16. Wildcard week¶

Instruction¶

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to):

What I want to make in this week¶

I’ve been presented with many options but I decided to make embroidery in this week.

I will create my original patch by digital fabrication.

What I used in this week¶

Design Process¶

- Design the image by illustration : ai.

-

file

Preparation for fabrication¶

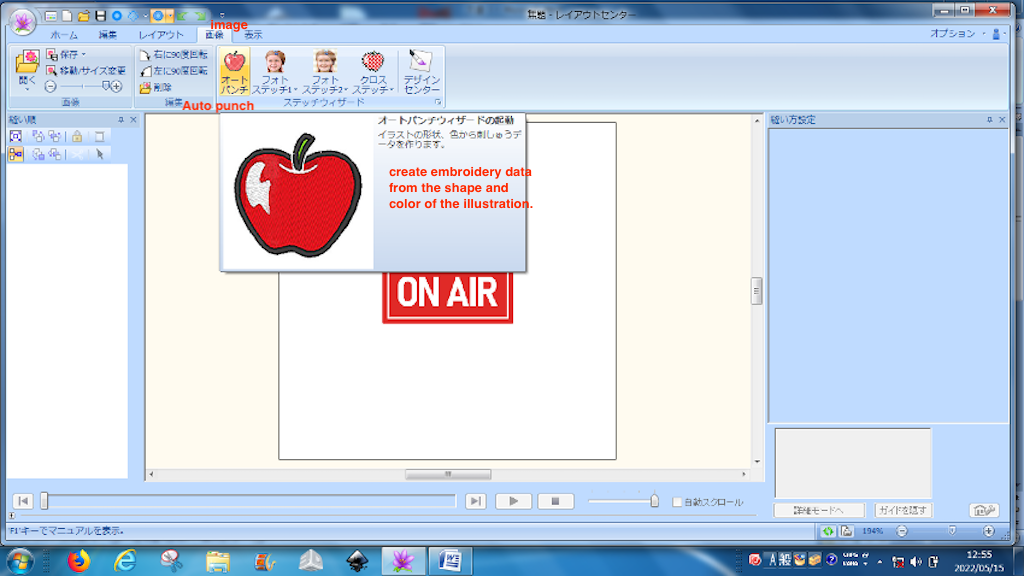

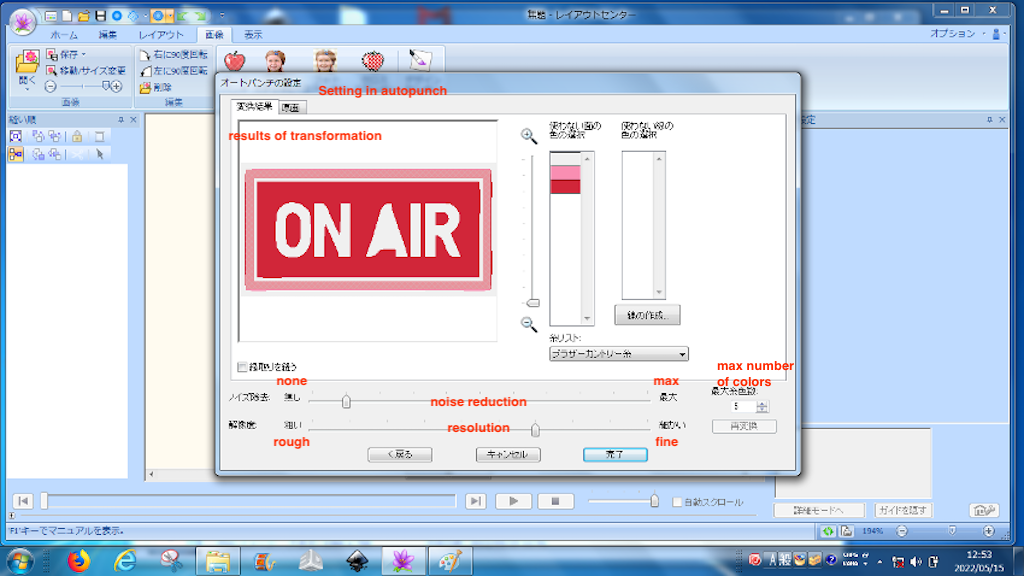

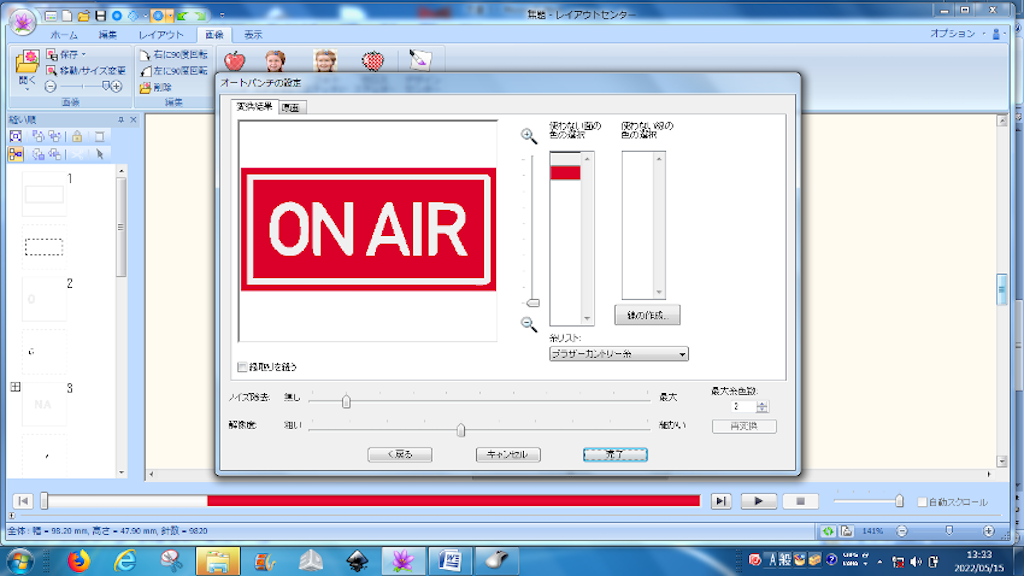

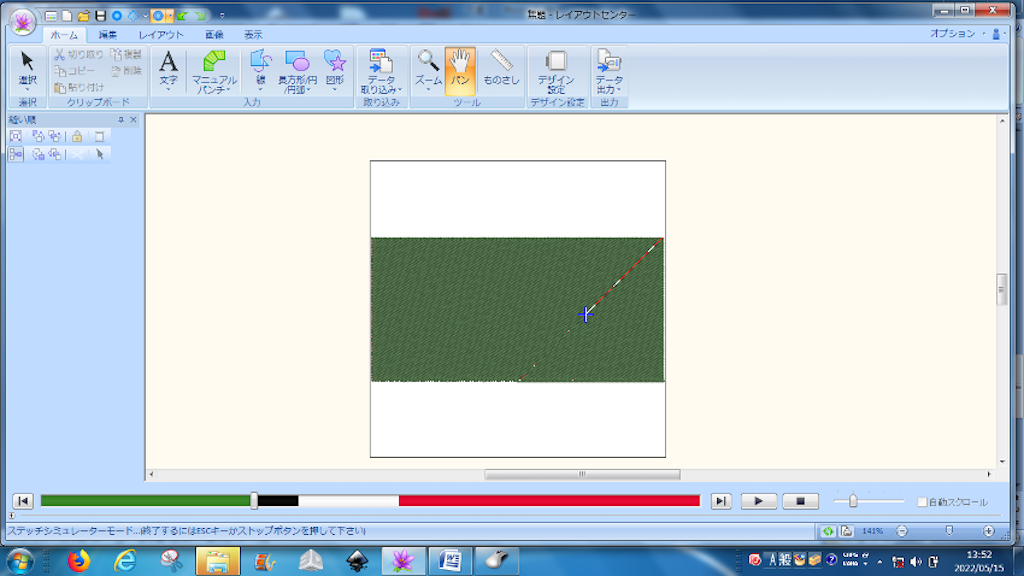

- software : Embroidery PRO NEXT

- Open the software

- select the “autopunch”

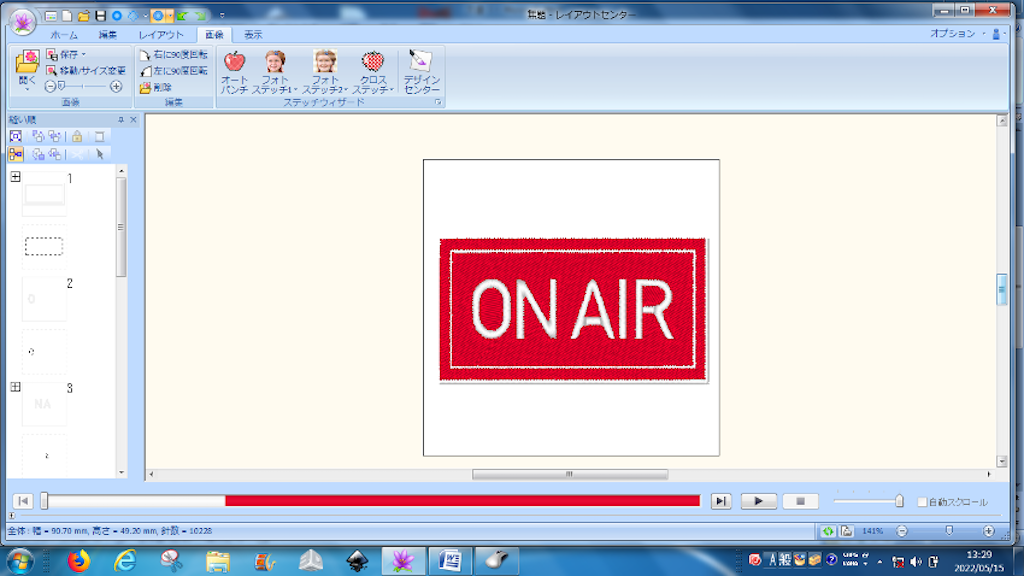

- transform the image to embroidery design

- Make the outer frame line thicker because it is thin.

Note: There are two types of stitches. : “Satin Stitch” and “Folding Stitch”

- Satin stitch:The luster of the threads looks beautiful and has a three-dimensional effect

- Folding Stitch : The fine seam like the grain of tatami mats. It is stronger and more durable than satin.

- If the figure is sewn first, it will be shifted by the amount of shrinkage, so sew the red color in the figure and then embroider the white letters.

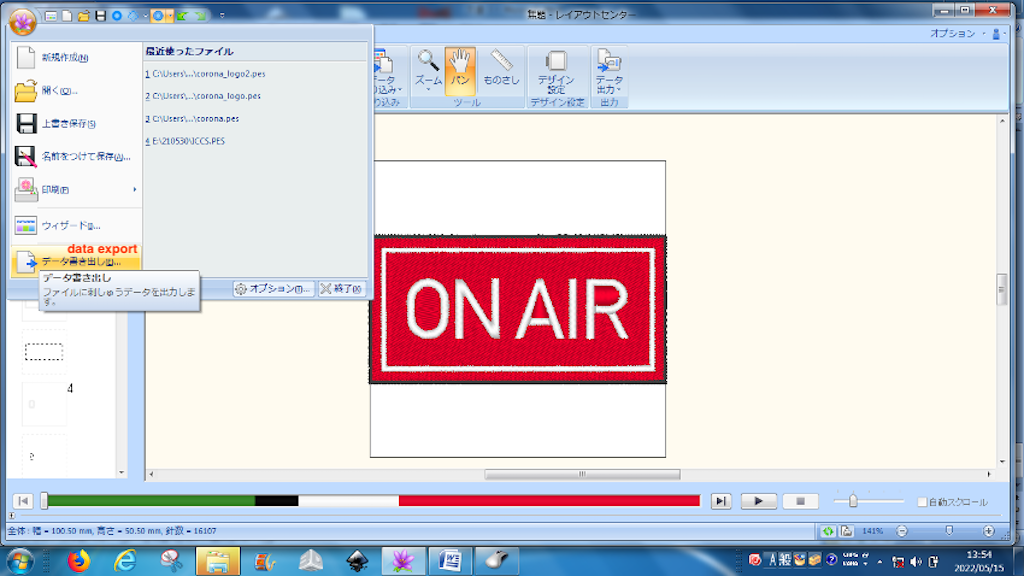

- Export the file to janome file (.jef)

Fabrication Process¶

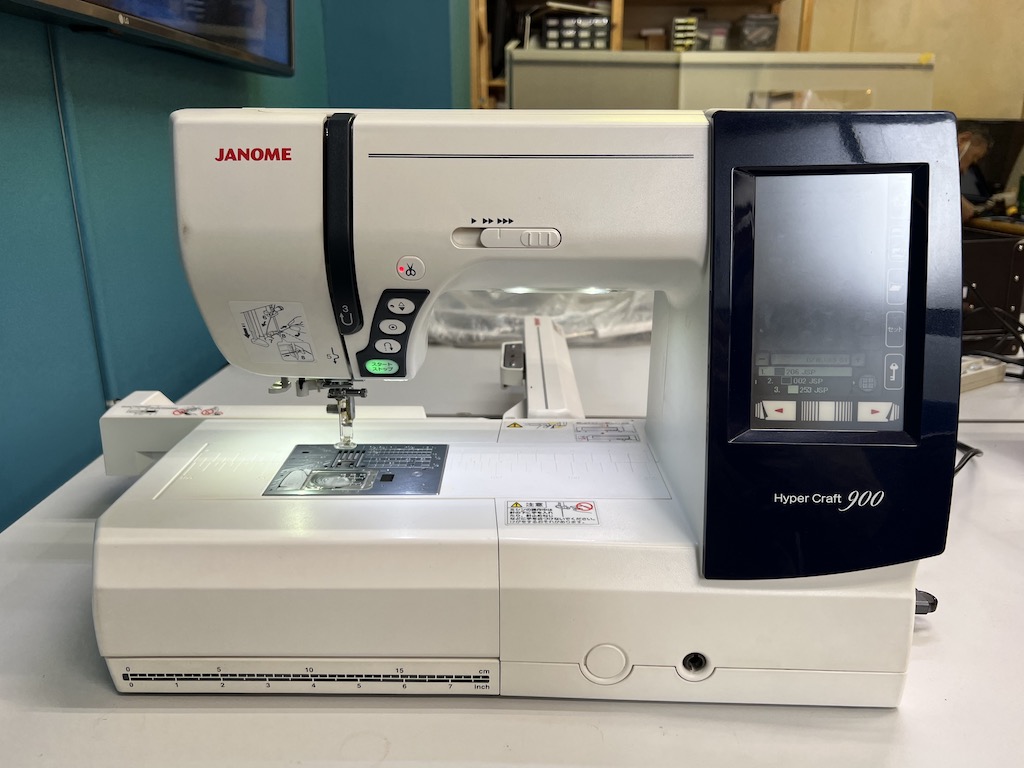

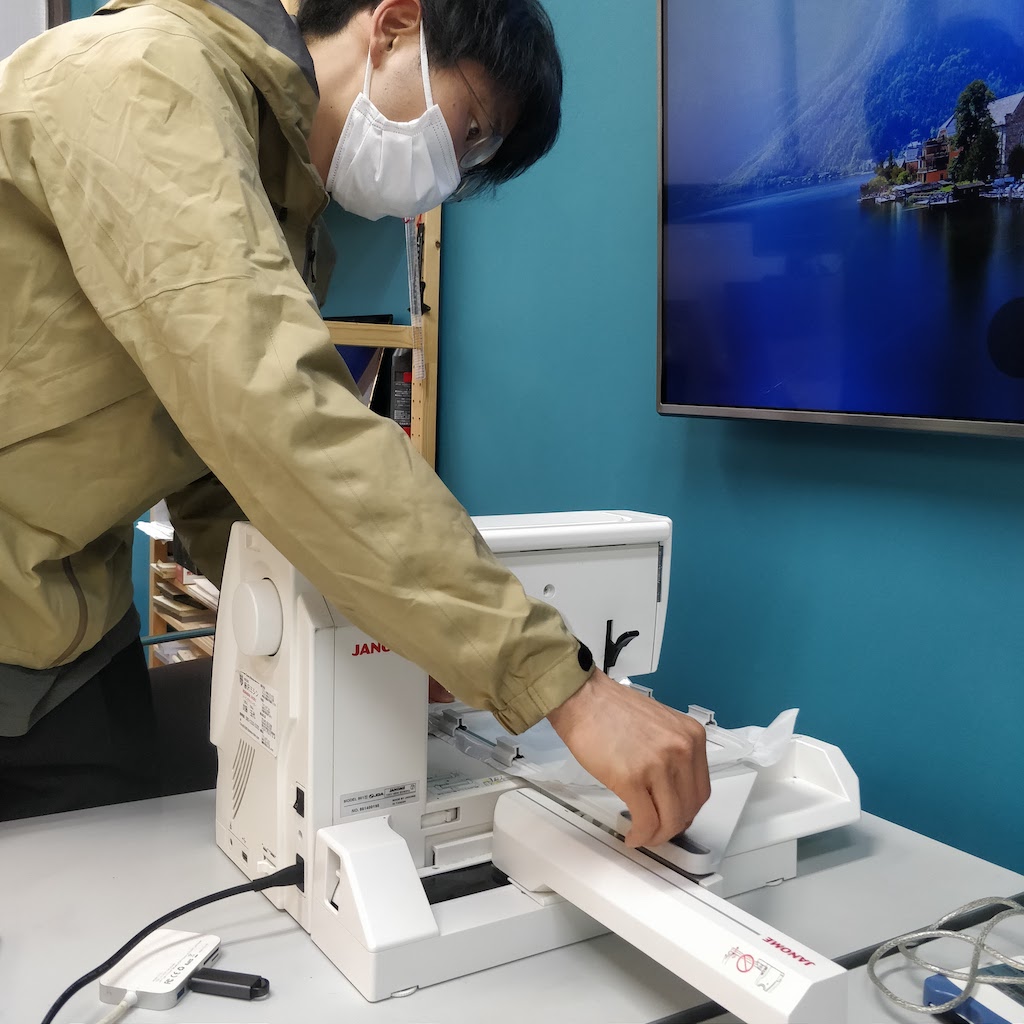

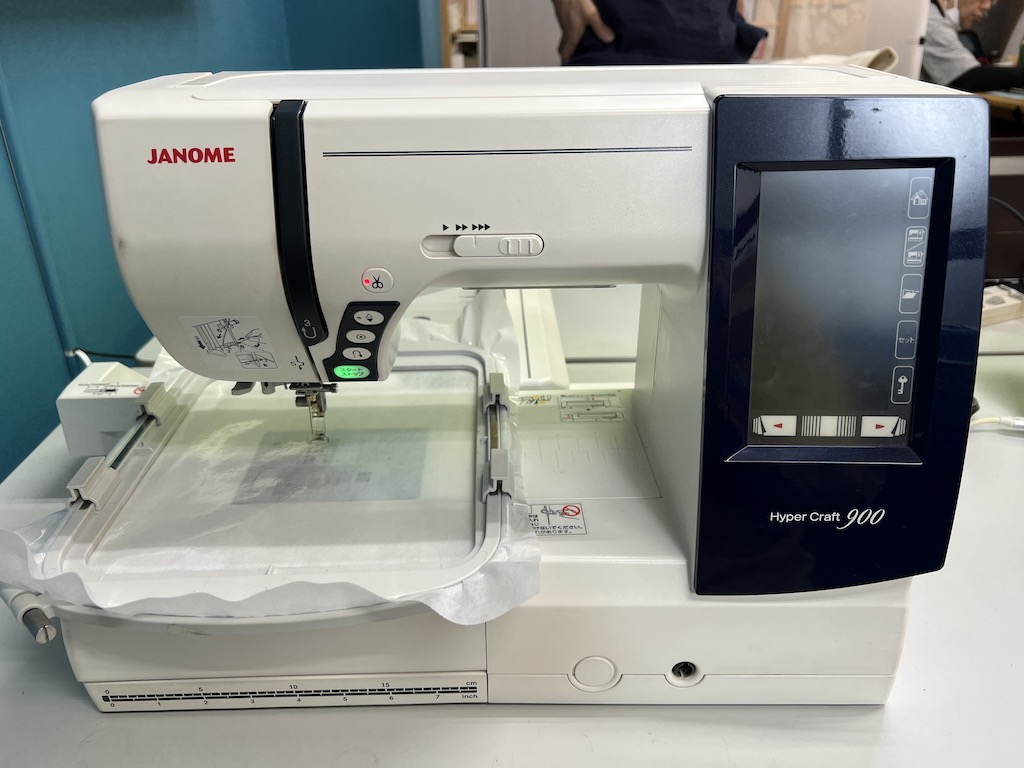

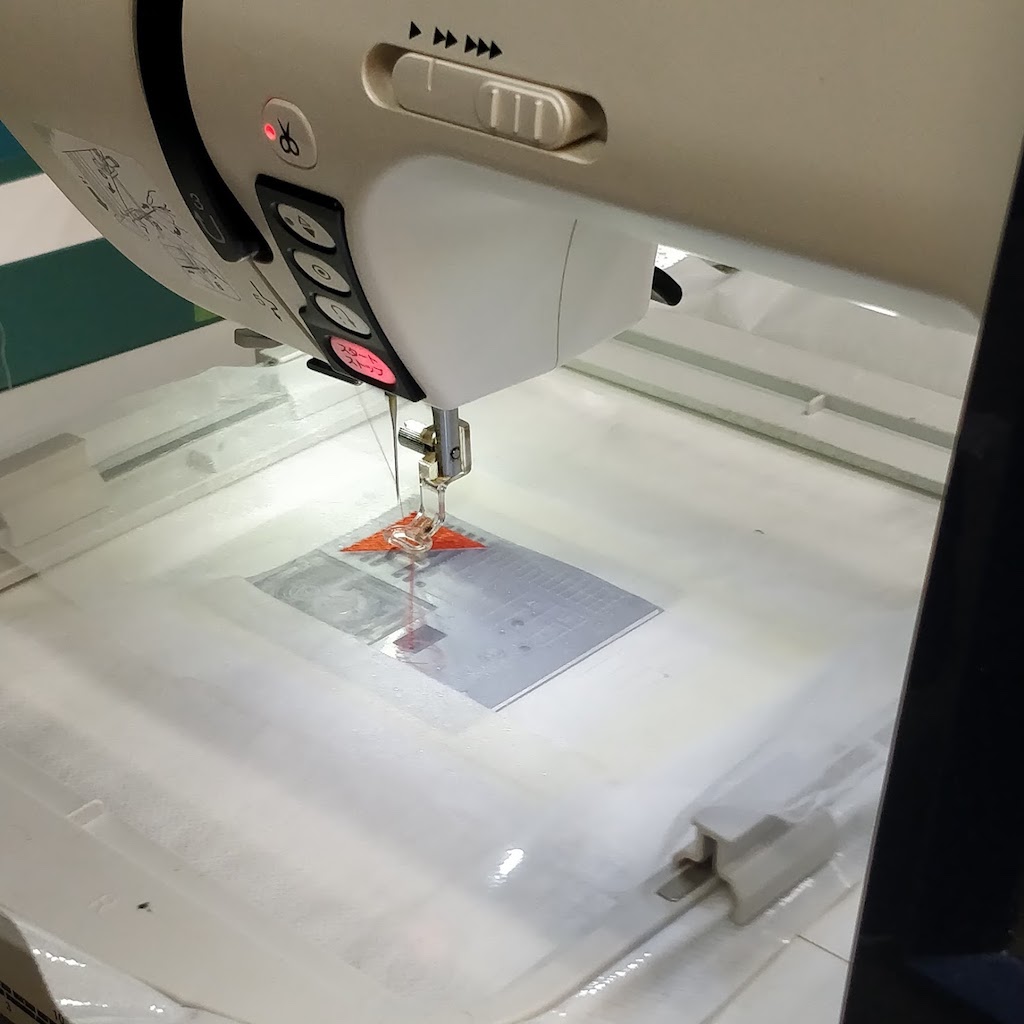

- Start sewing machine JANOME

- Mount the embroidery unit in the back.

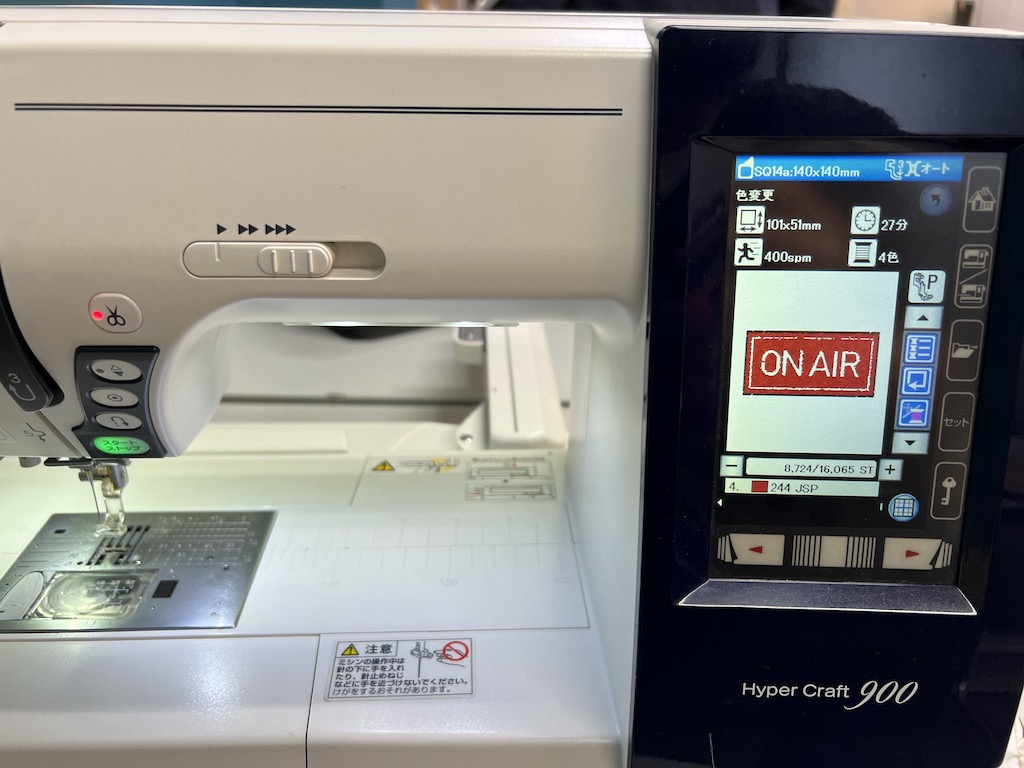

- Plug in the USB and wait for it to boot. Unplug it and transfer the data to the newly created file on the USB. (EMB > embf >)

- After switching to embroidery mode, plug the USB into the sewing machine again to load data

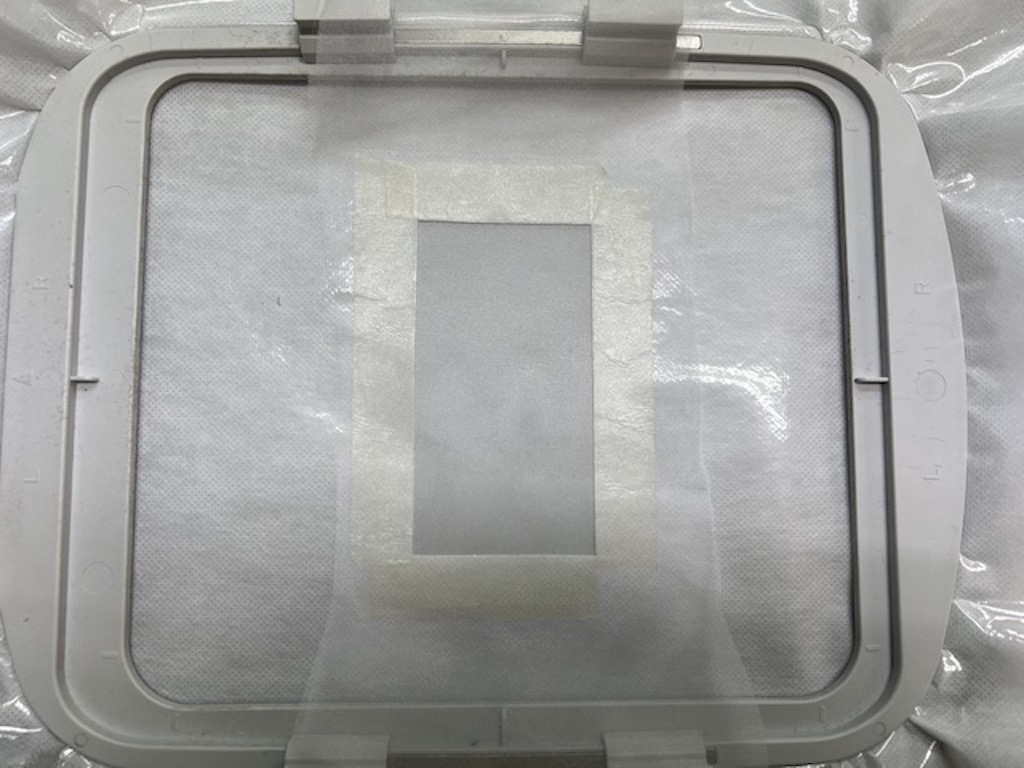

- Set the foundation for the place stitch and fit the good punch sheet into the embroidery frame. Pin it in place by pinning it

- Set the embroidery frame on the sewing machine (so that the good punch sheet is under the sewing machine)

- Select a thread and follow the instructions to set it up.

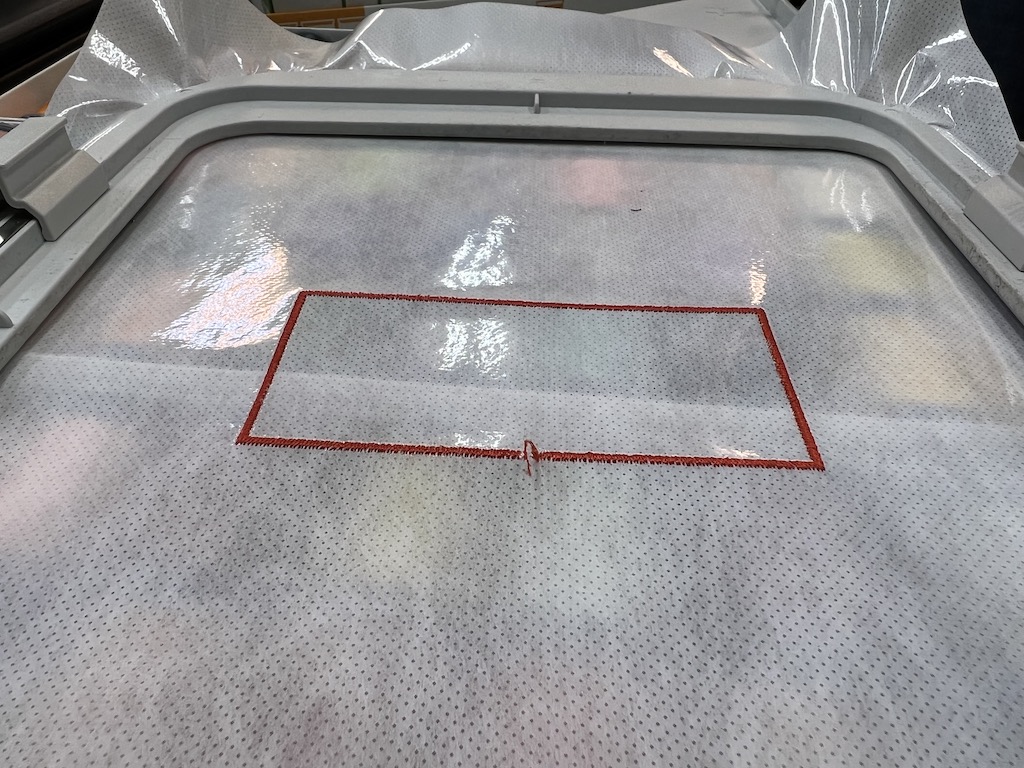

- To know the size, select the outer frame data (002 jsp) and stitch it

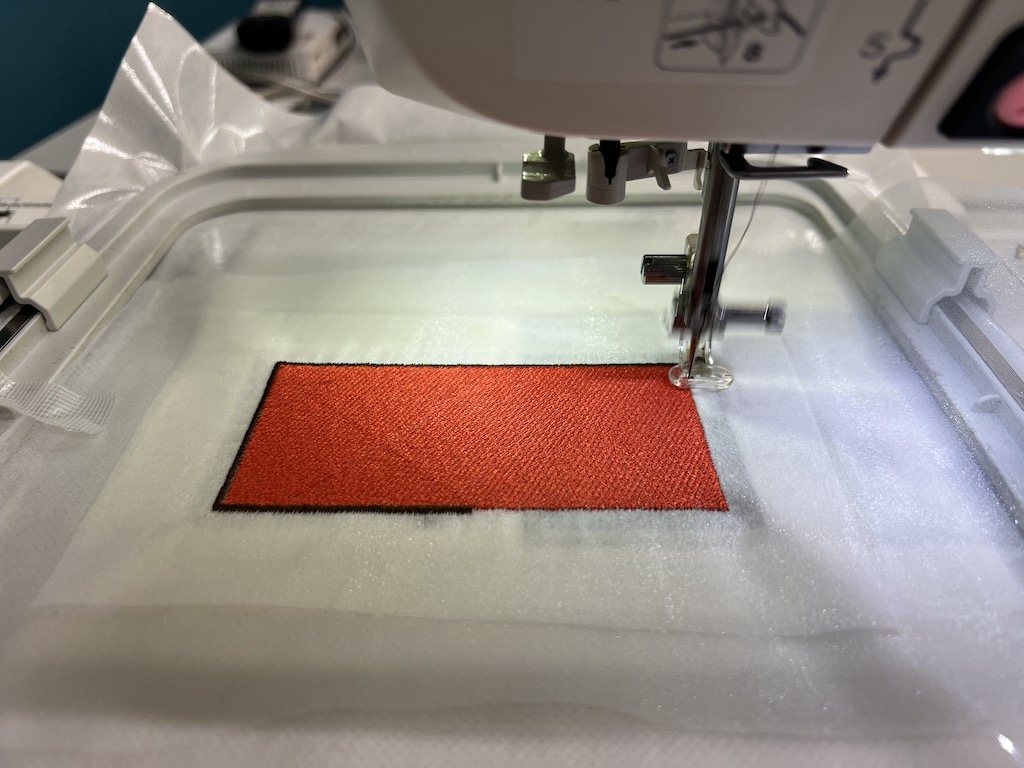

- Cut the good punch sheet to fit the painted pre-sewn frame.

- Apply a fusible interlining to the inside and attach the organdie to the outside of the glue.

- Set the sewing machine and start sewing:

- Apply in the following order: red thread → black thread → white thread

- red thread

movie

- change thread to black thread

-

change thread to white thread

-

The white letters looked a little thin, so I tried sewing only the white color twice.

Cutting out threads that are not necessary for the design.

-

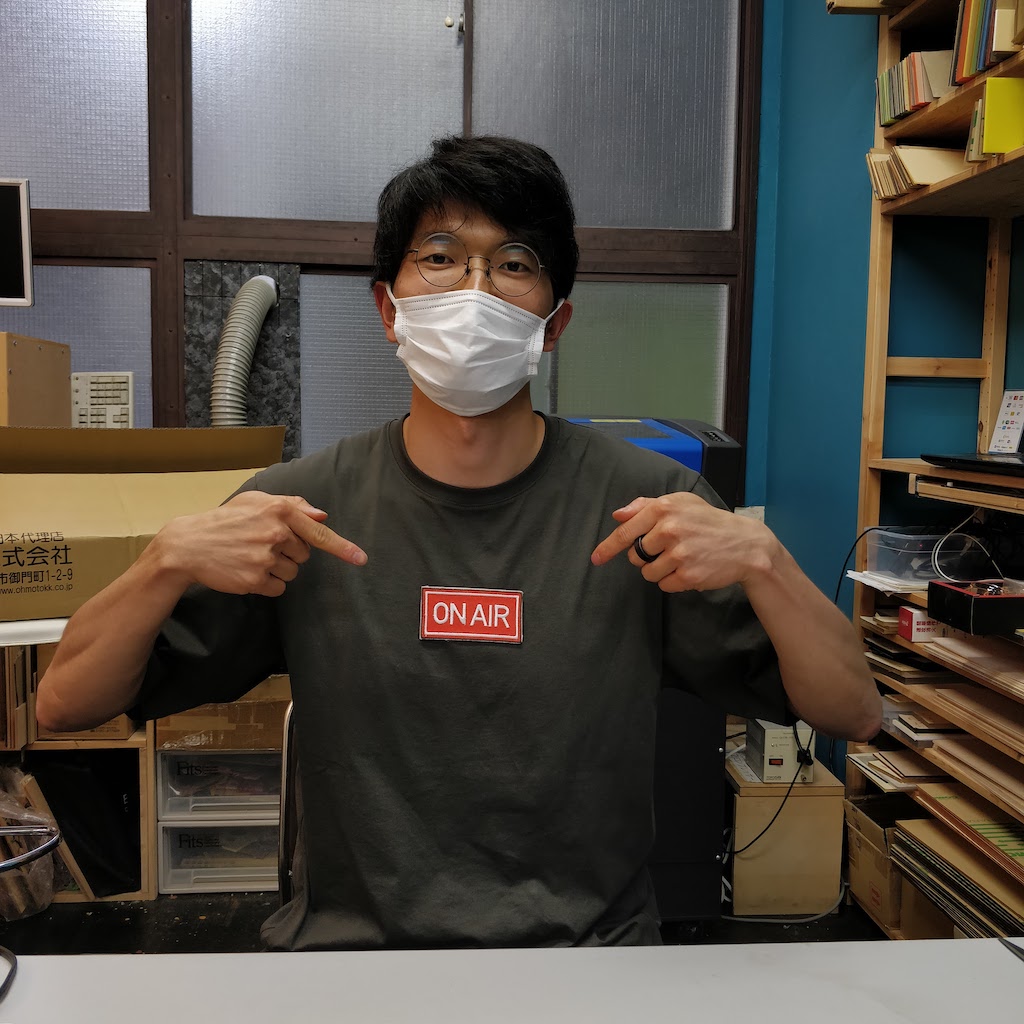

Cut 100um Ecellent (which is a kind of hot-melt film) to the size of organdie

-

Since the melting point of ecellent is 140°C, apply the iron on “medium (120-160°C)” to adhere. Do not forget to place a cookie sheet between the ironing board and the iron.

(bottom) ironing board - cooking sheet - hot-melt film - sewed patch - cloth - Iron (top)

-

Remove only the sheet and iron it onto the T-shirt by heat cutter HE-30.

-

Press the created patch to a T-shirt by ironing

-

Hero Shot!

What I learned in this week¶

- I could learn how to load a design onto a sewing machine and then output it for embroidery.

- Unlike the 2d and 3d designs I have experienced in the past, the fabrics are very good!

- The embroidery was tactile and I found myself liking it a lot.