Principles and practices

The Idea

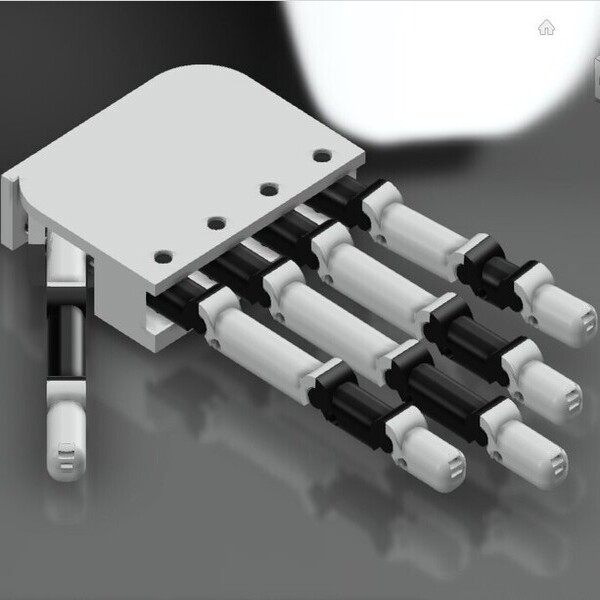

The goal of the project is to give a second chance to people who lost their hands by creating a prosthetic hand that perfectly fits and satisfies their daily needs. The design and fabrication of prosthetic hand can be summarized as follow:

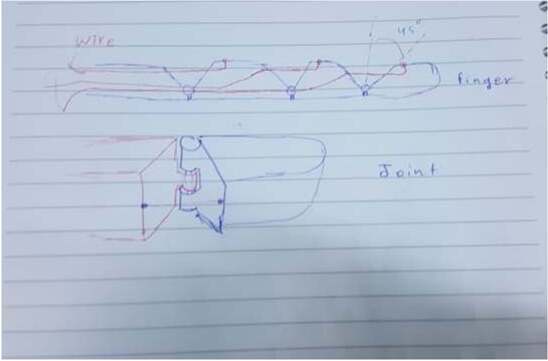

• The main structure will be printed in place, in other words, all parts of the main structure can be fabricated in a single stage using a 3D printer.

• Adjustable size, by connecting parametric CAD file dimensions with parameters that can be easily determined according to the required size.

• Easy to assemble, due to the small number of pieces required to be assembled to obtain the prosthetic limb.

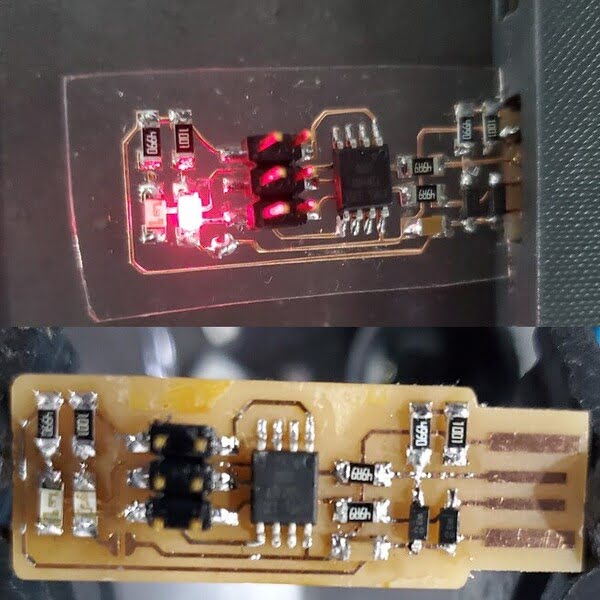

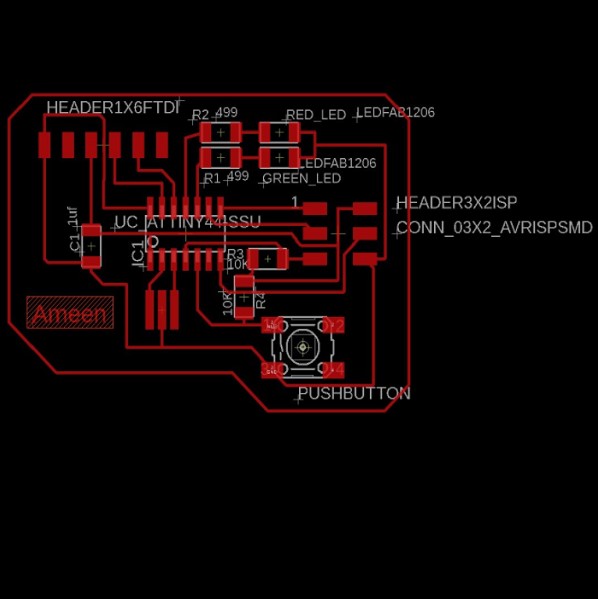

This project will allow anyone to take the design, adjust it to the required size and print it to have the main structure without the need of assembling 50-200 of small parts. The final stage of the project will be to add electronic components to the main structure easily since it was printed in a single stage, and the same components can be used in similar designs with different sizes.

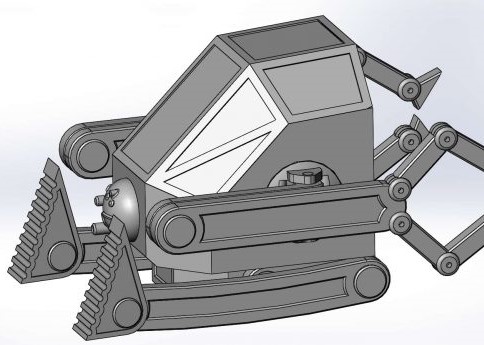

The Design

The prosthetic hand in the figure below was designed using Fusion 360, and motion study was involved to represent the capability and the movements of the prosthetic hand. This design represents the main structure.