Assignment#18: Project Development

My final project name ('Low cost IoT based smart storage system for onions') suggests, it is going to be used by medium-scale farmers and traders, restaurant owners, organizations having a community kitchen, etc. Based on the literature study and considering the need of the community farm that I am a part of, I decided to work on a problem of onion spoilage (onions that are stored in the warehouse for 5-6 months post-harvest).

Basically, if we look in to the problem statement, In India, 40-50% of the onions that are stored post-harvest get spoiled because of many reasons like- Weight loss, sprouting of bulbs, rotting, bacterial and fungal infections. Neck rot (rotting at the neck of the onion), bacterial rot, basal rot (fungus infection through wounds and scars at the base of the bulb) and other diseases are resulted out of improper storage.

In developing countries like India, proper handling and unscientific ways of storage is a matter of great concern. Onions are stored in poorly ventilated temporary structures. Each farmer has created their own storage method based on their needs, experience and resources available. These unscientific ways of storage result in higher losses in storage. Actually, losses start immediately after harvesting. The facility of onion storage post harvesting needs to be made available right at the time of sowing of seeds itself.

This project is developed to solve the storage related spoilage, rotting and losses through a cost-effective, IoT based smart mechanism of post-harvest onion bulk storage. The onions need to be stored in well ventilated area. My idea is to measure the temperature, humidity in and outside the storage room along with measuring the levels of Methane gas emmitted by onions stored. More the level of methane means the onions have started rotting. Upon measuring and monitoring the humidity, temperature and the methane concentration, the storage house will be ventilated and aerated sufficiently to keep the produce dry and cool. The system will also send notifications on temperature, humidity and methane gas level detected through web-based IoT channel and also through application developed as shown in the image below.

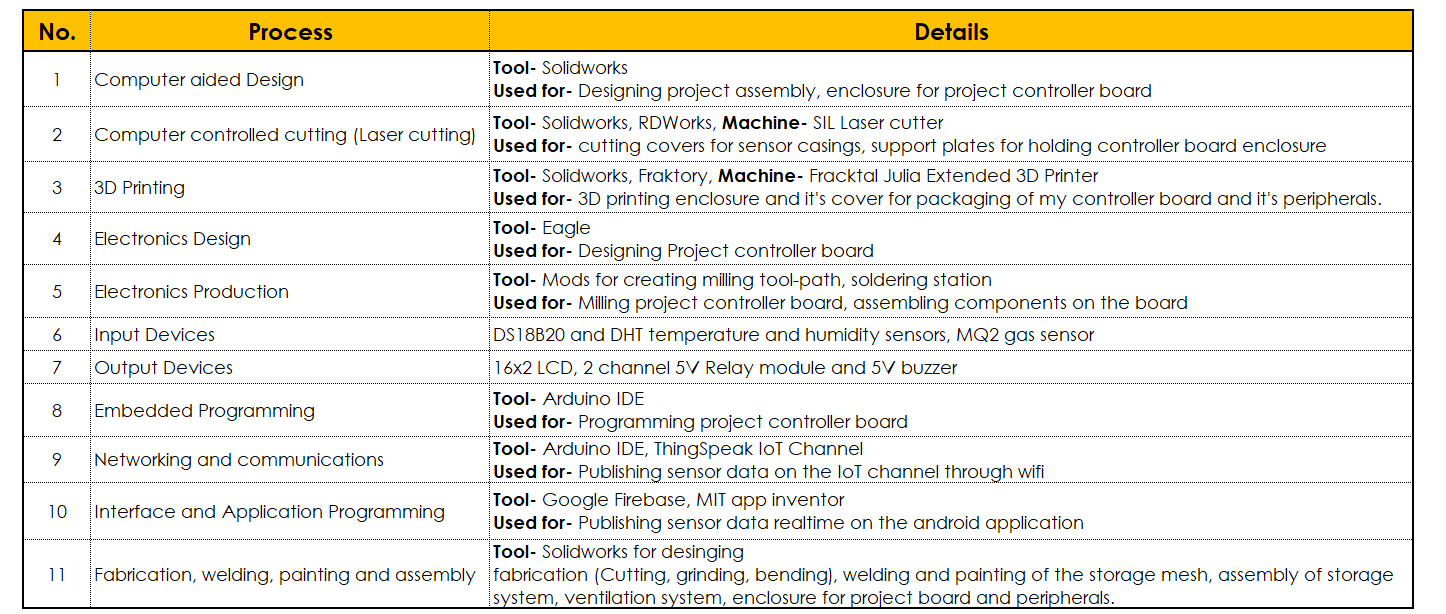

As per the essential requirements for the final project, it should consist of processes/ systems:

|

This week I needed to work on the final project and document the progress of my work.

Click here to go back to the topWhat tasks have been completed, and what tasks remain?

- 2D and 3D CAD modeling of various parts and the project assembly is completed.

- The laser cutting and 3D printing work is in progress and it will be completed by end of this week.

- PCB design and soldering is completed.

- Embedded Programming has been completed.

- All the electronic peripherals used in the project were tested with programming using a developed PCB board.

- ThingSpeak IoT channel has been setr-up and android application has also been completed.

- Fabrication and assembly onion storage is remaining.

- System integration is remaining.

- Final installation and testing is remaining

What has worked? what hasn't?

- The final project microcontroller board is working very well.

- All the peripherals (input and output devices) are working well except MQ gas sensor.

- Embedded Programming has been working well.

- Data on ThingSpeak is getting published and application is also working well.

- MQ2 sensor is not working the way it needs to be working.

- Fabrication of assembly is taking time.

What questions need to be resolved?

- Why does the MQ2 sensor give garbage value sometimes?

- How can I fix my LCD screen from giving garbage values when the relay is getting activated?

- How can I increase the speed of data upload on ThingSpeak?

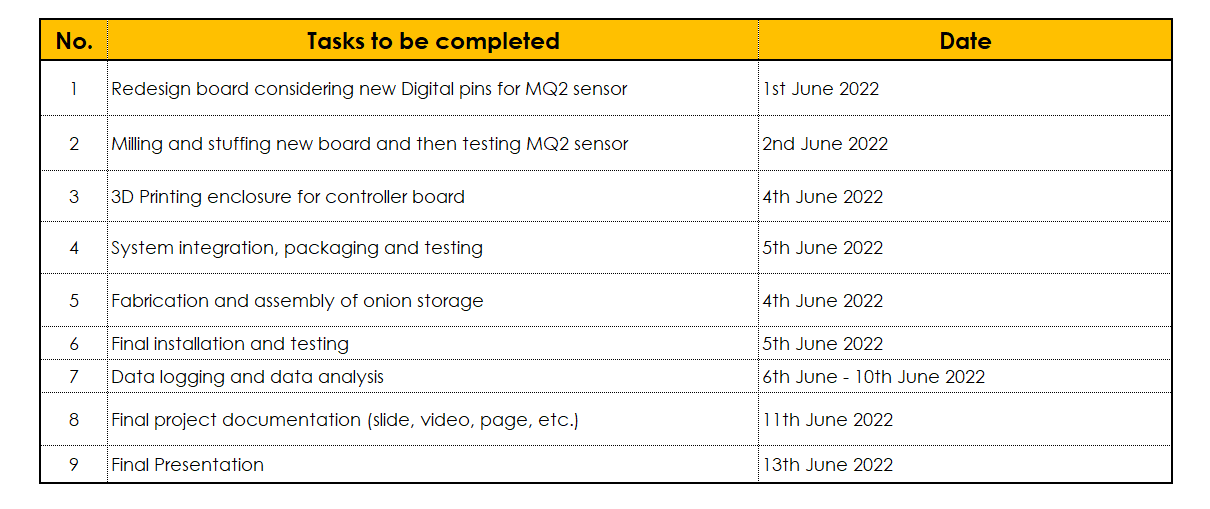

What will happen when?

|

Click here to go back to the top

What have you learned?

- I learned how to develop my own website and how to document my work.

- I was good at CAD, CAM but I was a beginner in the areas of electronics, I learned electronics from very beginning and I could learn till how I can design, mill, assemble and program my own PCB

- I learned quite a lot while designing my electronics board in eagle specifically about selection of parts in sketch, routing the traces in board file and how to make boards compact.

- I learned how to operate laser cutter and 3D printer machine effectively

- I learned embedded programming and different languages for embedded programming. I also learned about different development boards other than Arduino like, ESP32, Raspberry pi, etc.

- I learned application development

- In Machine week, I learned how to integrate assembled machine together along with the electronics and controller part. I also learned how to develop GUI using pronterface

- In wild card week, I learned how to operate plasma cutting machine

- While fabricating and assembling onion storage, I learned various fabrication tools like grinder, cutter, etc.

- This course taught me to prepare a detailed plan from idea generation to final prototyping and how to disseminate it to the target audience along with IPR, marketing plan, business model, financing, etc.

- Along with these technical skills, I learned how to manage time effectively and smartly

- And last but not the least- How to work in a team