Useful Links

comments

- Soft Robotic Walking and Crawling ✔

- Soft Robotic Gripper project from University of Novi Sad ✔

- Gripper Instructable ✔

- Another type of Gripper ✔

other comment

Yeah 3D print with clay and special materials is cool, but Soft Robotic is way cooler.

Soft robotics is a subfield of robotics that concerns the design, control, and fabrication of robots composed of compliant materials, instead of rigid links. It is area in which robots, more specifically robotic actuators, are modeled based on how living organisms move and adapt to their surroundings. Rather than using rigid actuators and materials for robot design, using soft actuators provides an additional level of flexibility and adaptability of robotic manipulators. Soft robotic actuators are typically pneumatic actuators which perform movement or contraction when air within actuators is compressed.

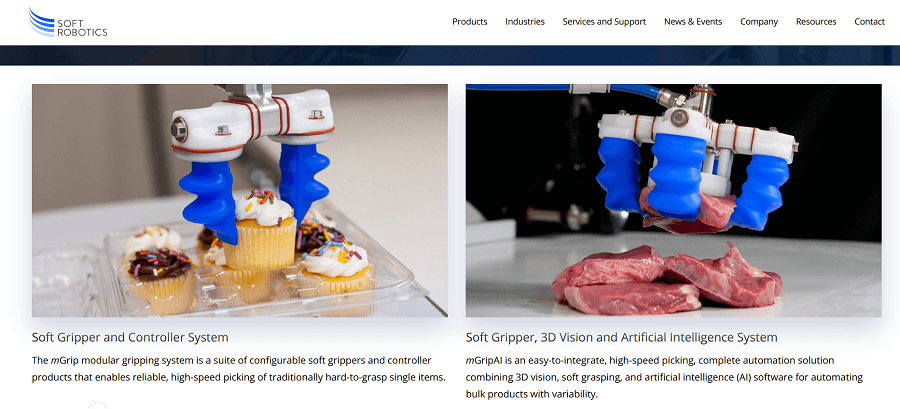

There is still a lot of research in this field and about its purpose in the future. For now, you can see being vastly used in Automatic picking solution for Food and Goods

So, taking inspiration from the images above, I wanted to attempt making my onw gripper.

The process of making a Soft-Robotic Gripper involves a Silicon Casting of a kind of shape that when inflated it bends in specific directions.

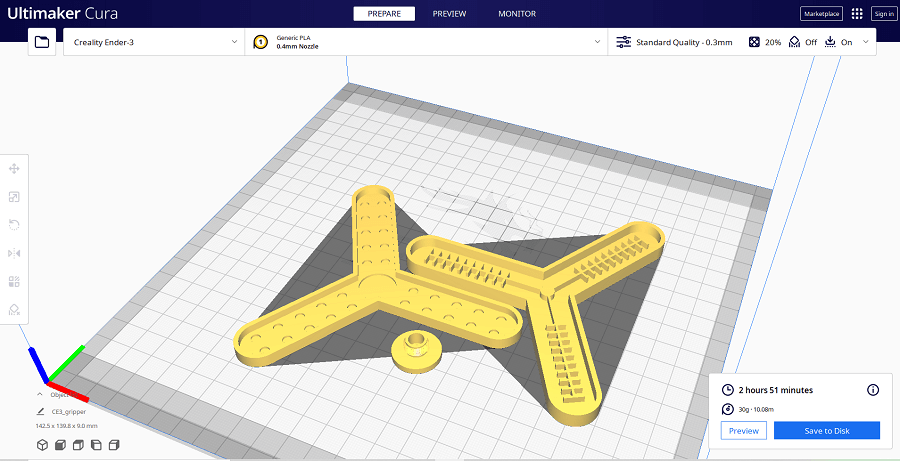

In my case I took the mold directly from this model that I 3D printed.

The model is composed of 3 parts:

As you will follow this journey, I realized at the end that just the first part is enough to achive a good project.

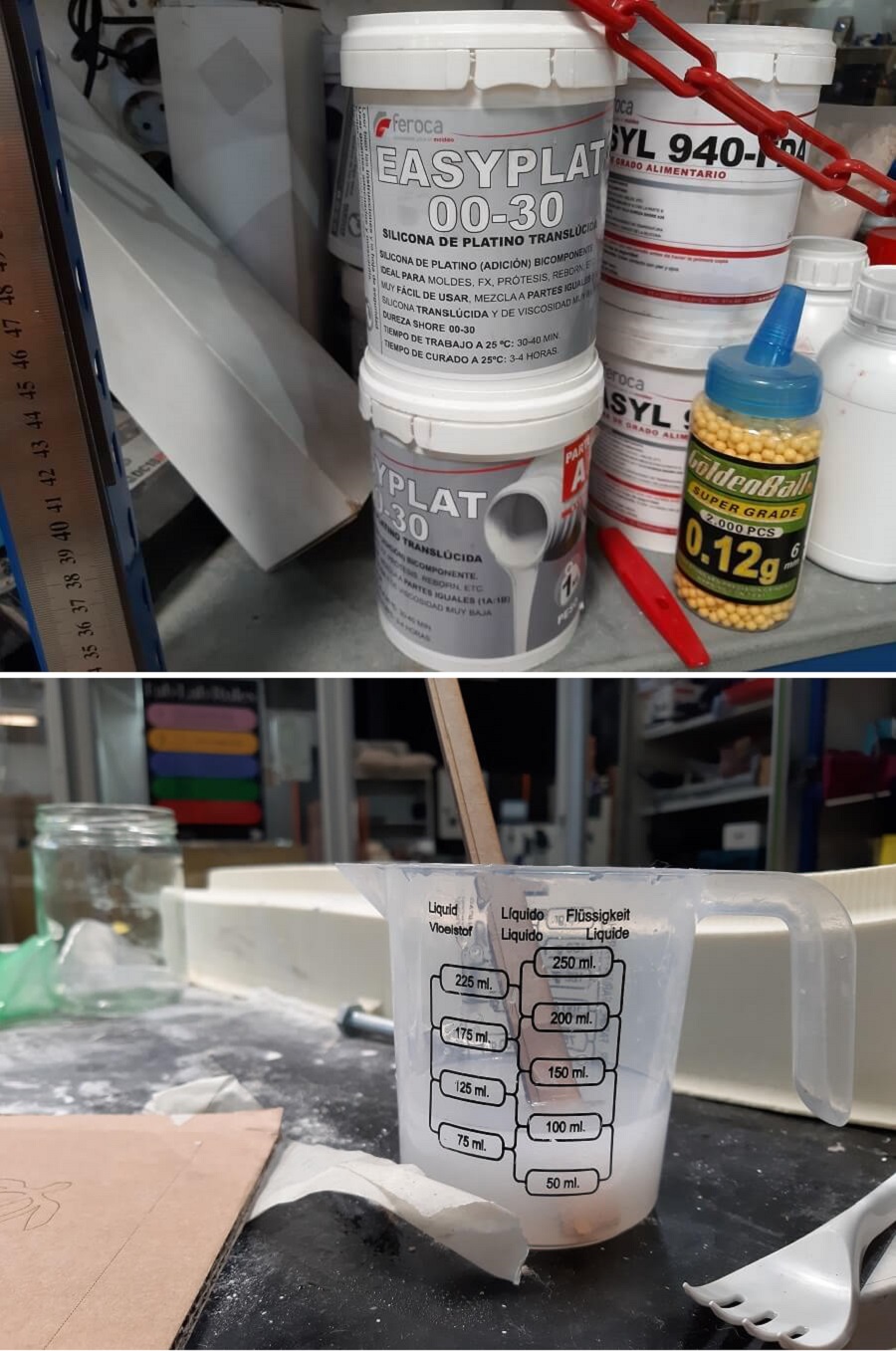

For Casting I used Easy Plat 00-30 (datasheet).

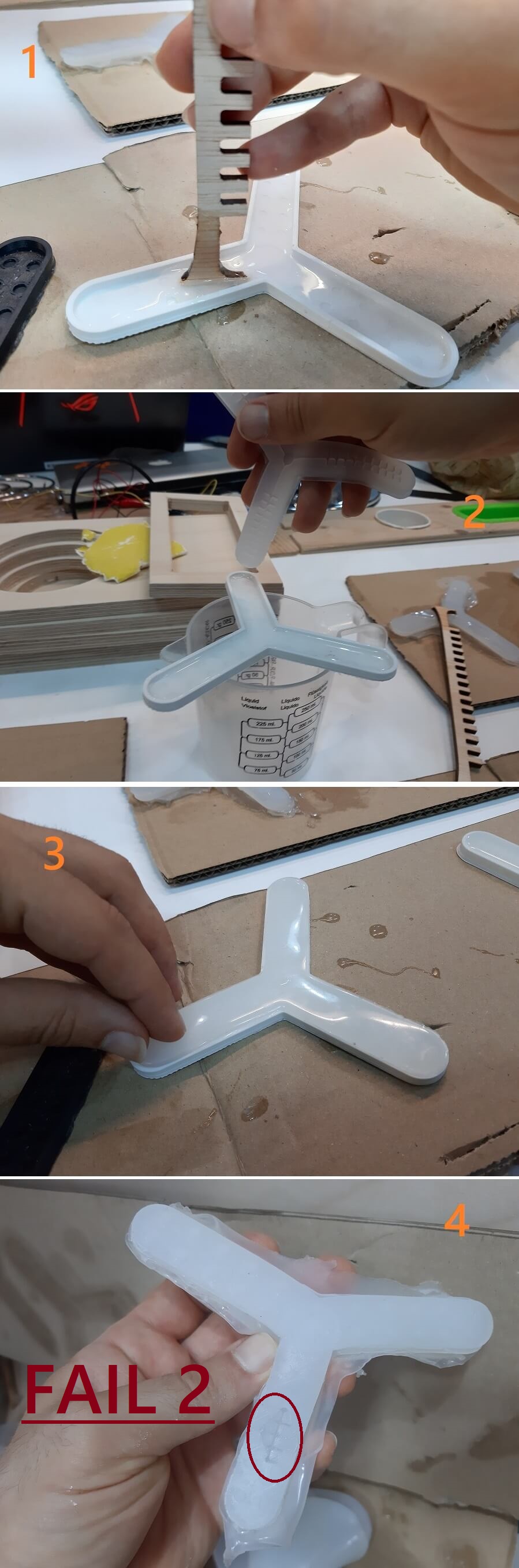

In the first attempt I casted both molds and then manually joined together with other silicon, the result did not end up being satisfing tho. The side layer was not strong enough to endure air pressure and on top of that the 2 shapes were very difficult to align manually.

Second attempt, to improve the alignment I proceded to cast just the first shape and then create a very thin layer on the base of the flat mold where after I put the first cast on top (as shown in the pic). This way I solved the alignment issue but the base layer ended up being to thin, fragile and not even.

As a third attempt I finally used a piece of fabric as the basic layer, this way you also enforce the bendable movement in the proper direction considering the fabric is pretty rigid.

Anyway I want to warn to not press to much while you "glue" the cast on the fabric, otherwise you can end up clogging the air channel preventing the functioning.

Once I had a satisfing model, I proceded creating a hole in the middle.

And started preparing the inflation

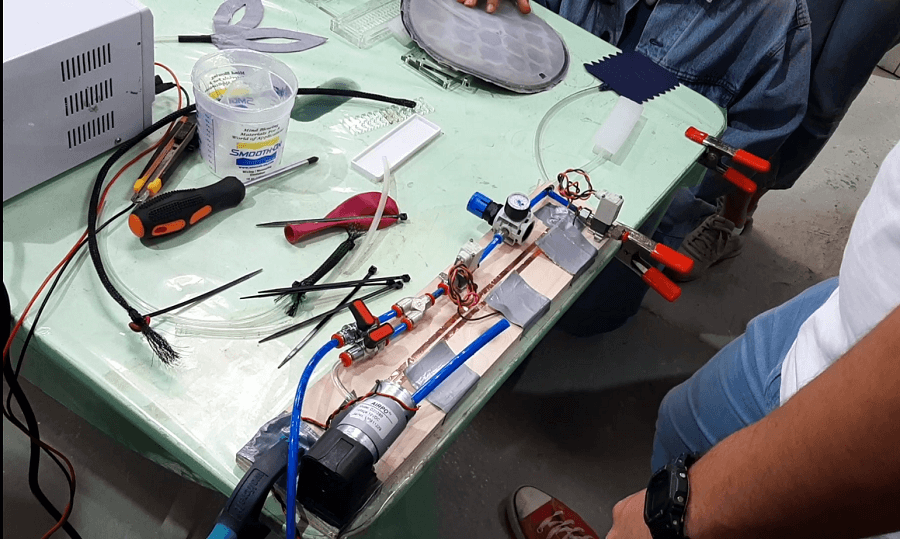

I used an air pump to inflate my device connect to an hand-made pump switch as displayed below:

Here I am picking an object with my soft robot:

Another cool soft-robot from the lab:

Copyright © 2018 - All Rights Reserved - Domain Name

Template by OS Templates