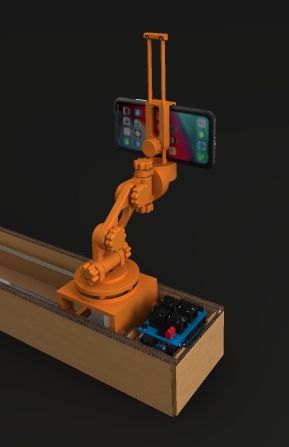

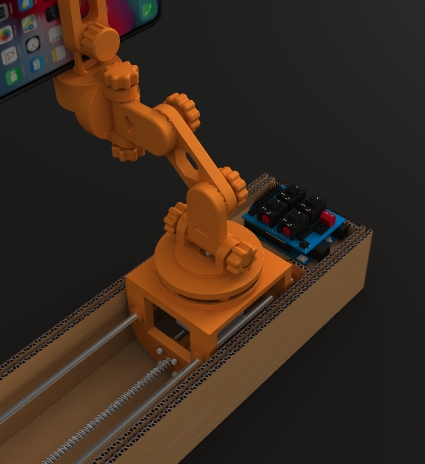

For the group

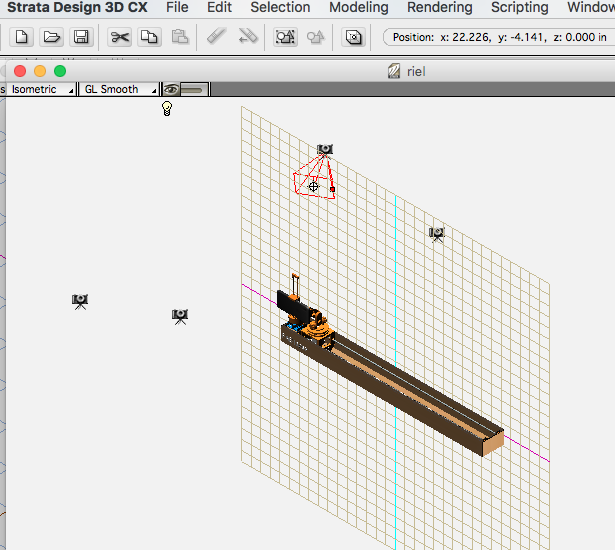

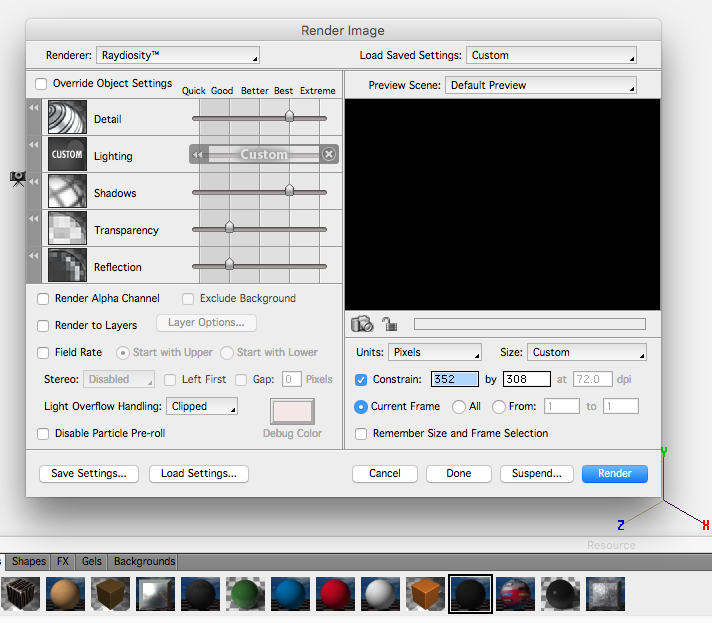

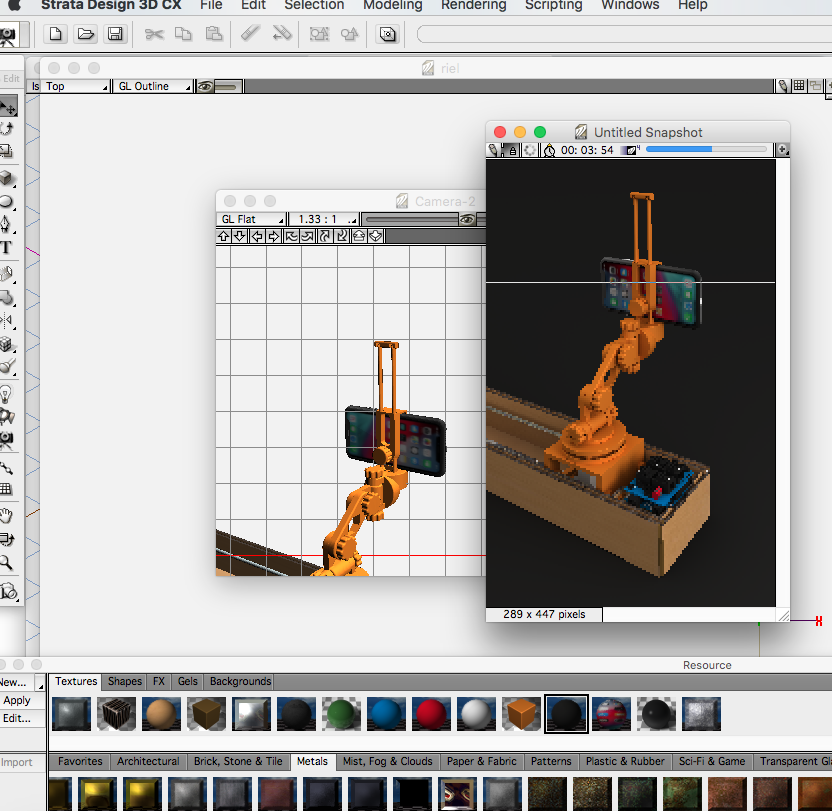

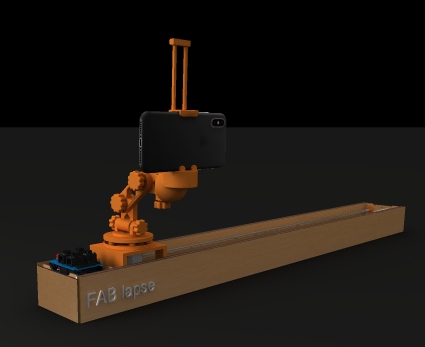

assignment activity i did the renders for the original version

that was intended to be fabricate of corrugated board.

and the link to the group assignment is: FabLabCDMX.

In lockdown

We where in lockdown when we first started to work on this assignment, we agreed between Querétaro and Mexico City to divide the activities of the project; programming and design in which I was involved with the rendering of the original design and later in the design, with Luis Hernández of the rotating base of the cell phone, because we thought that we could make it less complex , we talked about the adjustments that we thought were convenient to make to the movement and clamping system, thinking that we could use a bearing or only the pellets as a turning system and from there I began to make the preliminary sketches of the components and then start modeling them. I was working on that when Querétaro gave access to the Campus only to University employees, therefore, Querétaro had restricted access to the facilities and that was when I sent Luis the file so he could print it in 3D because there, in Querétaro, they started to assembly the machine.

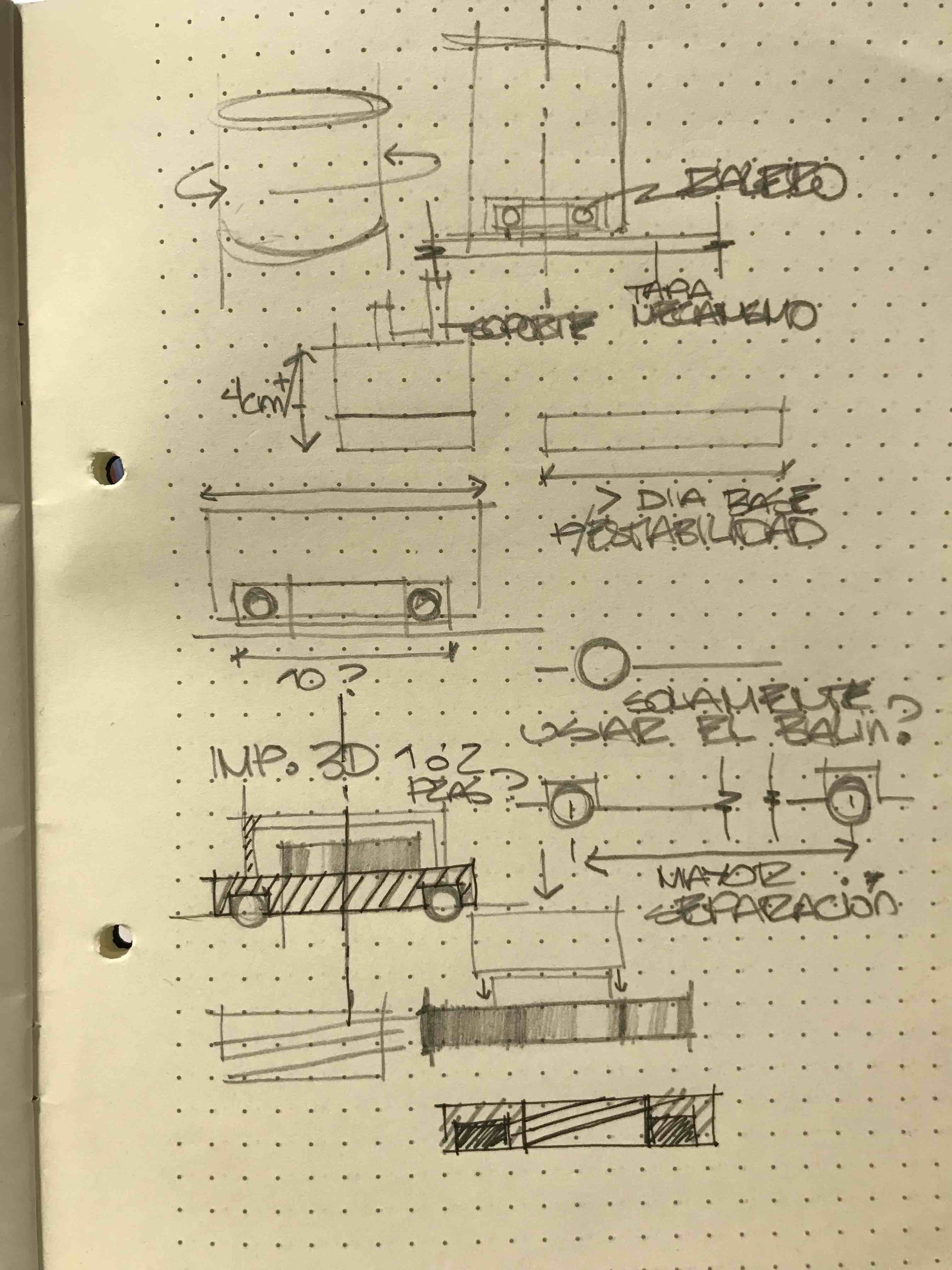

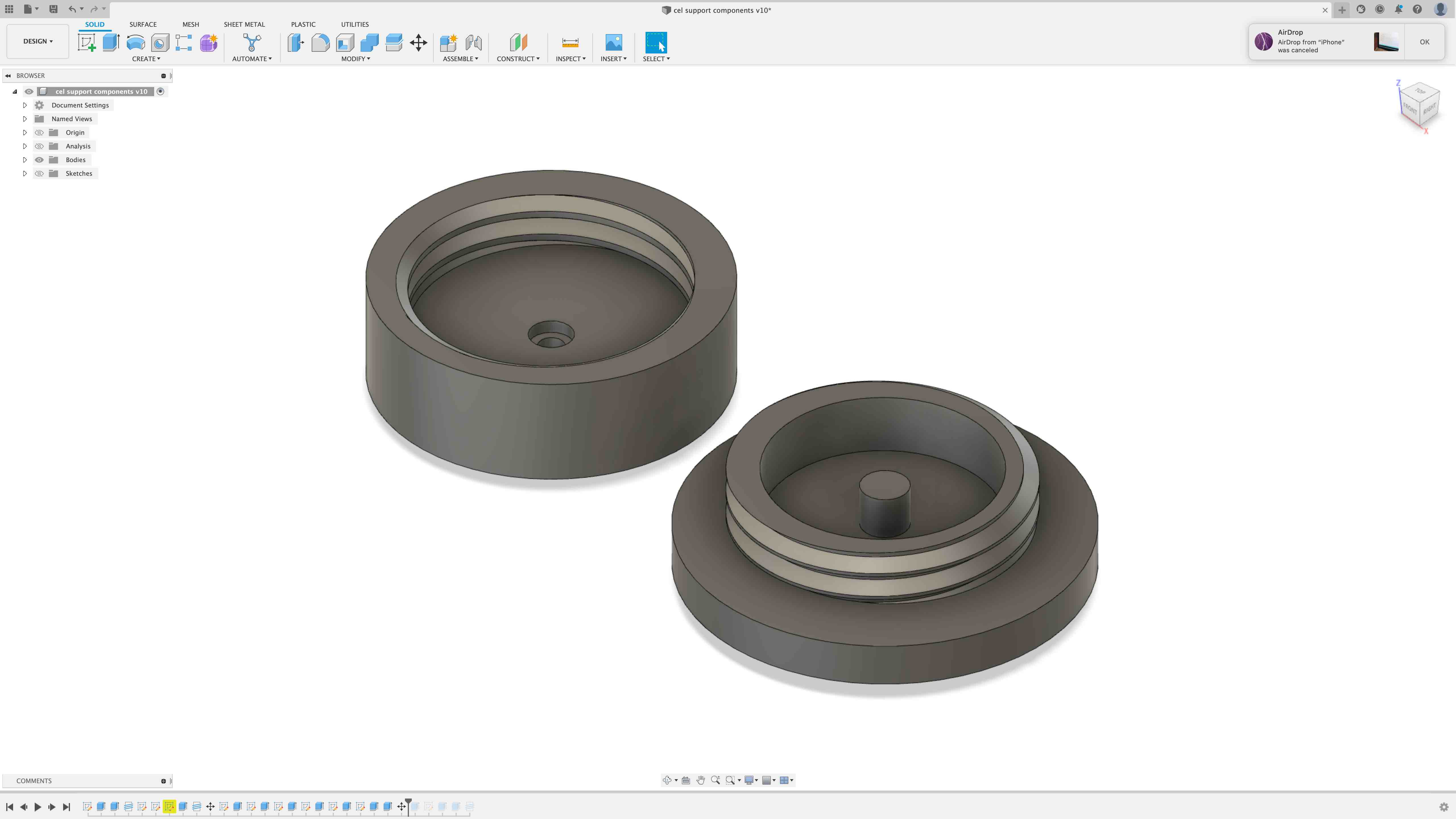

Here I start to

explore some design options of the rotating system, we thought

that we could only use the pellets, maybe a 1/2" pellets so the

base could turn more efficiently, and with this solution we could

have a wider base without using a big bearing system.

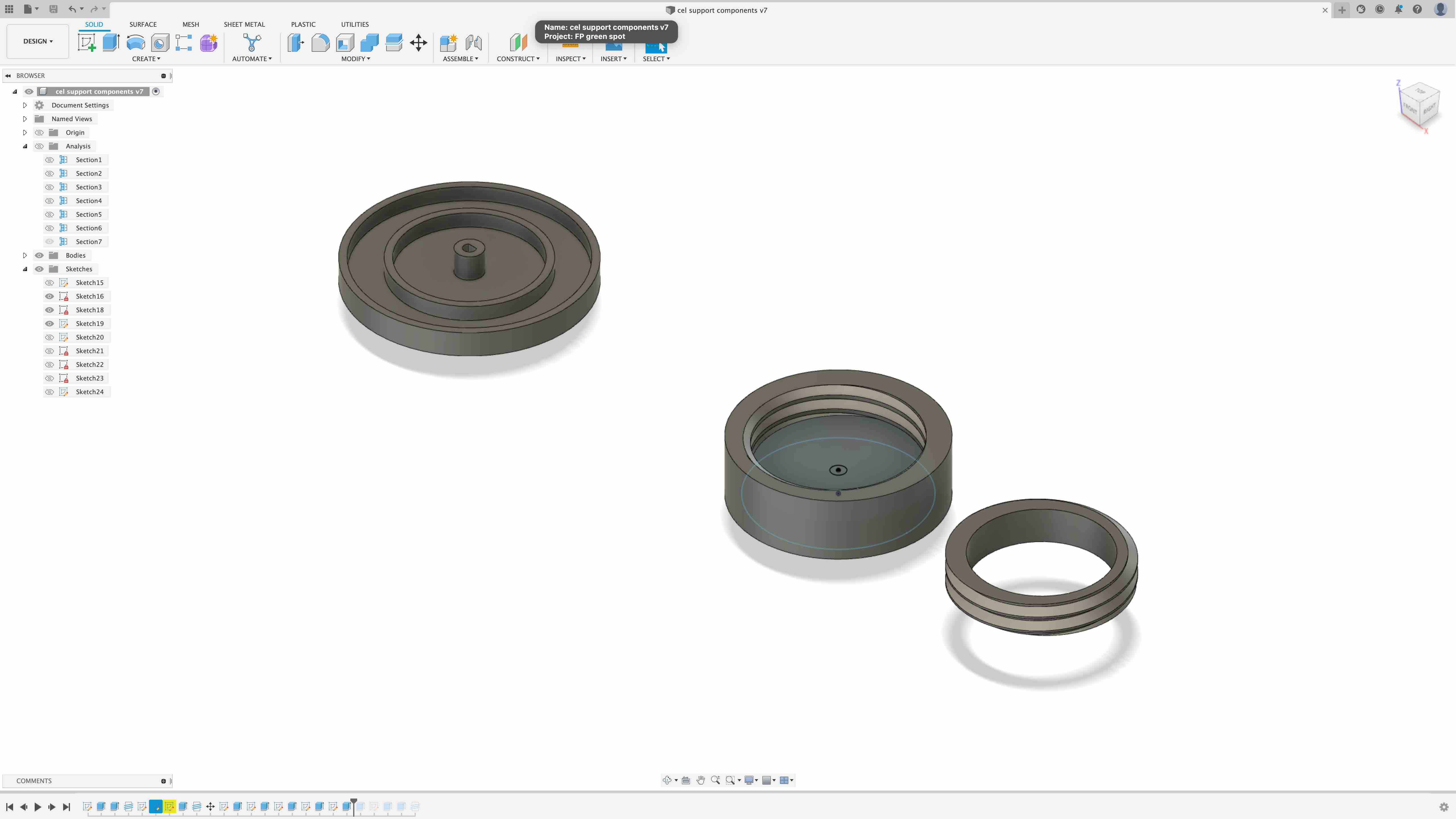

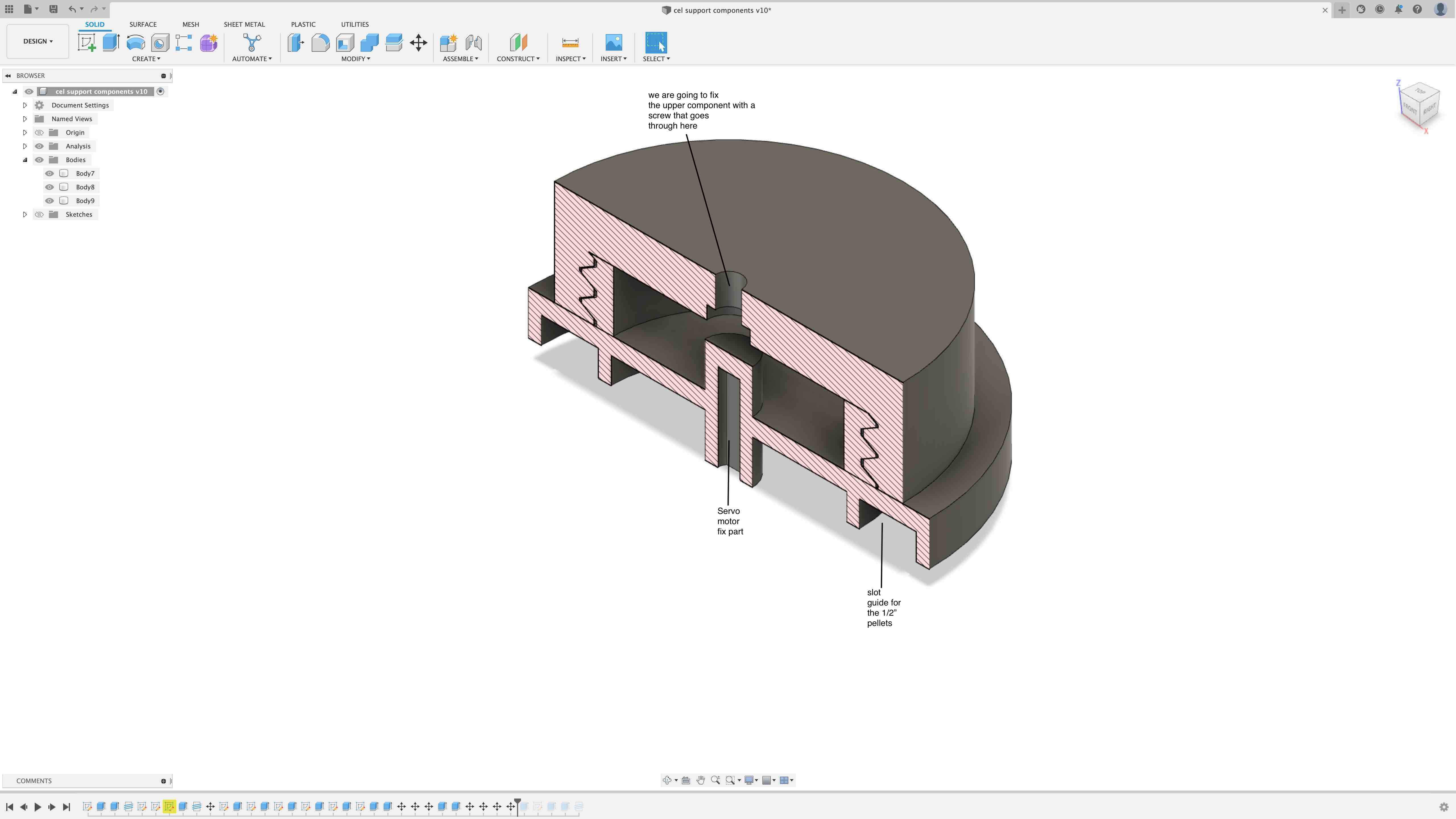

In this series of

images I model the components of the rotating base of the

cellphone, we can see the basic parts of the design; the slot

where the bearings are going to fit, the center piece where we are

going to fix the servo motor and in the upper cap with a central

hole where we are going to attach the cellphone clamp with a

screw.

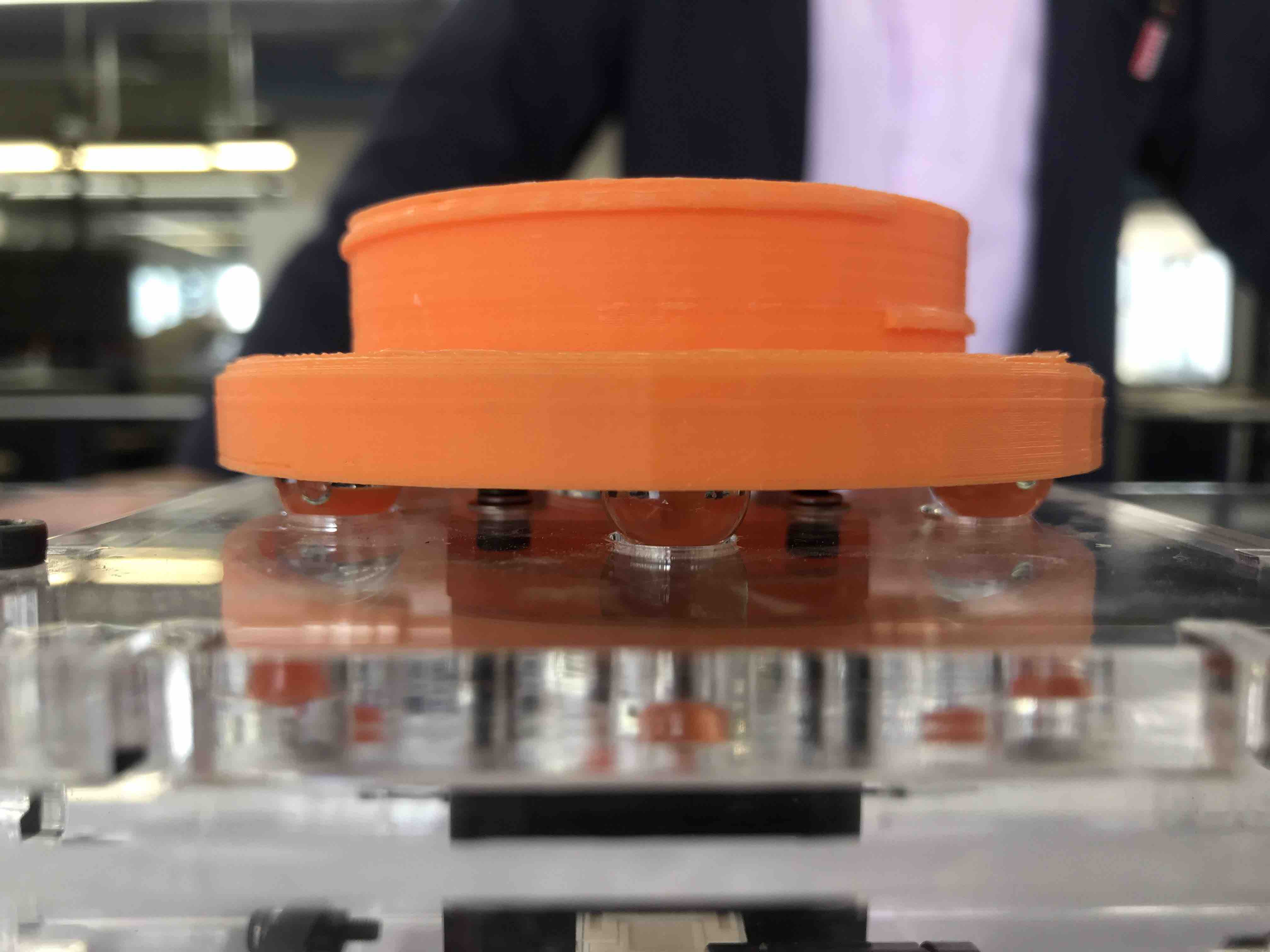

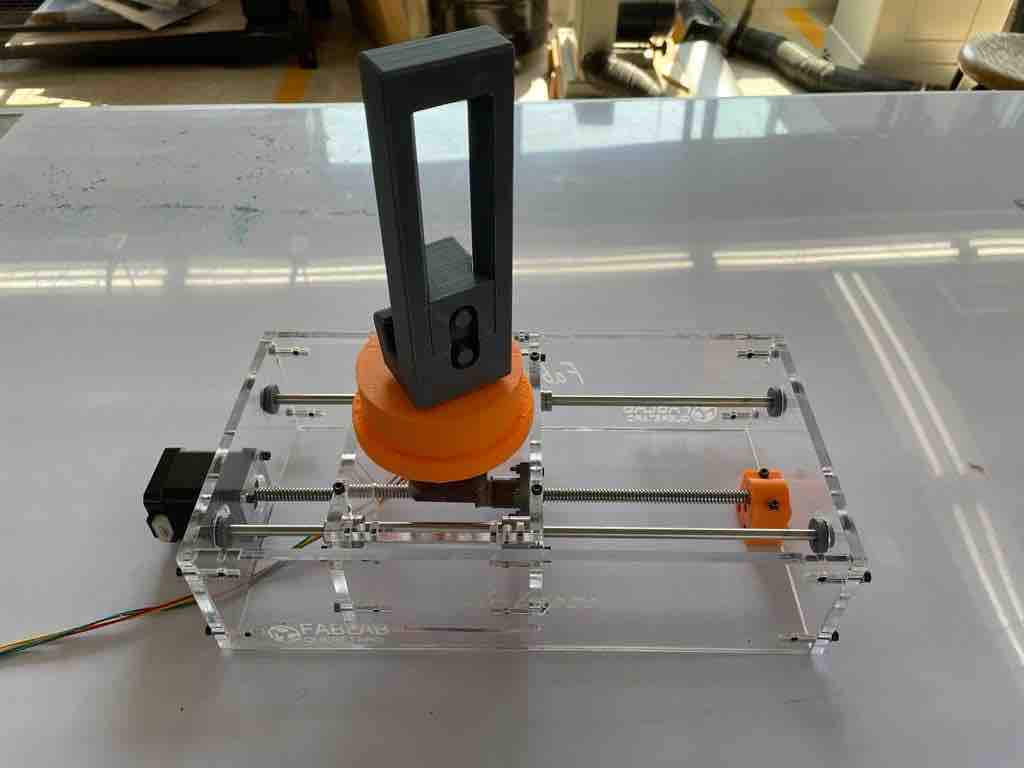

....Basically we

change the design of some components, like the external box, from

cardboard to acrylic and also the design of the smartphone

support. this support is fix to the servo and over some marbles

that act like a bearing si this support can rotate and be stable,

but there´s the problem, when it rotates it is not stable,

something with the balanced between the marbles and the inferior

part of the support.

My job was to figure

it out how to improve this, so I disarmed the support and took the

bottom that goes over the marbles

Here I can see that the

space design for the marble is wider than the marbles and this could

make the unbalance when the support starts to rotate.

So I think that maybe,

if I put something like an o´ring in the internal or outter diameter

of the groove, the displacement of the support when rotate

over the marbles could be fix, so I measure with a caliper the

diameter of the marble and the dimension of the groove.

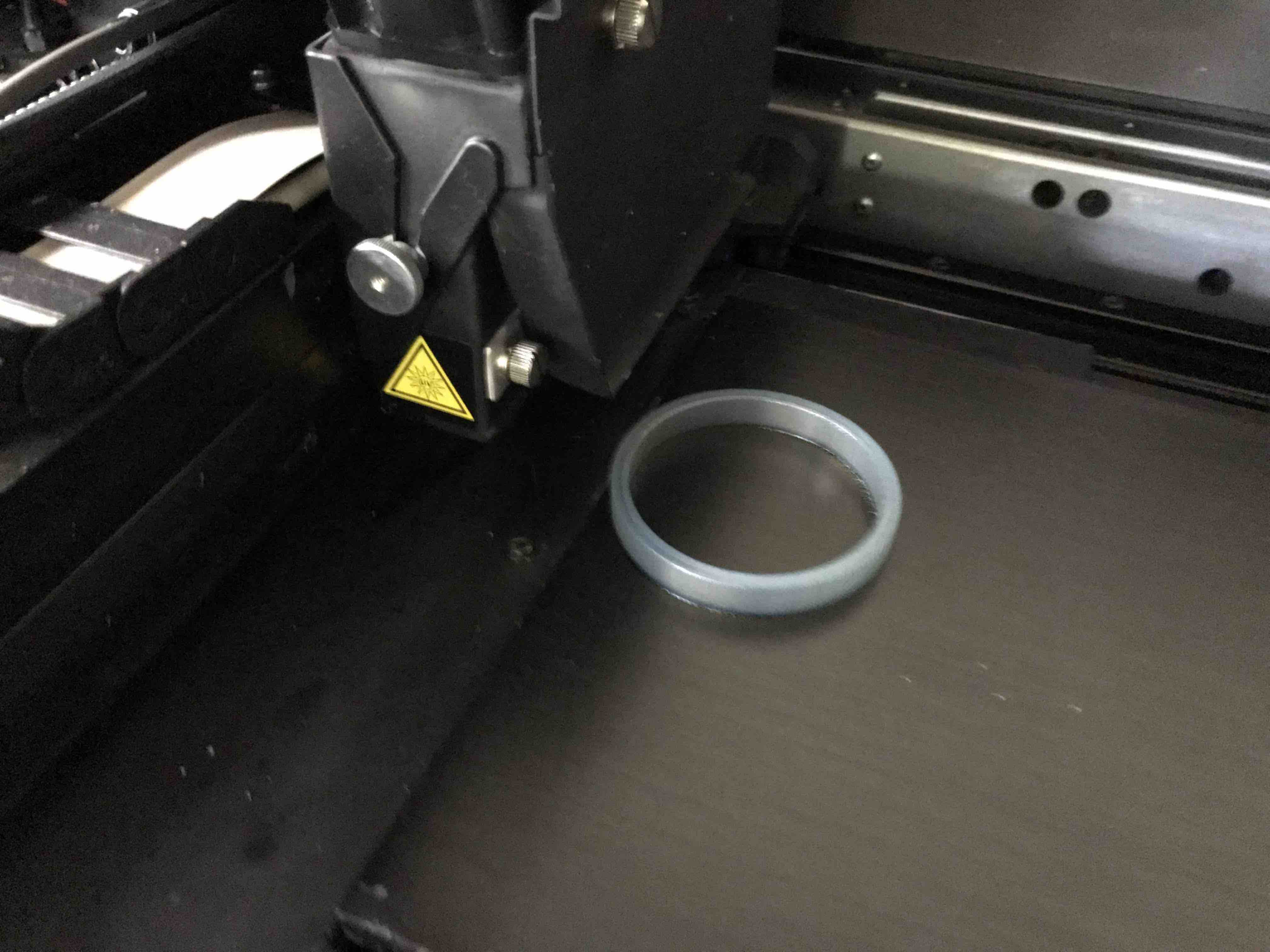

I print the o´ring in

VeroClear, using this Stratasys Objet30 Pro beacause of it thickness

of 0.77mm .

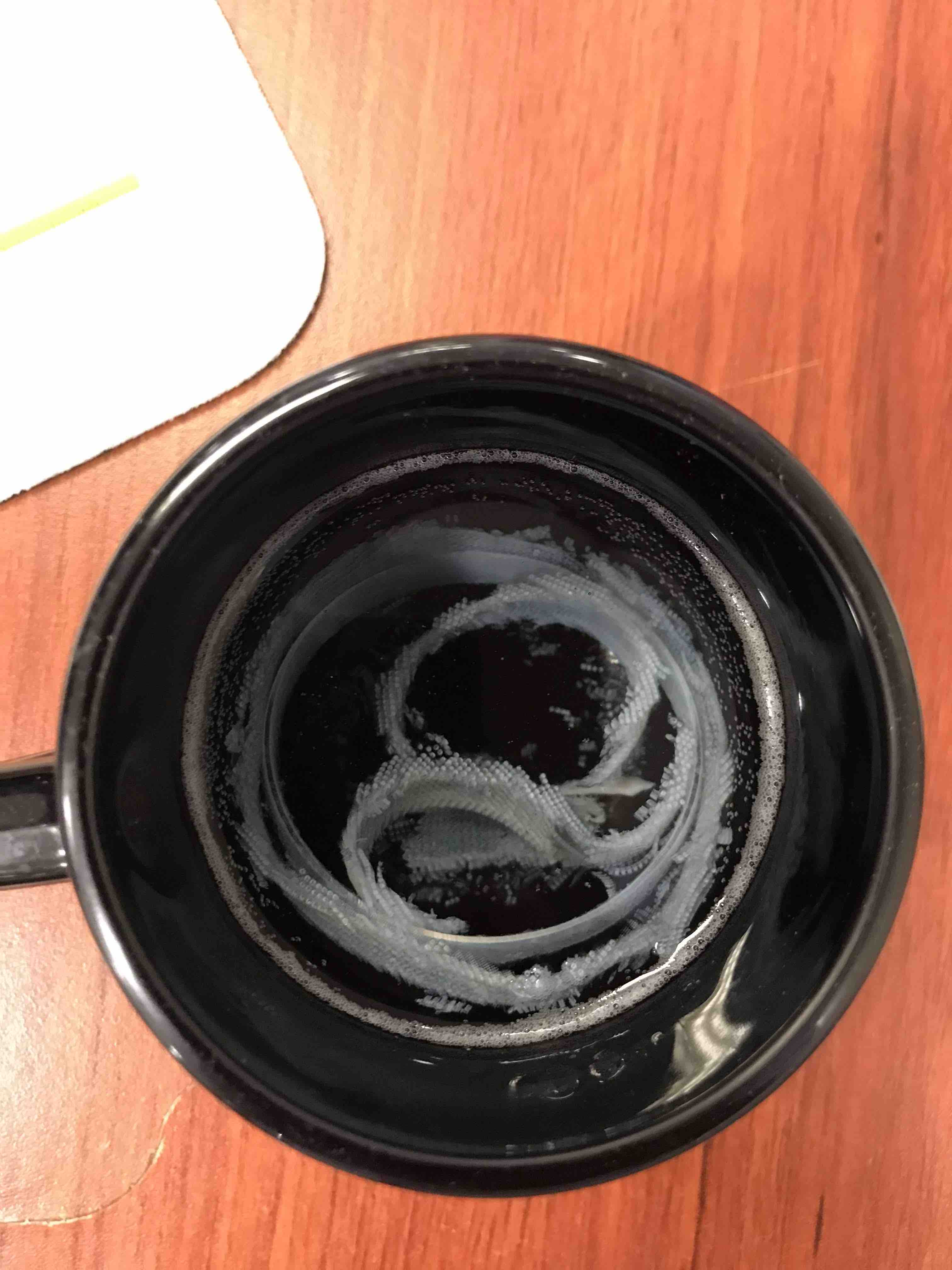

It looks kind of

thicker than expected but the final part is in the midle of this

ring, if you look carefully you can see it between the outer layers.

to remove the excess of

material I dipped the ring in water all night.

Then I put the o´ring

in place and the marble fits better.

And assemble everything

again. This fix the rotation problem as you can see in the "Header"

video at the beginning of the page and in the video below

video of the machine

functioning watching it from another smartphone with the horizon just

below the marbles and the balance looks fine.