Assignment#16: Applications and implications

What will it do?

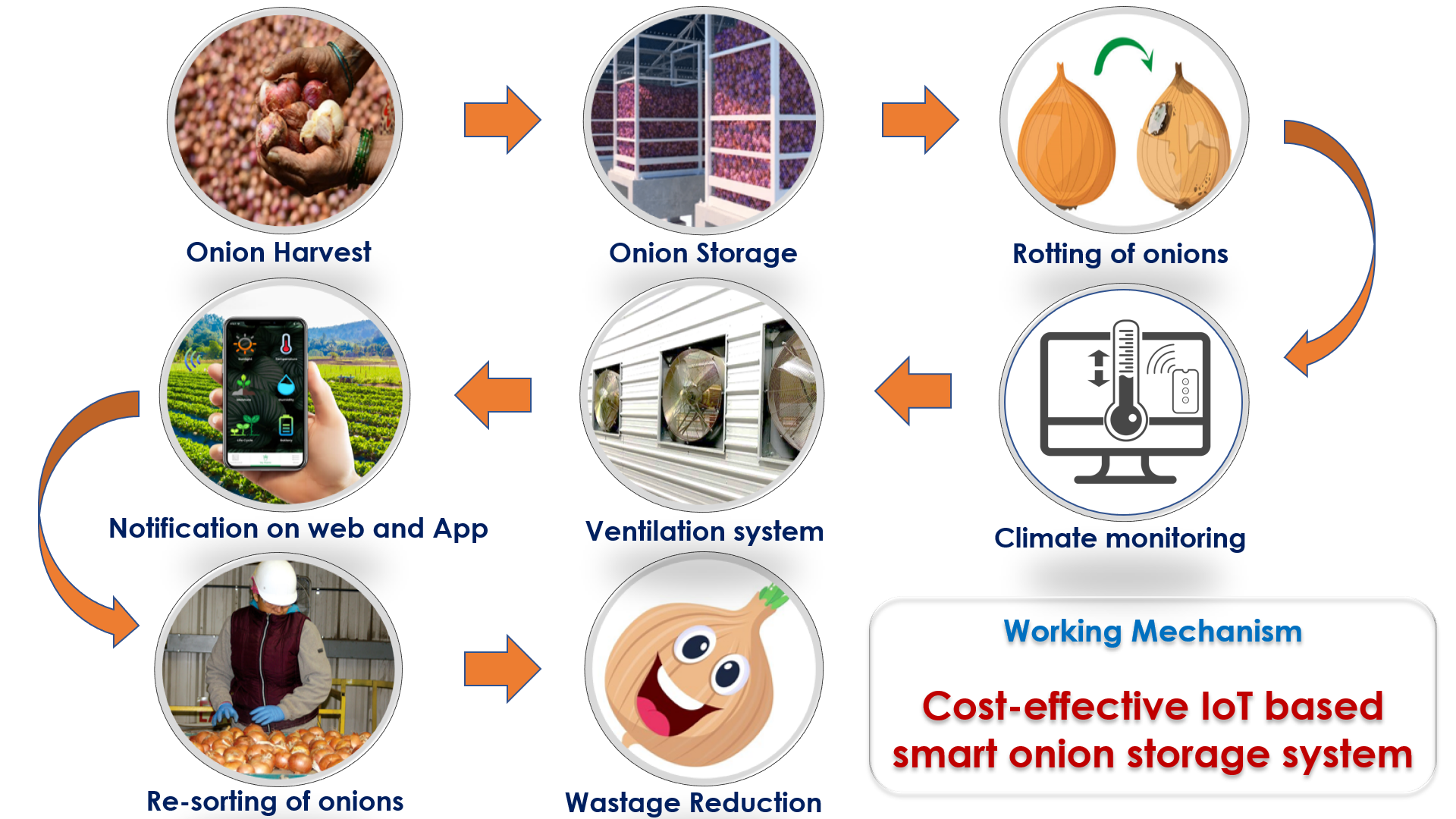

My final project name ('Low cost IoT based smart storage system for onions') suggests, it is going to be used by medium-scale farmers and traders, restaurant owners, organizations having a community kitchen, etc. Based on the literature study and considering the need of the community farm that I am a part of, I decided to work on a problem of onion spoilage (onions that are stored in the warehouse for 5-6 months post-harvest).

Basically, if we look in to the problem statement, In India, 40-50% of the onions that are stored post-harvest get spoiled because of many reasons like- Weight loss, sprouting of bulbs, rotting, bacterial and fungal infections. Neck rot (rotting at the neck of the onion), bacterial rot, basal rot (fungus infection through wounds and scars at the base of the bulb) and other diseases are resulted out of improper storage.

In developing countries like India, proper handling and unscientific ways of storage is a matter of great concern. Onions are stored in poorly ventilated temporary structures. Each farmer has created their own storage method based on their needs, experience and resources available. These unscientific ways of storage result in higher losses in storage. Actually, losses start immediately after harvesting. The facility of onion storage post harvesting needs to be made available right at the time of sowing of seeds itself.

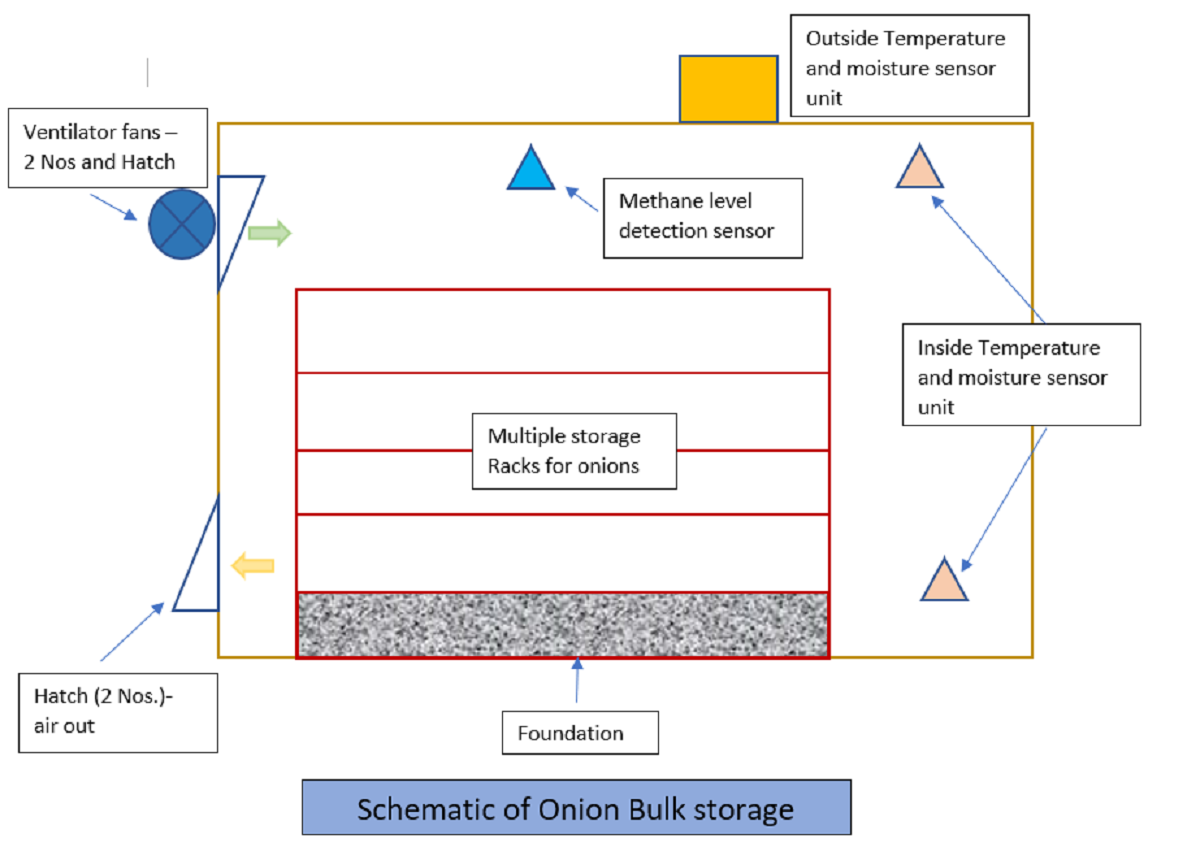

This project is developed to solve the storage related spoilage, rotting and losses through a cost-effective, IoT based smart mechanism of post-harvest onion bulk storage. The onions need to be stored in well ventilated area. My idea is to measure the temperature, humidity in and outside the storage room along with measuring the levels of Methane gas emmitted by onions stored. More the level of methane means the onions have started rotting. Upon measuring and monitoring the humidity, temperature and the methane concentration, the storage house will be ventilated and aerated sufficiently to keep the produce dry and cool. The system will also send notifications on temperature, humidity and methane gas level detected through web-based IoT channel and also through application developed as shown in the image below.

|

Click here to go back to the top

Who has done what beforehand?

I looked in to various online resources to learn more about the previous work done on this problem statement. Some people have worked on a simple ventilation system that runs day in and out irrespective of weather/climatic conditions. They do not worry much about optimum usage/utilization of the electricity.

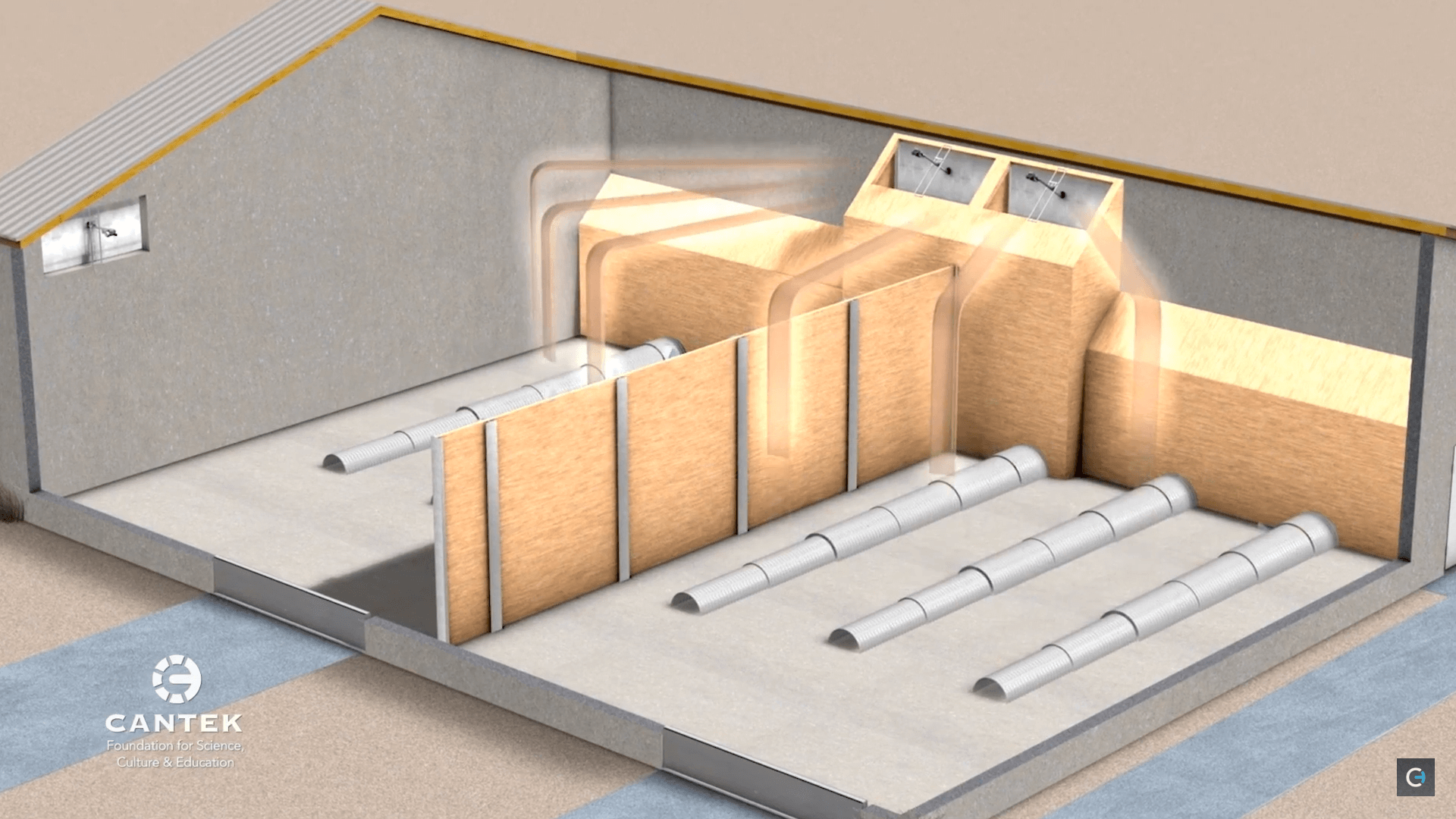

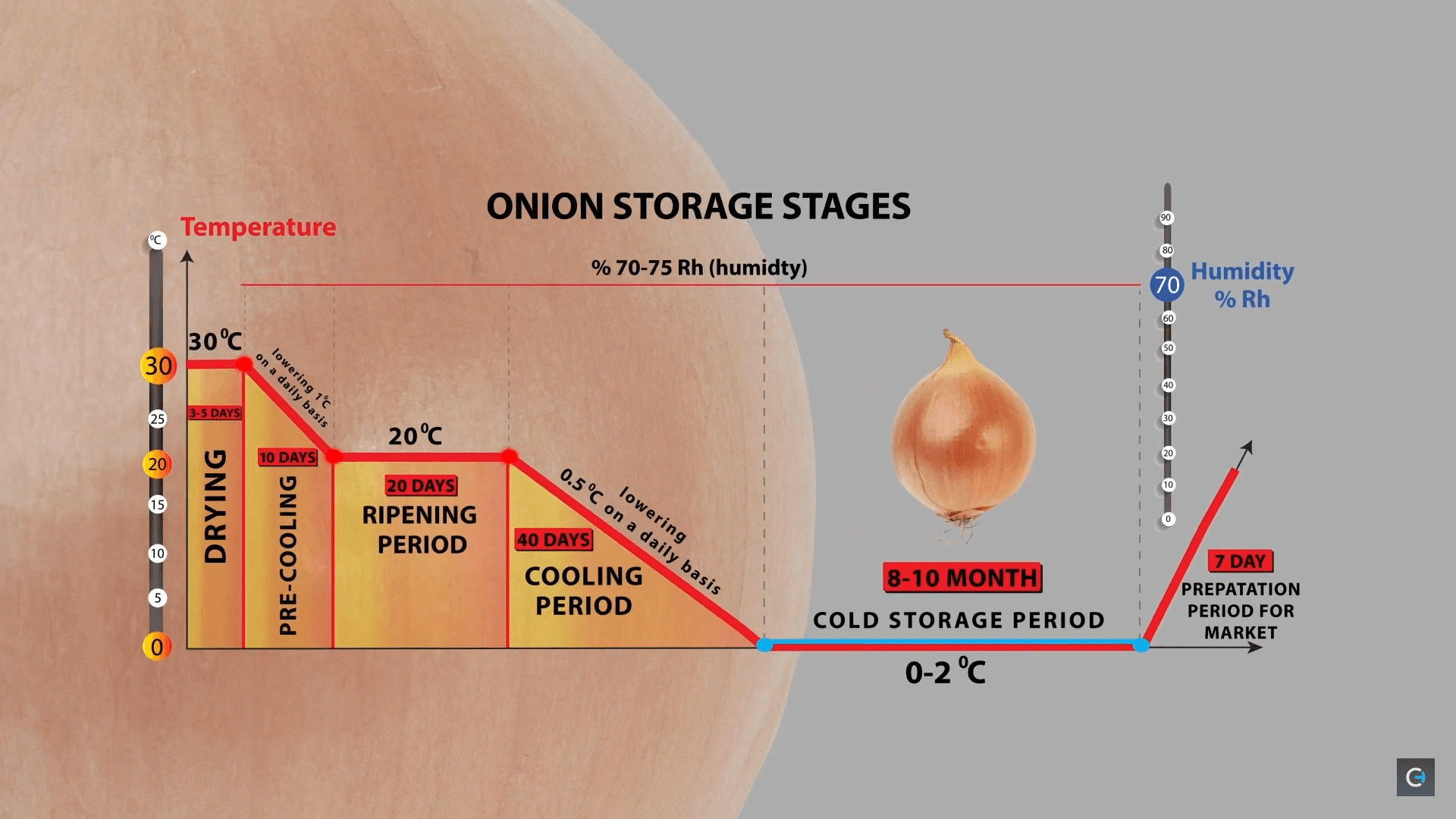

Most of the places, people are using the cold storage system as shown below, the cost of, which is 20 times more than that of the traditional storage system

|

|

Since these large cold storage systems are quite costly for small-mid scale farmers in developing contries like India, I was trying to still find out something low cost mechanisms that can be easily installed in the current storage systems without doing much of changes from construction point of view. So, I further found that there are many of the researchers, inventors, who have worked in solving this problem, have worked on developing micro-controller based devices.

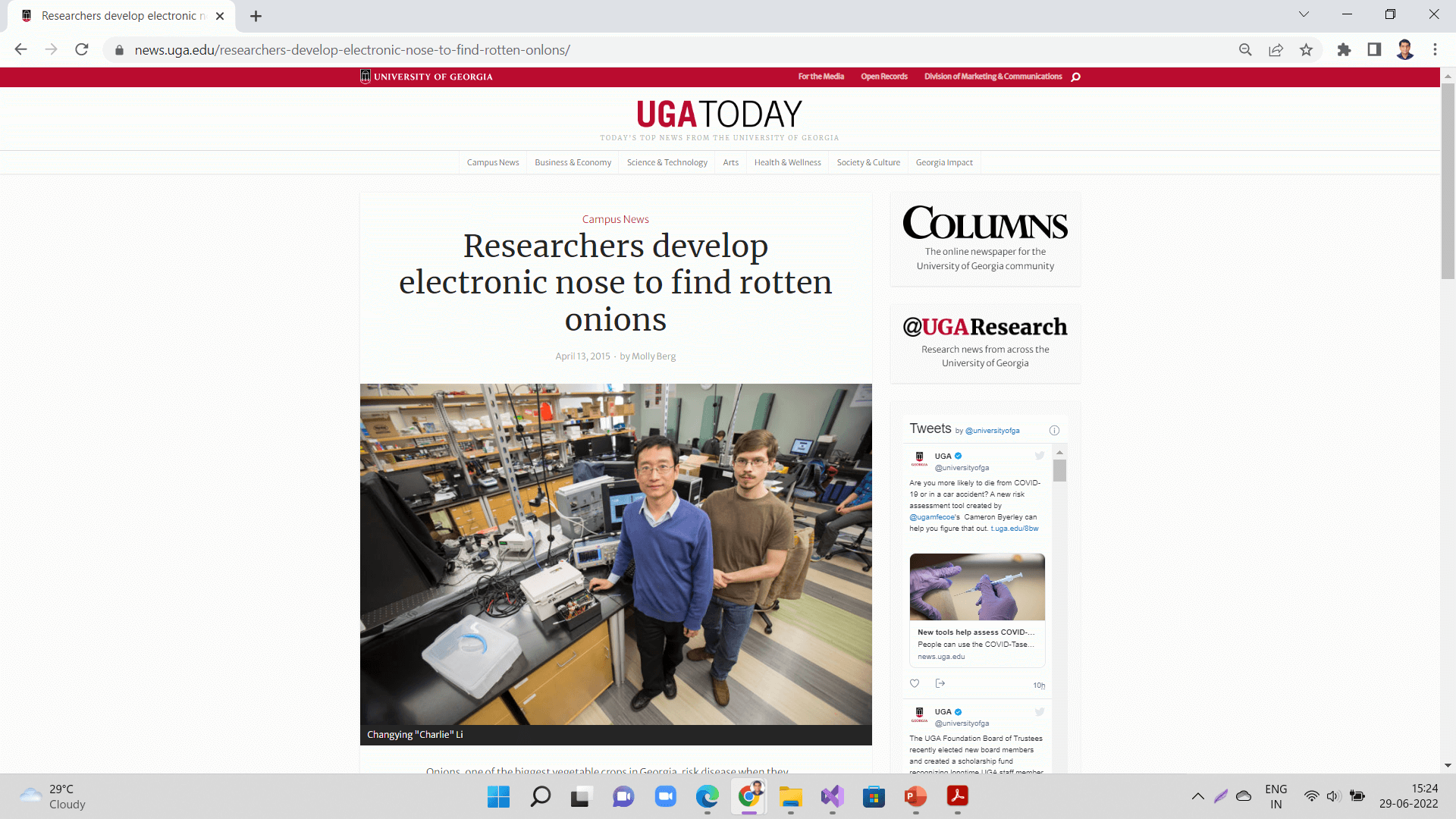

Some of them have also refered to e-nose developed for detecting odor from the rotten onions.

|

Vinay S. Sidawadkar et al. Proposed an IoT-based Preservation System using thermoelectric module, which is based on the Peltier effect is used to decrease the temperature inside the tank. Reference #1.

Mokshi Vyas et al. have designed 'Grid system onion storage methodology' which will help to reduce onion degradation due to temperature and humidity. If in the storage of onions, one of the onion starts degradation then this system will send the message to the farmer. Reference #2.

What will you design?

I I will be designing a low cost IoT based based system that will have temperature, humidity sensors (DS18B20 and/or DHT22), MQ2 gas sensors to detect the gases emitted from the rotten onions. This will in-turn switch ON and OFF the ventilation system for onions. This temperature sensors will detect if the ambient temperature or the temperature inside the onion storage is going above 30 Degree celcius and humidity sensor will tell if the humidity is going above 70%. The ventilator will be switched ON or off depending upon the micro-climatic conditions.

When the MQ gas sensor detects the methane gas released by the rotten onions, it will also send an alert to the farmers through buzzer and also througn an applicaiton developed.

|

|

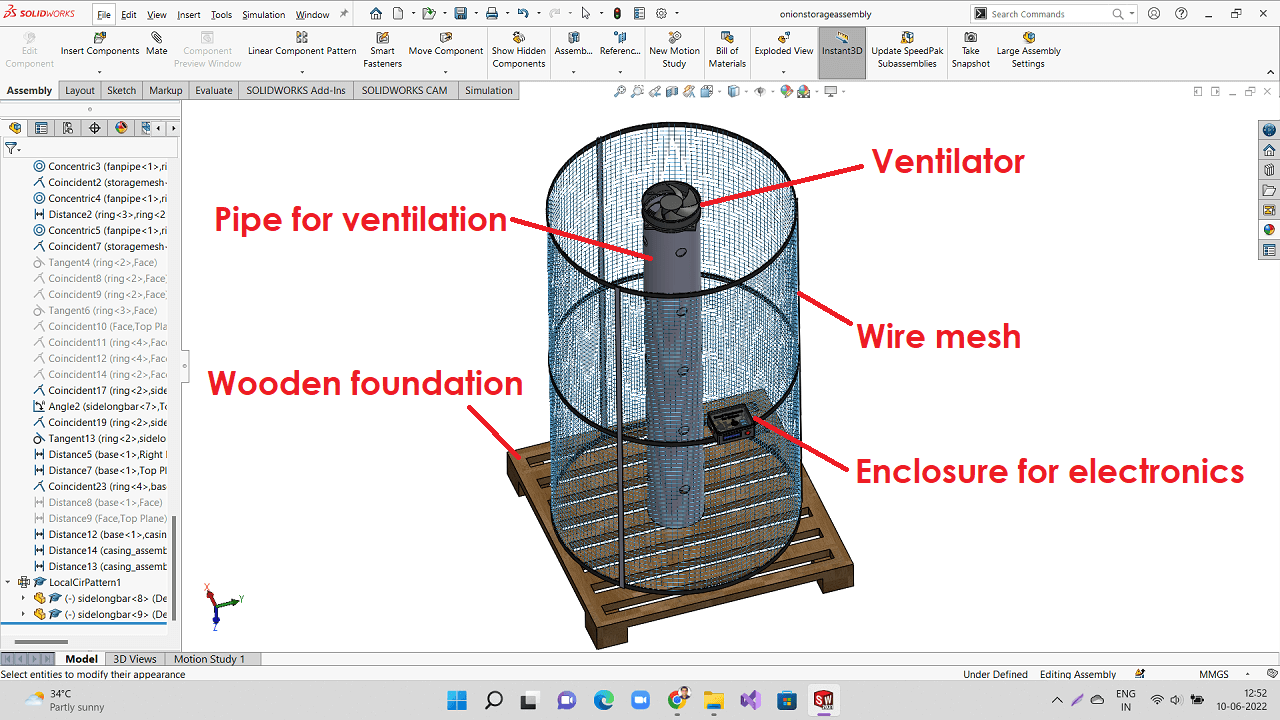

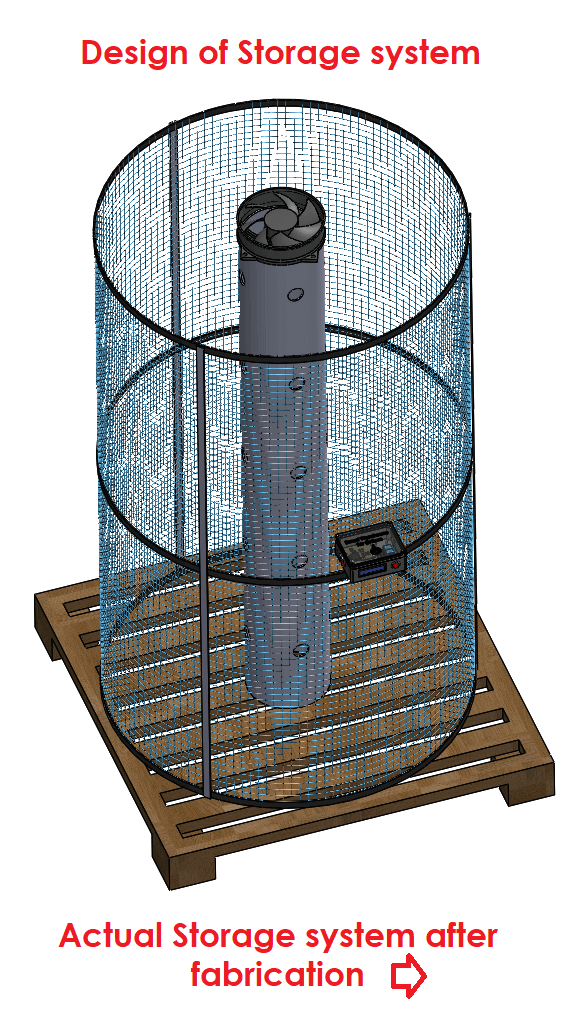

Following are the pictures of storage system designed and actual storage system I fabricated. I arranged these two pictures side-by-side to compare designed vs actual set-up.

|

|

Click here to go back to the top

What materials and components will be used? and How much will they cost?

For storage system fabrication and assembly, I will use the steel wire-mesh and steel plates. For ventilation, I will be using 7 inch diameter PVC pipe, ventilator fan and my electronics board with peripherals. Following is the table of Bill of Materials with costing as mentioned below.

| Components | Specification | Quantity | Unit Price | Cost in Rupees | Reference |

|---|---|---|---|---|---|

| ESP32 Wroom IC | Bluetooth, WiFi Transceiver Module 2.4GHz ~ 2.5GHz Surface Mount | 1 | 328 | 328 | Ref.1 |

| Resistor- SMD | RES SMD 100K OHM 1% 1/20W 0201 | 1 | 7.91 | 7.91 | Ref.2 |

| Resistor- SMD for LED | RES SMD 49.9 OHM 1% 1/20W 0201 | 1 | 7.91 | 7.91 | Ref.3 |

| Capacitor- SMD | CAP CER 1UF 6.3V X5R 0201 | 1 | 7.91 | 7.91 | Ref.4 |

| Capacitor- SMD | CAP CER 10UF 6.3V X5R 0603 | 1 | 9.49 | 9.49 | Ref.5 |

| Capacitor- SMD | 0.1 UF +/-10% 25V Ceramic Capacitor X5R 0402 (1005 Metric) | 1 | 7.91 | 7.91 | Ref.6 |

| Voltage Regulator | IC REG LINEAR 3.3V 1A SOT223 | 1 | 31.63 | 31.63 | Ref.7 |

| Sliding Switch | SWITCH SLIDE SPDT 100MA 12V | 1 | 88.56 | 88.56 | Ref.8 |

| Push Button | SWITCH SLIDE SPDT 100MA 12V | 1 | 16.60 | 16.60 | Ref.9 |

| Header Pins | 1x20 2.54mm Pitch (Right Angle) Male Header Berg Strip | 2 | 15.0 | 30.0 | Ref.10 |

| 16x2 LCD display | JHD 16x2 Character LCD Display With Blue Backlight | 1 | 179.0 | 179.0 | Ref.11 |

| I2C Module | IIC/I2C Serial Interface Adapter Module | 1 | 95.0 | 95.0 | Ref.12 |

| 2 Channel Relay Module | 5V 2 Channel Relay Module | 1 | 99.0 | 99.0 | Ref.13 |

| Ventilator Fan | FANON Axial Cooling Fan 172x150x50 mm 6 in oval Panel Cooling Exhaust Fan (Black) | 1 | 699.0 | 699.0 | Ref.14 |

| DHT22 Sensor module | DHT22 Digital Temperature and Humidity Sensor Module AM2302 | 1 | 261.0 | 261.0 | Ref.15 |

| DS18B20 Temperature sensor | DS18B20 Water Proof Temperature Probe - Black (1m) | 2 | 95.0 | 190.0 | Ref.16 |

| PCB Board | PCB Board- 6x4 in | 1 | 50.0 | 50.0 | Rajiv Electronics, Pune |

| Wire mesh | Wire mesh- 10ft x 5 ft | 1 | 950.0 | 950.0 | Chaudhary Hardware Shop, Pabal |

| Steel Plates | Steel Plates- 18ft x 1.5 inch | 3 | 200.0 | 600.0 | Chaudhary Hardware Shop, Pabal |

| Exhaust Pipe | Exhaust Pipe- 5ft x 7 inch | 1 | 750.0 | 750.0 | Chaudhary Hardware Shop, Pabal |

| Red oxide | Red oxide- 1 Ltr | 1 | 250.0 | 250.0 | Chaudhary Hardware Shop, Pabal |

| Grey Paint | Grey Paint- 1 Ltr | 1 | 440.0 | 440.0 | Chaudhary Hardware Shop, Pabal |

| Total Cost in INR | 6000.00 | ||||

| Total Cost in USD | 75.00 |

Click here to go back to the top

Where will they come from?

The metal parts for fabrication, PVC pipe for ventilation will be procured locally, all the components required for my final project controller board are ordered online from the resources given in the table above.

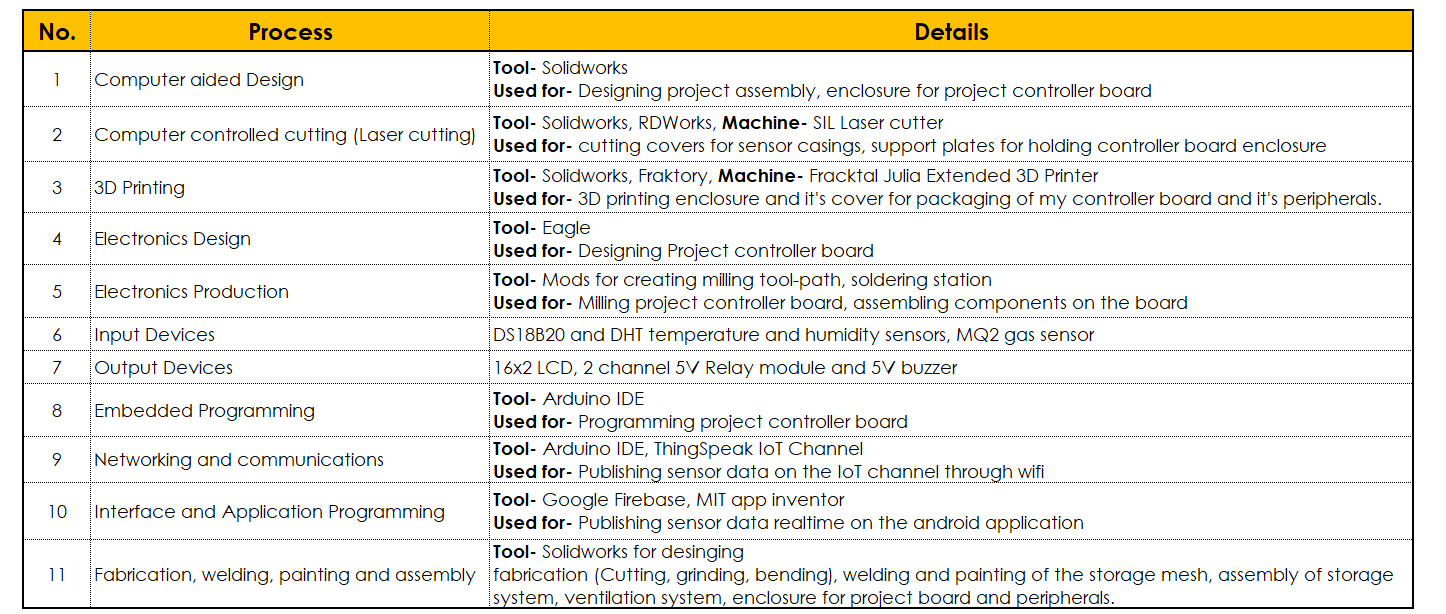

What parts and systems will be made?

Onion storage system will be fabricated and assembled in-house in Vigyan Ashram workshop, my final project board will be designed, milled and assembled at Fab lab. The enclosure for my electronics board will be 3D printed and all other support system for the box if any will be laser cut in the fab lab. The PVC pipe and ventilator fan for ventilation system will be purchased as standard bought-out components from the nearby market.

What processes will be used?

Onion storage system will be fabricated and assembled in-house in Vigyan Ashram workshop, my final project board will be designed, milled and assembled at Fab lab. The enclosure for my electronics board will be 3D printed and all other support system for the box if any will be laser cut in the fab lab. The PVC pipe and ventilator fan for ventilation system will be purchased as standard bought-out components from the nearby market.

|

Click here to go back to the top

What questions need to be answered?

- Will the programming of the inputs make the outputs work correctly or as desired?

- Will the MQ2 gas sensor function the way it needs to be performed?

- Will the ESP32 micro-controller be able send data over internet through it's in-built wifi module? and how fast?

- Which database I can use as a realtime database to collect and push the data to my application.

How will it be evaluated?

I will implement my project in Vigyan ashram kitchen and conduct trials. I will monitor temperature, humidity and gas sensor data that has been collected and analyze the same. I will keep on making minor changes based on this evaluation.

For next spiral and further project development, I will work with Vigyan Ashram fab lab team.