Assignment#1a: Principles and Practices

This assignment is about documenting my final project for fab academy 2022. I have documented the problem identified, objectives of the project, abstract and concept sketch of the solution.

Problem Statement: In India and other developing countries, there is almost 40-80% of onion harvested is spoiled because of various reasons. One of the prominent reasons is in-proper handling and unscientific ways of storage. Also The cost of cold storage is almost 10-12 times the cost of natural ventilated storage and 20 times than the traditional unscientific ways of storage, which is too high for a marginal farmers of a developing country like India.

This problem results in major social and health problems in India as a consequence of major finacial losses to the farmers.

Objectives of the Project

My objective is to solve the storage related spoilage, rotting and losses through a cost-effective, IoT based smart mechanism of post-harvest onion bulk storage.

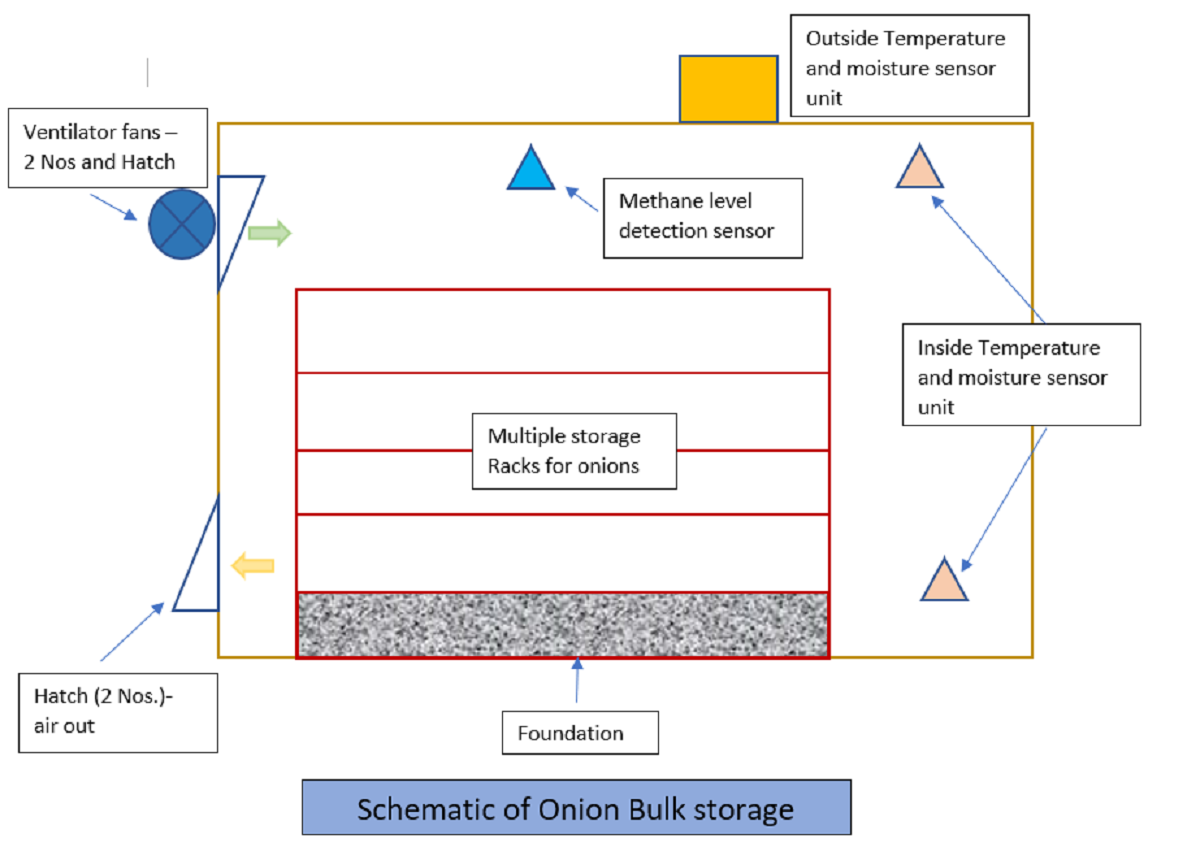

The onions need to be stored in well ventilated area. My idea is to measure the temperature, humidity in and outside the storage room along with measuring the levels of Methane gas emmitted by onions stored. More the level of methane means the onions have started rotting. Upon measuring and monitoring the humidity, temperature and the methane concentration, the storage house will be ventilated and aerated sufficiently to keep the produce dry and cool.

Abstract

Having been cultivated for 5,000 years, the onion has been a vital part our salads and meals along with its countless health benefits and strong aroma. The onion is the oldest and most widely used vegetable that can be cultivated in all types of soil all around the world. Being an irreplaceable aroma for the meals, the onion creates a large economy with the production of almost 100 million tons of round the world. The United Nations reports that the onion is grown in at least 175 countries and this figure doubles the number of wheat growing countries. Asia is the largest producer of the onion with a market share of 65 percent, while the Americas, Europe and Africa each has just over 10 percent of the market share.

China is the leader of onion production with 23 million tons in Asia and followed by India with production of over 19 million tons. China and India are followed by the United States with the production of over 3 million tons. Other large onion producers are respectively Iran, turkey, Pakistan, Egypt, Brazil and Mexico.

Although Asia has the biggest share in terms of production area and quantity, it does not rank as the leading Market in the global onion Market. This is due to high population density, insufficient storing spaces and the fact that they can't come out to foreign markets. While countries aim to increase their production for their citizens, they try to sell their surplus products on global markets for economic growth. If new investors prefer yellow onions considering the demands of developed countries markets, they should know that they would have a large market share. Nearly 90% of onions are consumed within the country they are grown. Therefore, the onion does not stand out in many parts of the world.

Traditional methods of storing onions are drying them with their stocks on and storing in a cool shelter, cave or dark storage after they are harvested until they are consumed. However, between 40 and 80 percent of the onion stored with this method result in spoilage. Neither economy nor our planet can afford these kinds of spoilage anymore. Onions now are stored in cold storage after the harvest. First onions need to be dried for a few days, then starts the maturing stage that enable skin and color formation to specific to the onion cultivated. Onions are prepared for cold storage by lowering the temperature at a maximum of 0.5 degree Celcius per day. Depending on the onion variety, they are stored at between 0 and 2 degrees Celsius in cold storage. Onions can be stored in cold storage up to 10 months without spoilage. Ventilation is vital in onion storage. After storing, onions are not transported straight from the cold storage before they are put on the market, but kept in temperature-controlled conditions in order to prevent condensation. Because of condensation, sprouting will happen immediately after they are taken out of cold storage resulting in poor pricing in the market.

Cold storages involve little difficult and elaborate processes and it is still not able to solve the problems of a marginal farmers in developing countries. The cost of cold storage is also a major factor, which is almost 10-12 times the cost of natural ventilated storage and 20 times than the traditional unscientific ways of storage, which is too high for a marginal farmers of a developing country like India.

Types of rotting and infections in onions

Only 20 million tons of global onion production of 100 million tons are stored with modern storage methods and spoilage still continues. Weight loss, sprouting of bulbs, rotting, bacterial and fungal infections are some of the ways the onion spoilage happen. Neck rot (rotting at the neck of the onion), bacterial rot, basal rot (fungus infection through wounds and scars at the base of the bulb) and other diseases are resulted out of improper storage.

|

|

|

In developing countries like India, proper handling and unscientific ways of storage is a matter of great concern. Onions are stored in poorly ventilated temporary structures. Each farmer has created their own storage method based on their needs, experience and resources available. These unscientific ways of storage result in higher losses in storage. Actually, losses start immediately after harvesting. The facility of onion storage post harvesting needs to be made available right at the time of sowing of seeds itself.

|

|

Social and Health Problems:

The marginal farmers in India, who can neither afford the cost of cold storage nor the huge of produce losses. With less to none yield, these farmers end up in committing suicides, which is a major social and financial issue. At the same time, to save their crop from these spoilages, they use a lot of pesticides to prevent these infections post harvesting. This ultimately results in creating long term health problems for people.

Click here to go back to the topSketch of the Final Project

Following is a sketch of the proposed cost-effective IoT based smart onion storage system.

|

Click here to go back to the top

What I would do differently

I will collect more data on the problem identified. I have spoken to a couple of farmers in our nearby area. I will continue to work with them on this project.

Click here to go back to the topSigning Agreements

|

I have read all terms of signing agreements as a Fab academy student. I accept the signing agreements and I will be abide by them.