Molding and casting.

and the link to the group assignment is: FabLabCDMX.

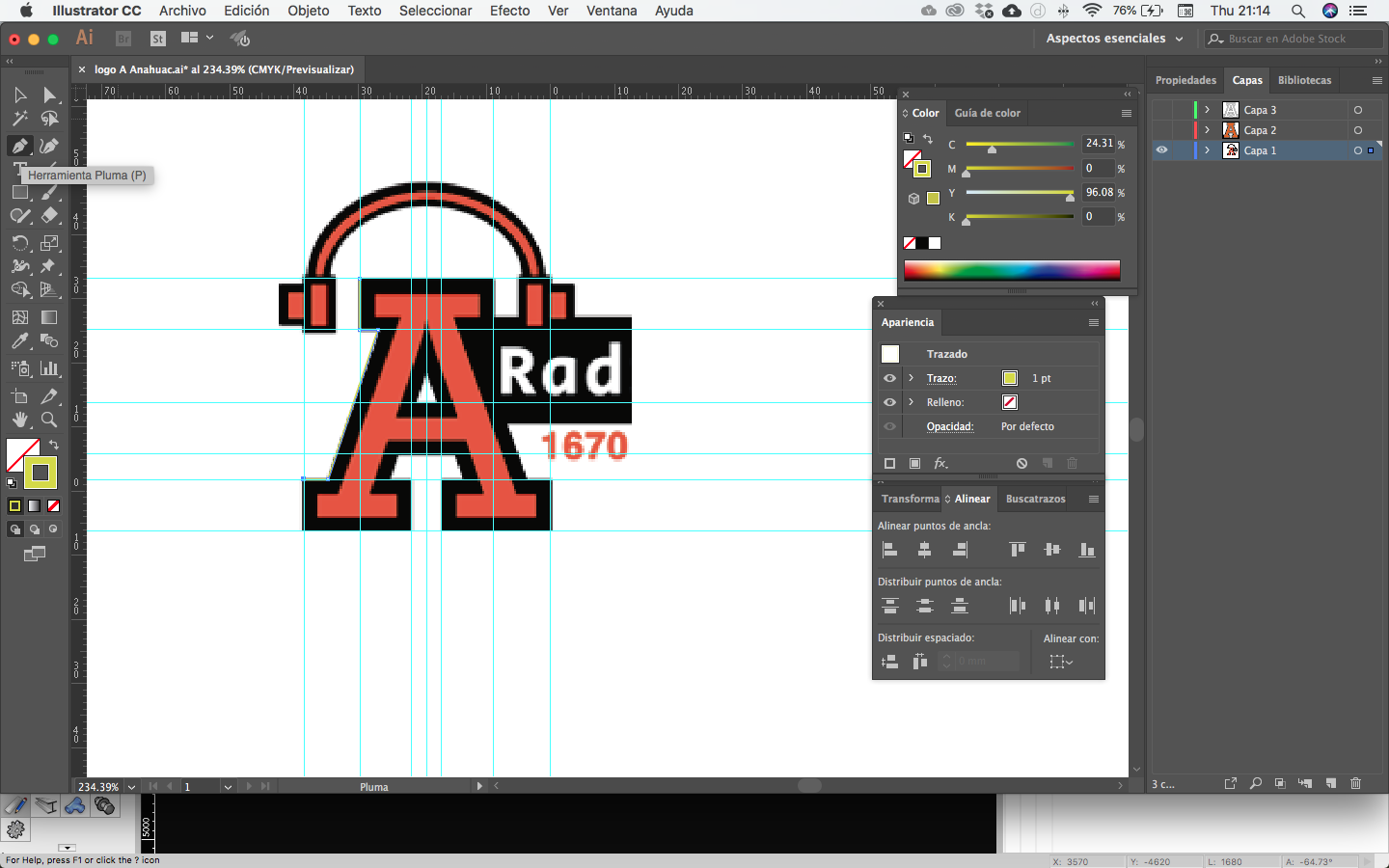

I want to

make the Universidad Anáhuac Logo that is an "A" because i

want to put it on my Final Project, so, I start looking

for a Vectorized image of the "A" logo, but I can´t find

it so I decide to retrace the "A" from the Radio Anáhuac

Logo in Illustrator, after that I opened it in

Vectorworks to transform this 2D trace into a 3D , then I

added it to a cube that will be the mold, the positive.

Then I mill the wax cube in the Roland machine to obtain

the mold of the A, then I cast silicone to obtain the

negative silicon mold and then I cast clear crystal resin

to obtain the final "A" logo.

Illustrator,

Vectorworks, RhinoCam, silicone, clear crystal resine,

catalyst, orange color aditive

I download it

and opened it in Illustrator

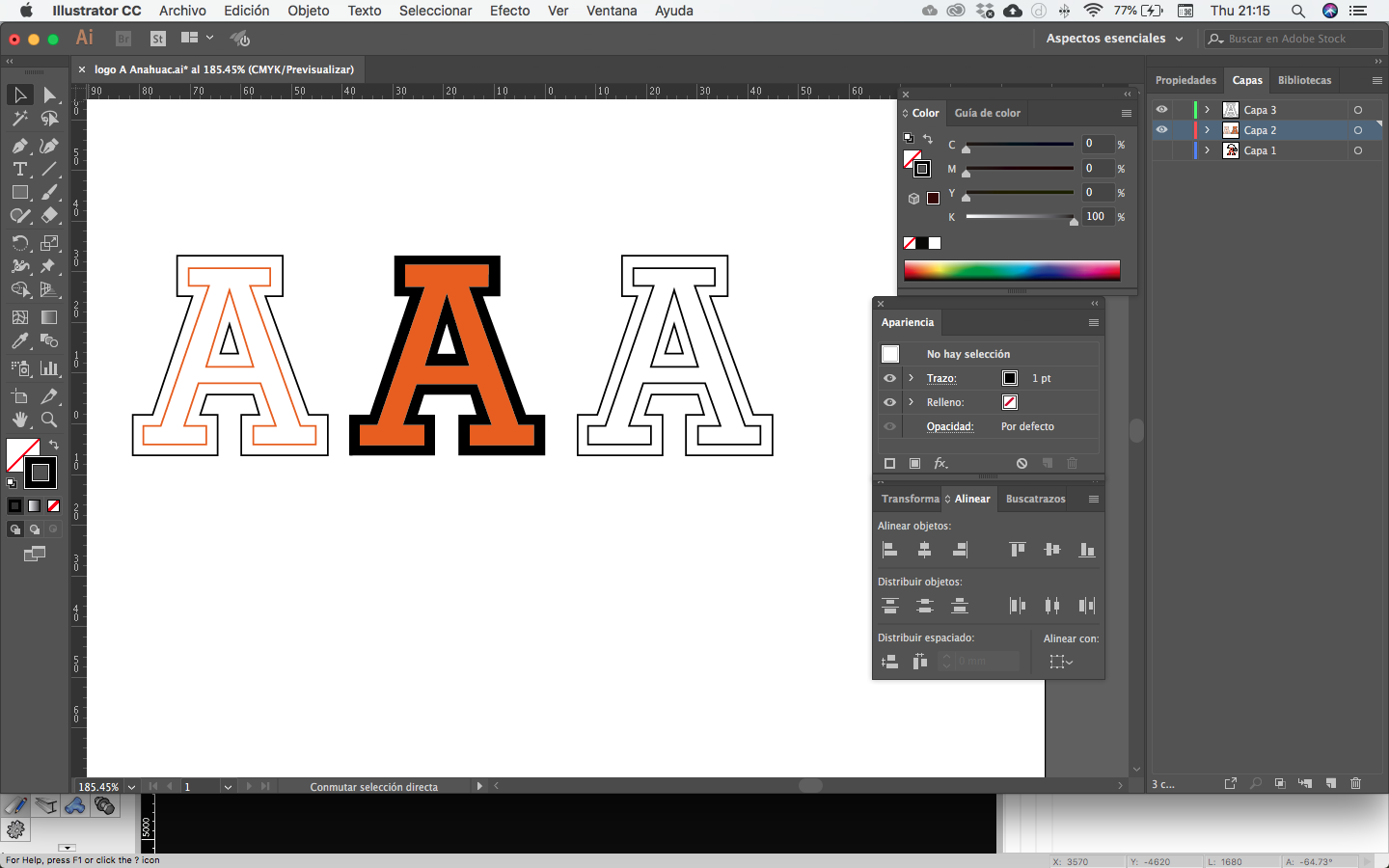

Then I retrace

the logo with the line and pen tools.

I export the A

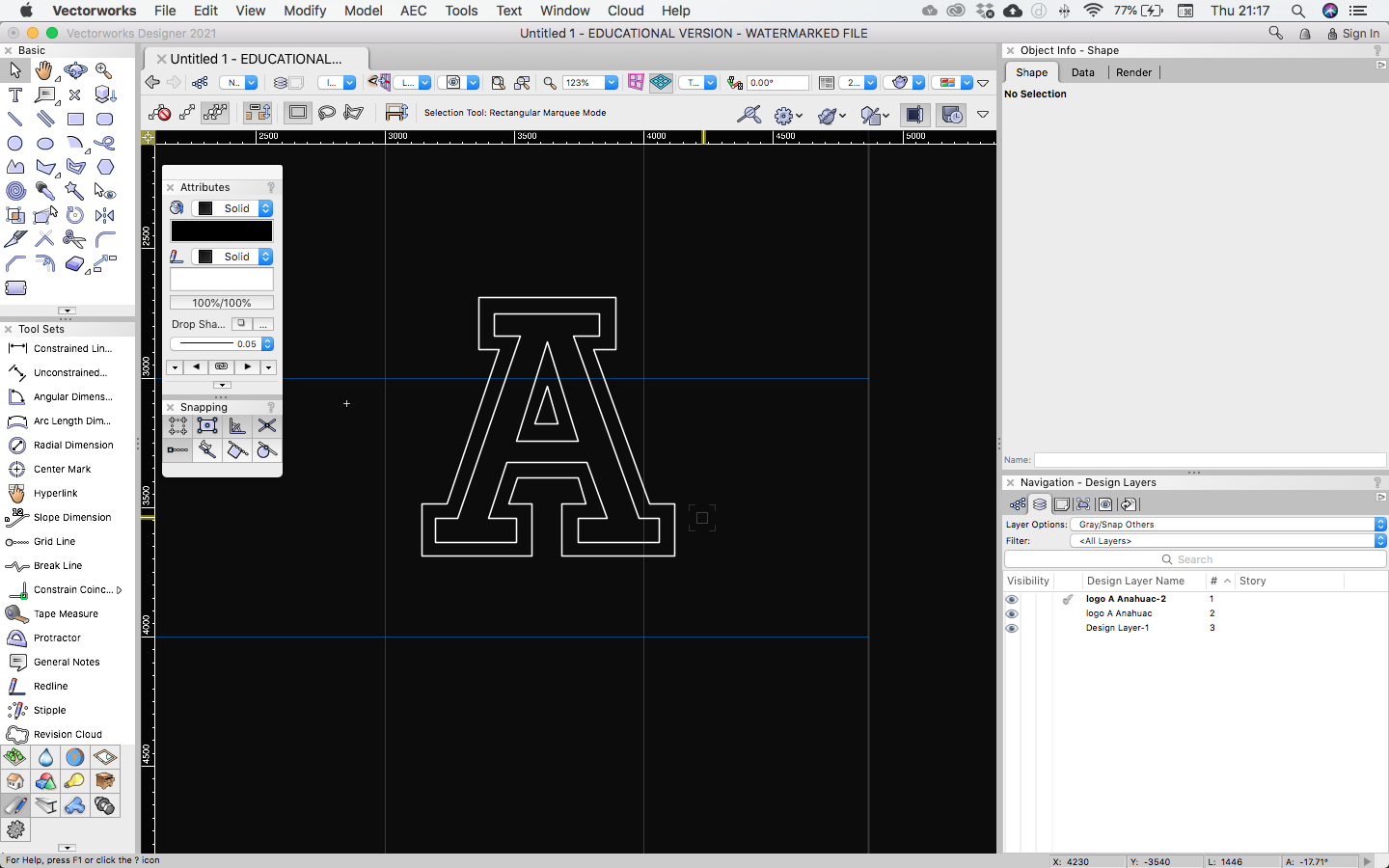

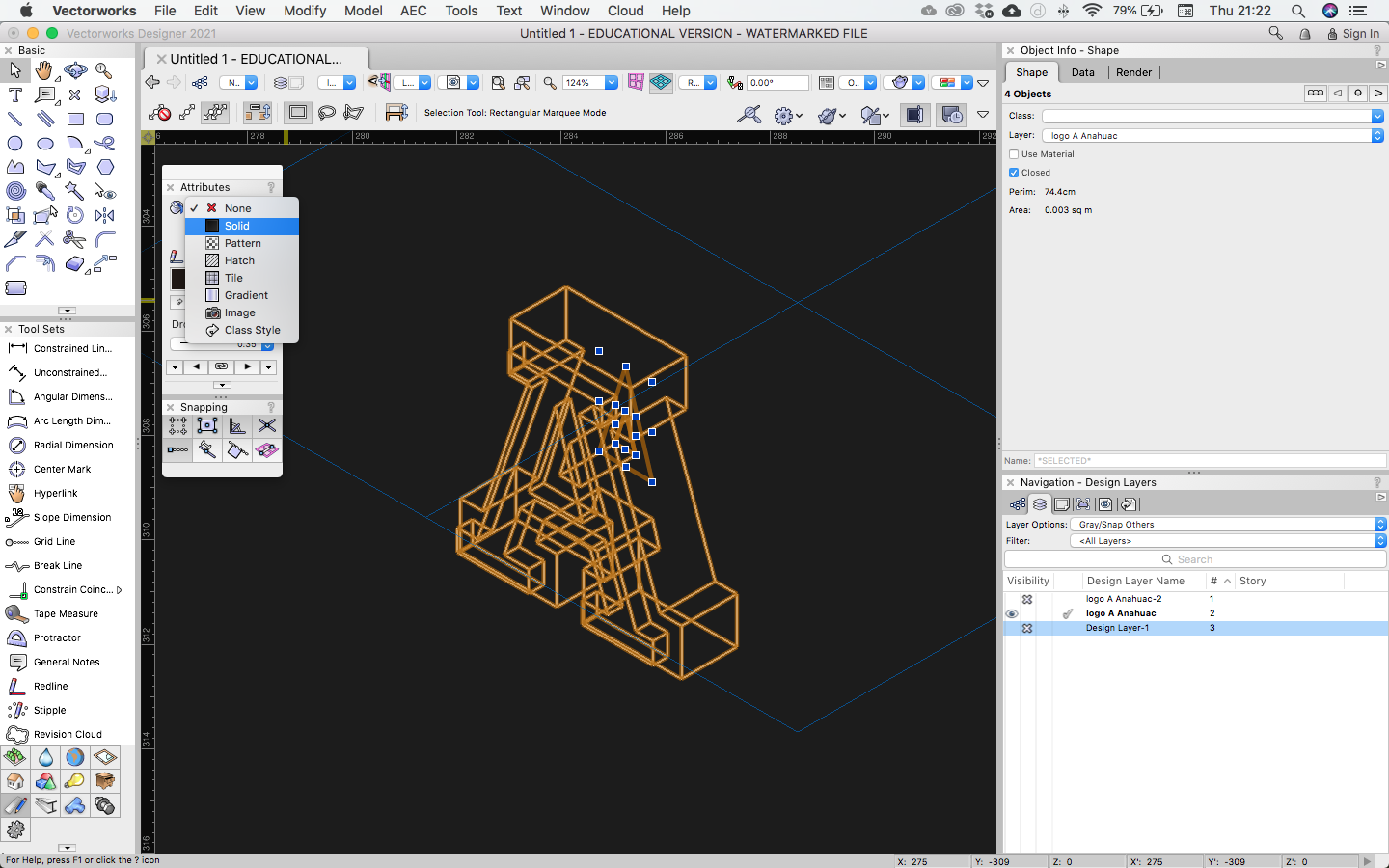

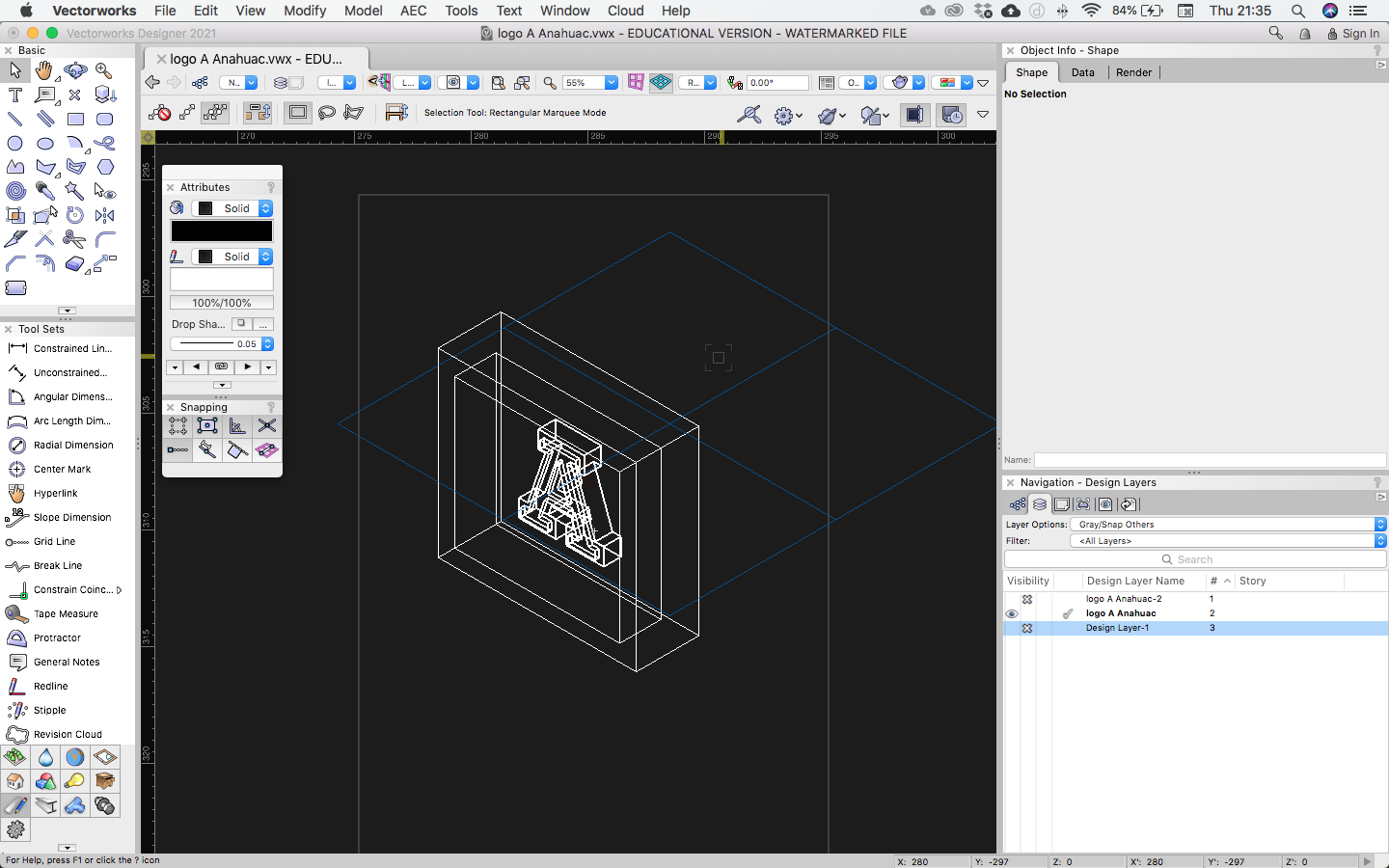

as a DWG file and then i opened it in Vectorworks to made

the 3D of it. Right now the size of the A doesn´t matter too

much right now, later we will adjust that.

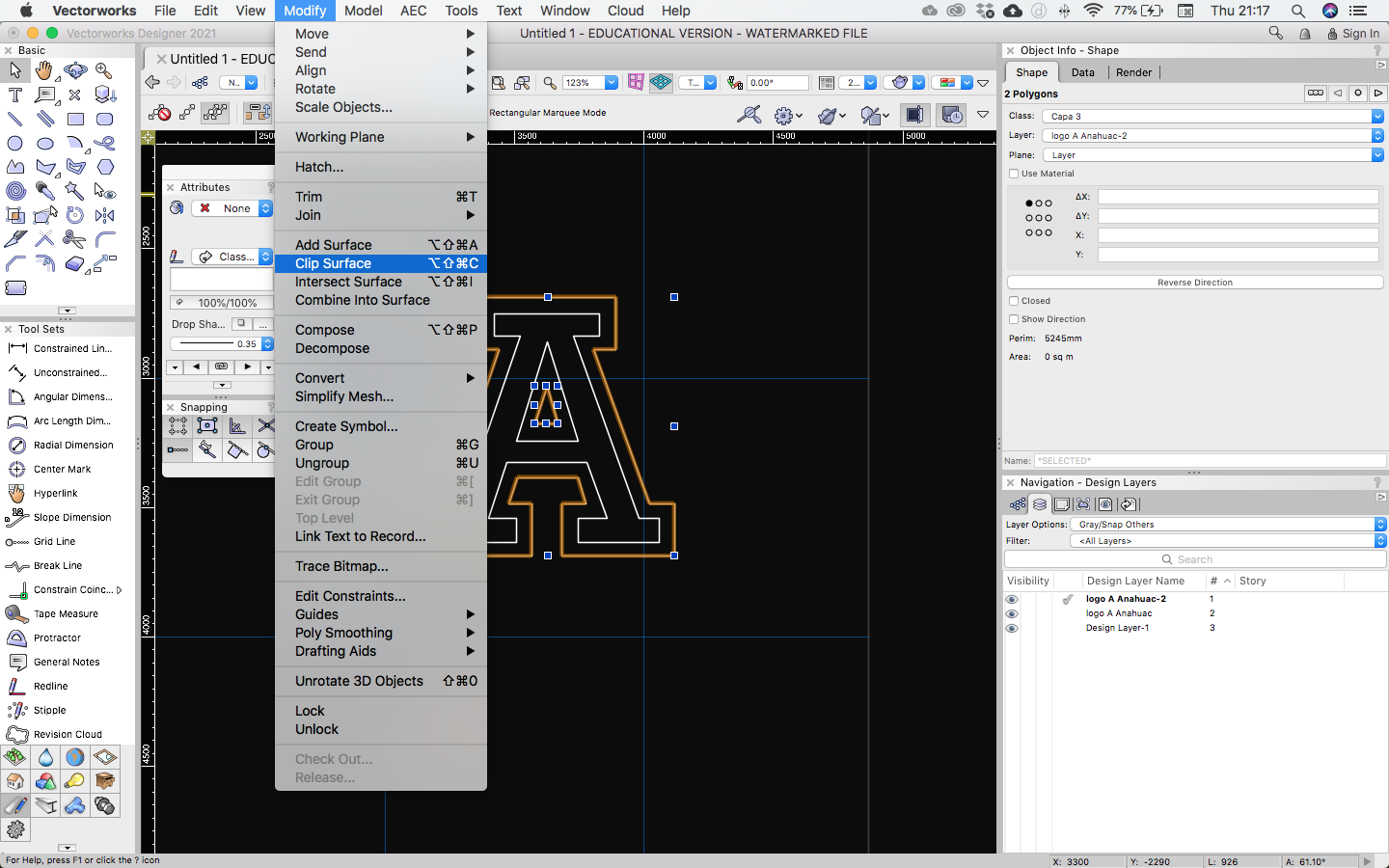

I clip the

center of the "A" logo with the clip surface function.

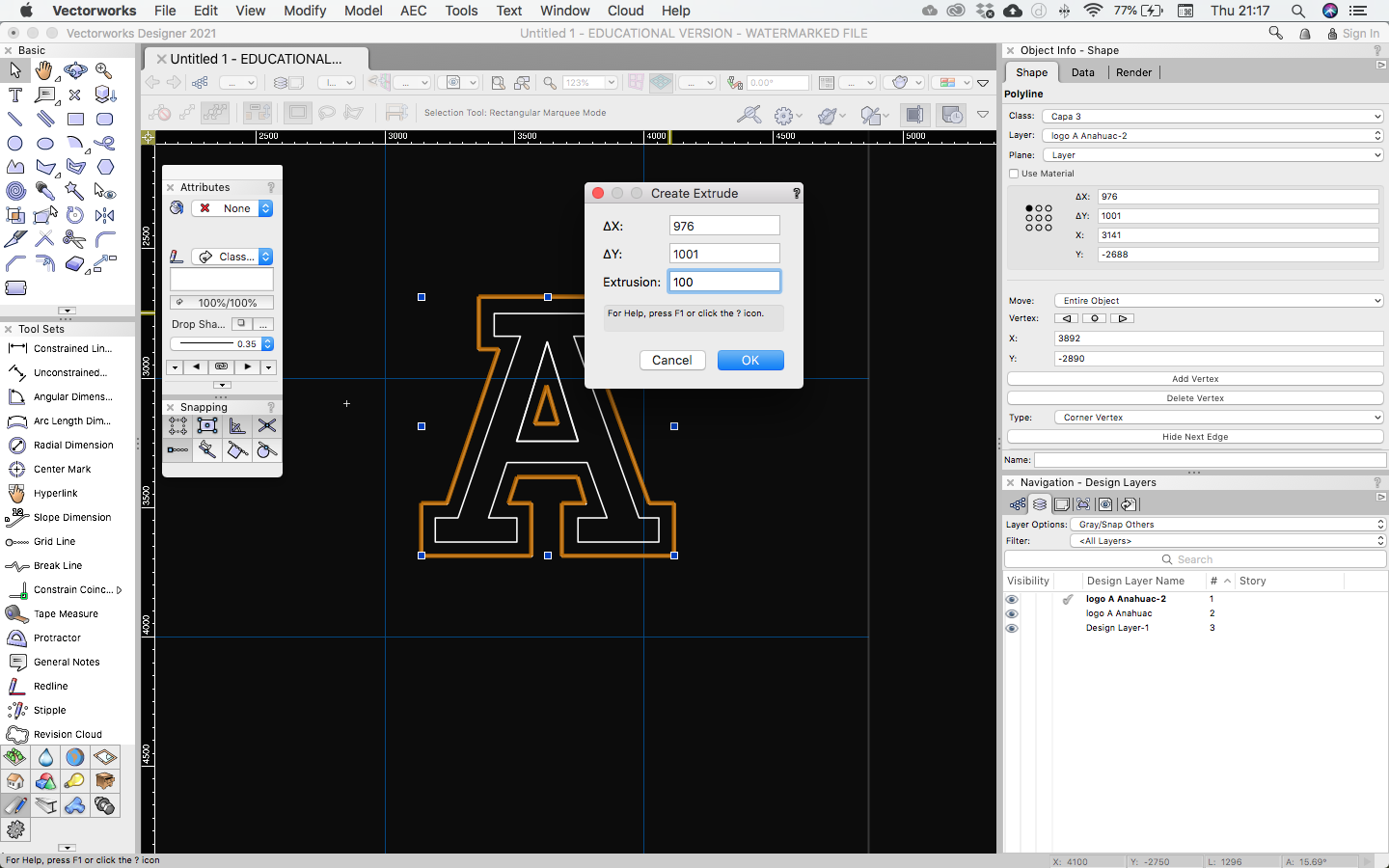

Then I perform

an extrusion of the "A" logo

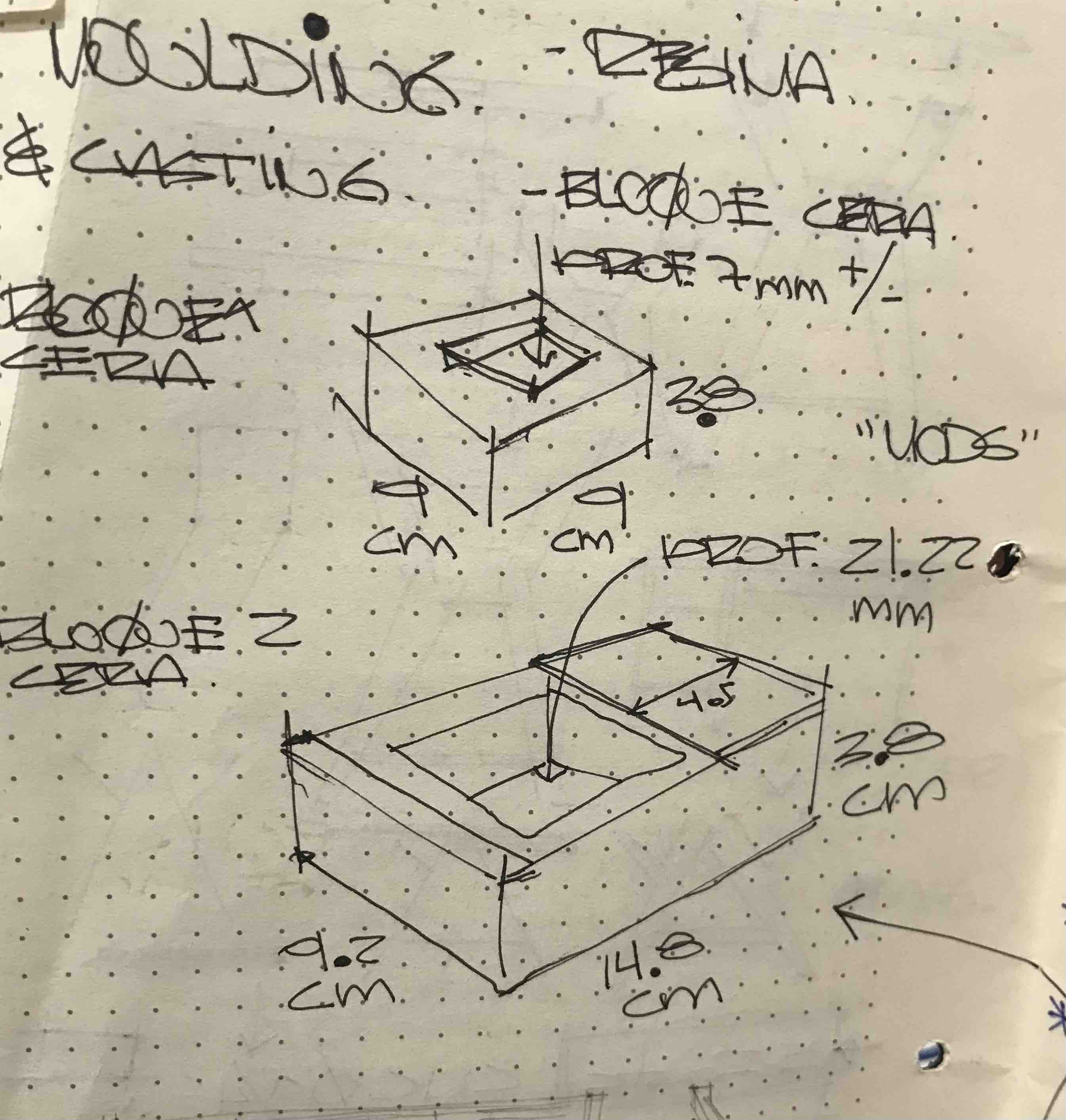

This is the

size of the available wax portion in the LAB, so I have to

adapt my design to that size: 9.2x14.8x3.8 with a free depth

of 2.12cm

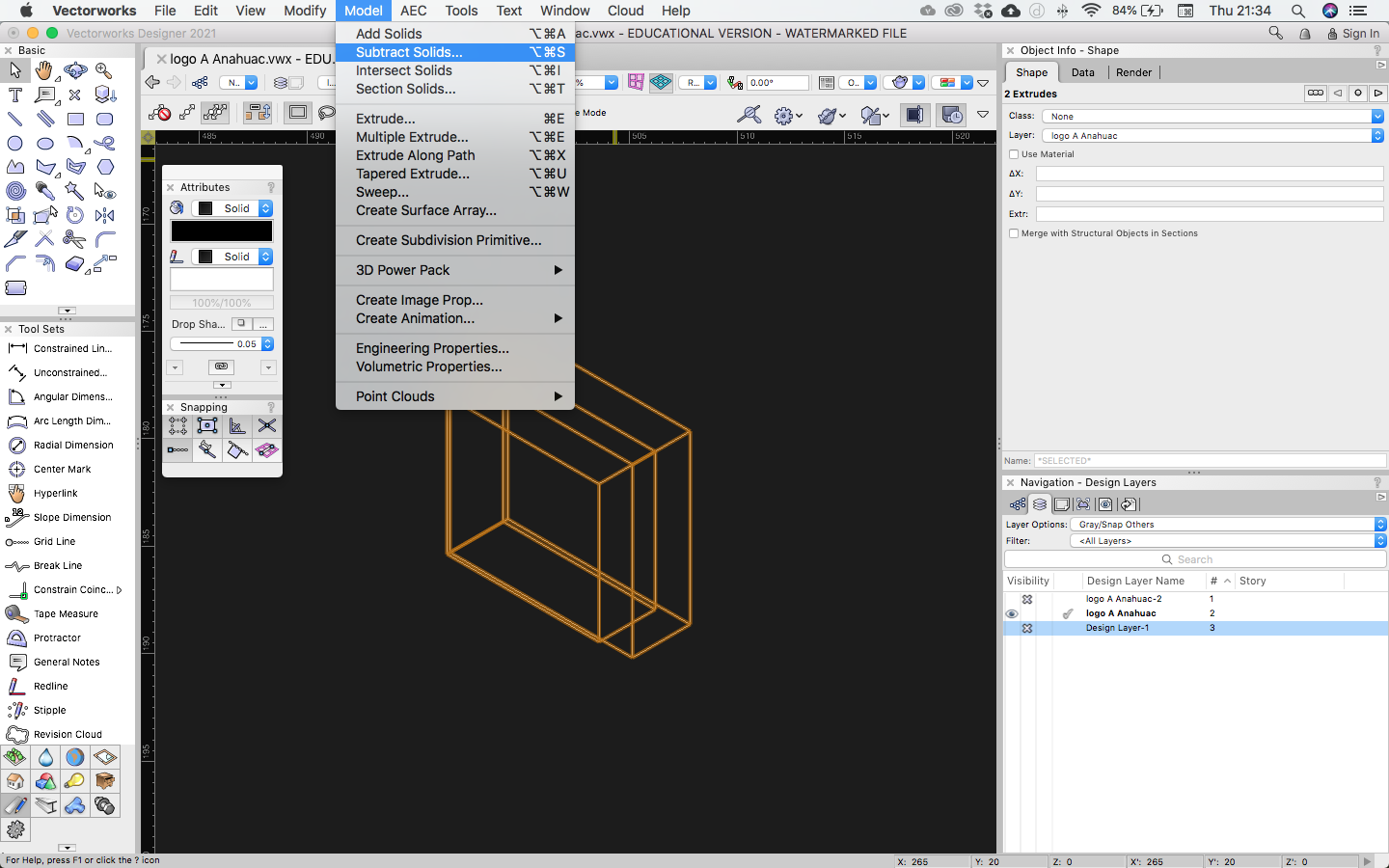

Then I draw and

extrude a square of the measures above in order to make the

shape of the wax cube where I´m going to mill the mould of

the A.

I scale and put

the A inside the cube to see if fits correctly, the size and

depth of the this mold is exactly dimensions of the

available wax.

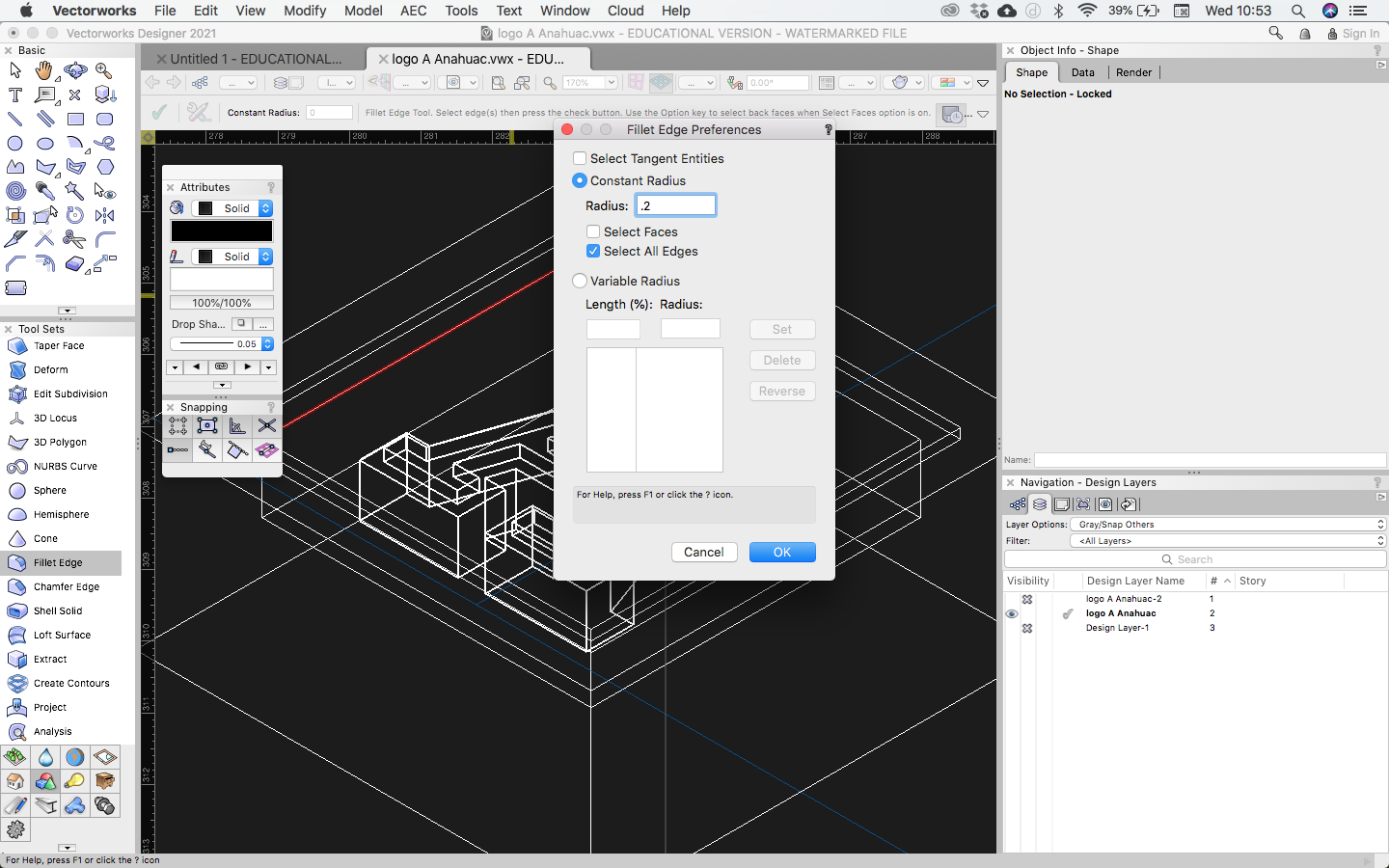

I made a fillet

in all the edges of the mold including the A to avoid

problems to demold the silicon.

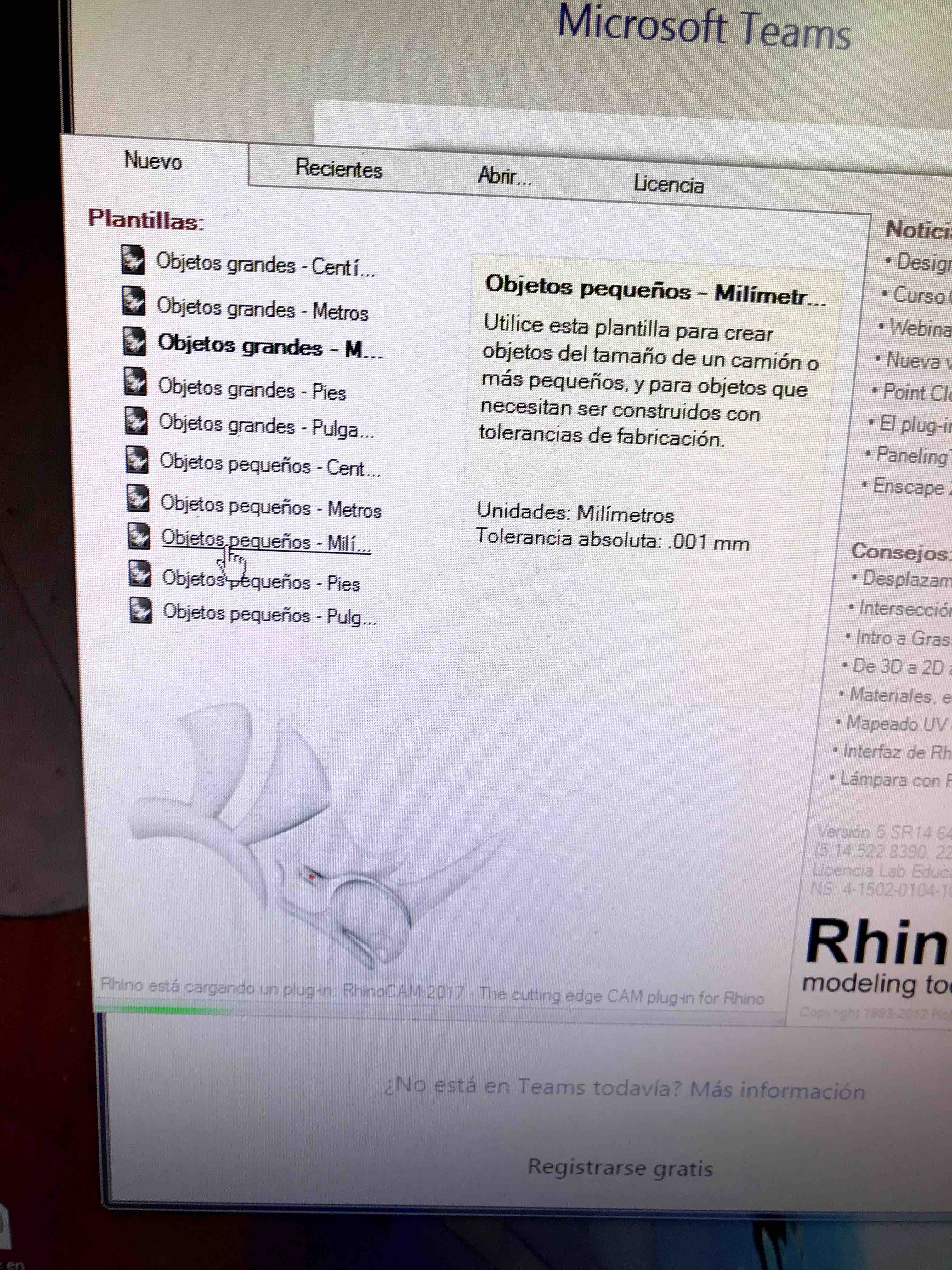

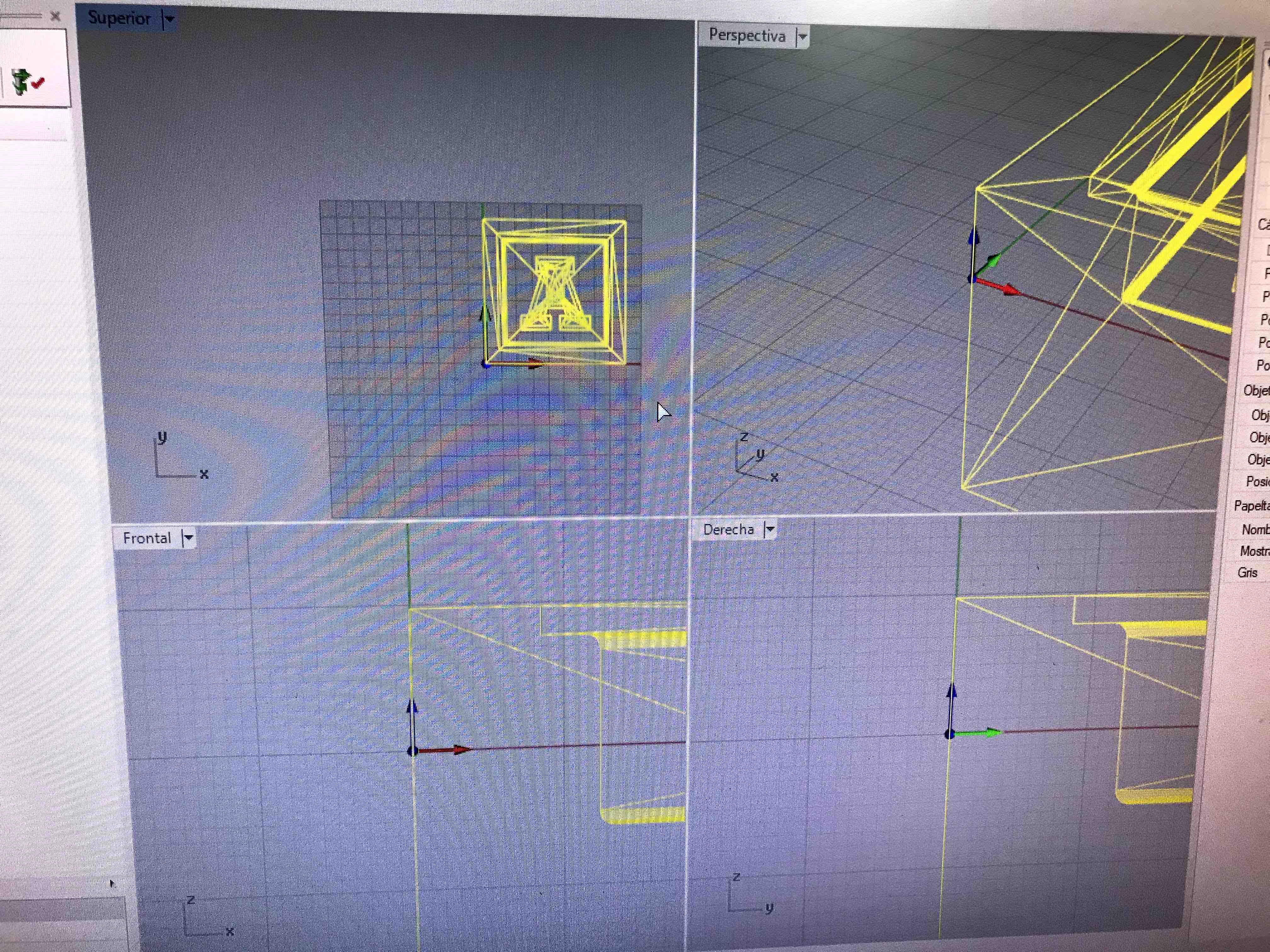

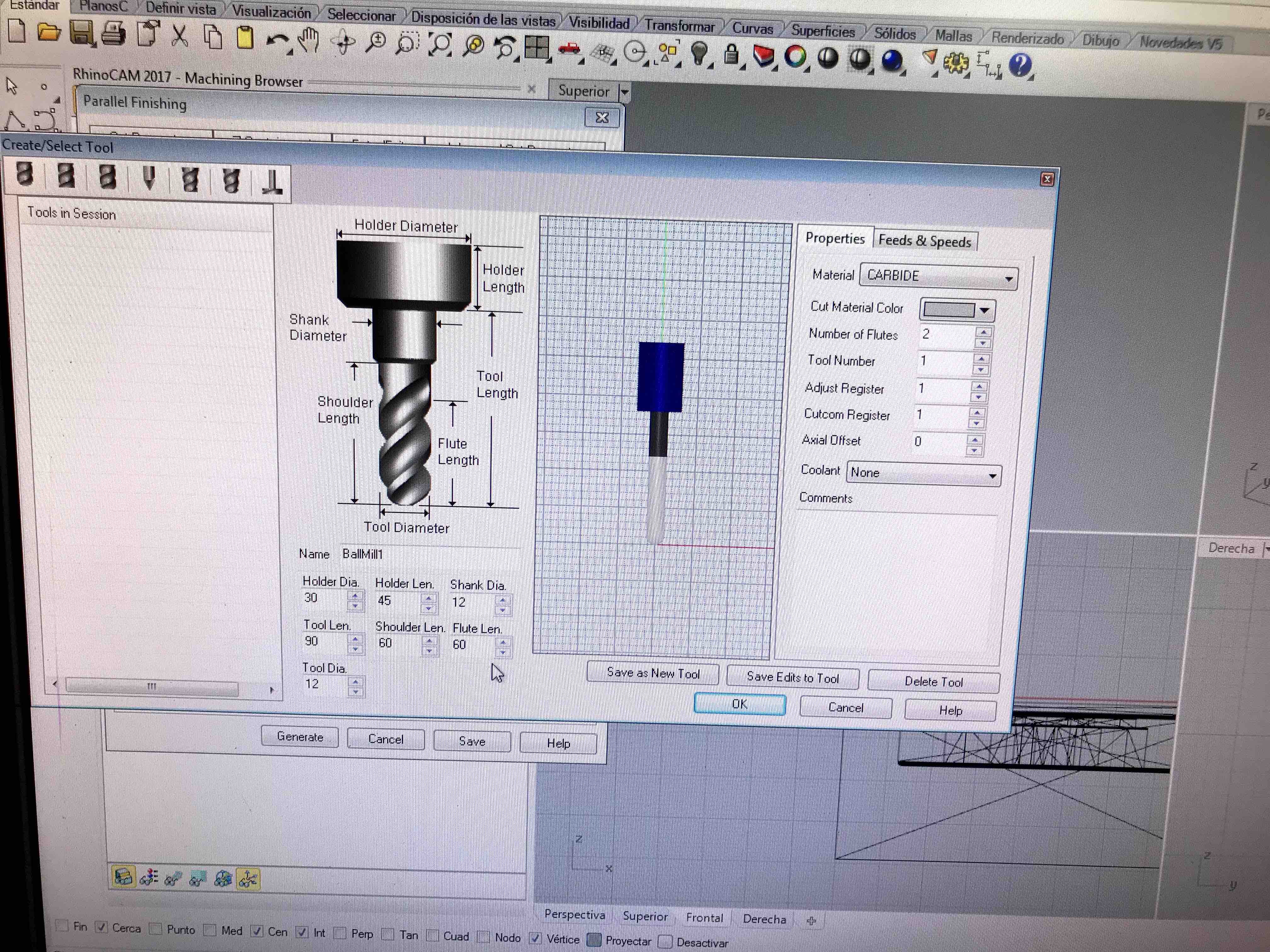

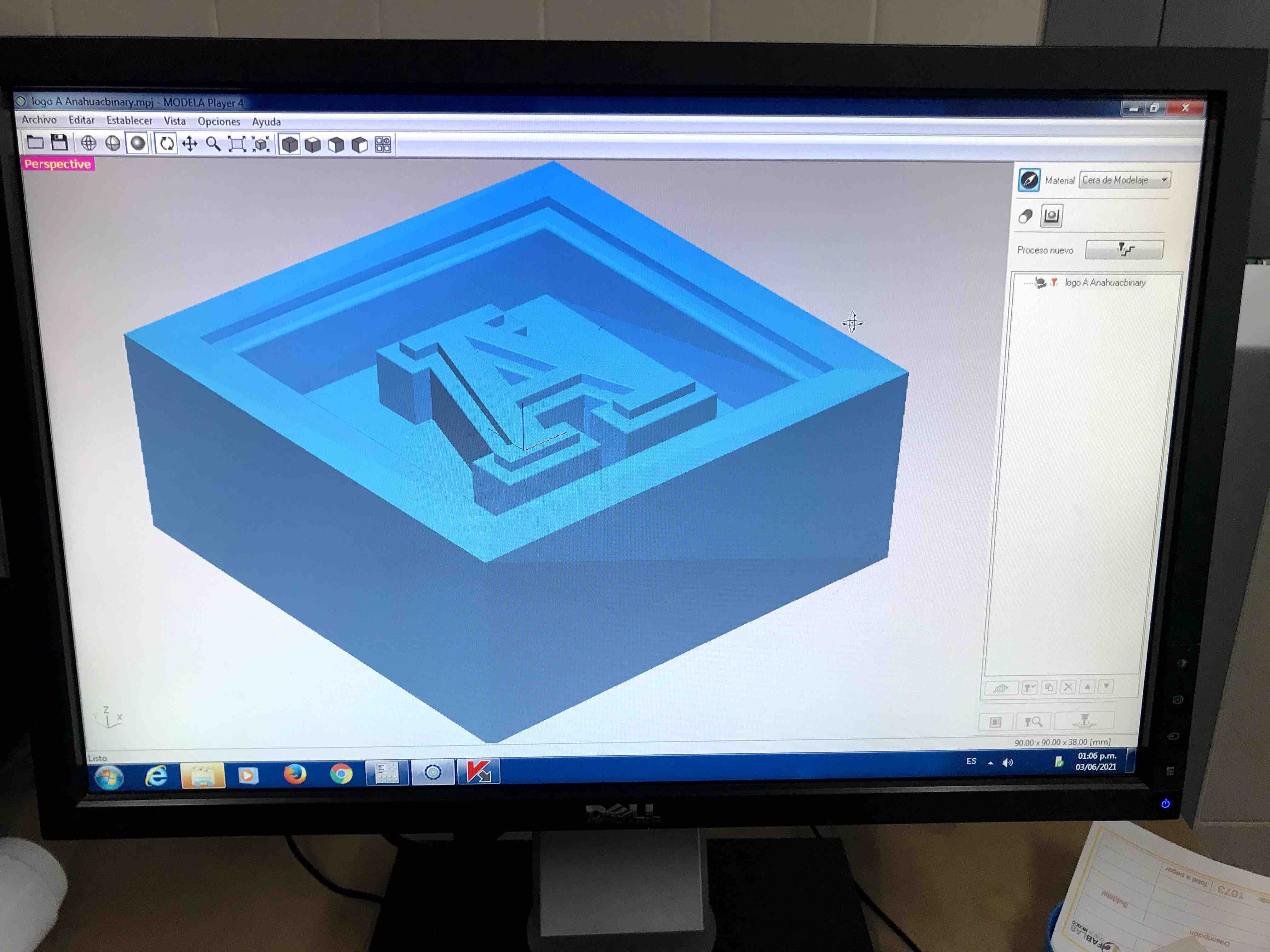

Now we are

going to open the 3D file into RhinoCam to do the setup

before milling

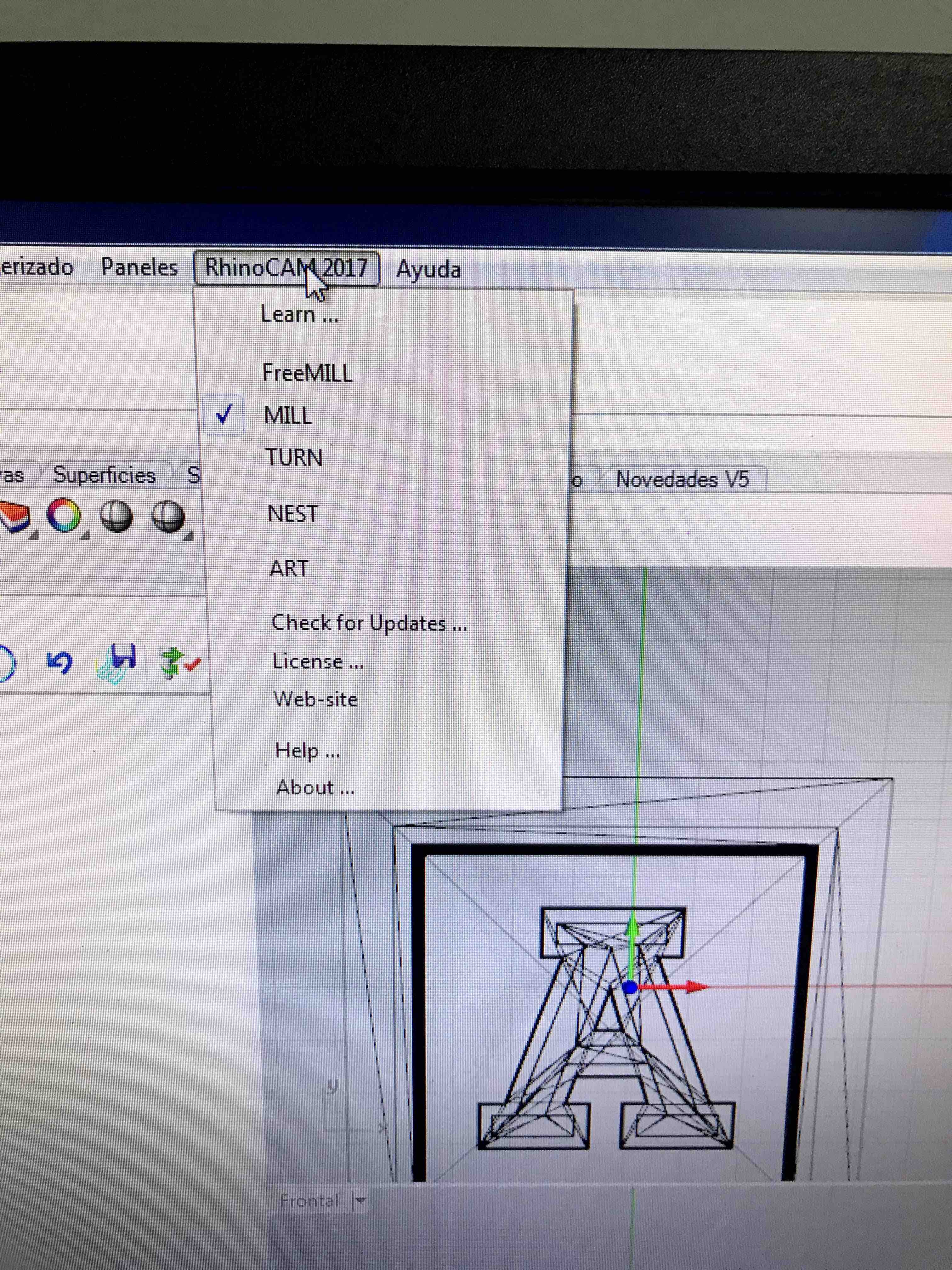

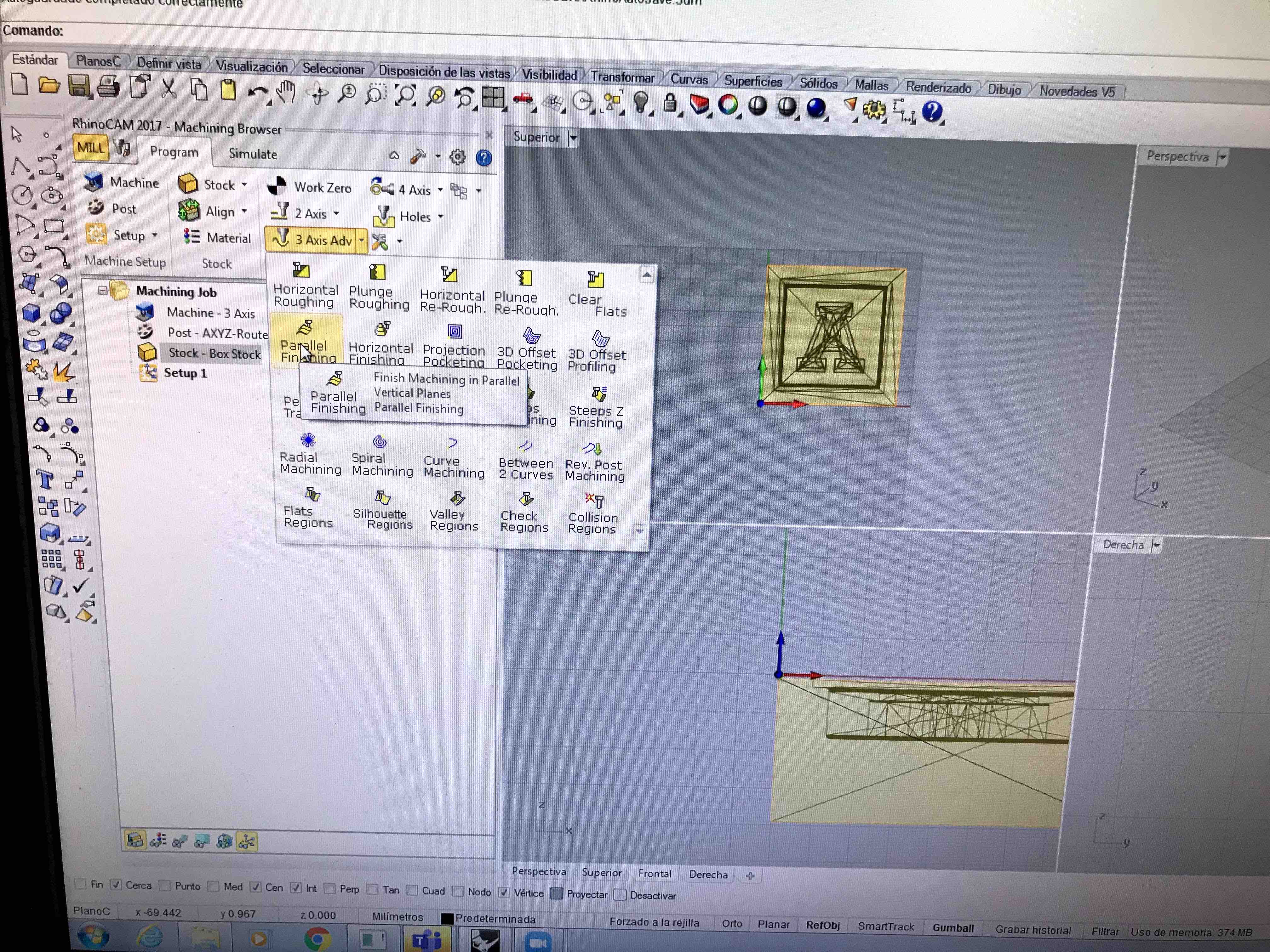

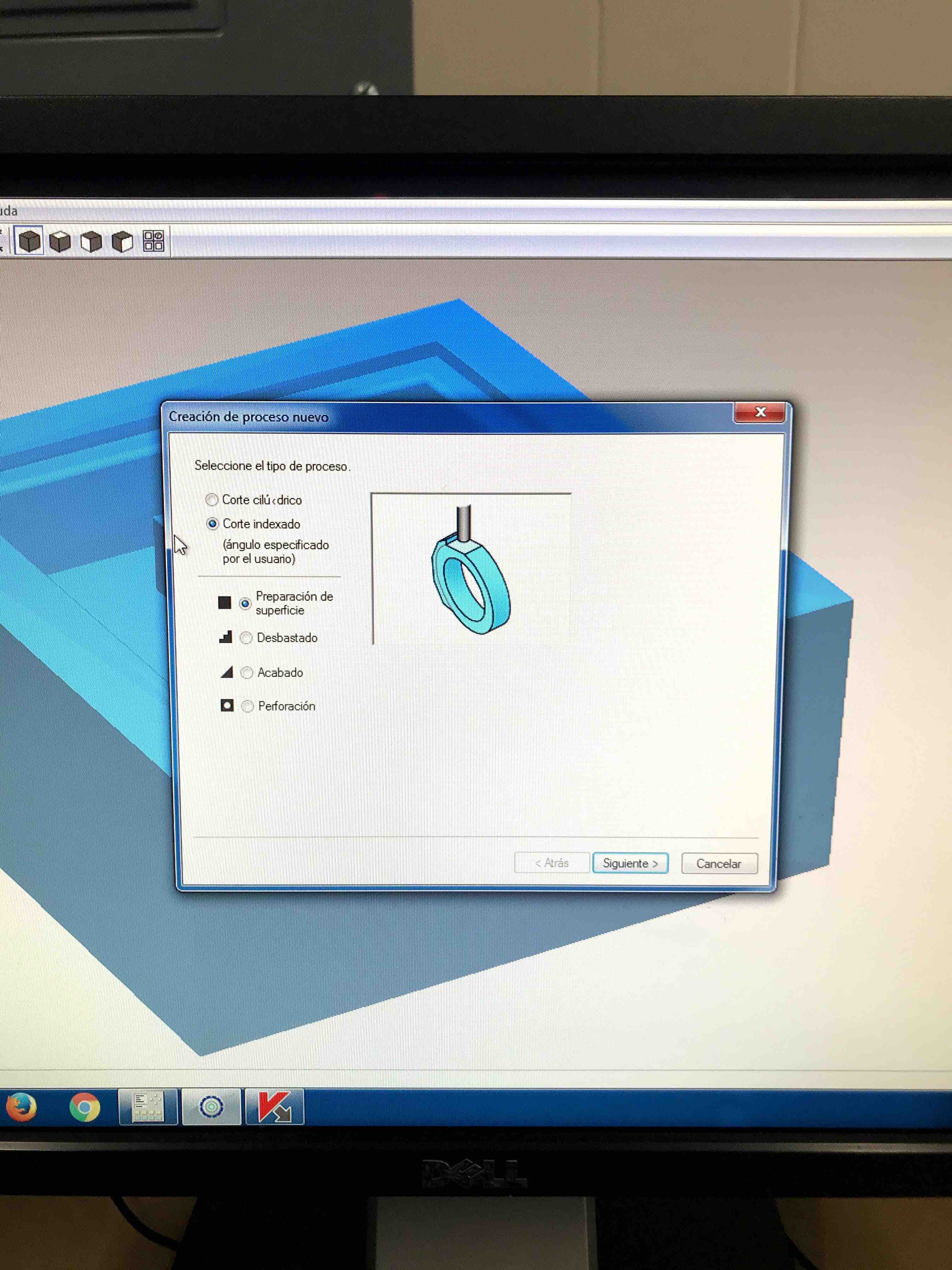

Choosing what

operation we are ging to do, in this case MILL

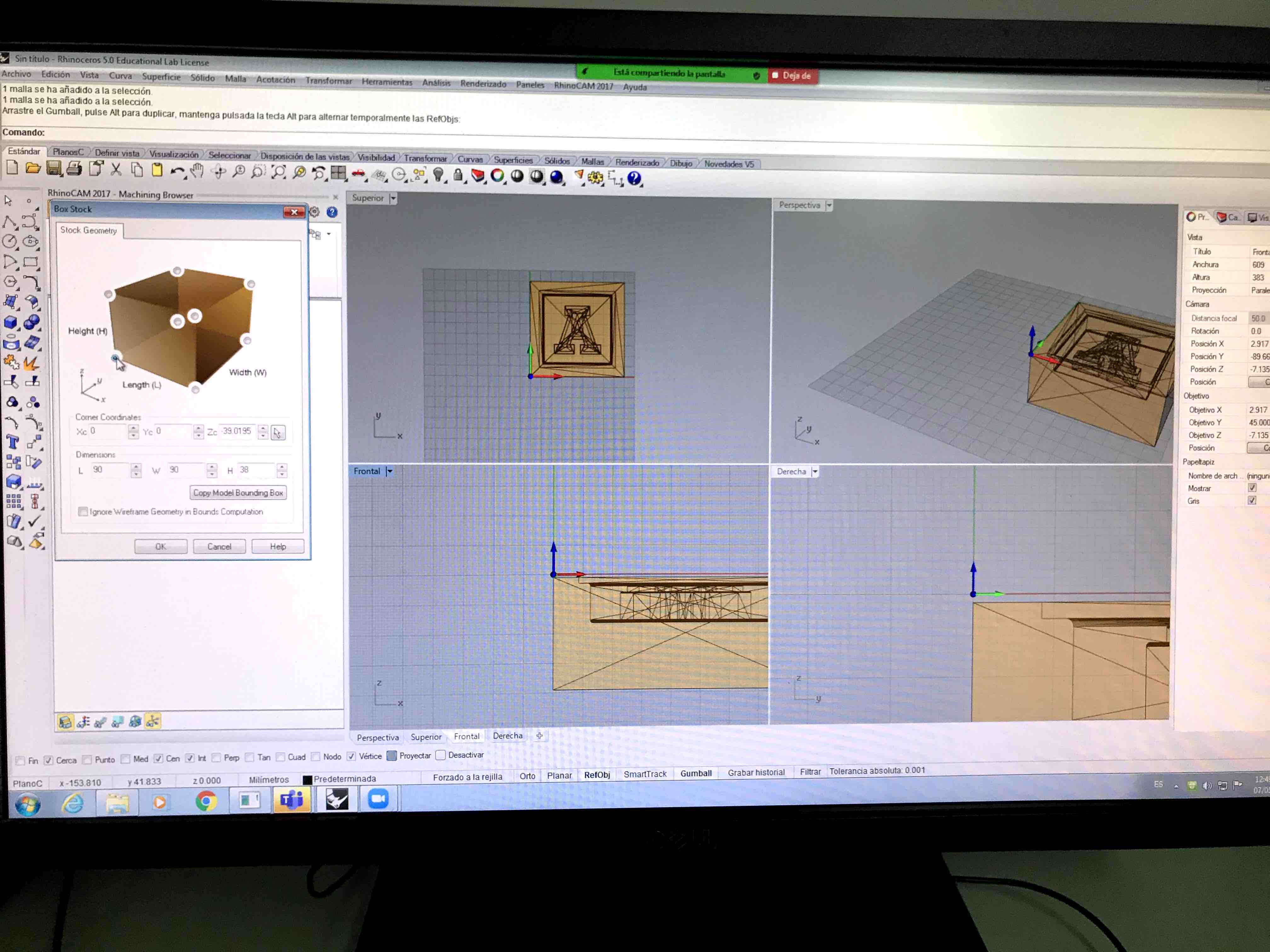

Placing the 3D

object.

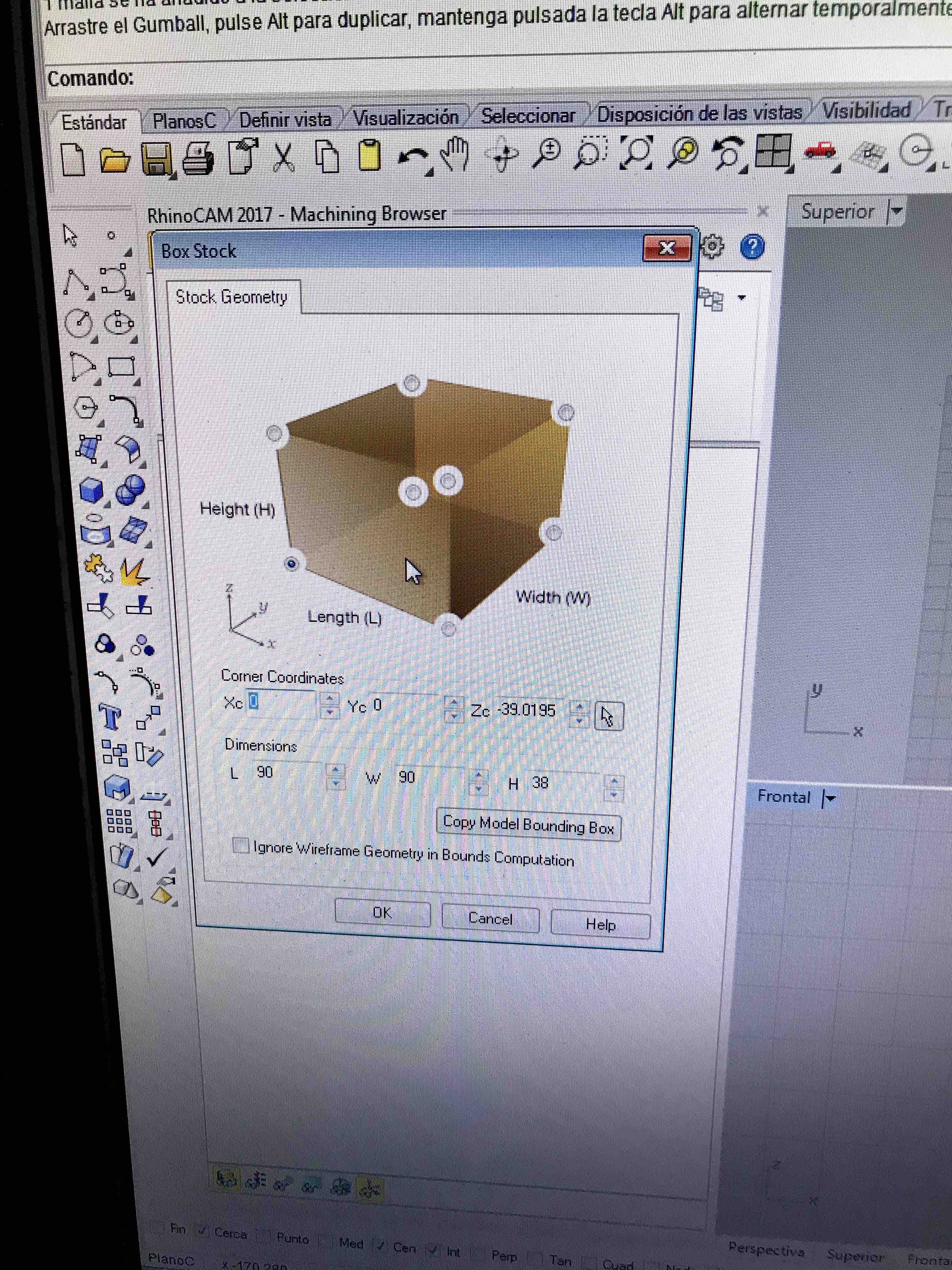

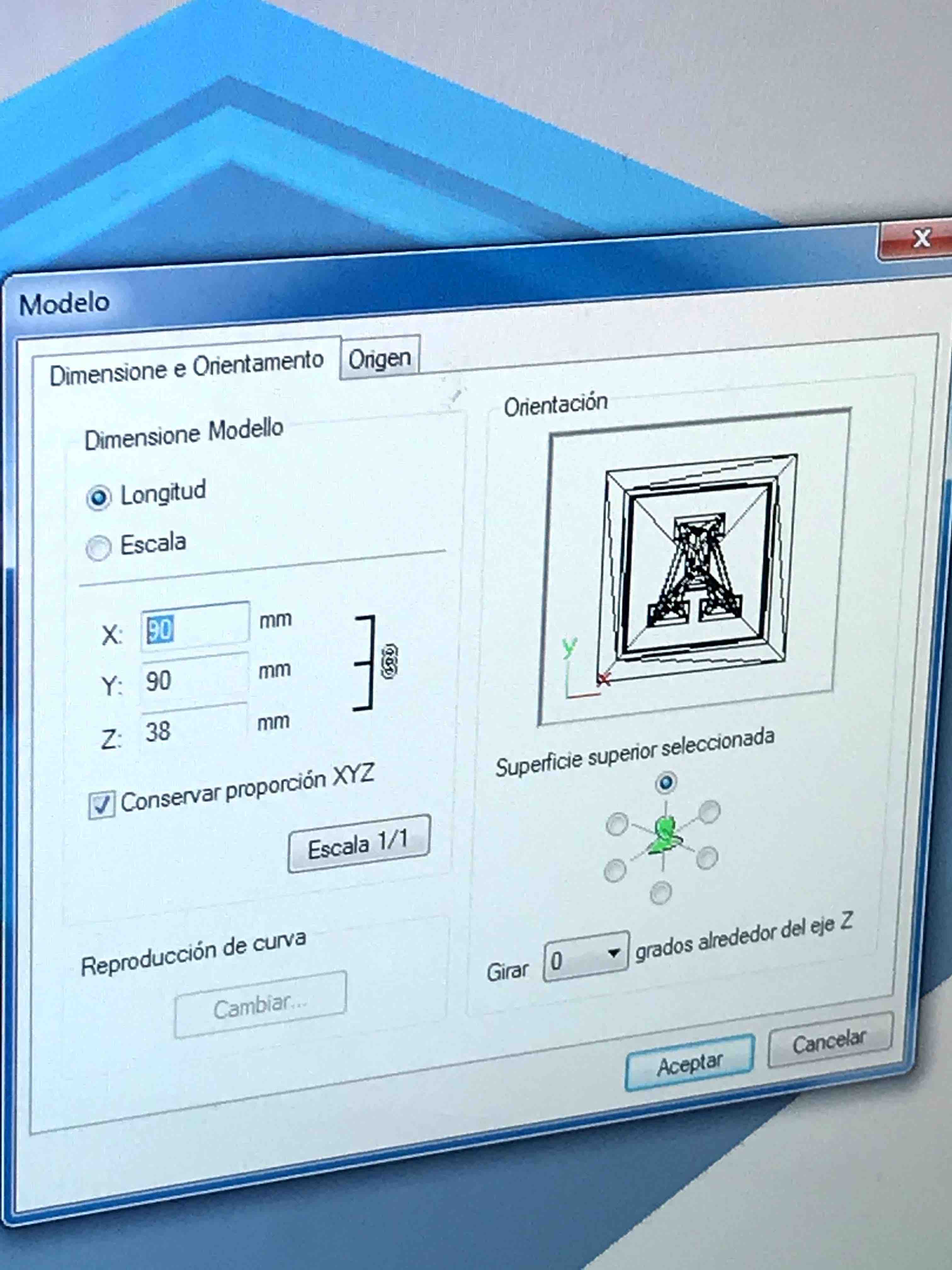

setting the

size of the cube 90x90x38mm

In the MILL

menu we choose parallel finish, this is the initial path

that the tool will do

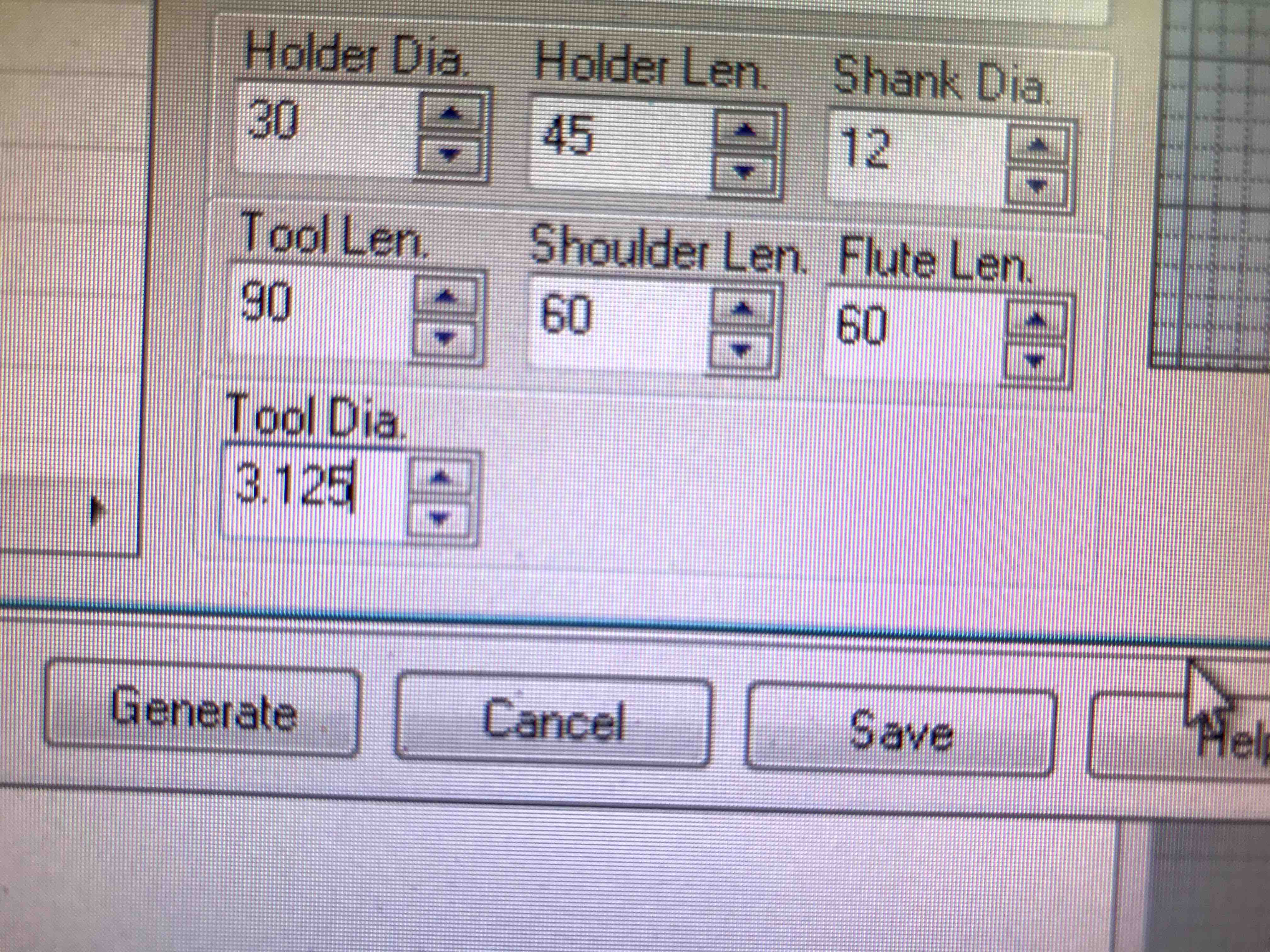

Choosing the

tooling properties of a straight flute tooling

and setting the

dia. of the tooling in 3.125mm.

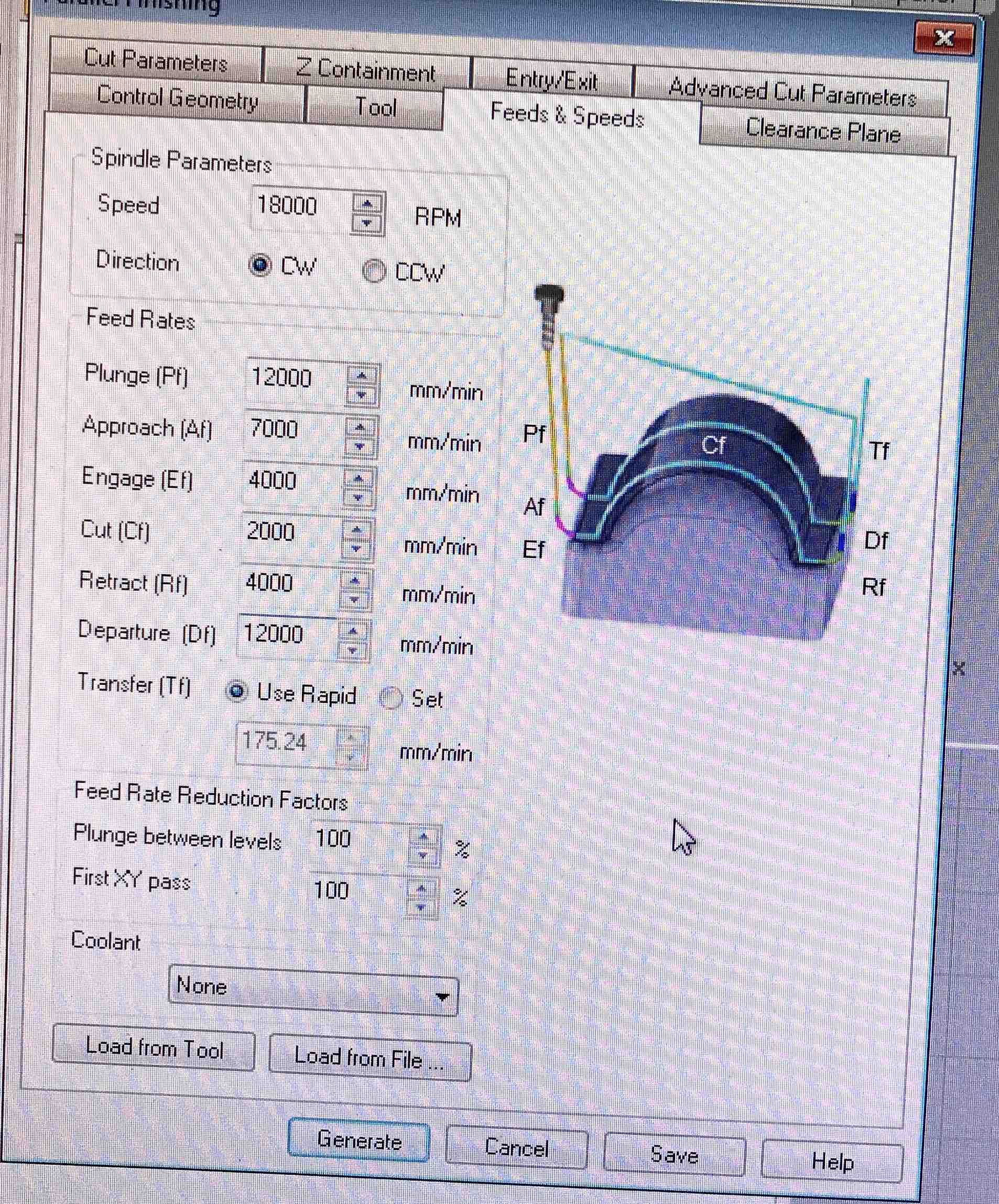

Settings:

rotation 18000RPM durection CW, PLUNGE 12000 mm/min,

Approach 7000 mm/min, Engage 4000 mm/min, Cut 2000 mm/min,

Retract 4000 mm/min, and Departure 12000mm /min.

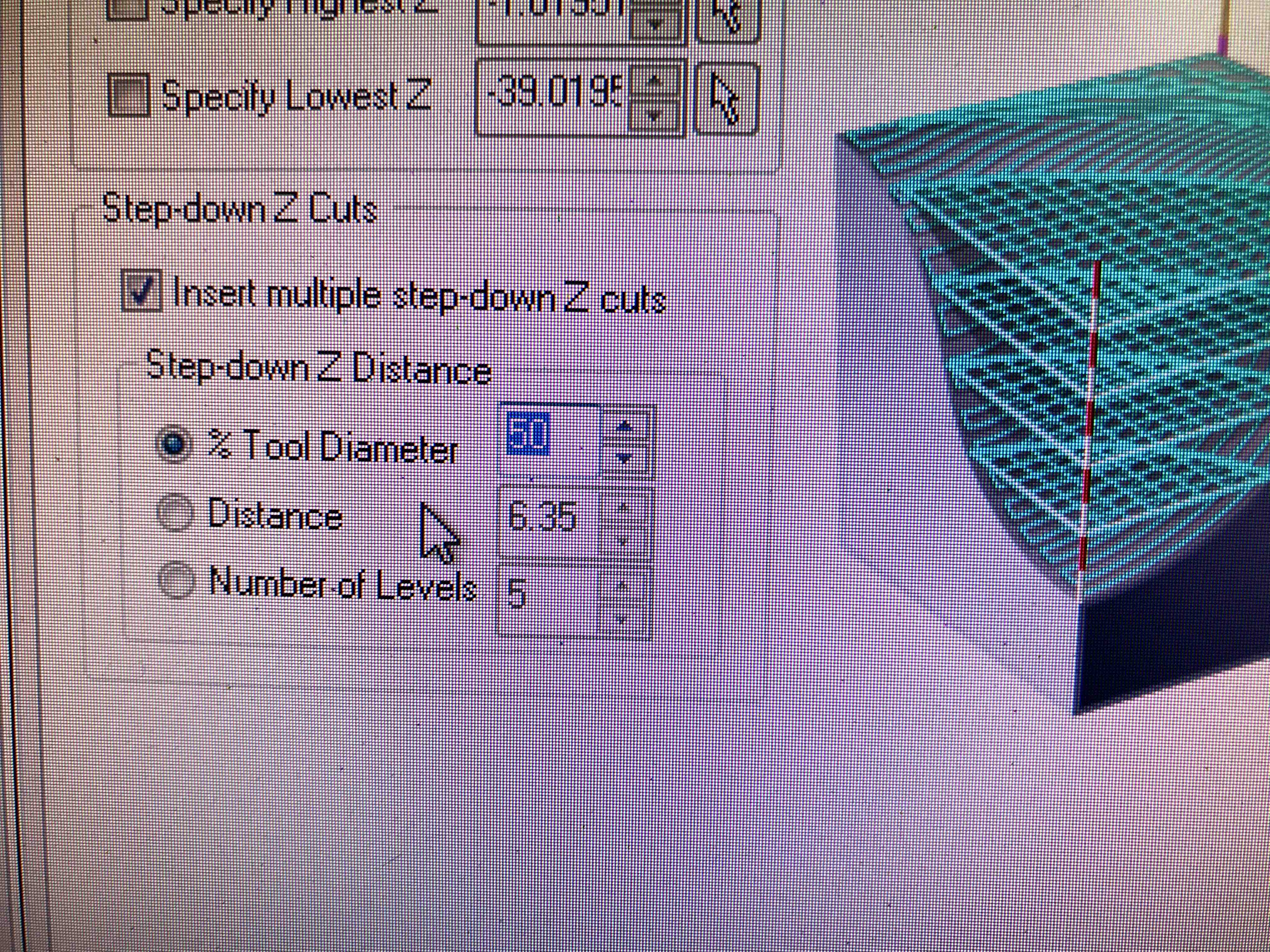

the setup of

the final finish, you can see here that the tool is going to

move in the Z direction steps no more of the 50% of the tool

diameter.

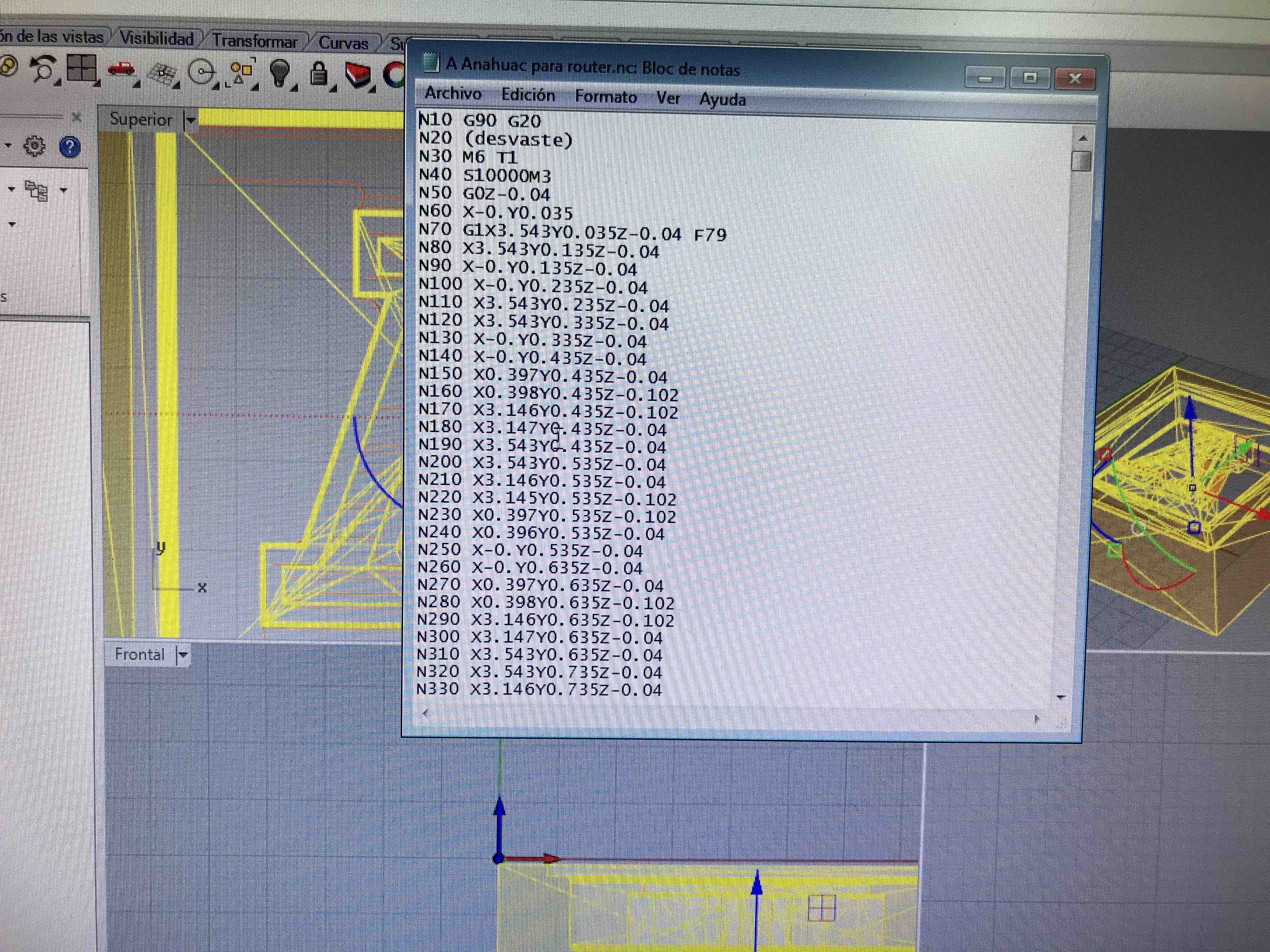

Generating the GCODE

Preparing the

last settings to start the milling process

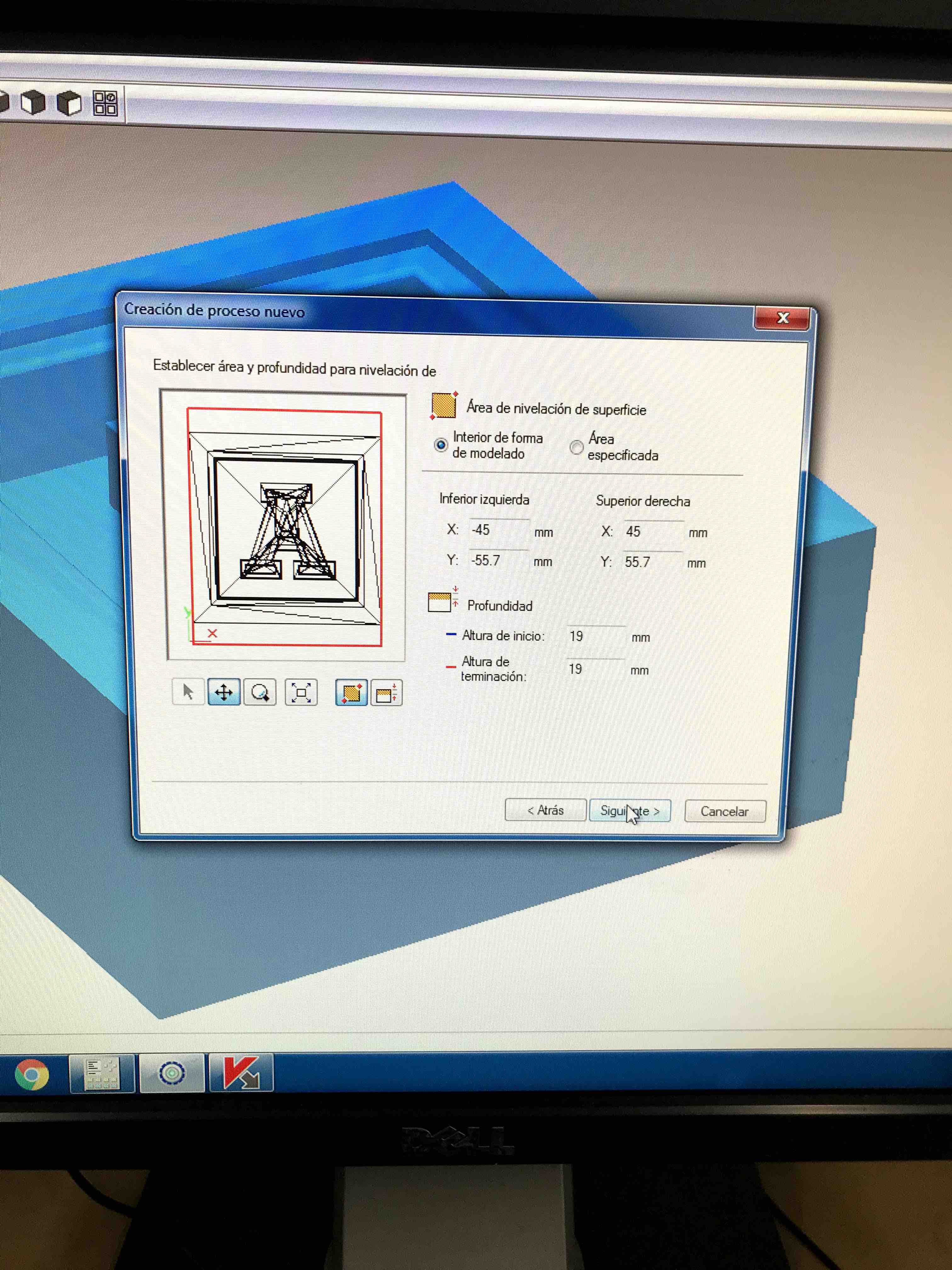

Here we need to

establish the area and depth to prepare the surface to level

it

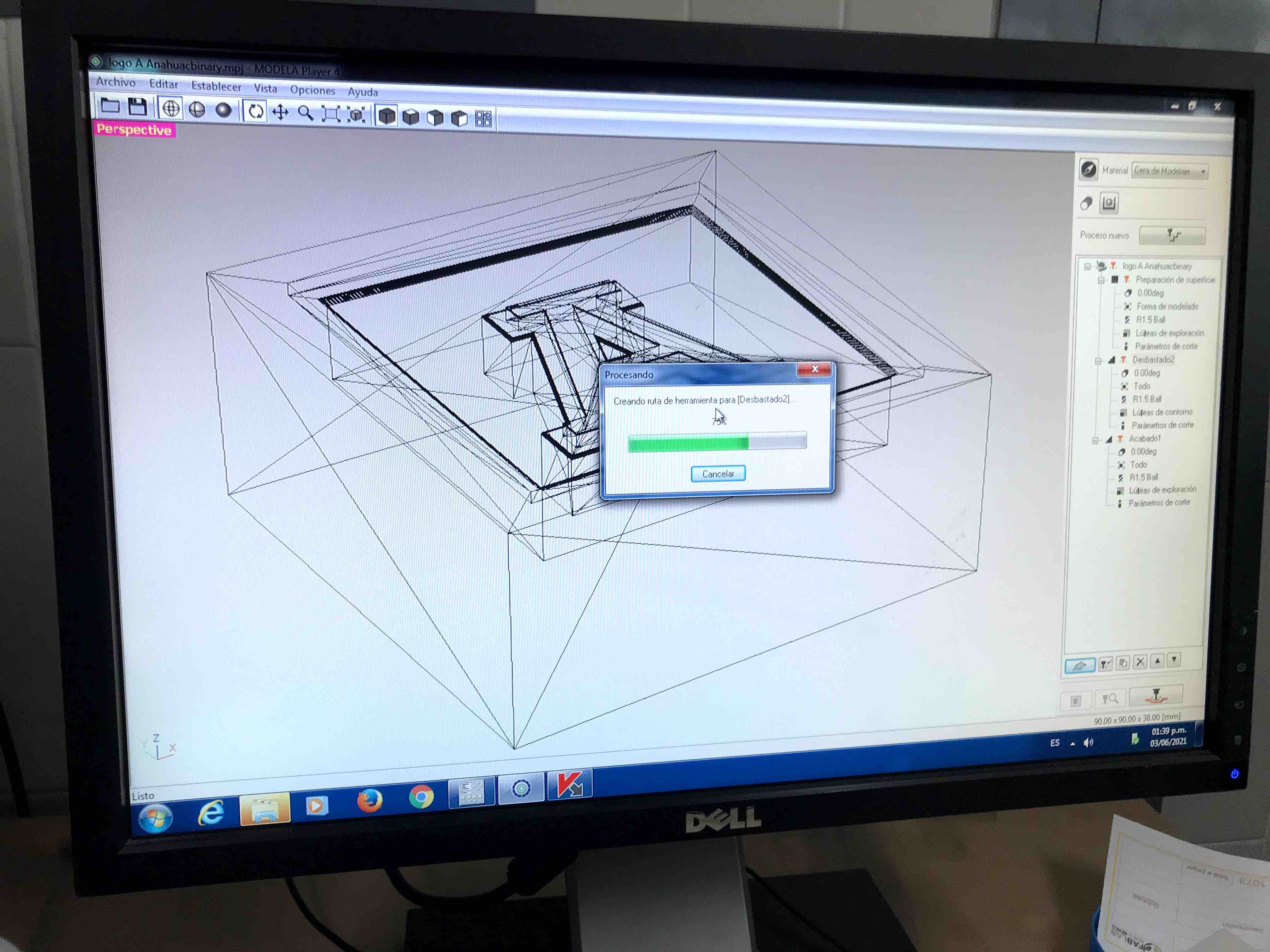

Creating the

path of the tool to follow

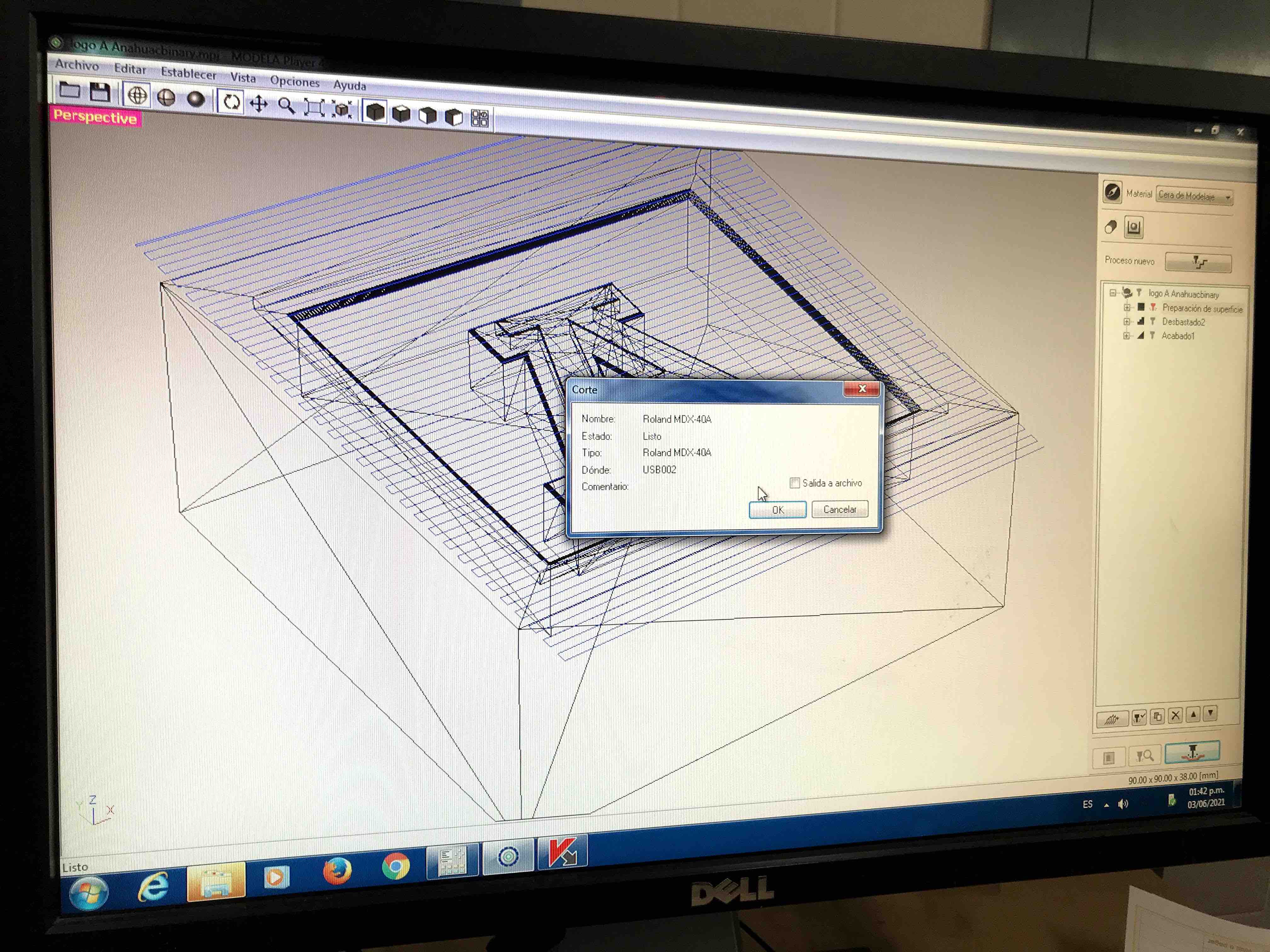

Everything

ready

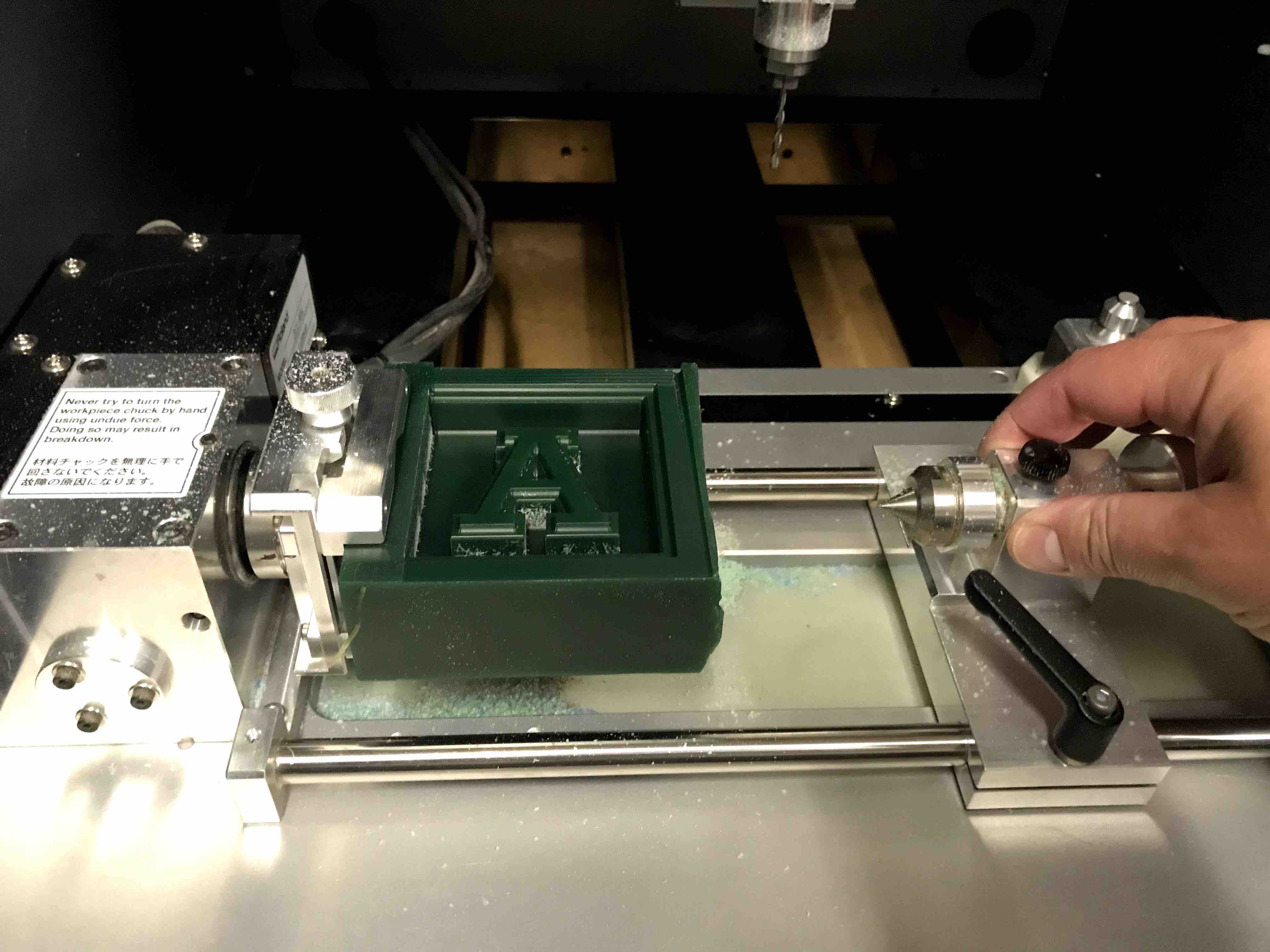

Checking the

correct hold of the wax cube in to the Roland machine and

being sure that is leveled

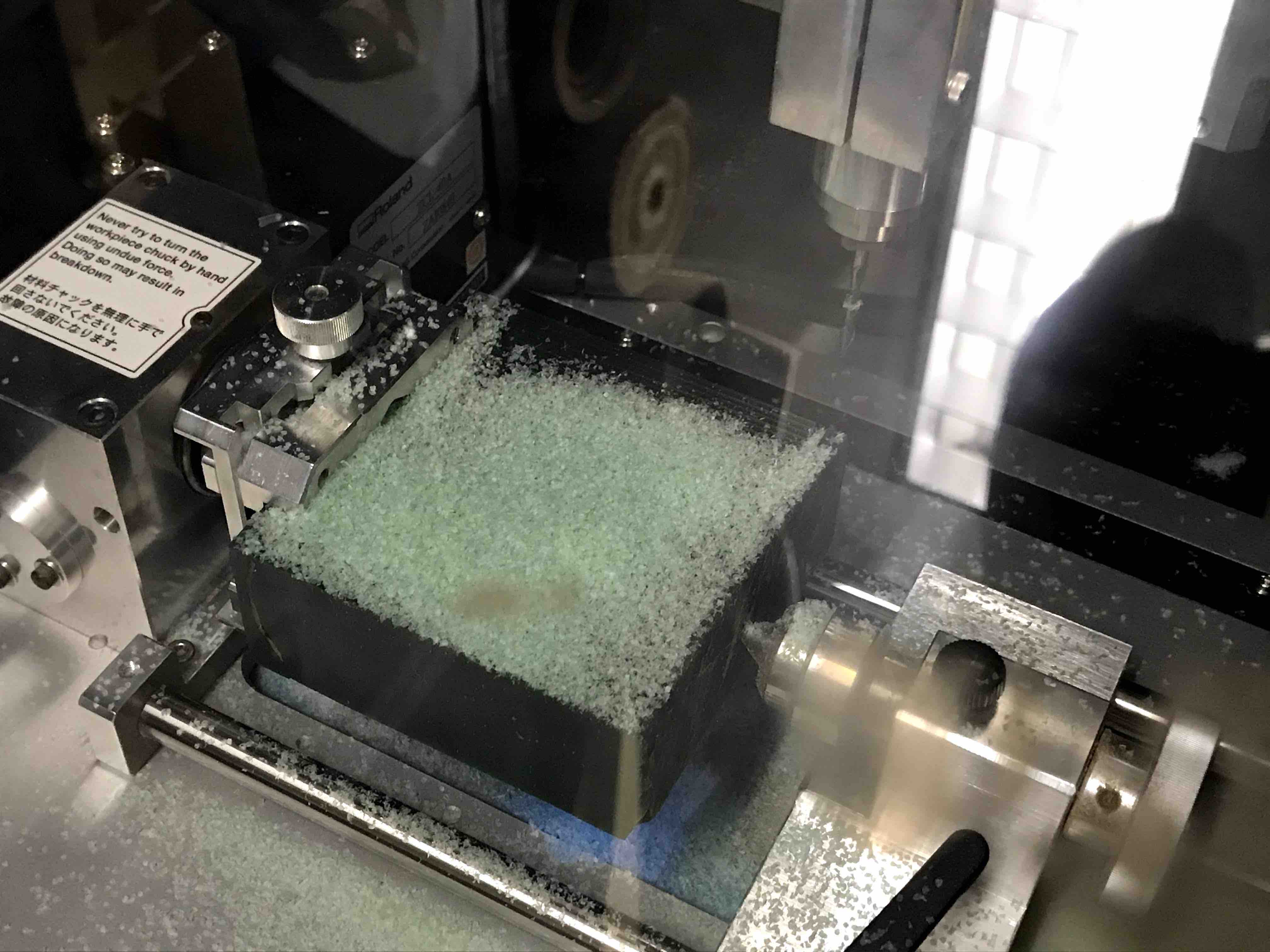

Starting the

milling process

Milling the

last details of the process

The milling

process finished.

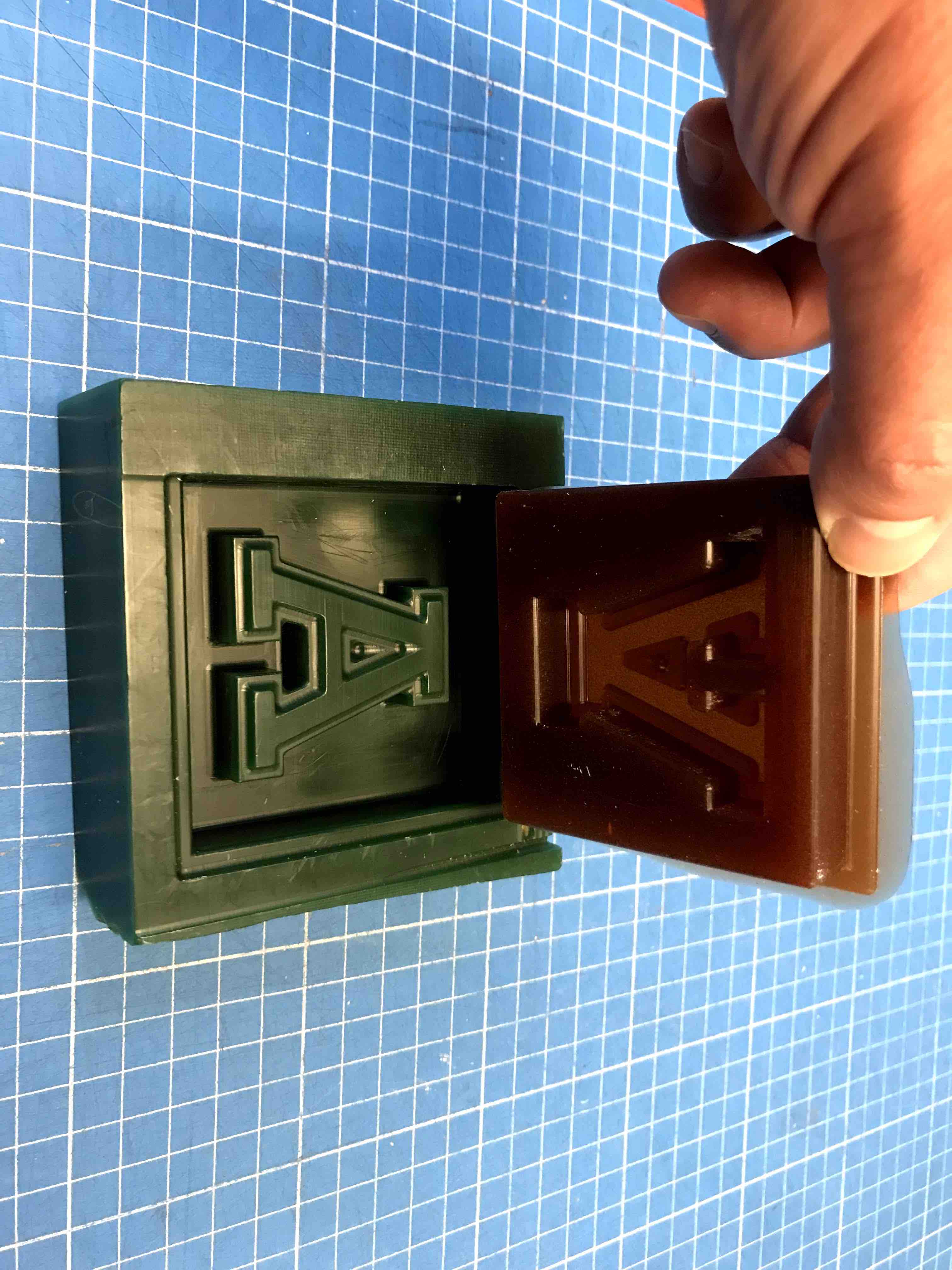

Now that I have

my positive mold I need to pour silicon to made the negative

mold,but, how silicon do I need to prepare? one option is to

pour water into the cavity so I can see the exact amount of

silicon I will need.

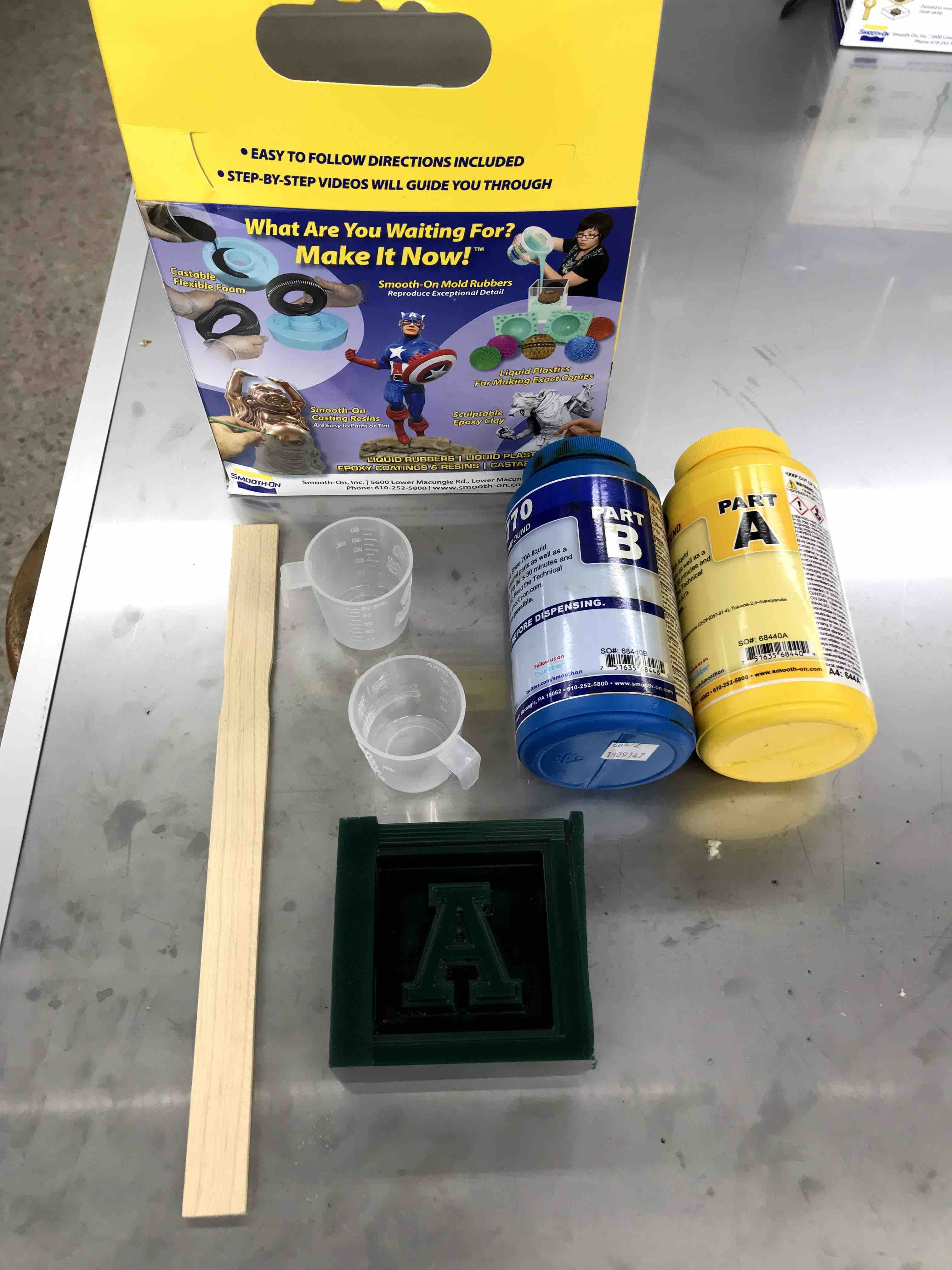

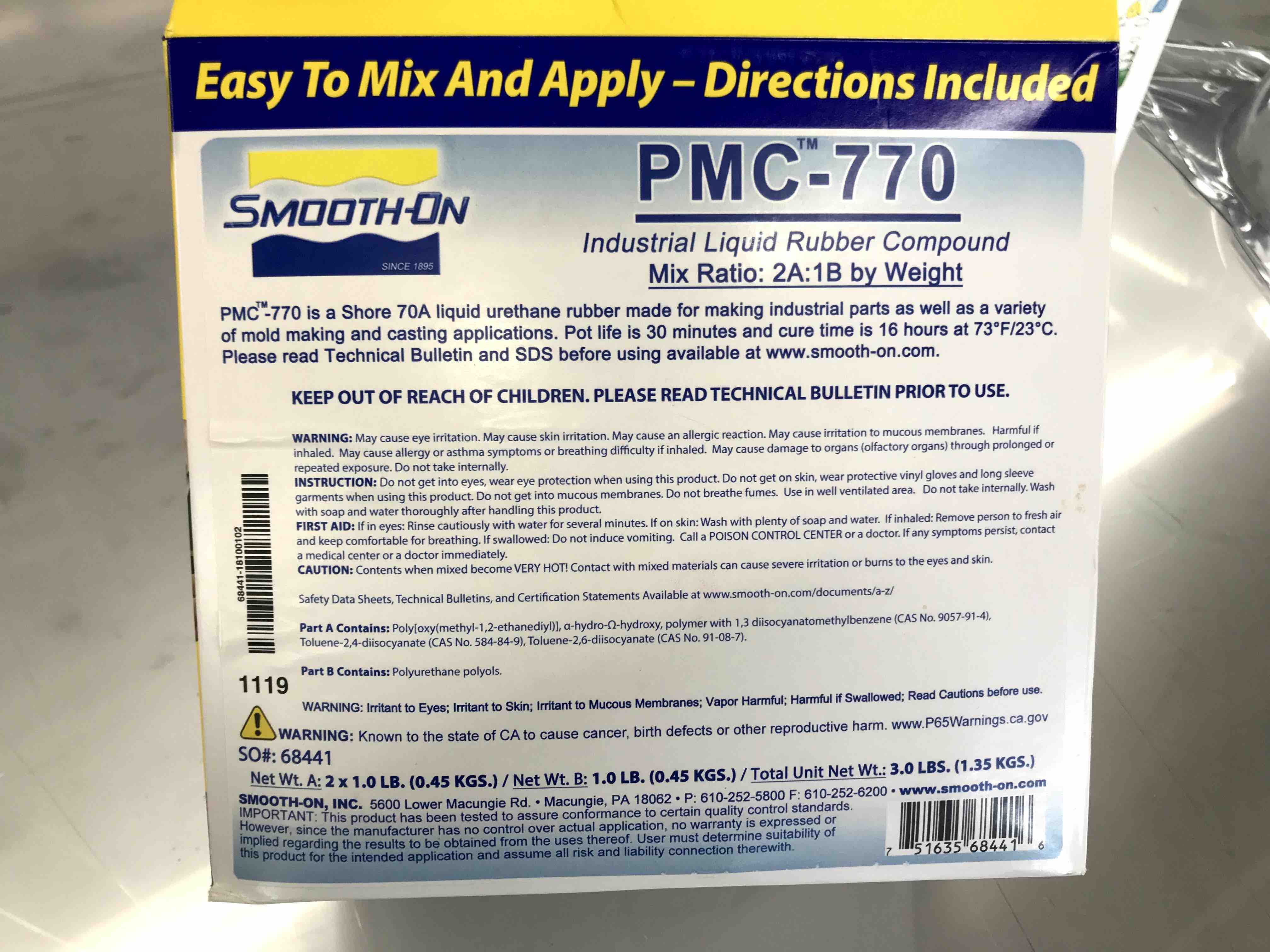

I´m going to

use this Smooth-On urethane rubber to made the negative

mold. We need to mix Part A with part B in a mix ratio of

2A:1B by Weight

Instructions

and safety data sheet.

Here I mix and

pour the urethane rubber into the mould and then we have to

wait almost 16hours to cure

Here I mix and

pour the urethane rubber into the mould and then we have to

wait almost 16hours to cure

Just perfect.

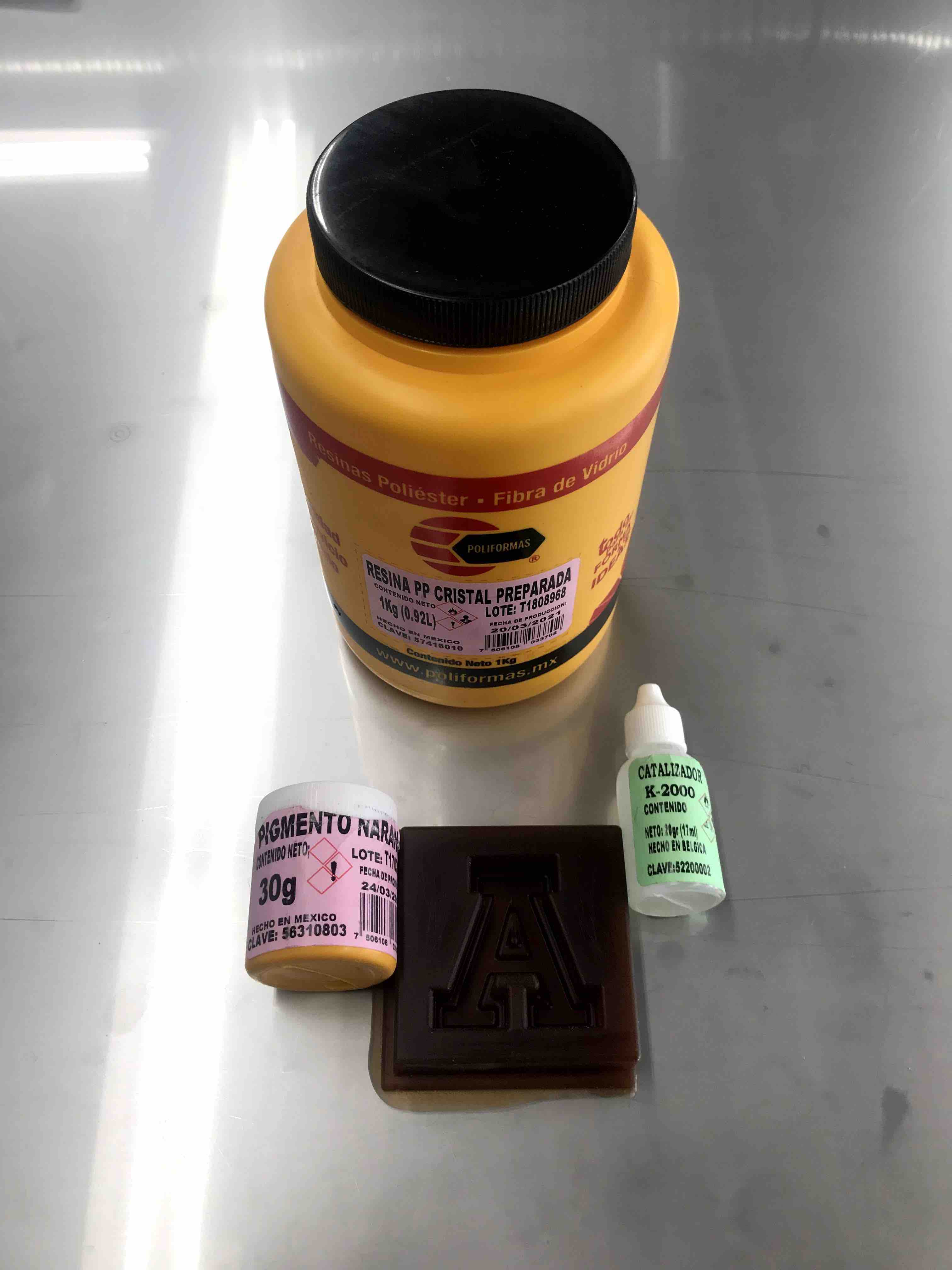

And now it´s

time to mix the cristal clear resine with orange color

aditive and the catalyst. The amount of catalyst is

40drops for 100gr of resin PP cristal, this can vary

depending of the size of the final piece, weather and

aditive if you use it.

Mixing the

crystal clear resin with orange aditive, check that the

color is uniform, and without bubbles.

The resin

waiting to cure in the urethan rubber mold, just wait, be

patience, more less 72hrs before it´s completely cure.

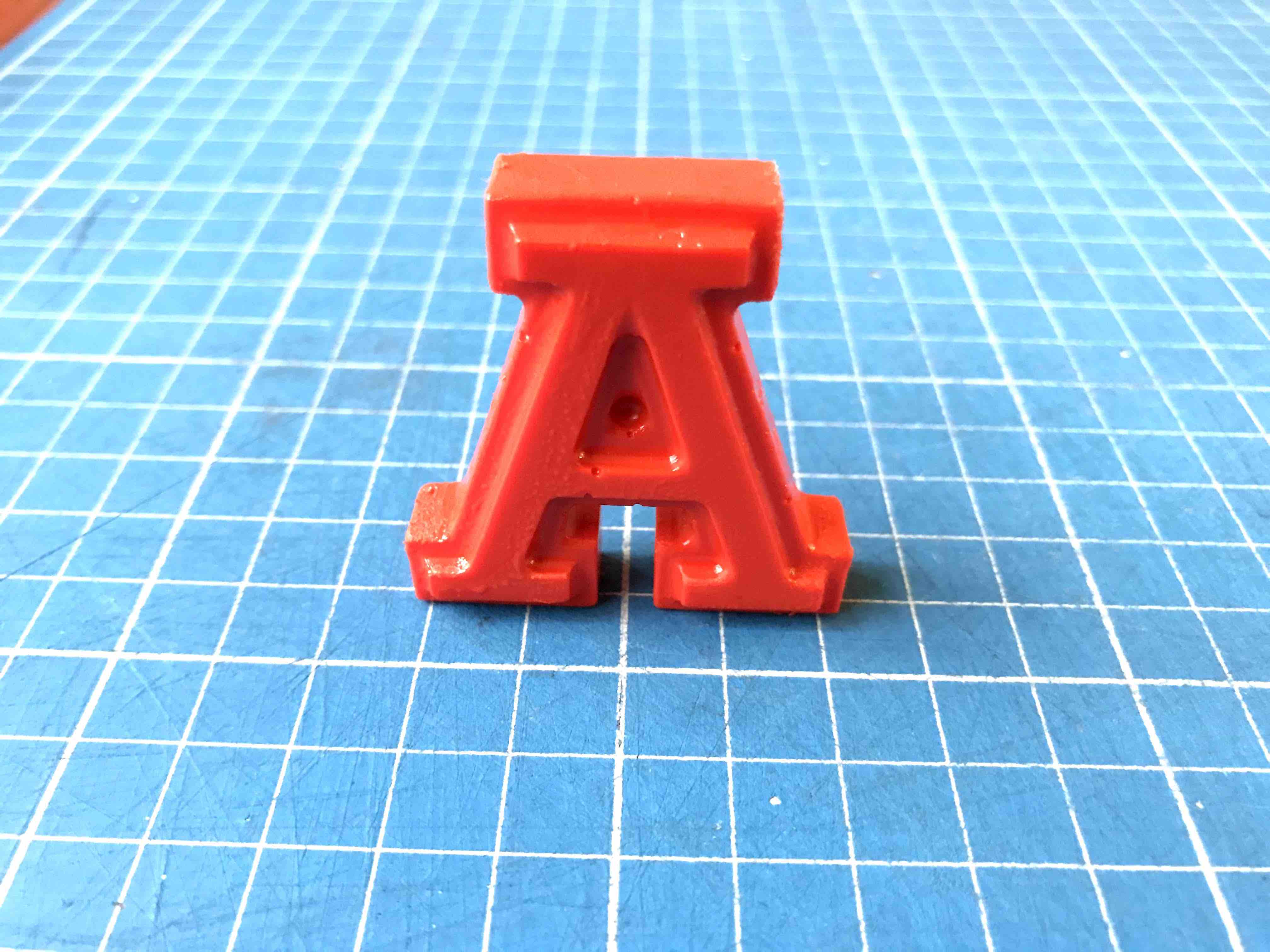

The final

piece, the A logo of the university.

the green spot

a place to re-connect