Wild card week

Assignment

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it.

With inspiration from my instructor Adriana Cabrera. I attempted to make a soft finger this week.

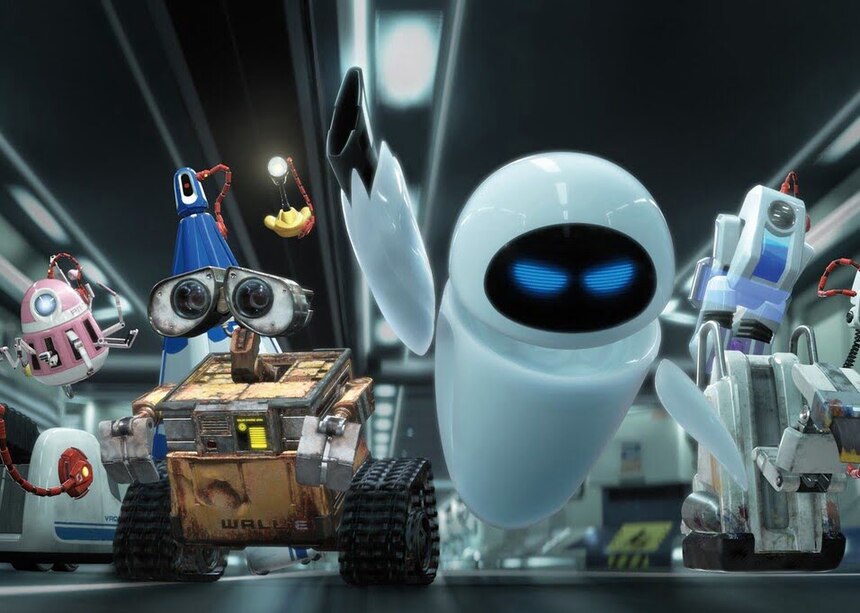

Hero Shot !

Soft Robotics & FlowIO

Soft robotics is a branch of robotics concerned with the design, control, and construction of robots made of flexible materials rather than rigid linkages. Soft robots' compliance, in contrast to rigid-bodied robots made of metals, ceramics, and hard plastics, can improve their safety when working in close proximity to humans.

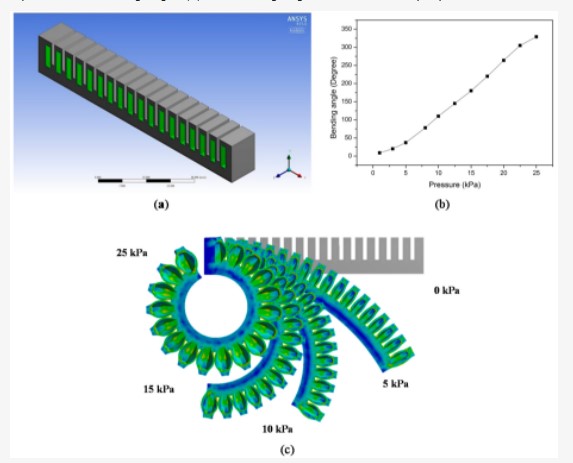

The Structure

The pneumatic actuator described as pneumatic network actuator, which consists of a number of channels placed in a row. The channels expand when the actuator is inflated, causing the actuator to deform in the longitudinal direction. As shown in Figure below, the actuator is made up of two layers: an active upper layer and a passive bottom layer. The active layer deforms when compressed air is injected into the channels, as seen in Figure below . When the input pressure is increased, the deformation and bending angle both increase significantly. Under this pressure range, there is an essentially linear relationship between pressure and bending angle, as shown in Figure below.

Source

FlowIO

"FlowIO is a miniature, modular, pneumatic development platform with a software toolkit for control, actuation, and sensing of soft robots and programmable materials. Five pneumatic ports and multiple fully-integrated modules to satisfy various pressure, flow, and size requirements make FlowIO suitable for most wearable and non-wearable pneumatic applications in HCI and soft robotics. FlowIO includes a software stack with APIs, Bluetooth capabilities, and web-GUI supported on all major mobile and desktop operating systems. The system is fully compatible with Arduino, JavaScript, and Google Chrome, while support for Scratch, Python, and Unity is planned for future development, making FlowIO suitable for makers from any technical background. Over a dozen people have used the FlowIO platform, ranging from high-school and college students to graduate students and researchers."

Source

For more Information

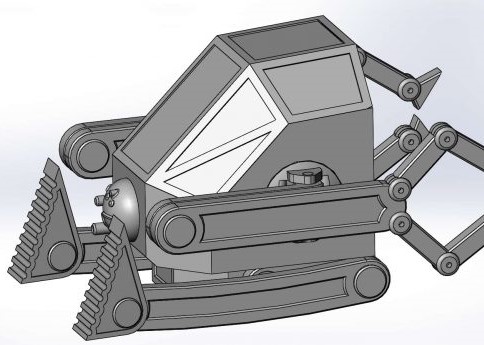

Design

One of the most common designs in soft robots that do bend is Consists of chambers connected to each other through channels to transfer air inside them. These soft robotics work when inflated, the chambers grow up, which leads to elongation at the top of the soft robotics, and the bottom must remain the same length, which leads to bending.This soft robot is made in two molding processes technic.

Download

.f3d

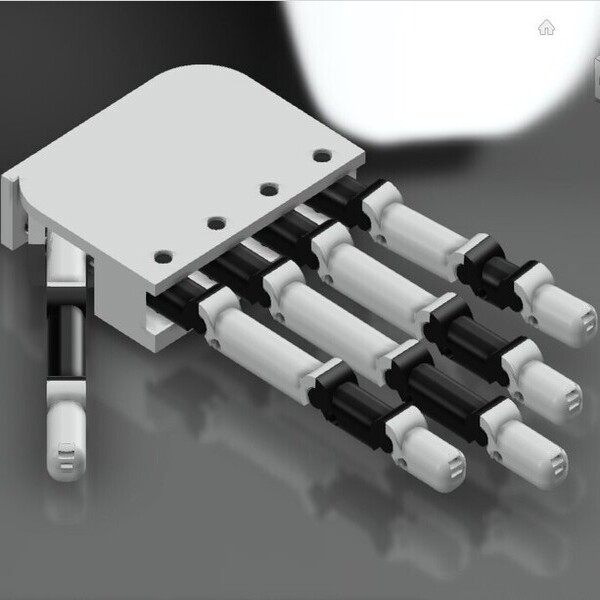

Each finger of the soft robots represents one of the fingers of the hand, so the palm of the hand must be fabricated to collect the fingers

Download

.f3d

The length of the finger can be controlled by hiding a number of compartments

Download

.f3d

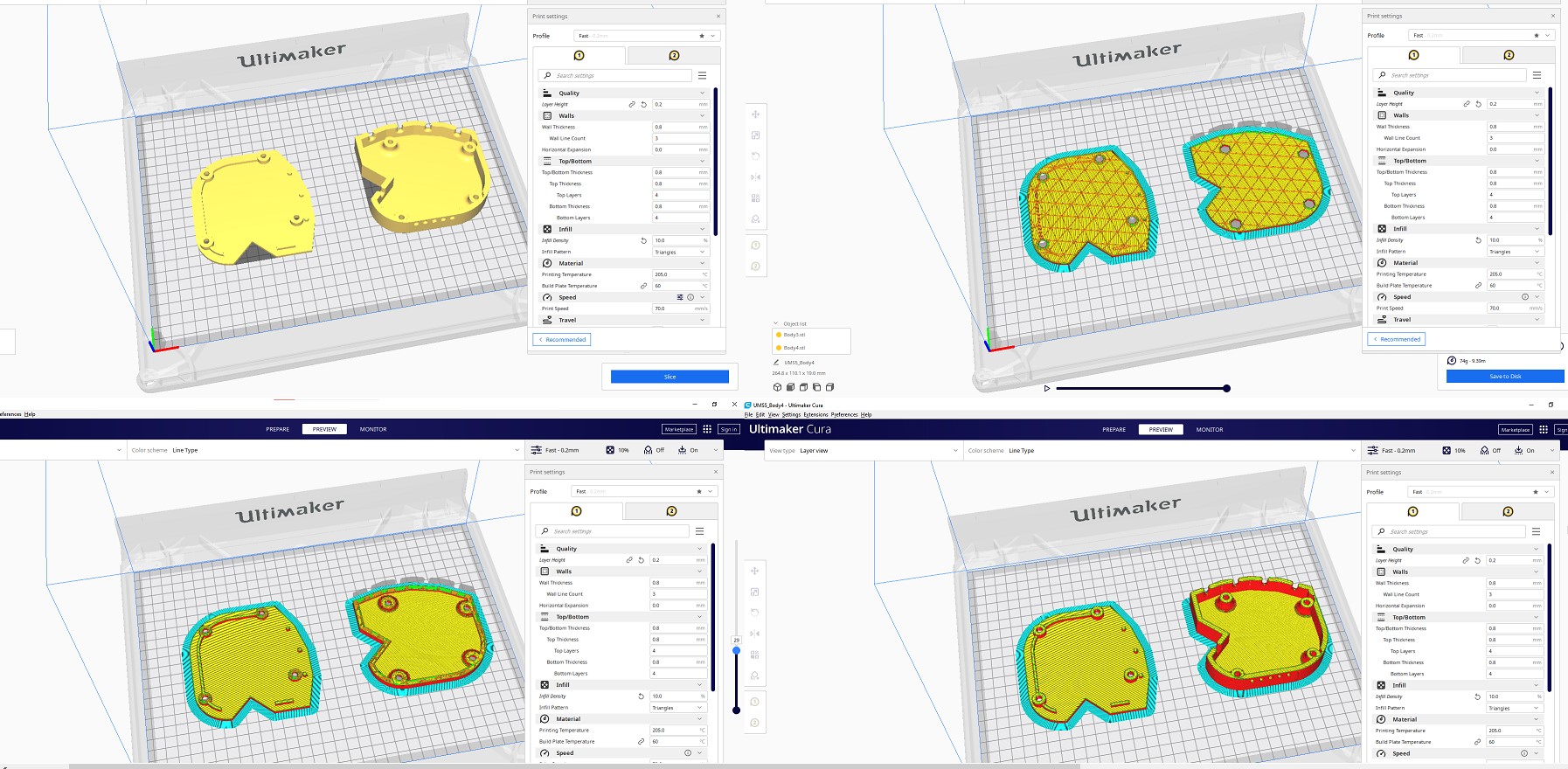

3D Printer

File to Download

plam.3mf

Print the palm of the hand so that you can collect the fingers of Soft Robotics on it

laser Cutter

File to Download

Base of Soft Robotics.rar

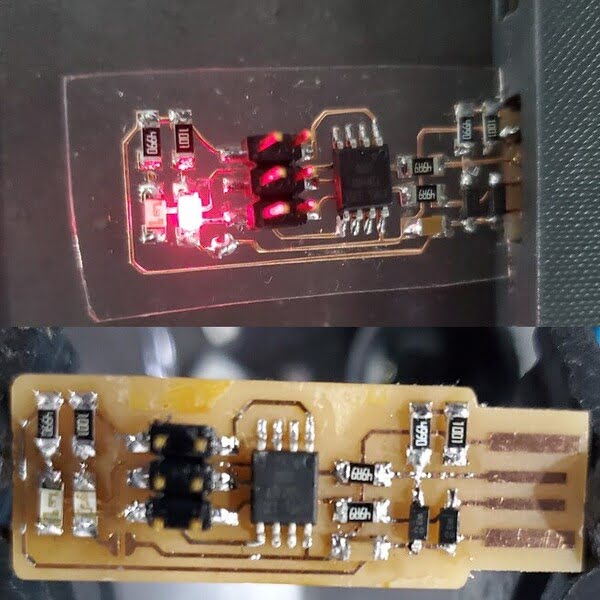

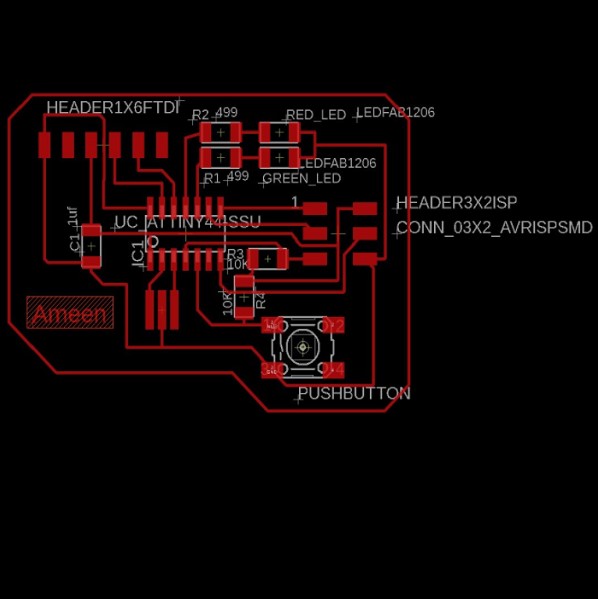

Cut the two pieces on the acrylic using a laser cutter and glue them on top of each other to become like the picture below.

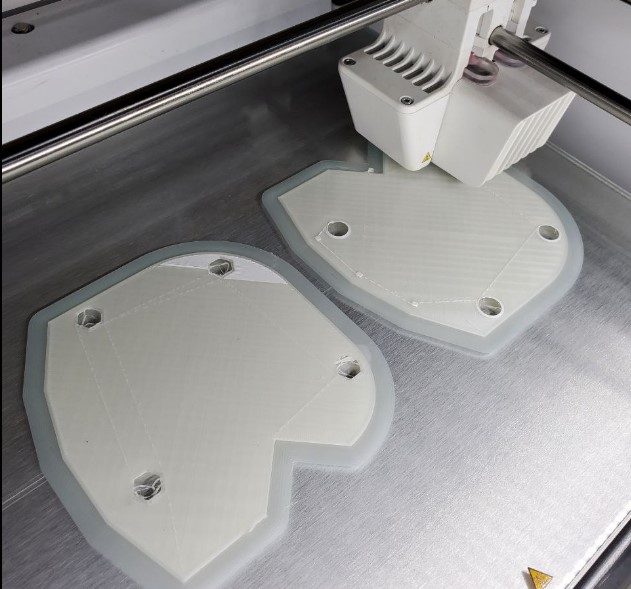

Molding and Casting

For the fabrication of soft robotics fingers, the two pieces( white and blue) must be obtained from Molding & Casting week.

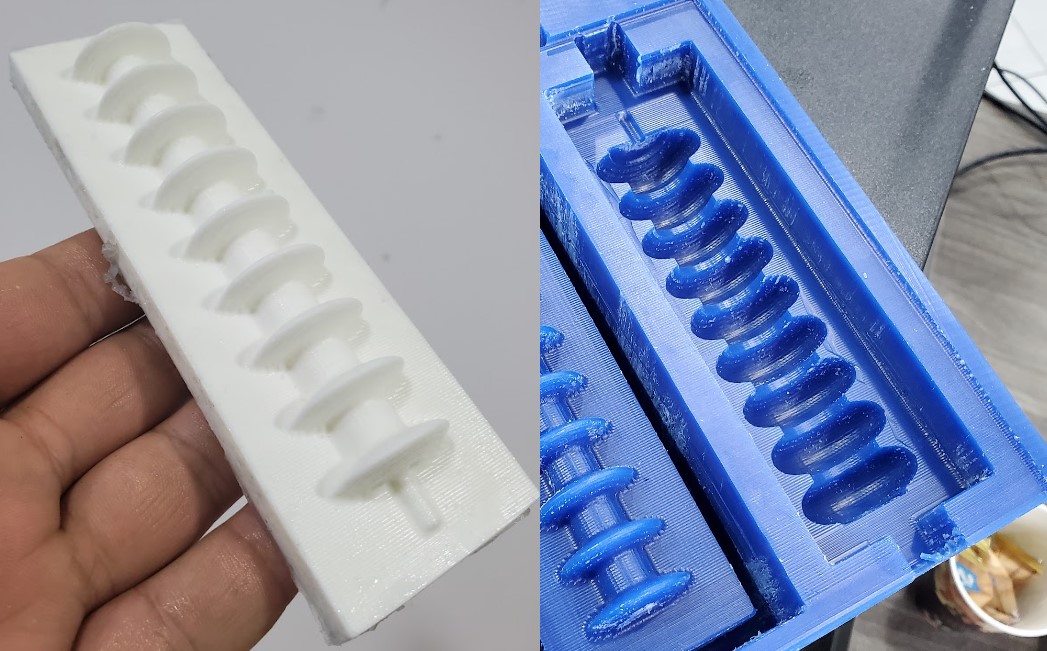

In the beginning, oil must be placed on two mold pieces to prevent the silicone from sticking to it, then we must put fabric threads in the chambers as in the picture to prevent radial movement and make the elongation in the longitudinal direction at the top of the soft Robert finger.

Next, Ecoflex™ 00-30 should be prepared by mixing 20 g of Compound A and 20 g of Compound B, then cast them into a mould, (cast carefully to prevent the fabric threads from moving) Continue casting until the chambers are full.

Now put the top piece of the mold and press it until the silicone comes out from the sides as shown in the picture below, make sure that it has come down to the end and it is level.

Although the time to cure the silicone is four hours, it is preferable to leave it at least 10 hours in the sun to dry completely and adhere with threads.

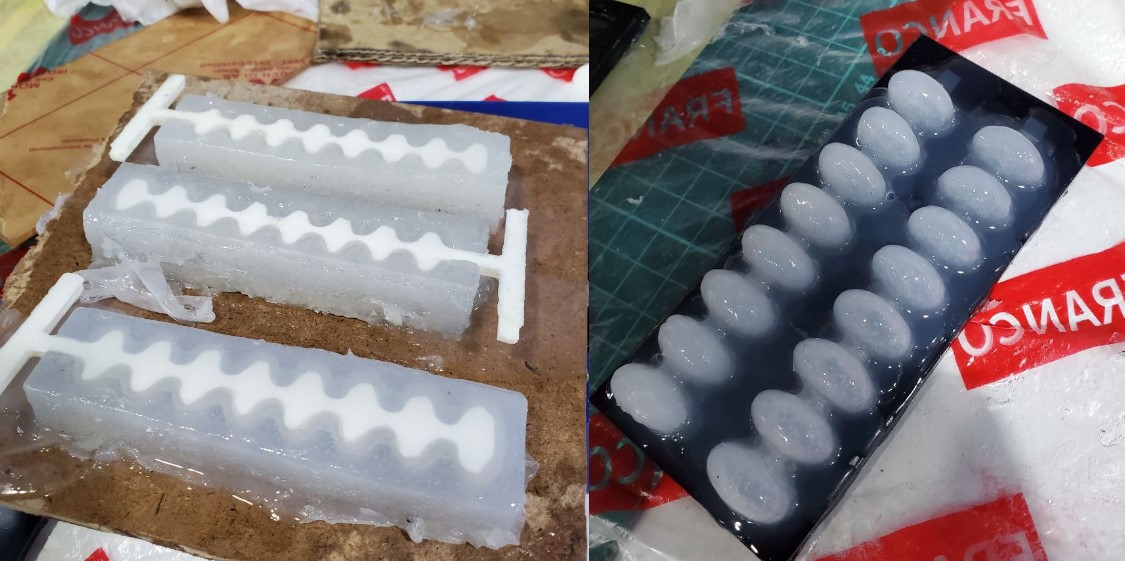

Cut the ends of the silicone and the excess threads with scissors, then put a piece of fabric in the form of the base of the soft robotics inside the second mold, then place the silicone on it, finally put the top part on it as in the pictures below

A very important note: the silicone adhesion area must be cleaned well (use water and alcohol, then dry it well)

Finally, after drying the silicone well, put the pipe in one end and enjoy using Soft Robtics.

Problems Fixed

All the steps have been done since the week of the molding and casting so far, but with a smaller size and less thickness (thickness equal to 2 mm), but it did not work because of the small thickness, as it caused the pressure irregularity resulting from the small difference in thickness between the walls, as It is normal to have a slight difference in wall thickness produced during manufacturing , but these differences have a great impact on the small thicknesses, and their effect disappears with the large thicknesses like 5 mm , Another problem that you will face because of the small thickness that it led to the explosion of the soft robotics in some cases, and the area of adhesion between the upper and lower part is small, which leads to a high Possibility of air escaping from the sticking area but Small thickness may be useful if you are dealing with a material that has a lower elongation coefficient than Eco Flex.

Another problem if you want to cast Ecoflex™ 00-30 on SORTA-Clear™ 18 you should use vaseline if you use oil it will stick to each other, Also, be careful when using Vaseline, as it will collect on the walls and will damage the surface so it must be applied well.

The last problem, and it was like a magic, was that when resin is casting over SORTA-Clear™ 18 silicone, it took days to harden. Although the excess resin that remained in the cup solidified after a quarter of an hour of mixing.