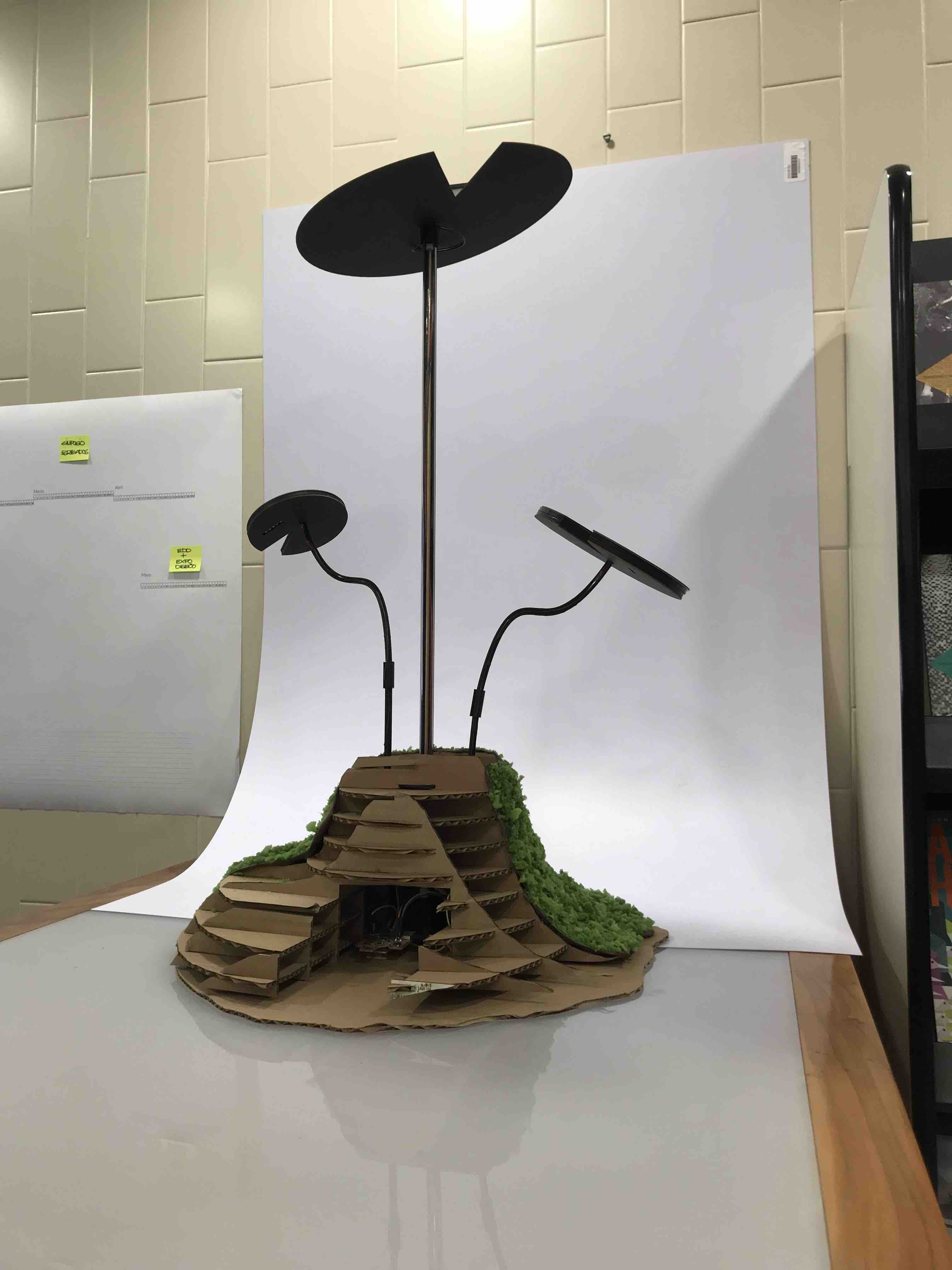

initial stages of the green spot

a place to re-connect

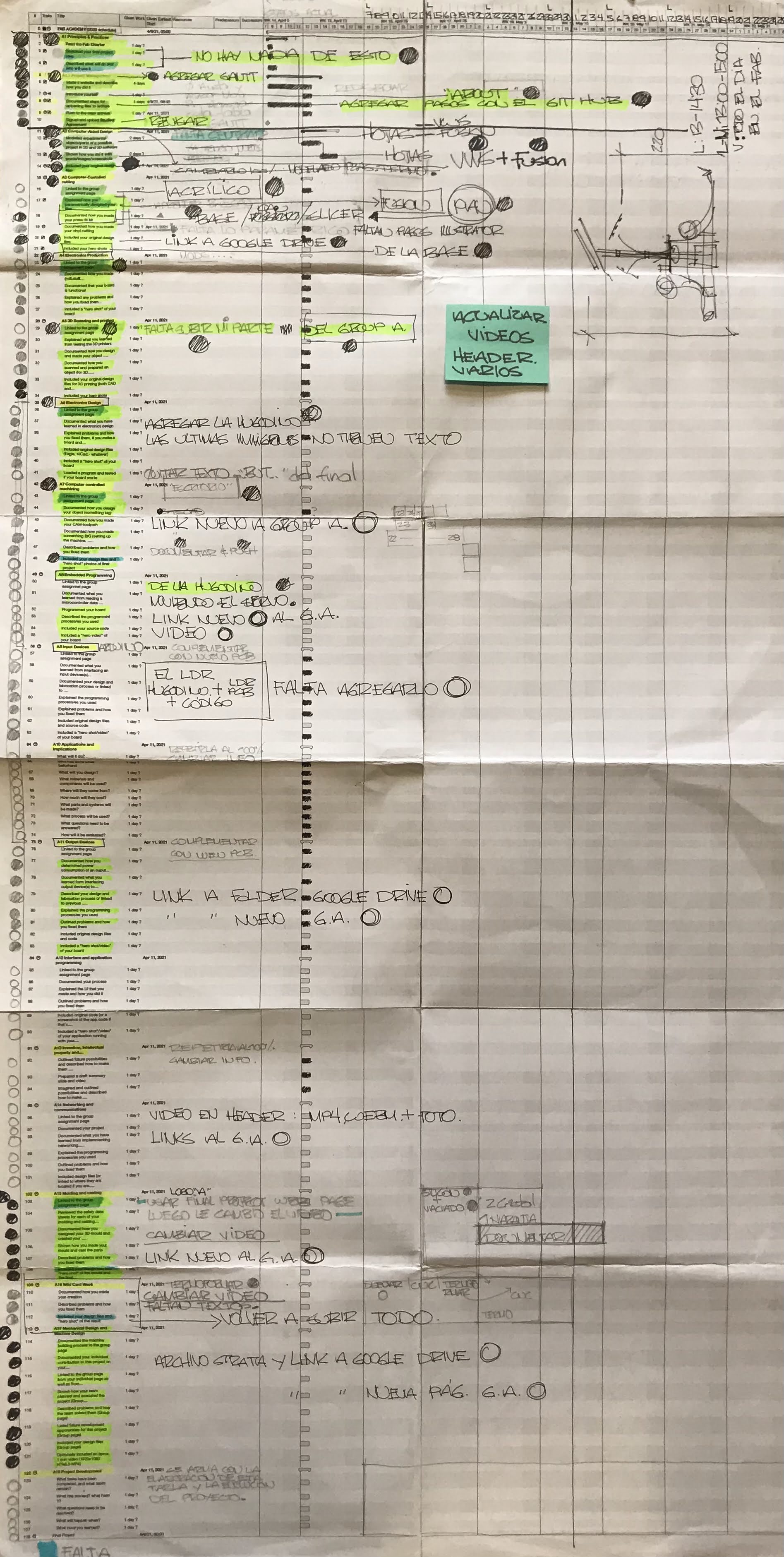

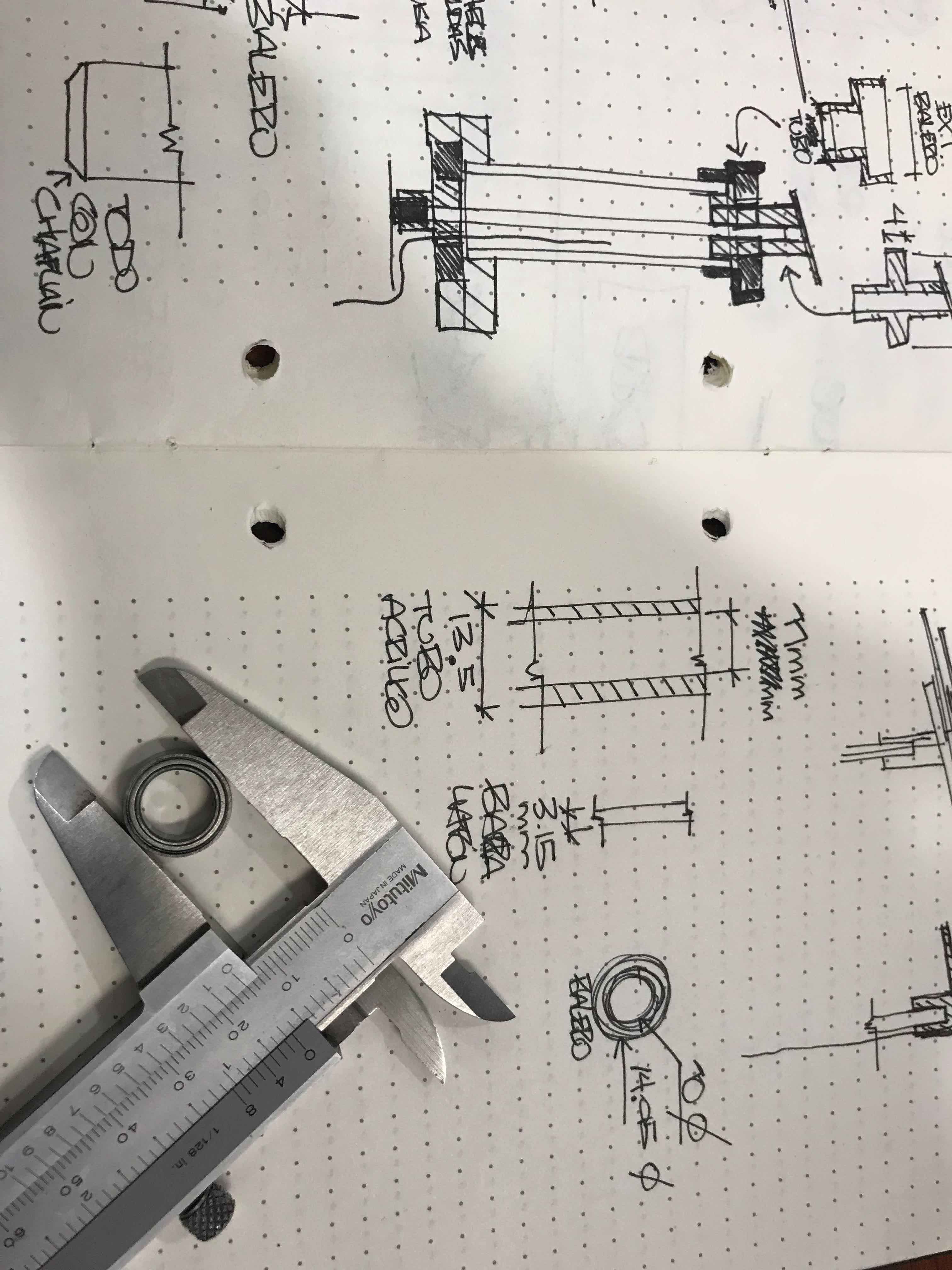

What tasks have been completed, and what tasks remain?

I already had my Final Project idea

and design but it remains the final shape of the base and to

scale the original design, also to fit the internal components

like the servo, the batteries, etc into the base

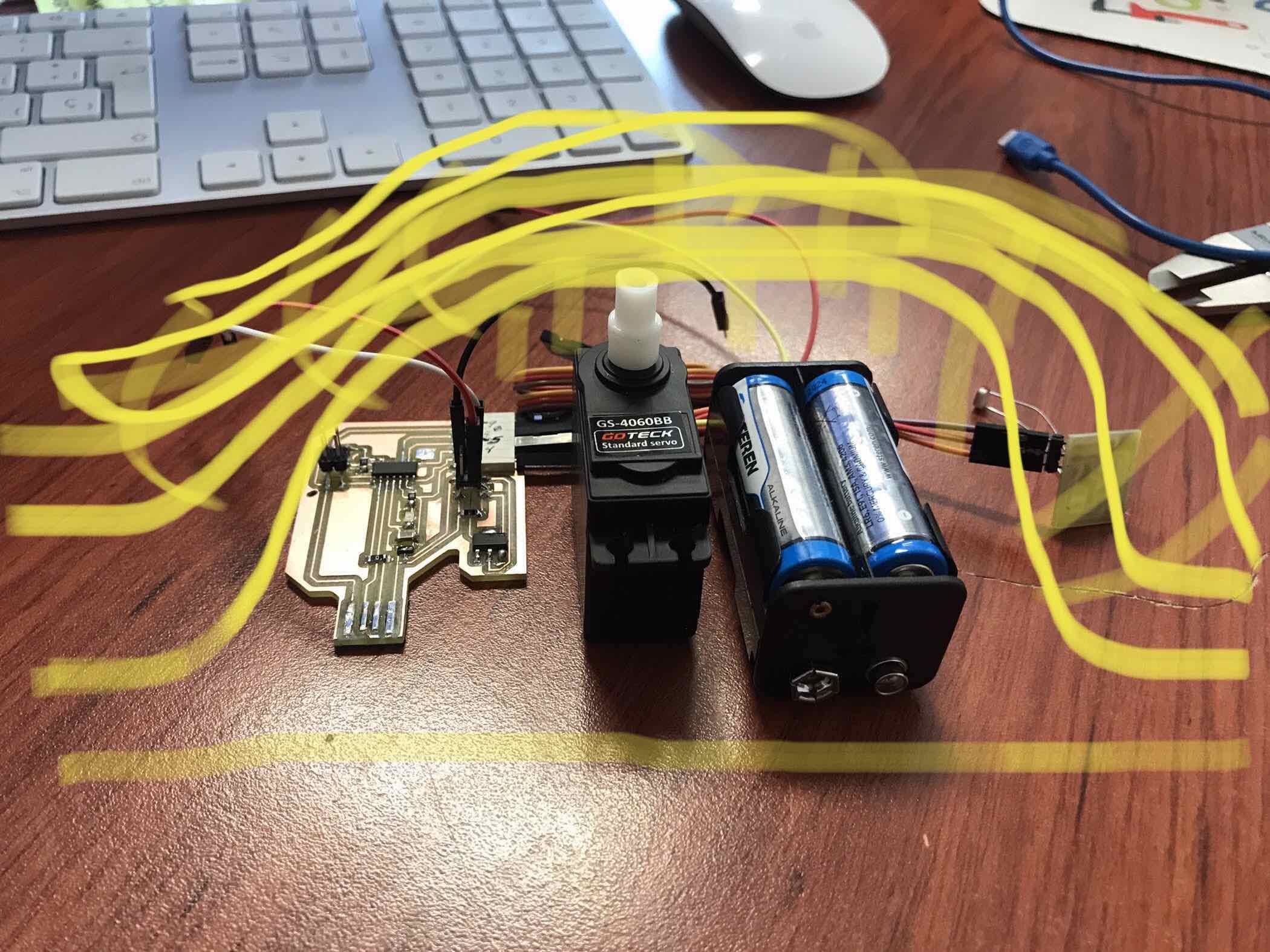

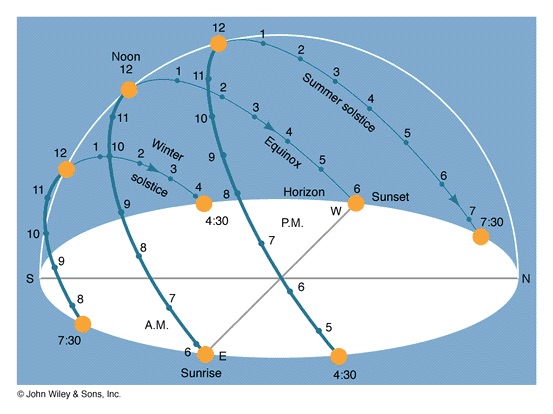

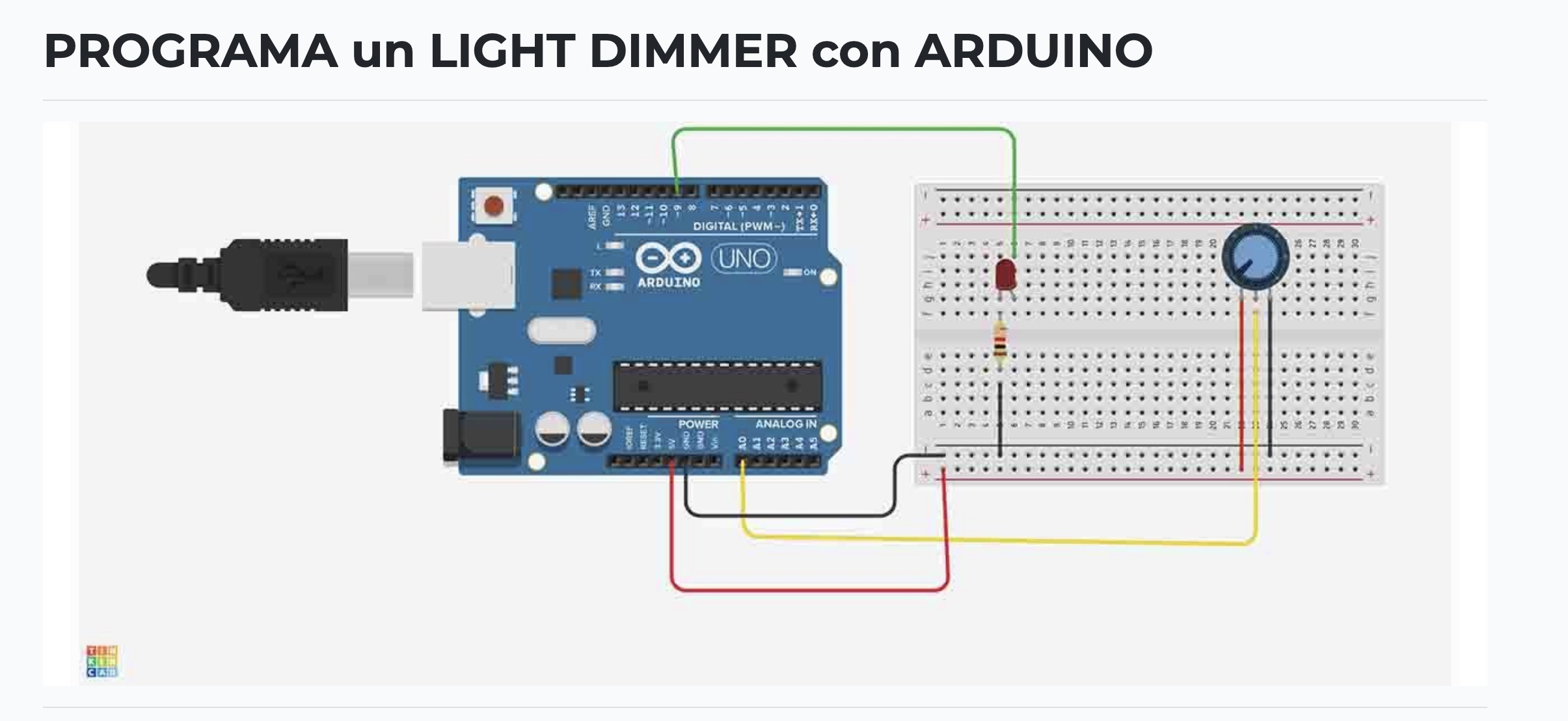

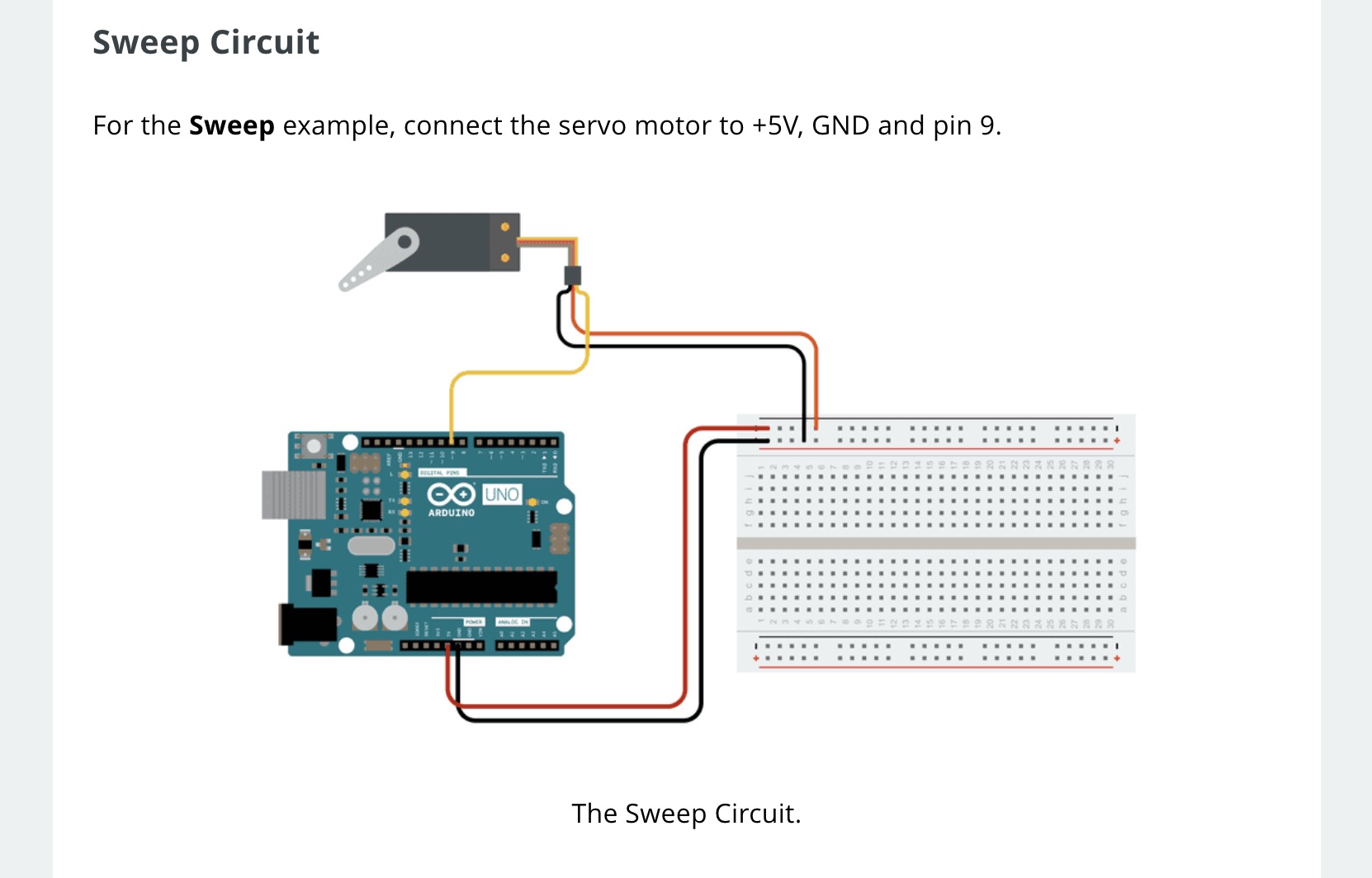

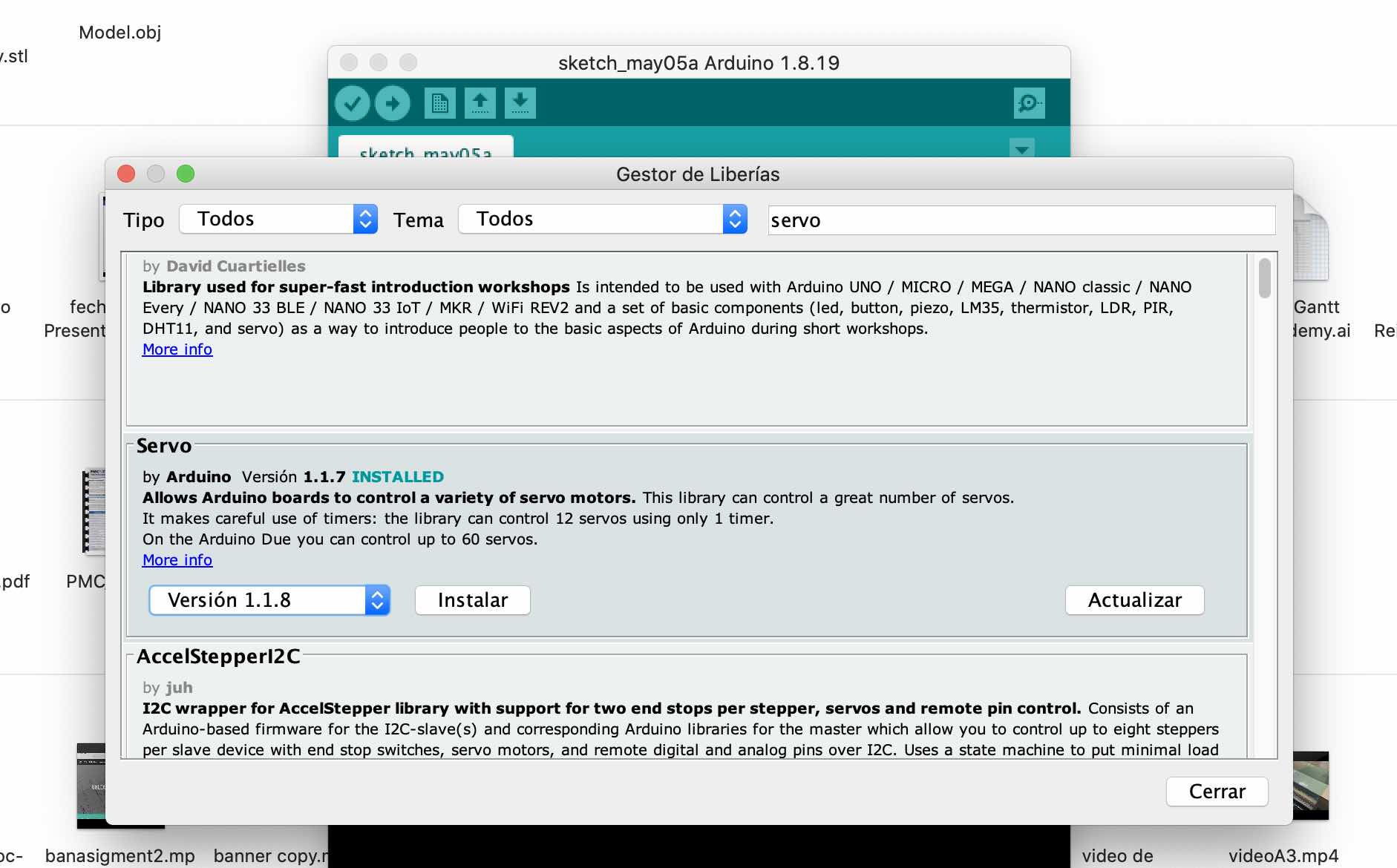

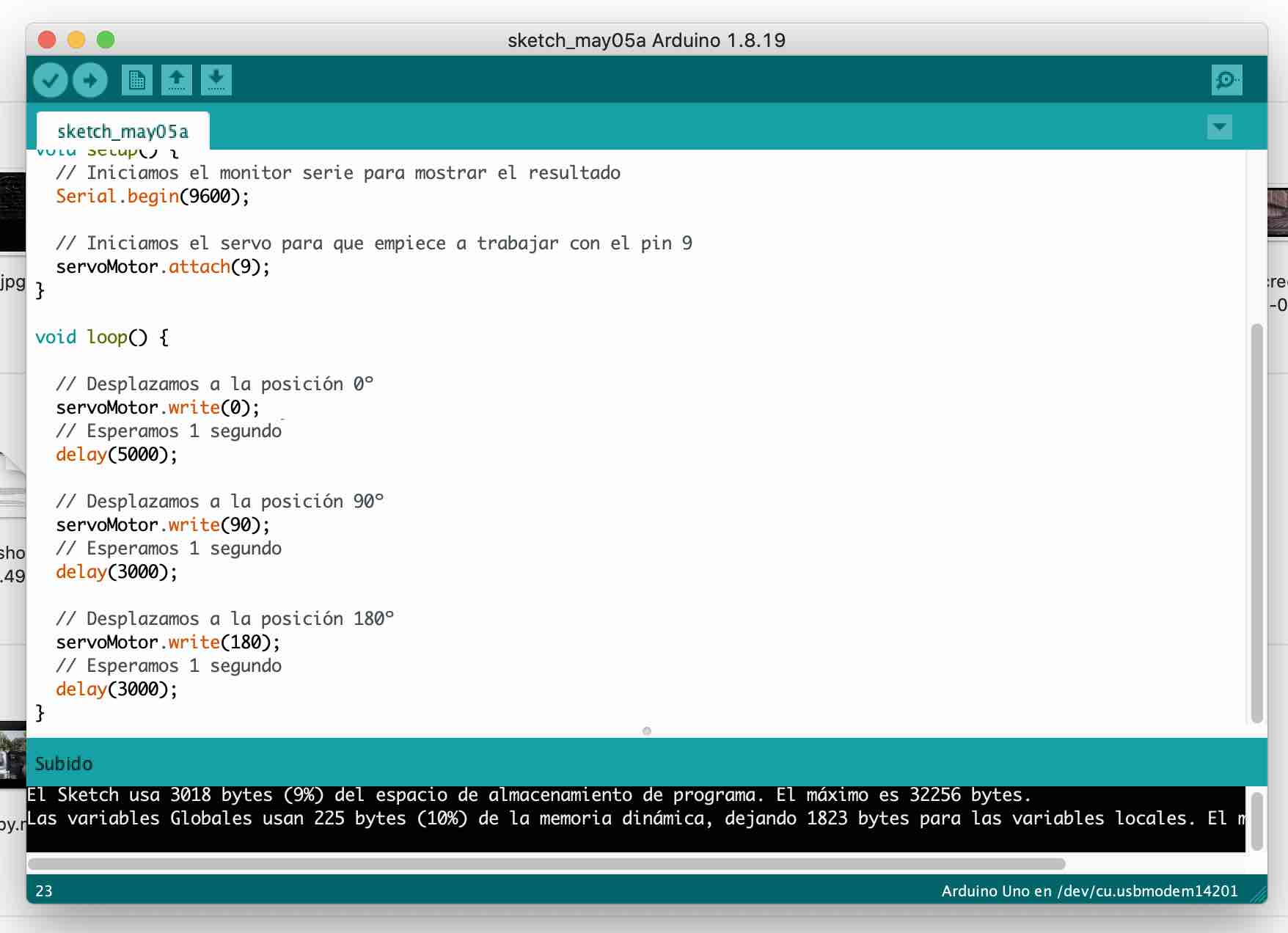

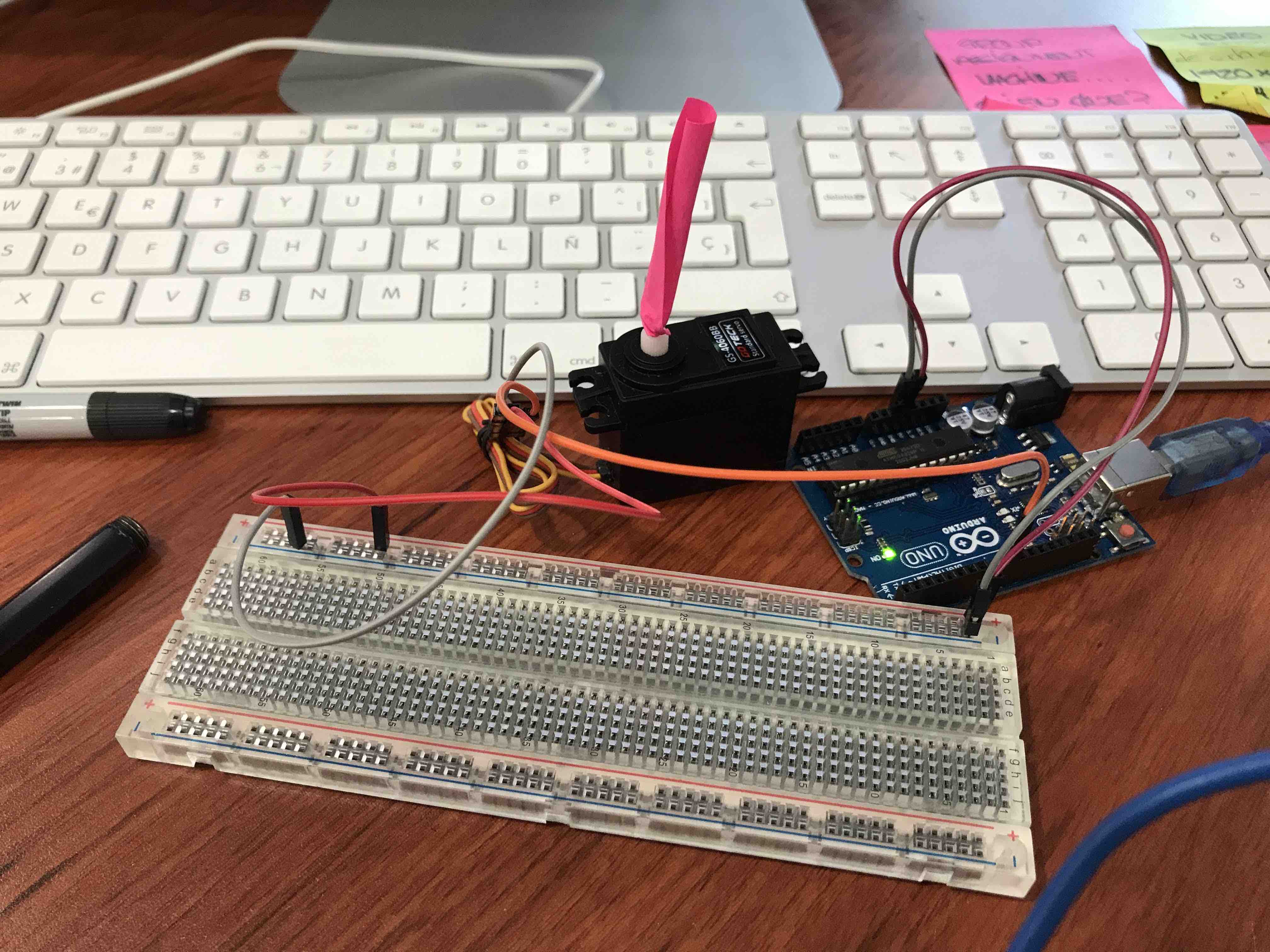

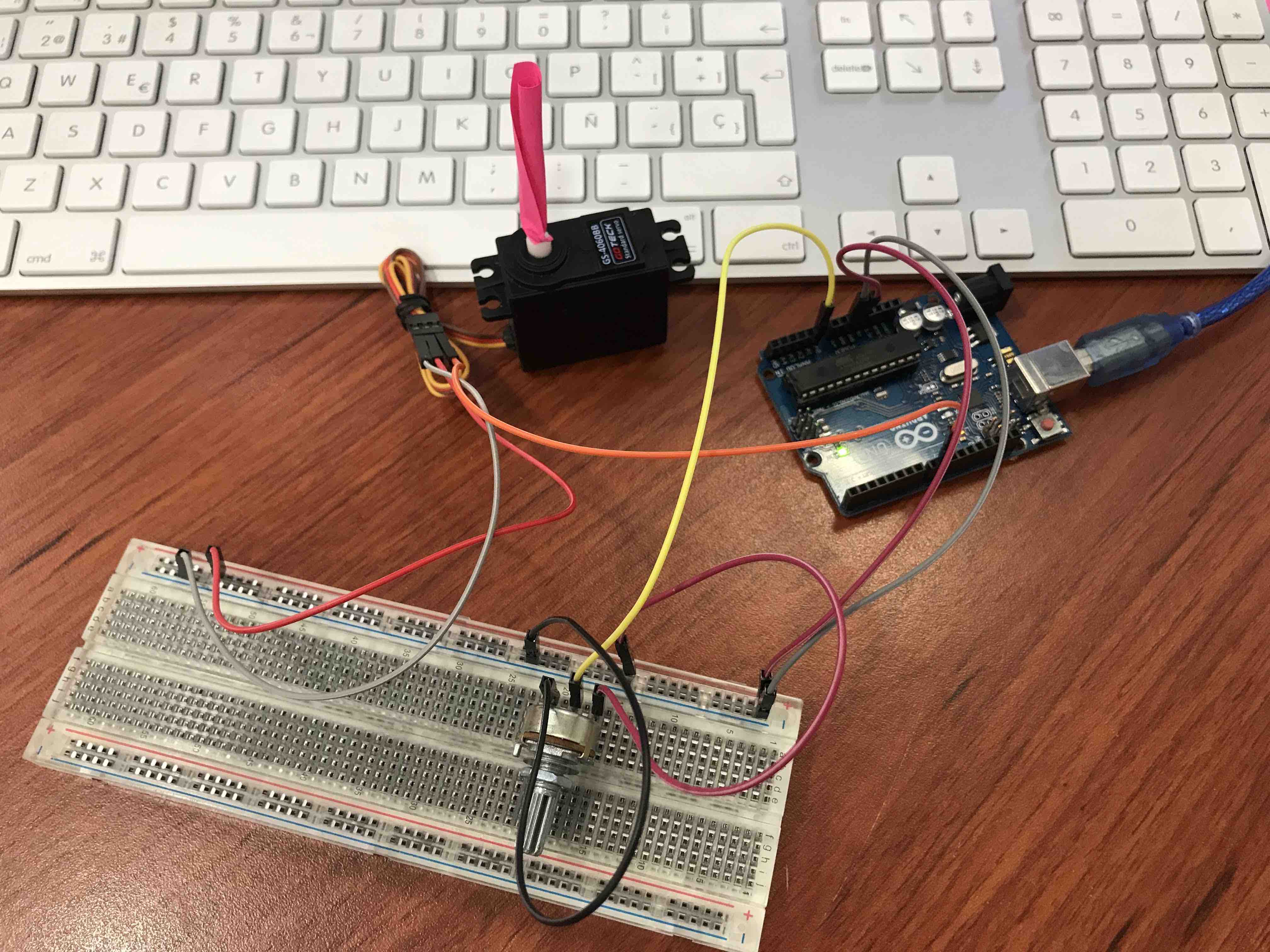

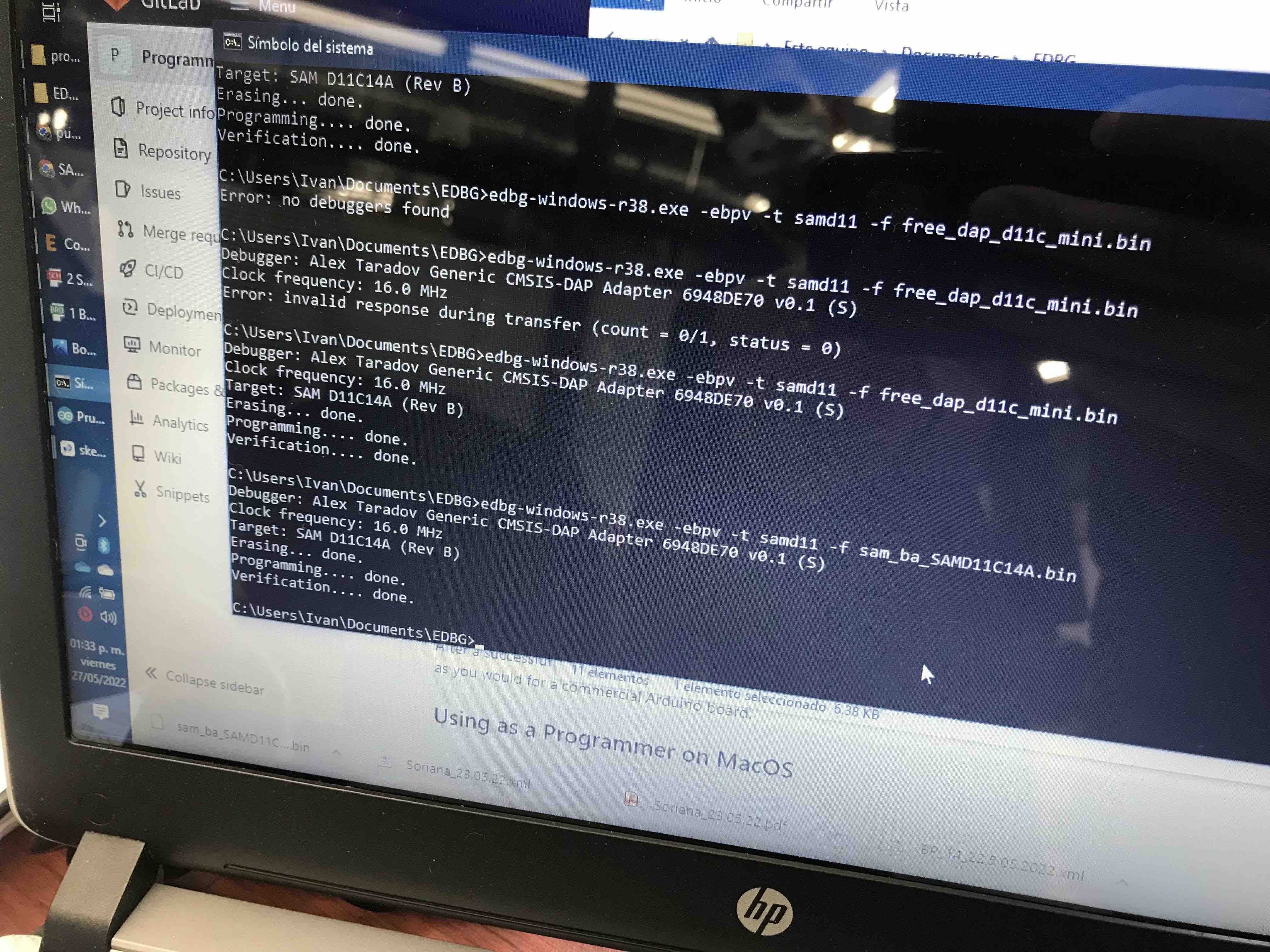

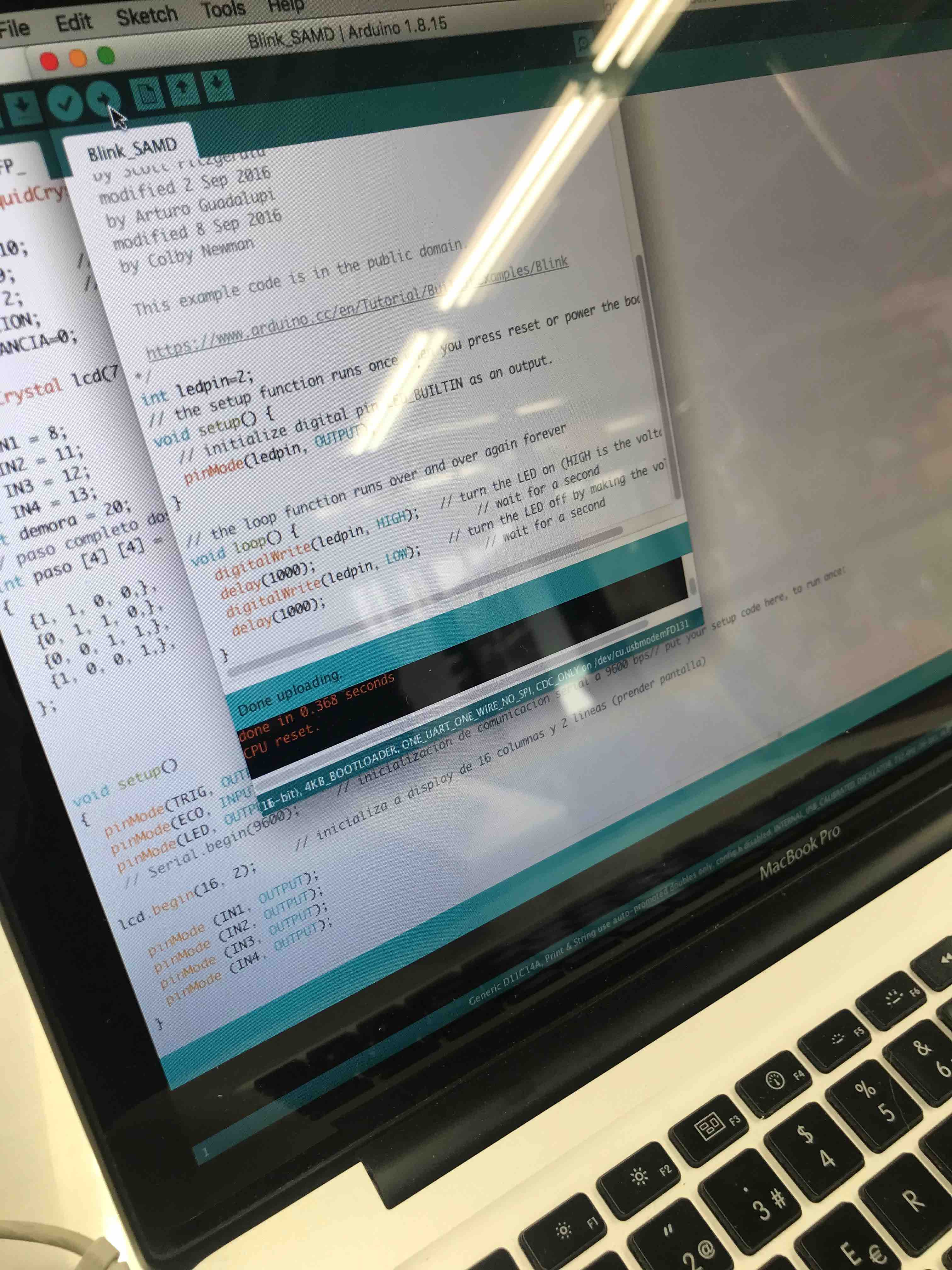

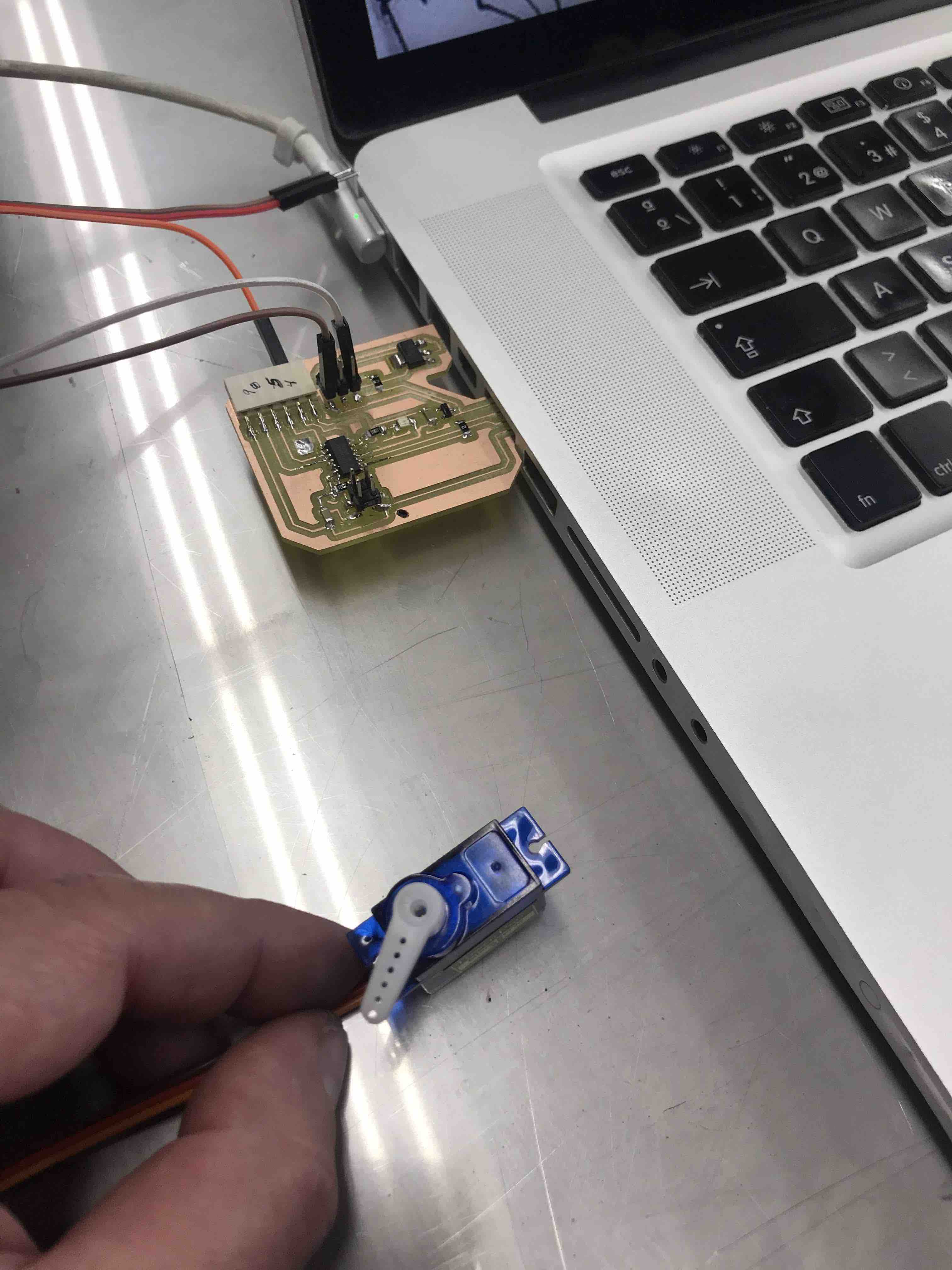

I already test the SAMD code in the Arduino IDE to move my servo and now I´m modyfing the code to position the servo in the right angle and with the delays like the time spend in that position during the day.

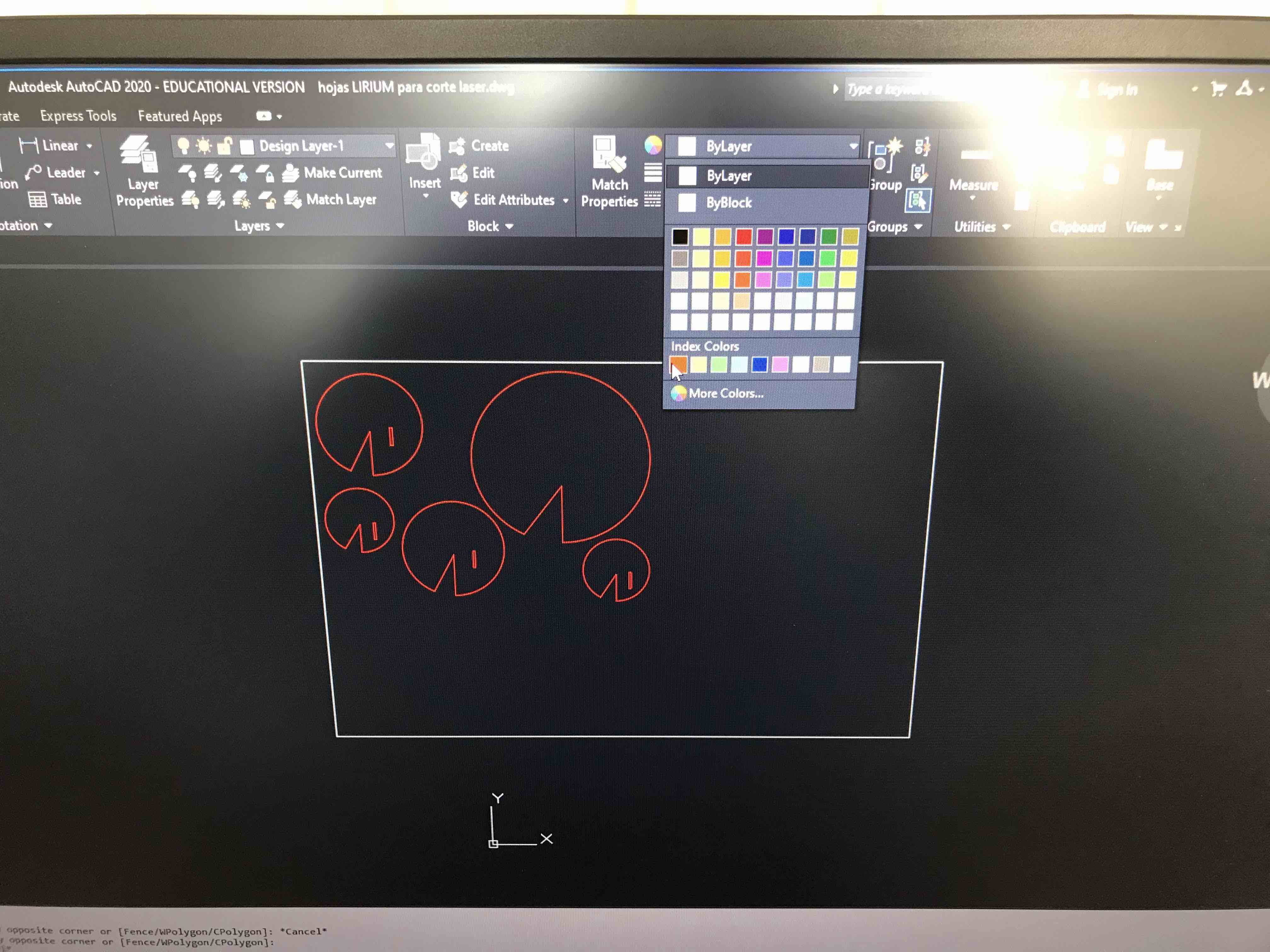

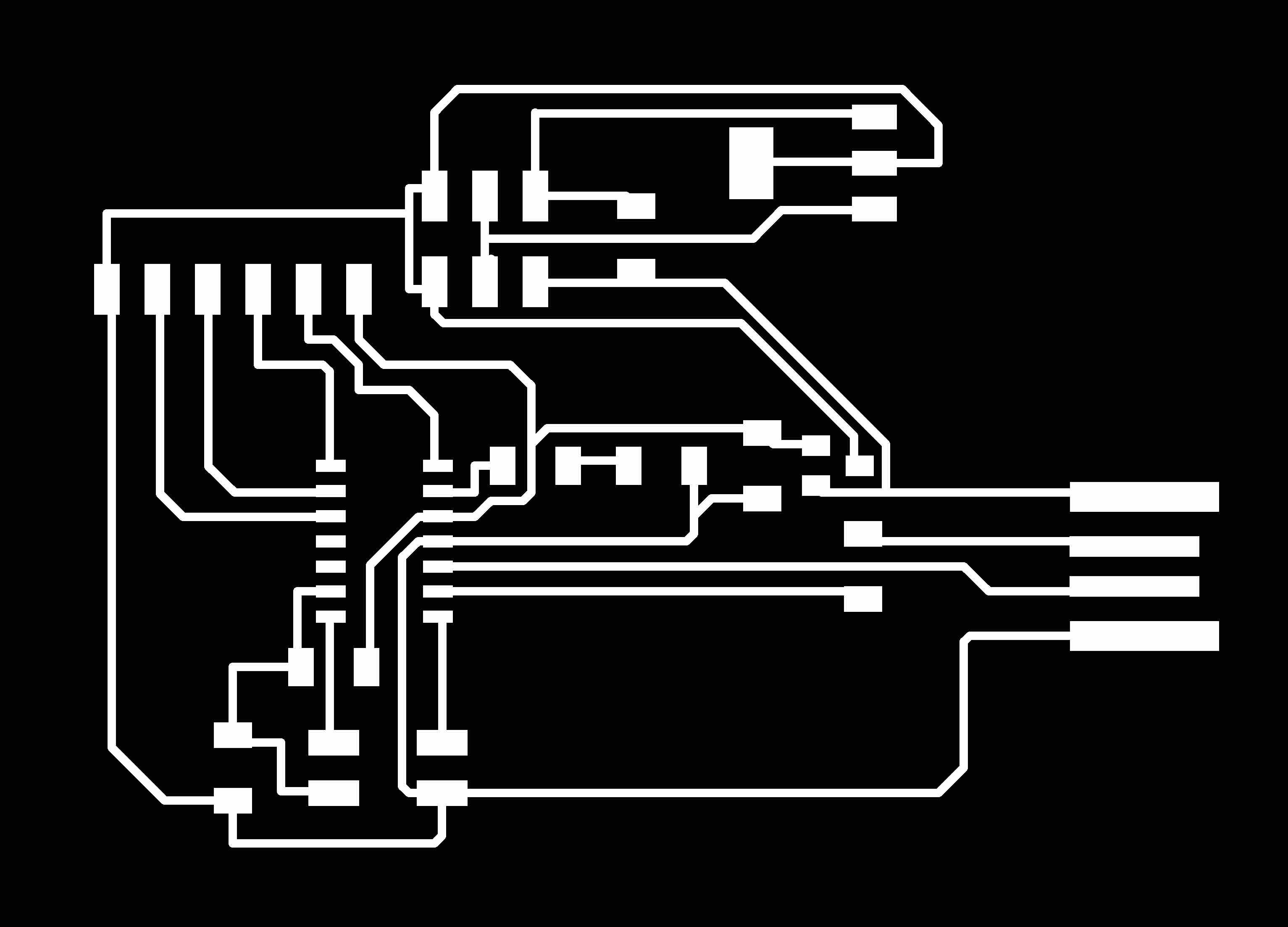

I have some 2d and 3d designs to be cut in the laser machine and to be print in the 3D printer.

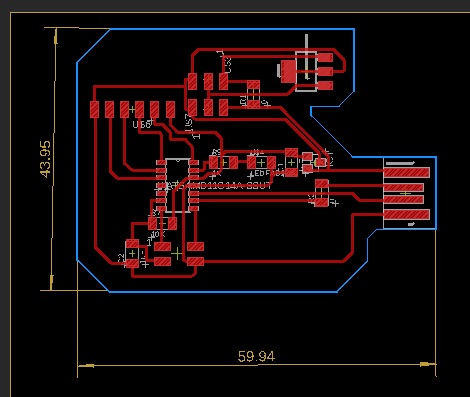

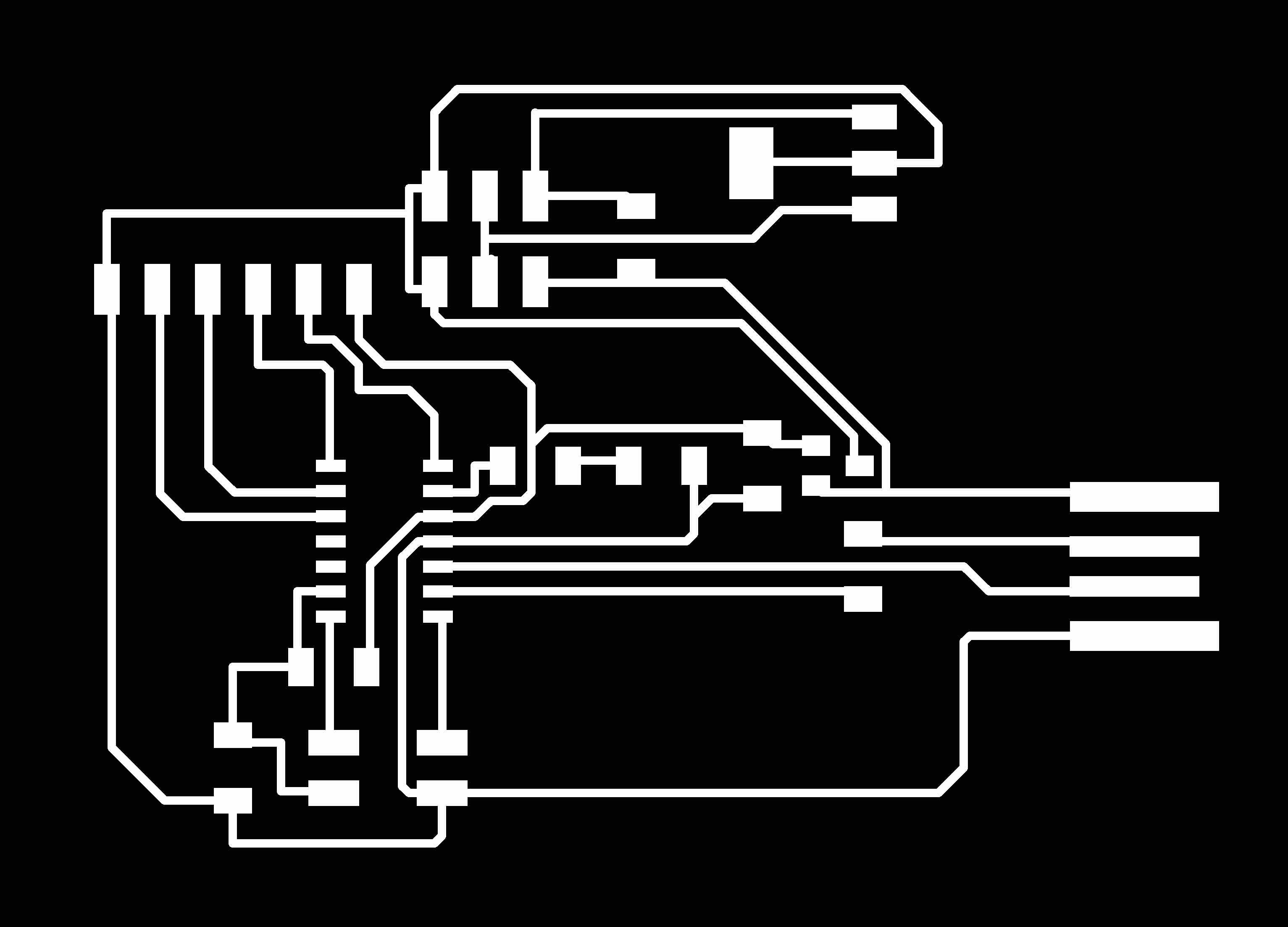

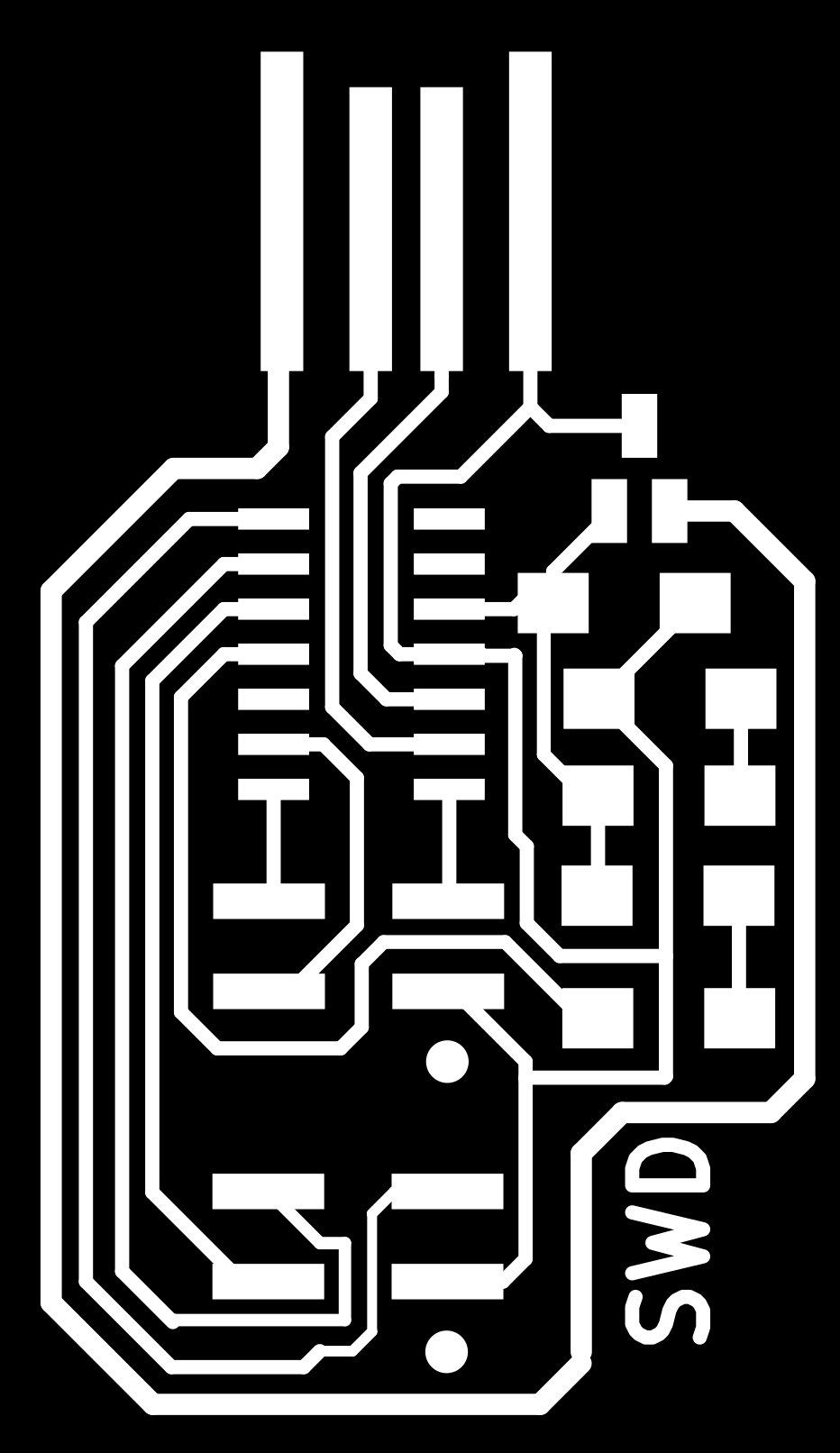

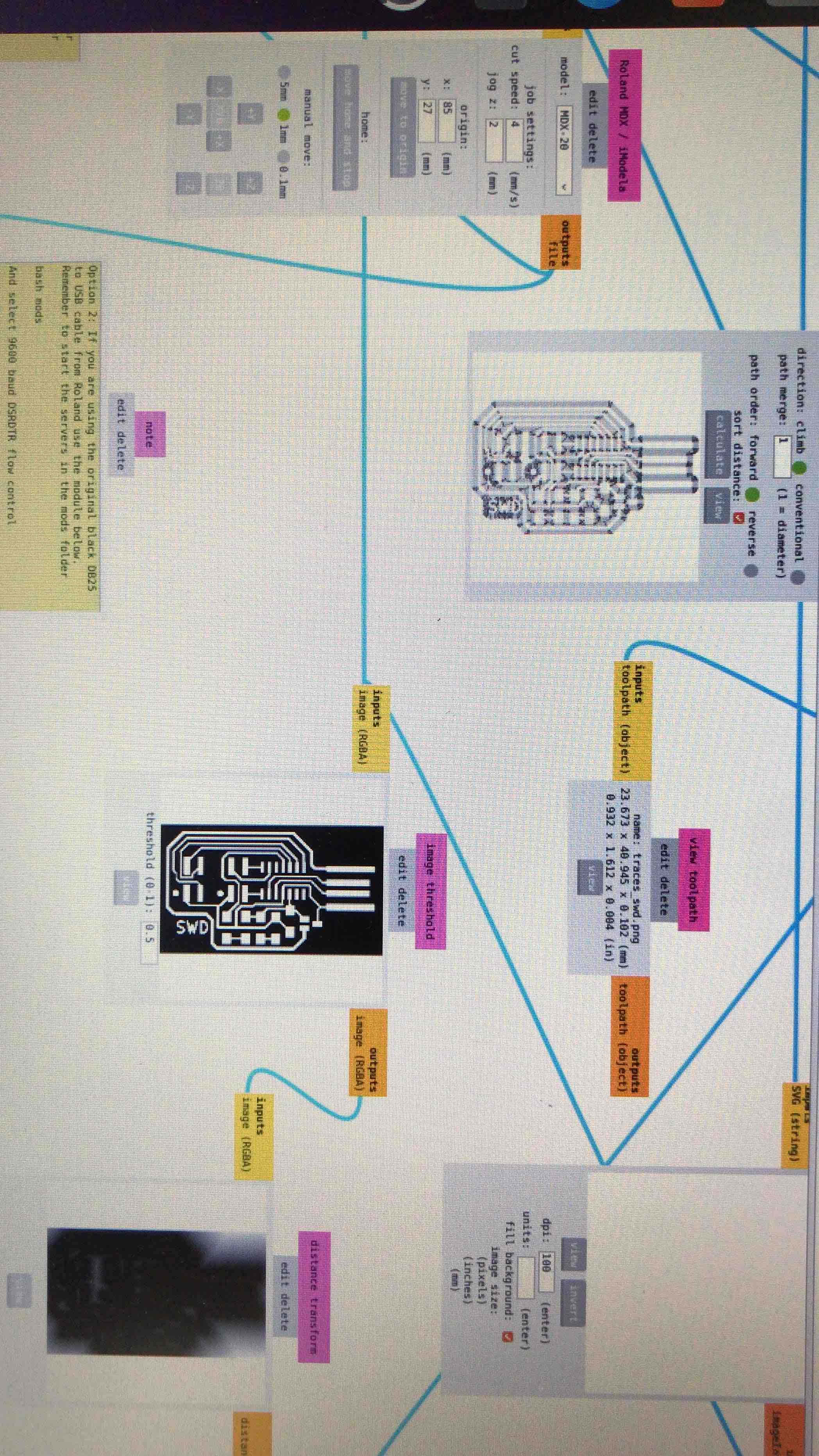

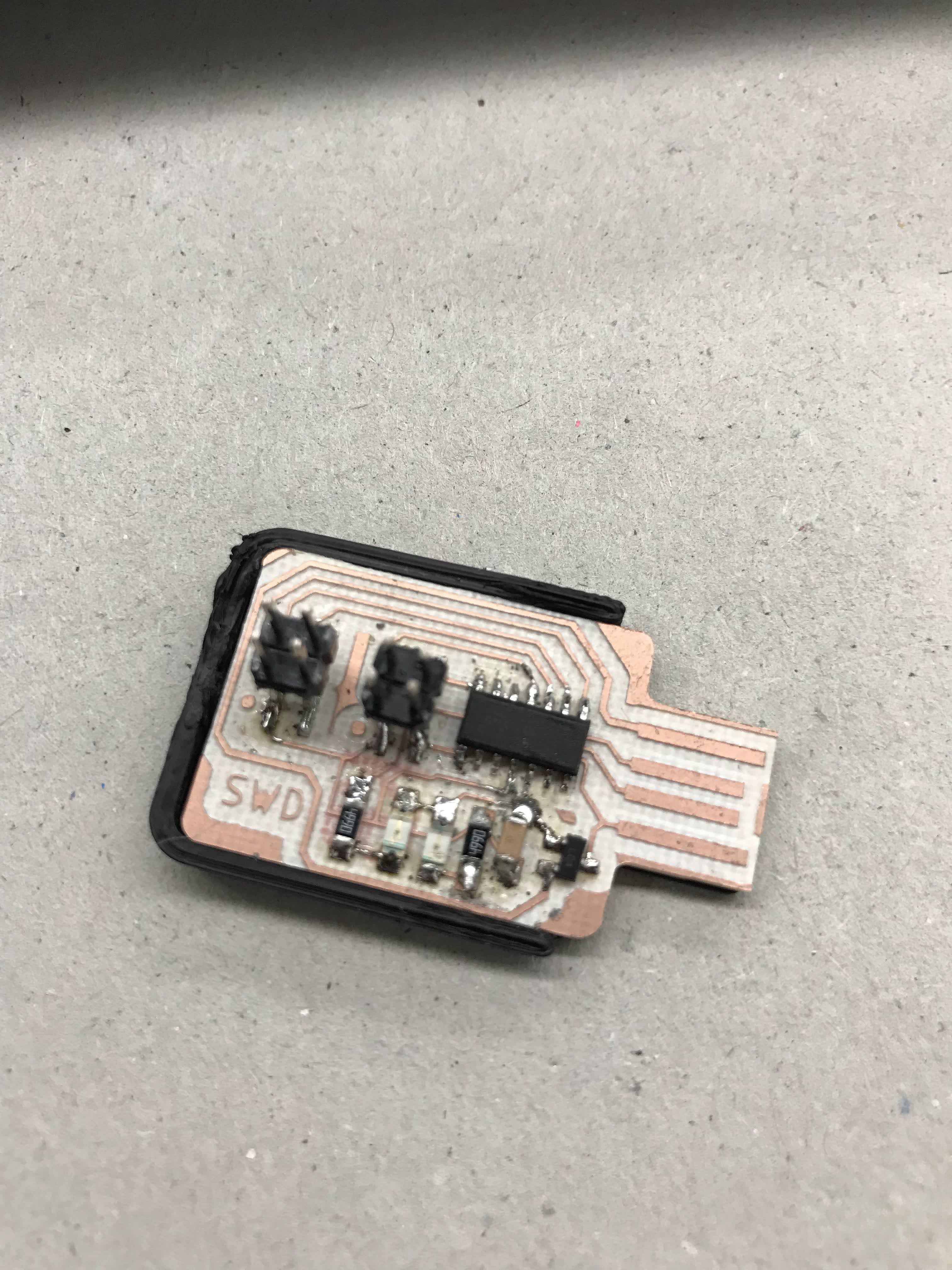

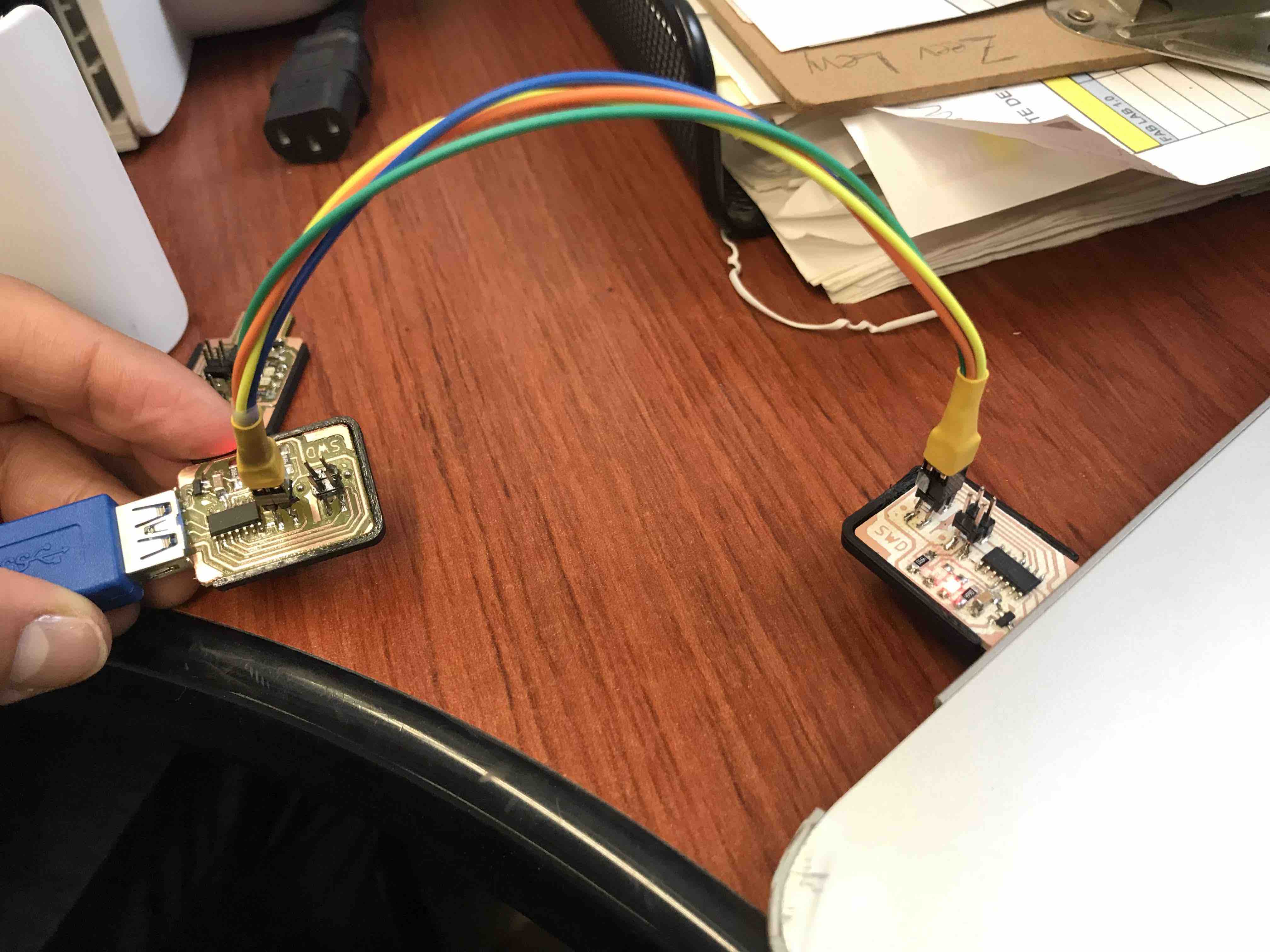

I have aditional boards, like the LDR one

It remain to put in the same code the servo and the LDR that turns on and off the LEDS.

Also, it remain the assemble of the

hole project, at this point I just made individual tests of the

different components.

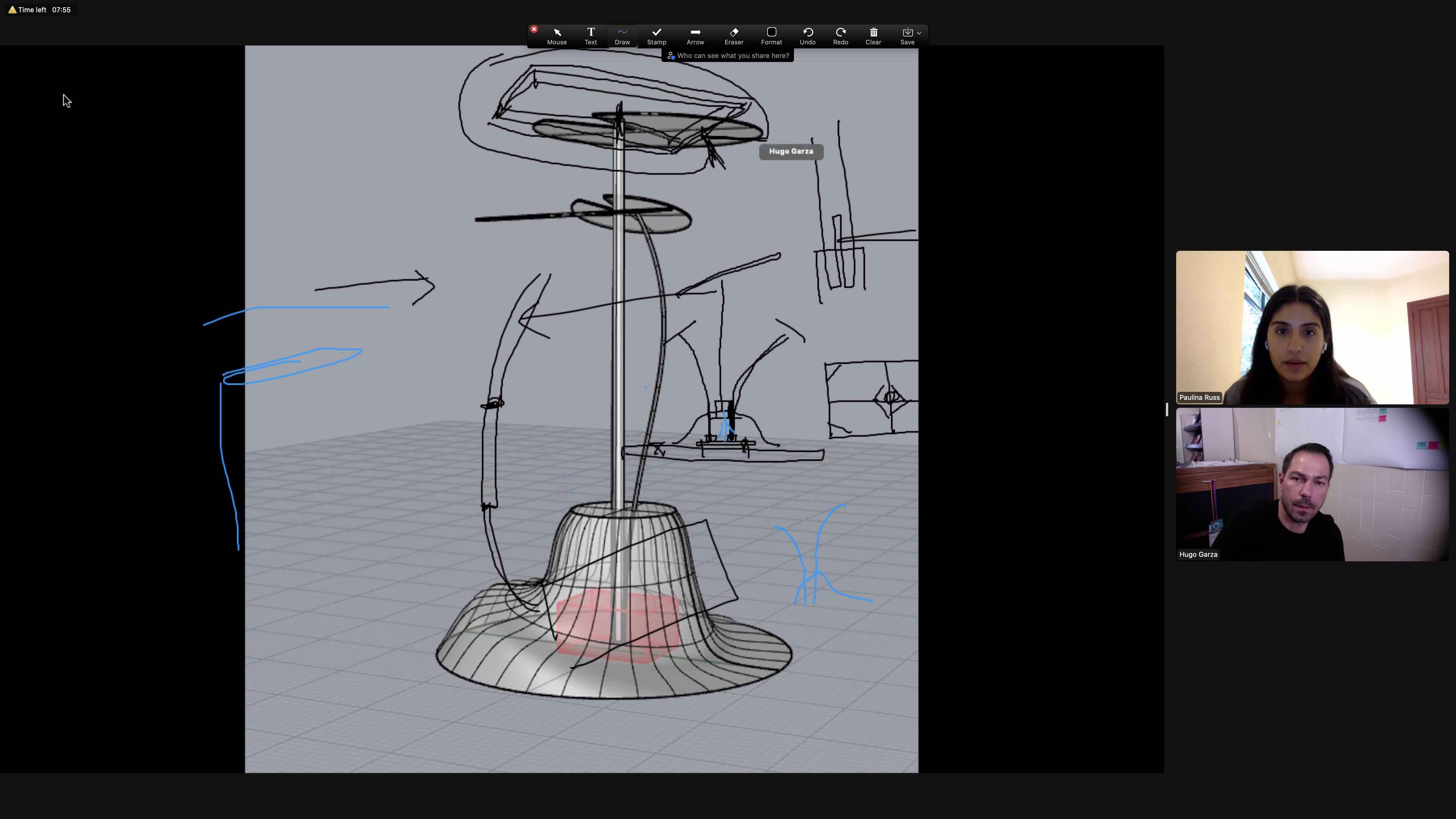

What has worked, what

hasn´t?

The new board works fine but the

drawing in rhino and the scale in Slicer it´s not the same when

you import the document, we need to fix this in order to laser

cut the base.

What questions need to be resolved?

the solar panels charge the 4pack of batteries?

The servo rotate the axis of the principal leaf when all the components where fit in place?

The length of the brass rod and of

the acrylic tube to fit in the base and into the assemble

component of the servo?

What will happen then?

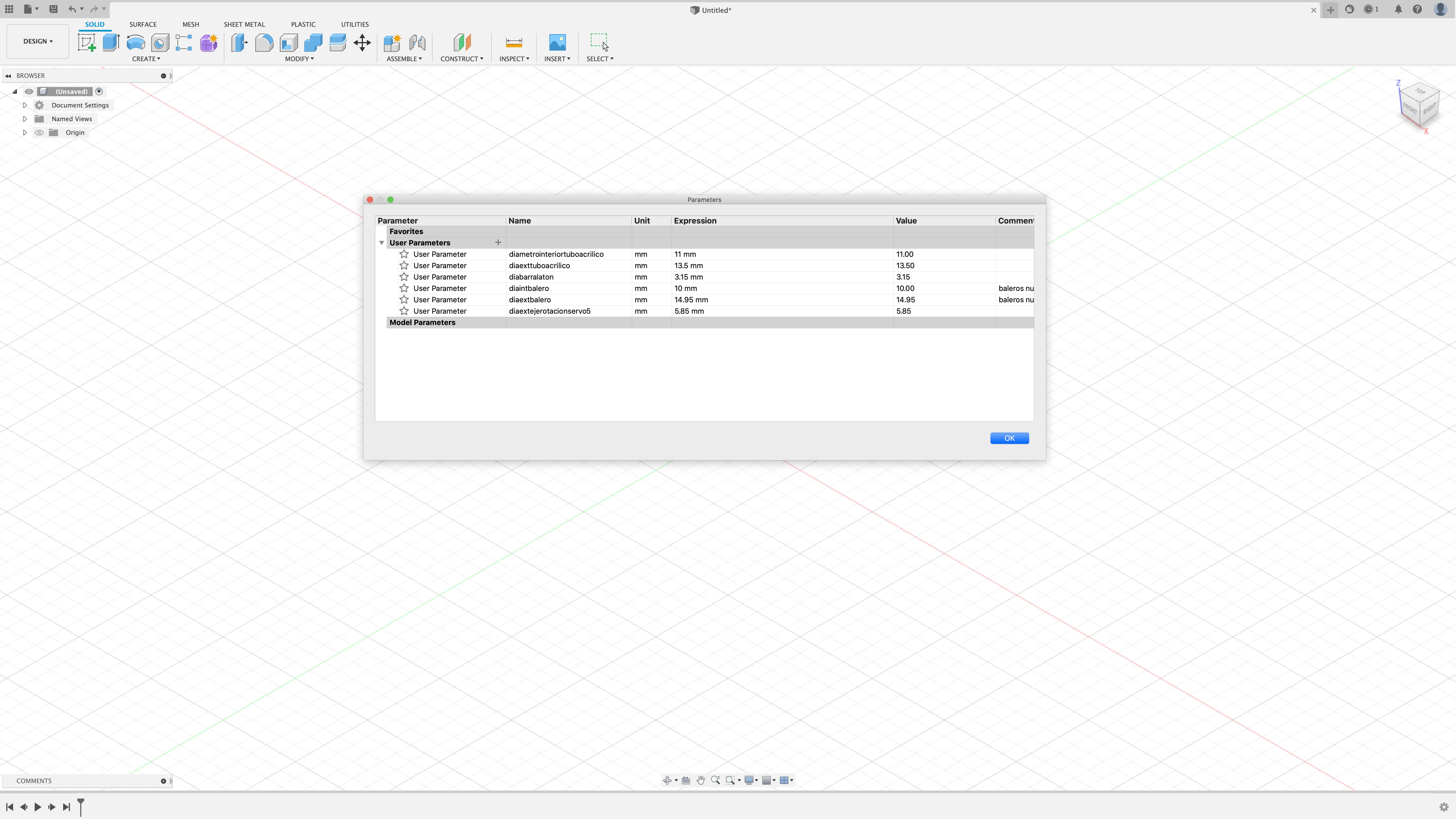

Everything is model in fusion, so i

can know in advance the lengths, and where the components fix,

but when you have all the pieces in person we can be sure if

everything goes well or maybe need some adjustments.

What have you learned?

That the assignments build together the final project, and if I know what´s going to be my final project I could work in the components of my final project from the beggining, but I change my mind so many times, and it was because the lockdown comes just right when we where starting the Academy and resume the activities in the labalmost 2 years later.

but I learned so great things about

programming, electronics,new software like fusion360 and

how everything is connected.

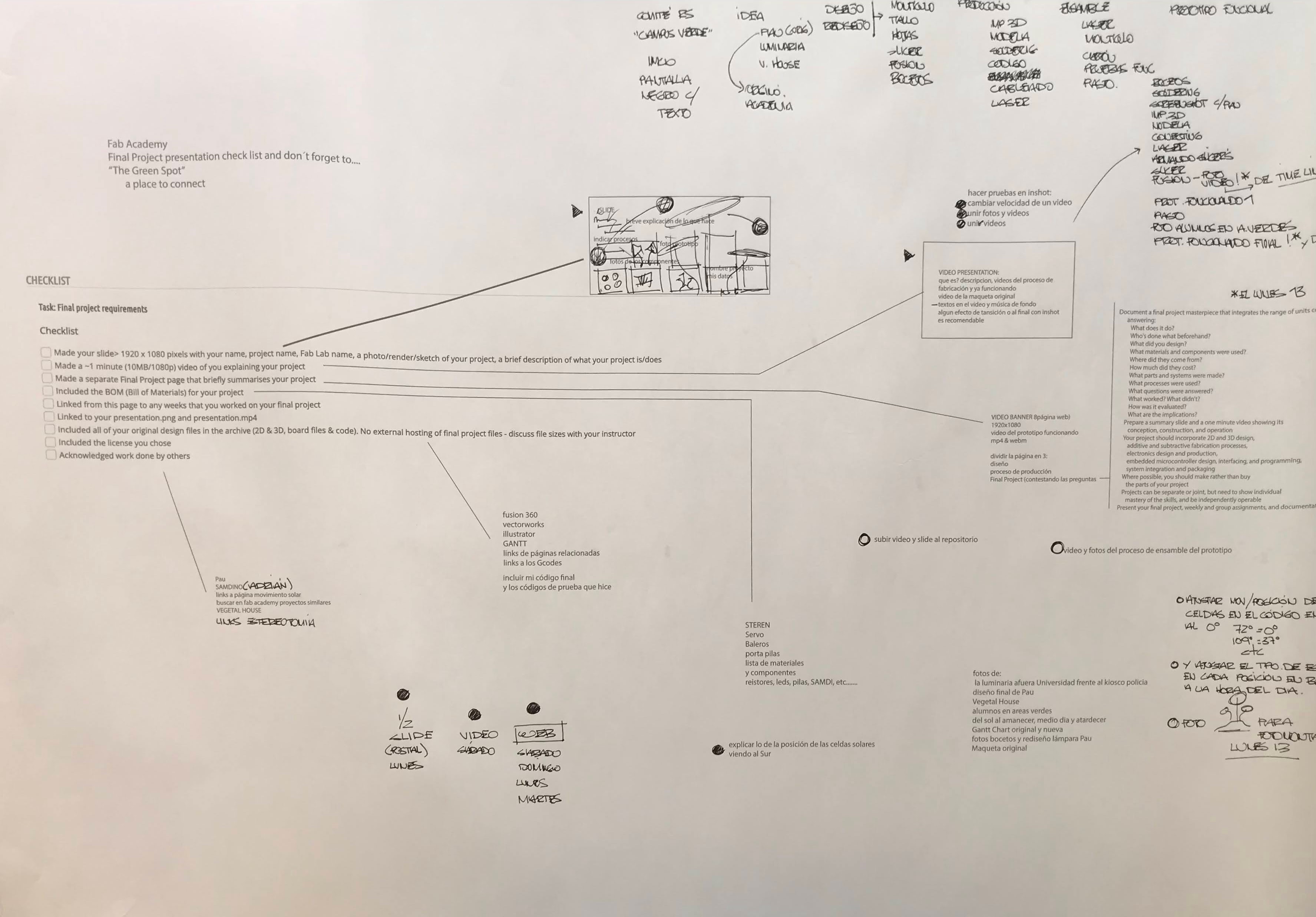

investigation

a place to re-connect

production

a place to re-connect

electronics

a place to re-connect

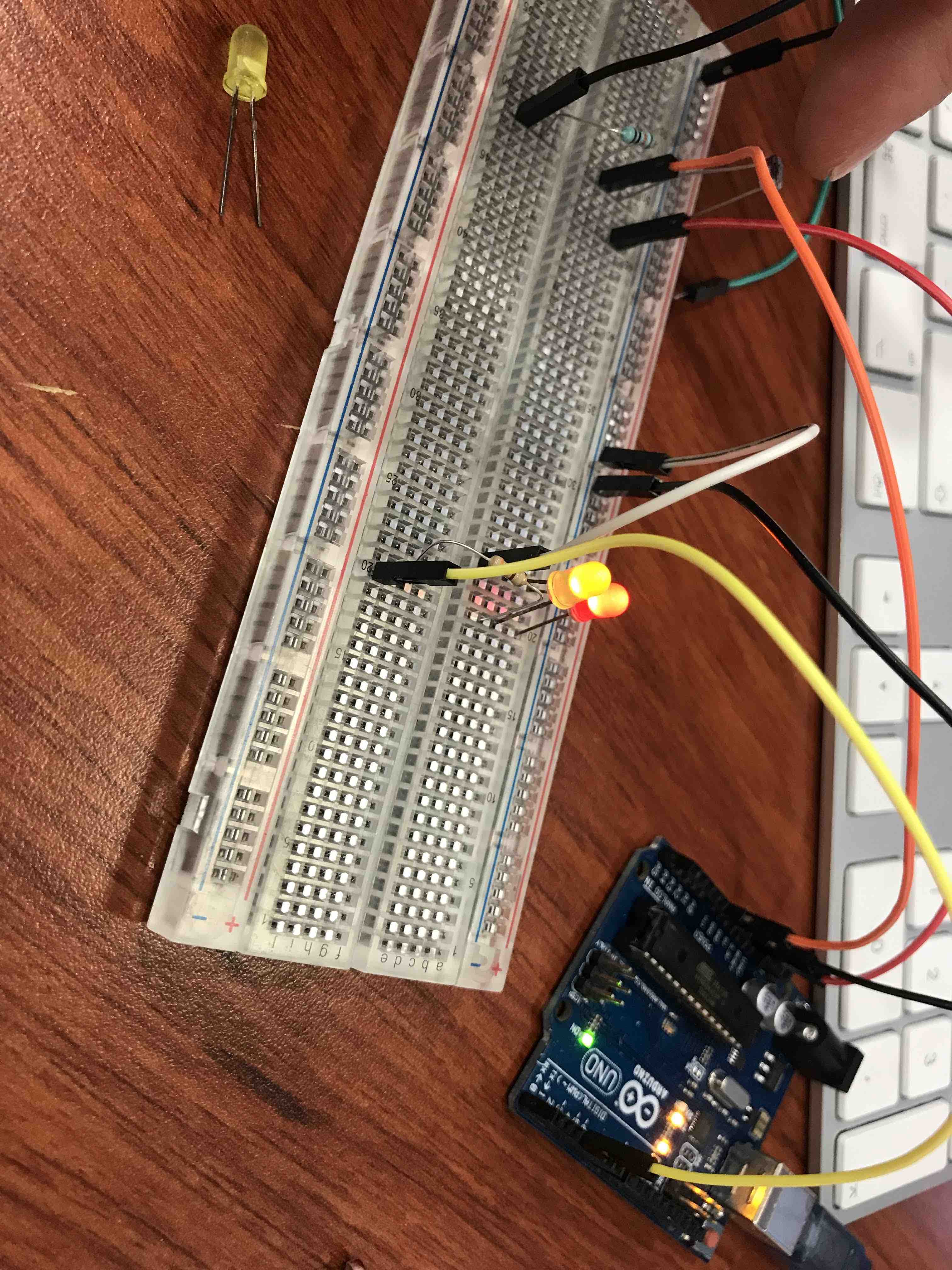

first Ilook for the schematics of Arduino for the Servo and the LEDS with LDR to start to do some programming and test the variables of the code

prototype

a place to re-connect