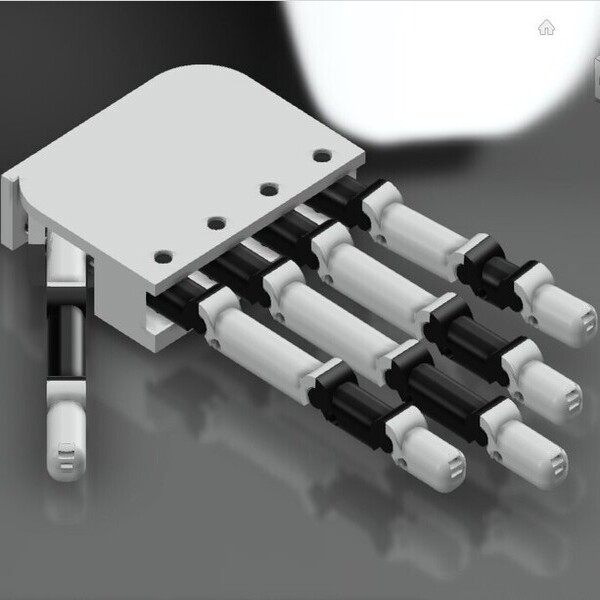

Mechanical Design

Clay Forming MSachine

Clay forming machine is a 4 axis CNC which designed with the motive of automating the process of forming clay, which will give this industry many advantages, the most important of which is accelerating the production process and increasing accuracy, in addition to the possibility of forming clay in ways that cannot be done by human hands . this machine did by 3 of fabacademy students This machine was designed, manufactured and programmed by the efforts of these students

Ameen Yousef: design & fabrication

Ismail Qashoue : fabrication & assembly

Aybak Al-daamsa: programing & assembly

1. The Design

text text

First conceptual design

Second conceptual design

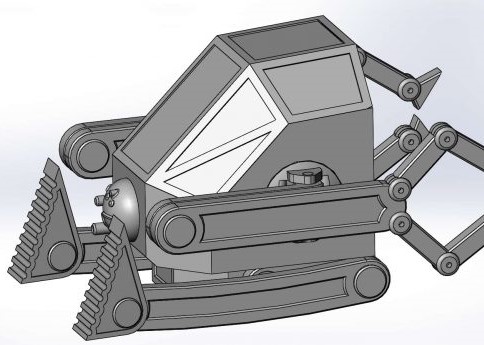

Final Design

3D Printed Part

First mechanism horizontal axis support 1

Download part

First mechanism horizontal axis support 1.f3d

First mechanism horizontal axis support 1.stl

First mechanism horizontal axis support 2

Download part

First mechanism horizontal axis support 2.f3d

First mechanism horizontal axis support 2.stl

First mechanism horizontal axis slaiding part

Download part

First mechanism horizontal axis slaiding part.f3d

First mechanism horizontal axis slaiding part.stl

First mechanism vertical axis sliding part

Download part

First mechanism vertical axis sliding part.f3d

First mechanism vertical axis sliding part.stl

First mechanism vertical axis support

Download part

First mechanism vertical axis support.f3d

First mechanism vertical axis support.stl

First mechanism tool spport

Download part

First mechanism tool spport.f3d

First mechanism tool spport.stl

Second mechanism horizontal axis support 1

Download part

Second mechanism horizontal axis support 1.f3d

Second mechanism horizontal axis support 1.stl

Second mechanism horizontal axis support 2

Download part

Second mechanism horizontal axis support 2.f3d

Second mechanism horizontal axis support 2.stl

Second mechanism horizontal axis slaiding part

Download part

Second mechanism horizontal axis slaiding part.f3d

Second mechanism horizontal axis slaiding part.stl

Second mechanism vertical axis sliding part

Download part

Second mechanism vertical axis sliding part.f3d

Second mechanism vertical axis sliding part.stl

Second mechanism vertical axis support

Download part

Second mechanism vertical axis support.f3d

Second mechanism vertical axis support.stl

Second mechanism tool spport

Download part

Second mechanism tool spport.f3d

Second mechanism tool spport.stl

Second mechanism tool

Download part

Second mechanism tool.f3d

Second mechanism tool.stl

Big motor support

Download part

Big motor support.f3d

Big motor support.stl

CNC part

Big bearing support

Download part

big bearing support.f3d

big bearing support.stl

Disk

Download part

Disk.f3d

Disk.stl

Disk support

Download part

Disk support.f3d

Disk support.stl

arc

Download part

Arc.f3d

Arc.stl

Turning & Miling

Download part

Shaft.f3d

Shaft.stl

Download part

Shaft.f3d

Shaft.stl

Mechanical part

Download part

BIG Bearing .f3d

BIG Bearing .stl

Download part

Sprocket.f3d

Sprocket.stl

Download part

SCROW NUT.f3d

SCROW NUT.stl

Download part

Block bearing.f3d

Block bearing.stl

Download part

Linear Bearing.f3d

Linear Bearing.stl

Download part

Secrw 600/500/400 mm.f3d

Secrw 600/500/400 mm.stl

Download part

Rod 500/470/400.f3d

Rod 500/470/400.stl

Download part

Aluminum frame.f3d

Aluminum frame.stl

Electrical part

Download part

Big motor .f3d

Big motor.stl

Download part

Steppar motor.f3d

Steppar motor.stl

Download part

Limit swich .f3d

Limit swich.stl

2. Fabrication

Assimbly

Assimbly

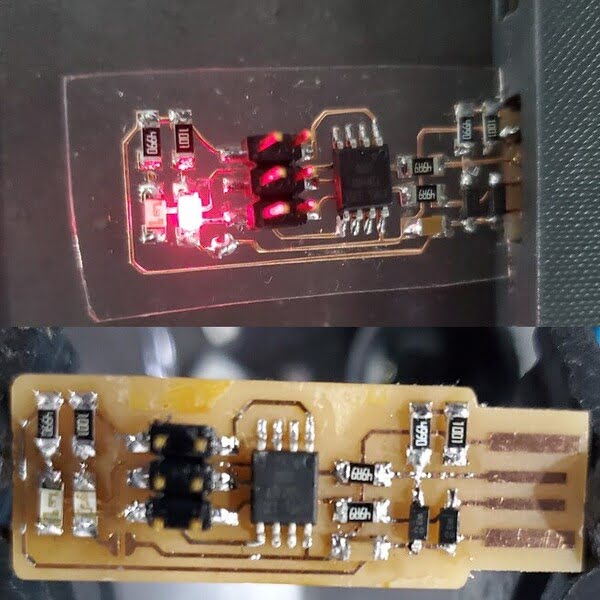

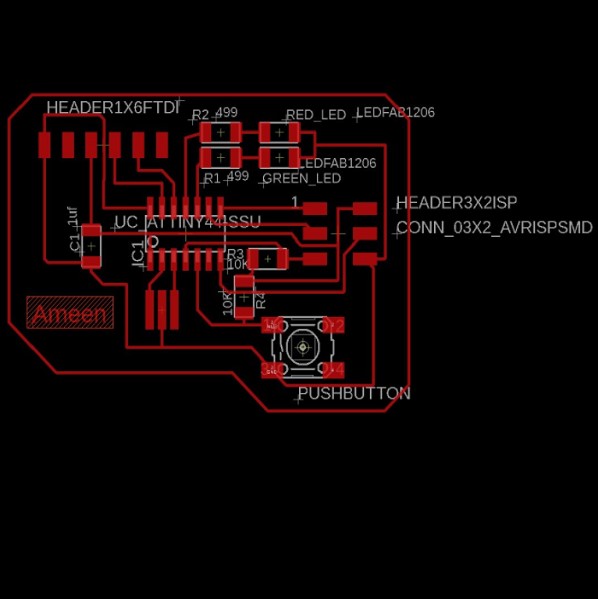

3. Electronics part

this is the bill of material for electronics components from a local supplier

- ARDUINO CNC SHIELD V3

- ARDUINO UNO - R3

- STEPSTICK A4988 STEPPER DRIVER

- STEPPER MOTOR ( NEMA17 ) 17HS4401

- ENDSTOP MECHANICAL LIMIT SWITCHSTEPPER MOTOR

- DC MOTOR MY6812 24VSTEPPER MOTOR

- 43A H-BRIDGE DRIVE BTS7960

- 24V 15A POWER SUPPLY

- 12V 15A AC DC ADAPTER POWER SUPPLY

wiring

basically we have two separate systems, one for outer geometry and the other for inner geometry so we need two controllers (Arduino UNO) with shields and 4 stepper motor drivers.

to control the disk speed we use a DC motor driver and this driver is capable to deal with 27V 43A which is the best choice for our system because we have a 24V 8A DC motor so this driver will handle the starting current safely which is 4 to 8 times the normal current

so let's start with the inner and outer axis we connect the stepper motors to the X and Z axis and the stepper driver to the same place so but make sure that the stepper driver is connected with the right orientation otherwise it will damage ( match the enable pins to each other and all the pins will be matched by automatically )

then connect the power supply cables to the 12V power supply, repeat this process for the inner and outer axis

4. Programing

Based on the CAD we have 4 axis machine, 2 axes for inner geometry and 2 axes for outer geometry also we have a high-speed DC motor for the clay disk.

GRBL

in order to program this machine, we consider the inner axis is separated from the outer axis. the DC motor will be controlled by PWM and adjusted by a variable resistor to provide the proper speed as needed.

so let's start with the main firmware for the system we use GRBL firmware which is a no-compromise, high-performance, low-cost alternative to parallel-port-based motion control for CNC milling. It will run on a vanilla Arduino (Duemillanove/Uno) as long as it sports an Atmega 328.

to install GRBL go to this GitHub repository then download the ZIP file

then we have to extract the ZIP and go to Arduino IDE to add the GRBL library go to sketch>>include library >>add .ZIP library then chose the file that you extracted it with name grbl

now let's upload the firmware on Arduino Uno go to file>>examples>>grbl>>grbl upload

upload the firmware

UGS

to control the CNC shield we need a software that gives instructions to the motors and by sending the g-code line by line to the Arduino Uno, there are several we choose Universal Gcode Sender UGS because is a self-contained Java application that includes all external dependencies and can be used on most computers running Windows, MacOSX or Linux.

so go to download page and install the UGS based on your operating system

after file extracting go to the bin folder then start ugsplatform64.exe and the UGS will open up

now let's connect to the Arduino so select GRBL firmware then select the COM number for your Arduino and the baud rate must be 115200

if the Arduino connected you will see the following lines on the console

Testing

6. Masterpiece