7. Electronics design¶

Instruction¶

Group Assignment

Individual Assignment

- Redraw one of the echo hello-world boards or something equivalent, add (at least) a button and LED (with current-limiting resistor) or equivalent input and output, check the design rules, make it, test it.

- Optionally, simulate its operation.

What I did this week¶

- Test the operation of a circuit board by multimeter and oscilloscope → Group Assignment

- Design: Redraw the circuit board with botton and LED → in this page

- Check: Design Rule Check and make the circuit board → in this page

- Make: Assemble electronic components to the board→ in this page

- Test: Write programme to the microcomputer on making breakout board→ in this page

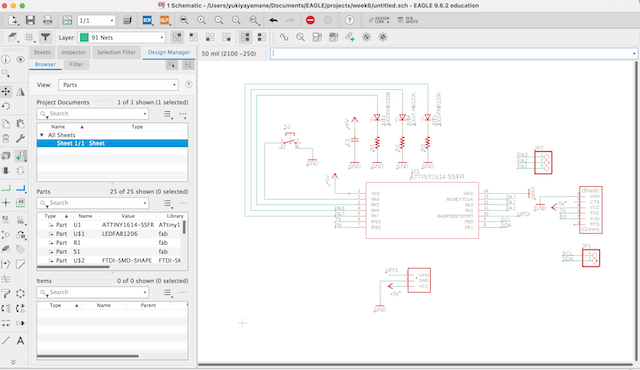

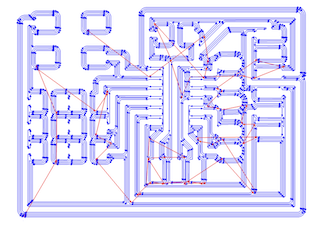

2. Design: Redraw and design in Eagle¶

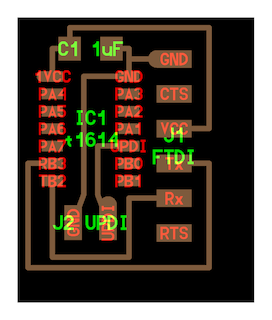

The board image i will make¶

- a button

- LED (with current-limiting resistor)

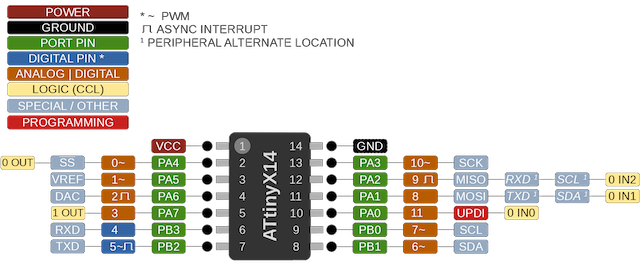

ATTINY 1614

-

add Library

-

eagle/fab.lbr

-

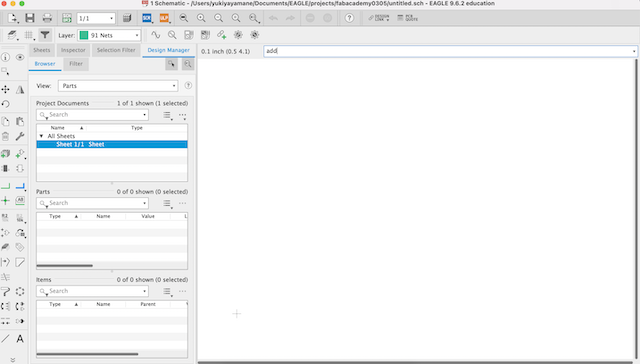

new > schematic

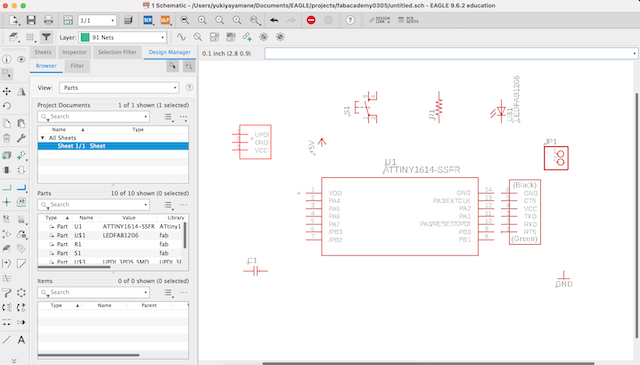

- “add” parts I will use

FAB > LEDFAB1216 FAB > R > R1206FAB(Register) FAB > SW_SWITCH_TACTILE_6MM FTDI-SMD-SHAPE UPDI_3POS_SMD_SHAPE PINHD-1X02 CAP_UNPOLARIZEDFAB 5V GND (Version 1)

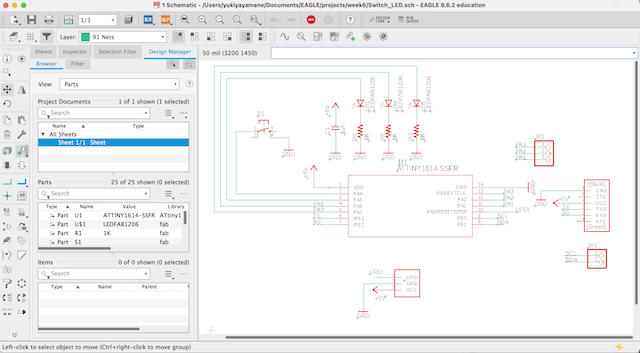

- net and move components in order

- set input “Value”

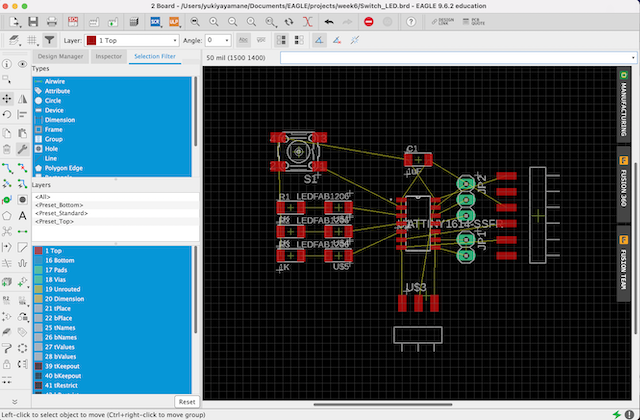

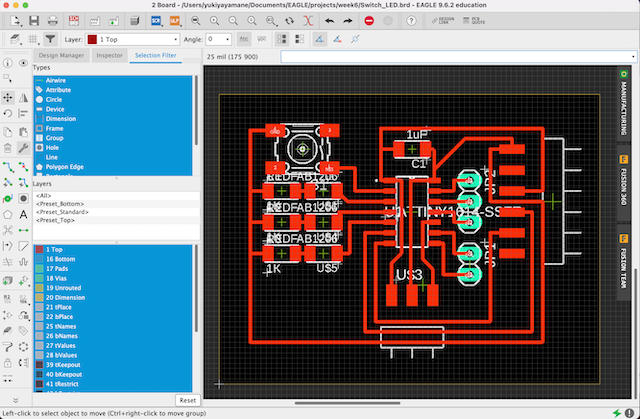

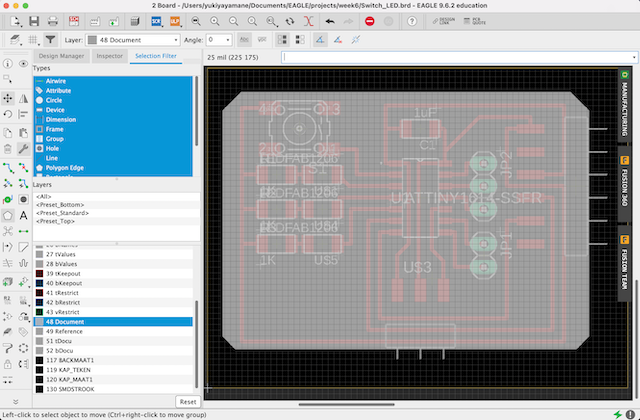

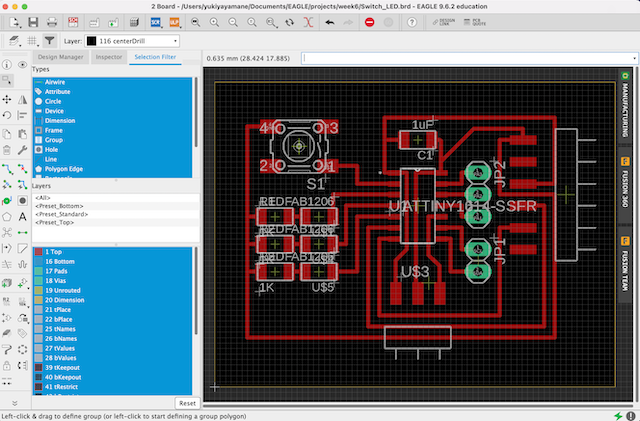

- switch to board mode and put these parts in order

- drawing by “Route Airwire”

- draw the layout by “POLYGON”

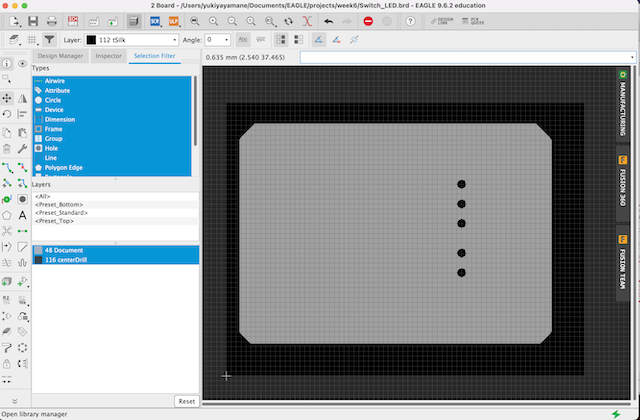

- Assign Shortcut of making hole to F12 in accordance with this instruction

option > assign > new

SET COLOR_LAYER 116 0;SET FILL_LAYER 116 1;run drill-aid 0

- making holes by press “F12”

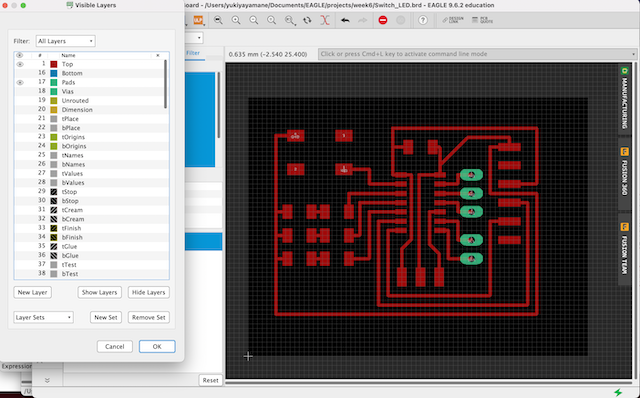

- hide layers and display only top and pats

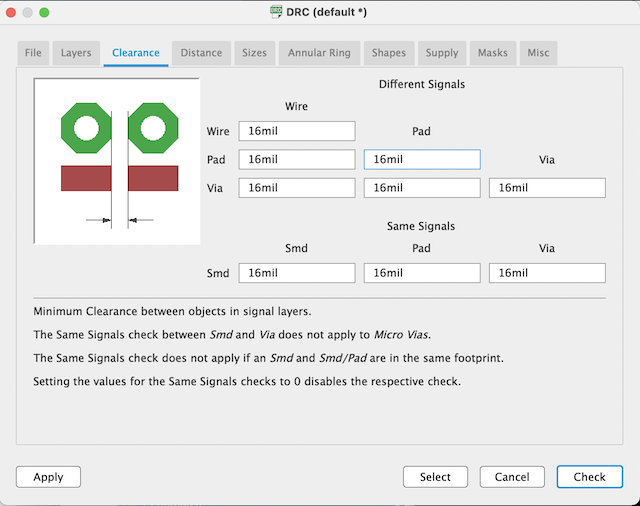

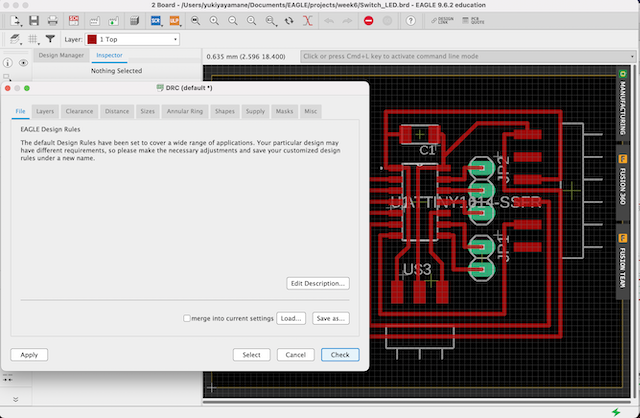

3. Check: DRC (Design Rule Check)¶

Validating your work through the use of a Design Rule Check (DRC).

- press drc and set clearance parameters “16mil”

- press command : drc

After that, nothing is displayed. Turns out there was no problem.

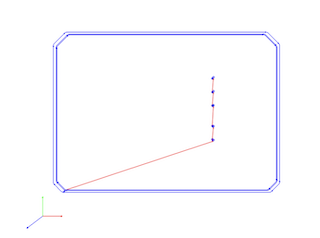

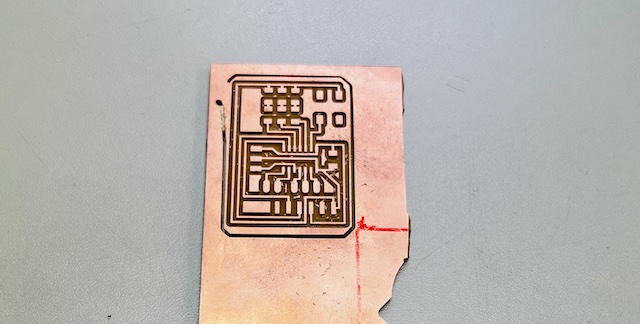

Draw pathroute by mods in accordance with exported the design data¶

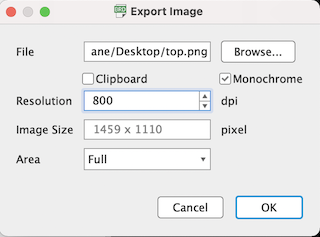

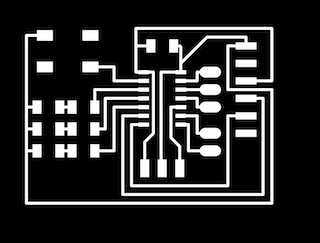

- select top and pad → export as filename “top”

file > export > image

- Export “top.png”image

- display only document and centerdrill

- export image as filename “holes_outline.png” in the same setting

- import the image to mods and calculate pathroute by mods

Size: 46.3 x 35.2 mm

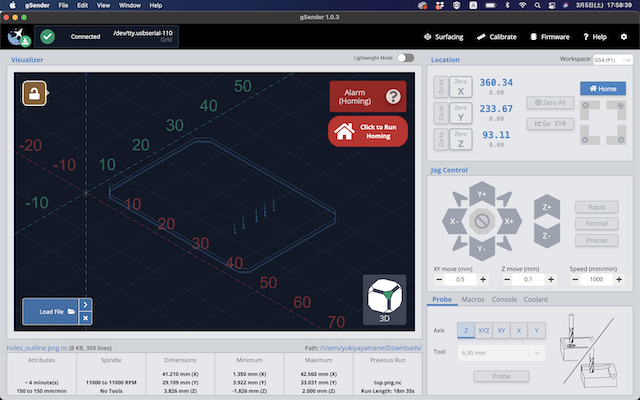

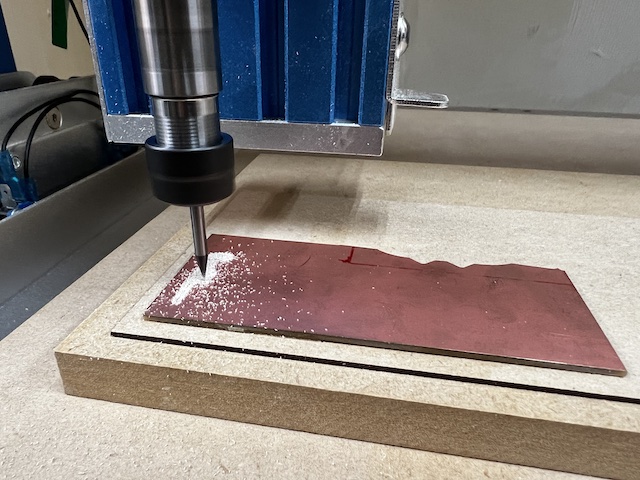

- launch the image in gSender and connect PC to CNC machine

CNC machine I used : Genmitsu PROVerXL 4030

- press homing

- install endmill (1/64) and set its position

- load file .nc and start job

- image of milling by 1/64

- after detaching endmill (1/64), install endmill (1/32) and set its position

- video of milling by 1/32

- done

At the end of milling, unfortunately the circuit board came un stick because the board wasn’t fixed enough by glue. So I couldn’t cut the board completely. As the cutting process was almost finished, I decided to cut the remaining by pliers.

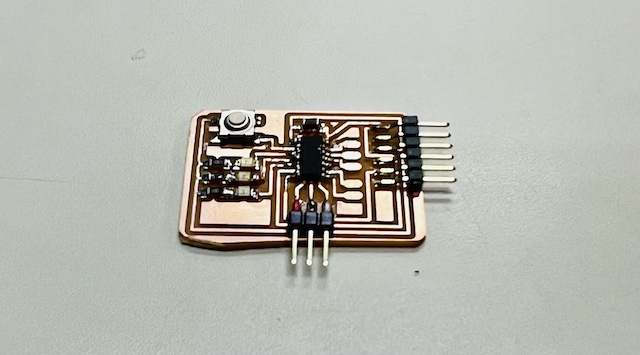

4. Make: Assemble electronic components to the circuit board¶

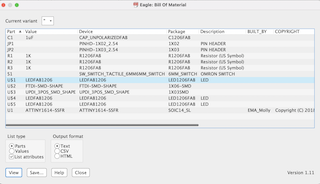

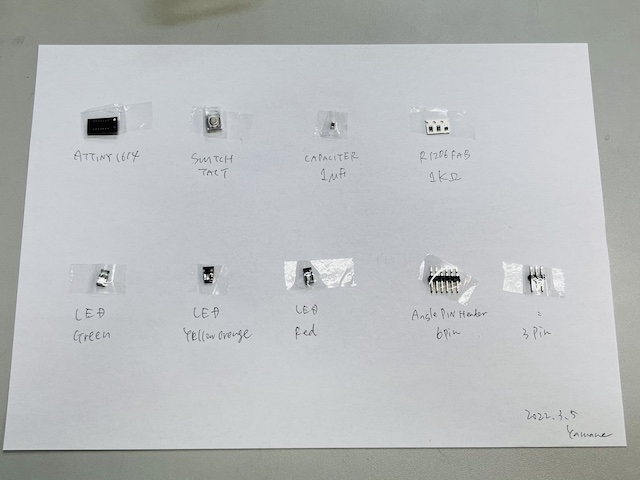

- export to “bom” from brd and display parts list

- collect components

- Soldering

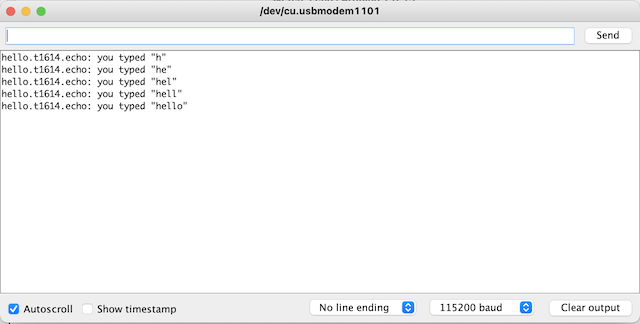

5. Test: Write programme to the microcomputer on making breakout board¶

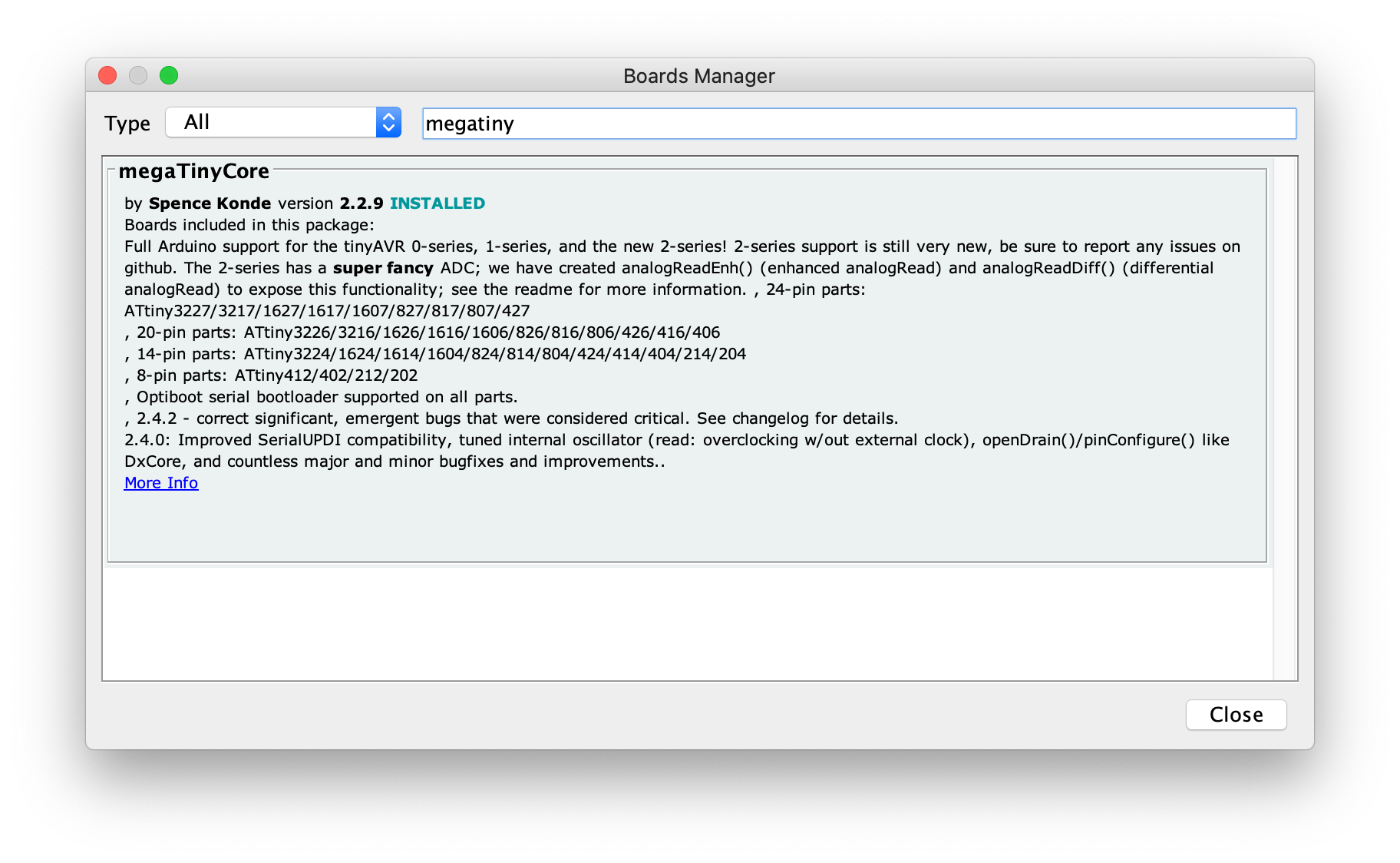

- setup ATtiny1614

File -> PreferencesAdditional Board Manager URLs:

http://drazzy.com/package_drazzy.com_index.json

Boards Manager

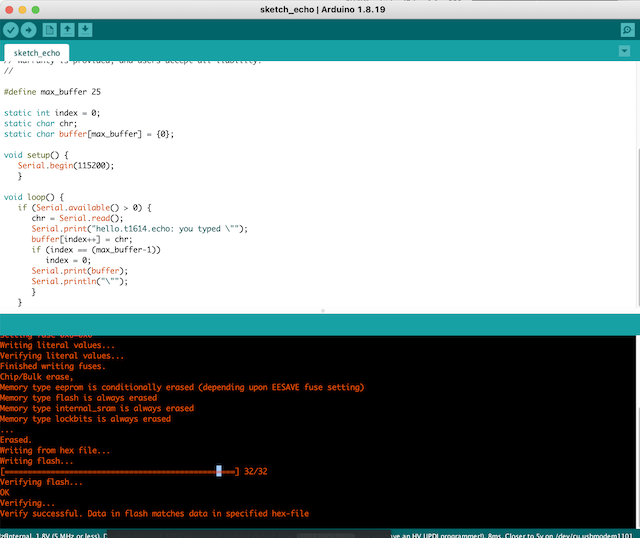

- write echo program to the breakout board

//

// hello.t1614.echo.ino

//

// tiny1614 echo hello-world

// 115200 baud

//

// Neil Gershenfeld 12/22/19

//

// This work may be reproduced, modified, distributed,

// performed, and displayed for any purpose, but must

// acknowledge this project. Copyright is retained and

// must be preserved. The work is provided as is; no

// warranty is provided, and users accept all liability.

//

#define max_buffer 25

static int index = 0;

static char chr;

static char buffer[max_buffer] = {0};

void setup() {

Serial.begin(115200);

}

void loop() {

if (Serial.available() > 0) {

chr = Serial.read();

Serial.print("hello.t1614.echo: you typed \"");

buffer[index++] = chr;

if (index == (max_buffer-1))

index = 0;

Serial.print(buffer);

Serial.println("\"");

}

}

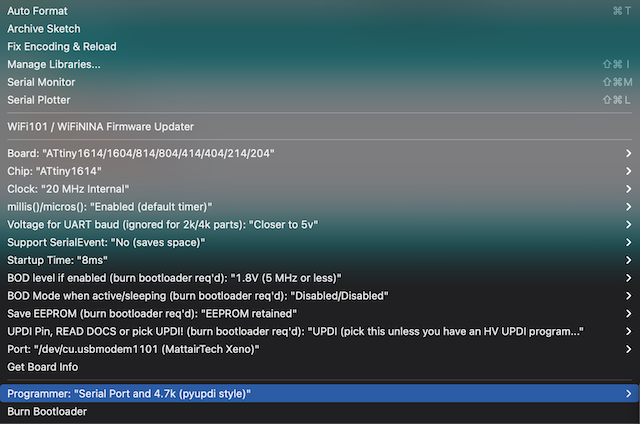

- setting in arduino

- complete writing

- Check with serial monitor by connecting to serial

- Confirmation that echo is returned without any problem.

- write the programme of Blink of Red/Yellow/Blue LED in turn

// the setup function runs once when you press reset or power the board

void setup() {

// initialize digital pin LED_BUILTIN as an output.

pinMode(1, OUTPUT);

pinMode(2, OUTPUT);

pinMode(3, OUTPUT);

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(1, HIGH); // turn the LED on (HIGH is the voltage level)

delay(1000); // wait for a second

digitalWrite(1, LOW); // turn the LED off by making the voltage LOW

delay(1000); // wait for a second

digitalWrite(2, HIGH); // turn the LED on (HIGH is the voltage level)

delay(1000); // wait for a second

digitalWrite(2, LOW); // turn the LED off by making the voltage LOW

delay(1000); // wait for a second

digitalWrite(3, HIGH); // turn the LED on (HIGH is the voltage level)

delay(1000); // wait for a second

digitalWrite(3, LOW); // turn the LED off by making the voltage LOW

delay(1000); // wait for a second

}

done!

What I learned this week¶

Individual and Group Assignment

- Understand how information can be sent through an electronic board.

- Using an oscilloscope allows you to feel that the microcontroller is working.

- Combination of only 0 and 1 can be conveyed the imformation to MCU by electrically controlled potential differences.

- The first thing to do after building a foundation is to write echo and blink of LED programme

- Imagined how amazing it is that every electronic device in the world is controlled by a microcomputer.

file¶

Acknowledgement¶

Mr.Tamiya and Ms.Kamei as supportive instructors in Fablab Kannai

and You!