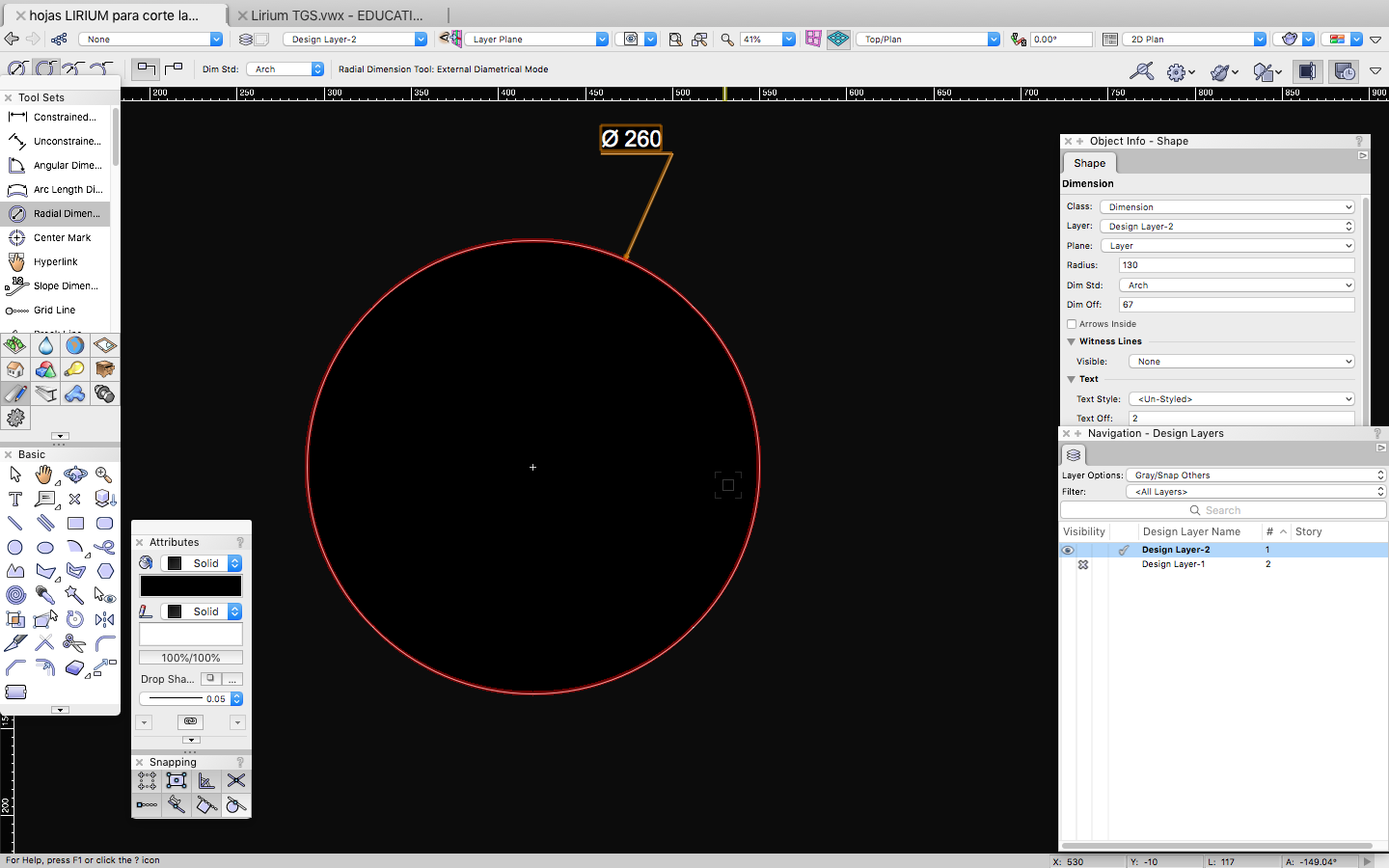

For this assignment

I will draw the leafs that would be part of the upper

system of my project, there will be the solar cells and the LED

lights, so in Vectorworks I will draw the circles and clip the

pacman mouth like distinct form of the lirium leaf and with that

shape defined, I will make in Fusion360 the 3D perymeter of the

leafs, with both pieces finsihed I would be able to shape the

leafs and put the electrical system on them.

Vectorworks,

Fusion360

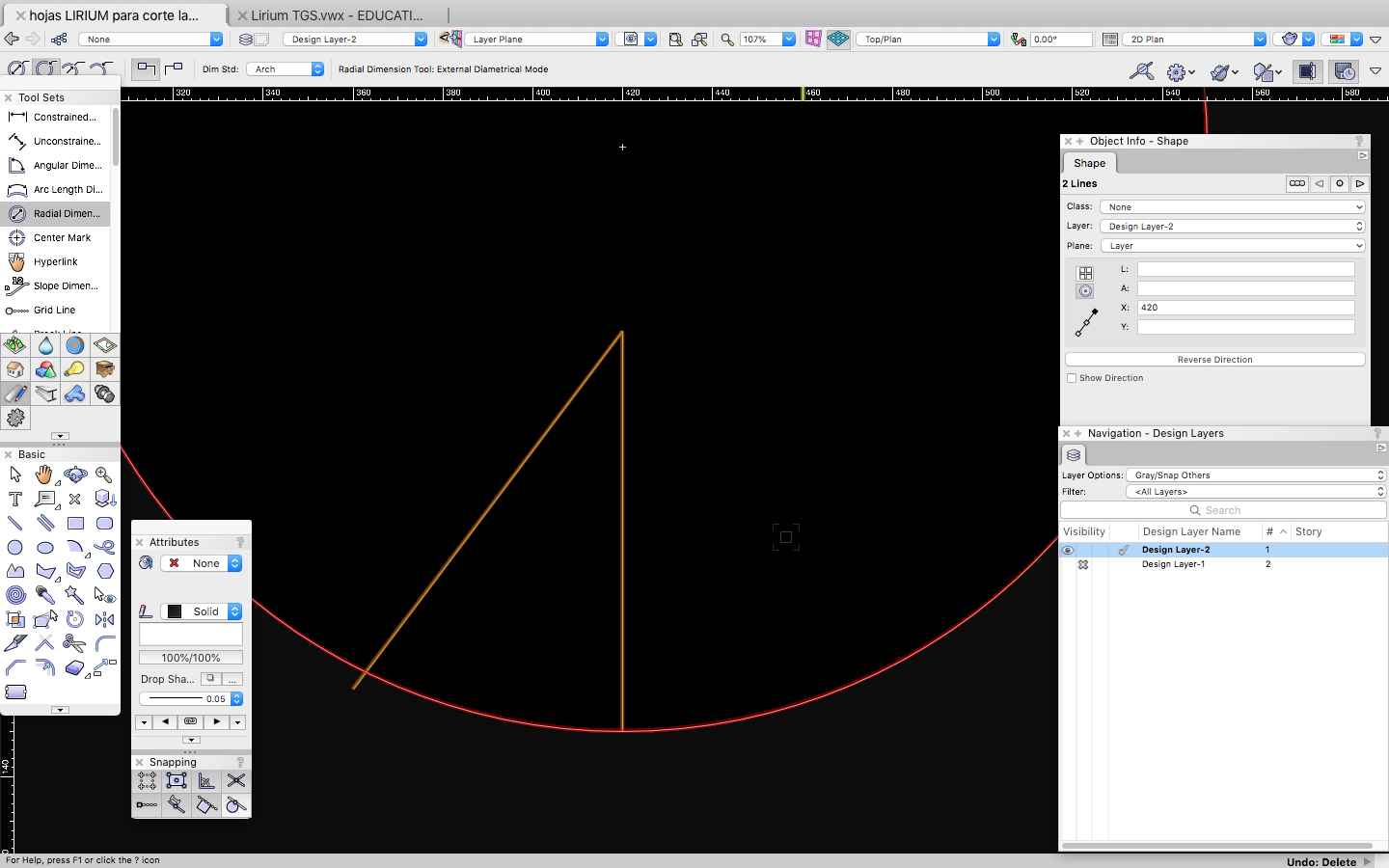

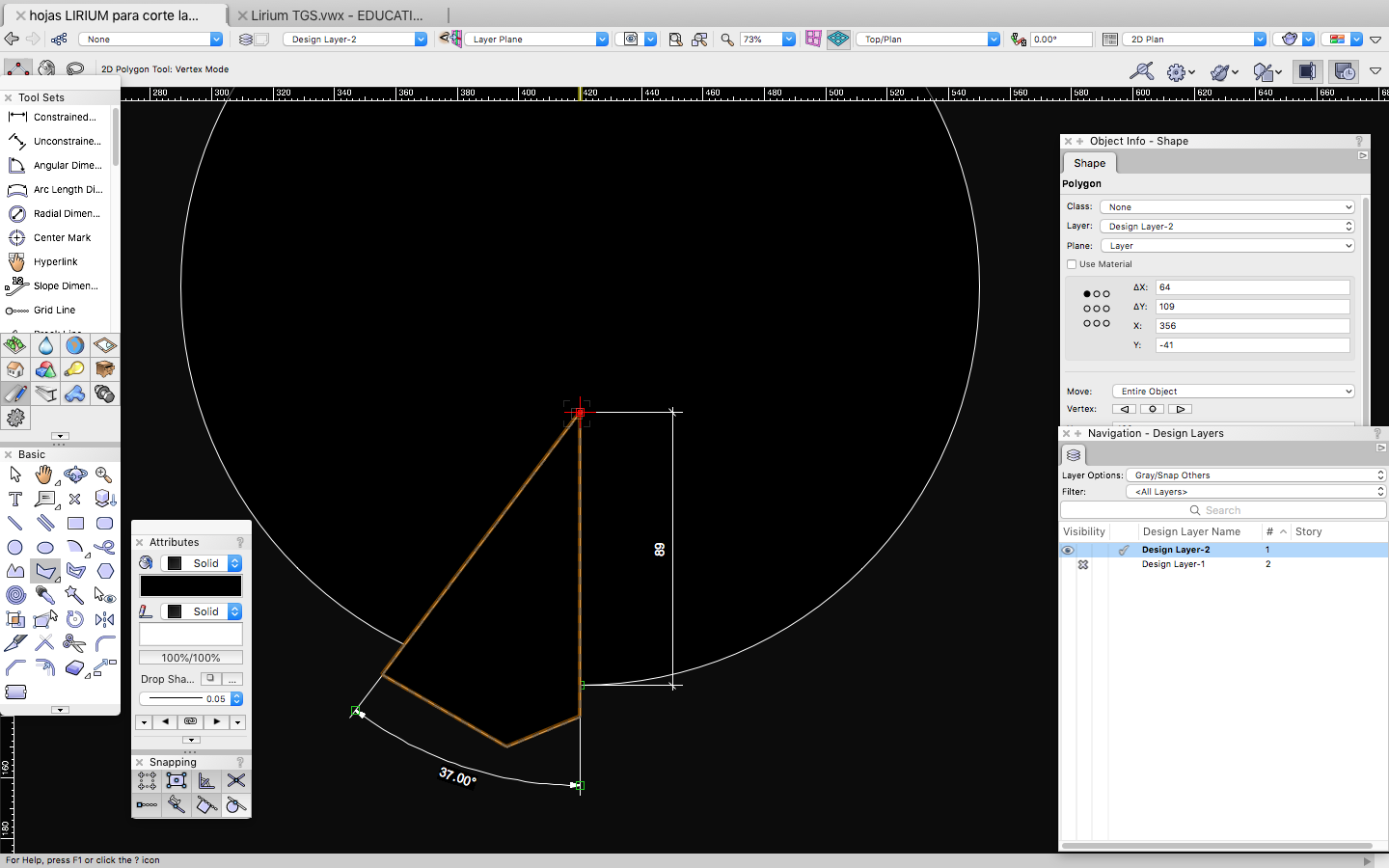

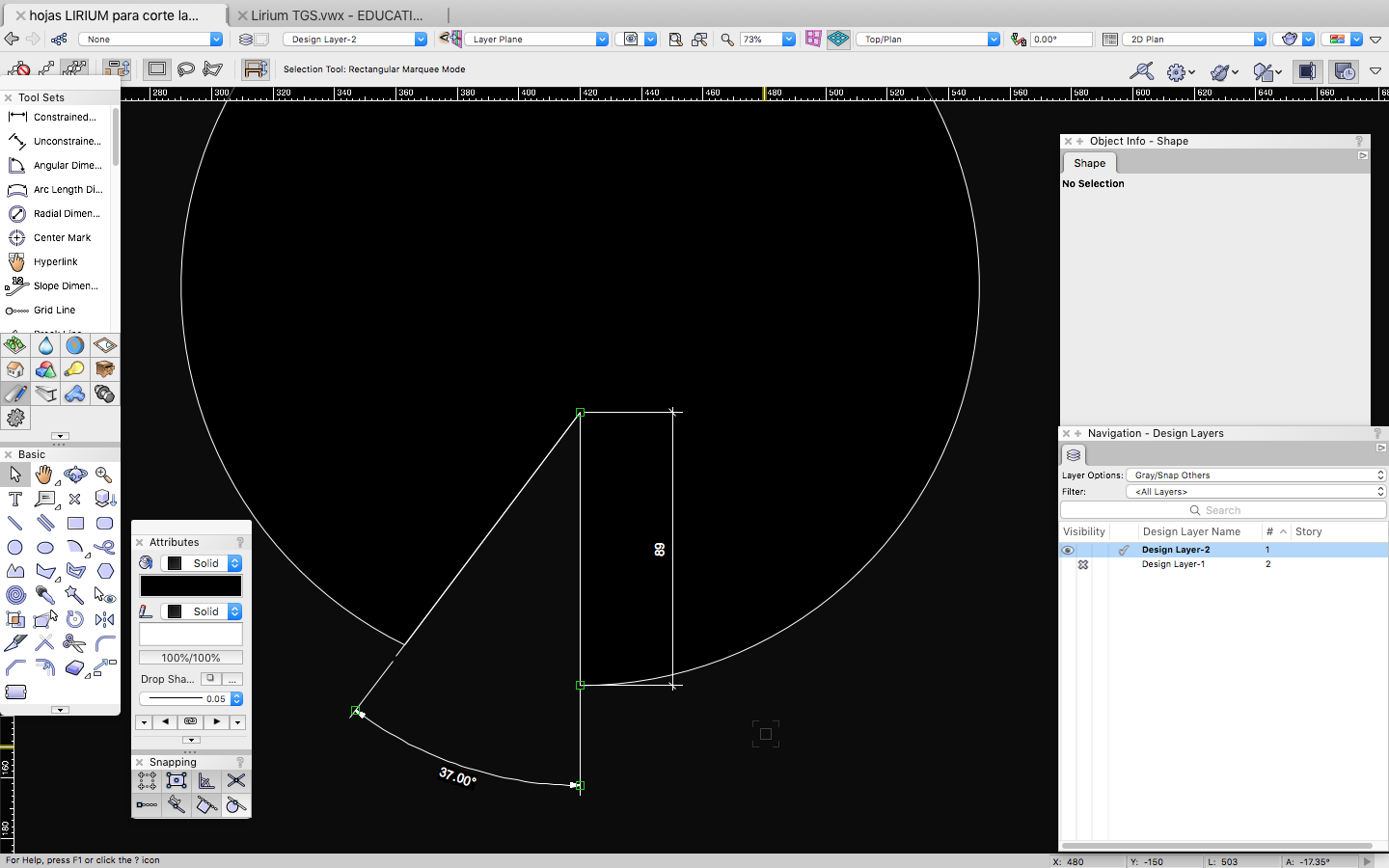

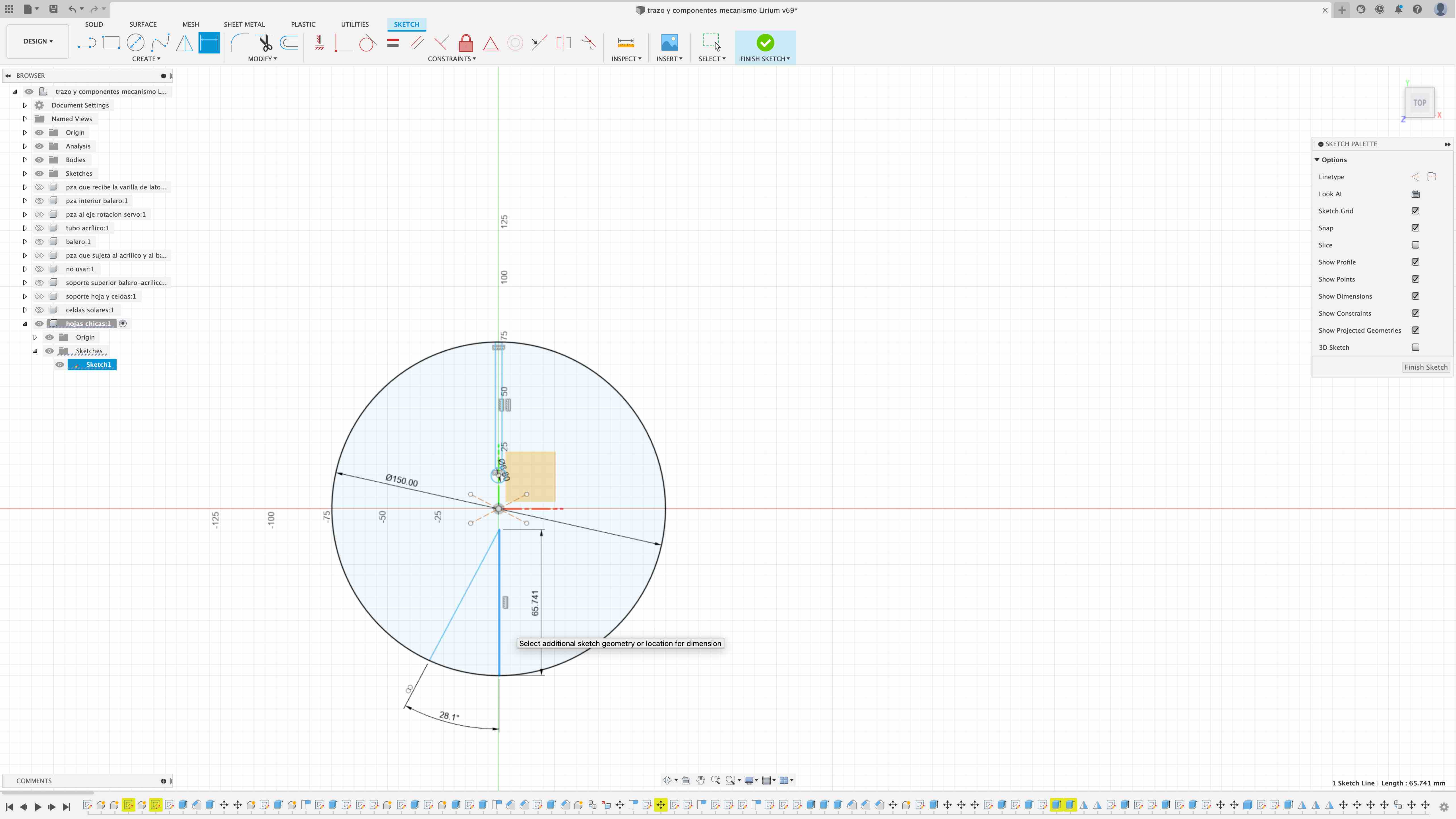

I draw a shape to cut

it form the circle, this will be the "mouth" of the leaf

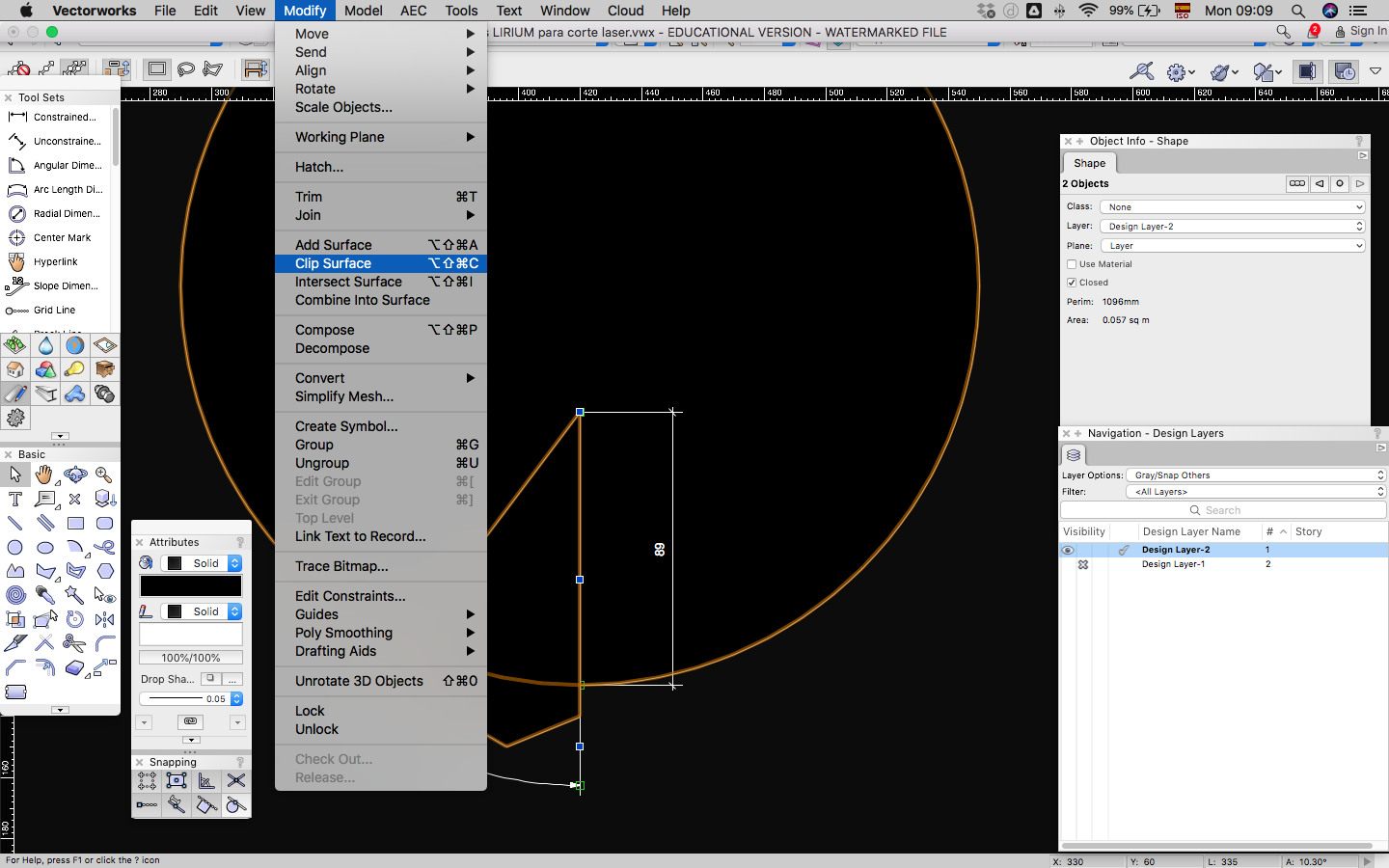

With the clip Surface

action, you will be able to remove the "triangle" I made to cut it

from the circle

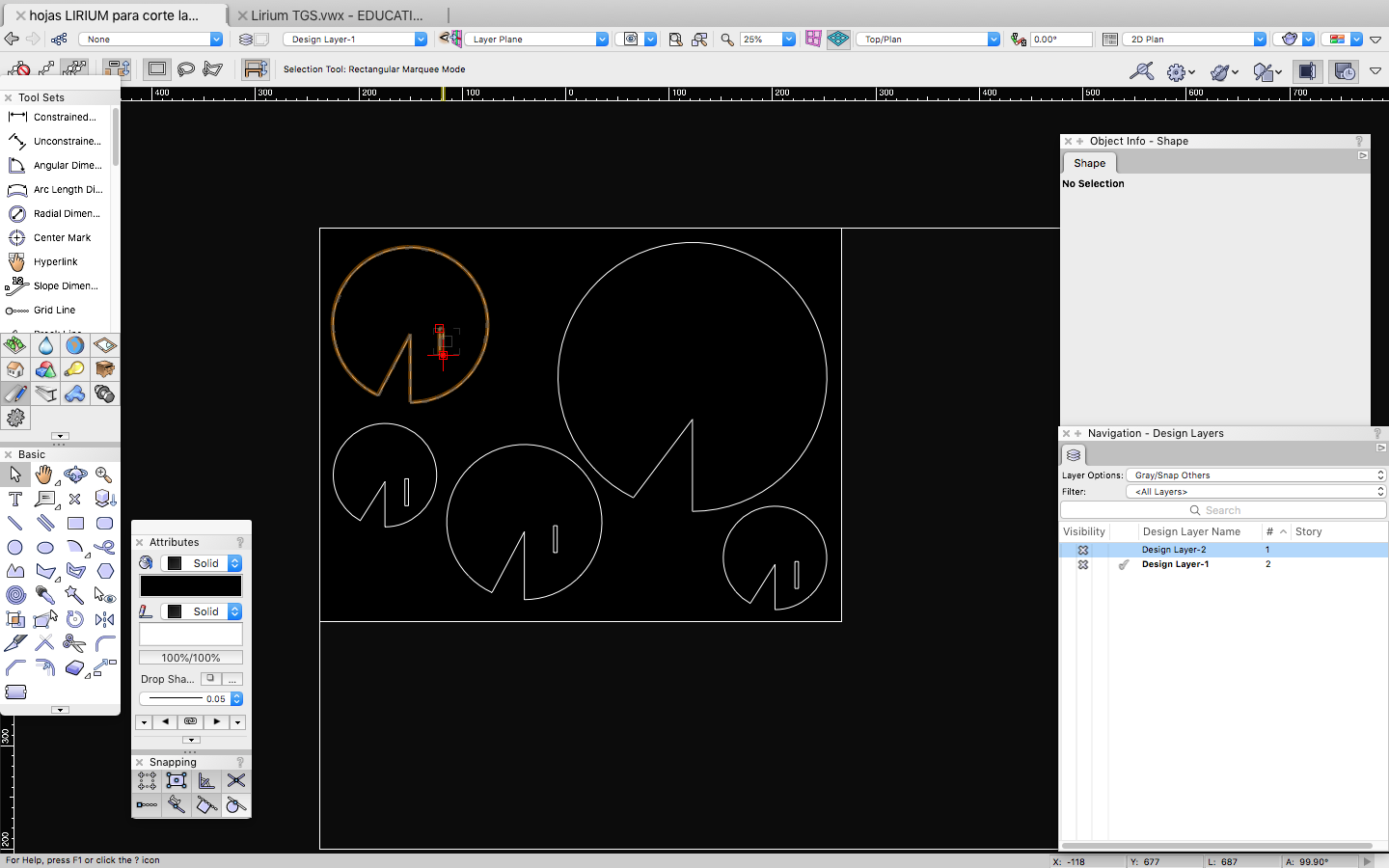

Here is the resulting

shape; the circle without the mouth like shape

Do the same with the

rest of the pieces and draw a rectangle that measure the size of the

cartonboard you are going to use to cut your pieces

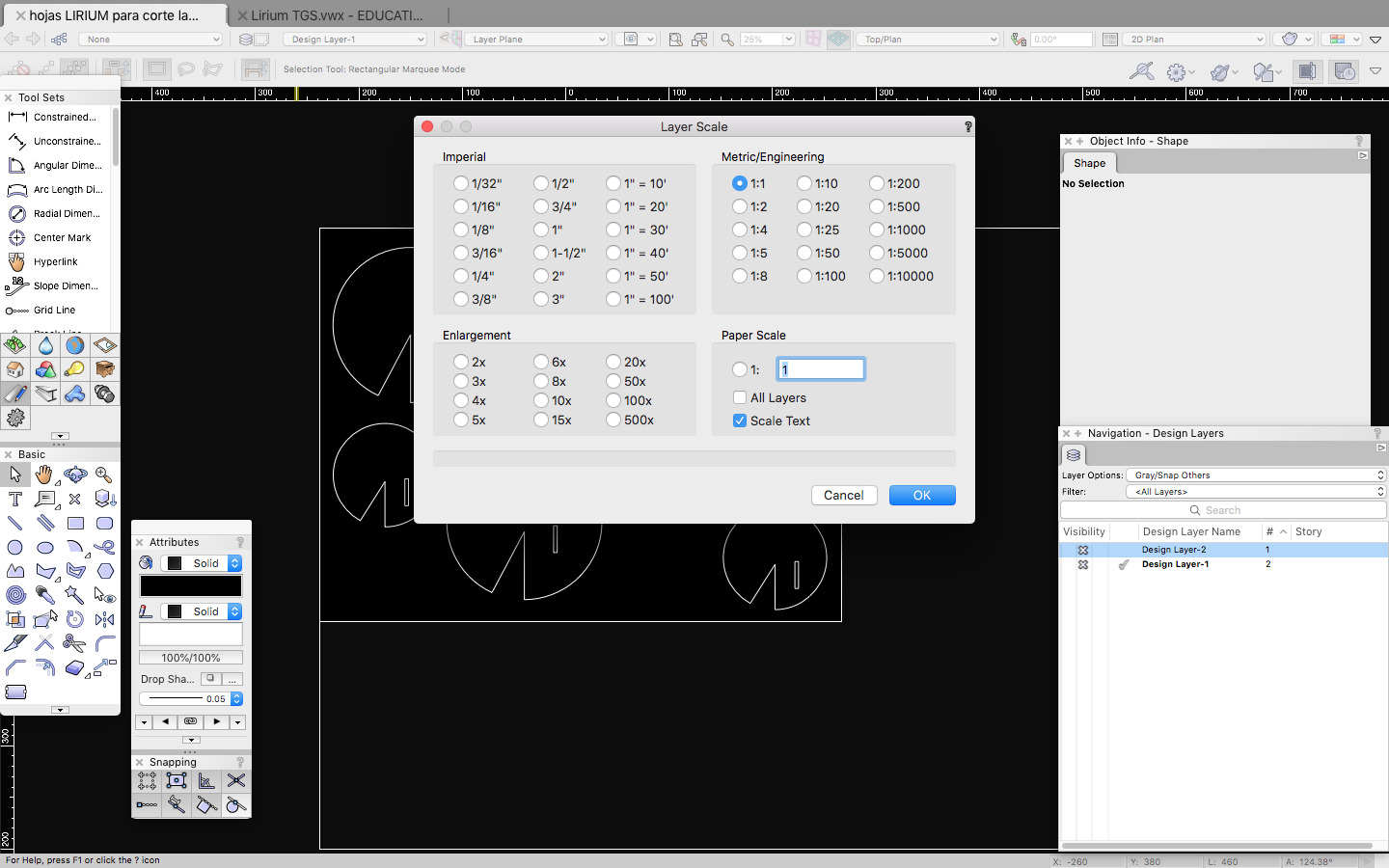

Scale 1:1 and in mm,

this is important

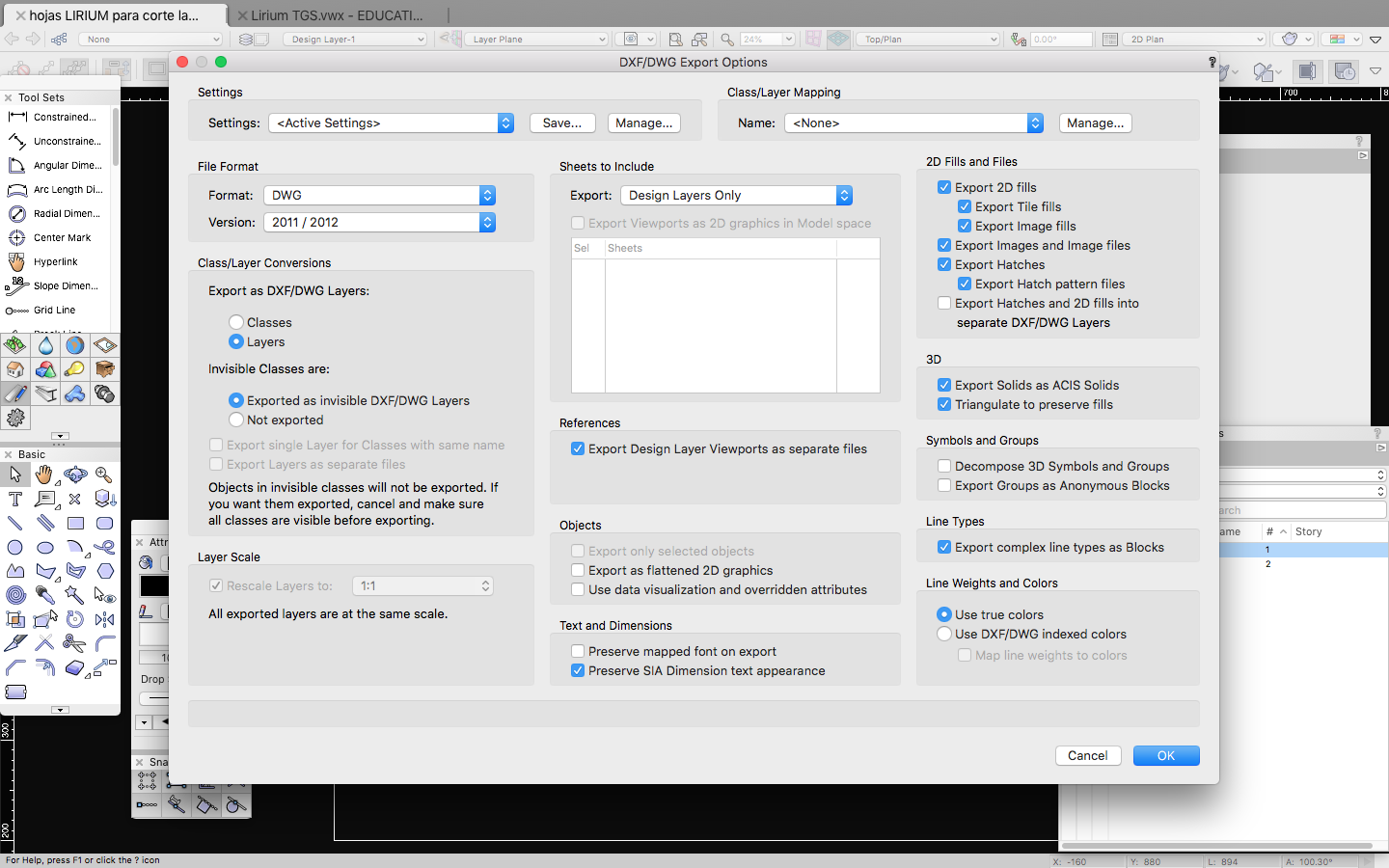

Export the archive to

.DWG to open it later in autocad.

In fusion360 I draw the

circle that will be the perimeter of the leafs, the triangle that

would be the pacman mouth like caracteristique lirium shape and the

inner circle with its support arm,

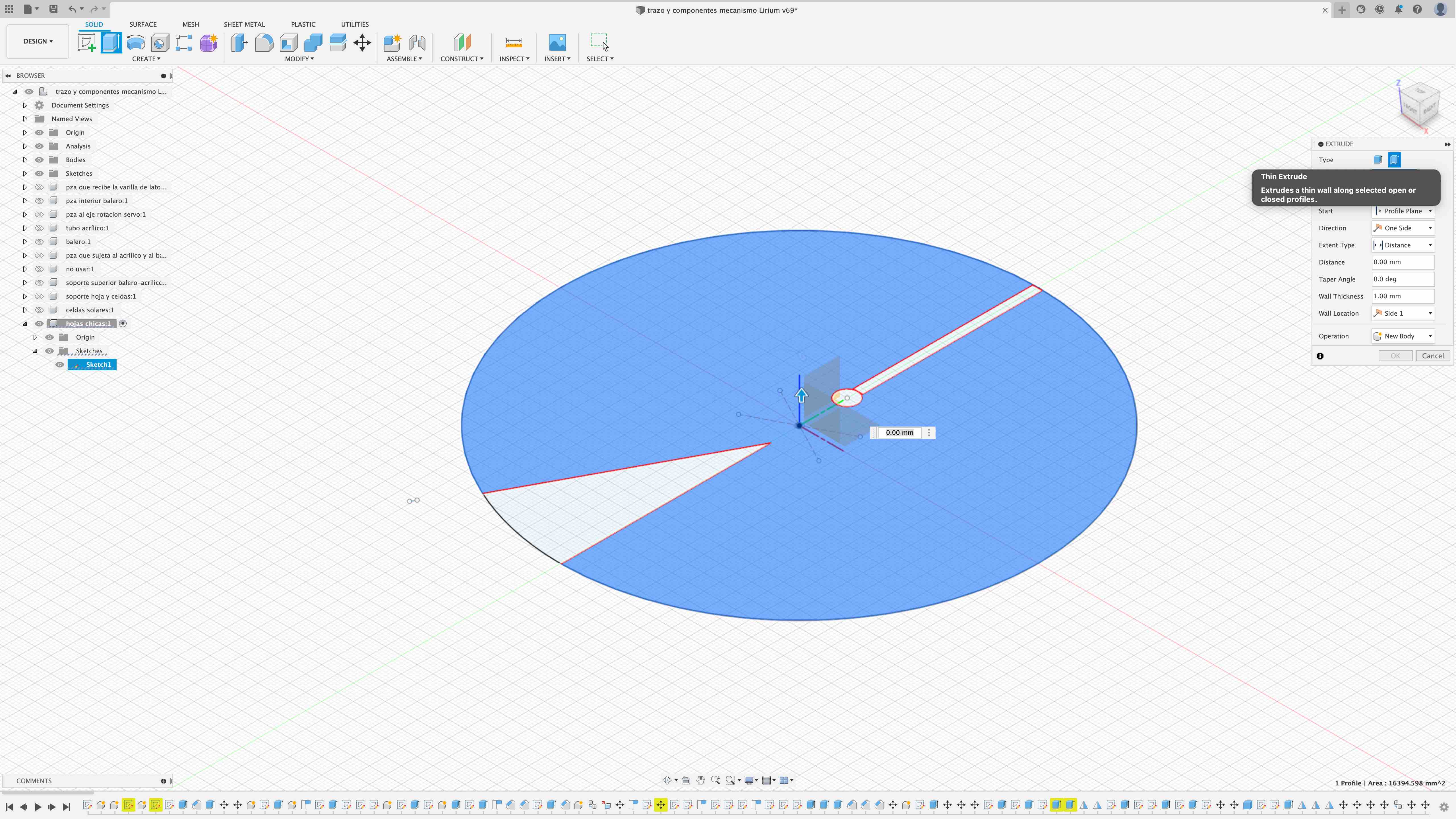

Then with the tool

extrude-thin extrude i will extrude only the perymeter of

the leaf: in the window of the tool you need to specify the wall

thickness and the distance (the high)

of the extrussion, its important to choose the direction

and the Wall location because with this you

specify if the thickness of the extrussion would be inside or

outside the line, in this case I choose side 1

than means in the interior because I need

the thickness of the extrusion to be inside the limits of the

circle.

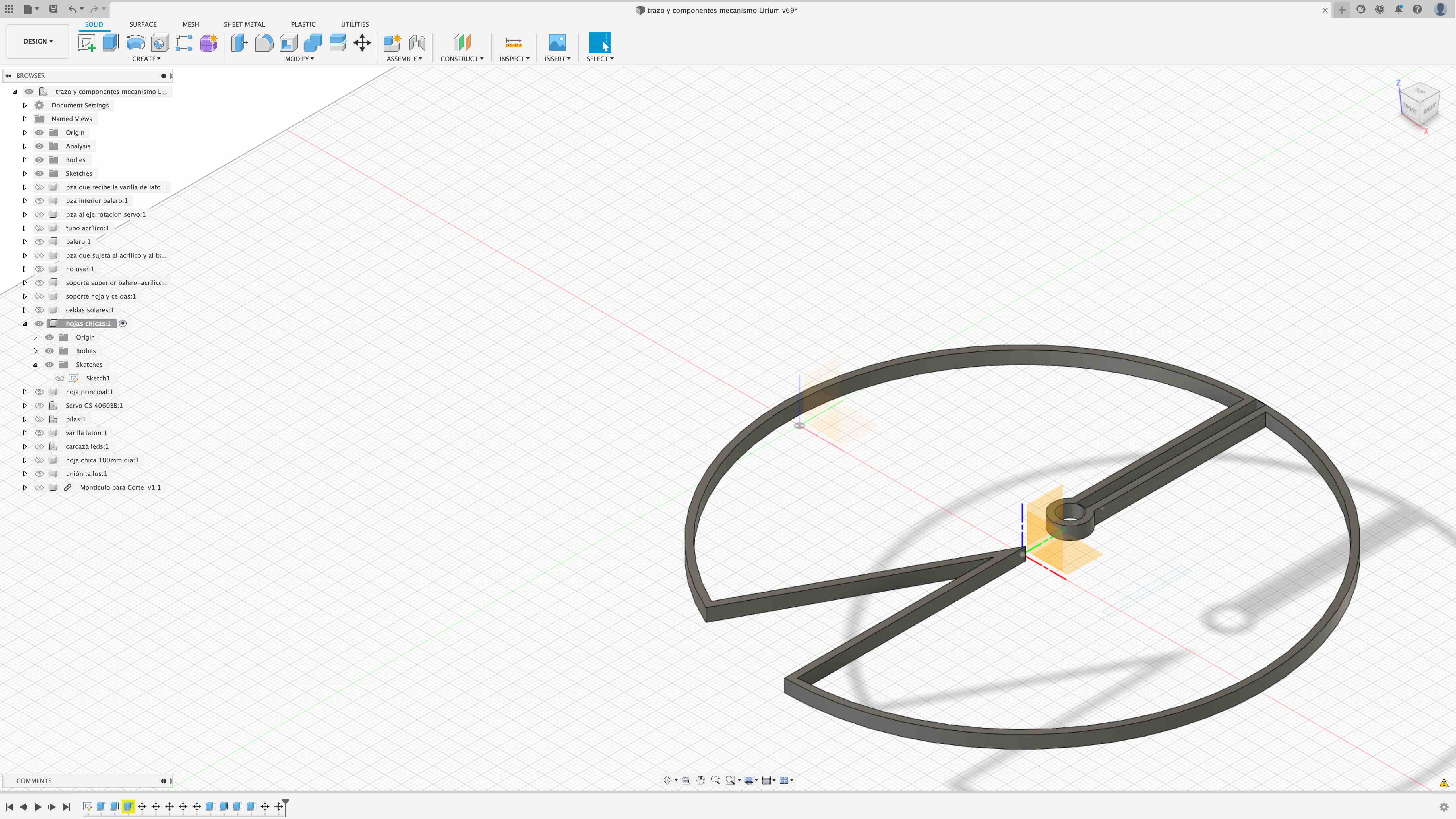

Here we can see the

extrussion of the leaf perymeter

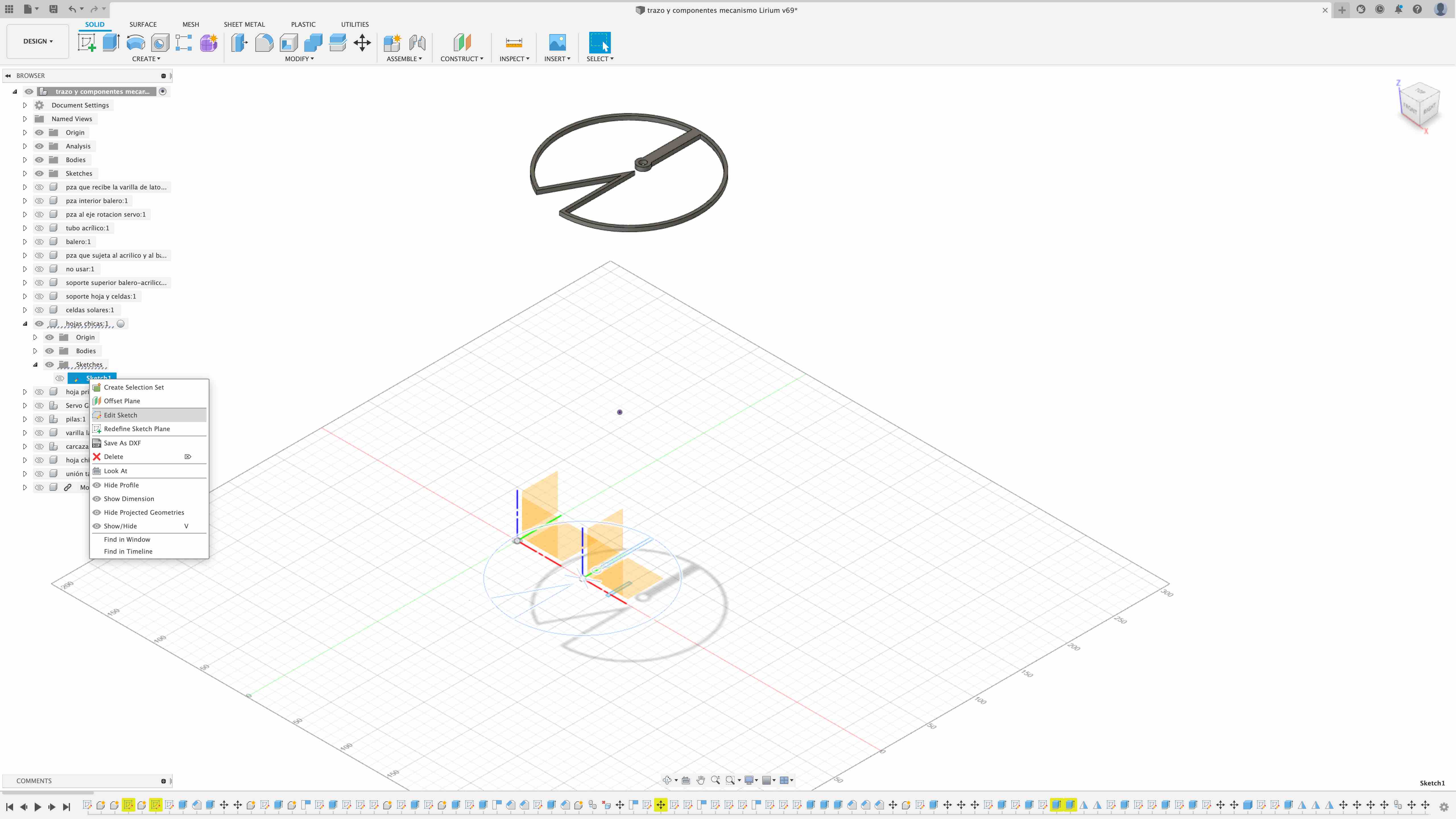

One really good thing

about fusion360 is that you keep the original

sketch and the "body"(the body is the 3d object that result from

extrude the sketch), that means that I can go to the original sketch

and modify something, and the body, in this case the extrusion would

be updated according to those modifications. You can see this in the

left menu, there, I´m selecting "edit

sketch" of the sketch 1 of the "hojas

chicas" component.

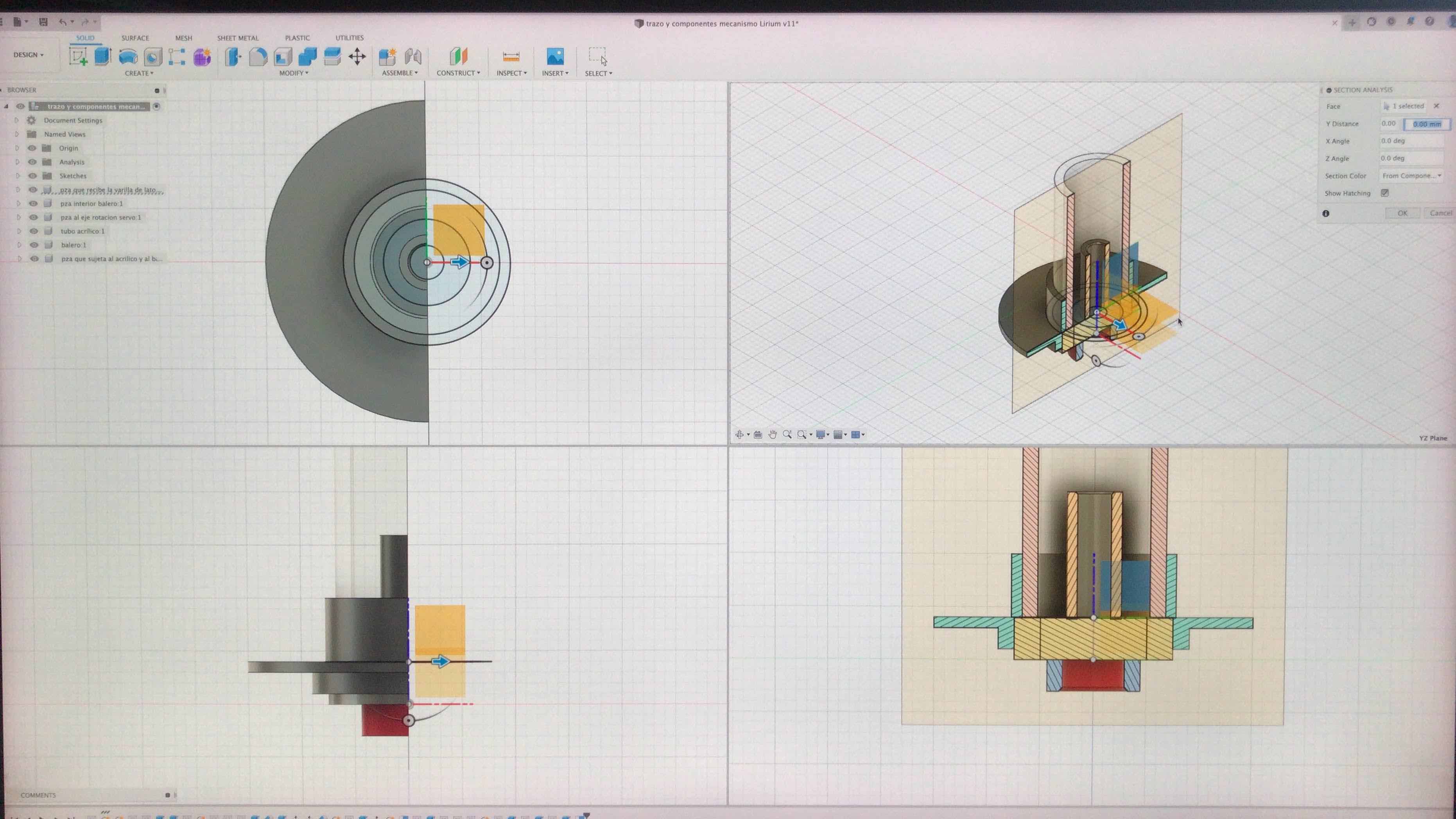

Another sample of some

3D components of my final project, here I assemble the rotation

pieces. Using the "section analysis" that is inside the INSPECT menu

we are able to see a longitudinal cut of the components to see if

everything is in it´s place and nothing interferes, if needed, I can

modify some parameters to change some dimensions.

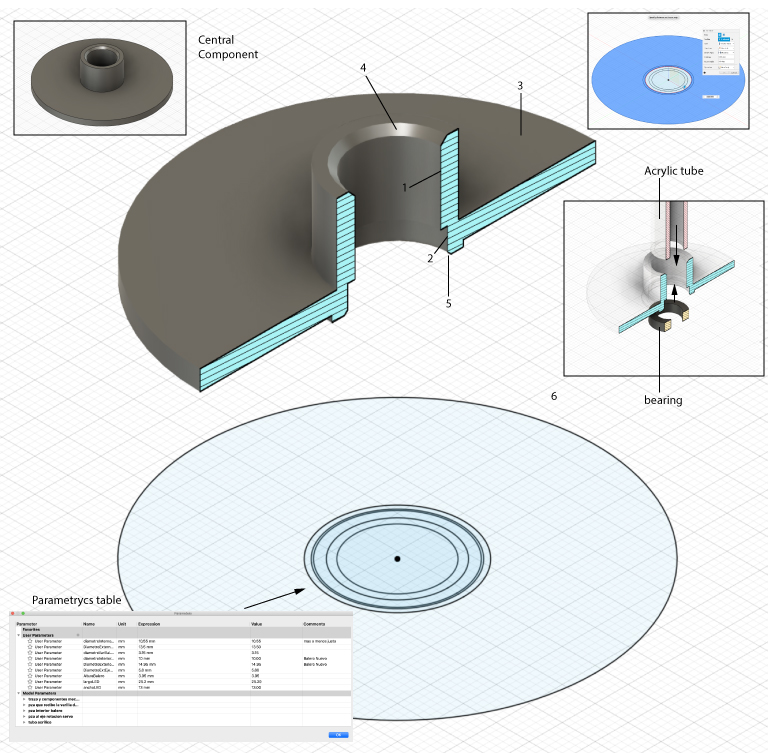

To model in 3D this

component, the Central Component, I knew in advanced that I will

need an Acrylic Tube and a Bearing, not quite sure about the

measures of those 2 objetcs but sure that I need to consider them

because one is going to act s the support of the upper leaf and the

later will be used as the rotating system. So, first I start making

my parametrycs table because all the circles of the Central

Component will be affected by each other, and also they can be

affected by the percentage of the contraction of the plastic (ABS or

PLA) in wich the component will be printed, so I write the

parametrics of the bearing, the acrylic tube among others, Then I

started with the sketches, here in fusion 360 is prefer to start

drawing sketches, it means that you start drawing basic forms

like circles, lines, rectangles, etc and you can put the dimension

of that sketch directly or using a parameter, in my case I use

parameters , then, it´s moment to make the 3D, to do so you can

extrude (pull) your sketches and you can choose from 2 options EXTRUDE

or THIN EXTRUDE this means that you can extrude the surface

of the circle or just the "perimeter" in my model I use both

options, the outer circle had a EXTRUDE option and the inner

ones the THIN EXTRUDE and when you select wich option you

need you specify the distance, angle and direction, this means that

you can "pull" in one or in two sides of the plane at once. After I

define this operations I made a chamfer in the edge where the

acrylic or the bearing will be introduce, this helps to avoid

resistance when introducing the objects into the Central Component.

To check if everything looks fine and fit into place I use the

Section Analysis tool to cut longitudinally the object.

1.space where the

Acrylic tube is going to fit

2.space where the

bearing is going to fit

3.round plate that will

join the central object to the base

4.Upper chamfer, to

allow the acrylic tube to fit better

5.Bearing chamfer, to

allow the bearing to fit better

6.Sketches, the initial

sketches of the design that later I will extrude to form the 3D

model