For this assignment

I want to make a desk, first I will make the drawings in 2D in

Vectorworks ,then I opene the file in RhinoCam to do

the settup of the CNC router specifying the tooling, the rpm,

the mmXs, the depth, etc then we need to send the information to

the CNC computer to set up origins, depth of material and

sacrifice bed , also we need to fix the board in the surface of

the CNC with some clamps then push play, latter, when the CNC

finished to cut all the pieces the assembly part begins, I made

this desk like a press fit kit and it include one open space at

the front to put a computer or books, 1 drawer and a superir

space to put some pens ands post its and an electrical contact.

Vectorworks,

Enrouter, CNC computer, CNC router, straight flute tooling

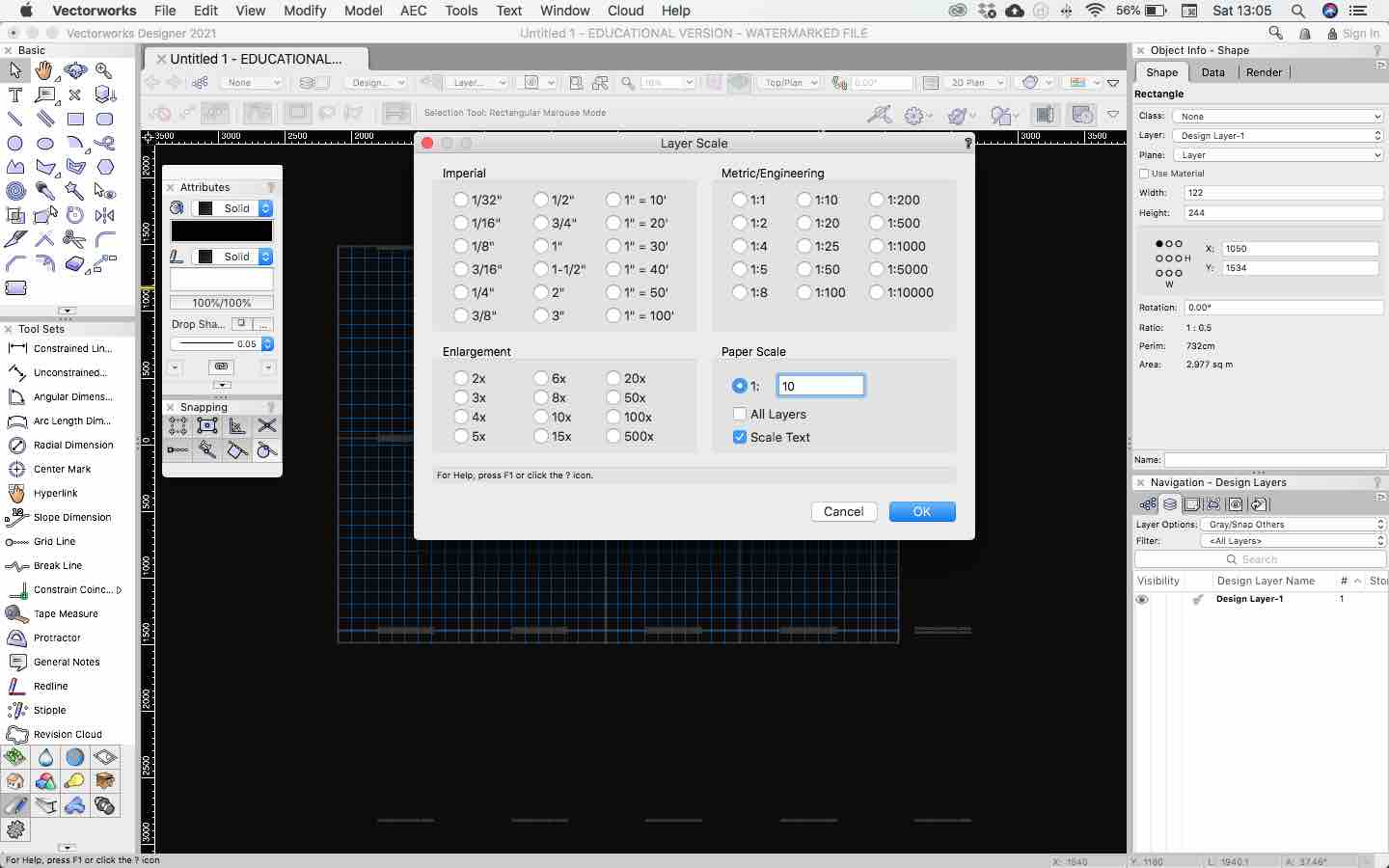

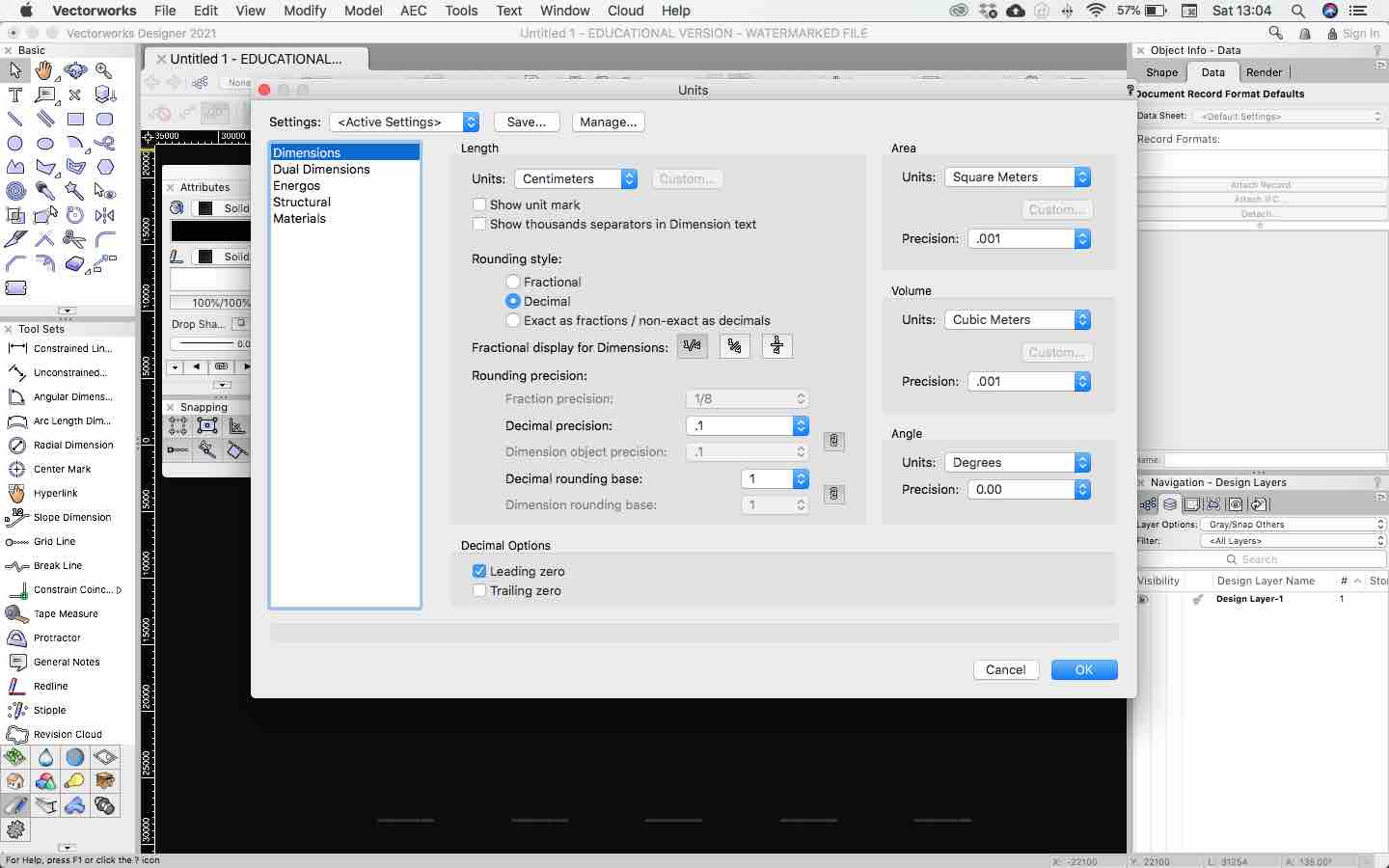

And the units in mm

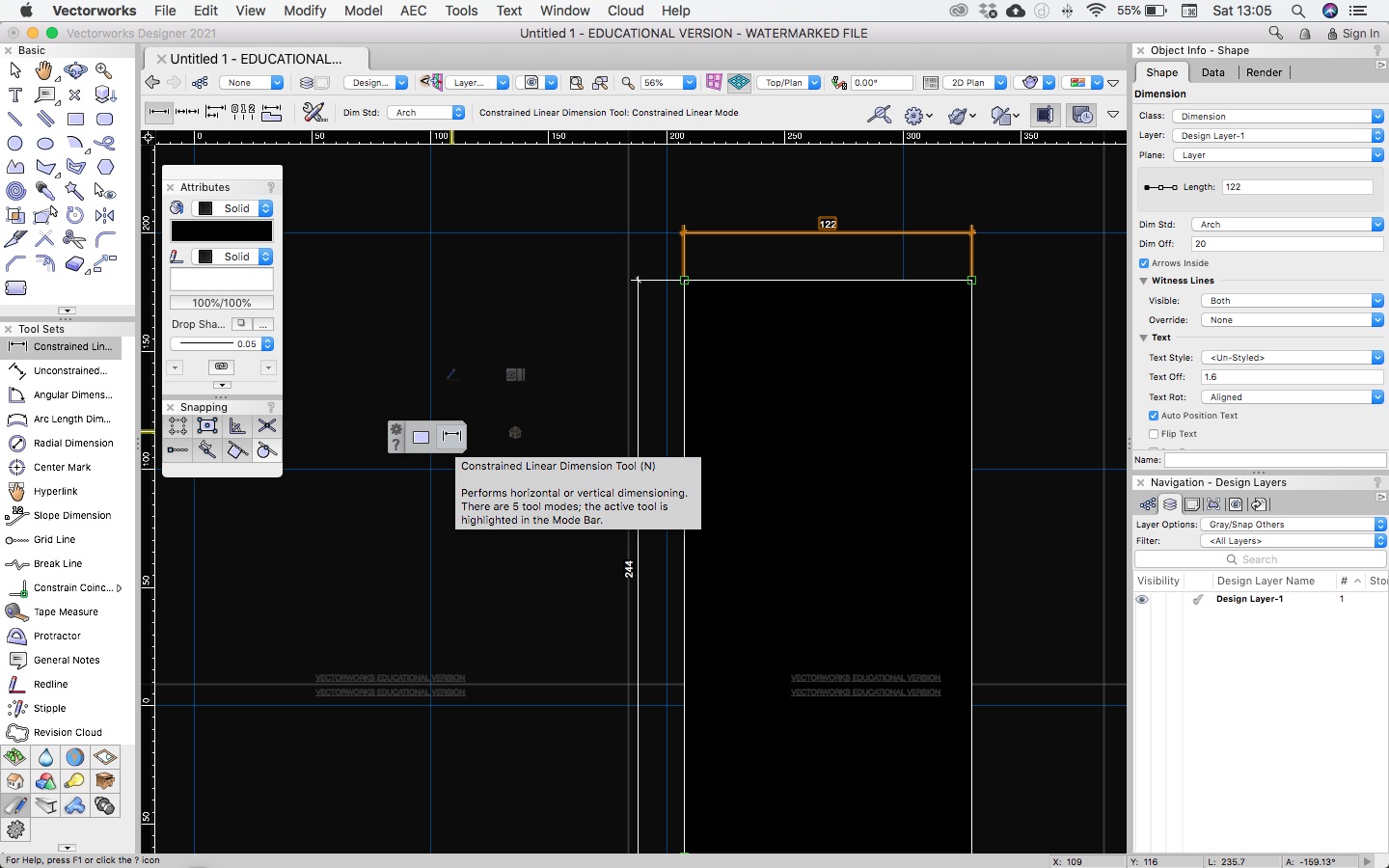

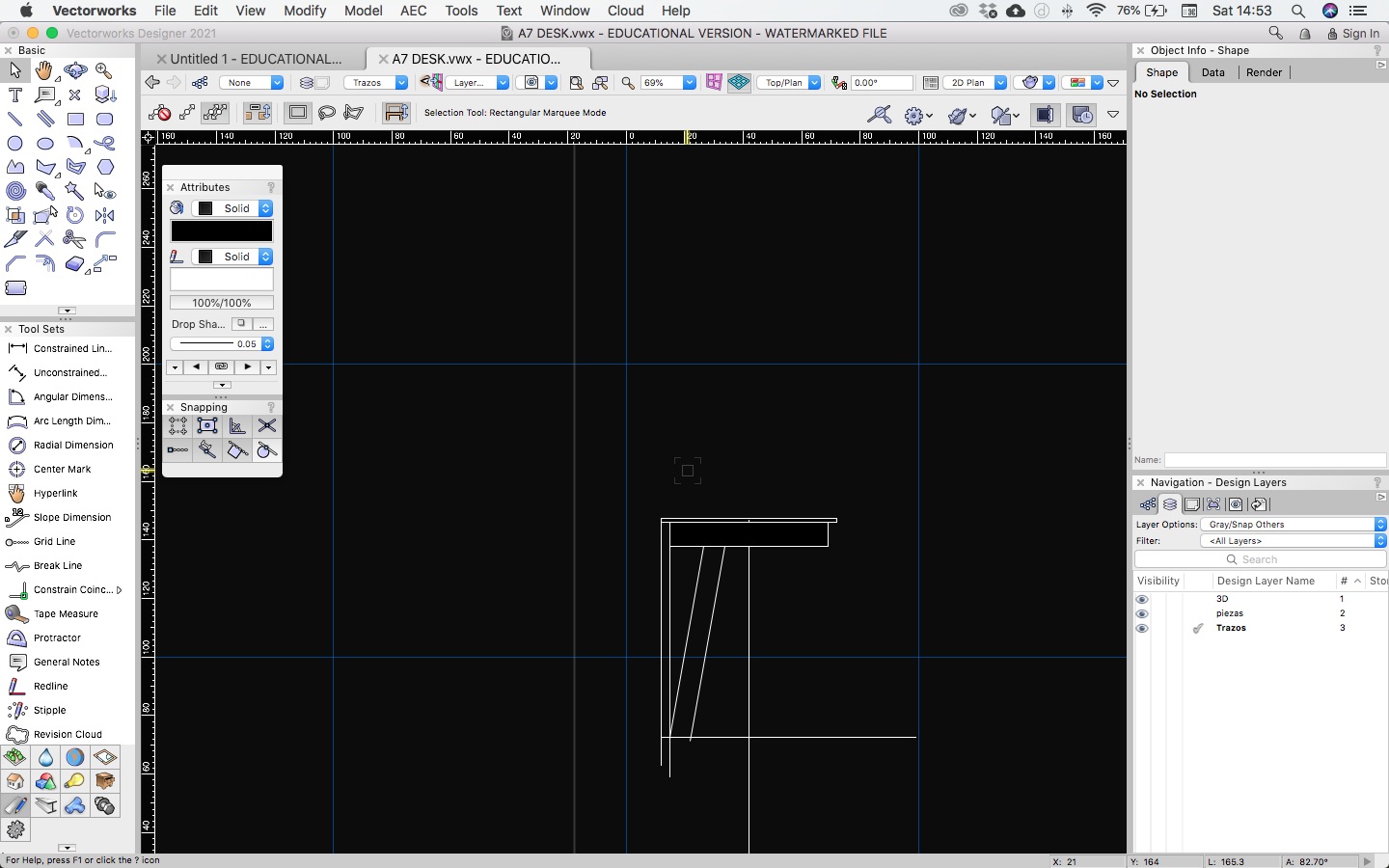

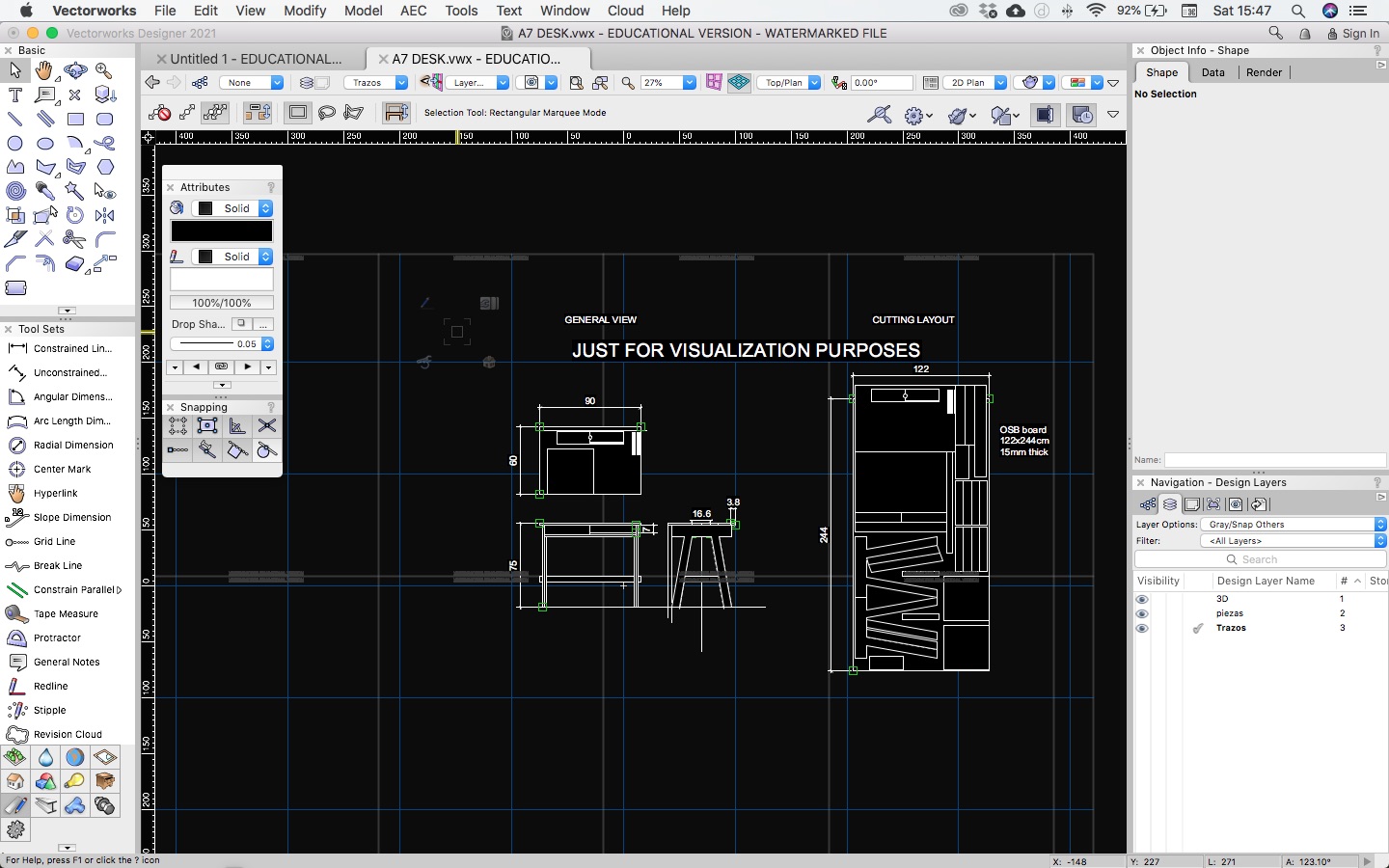

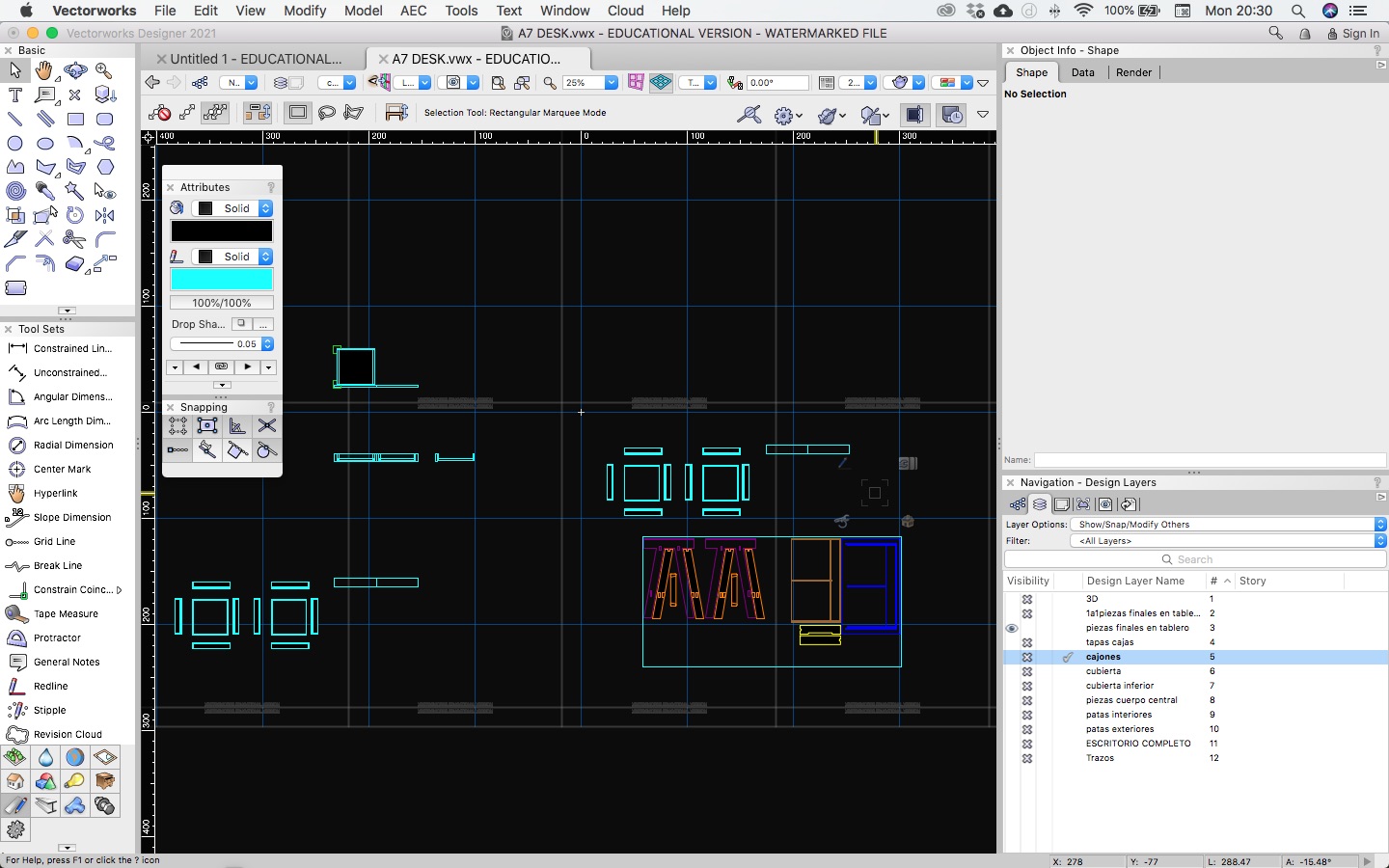

First I start drawing a

board size rectangle of 1220x2440mm

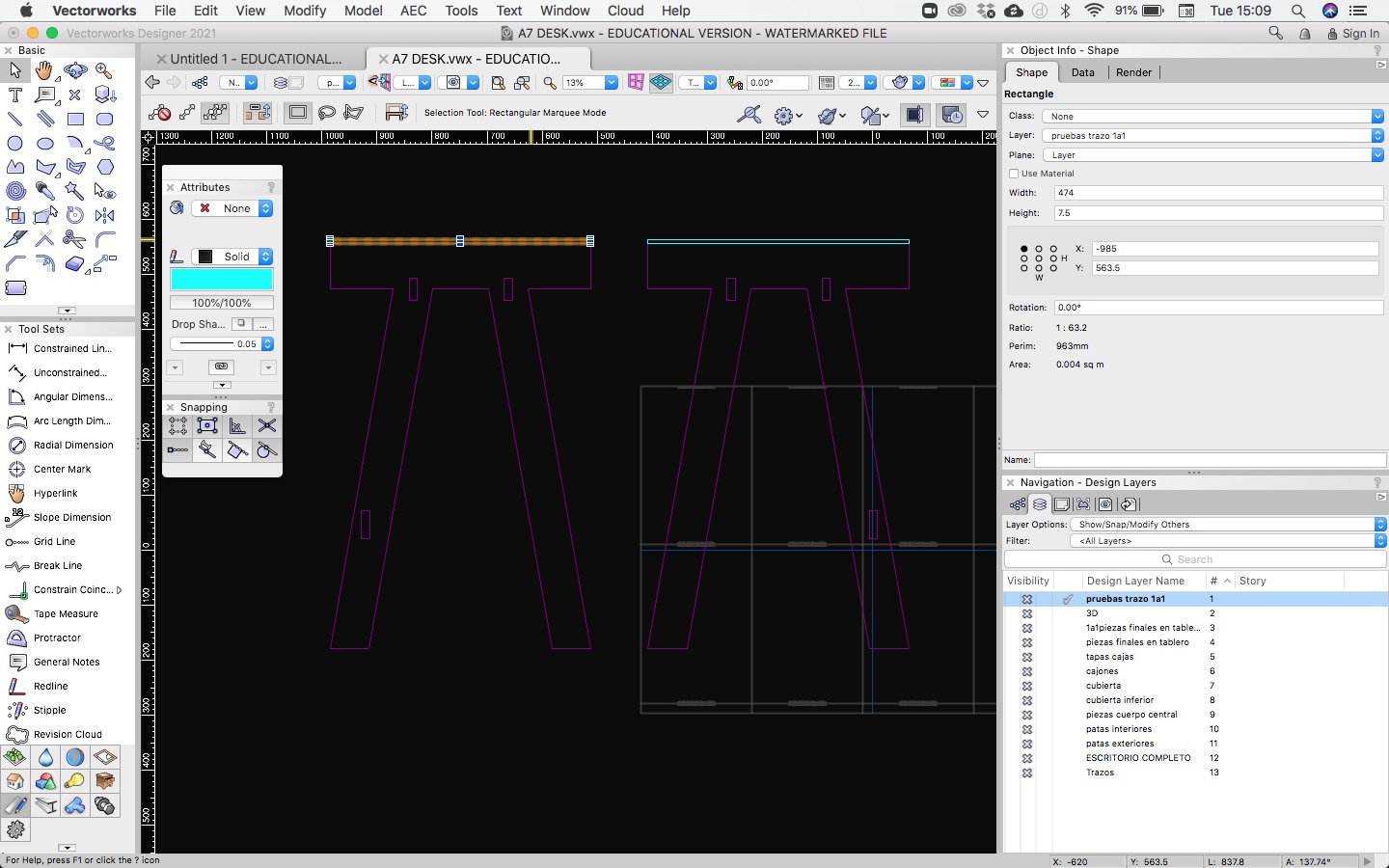

Here in left side view

of the desk I draw some construction lines to delimit the position

of the legs

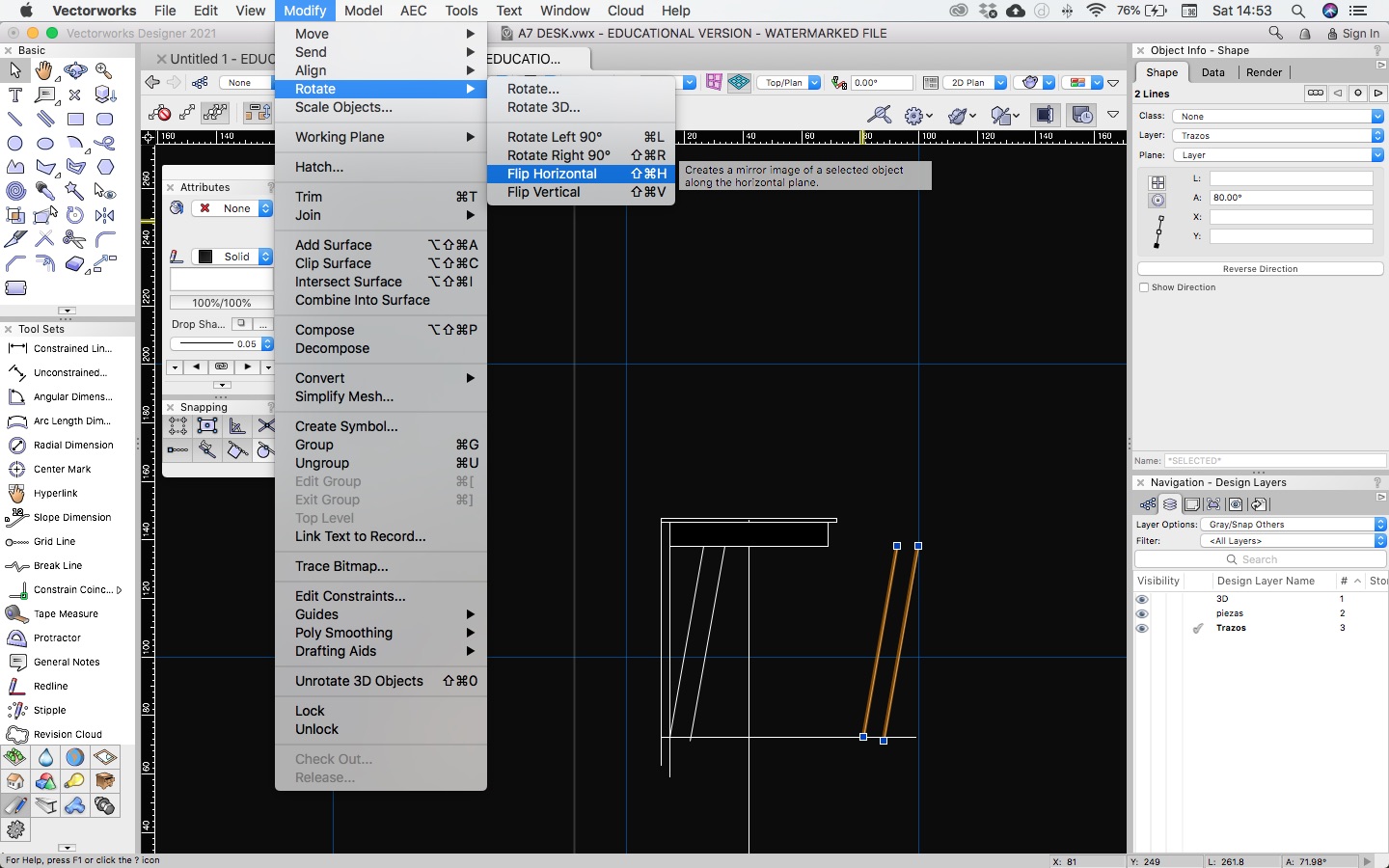

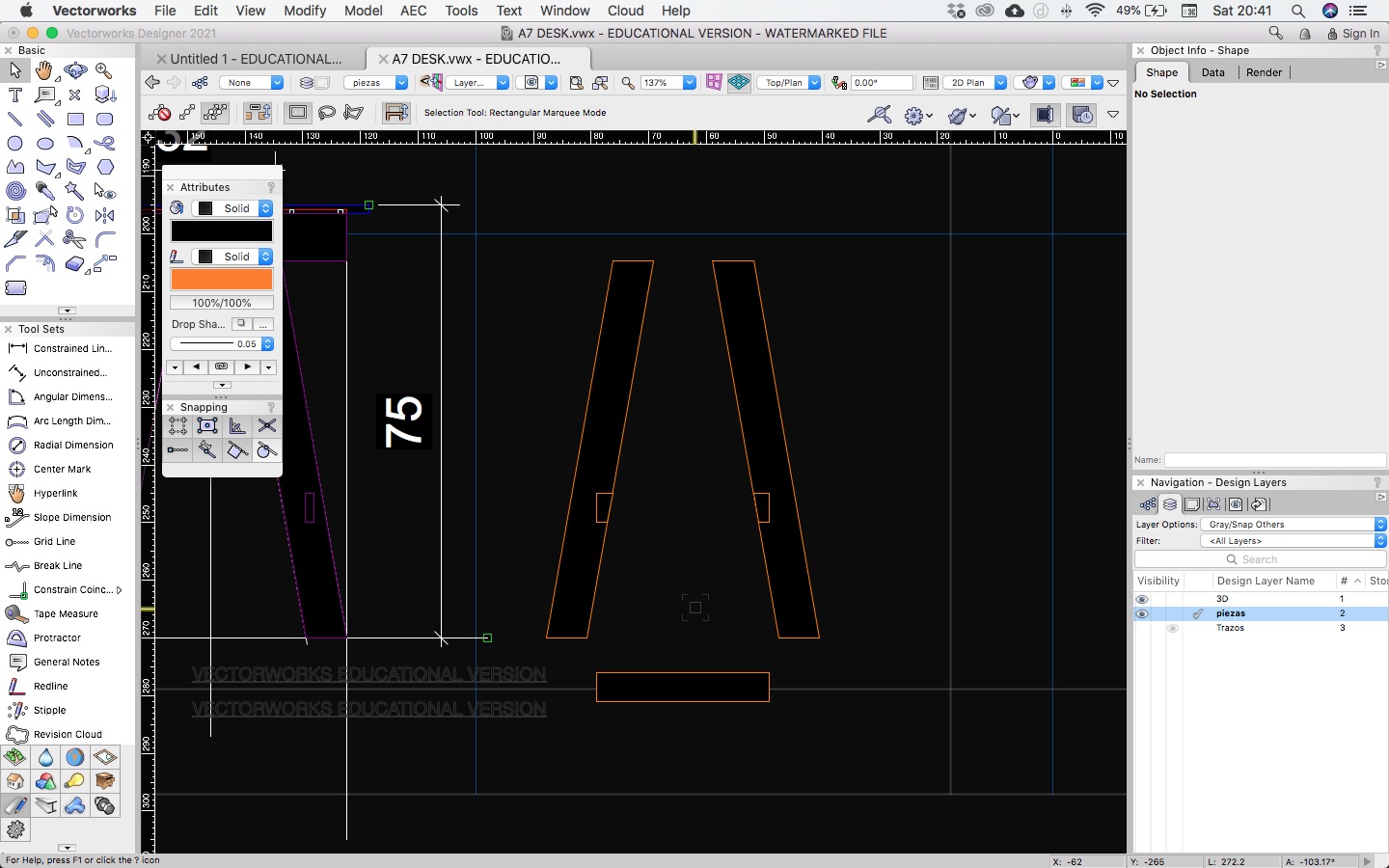

The legs where drawing

at fist with offset tool and then I mirror them

The side voiew with the

legs and starting to draw the front view

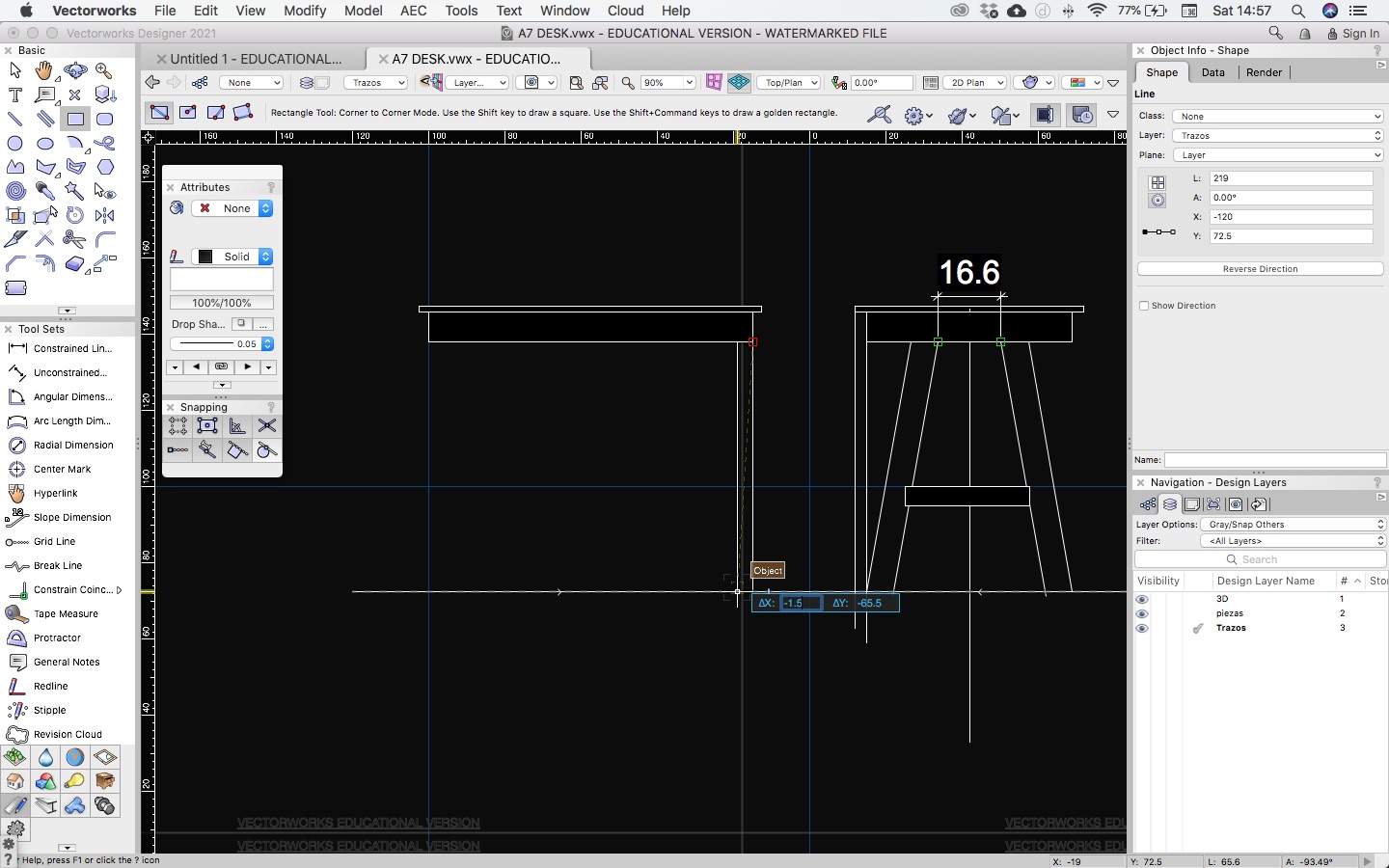

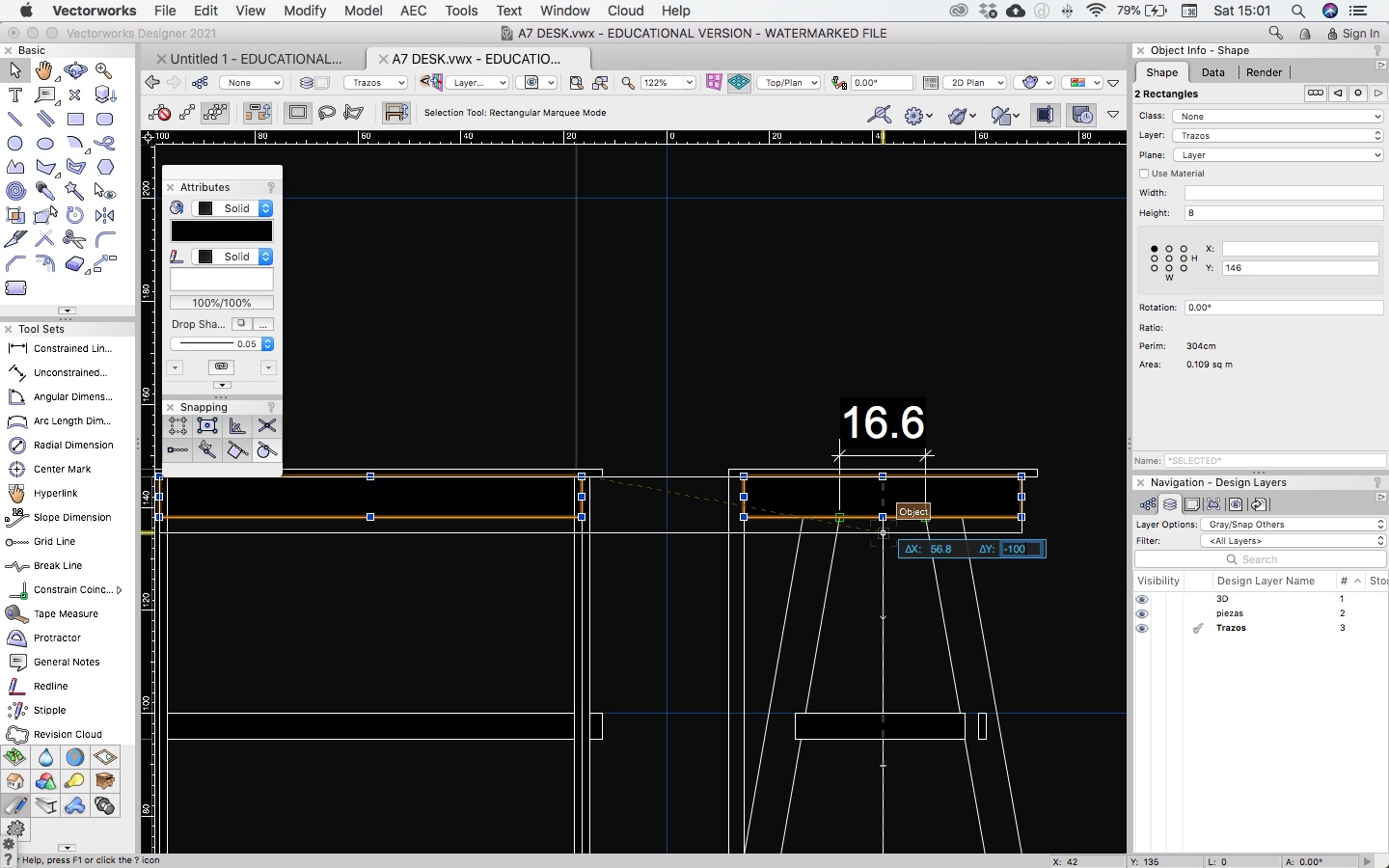

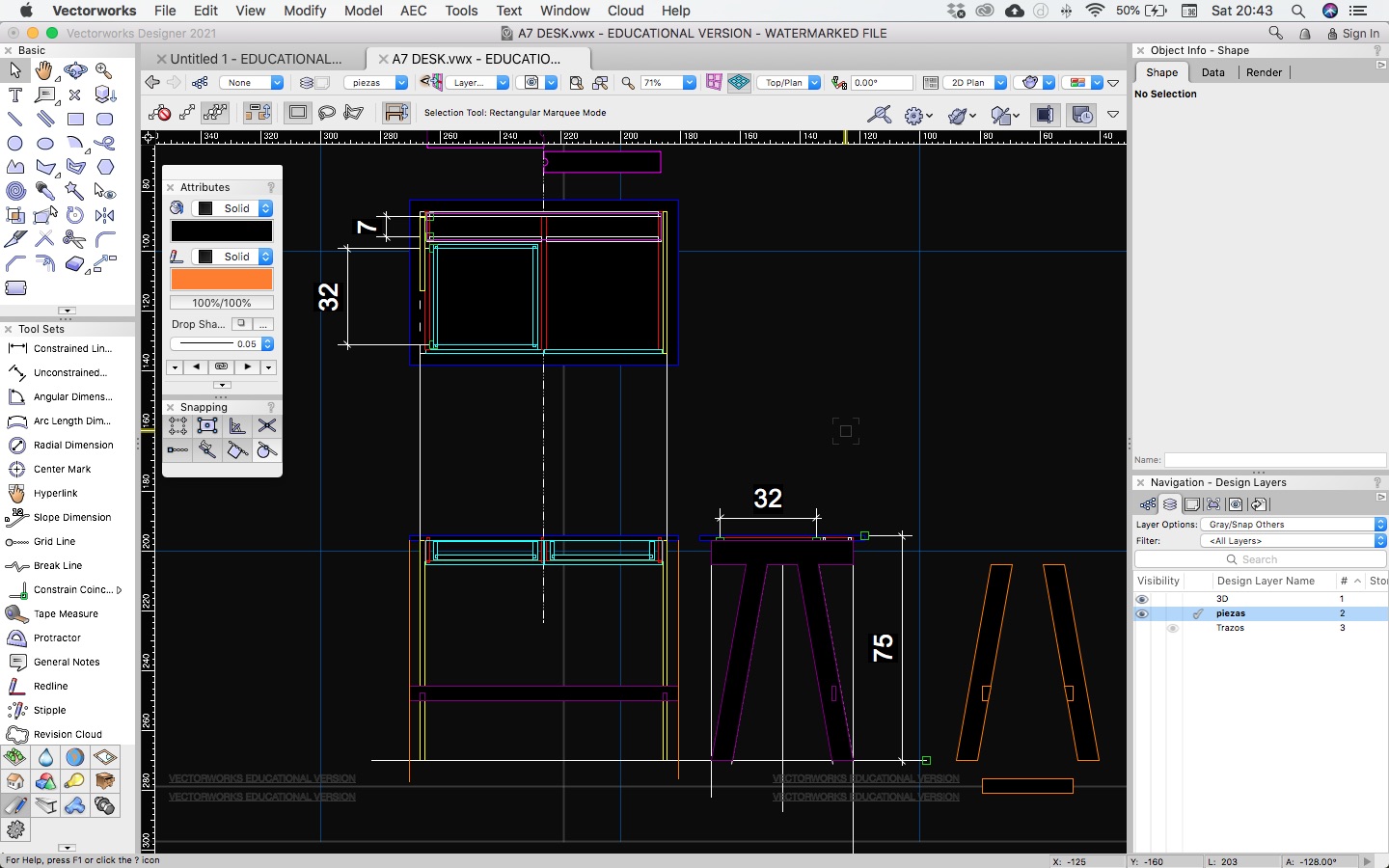

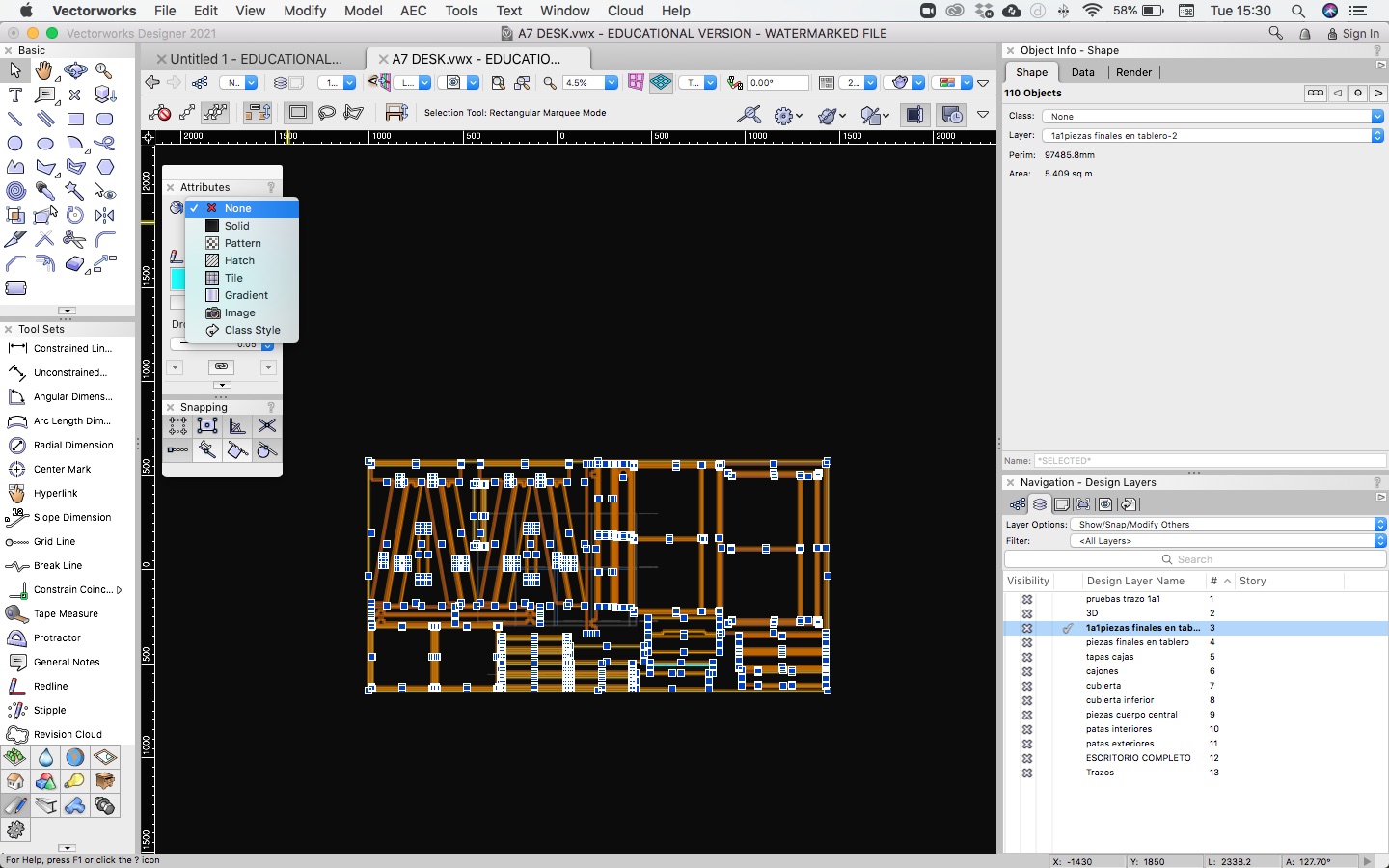

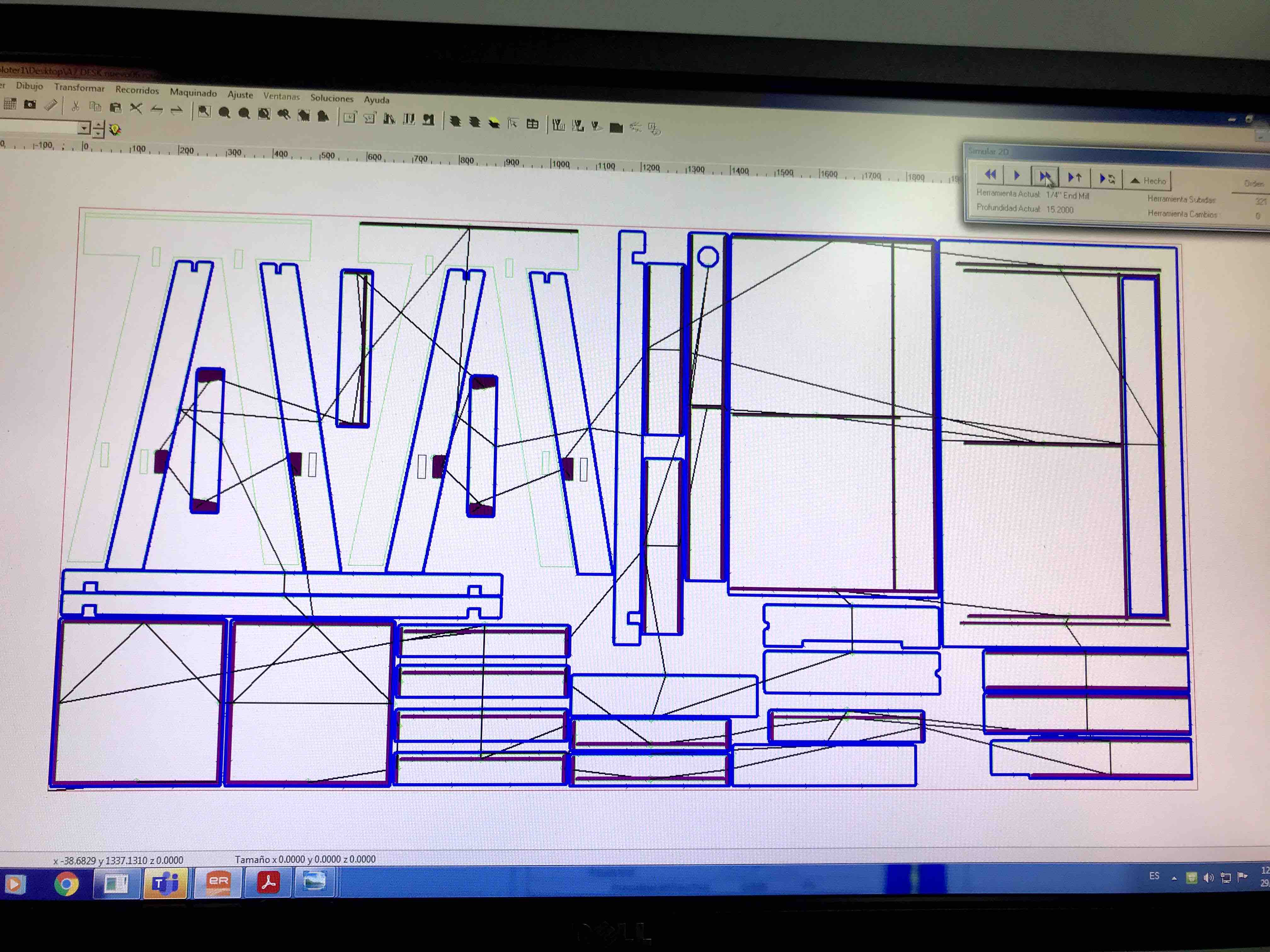

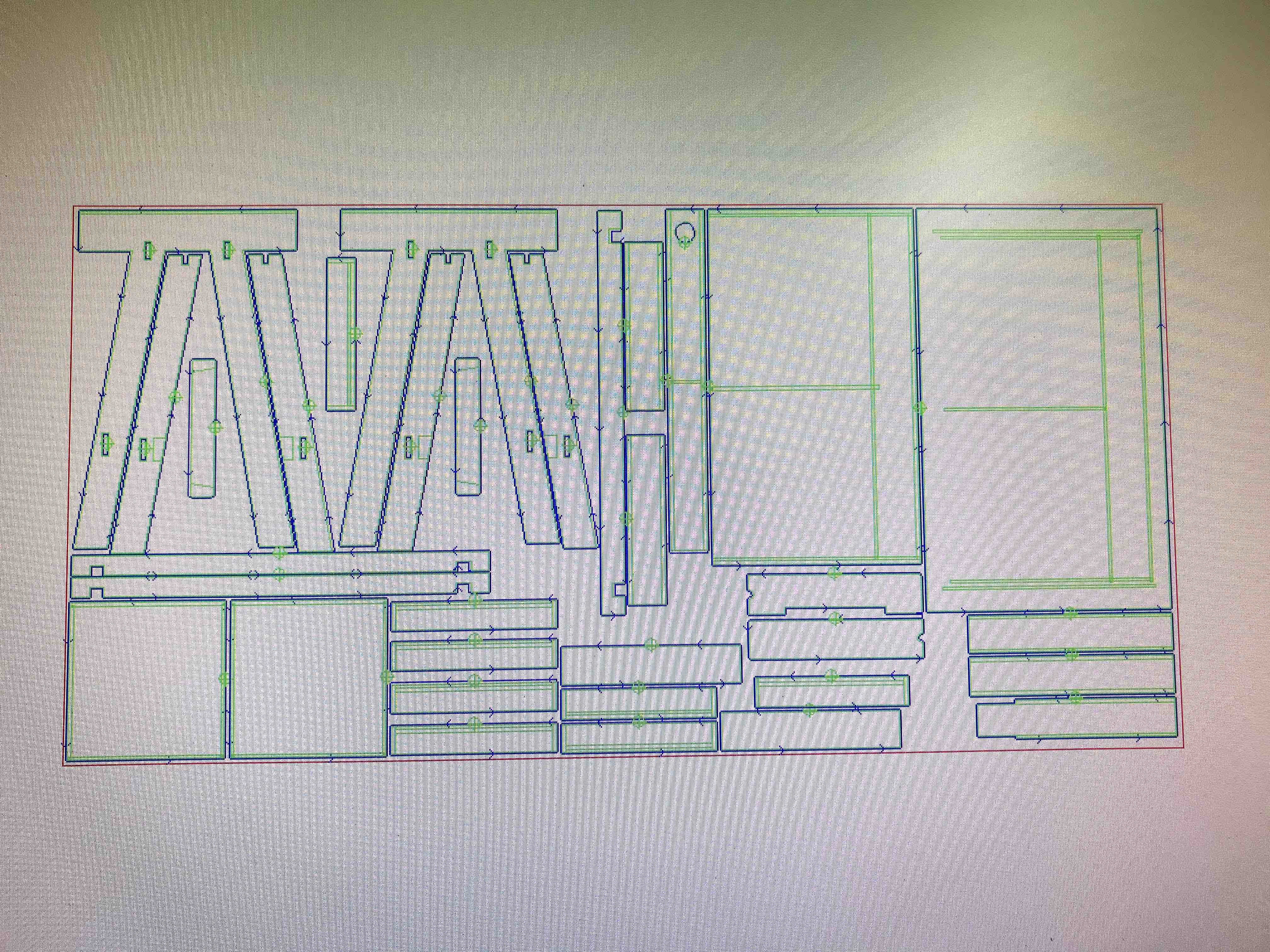

In hte left side of my

drawing there is the geeral views of the desk, then I put all the

pieces inside the OSB board rectangle

here we can see the

places where the legs support asemmble

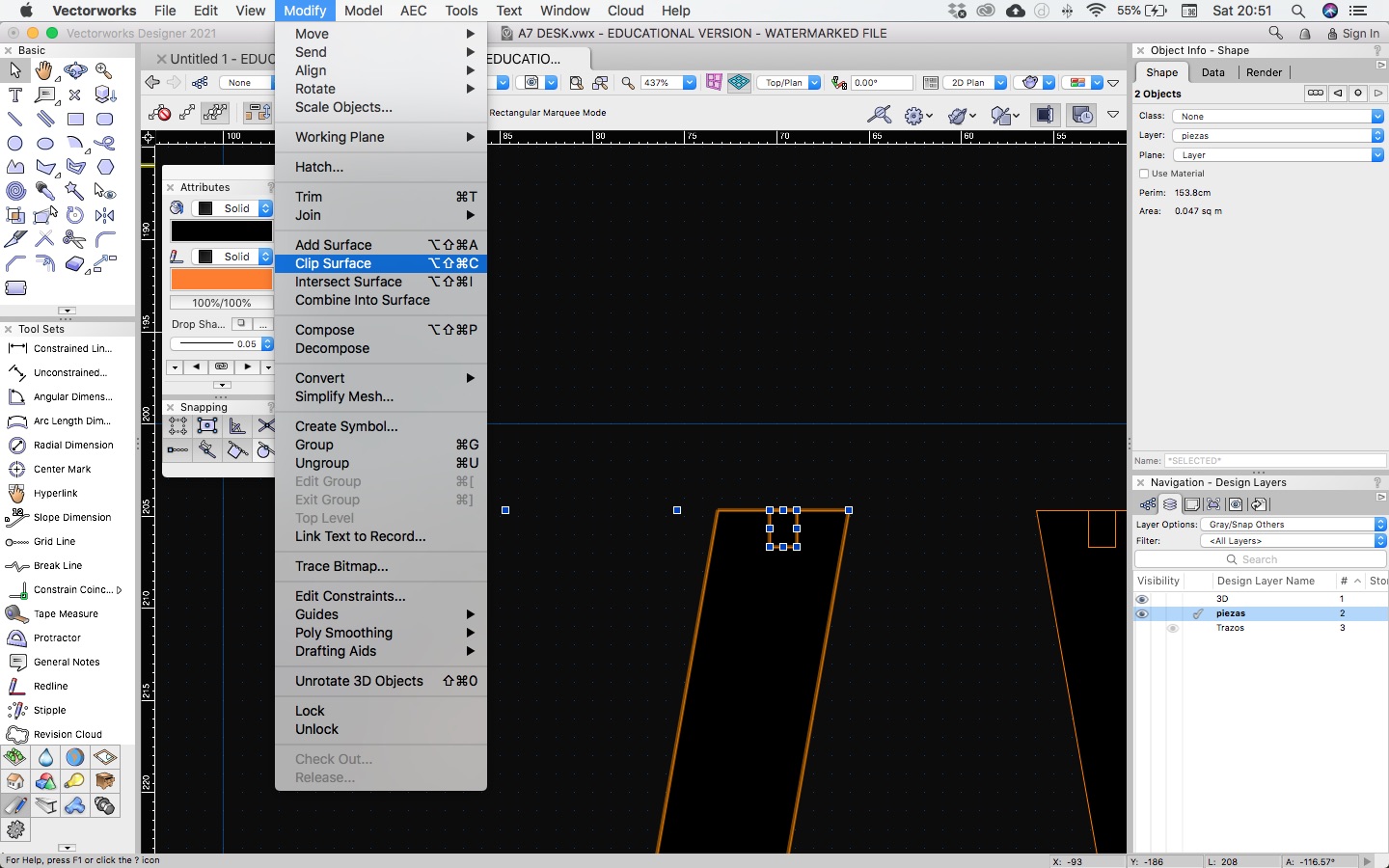

With the clip Surface

action I remove some section of the drawing where other parts

assemble

exploded view of the

drawers components

I made one layer for

each of the components of my desk and at the end I put them all in

one single layer with a 1:1 scale

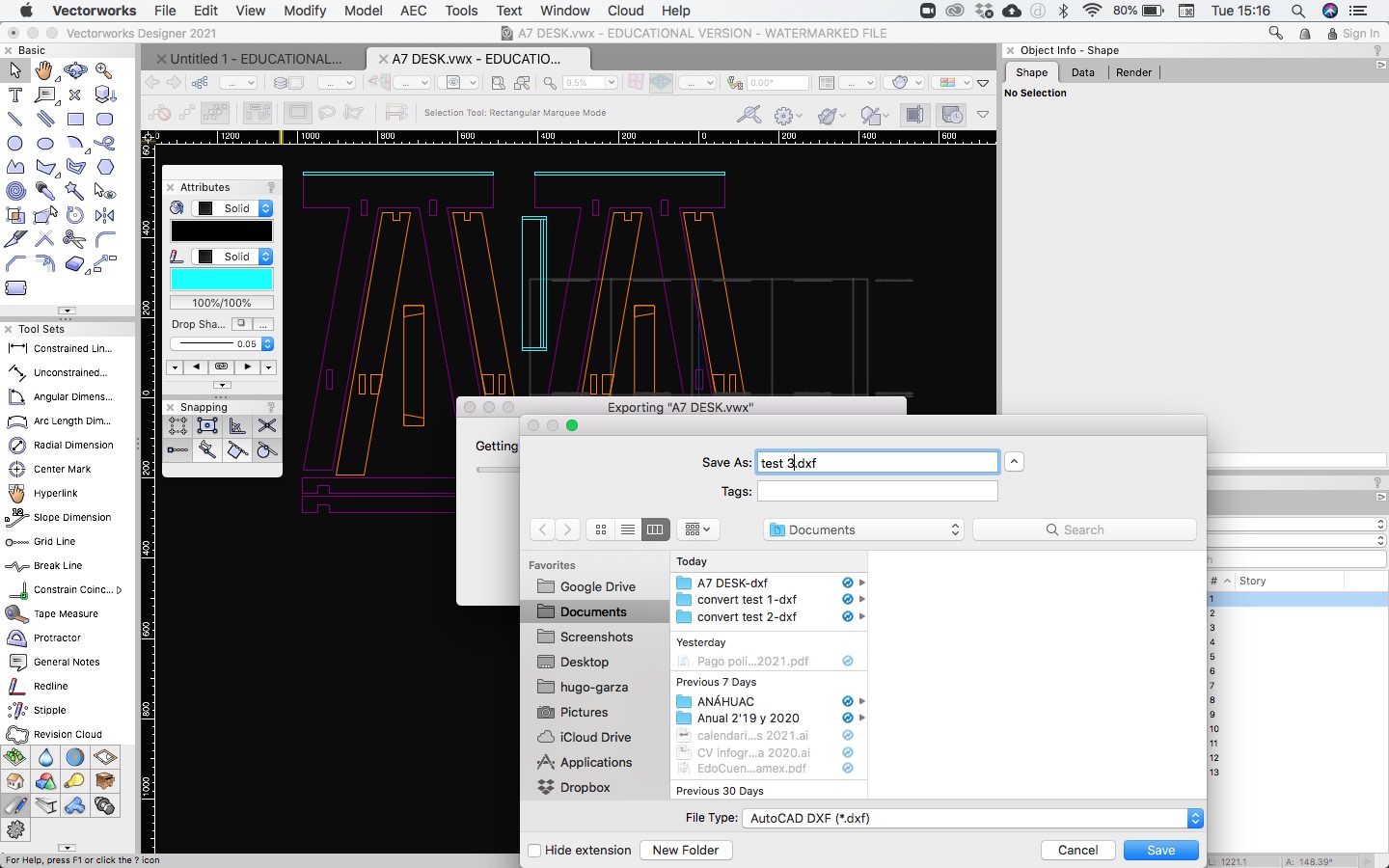

When all ready I

exported it in DXF format

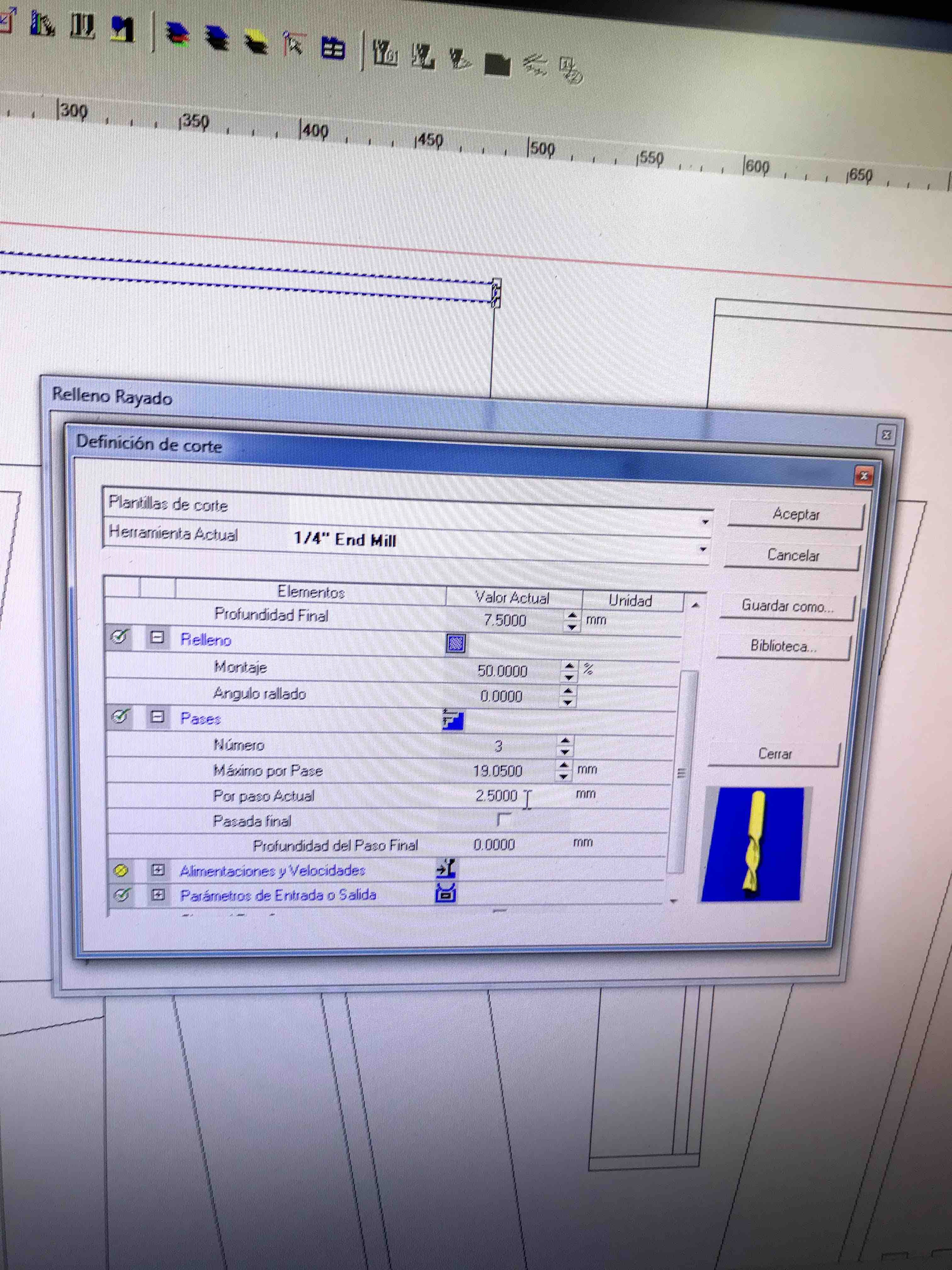

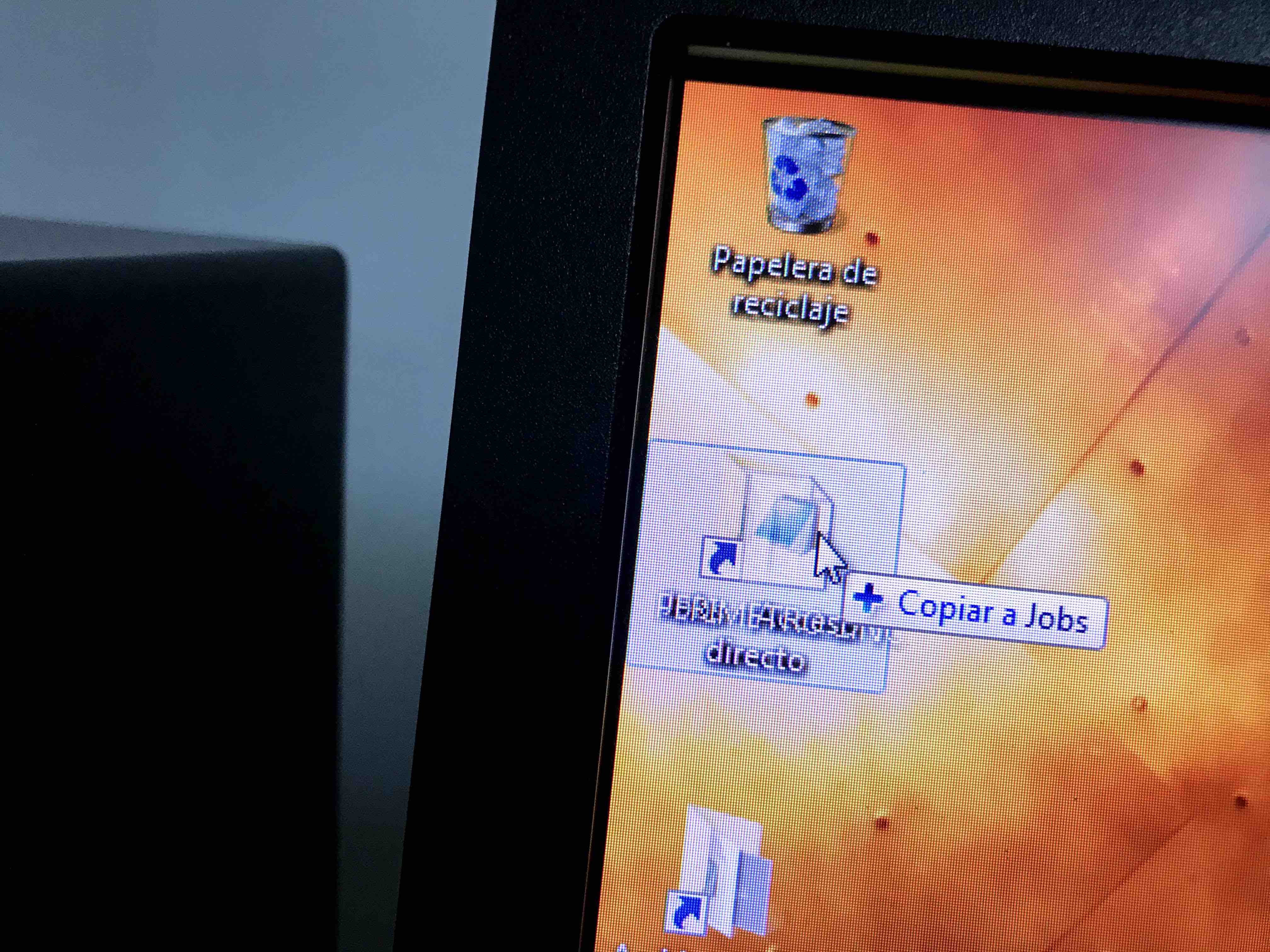

Here is the archive in

Enrouter

where we are going to

setup the CNC router settings

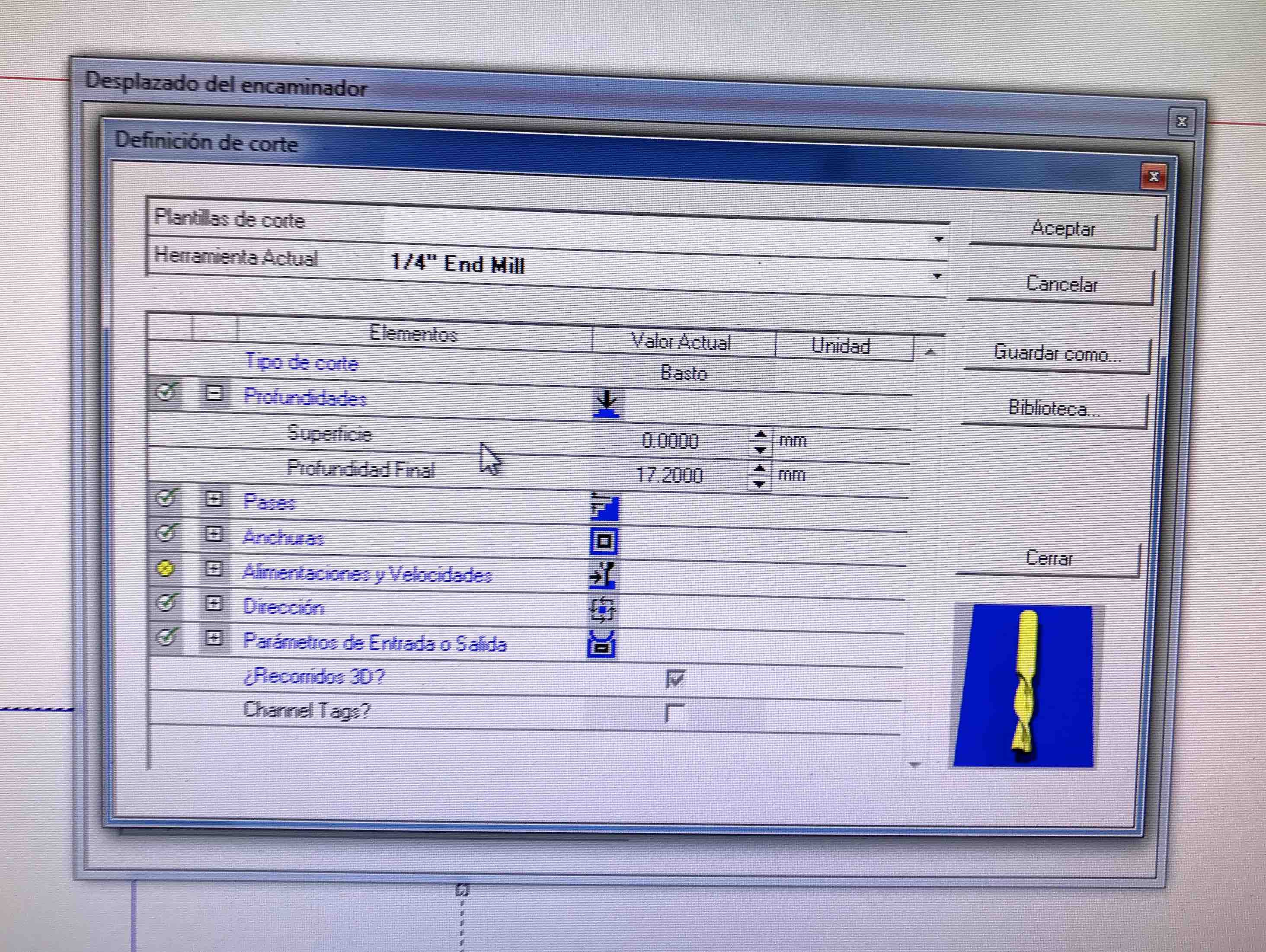

We are going to use a

straight flute 1/4" End Mill and we are setting a 17.2 mm depth

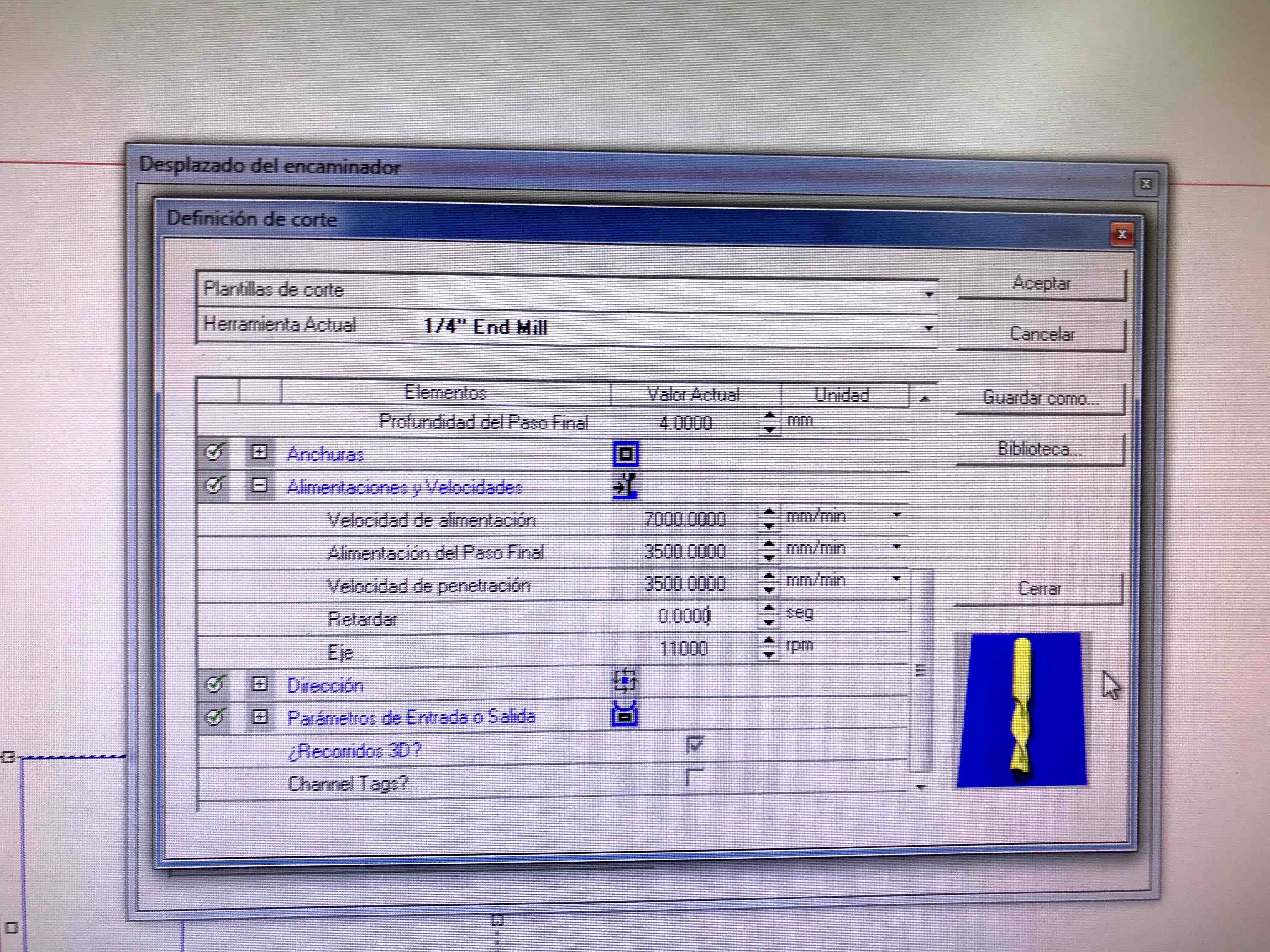

Final step depth in

4.00mm, Speed between 700 and 3500 during the the initial sequence

of router and during the cut and rotation speed of 11000rpm

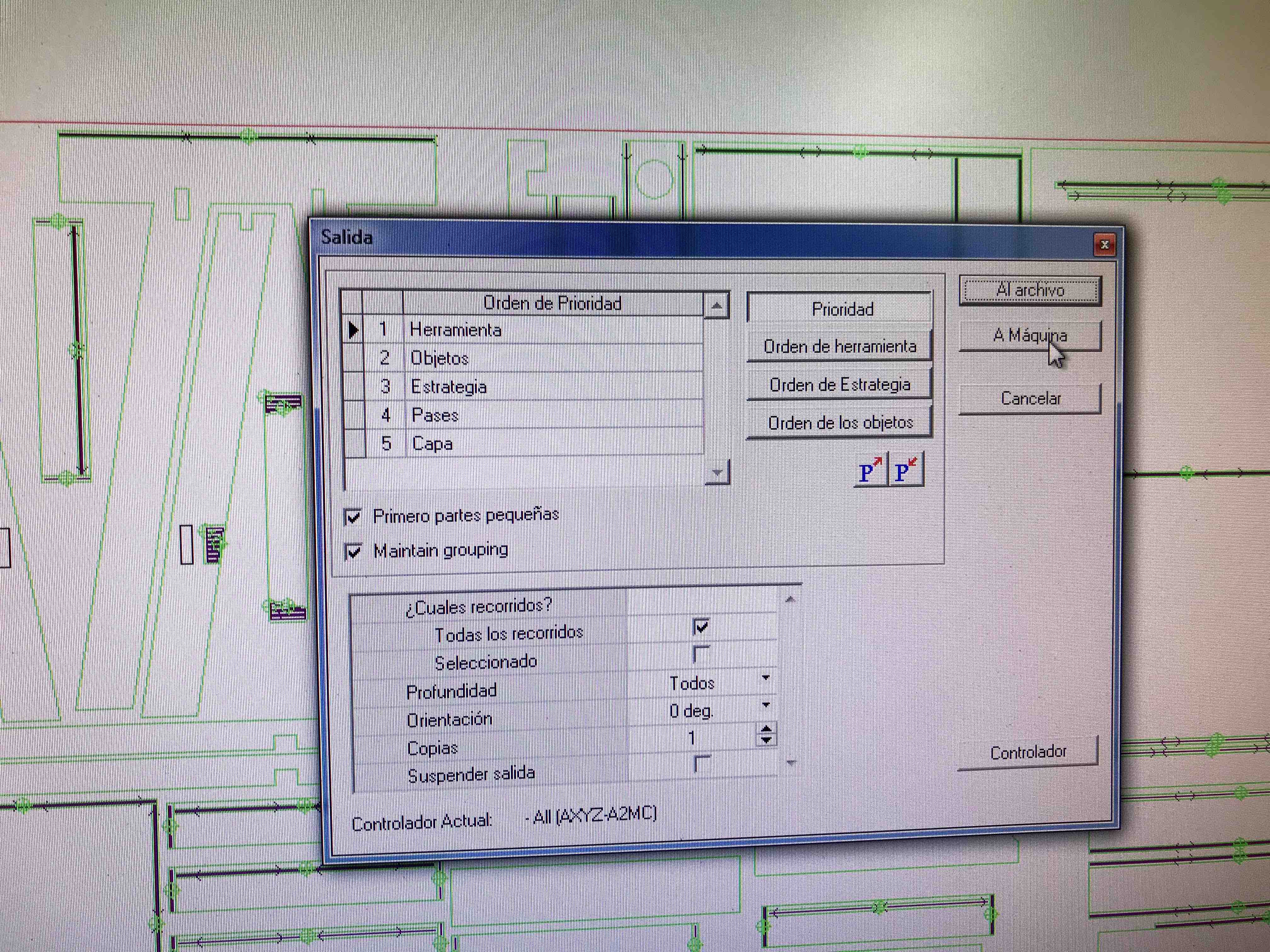

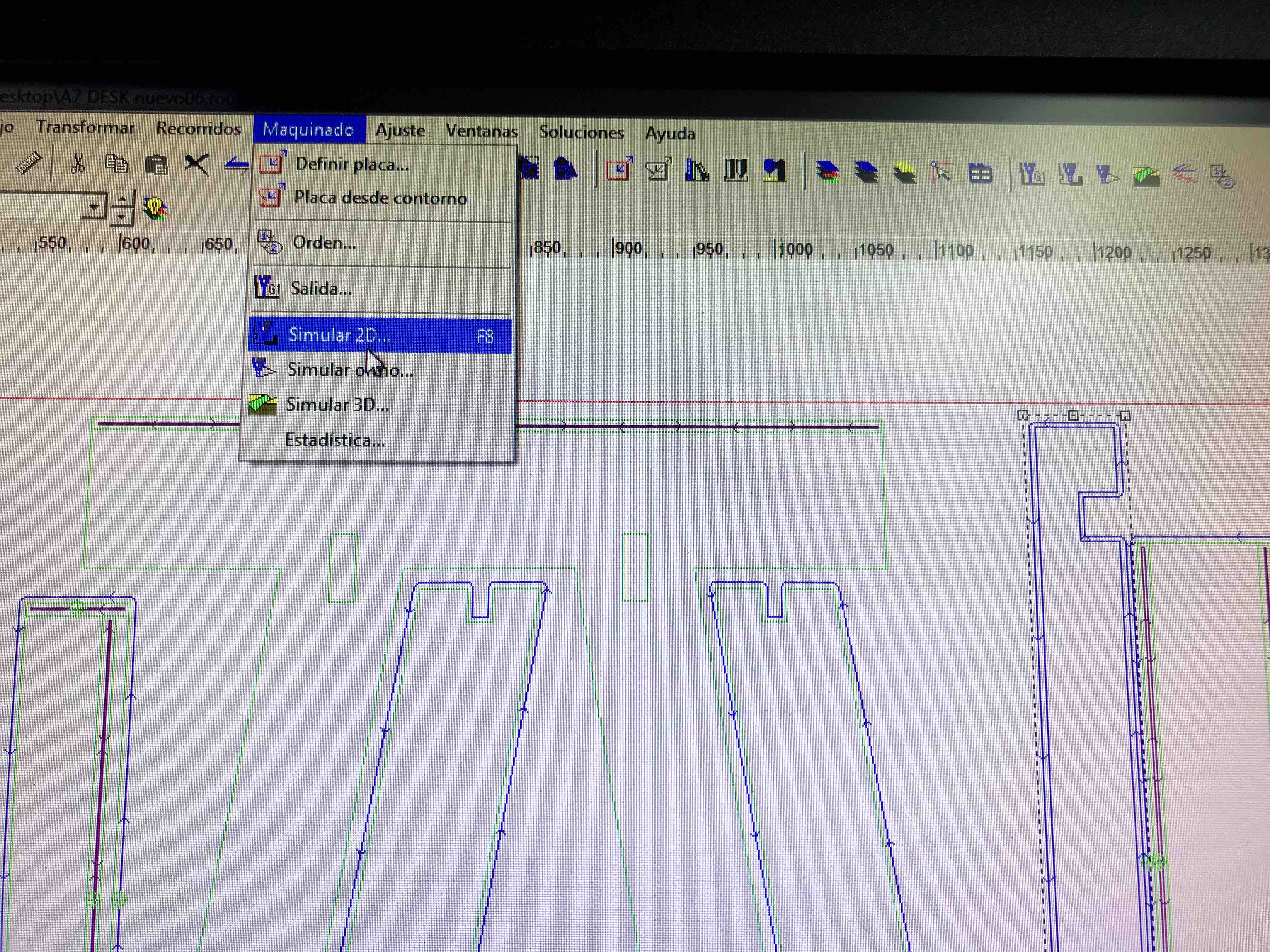

Here we simulate the

router path, the outer and inner cuts, first we must cut the

interior pieces and then the outside

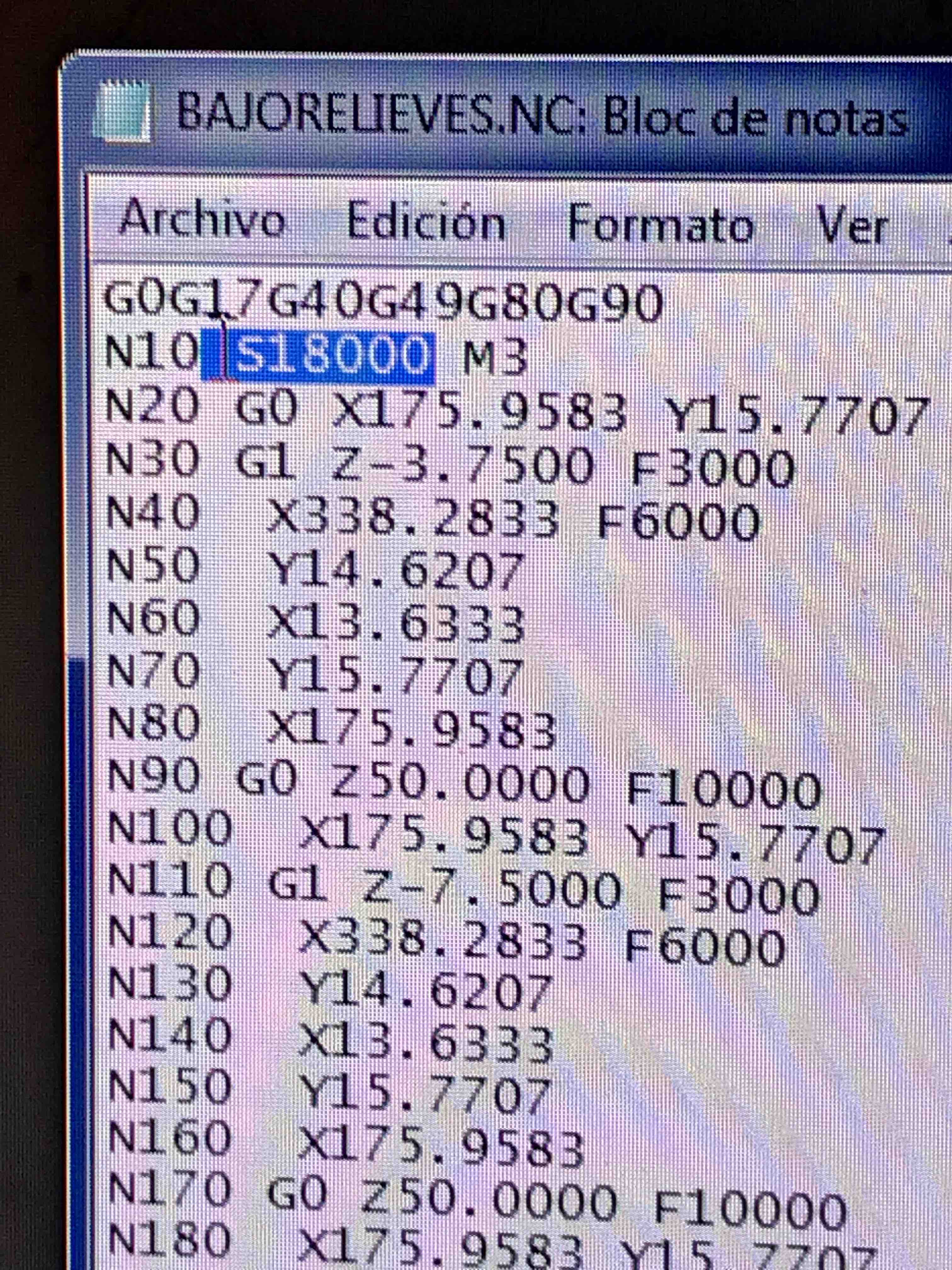

The Gcode

Then we send to "jobs"

the archive so we can see it in the CNC computer control

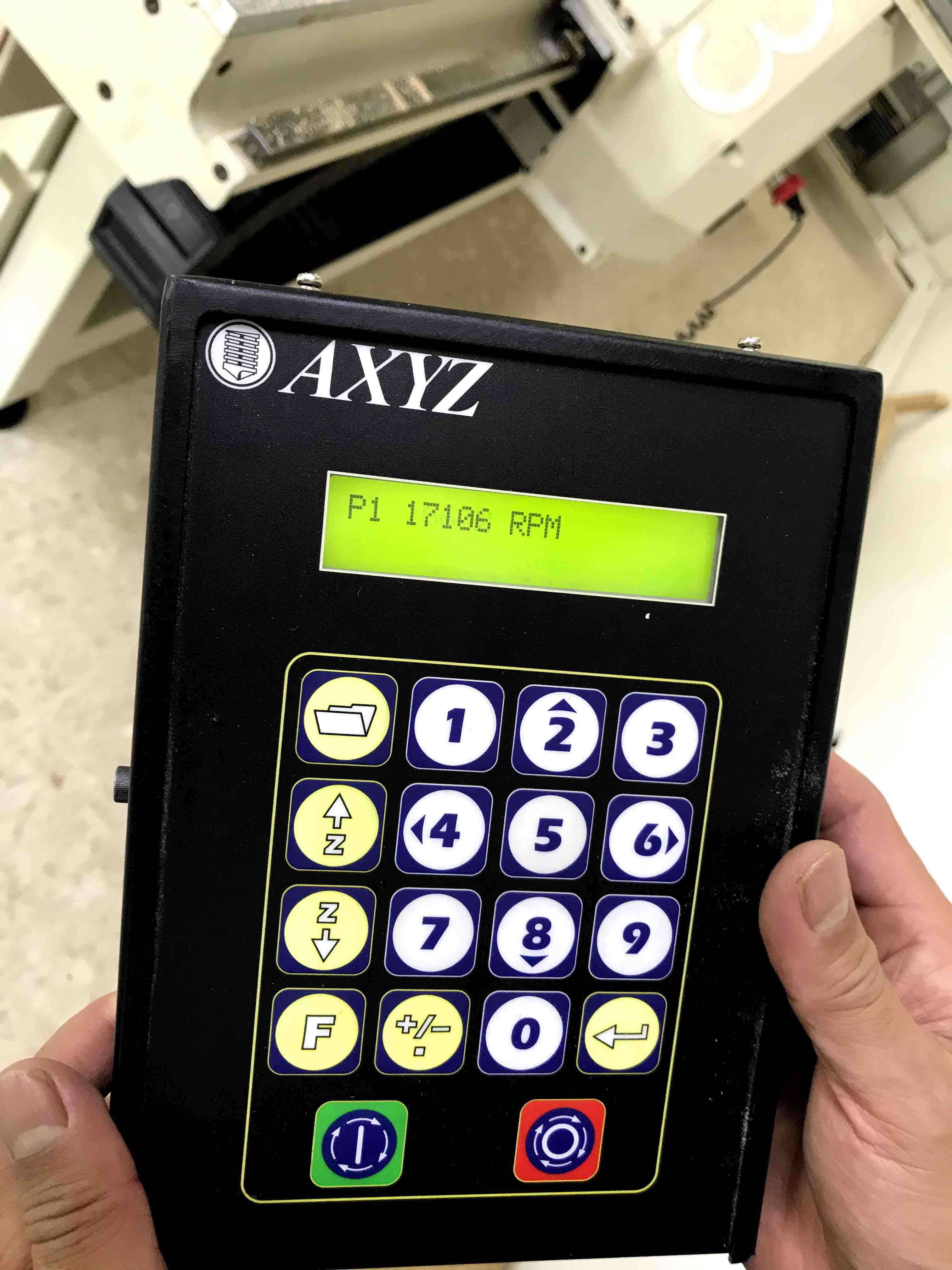

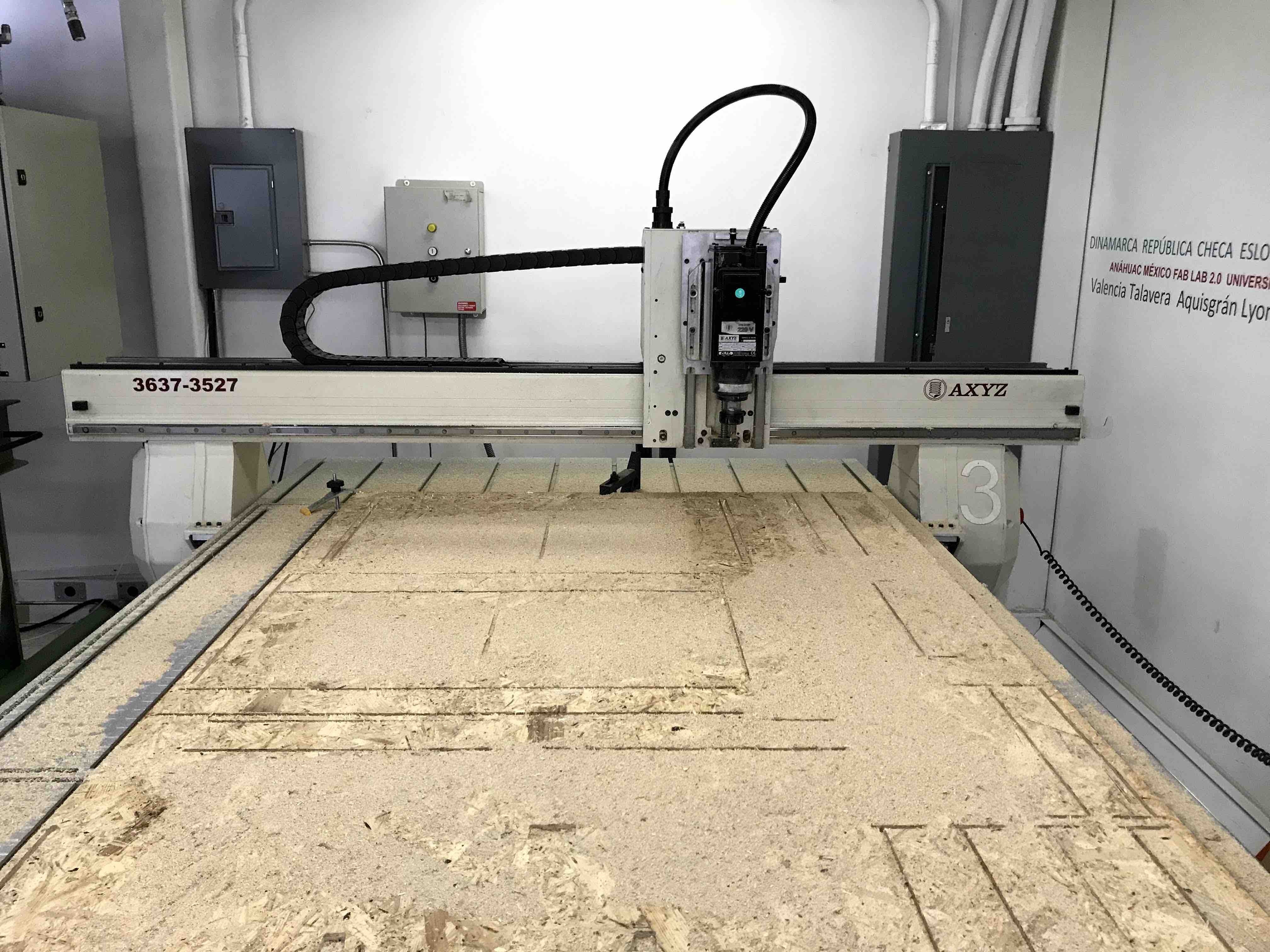

We are going to use a

AXYZ CNC model

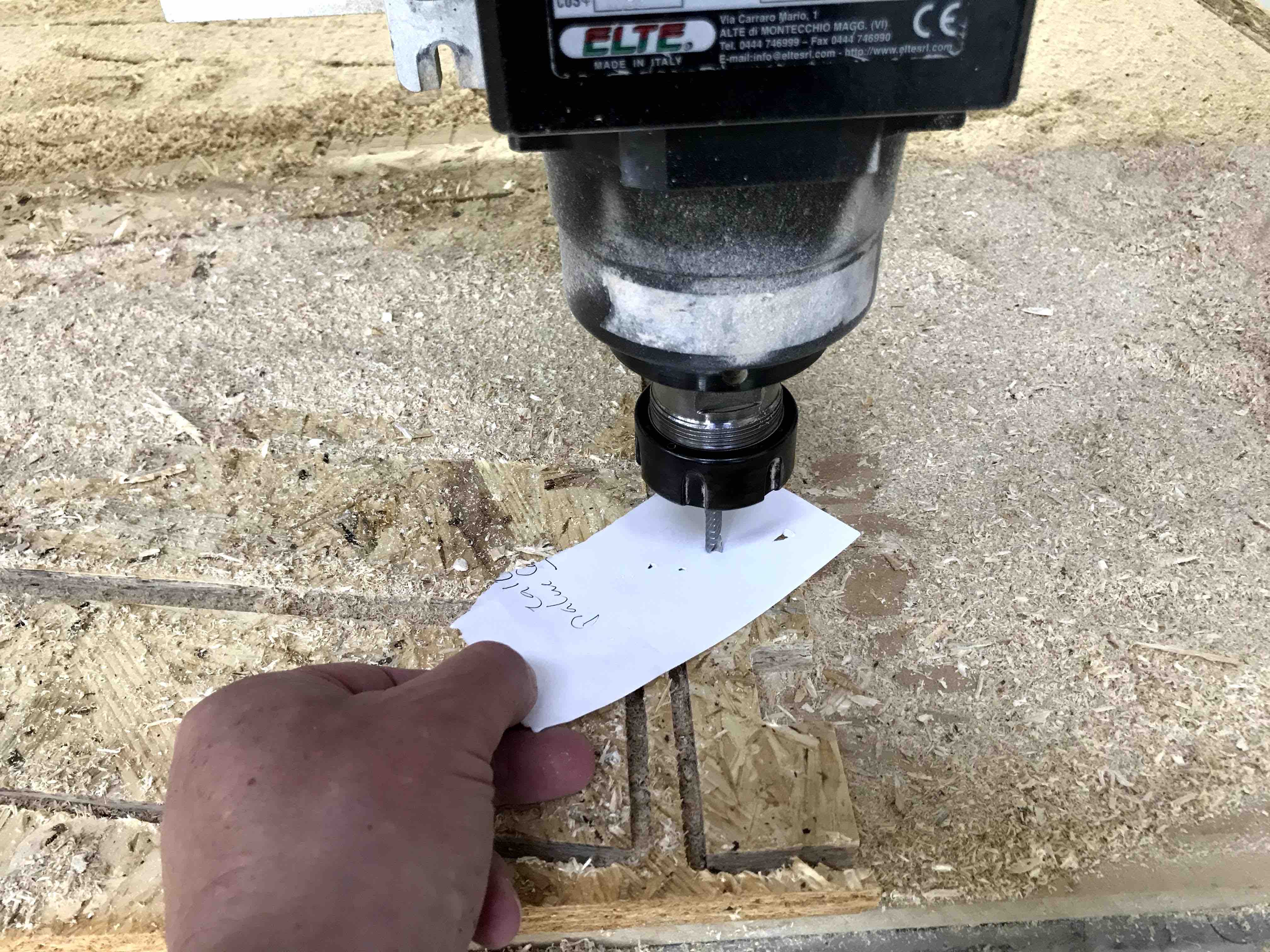

Here we are going to

measure and set the board thickness touching the surface of a piece

of paper with the tooling

setting the thickness

in 15.287mm

setting the origin

calling the archive to

cut

We are a few seconds

away to start cutting the desk

warming up and reaching

the RPM

The OSB board

Cutting the pieces of

the desk

detail view of

the bass relief of one of my pieces

The legs and lower

support totally assemble

A detail of one union

Detail of the crossbar

joint

The top cover with two

sections

The top cover just

about to be assemble to the top section

Both interior sections

of the desk

A free space in the

left and a drawer in the right

Two additional covers

in the top surface

A top view where we can

see a cable for charging a cellphone and the space for stationery