10 & 11th Week Assignment

Machine Design

Machine Design

We

reviewed different options, to work with, and decide to work on a machine that could draw some

geometric lines on "mates burilados"

Peruvians handmade traditional crafts. are produced - gourds carving with exceptionally detailed

representations of rural communities life. The gourds grow at the Peruvian coast, and they are sell as

touristic handicraft. Thus we though that some carved lines could be produce with a machine. We look for

examples, machines that could draw on irregular surfaces. Our instructor suggested to look for machines

that draw lines on eggs. My classmate was in charge of looking for similar projects, that share some

basic information on how to build them. He also found commercial options.

We

reviewed different options, to work with, and decide to work on a machine that could draw some

geometric lines on "mates burilados"

Peruvians handmade traditional crafts. are produced - gourds carving with exceptionally detailed

representations of rural communities life. The gourds grow at the Peruvian coast, and they are sell as

touristic handicraft. Thus we though that some carved lines could be produce with a machine. We look for

examples, machines that could draw on irregular surfaces. Our instructor suggested to look for machines

that draw lines on eggs. My classmate was in charge of looking for similar projects, that share some

basic information on how to build them. He also found commercial options.

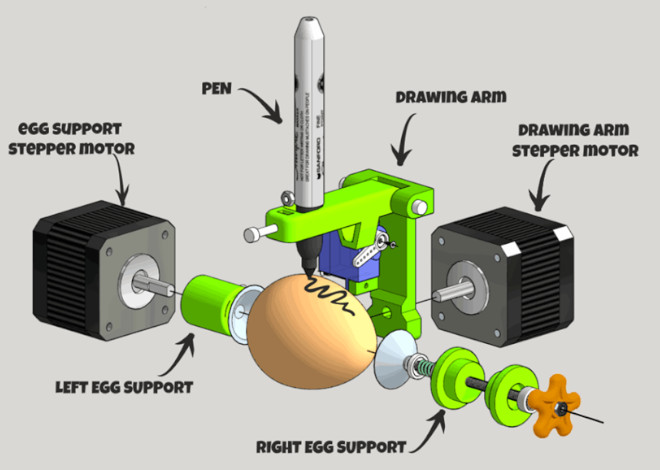

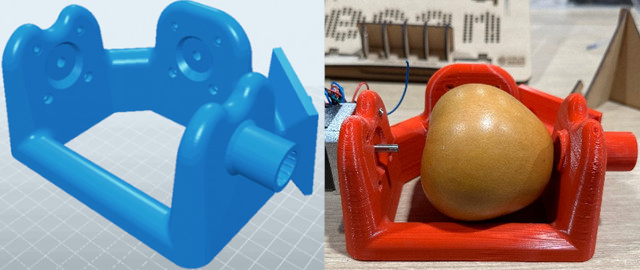

It is a CNC machine design by JJRobots to draw basic figures on eggs.

The key components in this design (as you can see in the picture) are:

It is a CNC machine design by JJRobots to draw basic figures on eggs.

The key components in this design (as you can see in the picture) are:

The major barrier with this design was that we need to use a DEVIA Board, that is not available locally.

However, we decide to test the framework’s design, like shown in the image below.

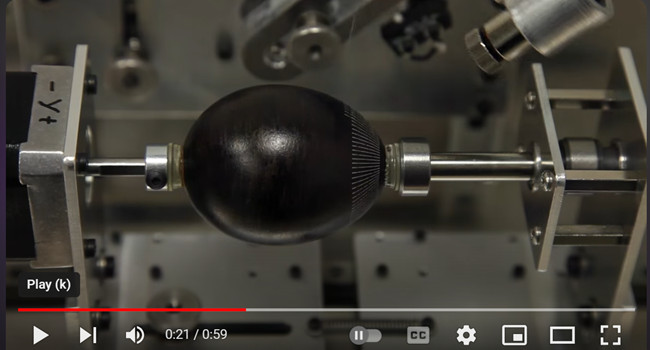

The EggBot Pro

This is a commercial device that allows to decorate different objects (that could be bigger that an egg).

It uses a solid aluminium main frame and 2 high-torque precision stepping motors to control rotation on X

axis and the movement on Y axis to generate the drawings. Also presents a pen lift mechanism using a

microservomotor. It uses a 16× microstepping to give a resolution of 3200 steps/revolution in both axes.

We noticed that this design uses NEMA 17 Stepper Motor Mounting Brackets, similar to the ones used in

some 3D printer modelss Which brings stepper motors stability within the whole mechanism. Thus, we decided to

include this commercial elements to design our main frame, instead of printing them, in order to ensure

stability, considering that rotation and Y movement at the same time could be challenging.

Engraving Easter Eggs with Laser machine

we found this variation of the egg-bot that includes a laser to engrave eggs,

created by untitled.house and that you can find in its Youtube channel. Instead of a pen, it uses a

water cooled 1 W laser diode. In this case the main frame is also made from aluminium.

we found this variation of the egg-bot that includes a laser to engrave eggs,

created by untitled.house and that you can find in its Youtube channel. Instead of a pen, it uses a

water cooled 1 W laser diode. In this case the main frame is also made from aluminium.

This could be considered for a second stage of our

project. In that case we will need to import the laser diode and test it with a different main frames

and components.

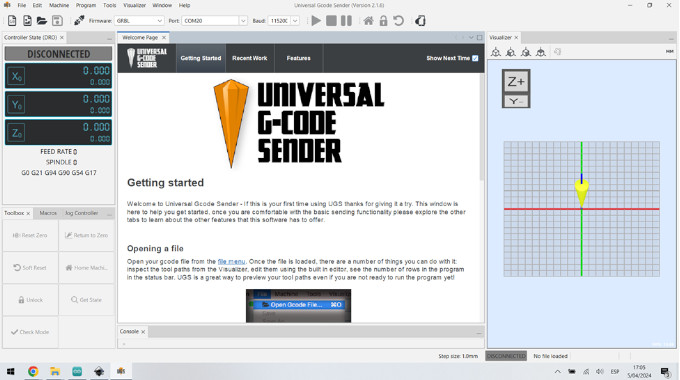

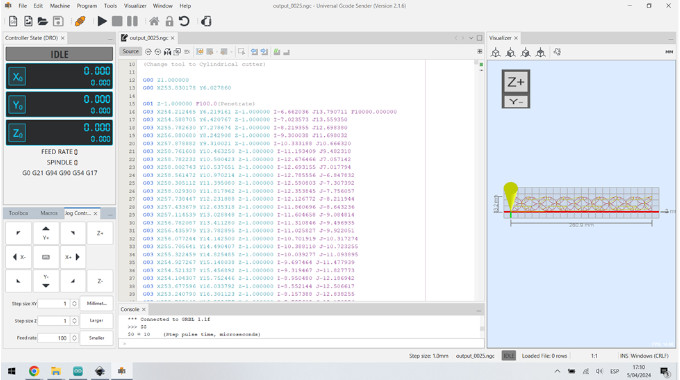

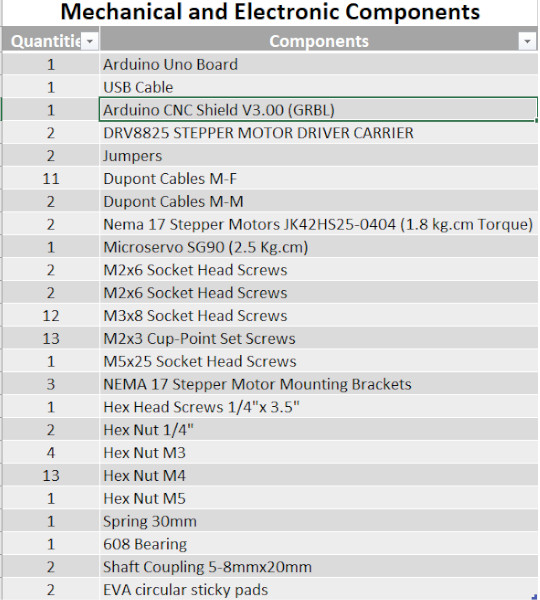

For this asignment we are allowed to use commercial devices, with our instructor support we select commercial boards

and devices that we can use for this machine design. In this case, to build this XYZ Axis Plotter (CNC machine),

all the mechanical and electronic devices that you’ll need to create this bot are:

For this asignment

we are allowed to use commercial devices, with our instructor support we select commercial boards and

devices that we can use for this machine design. In this case, we will need to build XYZ Axis Plotter

(CNC machine), so we will need to control stepper motors. Also, we will require a microcontroler which

let us run GCode programing. As part of my contribution at this stage, I will provide devices's

technical

information, outlining the main characteristics that we will need to ensamble and programing it.

For this asignment

we are allowed to use commercial devices, with our instructor support we select commercial boards and

devices that we can use for this machine design. In this case, we will need to build XYZ Axis Plotter

(CNC machine), so we will need to control stepper motors. Also, we will require a microcontroler which

let us run GCode programing. As part of my contribution at this stage, I will provide devices's

technical

information, outlining the main characteristics that we will need to ensamble and programing it.

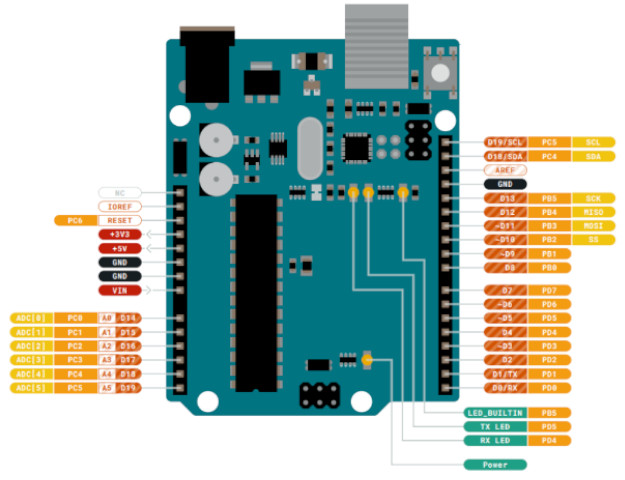

In

our case

we

choose to use from the FabAcademy Inventory the Arduino Uno.This board, base on its data

sheet

information, equipped with the well-known ATmega328P and the ATMega 16U2 Processor. It contains

everything needed to support the microcontroller; simply connect it to a computer with a USB

cable, with a AC-to-DC adapter or battery to get started. (AC power plugs: used to connect devices to

wall outlets. DC power Connector

jacks:used to connect devices to power supplies or batteries). USB connectors: used to provide

power to and transfer data between devices. One of the major feature of Uno Wifi is the

support of OTA (Over-the-air) programming for Arduino sketches and for Wifi firmware. Recommended

In

our case

we

choose to use from the FabAcademy Inventory the Arduino Uno.This board, base on its data

sheet

information, equipped with the well-known ATmega328P and the ATMega 16U2 Processor. It contains

everything needed to support the microcontroller; simply connect it to a computer with a USB

cable, with a AC-to-DC adapter or battery to get started. (AC power plugs: used to connect devices to

wall outlets. DC power Connector

jacks:used to connect devices to power supplies or batteries). USB connectors: used to provide

power to and transfer data between devices. One of the major feature of Uno Wifi is the

support of OTA (Over-the-air) programming for Arduino sketches and for Wifi firmware. Recommended

Arduino Uno has:

| Item | Description |

|---|---|

| Input Voltage (recomended) | 7-12 V |

| Input Voltage (limit) | 6-20 V |

| Power Consumption | 130 mA (sleepmode 80mA) |

| PCB Size | 53.4 x 68.6 mm |

| Weight | 0.025 Kg |

| RAM | 8 MB instruction, 12 MB data |

| Operating Conditions | Min 40 °C (-40°F) and Max 85 °C ( 185°F) (VIN) Input voltage 6-20 V Imput voltage form USB connector 5.5V |

| Product Code | A000133 |

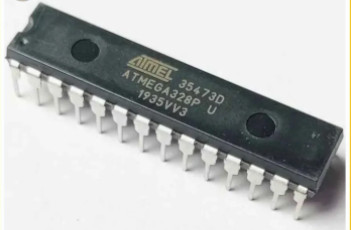

The Main Processor running at up to 20 MHz. Most of its pins are connected to the external headers, however some are reserved for internal communication with the USB Bridge coprocessor. omes preprogrammed with a bootloader that allows you to upload new code to it without the use of an external hardware programmer.

| Item | Description |

|---|---|

| Microcontroller | ATmega328P |

| Architecture | Advanced RISC |

| Operating Voltage | 2.7V to 5.5V |

| Flash Memory | 32KB. |

| SRAM | 2KB |

| Clock Speed | 16MHz |

| Digital I/O Pins | 14, (2 serial communication - 2 external interrupts) |

| Analog Input Pins | 6 |

| Timer/Counter Pins | 3 |

| Crystal Oscillator Pins | 2 |

| EEPROM | 1KB |

| DC Current per I/0 | 20 mA |

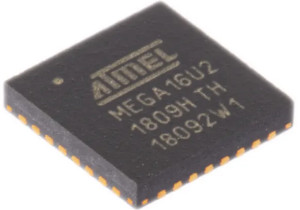

| Item | Description |

|---|---|

| Processor | ATmega 16U2 |

| Architecture | RISC |

| Operating Voltage | 2.7 - 5.5V |

| Operating Frecuency | 8 Mhz at 2.7V & 16MHz at 4.5 V |

| Operation Temperature | Industrial (-40°C to +85°C) |

| Data Memories | 16KB on In-System Self-Programmable Flash |

| EEPROM | 512 |

| SRAM | 512 |

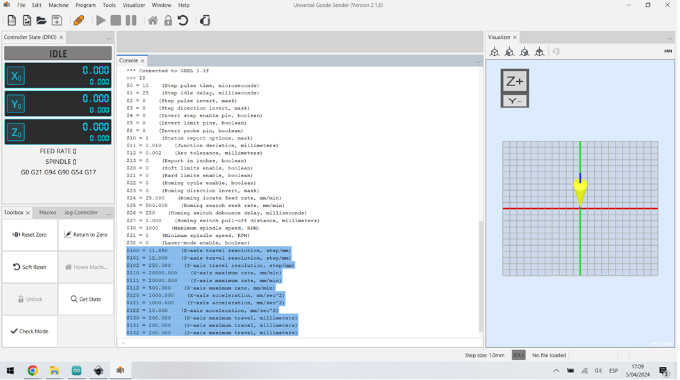

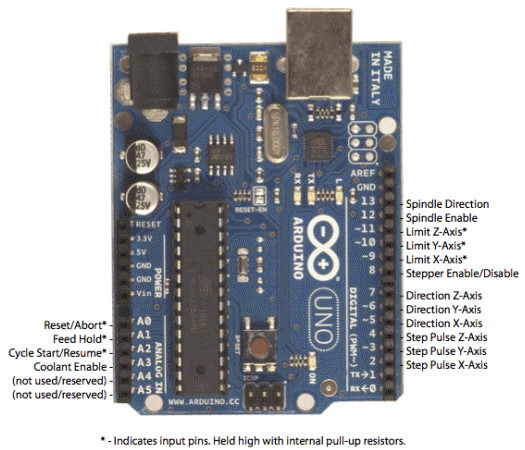

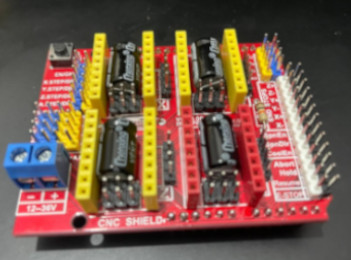

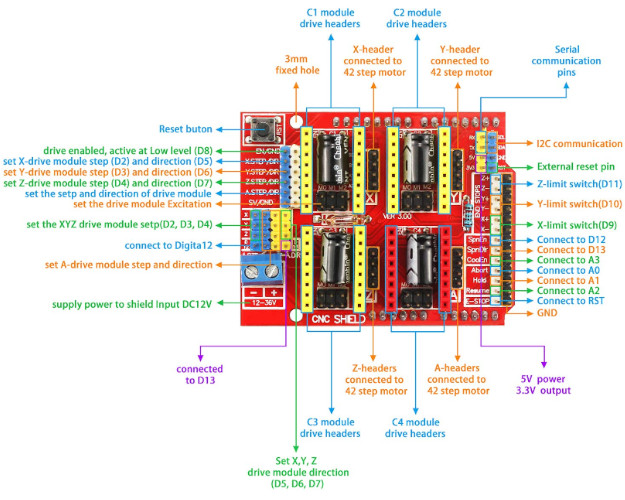

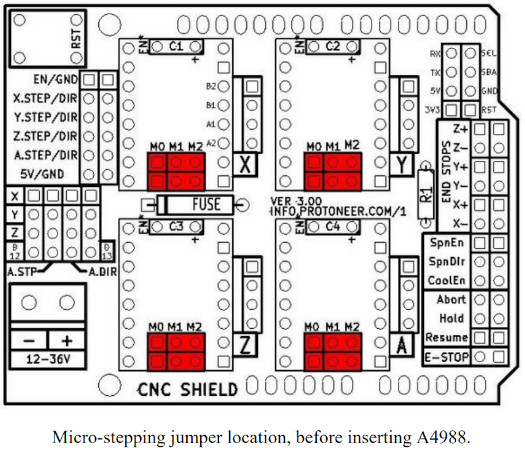

In our case we

choose to use from the FabAcademy Inventory the Arduino CNC Shield V3.00.This board, base on its data sheet

information, uses opensource firmware on Arduino to control 4 stepper motors using 4 pieces of A4988

Stepper

Motor driver breakout board, together with ArduinoUno, we can build all kinds of robotics, linear motion

project or projects including CNC routers, laser cutters and even pick&place machines. It uses e

software

called GRBL. Arduino Uno that takes G-Code commands via Serial and turns the commands into motor

signals.

In our case we

choose to use from the FabAcademy Inventory the Arduino CNC Shield V3.00.This board, base on its data sheet

information, uses opensource firmware on Arduino to control 4 stepper motors using 4 pieces of A4988

Stepper

Motor driver breakout board, together with ArduinoUno, we can build all kinds of robotics, linear motion

project or projects including CNC routers, laser cutters and even pick&place machines. It uses e

software

called GRBL. Arduino Uno that takes G-Code commands via Serial and turns the commands into motor

signals.

CNC Shield has:

| Item | Description |

|---|---|

| Input voltage: | 12-36V |

| Motor drivers: | Supports up to 4 stepper motors |

| Stepper motor driver: | Compatible with A4988/DRV8825 motor drivers |

| Power supply: | One terminal block is available for connecting the external power supply |

| Pin headers: | Expansion headers for adding additional functionality such as limit switches, end stops, and spindle control |

| Compatibility: | Compatible with the GRBL firmware and other popular CNC software |

Osoyoo web, provides this information, and a guideline for hardware installation.

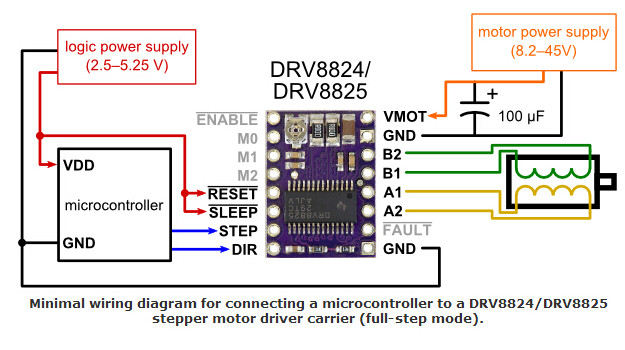

The DRV8825

provides an integrated motor driver solution for printers, scanners, and other automated equipment

applications. The device has two H-bridge drivers and a microstepping indexer, and is intended to

drive

a bipolar stepper motor. The output driver block consists of N-channel power MOSFET’s configured as

full

H-bridges to drive the motor windings. The DRV8825 is capable of driving up to 2.5 A of current from

each output (with proper heat sinking, at 24 V and 25°C).

A simple STEP/DIR interface allows easy interfacing to controller circuits. Mode pins allow for

configuration of the motor in full-step up to 1/32-step modes. Decay mode is configurable so that

slow

decay, fast decay, or mixed decay can be used. A low-power sleep mode is provided which shuts down

internal circuitry to achieve very low quiescent current draw. This sleep mode can be set using a

dedicated nSLEEP pin. You can find the datasheet here

The DRV8825

provides an integrated motor driver solution for printers, scanners, and other automated equipment

applications. The device has two H-bridge drivers and a microstepping indexer, and is intended to

drive

a bipolar stepper motor. The output driver block consists of N-channel power MOSFET’s configured as

full

H-bridges to drive the motor windings. The DRV8825 is capable of driving up to 2.5 A of current from

each output (with proper heat sinking, at 24 V and 25°C).

A simple STEP/DIR interface allows easy interfacing to controller circuits. Mode pins allow for

configuration of the motor in full-step up to 1/32-step modes. Decay mode is configurable so that

slow

decay, fast decay, or mixed decay can be used. A low-power sleep mode is provided which shuts down

internal circuitry to achieve very low quiescent current draw. This sleep mode can be set using a

dedicated nSLEEP pin. You can find the datasheet here

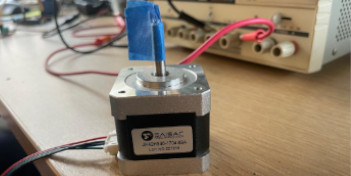

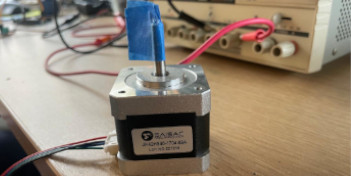

This

product offer a shaft motion consists of discrete angular movements of

essentially uniform magnitude when driven from a sequentially switched DC power supply, such being

describe at Electromate.com . It works with digital signals. One digital pulse to a

step

motor drive or translator causes the motor to increment one precise angle of motion. As the digital

pulses increase in frequency, the step movement changes into continuous rotation. So we can test it

at

full motion. It has windings in the stator and permanent magnets attached to the rotor. It provides

fixed mechanical increments of motion (referred as steps, and generally specified in degrees). They

are

considered ideal for applications that require quick positioning over a short distance, Allowing the

use

of an open-loop controller, which simplifies machine design and lowers cost compared to servo motor

systems.

This

product offer a shaft motion consists of discrete angular movements of

essentially uniform magnitude when driven from a sequentially switched DC power supply, such being

describe at Electromate.com . It works with digital signals. One digital pulse to a

step

motor drive or translator causes the motor to increment one precise angle of motion. As the digital

pulses increase in frequency, the step movement changes into continuous rotation. So we can test it

at

full motion. It has windings in the stator and permanent magnets attached to the rotor. It provides

fixed mechanical increments of motion (referred as steps, and generally specified in degrees). They

are

considered ideal for applications that require quick positioning over a short distance, Allowing the

use

of an open-loop controller, which simplifies machine design and lowers cost compared to servo motor

systems.

This device holds a NEMA denomitation, that accounts for the National Electrical Manufacturers Association acronym. This mean that is standirized motor size, including designations that can help as learn more about the size and capability of practically any particular motor. Step motors are categorized by NEMA frame size, such as "size 11" or "size 23" or “size 34”. NEMA 17 stepper motors are those that have a 1.8 degree step angle (200 steps/revolution) with a 1.7 x 1.7 inch faceplate. They typically have more torque than smaller variants, such as NEMA 14 and have a recommended driving voltage of 12-24V. These steppers are also RoHS compliant (acronym for "Restriction of Hazardous Substances." A European Union directive that regulates the use of certain hazardous substances in electrical and electronic equipment - EEE).

| Item | Description |

|---|---|

| Model No. | JK42HS25-0404 |

| Step Angle | 1.8° |

| Motor Length | 25 (L)mm |

| Current/Phase | 0.4 A |

| Resistance/Phase | 24 Ω |

| Inductance/Phase | 36mH |

| Holding Torque | 1.8 kg.cm |

| # of Leads | 4 |

| Detent Torque | 75 g.cm |

| Rotor Inertia | 20 g.cm |

| Mass | 0.15 Kg/td> |

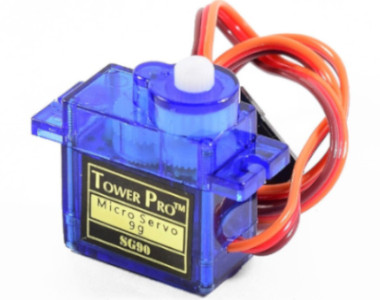

Tiny and

lightweight (it will fit in small places) with high output power. Servo can rotate approximately 180

degrees (90 in each direction), and works just like the standard kinds but smaller. You can use any

servo code, hardware or library to control these servos. With feedback & gear box. In our case it

came with a 8 different horns models (arms). We decided to use the one thah only have one arm.

Regarding arms positions, it is necessary to highlight:

Tiny and

lightweight (it will fit in small places) with high output power. Servo can rotate approximately 180

degrees (90 in each direction), and works just like the standard kinds but smaller. You can use any

servo code, hardware or library to control these servos. With feedback & gear box. In our case it

came with a 8 different horns models (arms). We decided to use the one thah only have one arm.

Regarding arms positions, it is necessary to highlight:

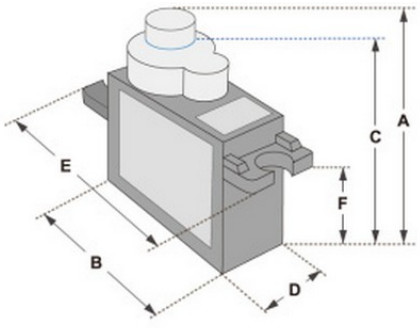

You can find the datasheet here .

| Item | Description |

|---|---|

| A (mm) | 32 |

| B (mm) | 23 |

| C (mm) | 28.5 |

| D (mm) | 12 |

| E (mm) | 32 |

| F (mm) | 19.5 |

| Speed (Sec) | 0.1 |

| Torque (kg-cm | 25 |

| Weight (g) | 14.7 |

| Voltage | 4.8-6 |

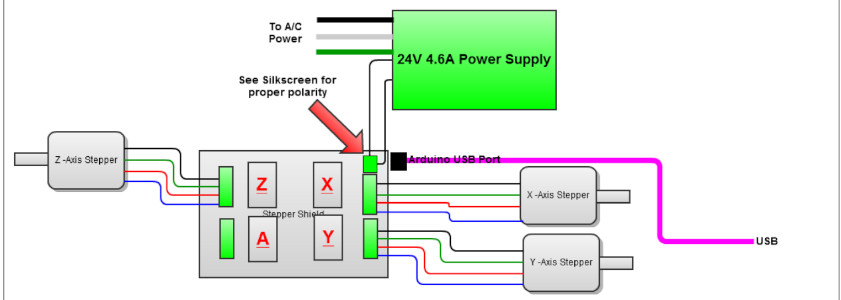

The purpose is to connect steppers motor to CNC Shield board as the below block diagram, that shows

the CNC Shield connected to 3-stepper motor:

| Item | Description |

|---|---|

| PWM Microstepping Stepper Motor Driver | Built-In Microstepping Indexer / Up to 1/32 Microstepping |

| Multiple Decay Modes | Mixed / Slow / Fast |

| Operating Supply Voltage Range | 8.2-V to 45-V |

| Reference Output | 2.5-A at 24 V and TA = 25°C |

| Reference Output | Built-In 3.3-V |

| Body Size | 9.70 mm × 6.40 mm |