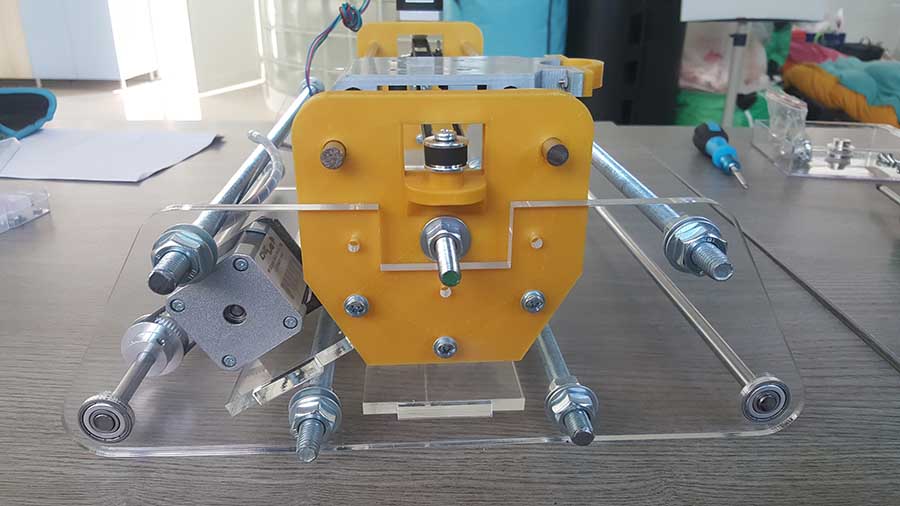

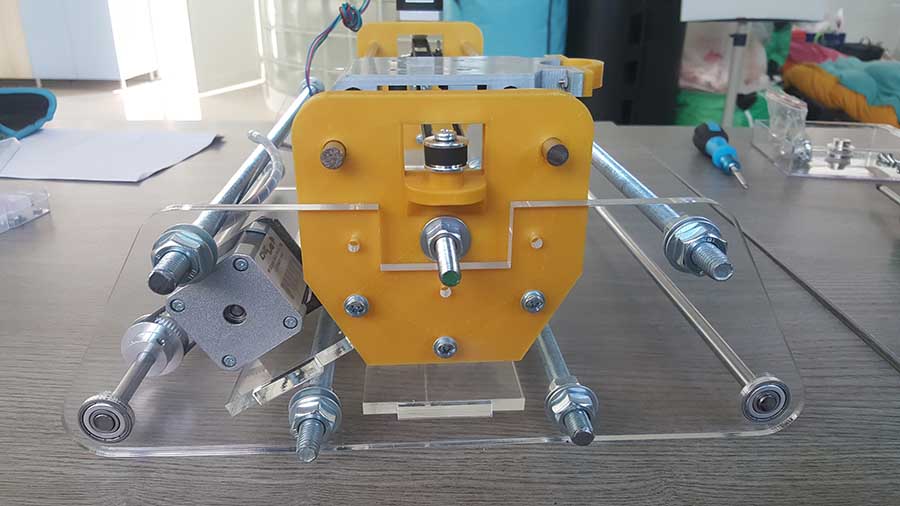

The machine will move forward with the wheel mechanism(X axis), and move the sand container sideways on the linear rail mechanism (Y axis).

Our project is composed of 4 main parts and distributed among the group members:

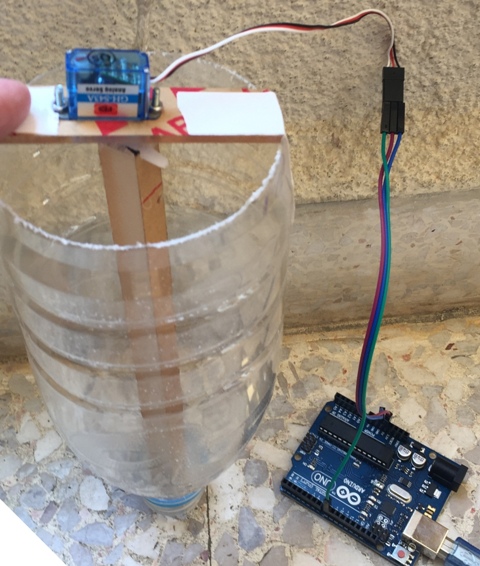

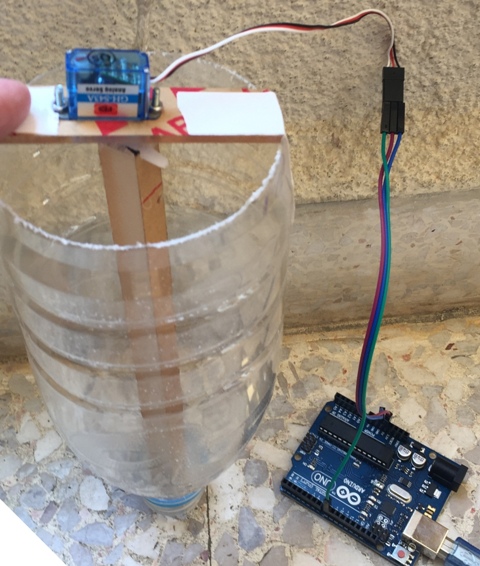

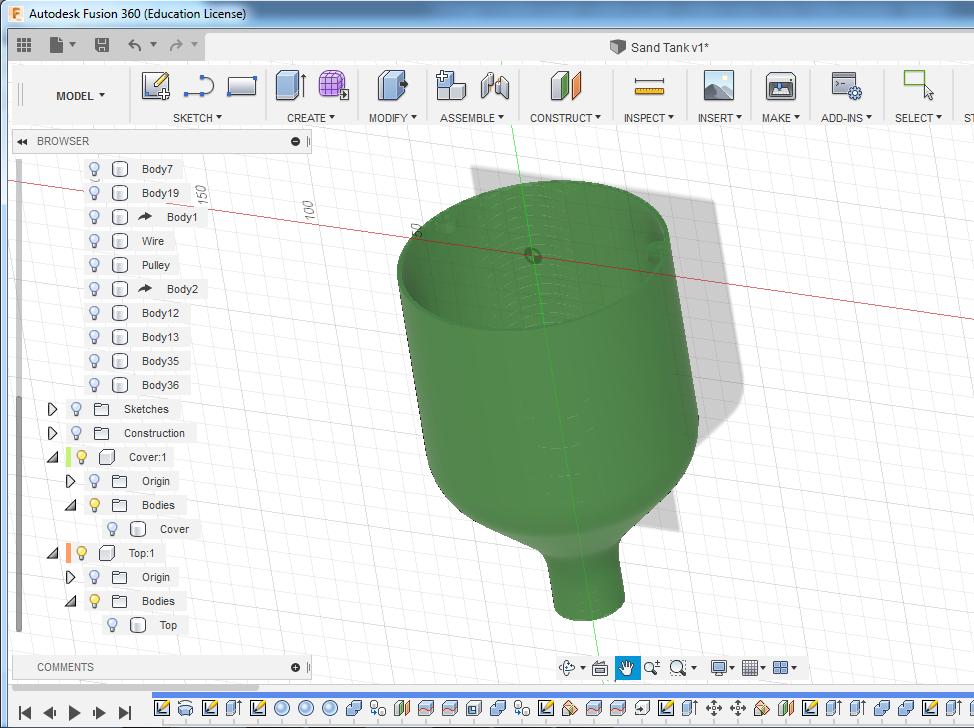

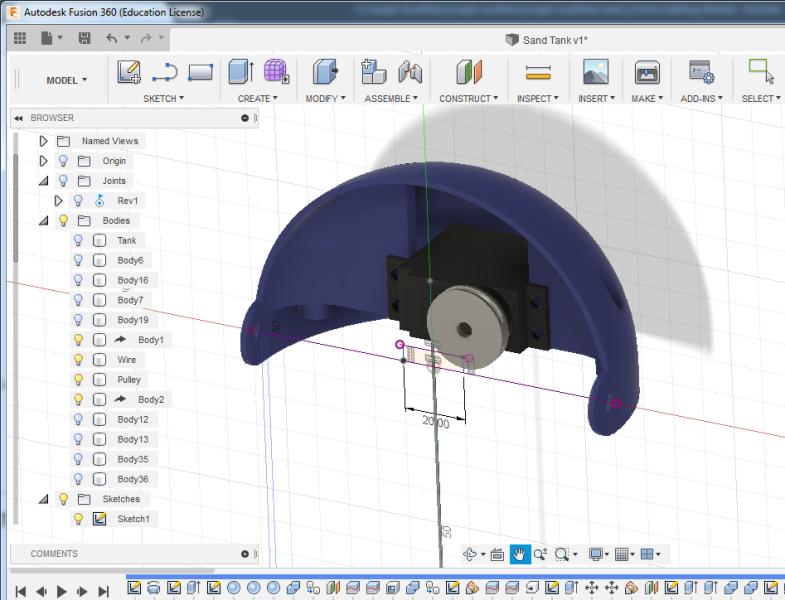

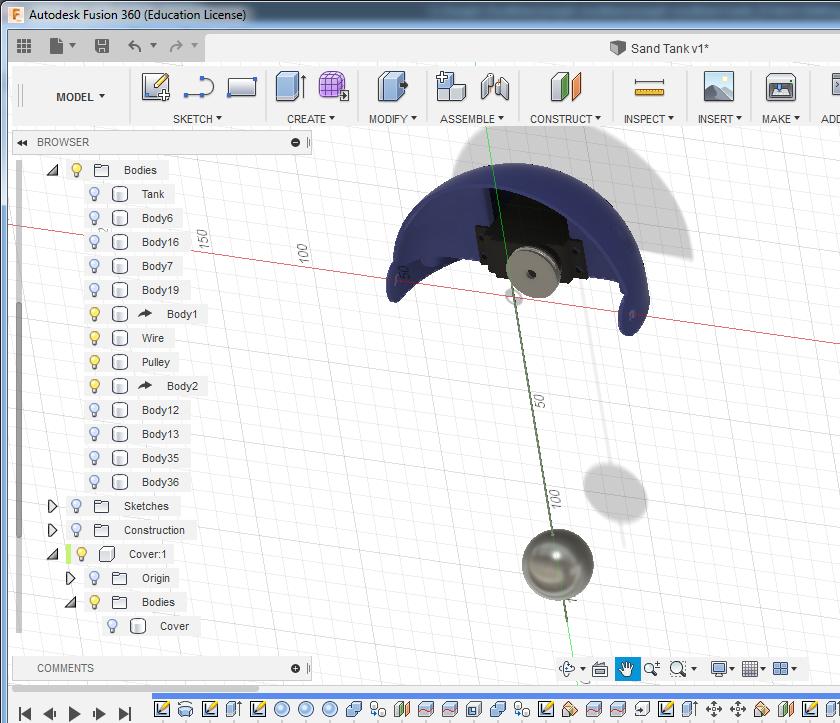

The team members suggested an improvement of the basic idea by changing the valve closing mechanism. The concept is to use a sphere to close the container outlet and commend it by a servo motor fixed in the top of the container in an enclosed design.

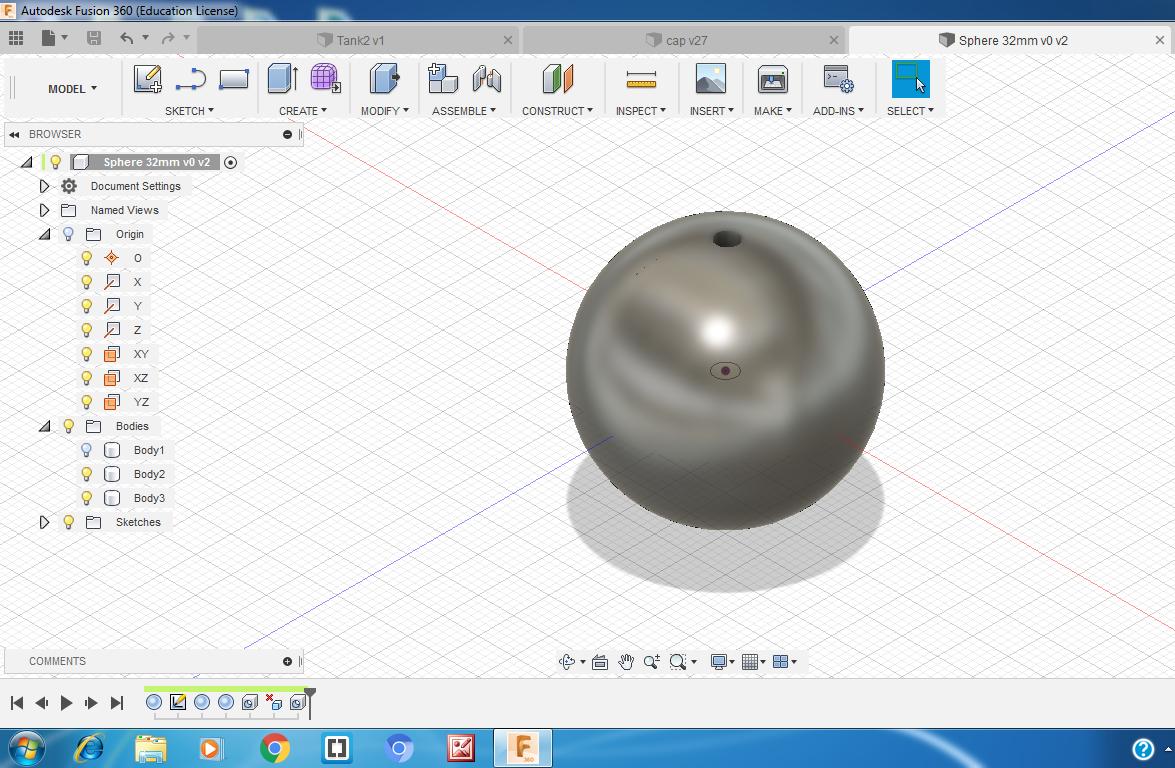

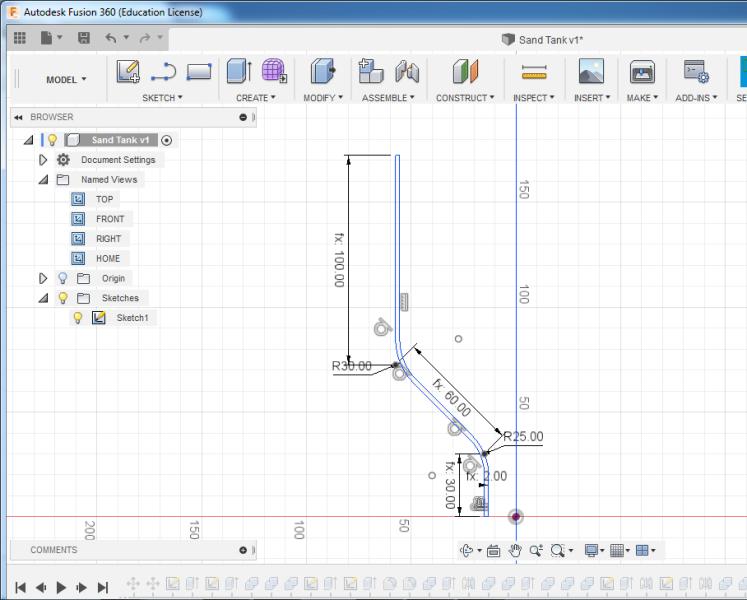

The design of the 32 mm sphere:

After 3D printing a first prototype of the sphere we discovered that it needs to me more heavy so we decided to 3D print another sphere by softly minimizing its diameter and filling it with more material by using the (fill) option.

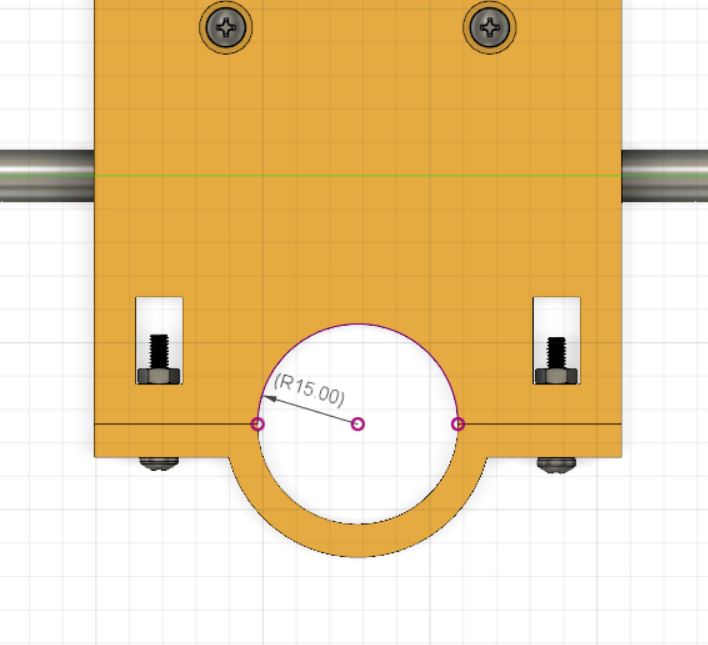

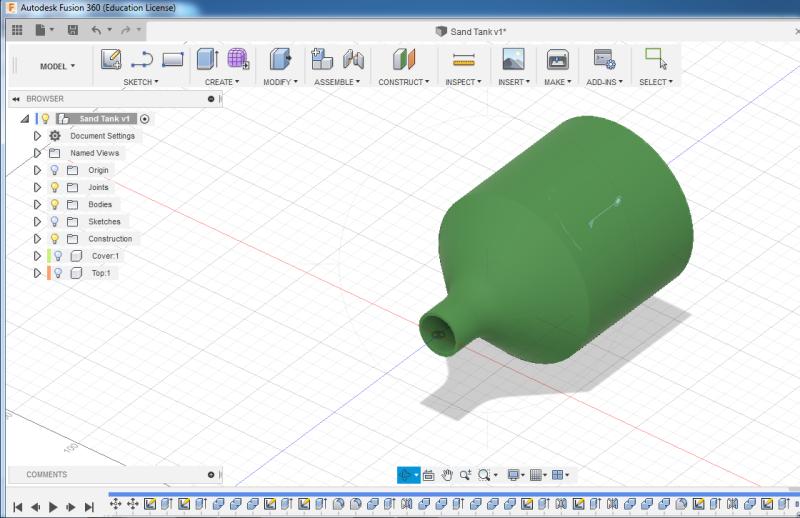

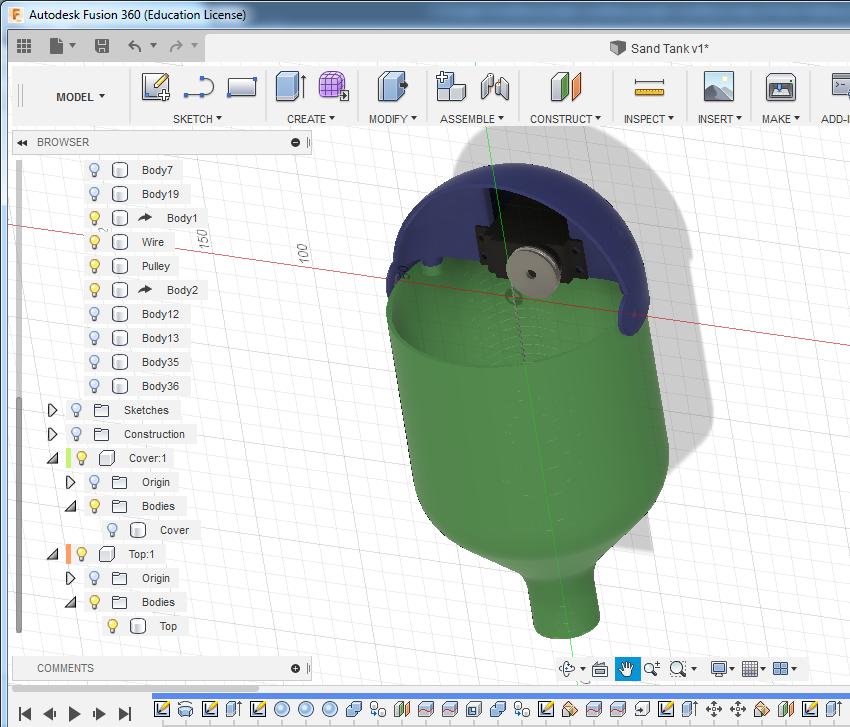

I draw the container according to the above holder inner diameter (30mm), and 3D printed it.

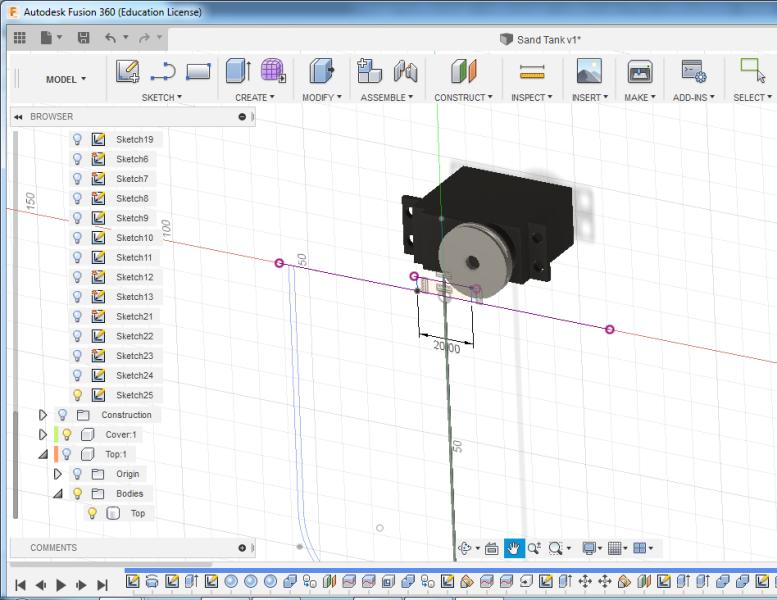

I used Futaba S3003 servo motor:

The cord is positioned in the center of the tank to be able to move up and down the sphere and open/close the lower outlet. According to the wheel diameter the servo is fixed off-center.

The Sand Tank in .stl format,

The 32mm Sphere in .stl format

For the other parts you can check my friends page.

This work is licensed under a Creative Commons Attribution 4.0 International License.