18. Applications and Implications¶

Week 18 · 2023.05.17-2023.05.24

During this week I focused on pushing forward my final project, taking in account different aspects related to deliver right on schedule.

- [x] What will it do?

- [x] Who has done what beforehand?

- [x] What will you design?

- [x] What materials and components will be used?

- [x] Where will they come from?

- [x] How much will they cost?

- [x] What parts and systems will be made?

- [x] What processes will be used?

- [x] What questions need to be answered?

- [x] How will it be evaluated?

What will it do?¶

Handheld Powertool Workbench for Robotic Fabrication. This is a workbench that assists in robotic fabrication with the integration of a handheld power tool. With several workbenches like this one it is possible to concatenate different fabrication processes into one production line. It is mainly directed at this stage towards fabrication with plywood parts.

Who’s done what beforehand?¶

There are some research proposals that deal with how to grip a tool, such as Kemp C. C., Edsinger A. (2006) that explores on which side a robotic arm should grab a tool, and which part is the useful part of the tool, Hoffmann H., Chen Z., Earl D., Mitchell D., Salemi B., Sinapov J. (2014) points towards handheld powertool use, how the tool is grabbed and how to point towards a target for making it work.

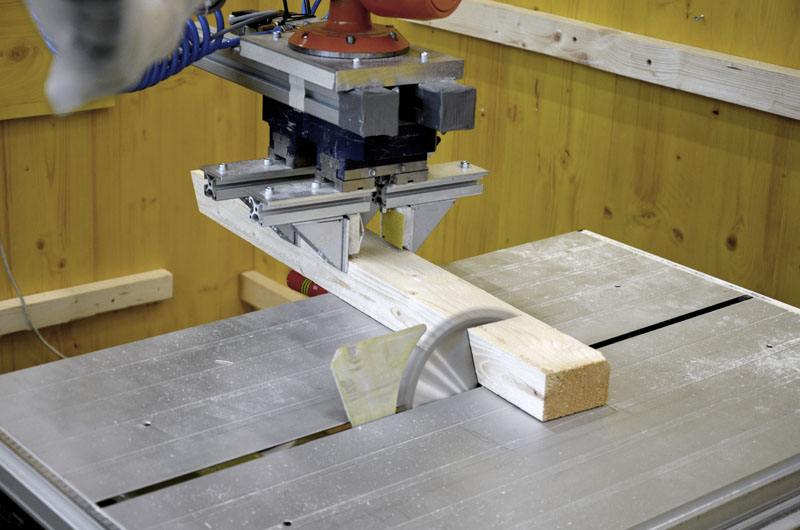

On the other hand, there have been some colaborative processes where the robotic arm delivers or moves the material towards or away from a static tool, in Loucka M., Menges A., Krieg O. and Correa D. Robotically Fabricated Gluelam. ITECH M.Sc. 2014 the robotic arm grabs and repositions coupled wood strips to acquire a specific shape, while in Menges A., Knippers J., ICD/ITKE Research Pavilion 2013/14, 2014 a couple of robotic arms take work together in winding fibers.

One of closest developments I have found in this matter is Gramazio F. and Kohler M. Complex Timber Structure resarch. 2012. Since it handles wood pieces with a gripper, out of sawing and then into a metallic tip that punctures microperforations in the wood that help impregnating glue for joining different parts.

Another effort worth observing for this purpose is such of the Fablab Ciudad de México, where a Sawing fixture was used for exploring this kind of processes.

What will you design? What materials and components will be used?¶

There are several components designed in this project:

What parts and systems will be made? and What processes will be used?¶

Workbench with substractive fabrication (laser or milling), fixation for handheld toold (3d printing + substractive fabrication), weights in the workbench (molding and casting), gripper paddles (3d printing), electronics and wiring (electronic design, embedded programming, input and output devices), adapter for gripper with battery bank + board + ultrasonic sensor (3d printing), Adapter for IRC5 with battery bank (3d printing).

What questions need to be answered?¶

Is this device practical, does the gripper have a firm grip on the boards, is it possible to concatenate different processes

How will it be evaluated?¶

The first term of evaluation will be parced upon the capacity of a board element to be able to be processed with the handheld tool. And on second term, how precise is this method

Basic goal Schedule¶

Monday May 29th, Workbench enclosure ready Wednesday May 31st, Fixation for gripper ready Friday June 2nd, Programming and integration done