Project Development

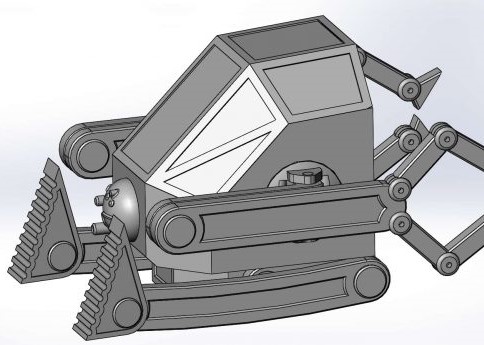

I'm almost done with my final project at this point. Only slight modifications have been made to the concept I presented in week 1 overall. The same idea and goal are still being worked on. I will describe this week the progress I have made on my final project.

What tasks have been completed, and what tasks remain?

The tasks for creating my final project are shown in the table below.

| Task | Percent Completed |

|---|---|

| Concept and purpose | 100% |

| Adopt how it works | 100% |

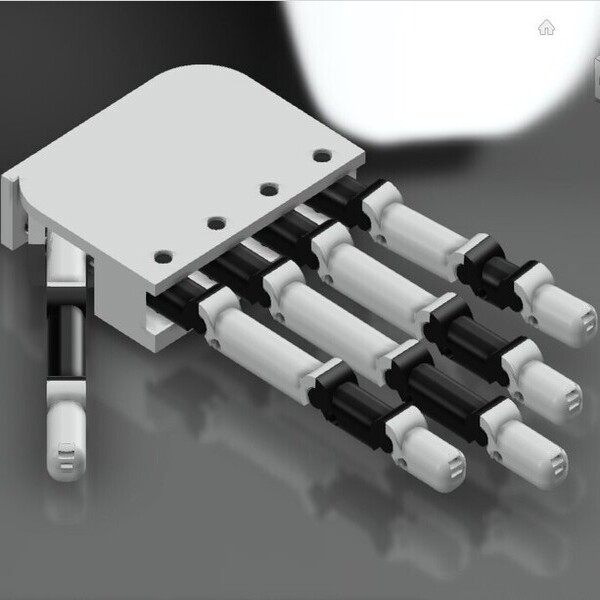

| 3D printing | 100% |

| components selection/td> | 100% |

| Assembly | 80% |

| Movement Testing | 100% |

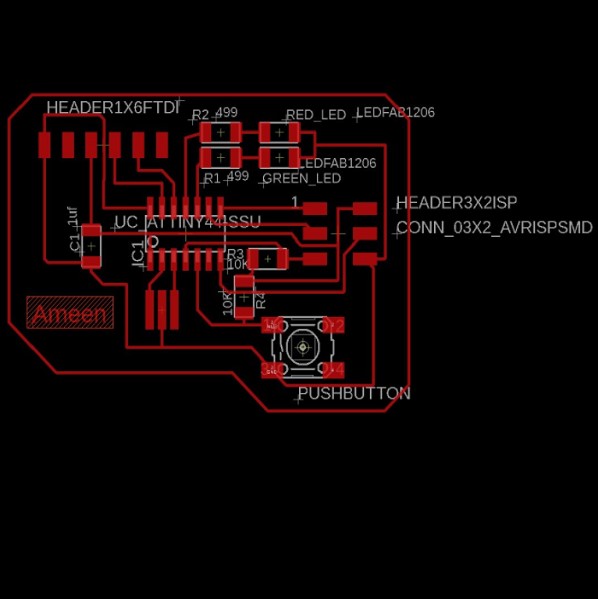

| Schematic design | 100% |

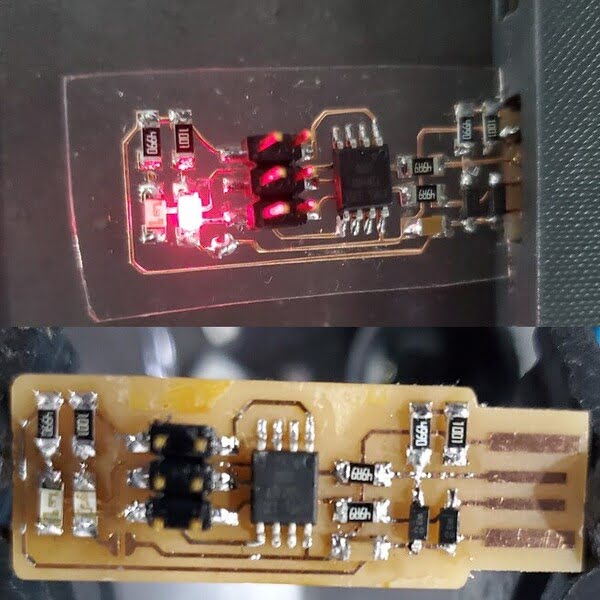

| PCB design | 100% |

| PCB milling and soldering | 100% |

| PCB Testing | 100% |

| Writing the Codes | 20% |

| Testing system Operation | 100% |

| Molding and Casting | 100% |

| Sewing | 100% |

| Documentation | 30% |

What has worked? what hasn’t?

Tasks with full completion work well. Up to this point, nothing has failed. Progress on thask that are partially completed in progressing . There were various challenges with the Code, the connection between the real and prosthetic hands, choosing the right rubber and string, sensor calibration, and string friction with nylon , but everything going fine .

What questions need to be resolved?

At this stage, the code is the subject of almost all the questions that need to be answered,This hand comprises 15 motors and relies on an EMG signal, which is a signal that originates from the muscles, making it exceedingly difficult to control because it has so many distinct motions. The tool must be user-friendly and simple to use so that users may gain the desired results from it.

What will happen when?

The following tasks need to be finished as the next phase. -Integration -Writing the codes -Testing system operation -Final project documentation I've already begun coding and testing system functionality (working in parallel). When I finish those two, more work should begin (working is series). I set a goal to complete all tasks, except documentation, by June 12, 2020, which gives me one day to presentation .

What have you learned?

-It has been a rigorous path of learning, acquiring new abilities, and deep understanding. It could be challenging to enumerate all I have learnt, but there are undoubtedly plenty.

-How to select the right way to fabricate parts

-learn about EEG & EMG signal

-It is simple to integrate all of the system's components once they have been developed individually, tested, and verified to function as needed.

-There are always two ways to produce something: an easy method and a difficult way. Don't try harder; try smarter.

-Before beginning to deal with machines, take the time to look, search, comprehend, and create a decent design.

-There is always information that you don't know but that others do. Educate others and exchange knowledge.