12. Mechanical design / Machine design¶

Instruction¶

1.1 Mechanical Design (part 1 of 2)¶

Group assignment: Design a machine that includes mechanism + actuation + automation Build the mechanical parts and operate it manually. Document the group project -> FabLab Armenia Dilijan and Fablab Kannai Group Page

Individual assignment:Document your individual contribution. -> in this page

1.2 Machine Design (part 2 of 2)¶

Group assignment:Actuate and automate your machine. Document the group project -> FabLab Armenia Dilijan and Fablab Kannai Group Page

Individual assignment:Document your individual contribution. -> in this page

Briefing¶

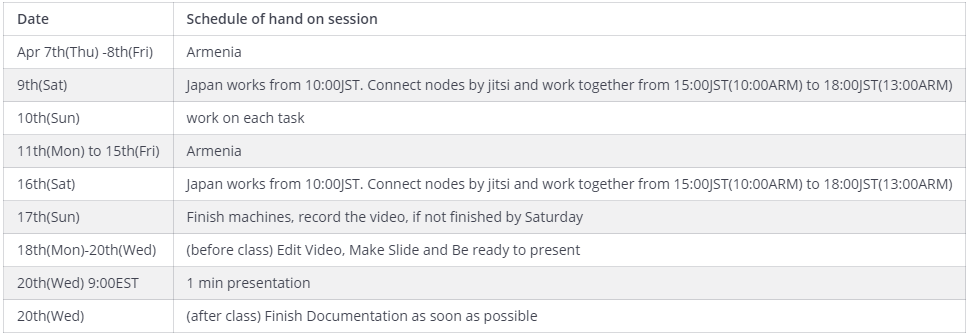

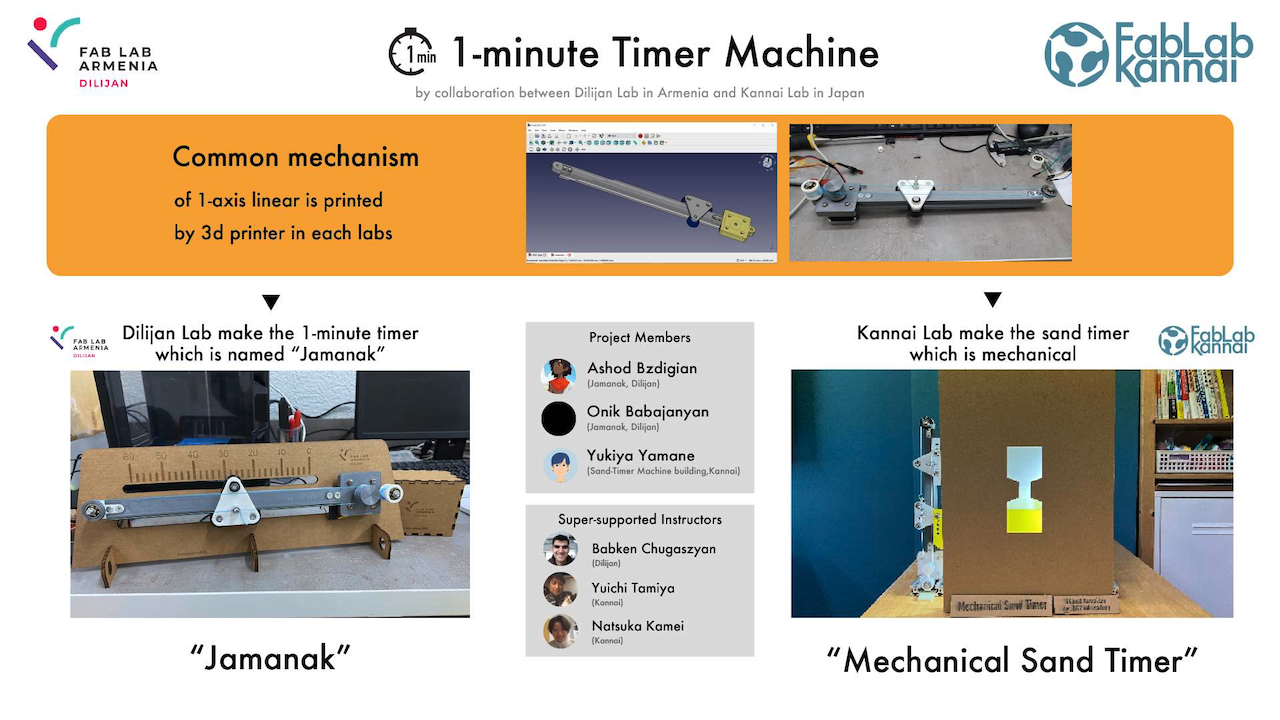

We decided to collaborate with Dilijian, Armenia for this assignment.

First we created a group in Mattermost to keep in touch and to upload different content for us.

We started dividing the time with a schedule, so we would have a tidy process.

And as well, we had regular meetingsx

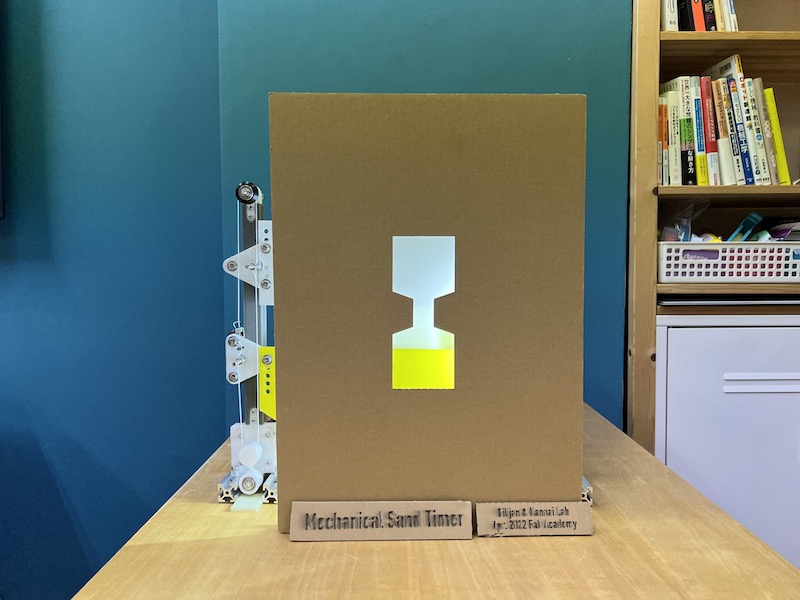

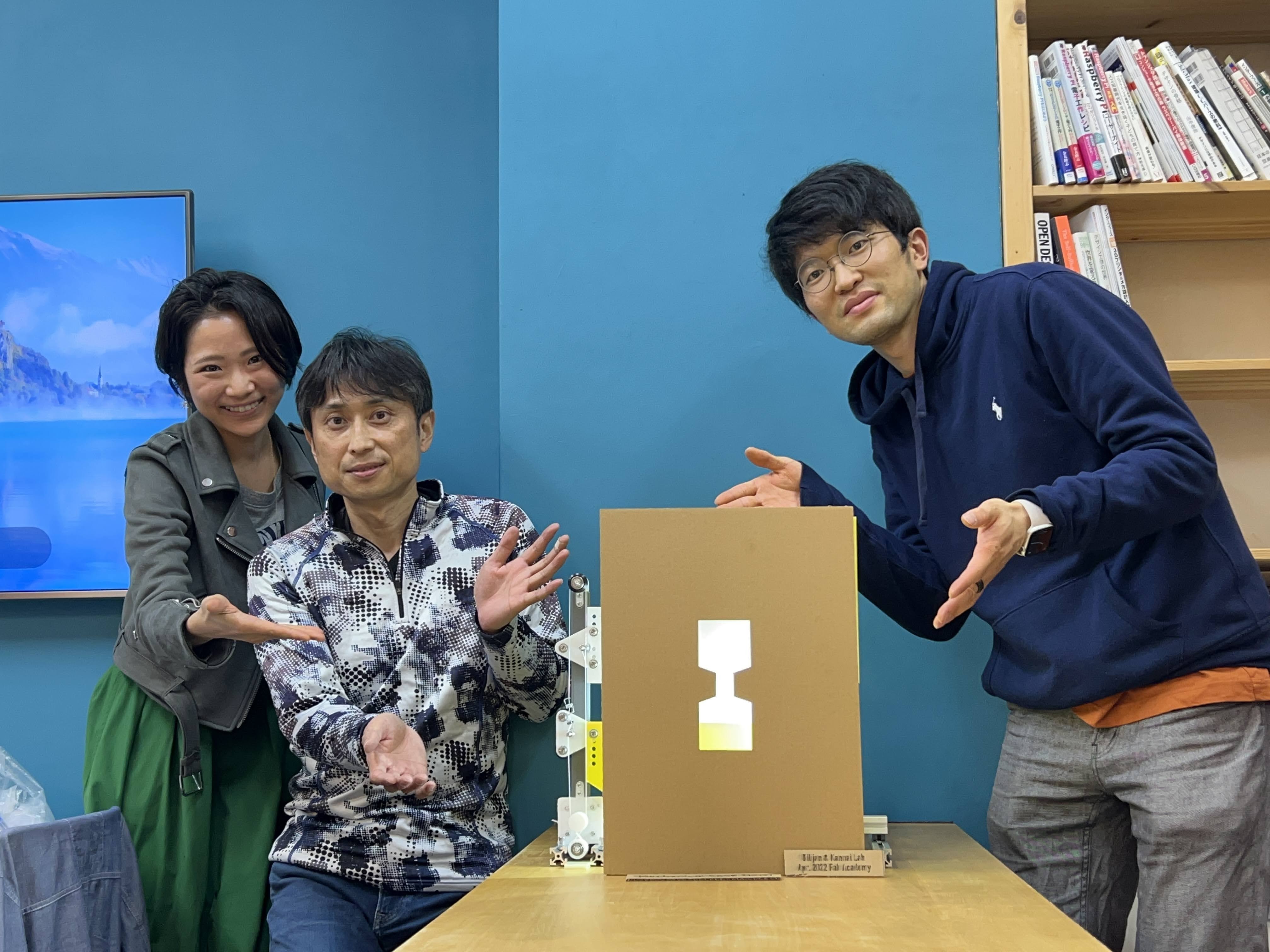

Final Product¶

Details are written in **Dilijian-Kannai Group Site.**

Design Process¶

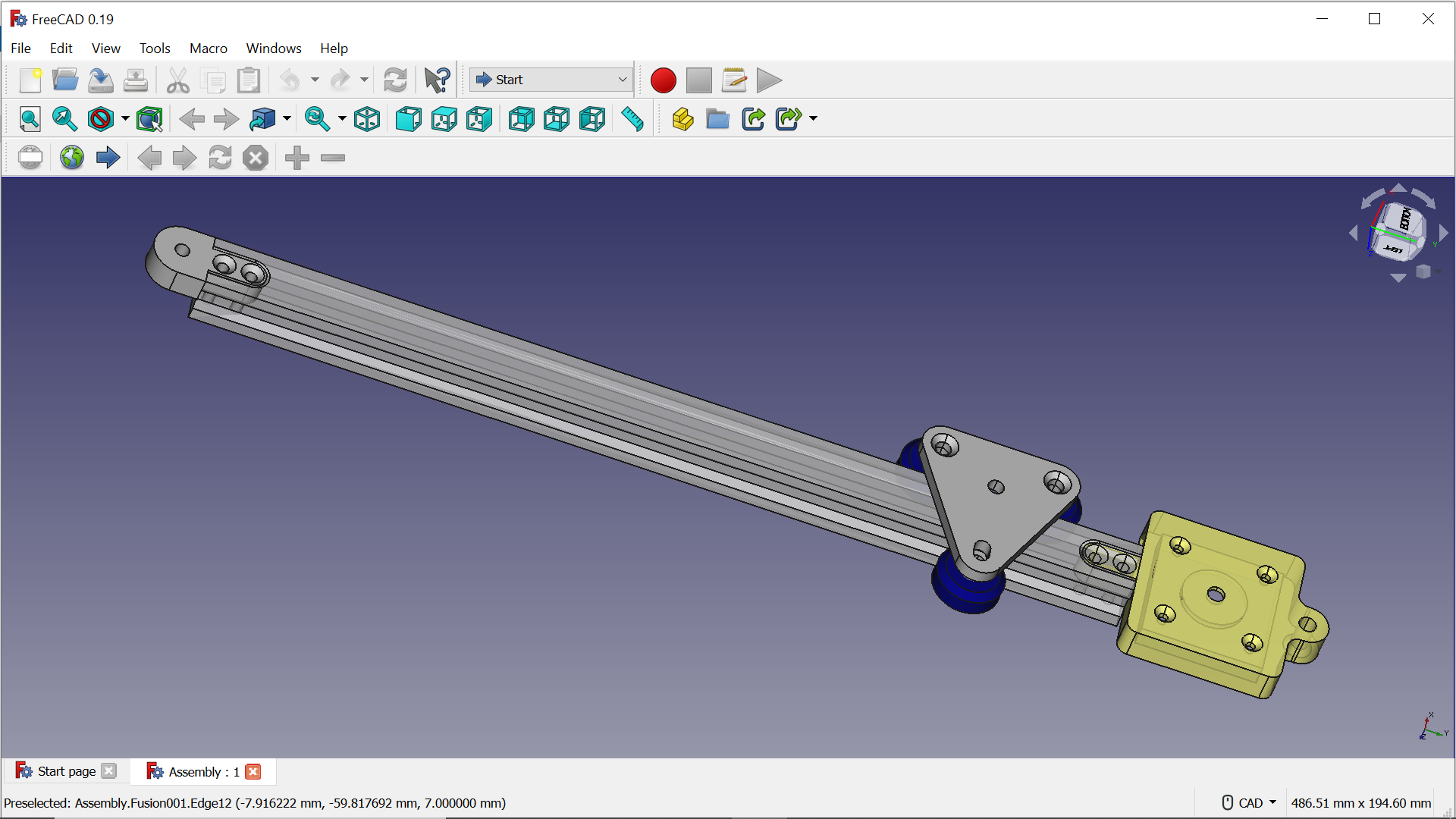

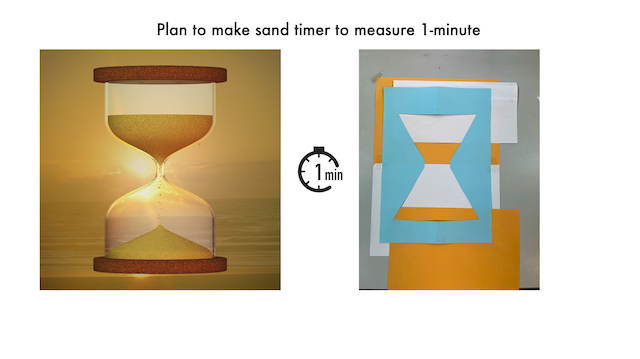

It was decided that the 1 liniar axis moving parts to be output by 3D printing would be common parts with the lab. We decided to use that common component to build a timer that would measure one minute in each of the two labs.

Building Process : Common parts with Dilijian Lab¶

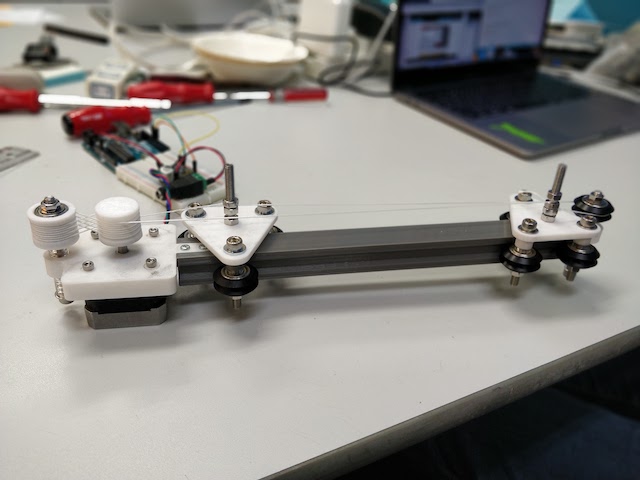

- Our common parts of 1-axis linear between in Dilijan lab and in Kannai lab

- which are 3d printable parts

- We usedCommon axis parts by 3d printer

Extrusion Rail (Meshed)_250mm.stl

Carrier with ribs (Meshed).stl

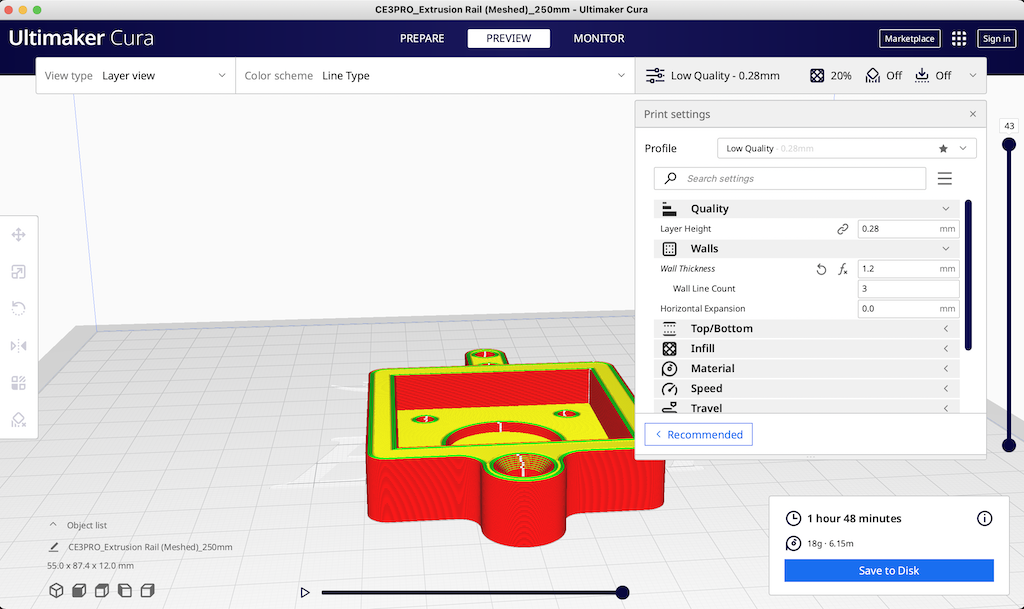

Due to the size limitation of the 3D printer

Extrusion rails only 280mm → 250mm

Transform 3d data to g-code by Cura

Low quality

Walls Wallthickness 1.2mm

Infill 20% cubic

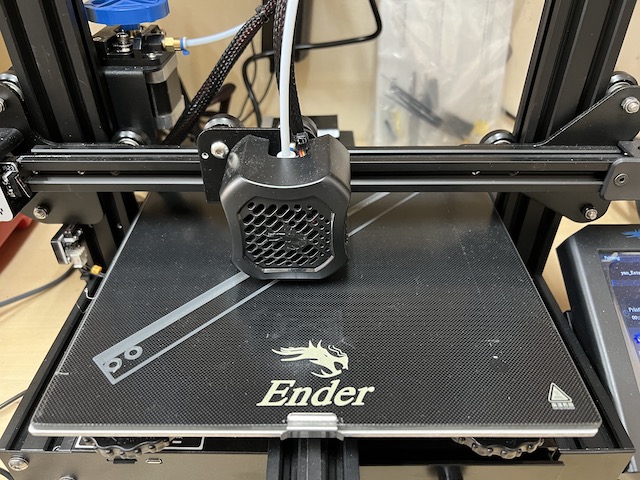

- 3D printed to make parts by Ender

- stepper motor

We decided to use this stepper motor

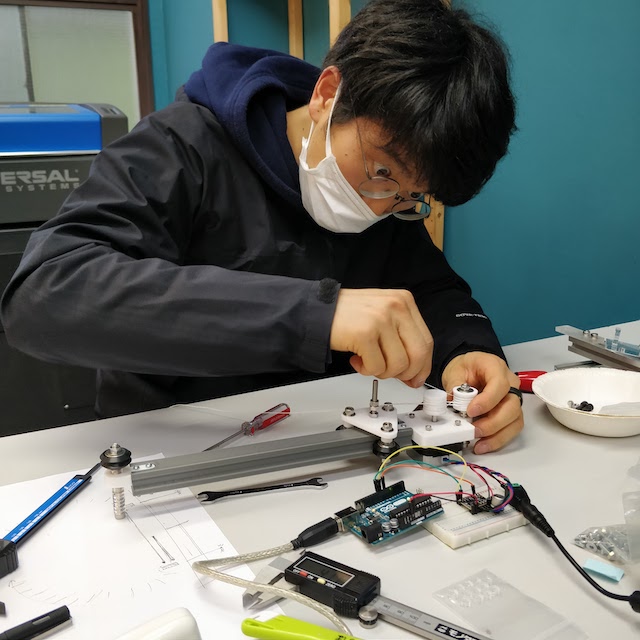

- Assembling

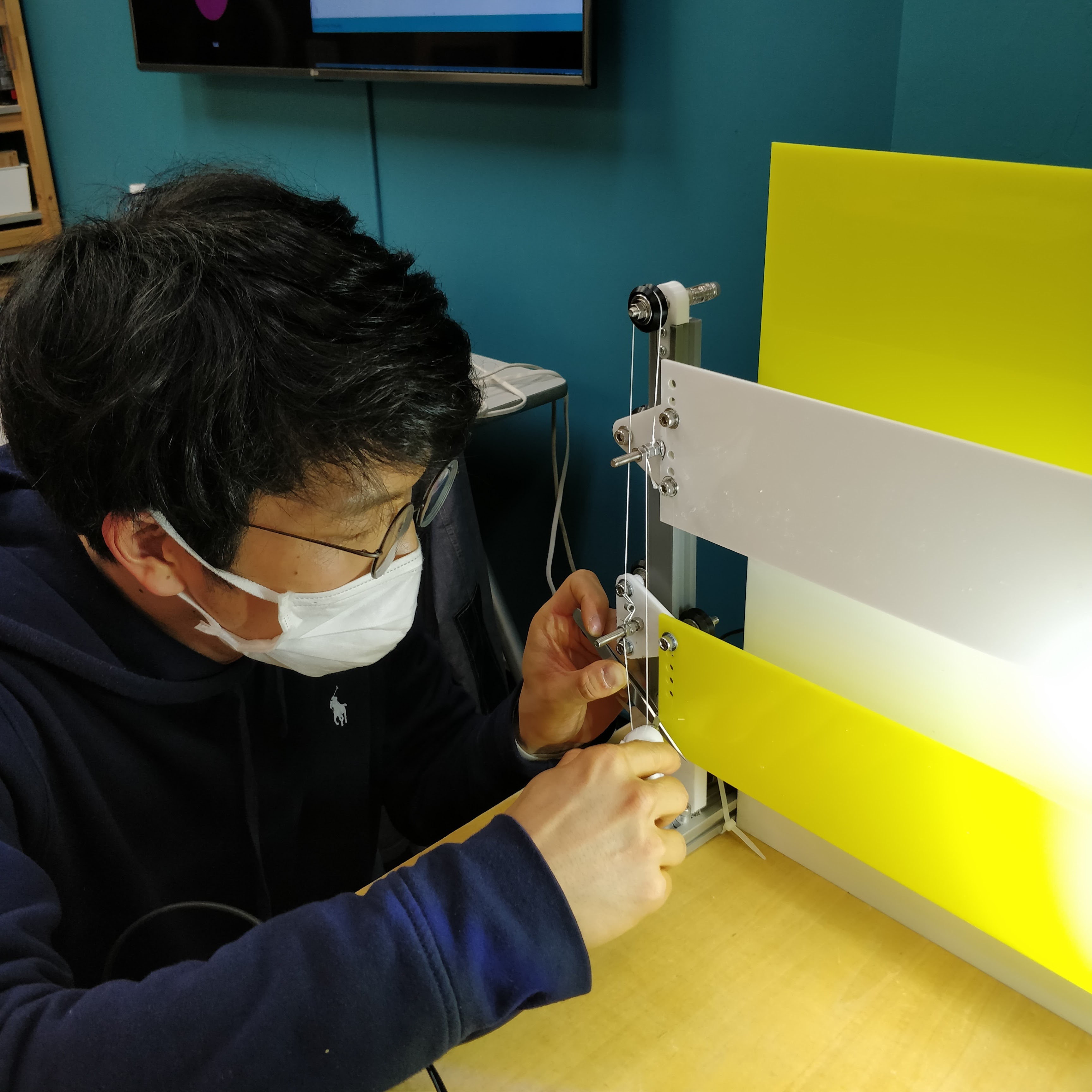

The kite string was wired to create the mechanism carefully.

- finish to make the common parts with Dilijan Lab

- Moving Test

Programming¶

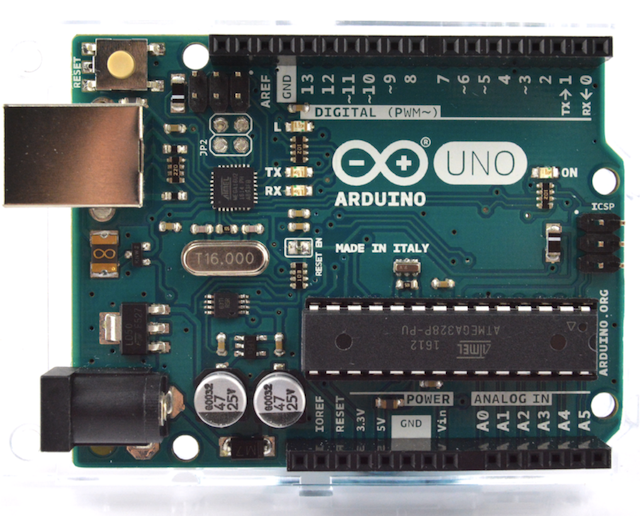

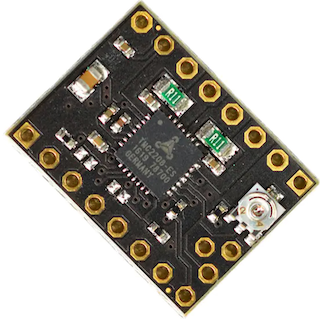

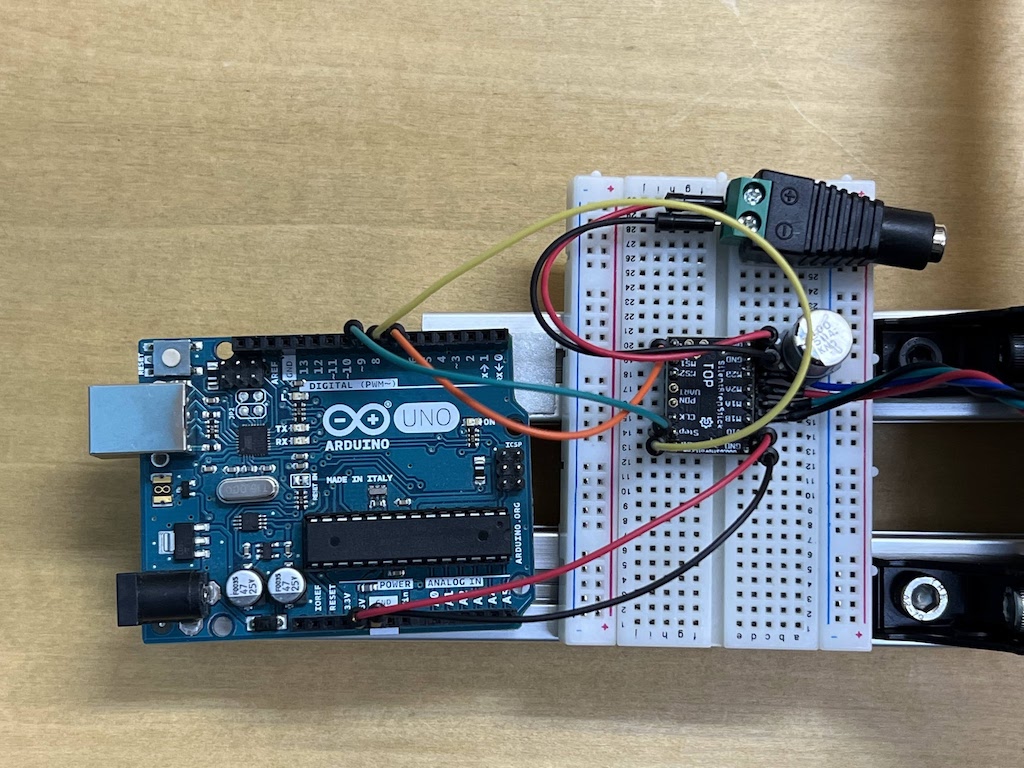

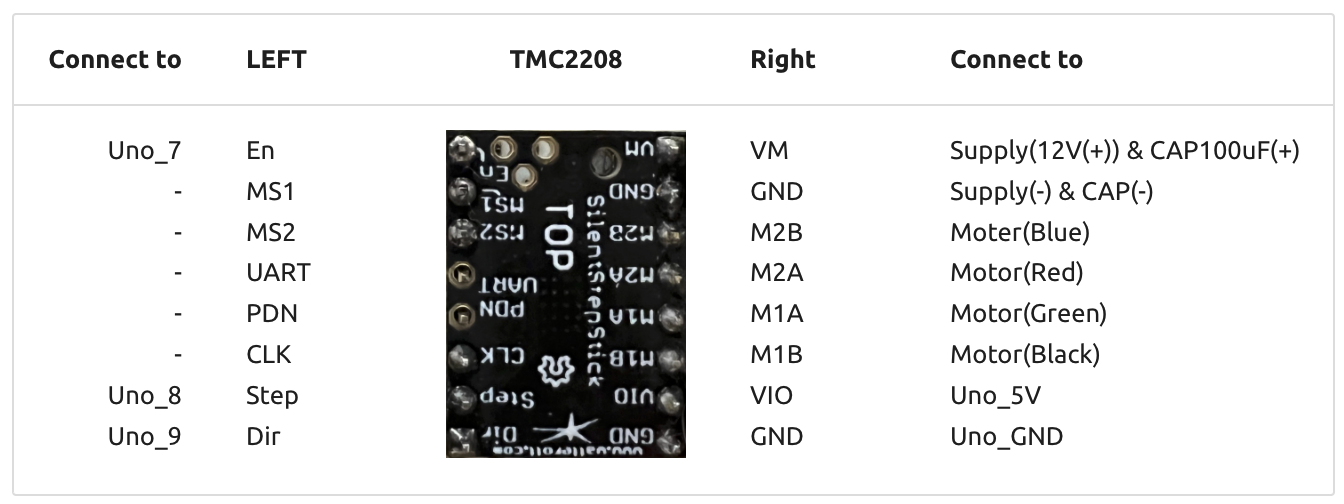

We decided to use Arduino Uno to control the move of the stepper motor. To use it, I connected Arduino Uno to Stepper Motor Driver TMC2208 refering to this Kannai Lab’s instruction Page.

Arduino uno

Stepper motor Driver TMC 2208

Connection

Test 1 : Move to 1 direction¶

Ref. GitHub project page

Download TMC220X.ino from here

/*

SilentStepStick TMC2208/TMC2209 Example

Rsense: 0.11 Ohm

Other examples/libraries can be found here:

https://github.com/teemuatlut/TMCStepper

https://github.com/trinamic/TMC-API

https://github.com/manoukianv/TMC2208Pilot

Example source code free to use.

Further information: https://learn.watterott.com/license/

*/

// Note: You also have to connect GND, 5V/VIO and VM.

// A connection diagram can be found in the schematics.

#define EN_PIN 7 //enable (CFG6)

#define DIR_PIN 8 //direction

#define STEP_PIN 9 //step

void setup()

{

//set pin modes

pinMode(EN_PIN, OUTPUT);

digitalWrite(EN_PIN, HIGH); //deactivate driver (LOW active)

pinMode(DIR_PIN, OUTPUT);

digitalWrite(DIR_PIN, LOW); //LOW to CCW

//digitalWrite(DIR_PIN, HIGH); //HIGH to CW

pinMode(STEP_PIN, OUTPUT);

digitalWrite(STEP_PIN, LOW);

digitalWrite(EN_PIN, LOW); //activate driver

}

void loop()

{

//make steps

digitalWrite(STEP_PIN, HIGH);

delay(2);

digitalWrite(STEP_PIN, LOW);

delay(2);

}

It worked well.

Test 2 : Move back and forth¶

arrange code

/*

SilentStepStick TMC2208/TMC2209 Example

Rsense: 0.11 Ohm

Other examples/libraries can be found here:

https://github.com/teemuatlut/TMCStepper

https://github.com/trinamic/TMC-API

https://github.com/manoukianv/TMC2208Pilot

Example source code free to use.

Further information: https://learn.watterott.com/license/

*/

// Note: You also have to connect GND, 5V/VIO and VM.

// A connection diagram can be found in the schematics.

#define EN_PIN 7 //enable (CFG6)

#define DIR_PIN 8 //direction

#define STEP_PIN 9 //step

void setup()

{

//set pin modes

pinMode(EN_PIN, OUTPUT);

digitalWrite(EN_PIN, HIGH); //deactivate driver (LOW active)

pinMode(DIR_PIN, OUTPUT);

//digitalWrite(DIR_PIN, LOW); //LOW to CCW

digitalWrite(DIR_PIN, HIGH); //HIGH to CW

pinMode(STEP_PIN, OUTPUT);

digitalWrite(STEP_PIN, LOW);

digitalWrite(EN_PIN, LOW); //activate driver

}

void loop()

{

for (int i = 0; i <= 255; i++){

digitalWrite(DIR_PIN, LOW); //LOW to CCW

//make steps

digitalWrite(STEP_PIN, HIGH);

delay(2);

digitalWrite(STEP_PIN, LOW);

delay(2);

}

for (int i = 0; i <= 255; i++){

digitalWrite(DIR_PIN, HIGH); //HIGH to CW

//make steps

digitalWrite(STEP_PIN, HIGH);

delay(2);

digitalWrite(STEP_PIN, LOW);

delay(2);

}

}

Test 3 : Experiment about how to proceed¶

Since the time to turn the axis = the width of movement is controlled by changing the value of i, I set the value of i appropriately and observed how many centimeters the axis moved.

/*

SilentStepStick TMC2208/TMC2209 Example

Rsense: 0.11 Ohm

Other examples/libraries can be found here:

https://github.com/teemuatlut/TMCStepper

https://github.com/trinamic/TMC-API

https://github.com/manoukianv/TMC2208Pilot

Example source code free to use.

Further information: https://learn.watterott.com/license/

*/

// Note: You also have to connect GND, 5V/VIO and VM.

// A connection diagram can be found in the schematics.

#define EN_PIN 7 //enable (CFG6)

#define DIR_PIN 8 //direction

#define STEP_PIN 9 //step

void setup()

{

//set pin modes

pinMode(EN_PIN, OUTPUT);

digitalWrite(EN_PIN, HIGH); //deactivate driver (LOW active)

pinMode(DIR_PIN, OUTPUT);

//digitalWrite(DIR_PIN, LOW); //LOW to CCW

digitalWrite(DIR_PIN, HIGH); //HIGH to CW

pinMode(STEP_PIN, OUTPUT);

digitalWrite(STEP_PIN, LOW);

digitalWrite(EN_PIN, LOW); //activate driver

}

void loop()

{

delay(5000);

for (int i = 0; i <= 1600; i++){

digitalWrite(DIR_PIN, LOW); //LOW to CCW

//make steps

digitalWrite(STEP_PIN, HIGH);

delay(2);

digitalWrite(STEP_PIN, LOW);

delay(2);

}

delay(5000);

}

When i=500, it moved 20.8 mm.

i=500 *4 millsec =2 sec

Since moving 1.8 degrees is 1/8 microsteps, I calculated how many times it should be repeated

1.8 / 8 * i [steps] = 360

i = 1600 [steps] should be one revolution. The diameter of the gear is 20.6 mm, so the circumference is 3.14 * 20.6 mm * 1 round = 64.684 mm

When we actually measured the distance moved, the distance moved was exactly as it should be. So to count “1 sec”, I set “i=800”.

Final code : Programs that measure a minute¶

/*

SilentStepStick TMC2208/TMC2209 Example

Rsense: 0.11 Ohm

Other examples/libraries can be found here:

https://github.com/teemuatlut/TMCStepper

https://github.com/trinamic/TMC-API

https://github.com/manoukianv/TMC2208Pilot

Example source code free to use.

Further information: https://learn.watterott.com/license/

*/

// Note: You also have to connect GND, 5V/VIO and VM.

// A connection diagram can be found in the schematics.

#define EN_PIN 7 //enable (CFG6)

#define DIR_PIN 8 //direction

#define STEP_PIN 9 //step

void setup()

{

//set pin modes

pinMode(EN_PIN, OUTPUT);

digitalWrite(EN_PIN, HIGH); //deactivate driver (LOW active)

pinMode(DIR_PIN, OUTPUT);

digitalWrite(DIR_PIN, LOW); //LOW to CCW

//digitalWrite(DIR_PIN, HIGH); //HIGH to CW

pinMode(STEP_PIN, OUTPUT);

digitalWrite(STEP_PIN, LOW);

digitalWrite(EN_PIN, LOW); //activate driver

}

void loop()

{

delay(3000);

for (int i = 0; i <= 800; i++){ // center to xx cm in 30 sec

digitalWrite(DIR_PIN, HIGH); //LOW to CCW

//make steps

digitalWrite(STEP_PIN, HIGH);

delay(2);

digitalWrite(STEP_PIN, LOW);

delay(73);

}

delay(3000);

}

Original Parts in Kannai¶

What to create with a mechanism that measures one minute.

- Ideation

- Prototype of sand timer by 1-axis linear

Prototype the use of two moving boards to see if an hourglass movement can be achieved.

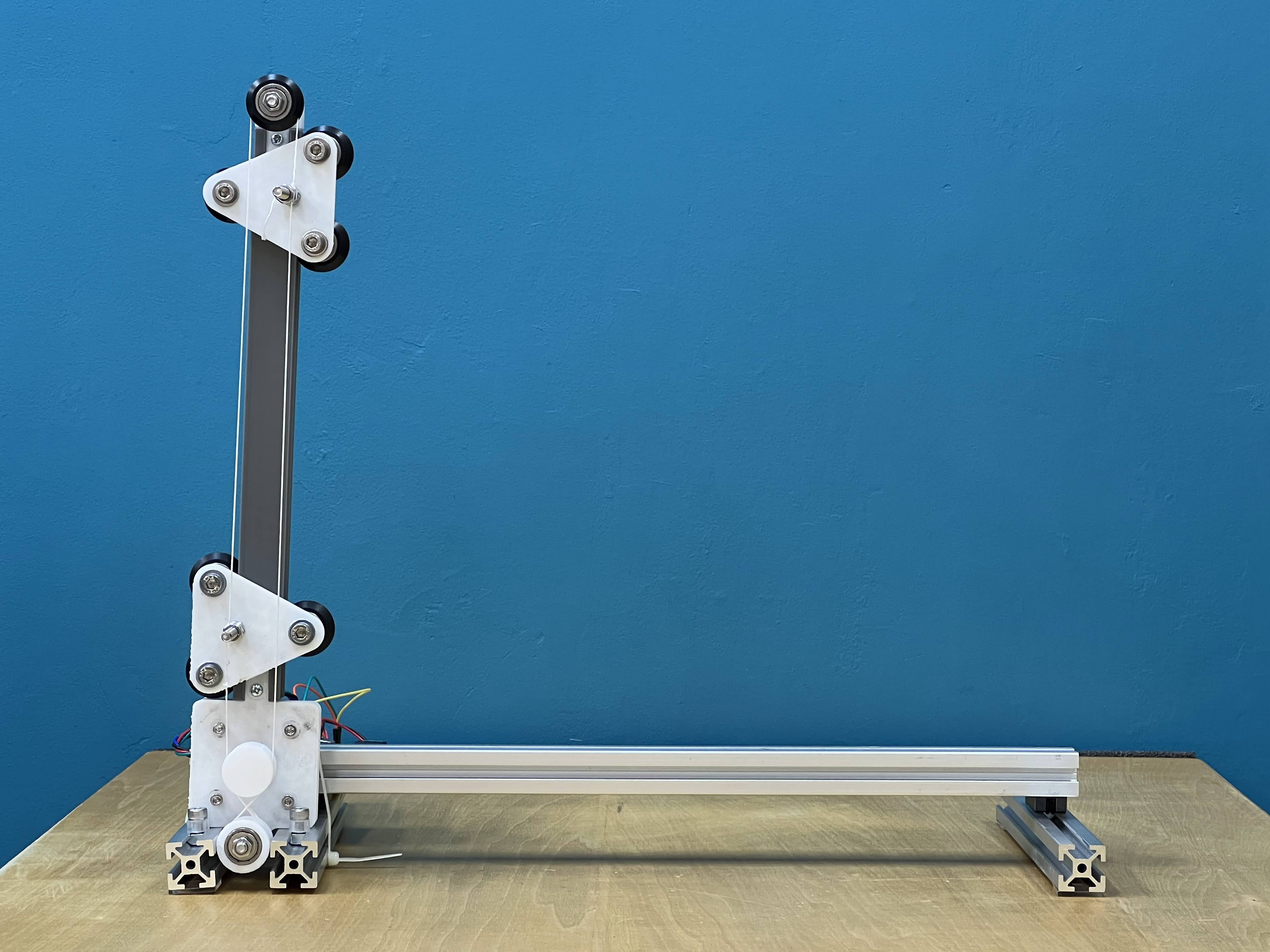

- Finish to make the structure of vertical 1-axis linear

- embed programming

1 minute count programme

/*

SilentStepStick TMC2208/TMC2209 Example

Rsense: 0.11 Ohm

Other examples/libraries can be found here:

https://github.com/teemuatlut/TMCStepper

https://github.com/trinamic/TMC-API

https://github.com/manoukianv/TMC2208Pilot

Example source code free to use.

Further information: https://learn.watterott.com/license/

*/

// Note: You also have to connect GND, 5V/VIO and VM.

// A connection diagram can be found in the schematics.

#define EN_PIN 7 //enable (CFG6)

#define DIR_PIN 8 //direction

#define STEP_PIN 9 //step

void setup()

{

//set pin modes

pinMode(EN_PIN, OUTPUT);

digitalWrite(EN_PIN, HIGH); //deactivate driver (LOW active)

pinMode(DIR_PIN, OUTPUT);

digitalWrite(DIR_PIN, LOW); //LOW to CCW

//digitalWrite(DIR_PIN, HIGH); //HIGH to CW

pinMode(STEP_PIN, OUTPUT);

digitalWrite(STEP_PIN, LOW);

digitalWrite(EN_PIN, LOW); //activate driver

}

void loop()

{

delay(3000);

for (int i = 0; i <= 800; i++){ // center to xx cm in 30 sec

digitalWrite(DIR_PIN, HIGH); //LOW to CCW

//make steps

digitalWrite(STEP_PIN, HIGH);

delay(2);

digitalWrite(STEP_PIN, LOW);

delay(73);

}

delay(3000);

}

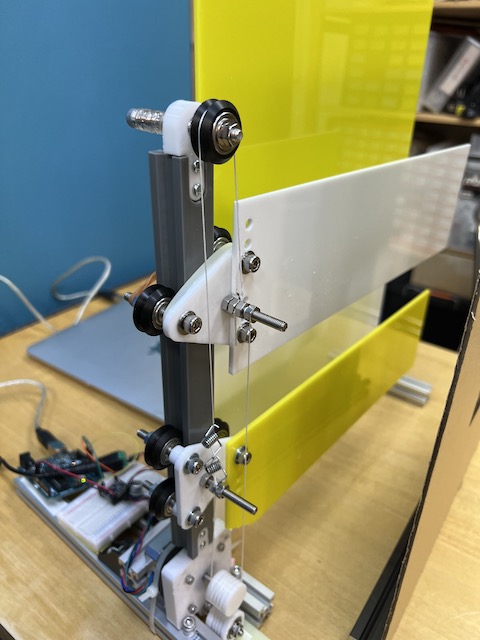

-

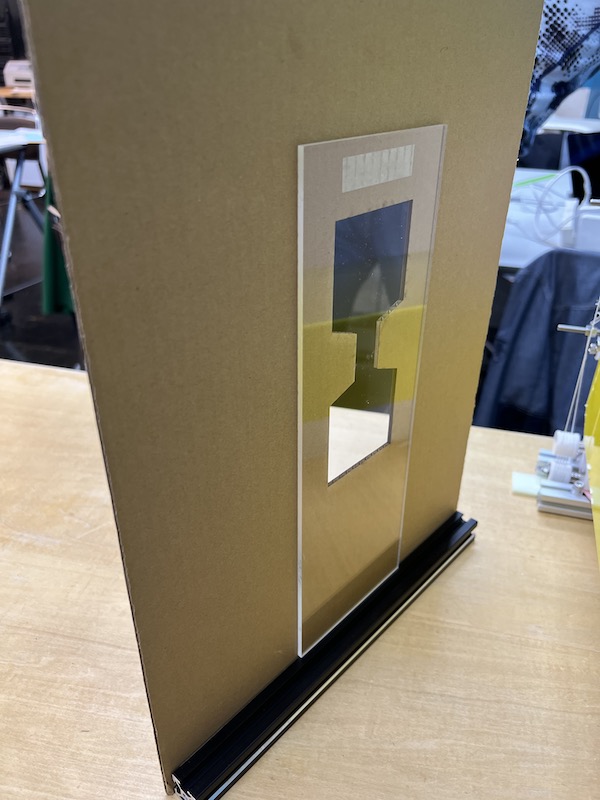

cut acrylic boards by laser cutter and set up them

mechanism of sand timer.

- mechanism test

-

cut cardboard by laser cutter and put the acliryc board on the cardboard

-

hero shot