For this assignment

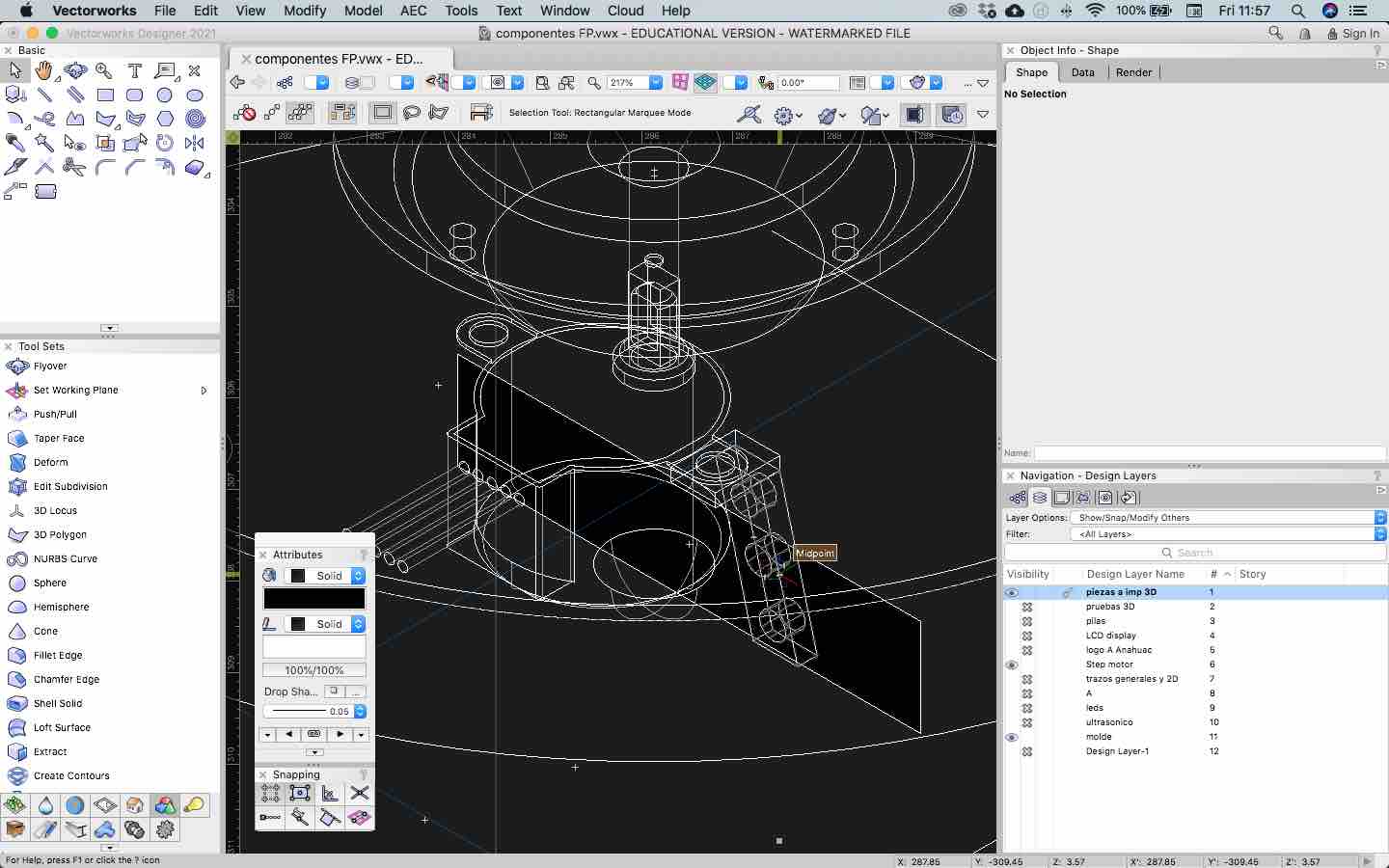

I vacuum form the cover of one of my Final Project proposal. For

this assignment I made the 3D design of the cover, then I glue

together some 15mm natural MDF pieces tht would be CNC machining

into the mold, RhinoCAM to setup the tooling and the CNC

settings for this project, a band saw for cutting the perimeter

of the mold, cal.40 polystyrene and a vacuum form machine

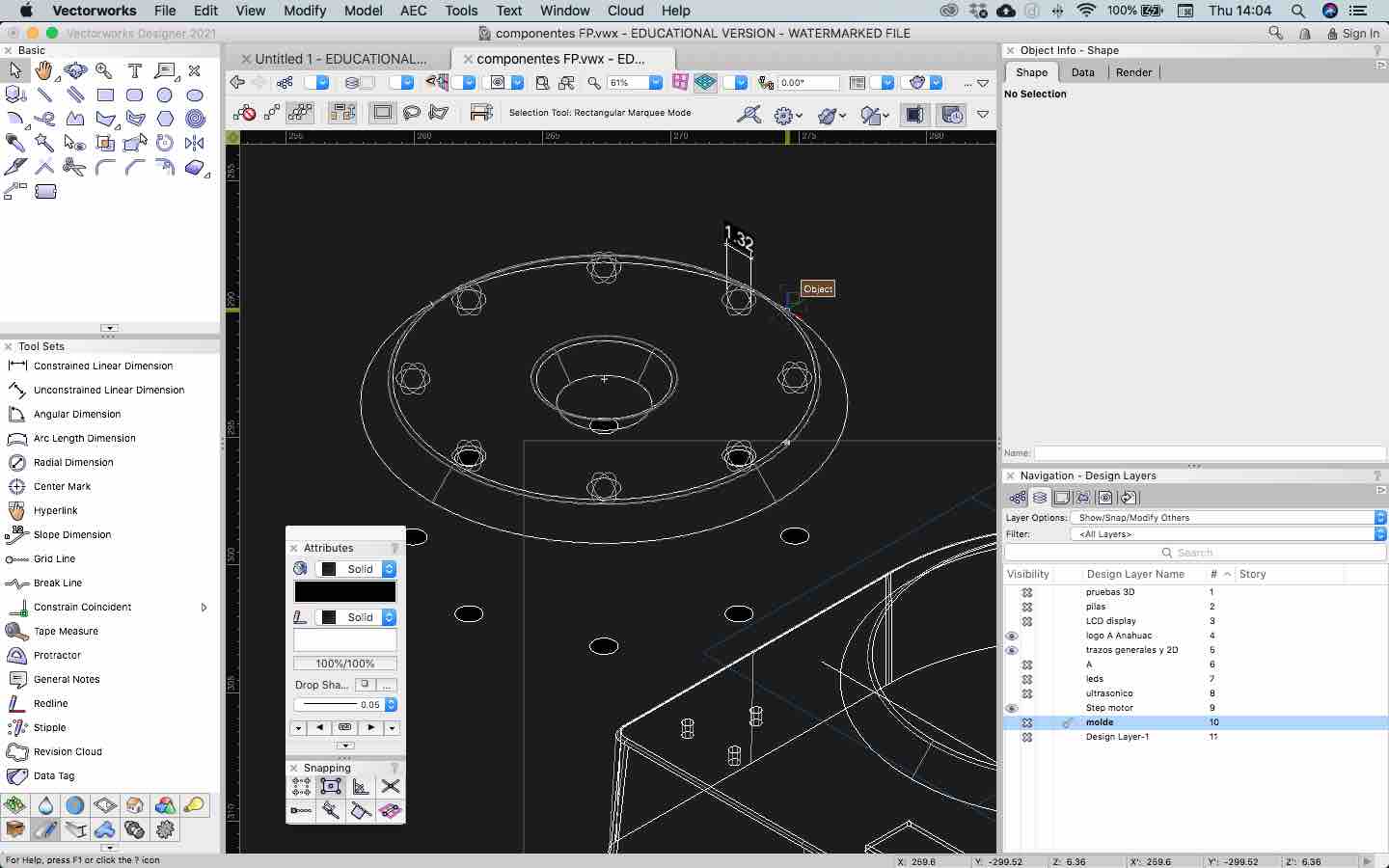

Vectorworks,

Rhino CAM, CNC router, band saw, vacuum machine.

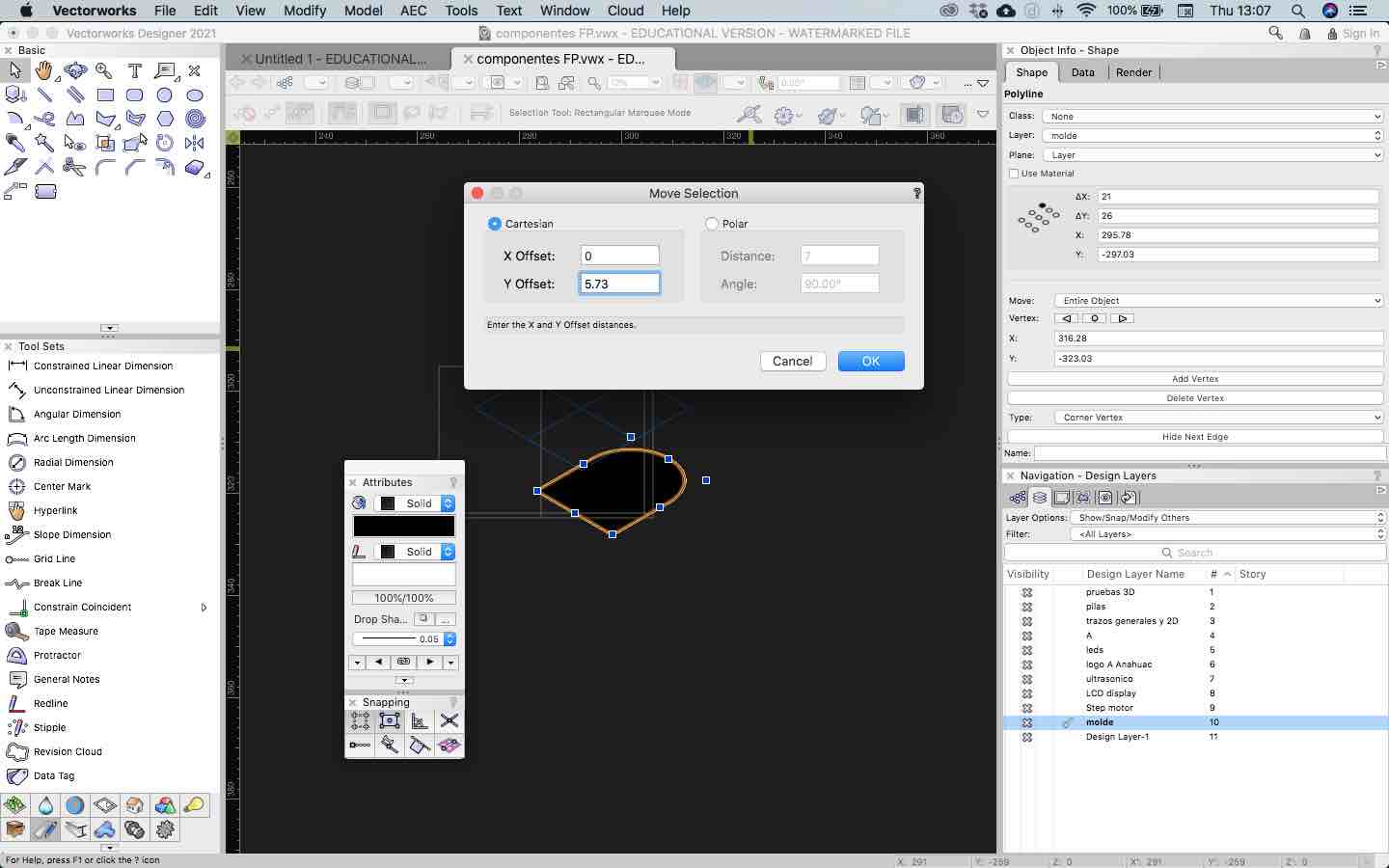

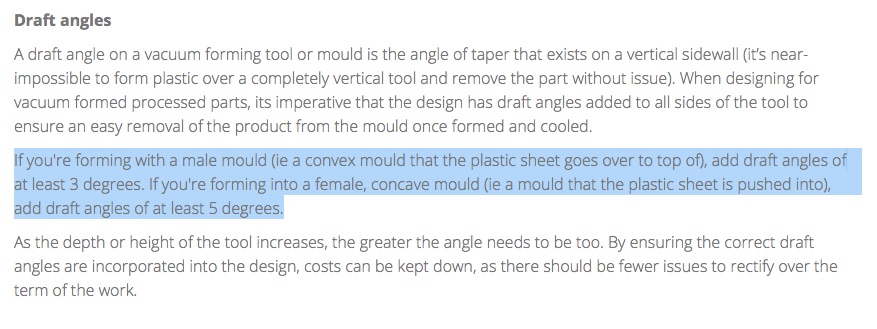

Before continuing, some

important information to consider about the mold angle so we can

de-mold easily.

In our case, I´m making

a "male" mould

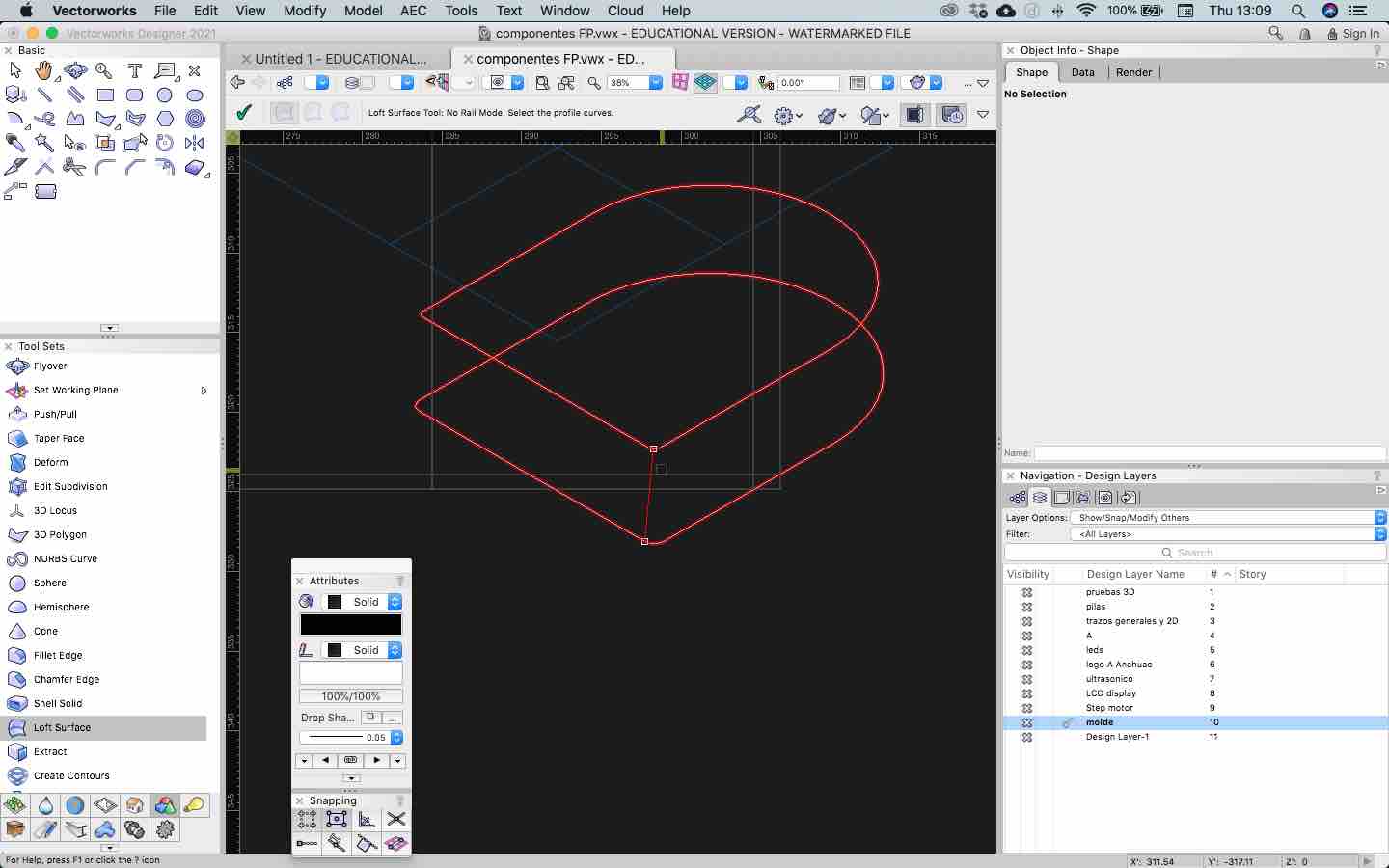

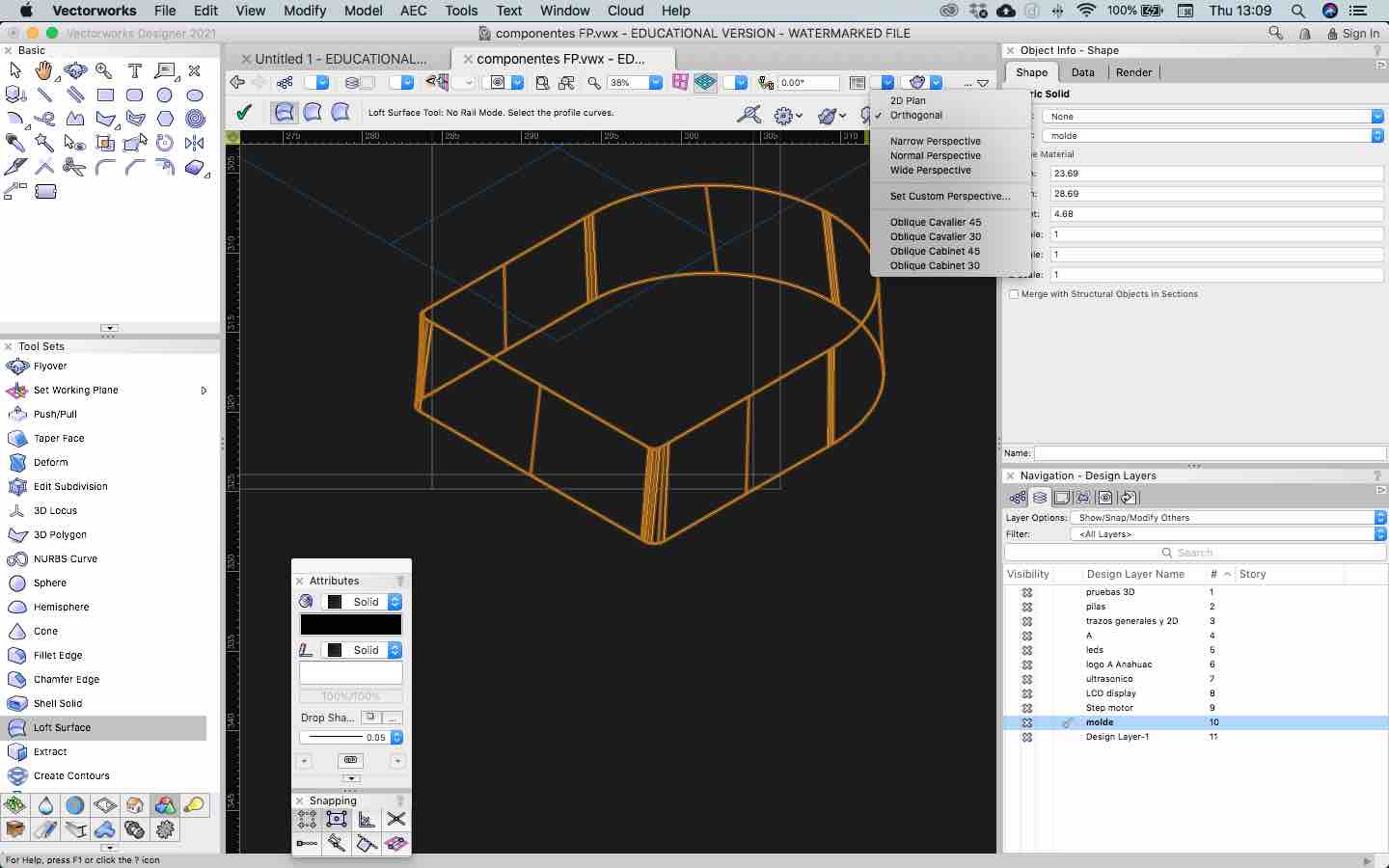

Now I´m ready to use

the LOFT tool

I always conserve the

original basic shapes like kind of time line doing, so if I want to

change something it´s more easy.

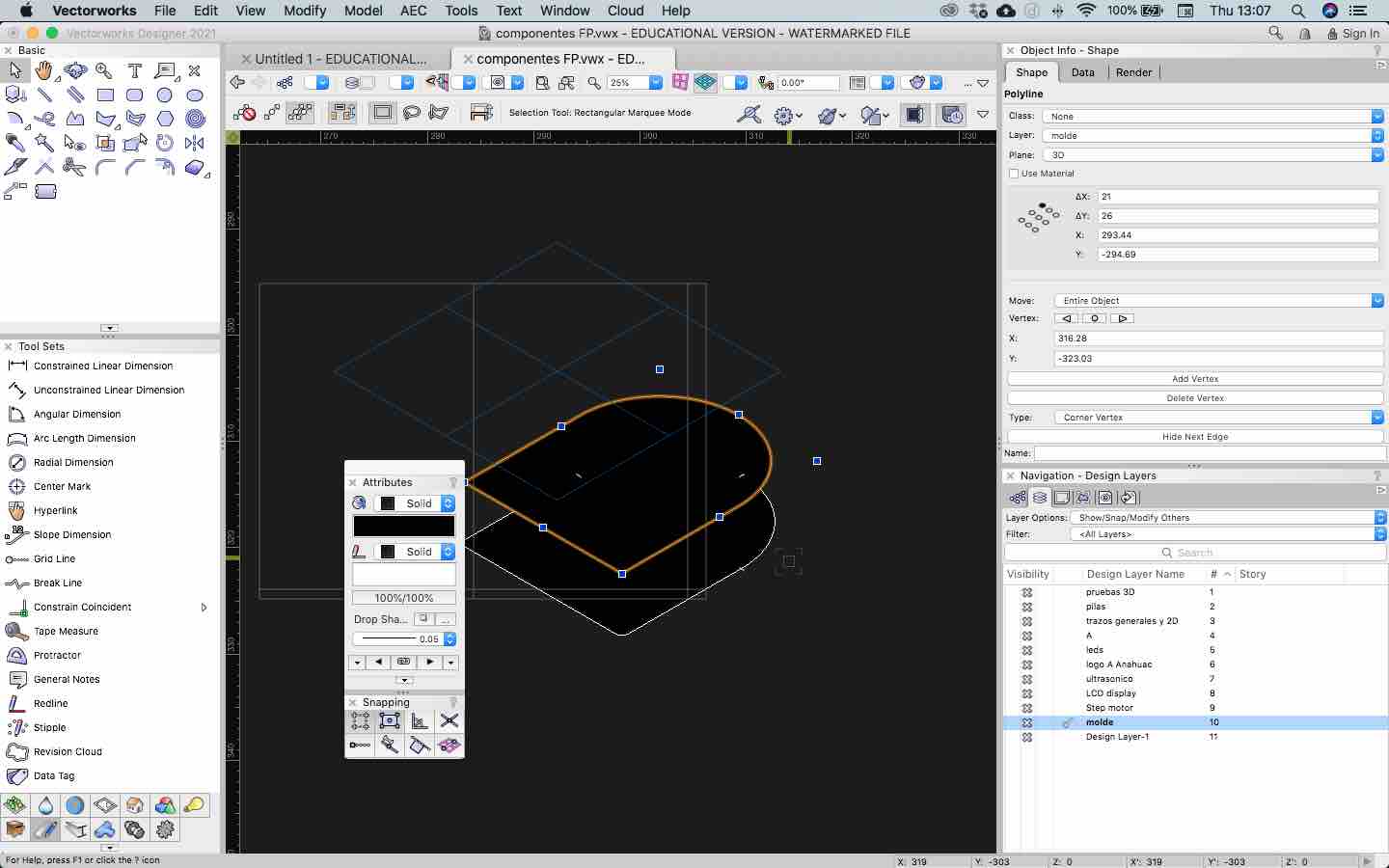

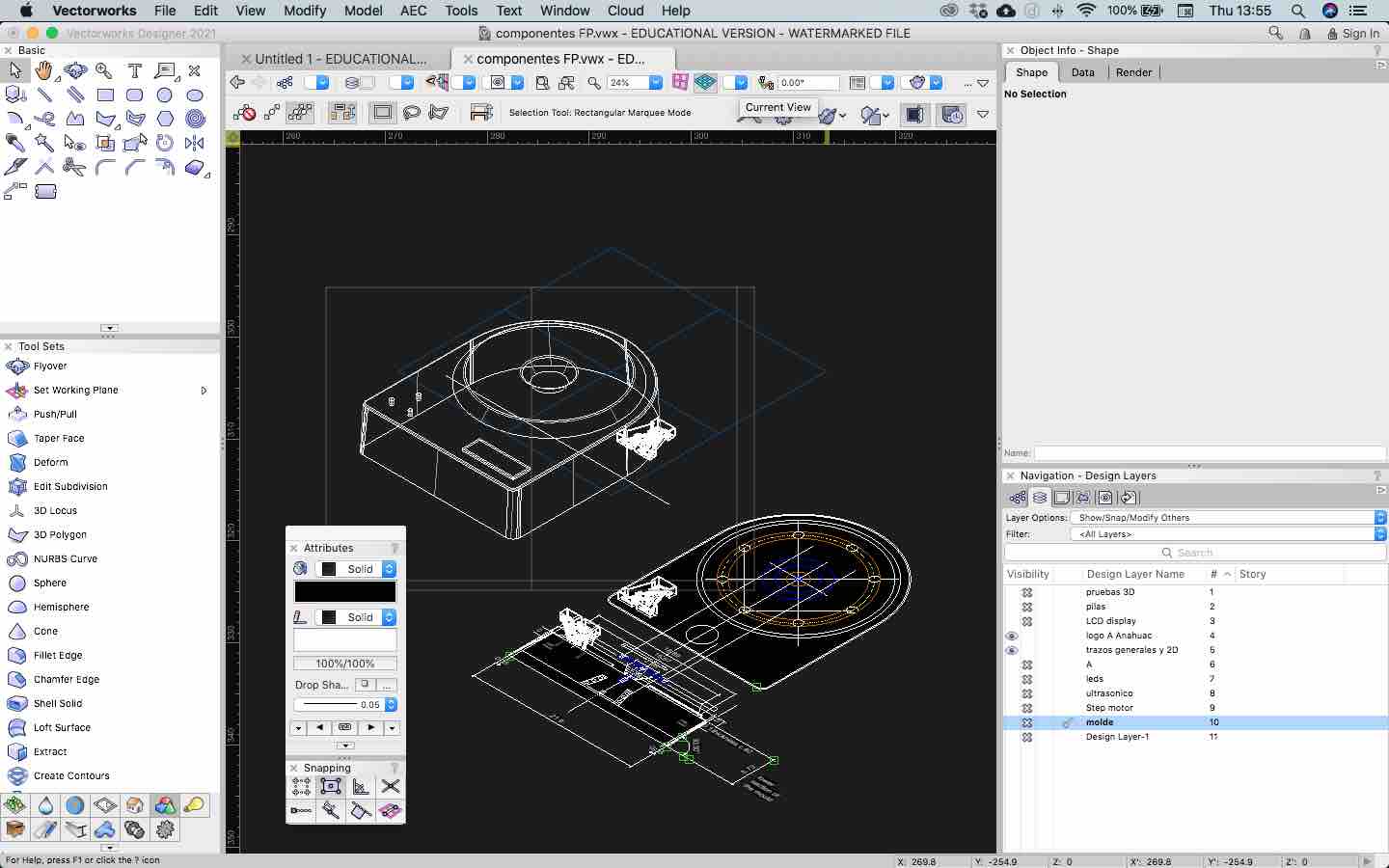

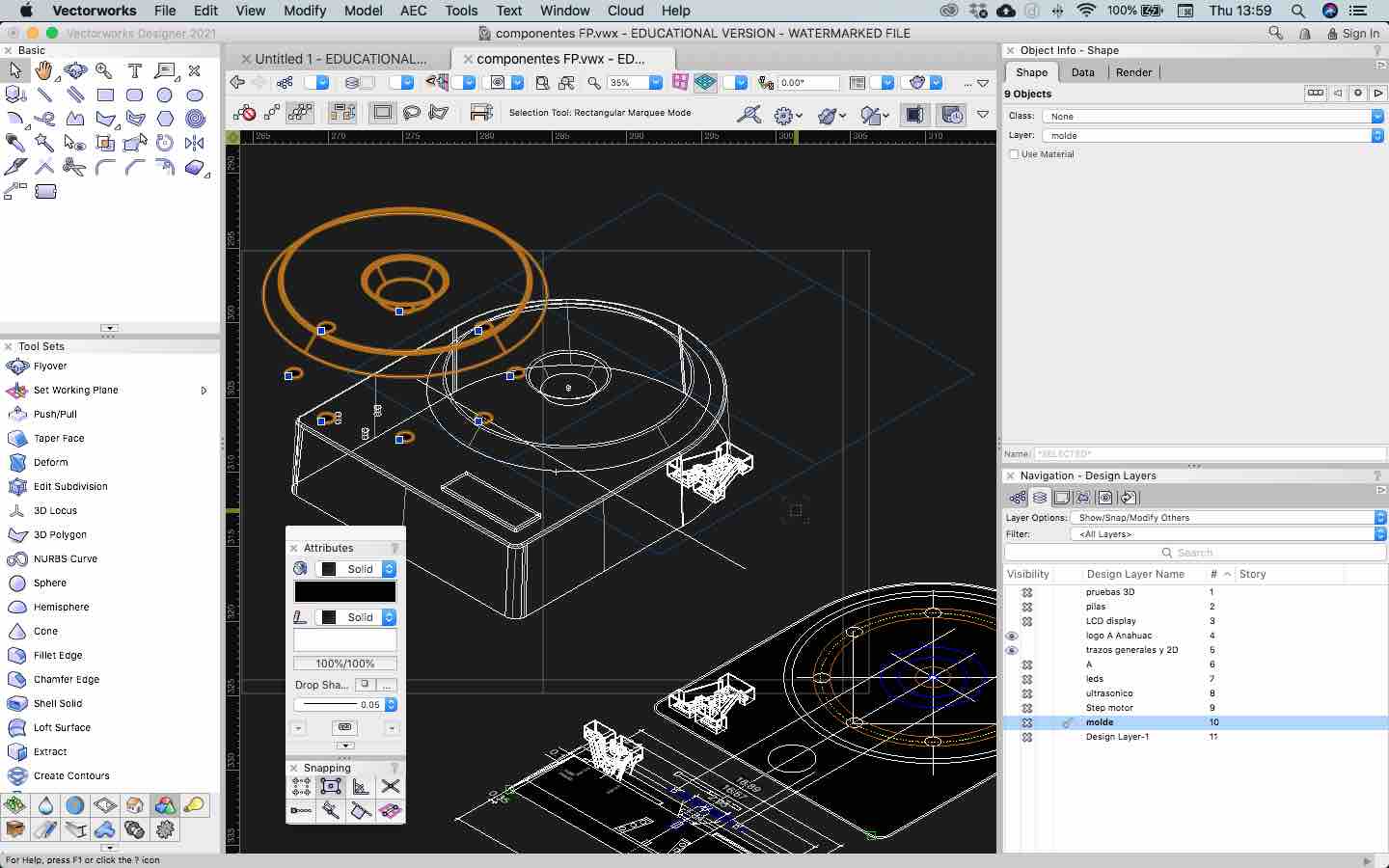

Here you can see that I

atached to the basic geometry the LCD rectangle, the pins of the A

logo and the part who will receive the "lazy susan" piece.

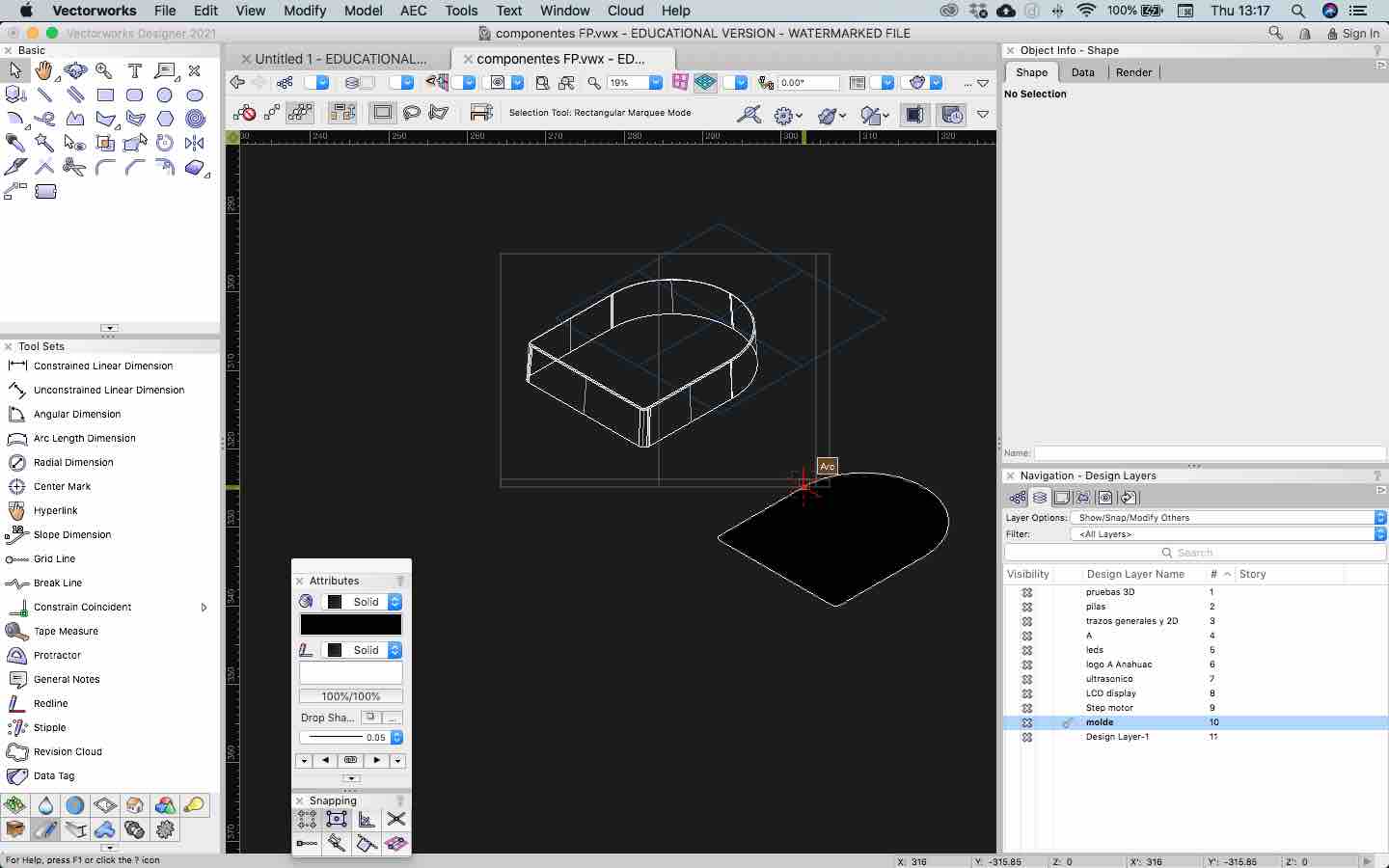

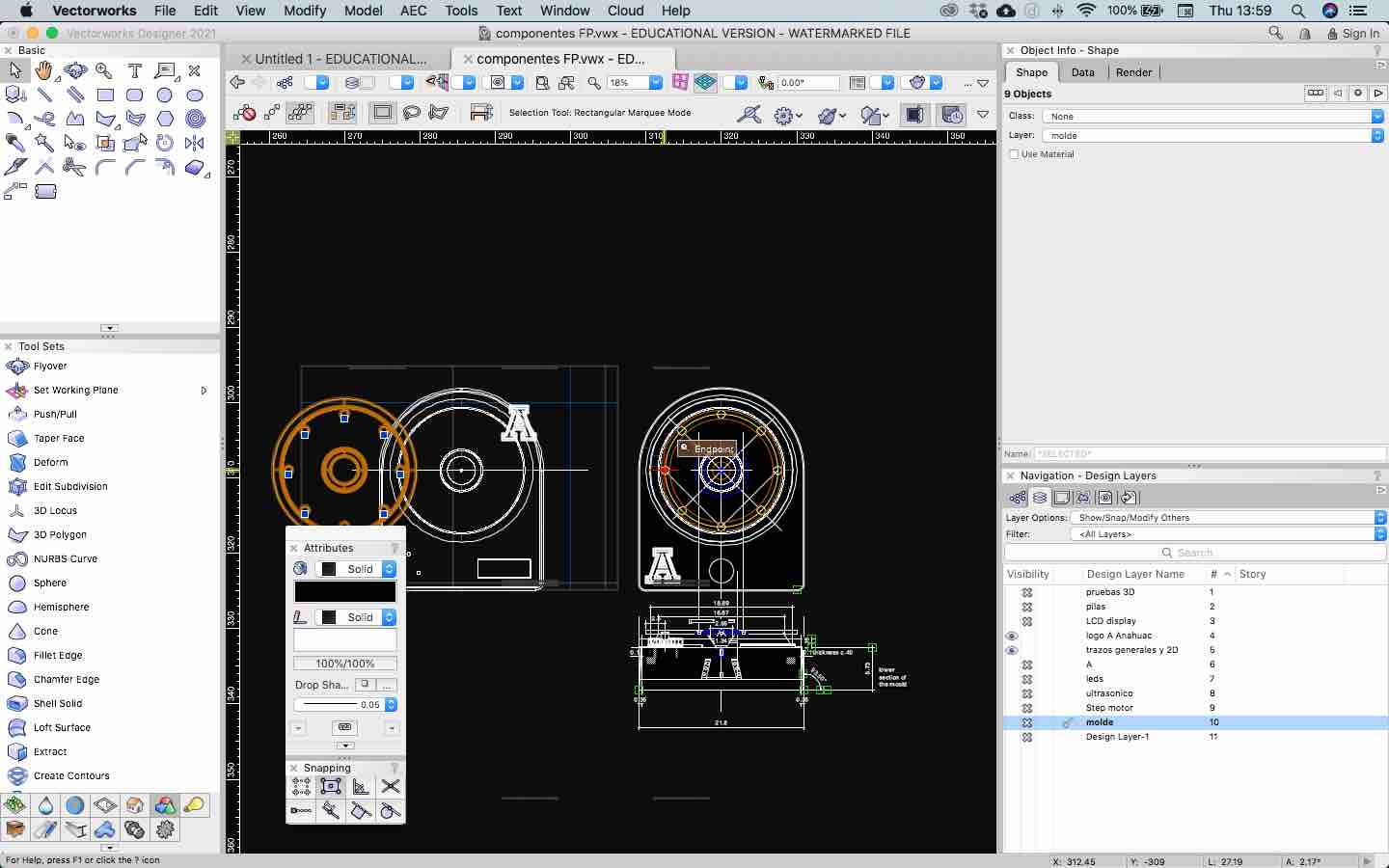

Top and front view of

the mould and construction drawings

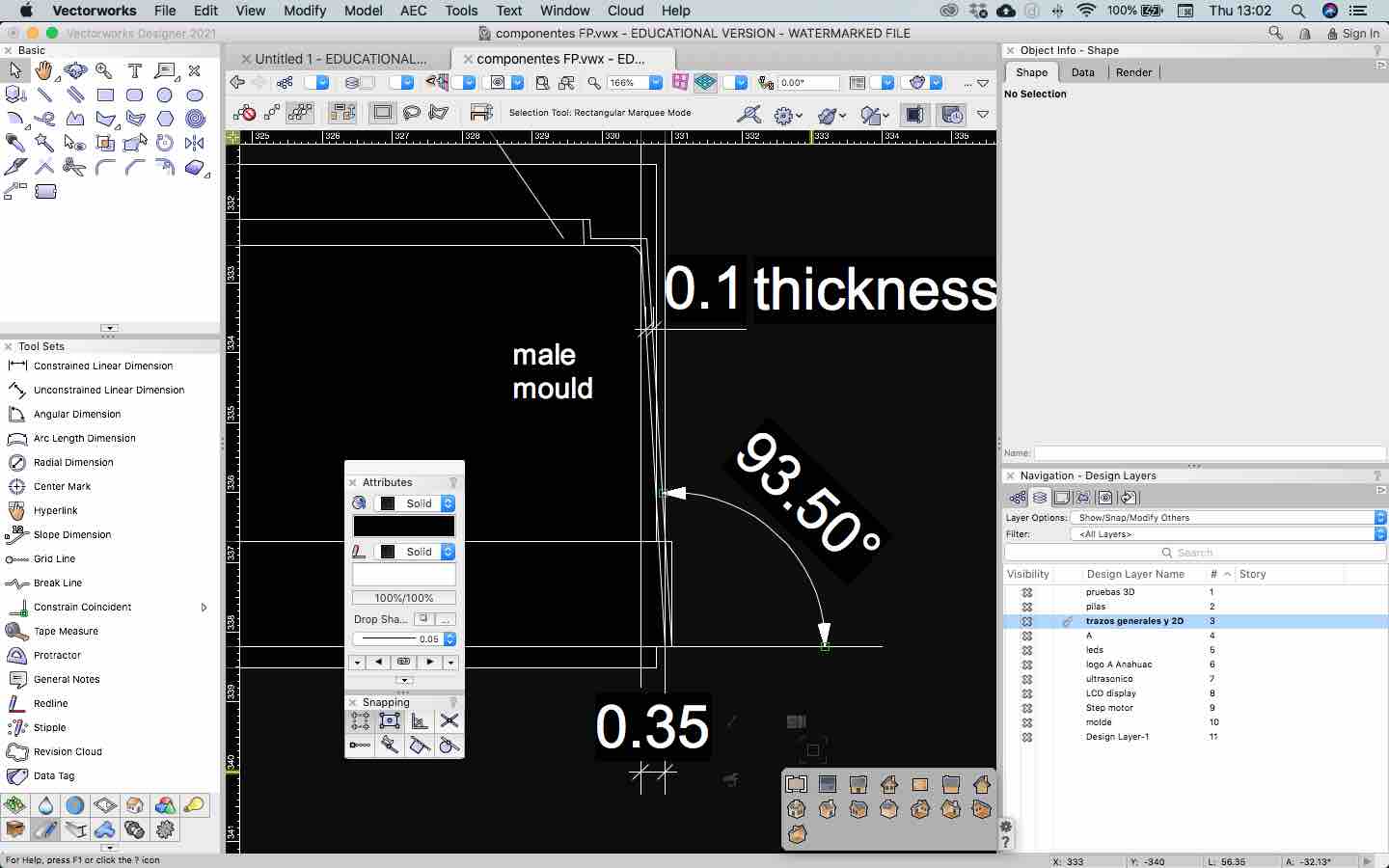

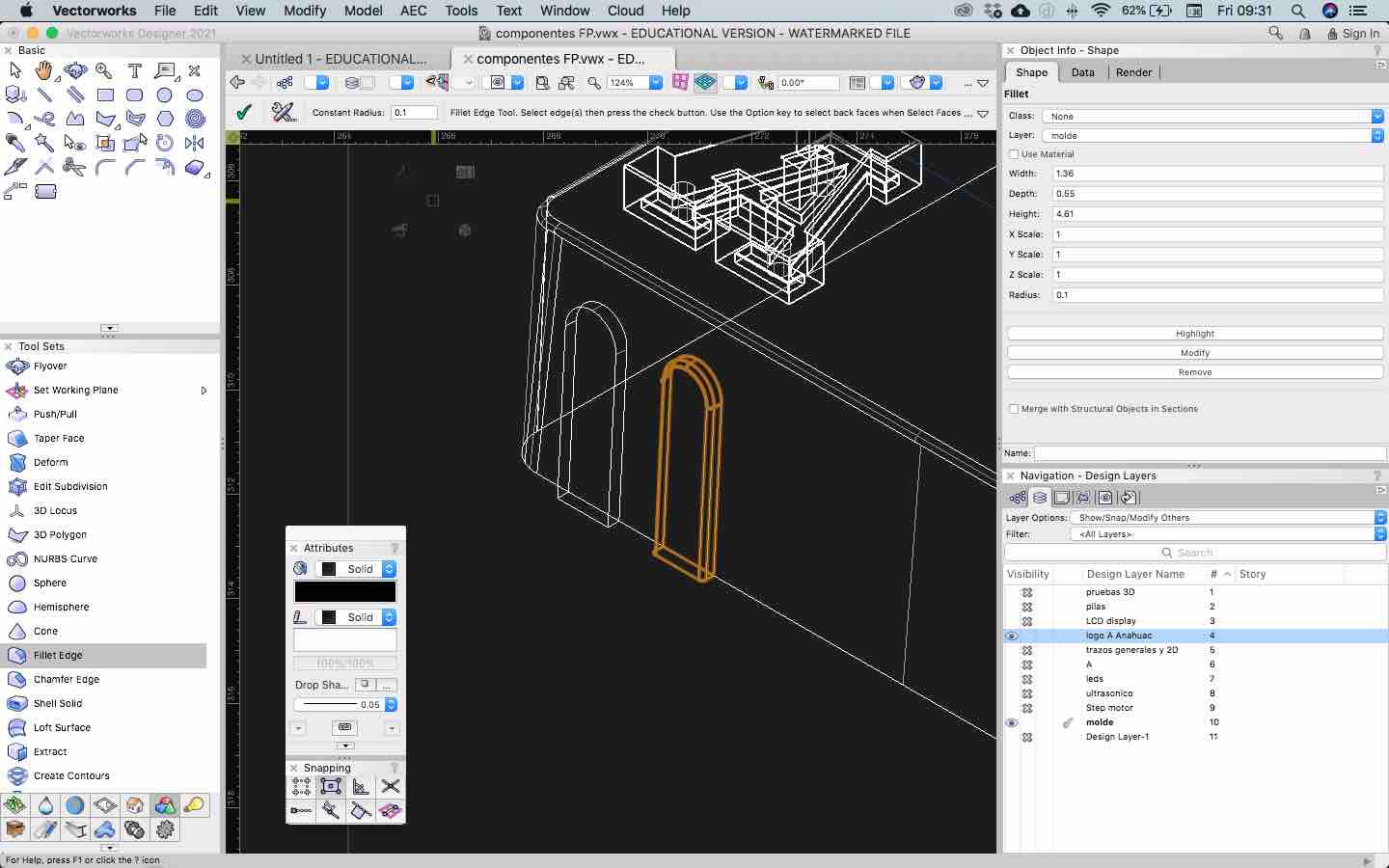

Detail of the mould

angle and material thickness : 1mm polystyrene

Detail of the

concavities that will receive the ball-bearings for the "lazy susan"

to turn around and help it to support the weight of the pieces

exhibit on it.

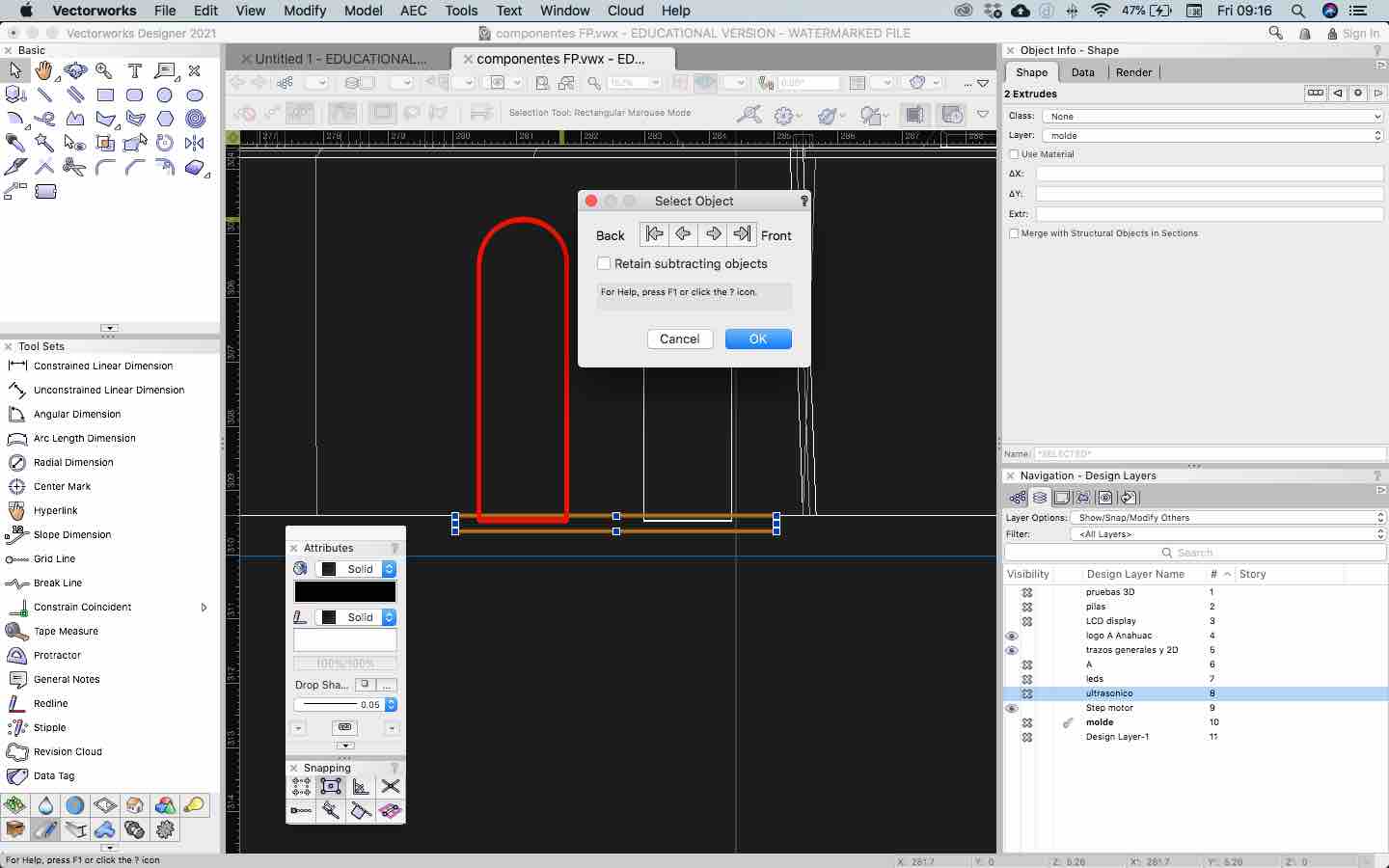

This are the shapes

that would be the place where the proximity sensor will be fixed.

Almost done.

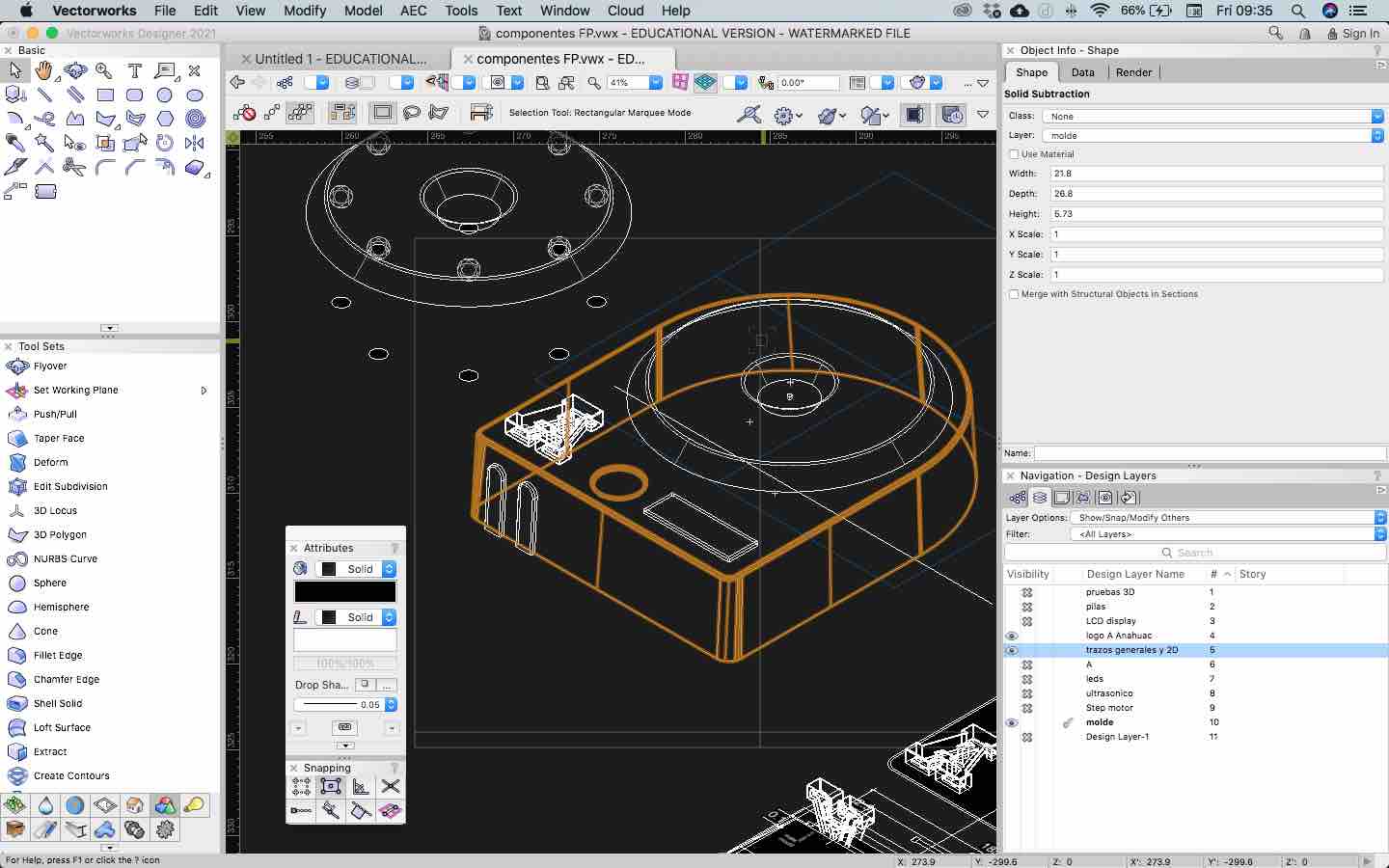

Here we can see the

Stepmotor inside the cover to check the distance between the step

axis and the top cover.

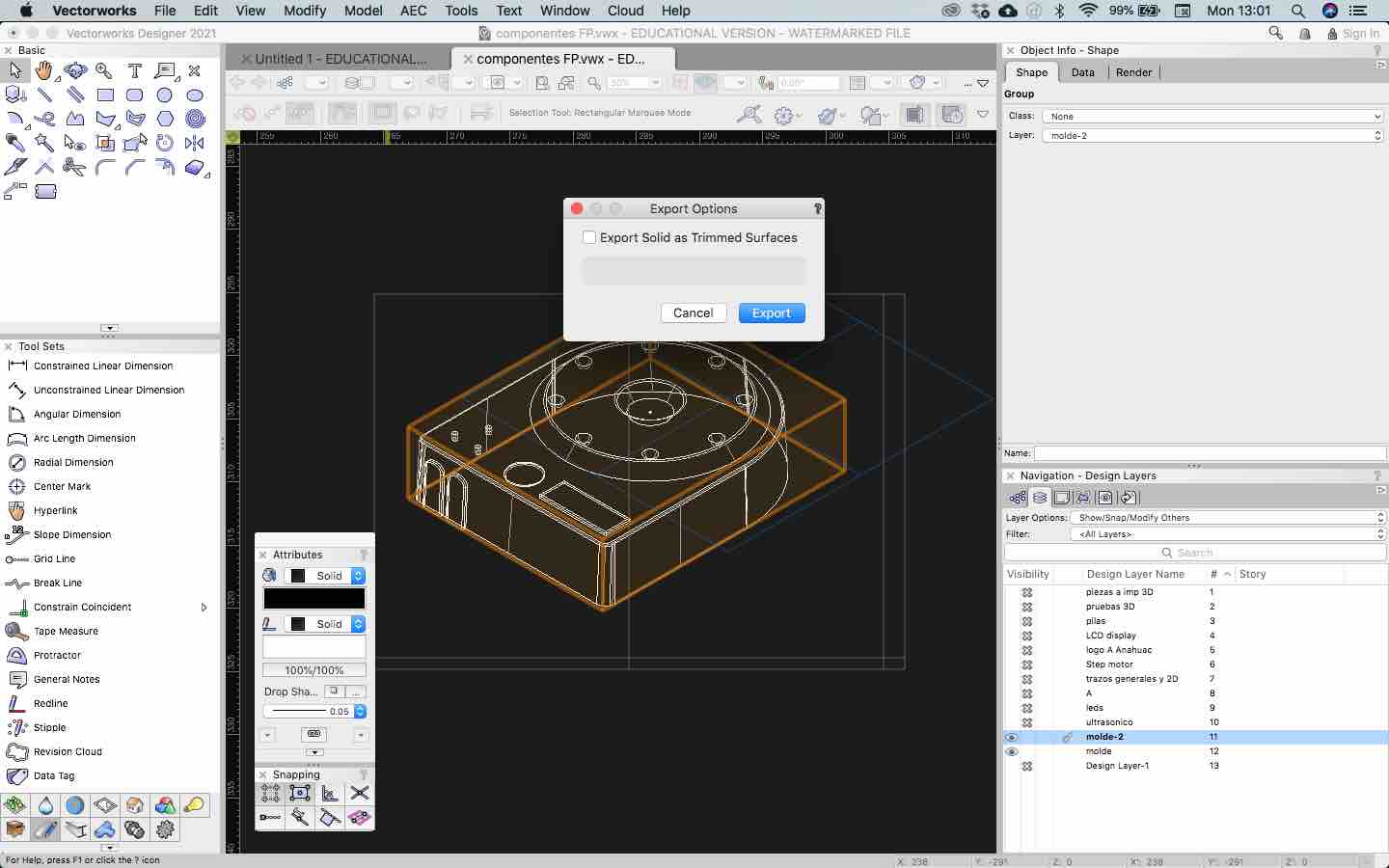

Export the final 3D

into a .OBJ archive

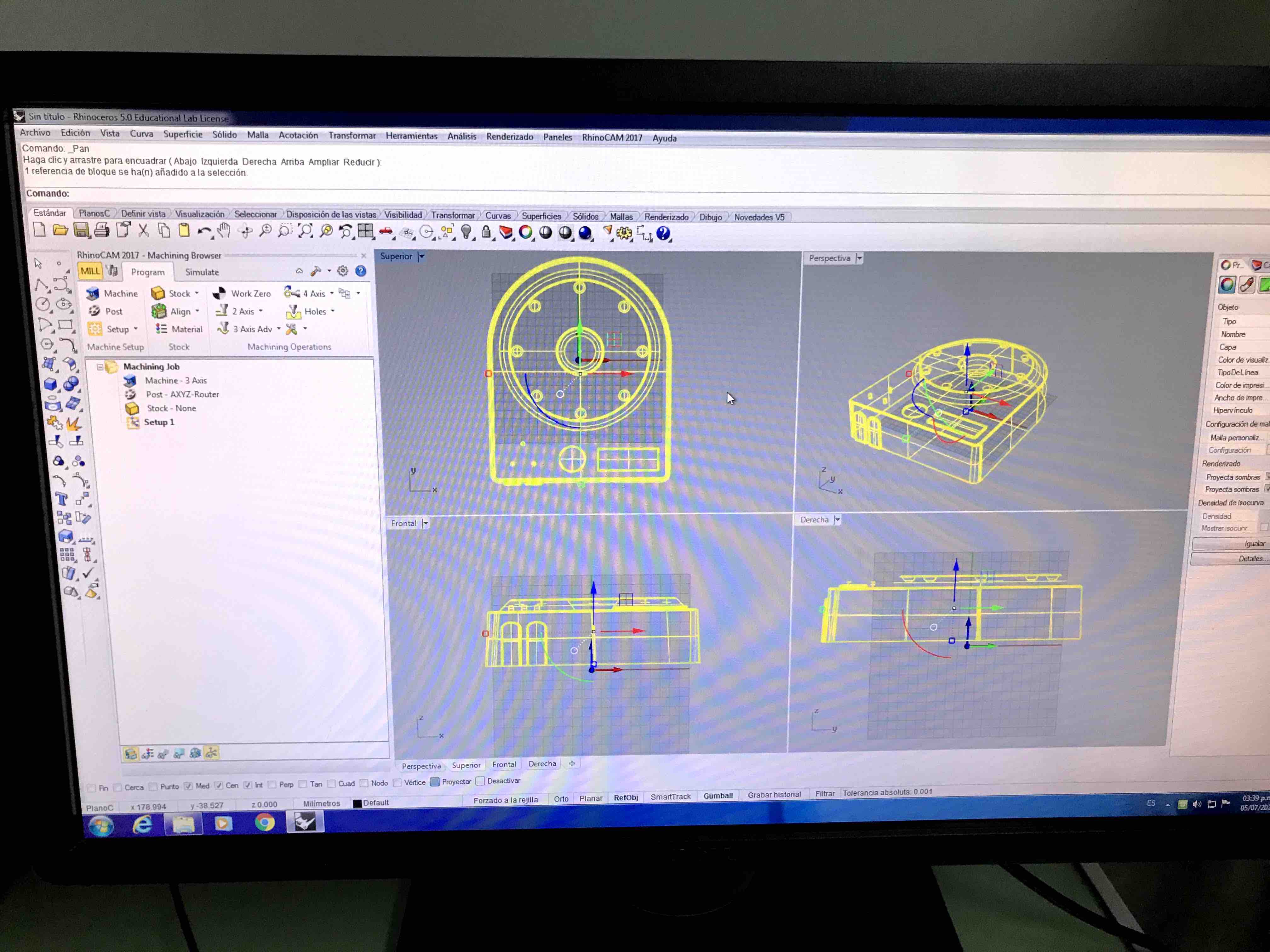

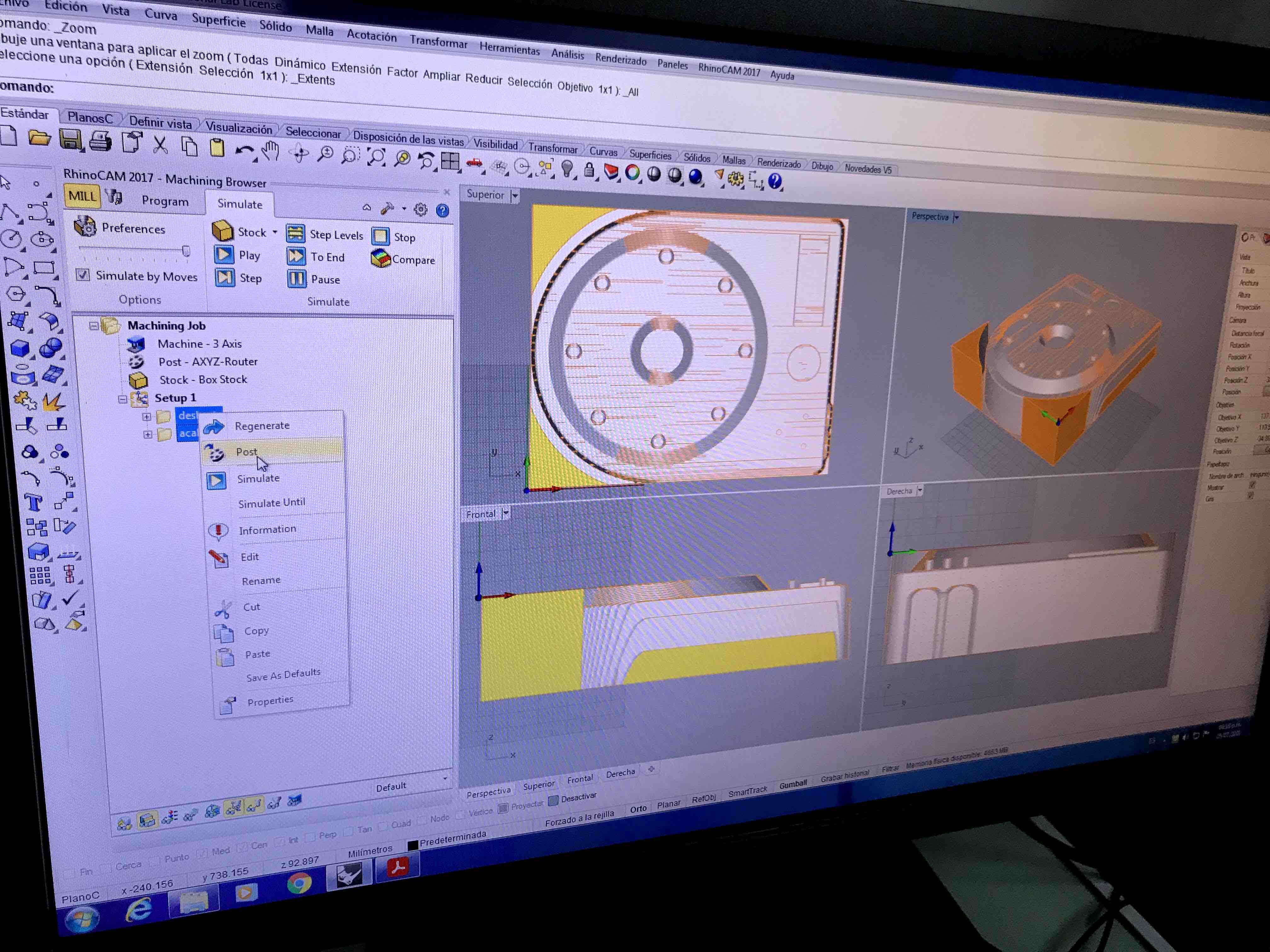

Here is the archive

imported into Rhino CAM

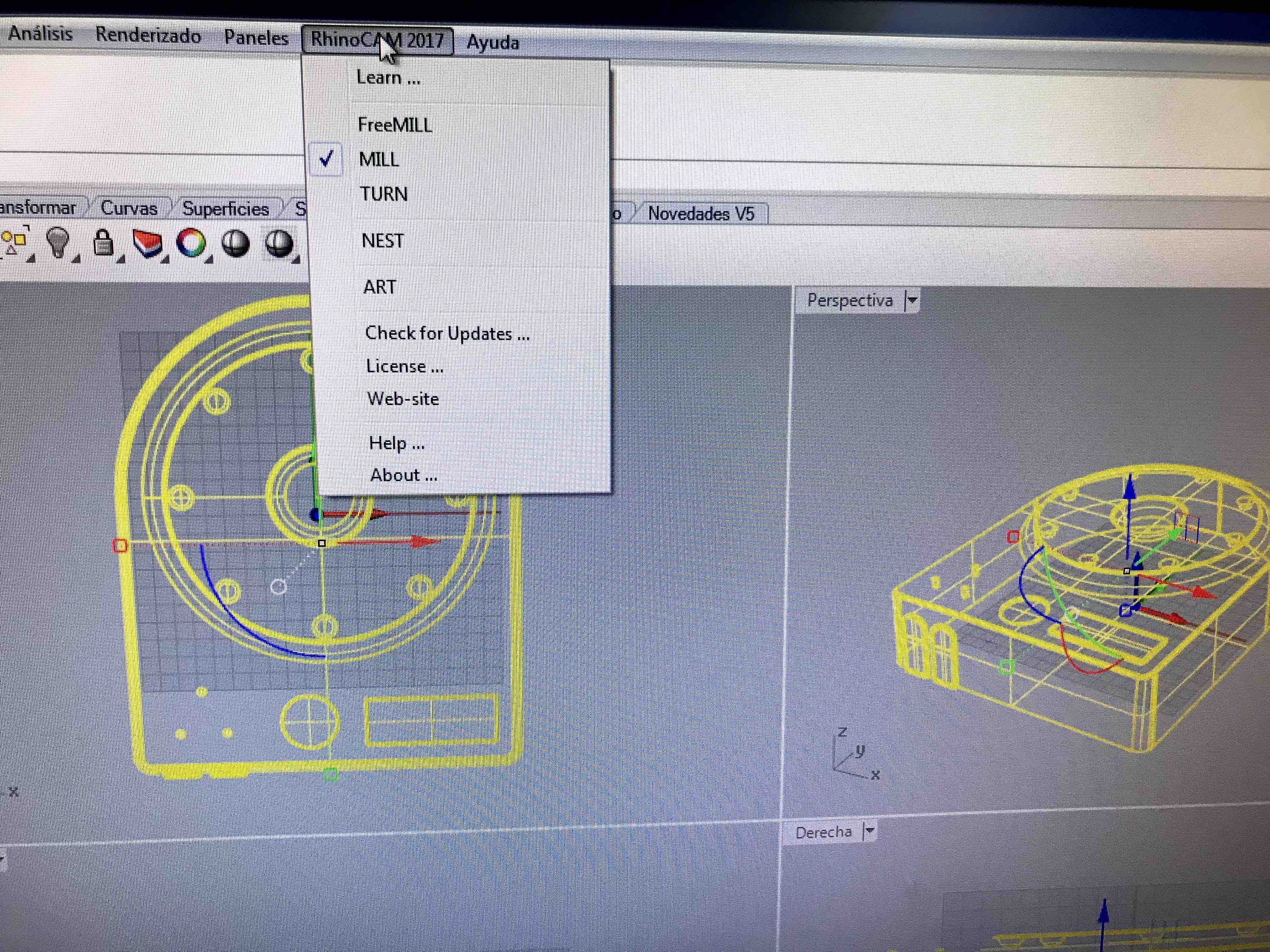

Select MILL from the

upper menu

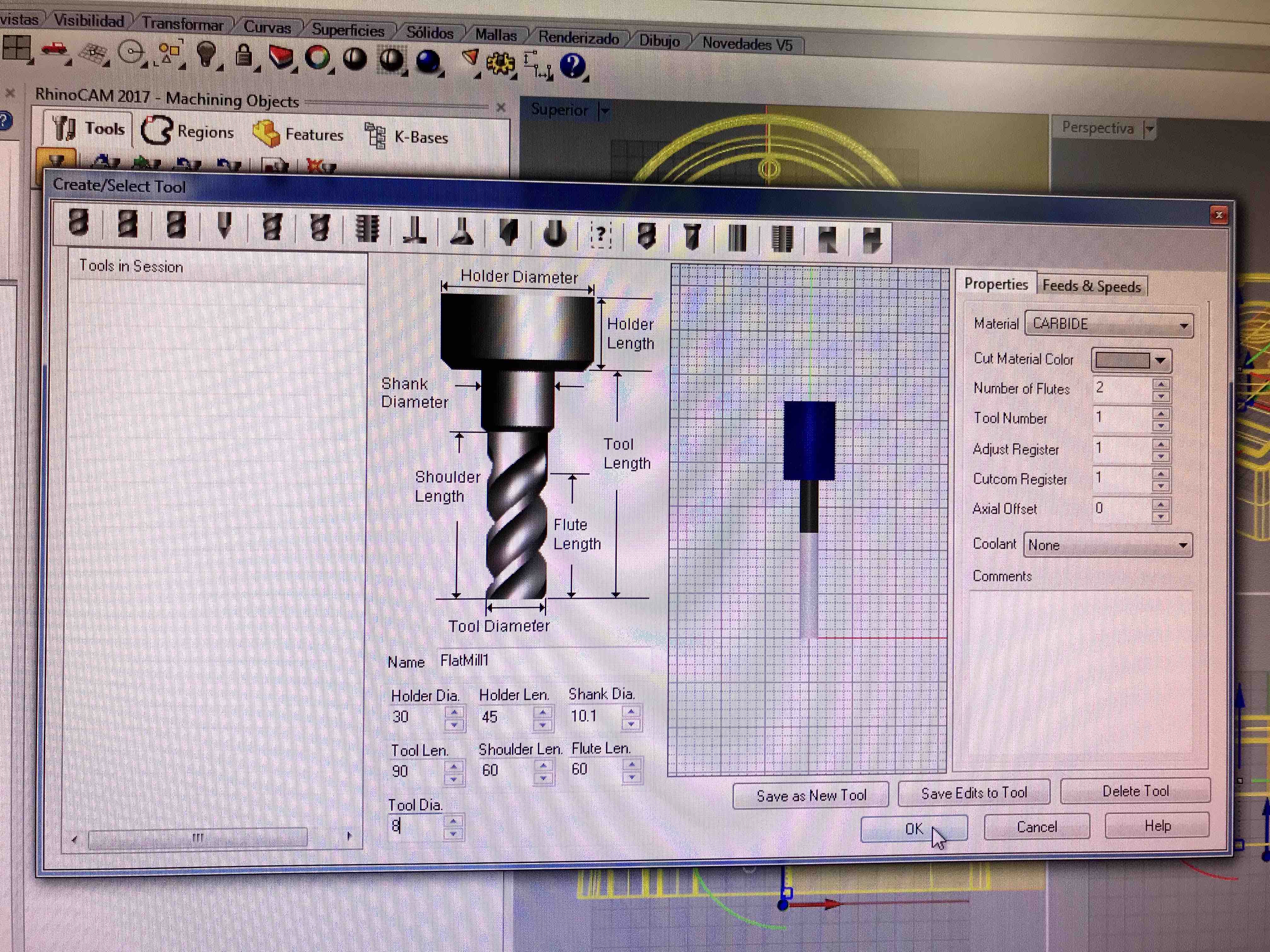

Here are the settings

of the tooling: straight 2 flute, 8mm dia.

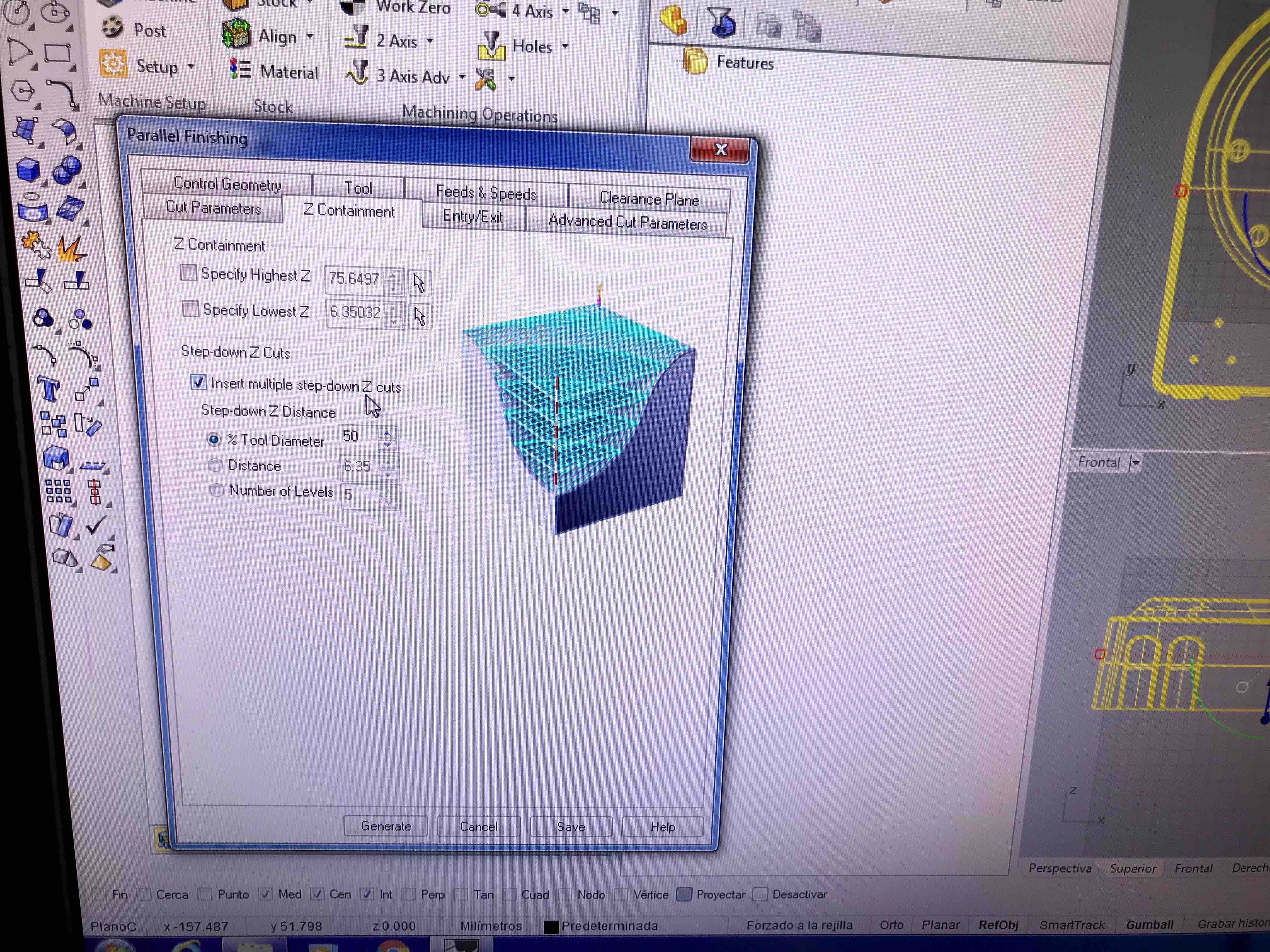

Here we are setting the

deep of the Z distance that would be 50% of the tooling dia.

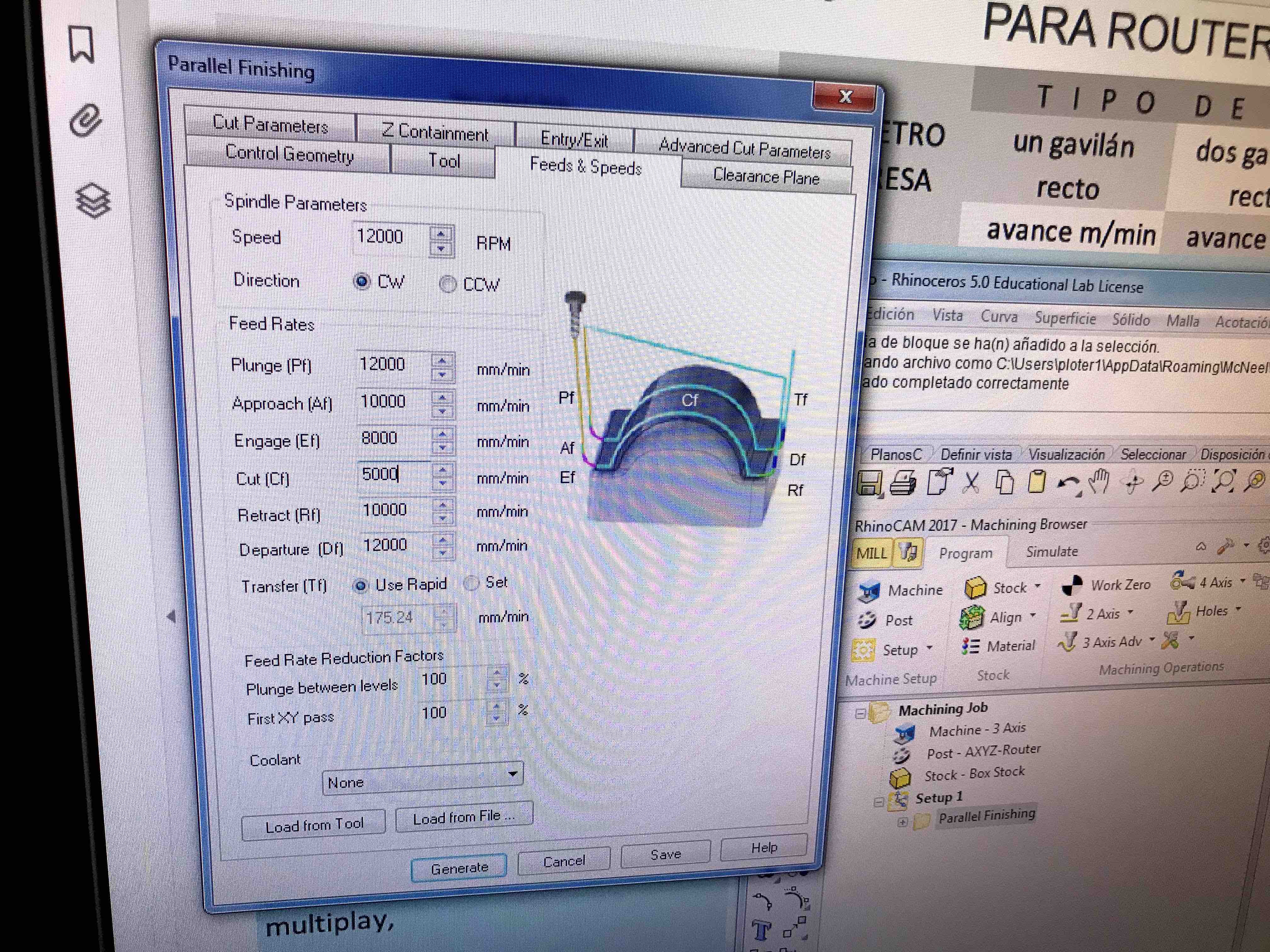

Then the rotation

speed at 1200RPM and the cut at 5000mm/min

We can see here how

it´s going to be our finish mould.

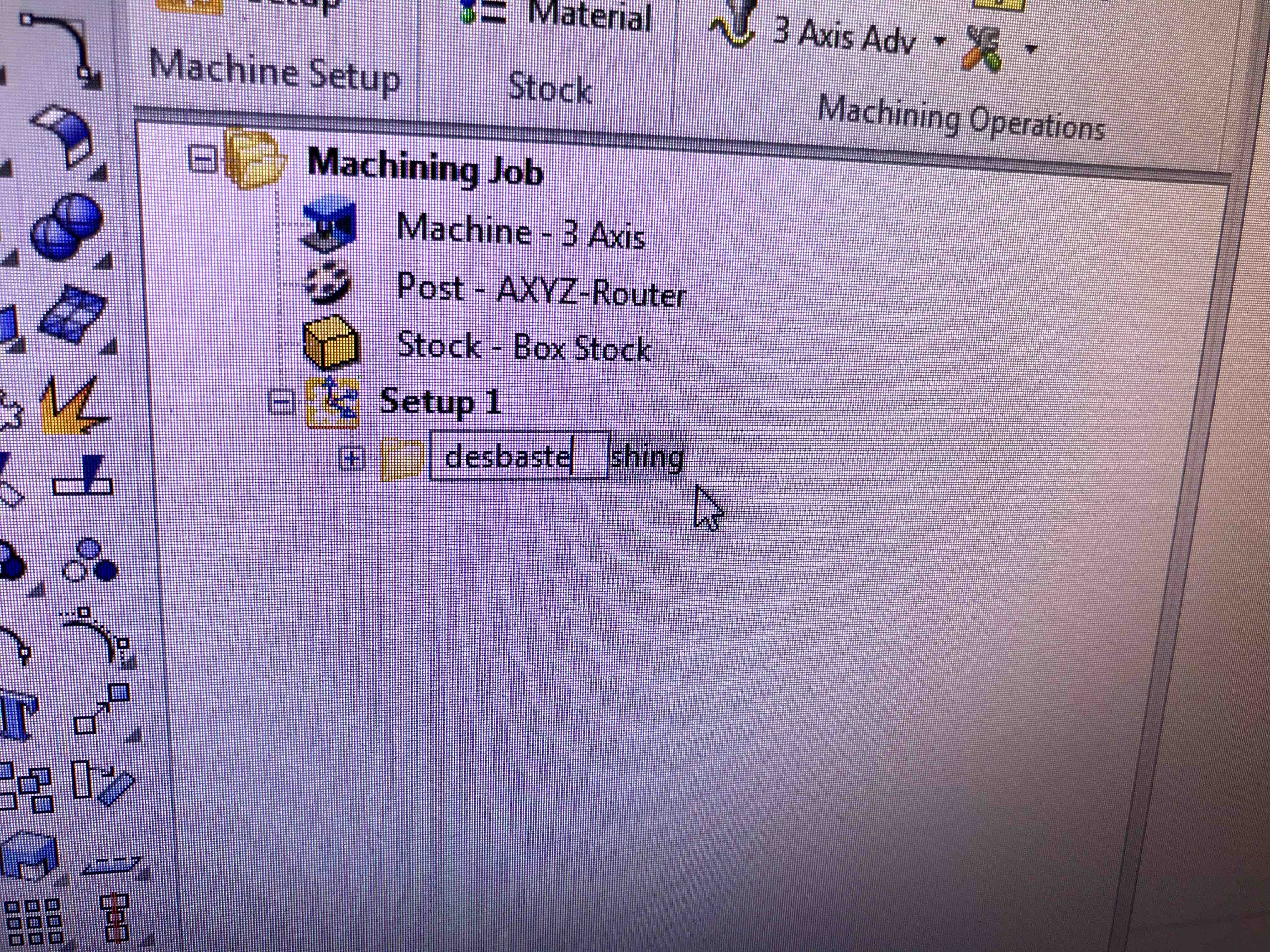

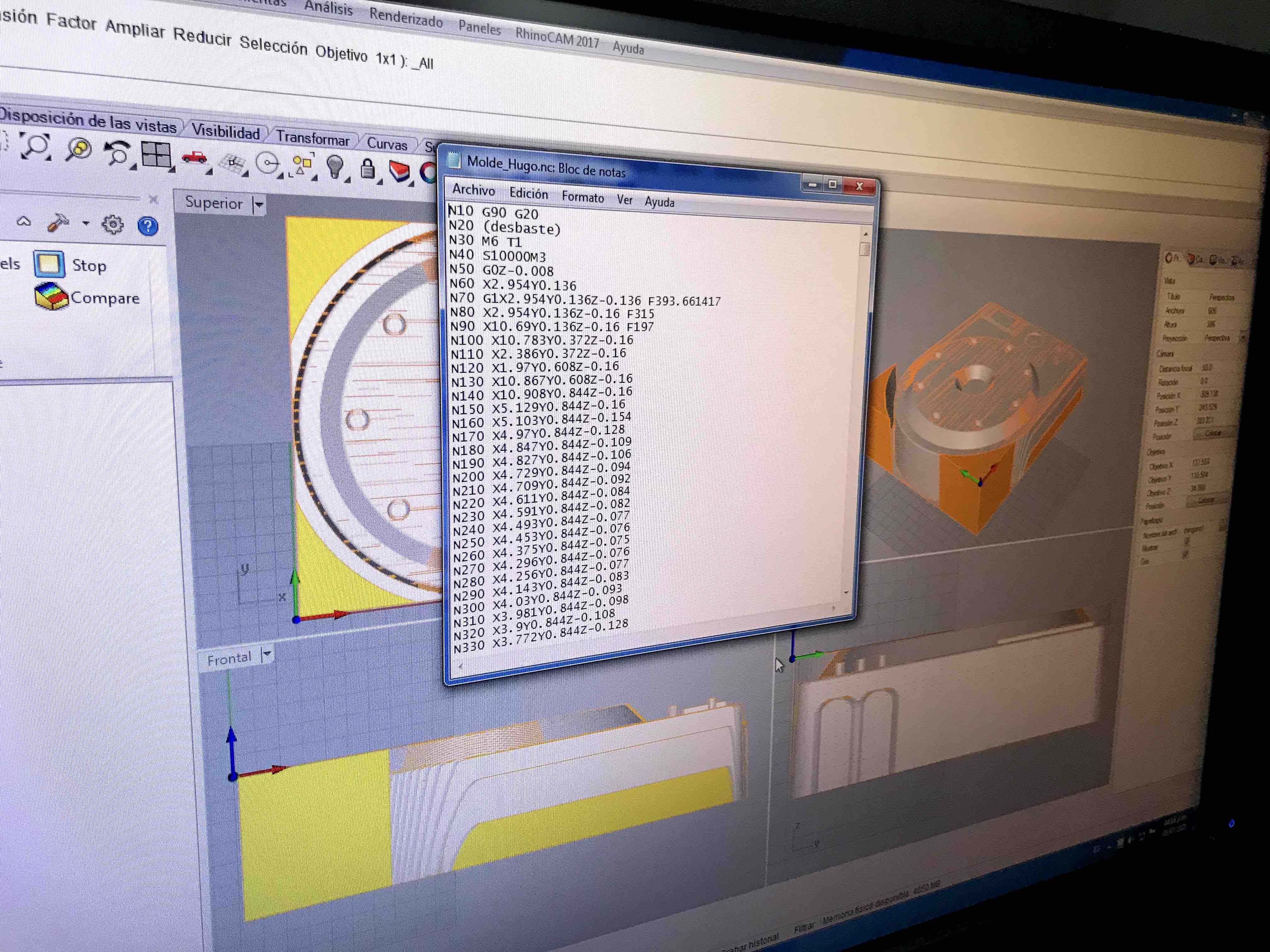

if everything is fine,

the we need to generate the G code

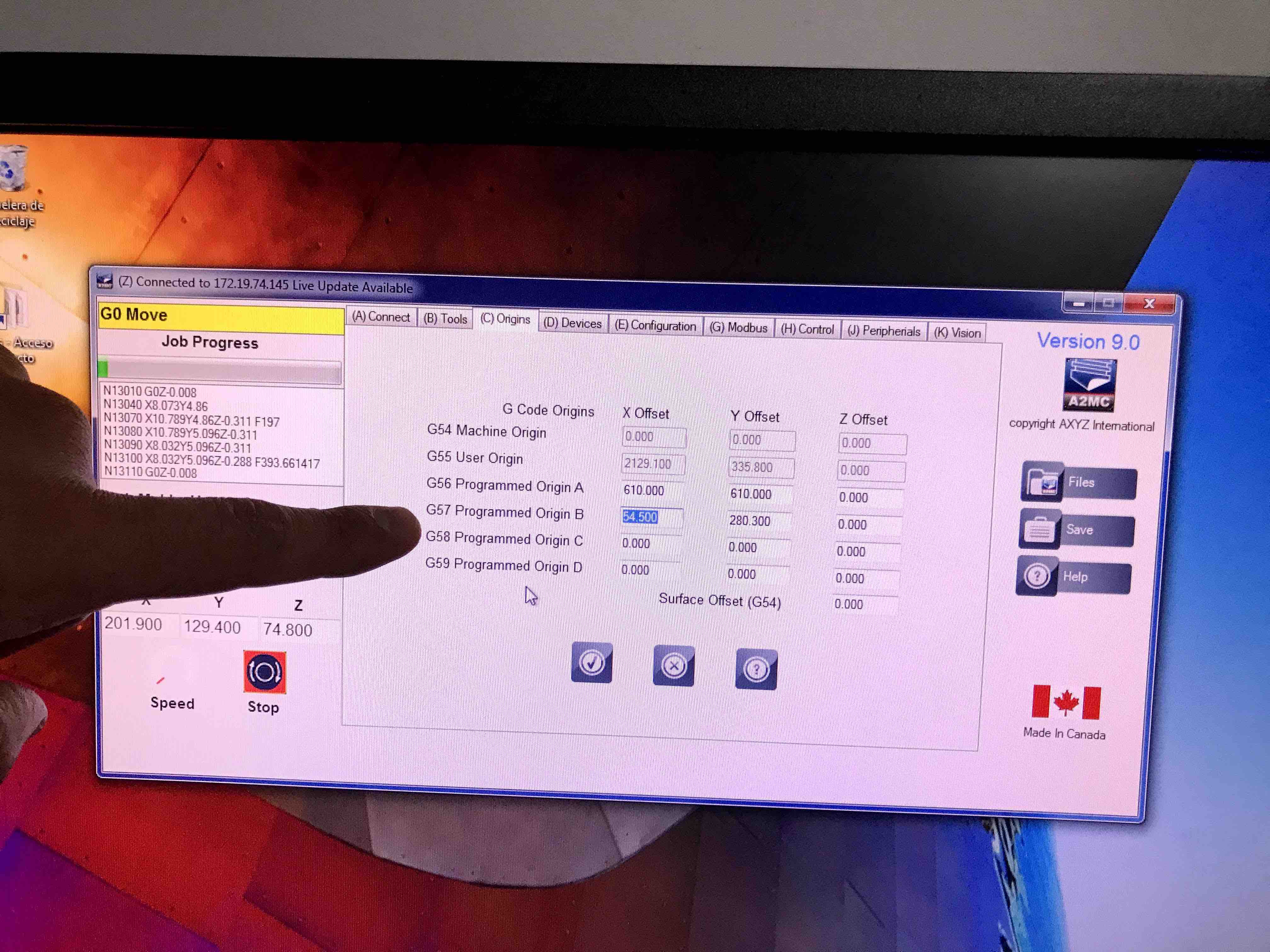

Here is the origin

setting that we are going to use; G57 Origin B

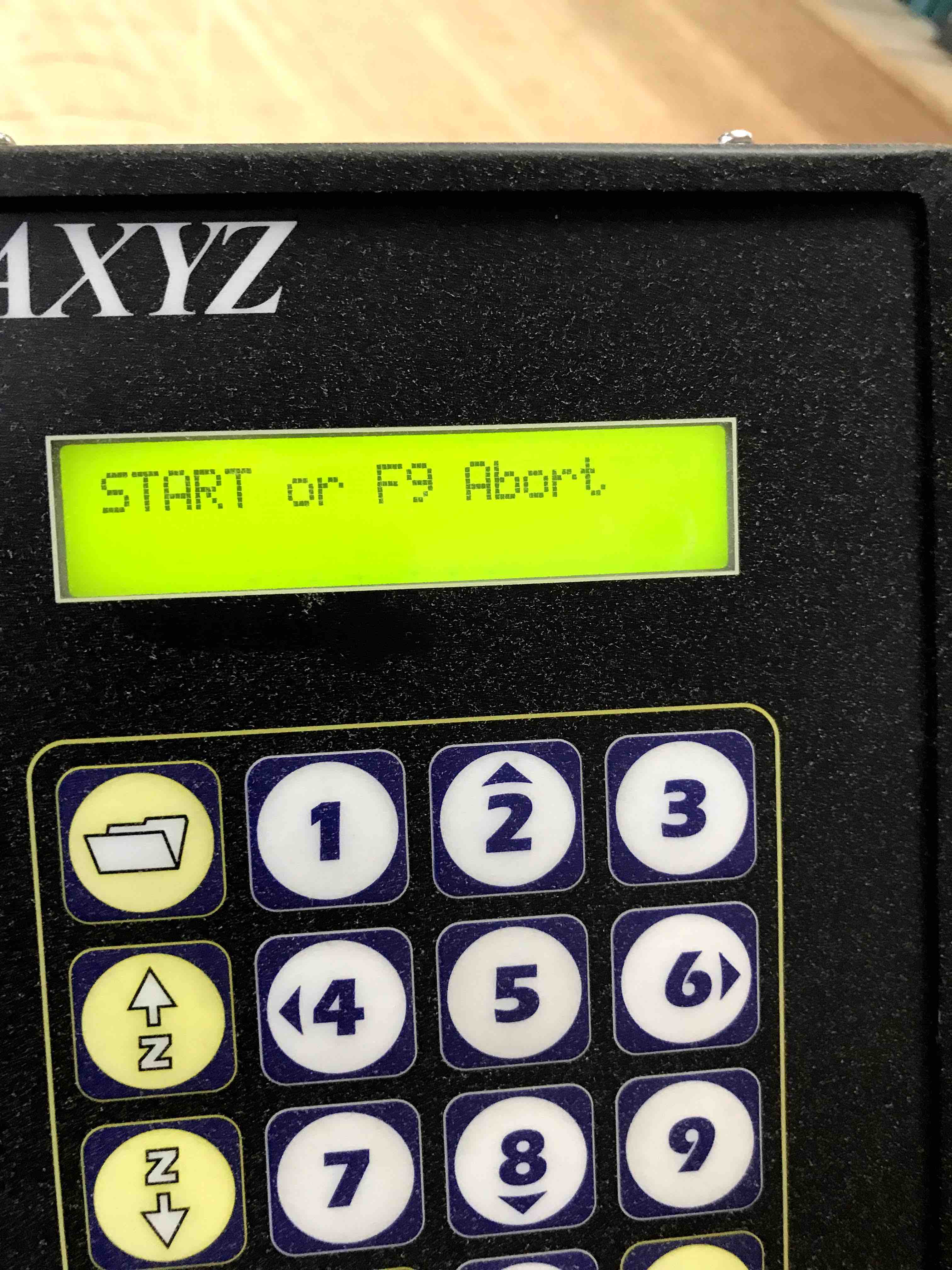

Ready to push play

A detail view of the

MDF in the CNC router

The mould getting

shape.

The mould finished

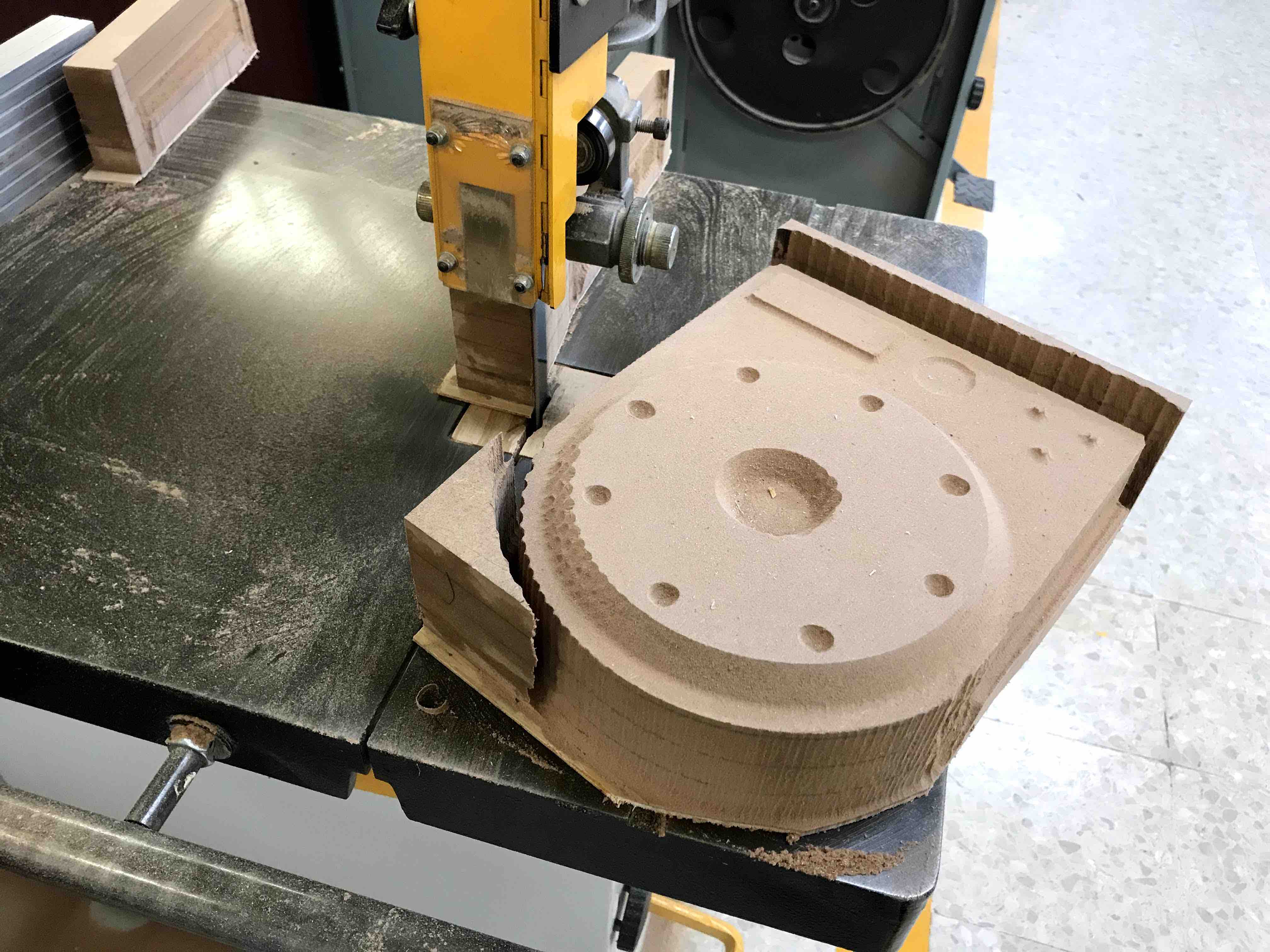

I´m using a band saw to

cut the extra material of the perimeter.

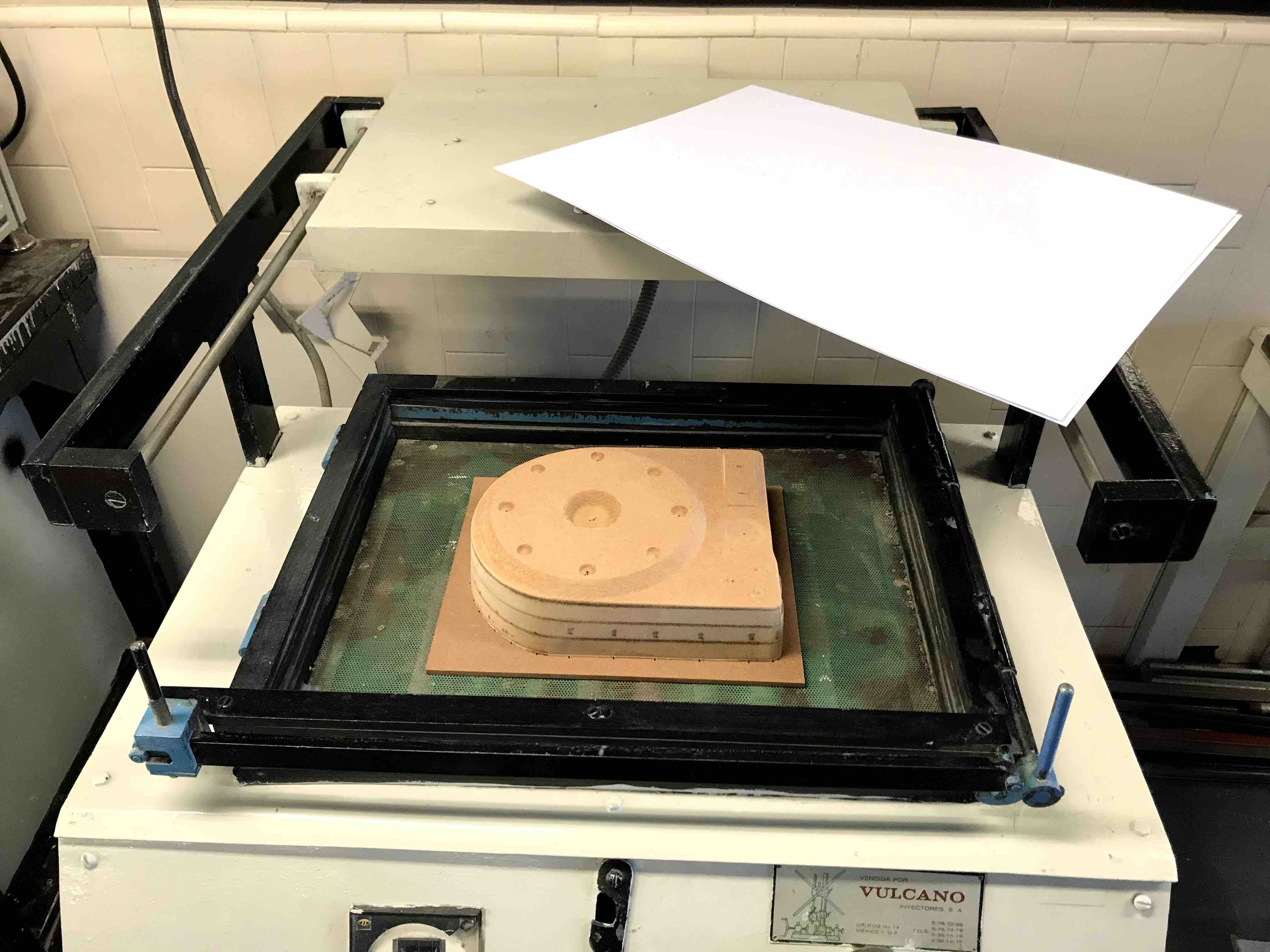

Here is the finished

mould, then I attached a base of 3mmMDF, this will help me to cut

the perimeter of the vacuum formed polysteryne.

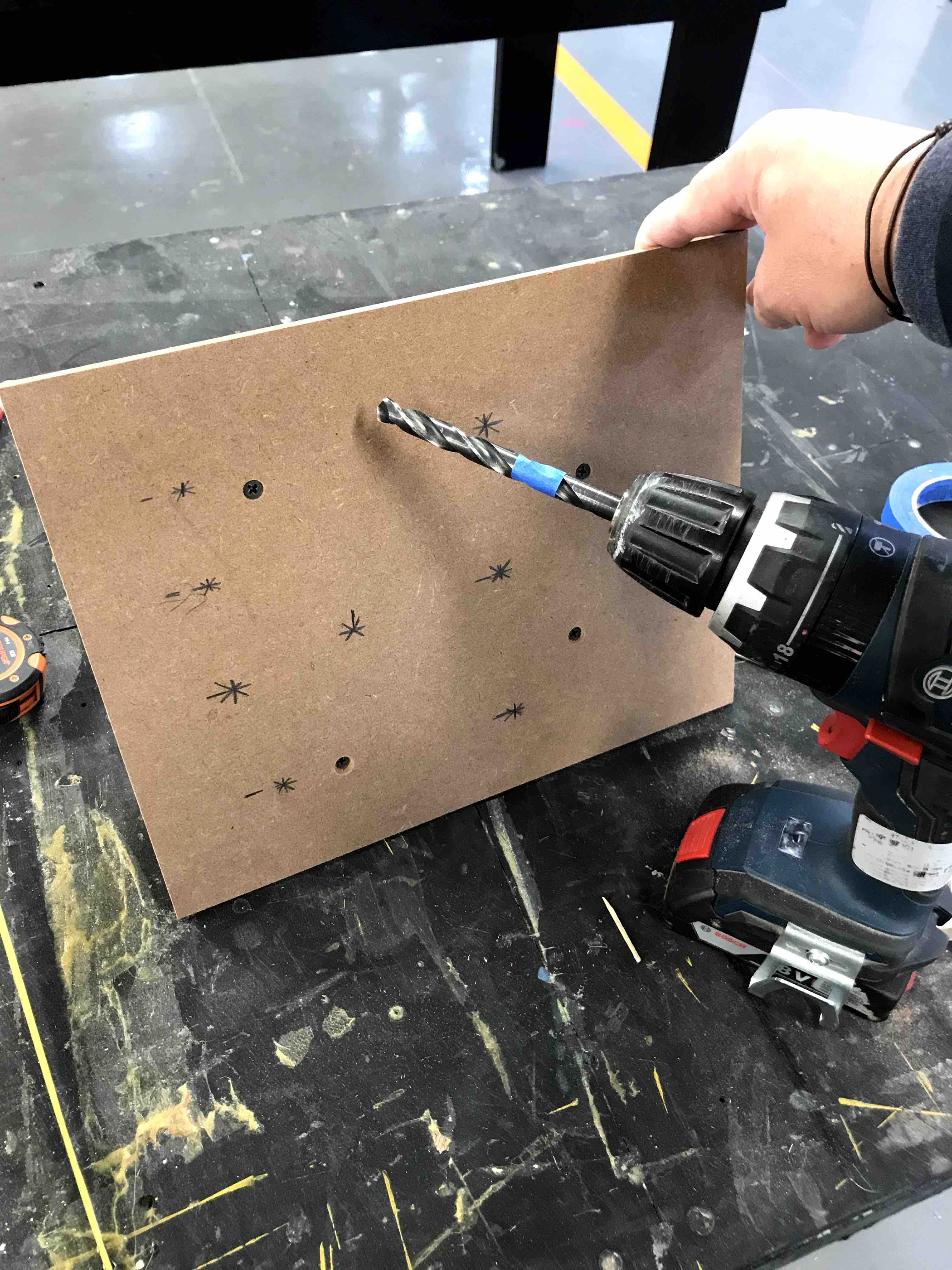

It is recommended to

make some holes in the bottom of the mould so the vacuum could be

more effective

The mould in the vacuum

form machine and the styrene before fix it in to it

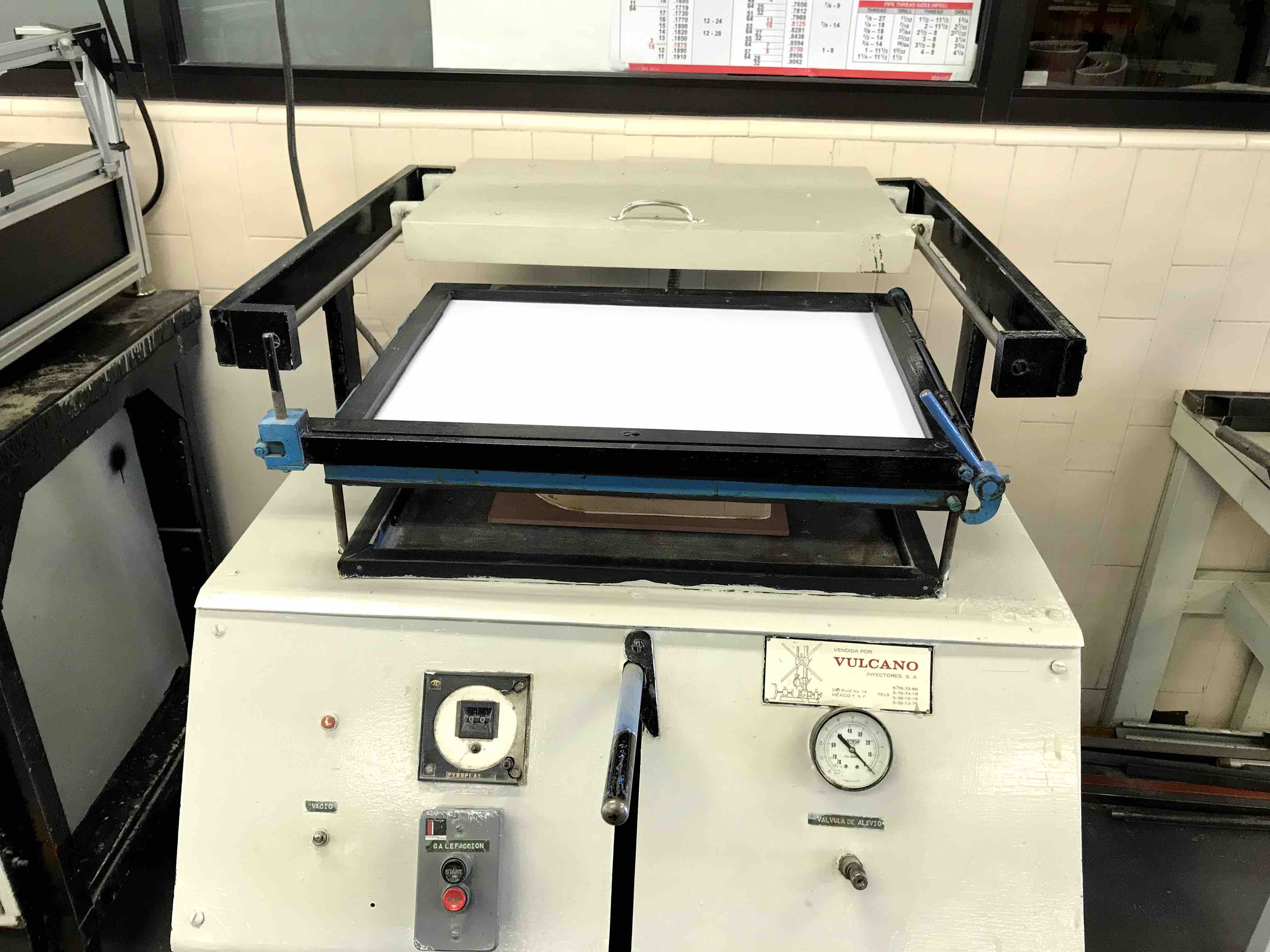

The styrene is fixed in

the machine just below the heat resistance.

The resistence are

heating the styrene

When the styrene is

ready to be vacuum form, we need to low down the styrene and then

push the "vacuum" button.

When the styrene looks

like is loosing shape that´s the moment to vacuum form.

Ready,

thestyrene just vacuum formed overthe mould

Ready,

thestyrene just vacuum formed overthe mould

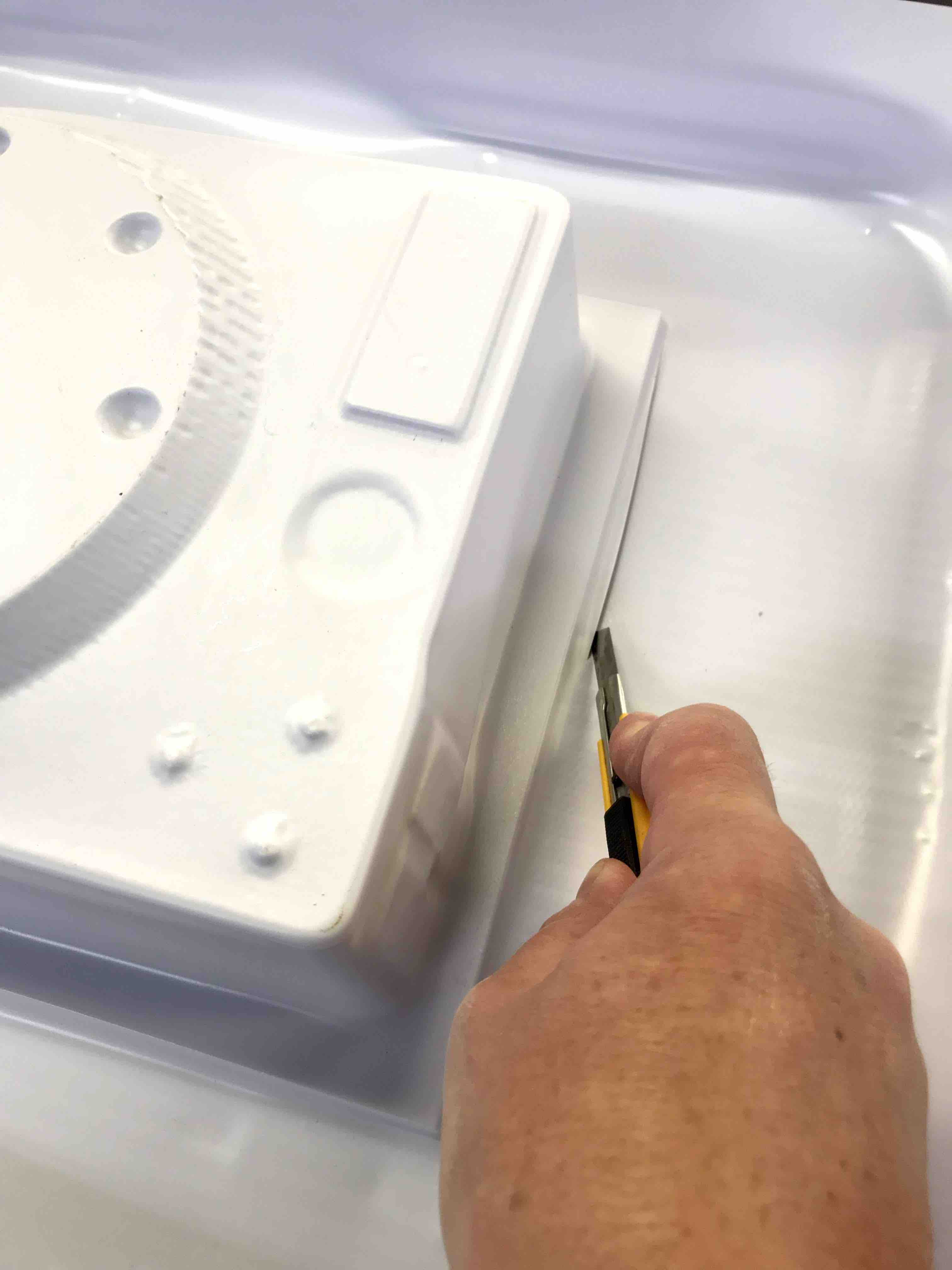

Then i cut the

perimeter with a cutter by hand following the contour.

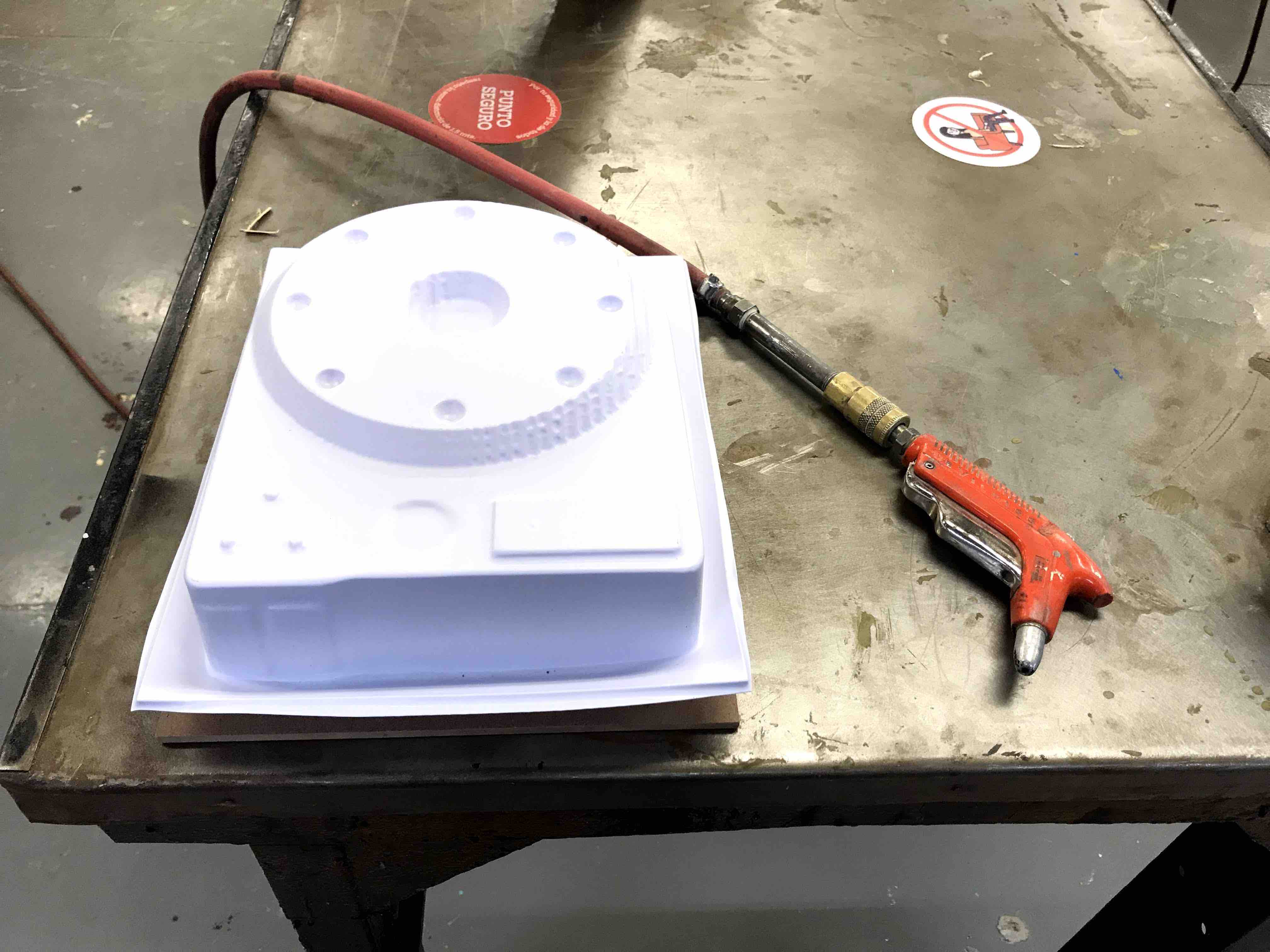

To demold I push some

air into the rear holes so the styrene could demold.

The cover with the A

logo tha I made in the Moulding and Casting assignment.