Arduino Uno,

LCD display, breadboard, Dupont cables, Code, Eagle, copper

plate (for the PCB), Modela machine, Welding, microcomponents,

SAMD11

First I weld the set

of jumpers to the LCD display

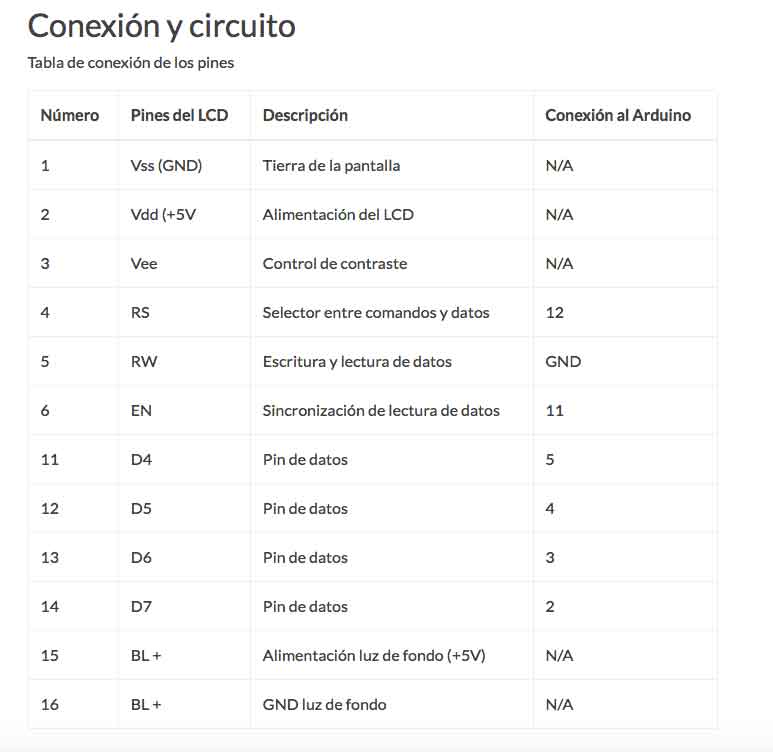

Number, Pin,

Decription and connection to Arduino

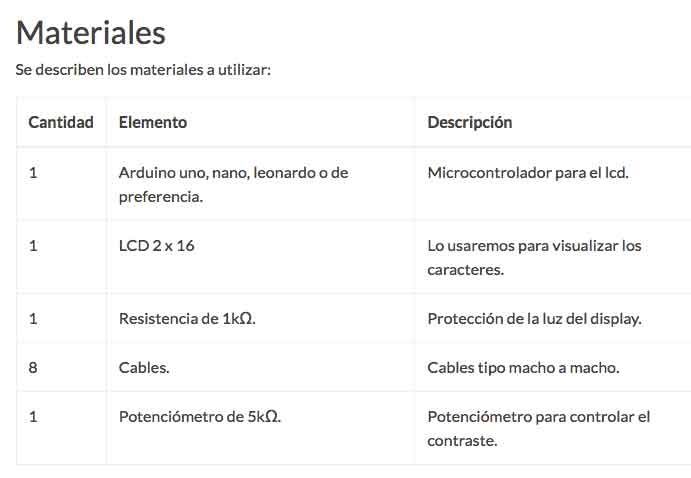

List of materials

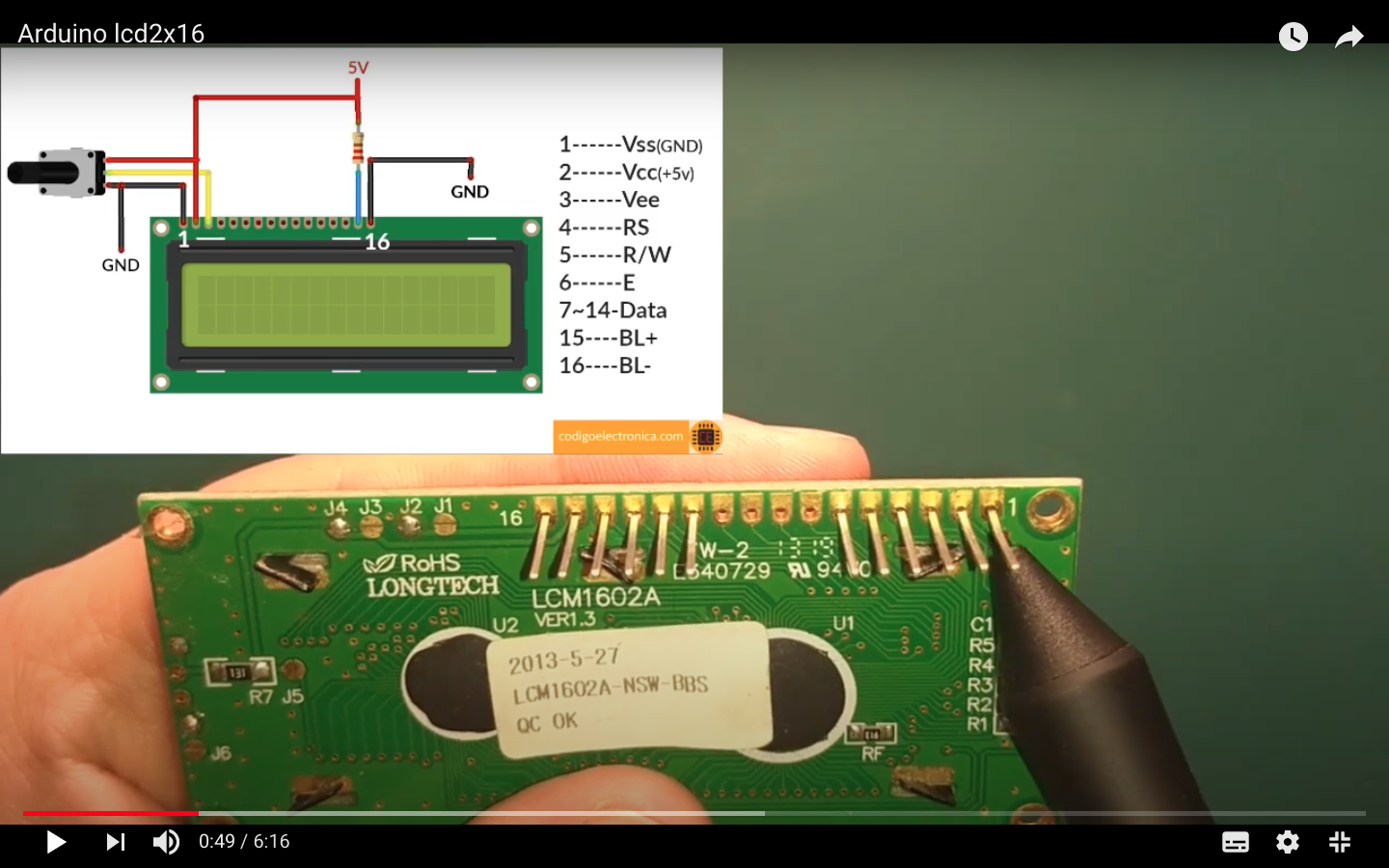

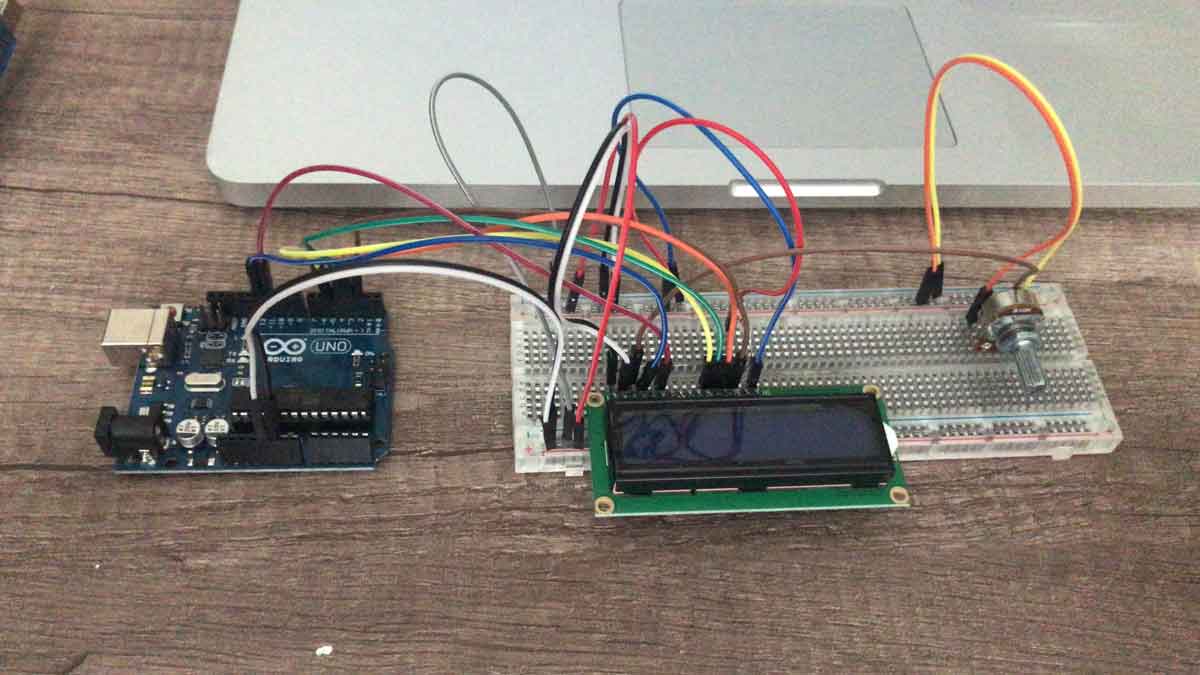

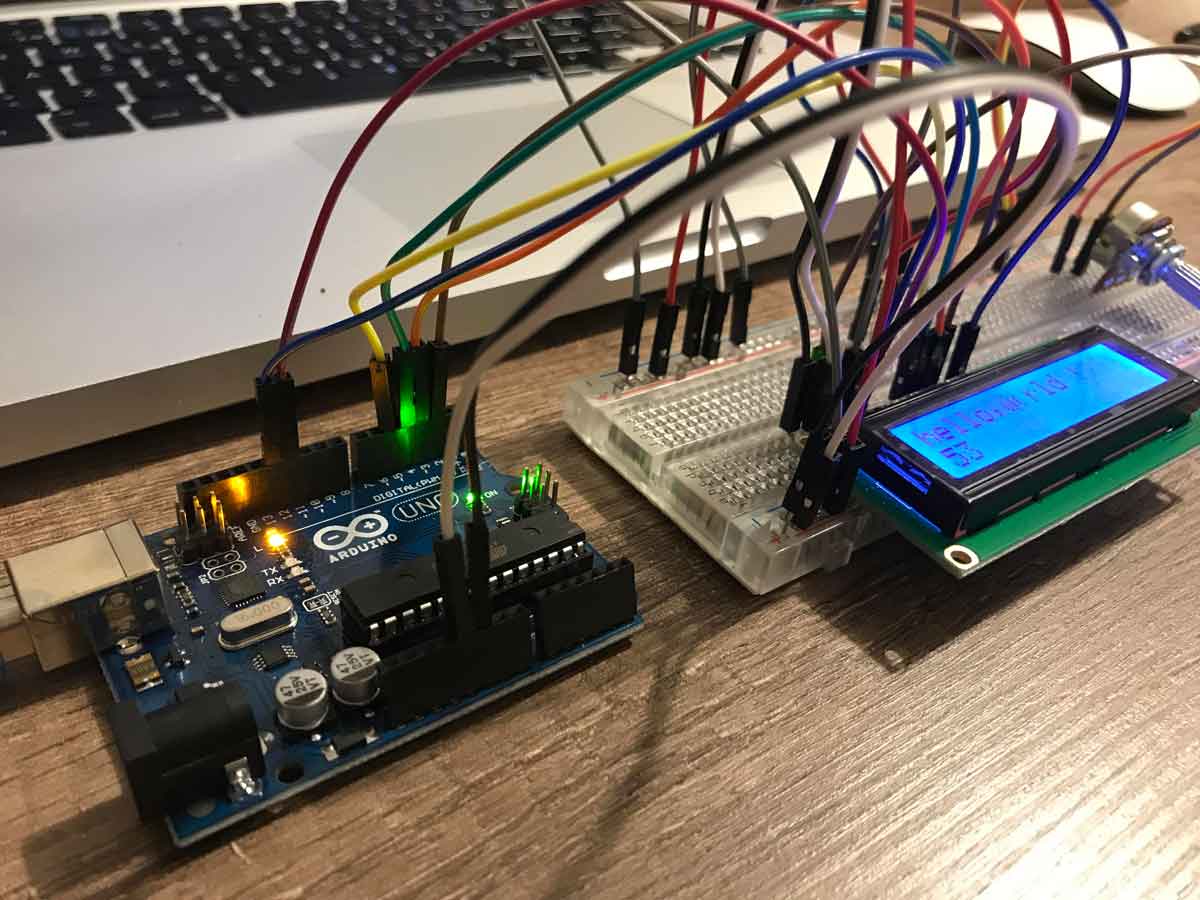

Connections between

the arduino and the breadboard to connect the LCD disply and the

potentiometer

First connections:

ground and VCC

All the other

connections following the schematic above

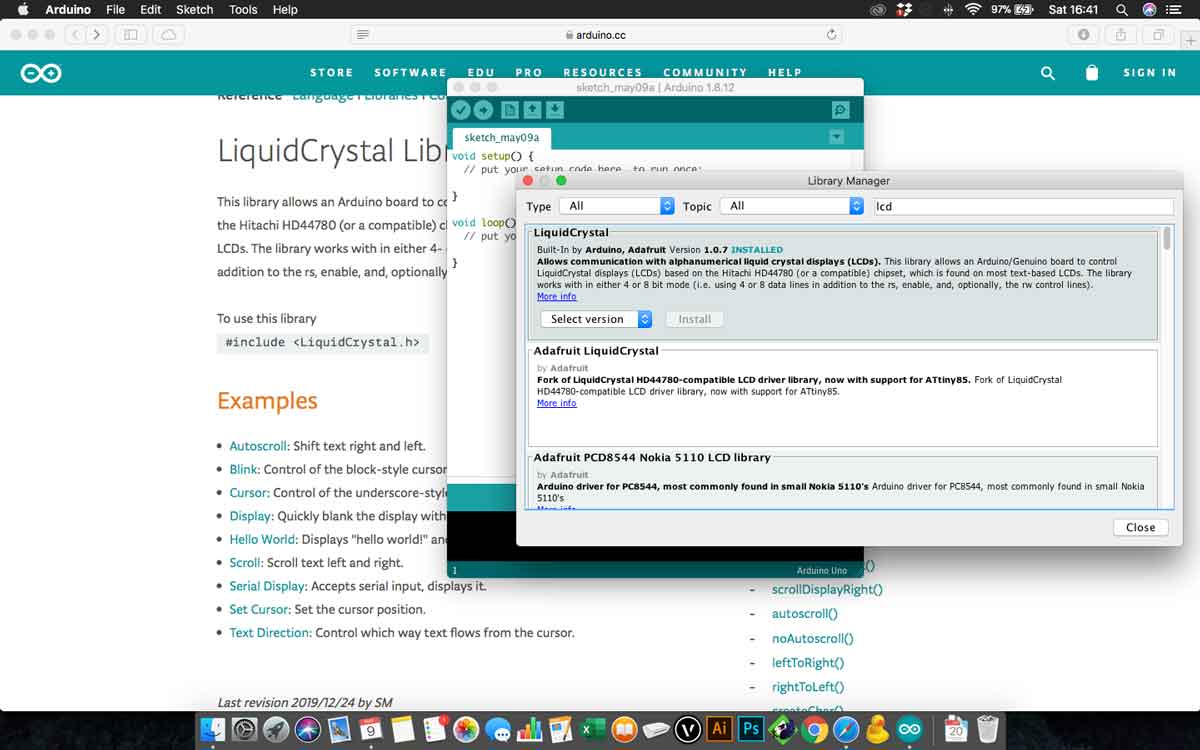

Then I need to add

some libraries to the Arduino

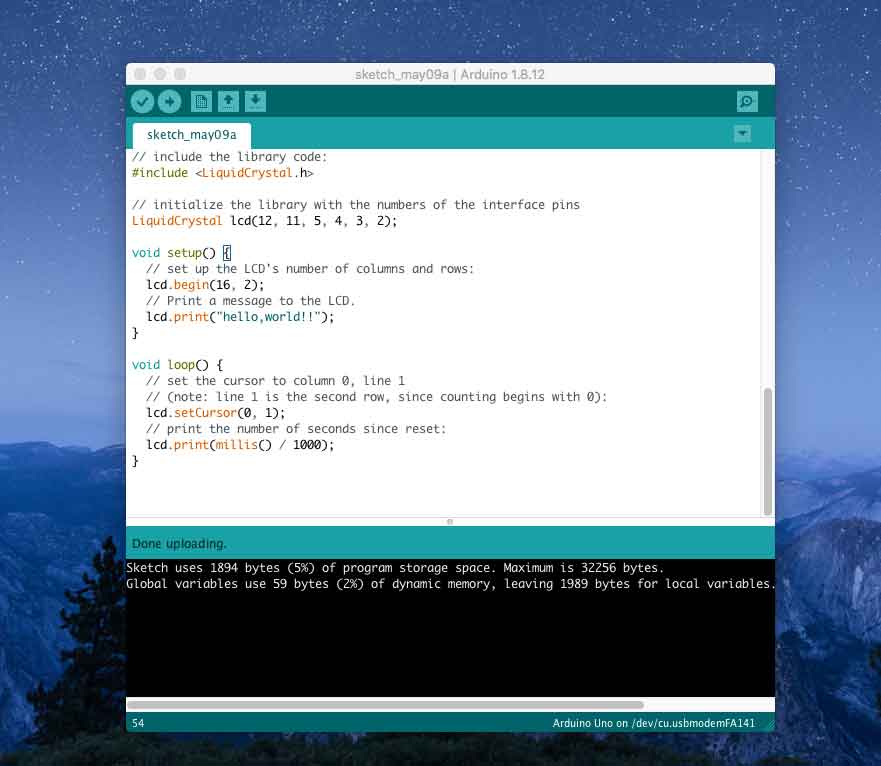

And this is the

original code i use to tst the LCD display, later i change some

lines to adapt it to my future project.

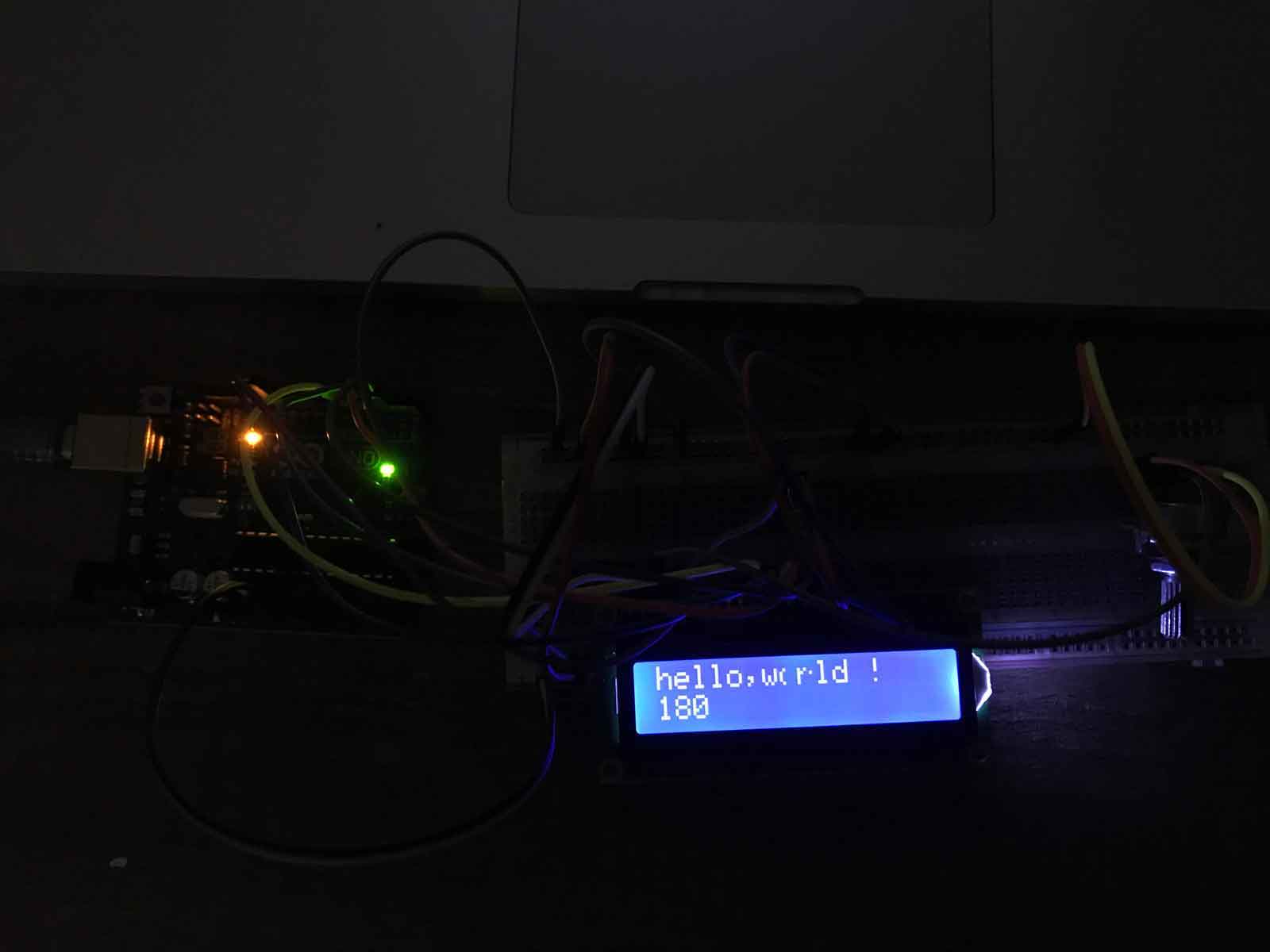

Every seems fine, the

code works properly and the LCD shows the text, with the

potentiometer you can adjust the contrast of the display

almost 2 years later, when we return to the lab.....

and the link to the group assignment is: FabLabCDMX.

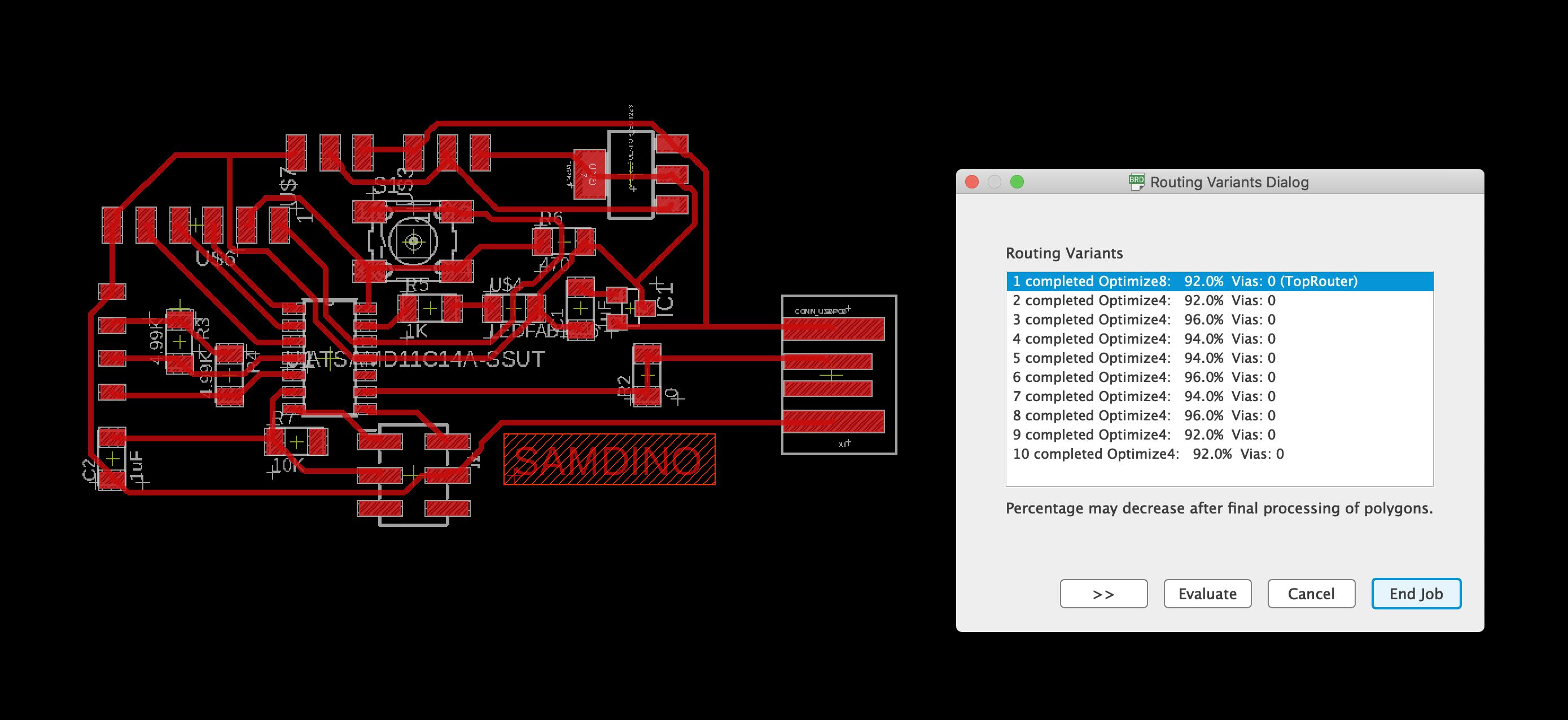

The original

SAMDINO, I use this design as the initial design, then I

change some components and made a new schematic in order to

fit my Final Project rqueriments

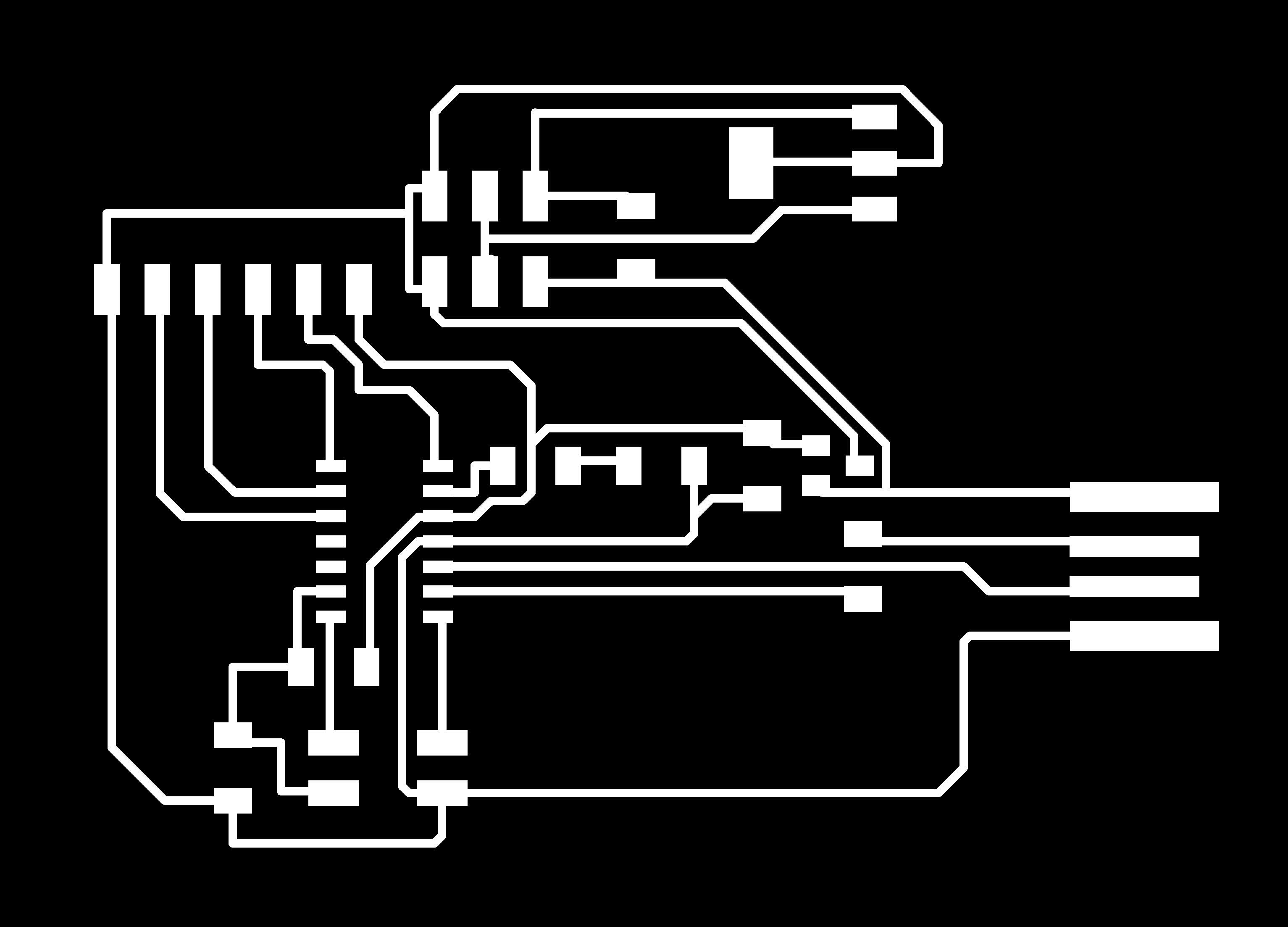

A PNG image of

my PCB, we need to export the image in this format to open

it in MODS

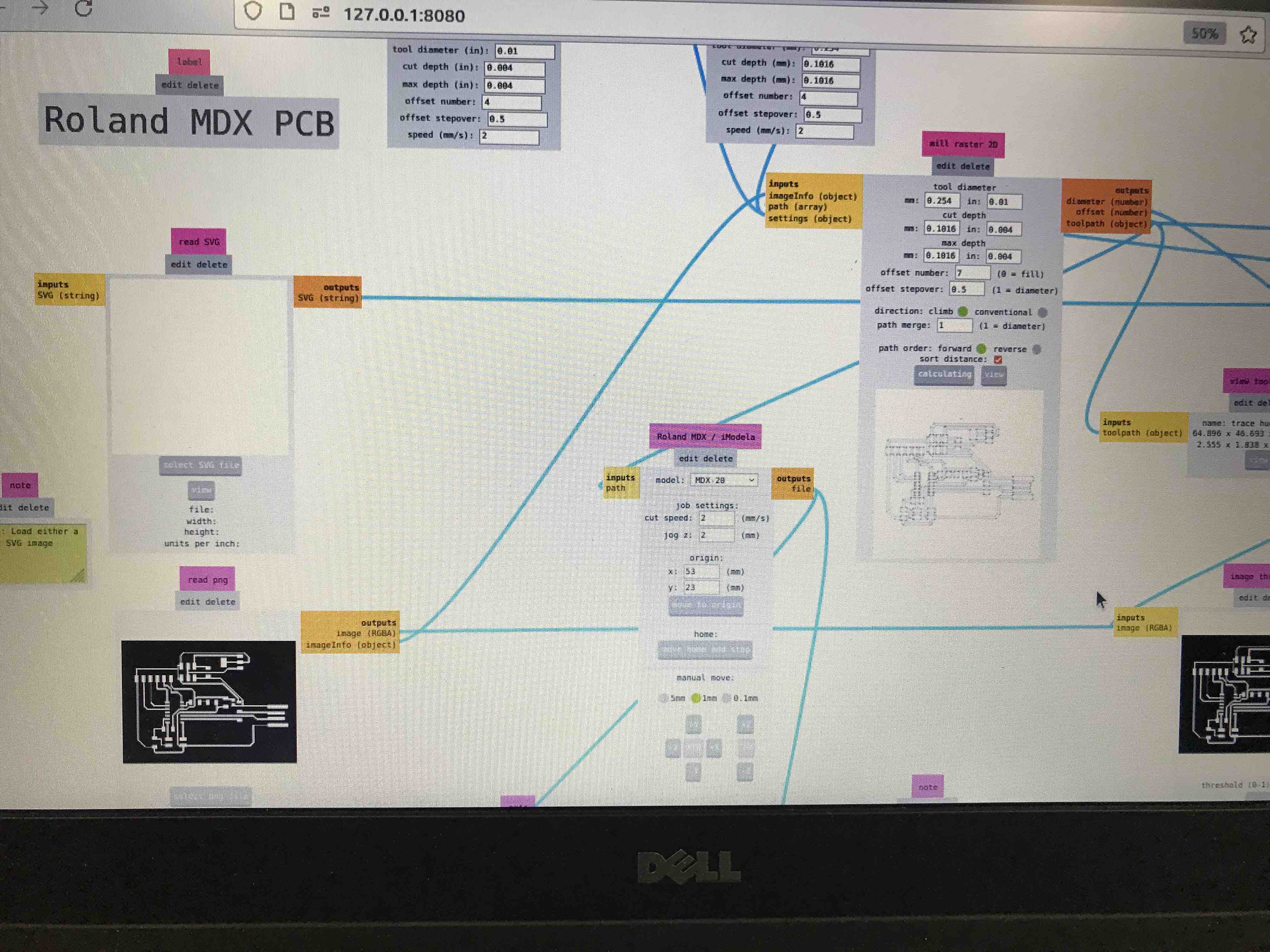

I use MODS to

set up the Modela for milling my PCB

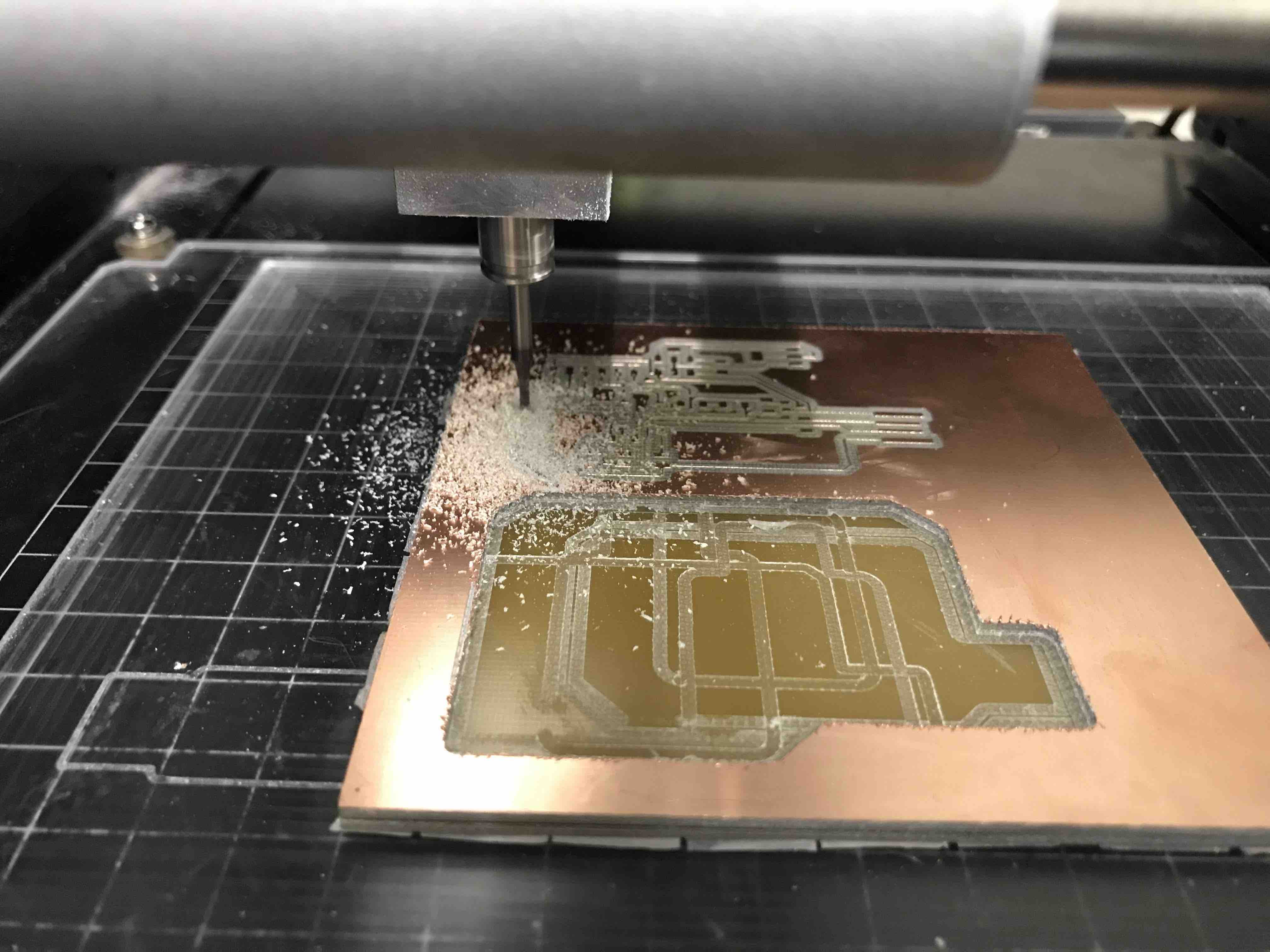

The Modela

machining my PCB in the copper plate

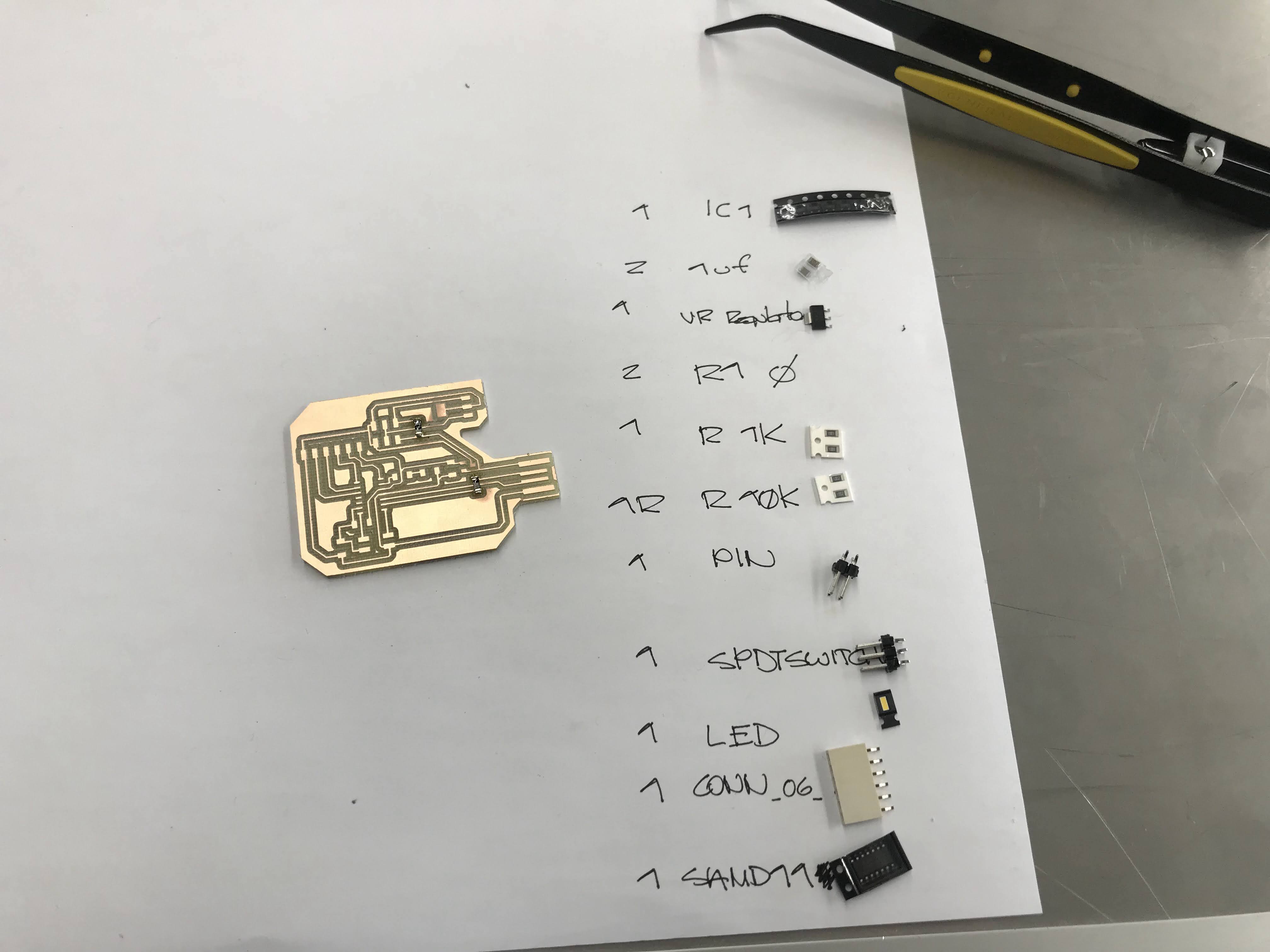

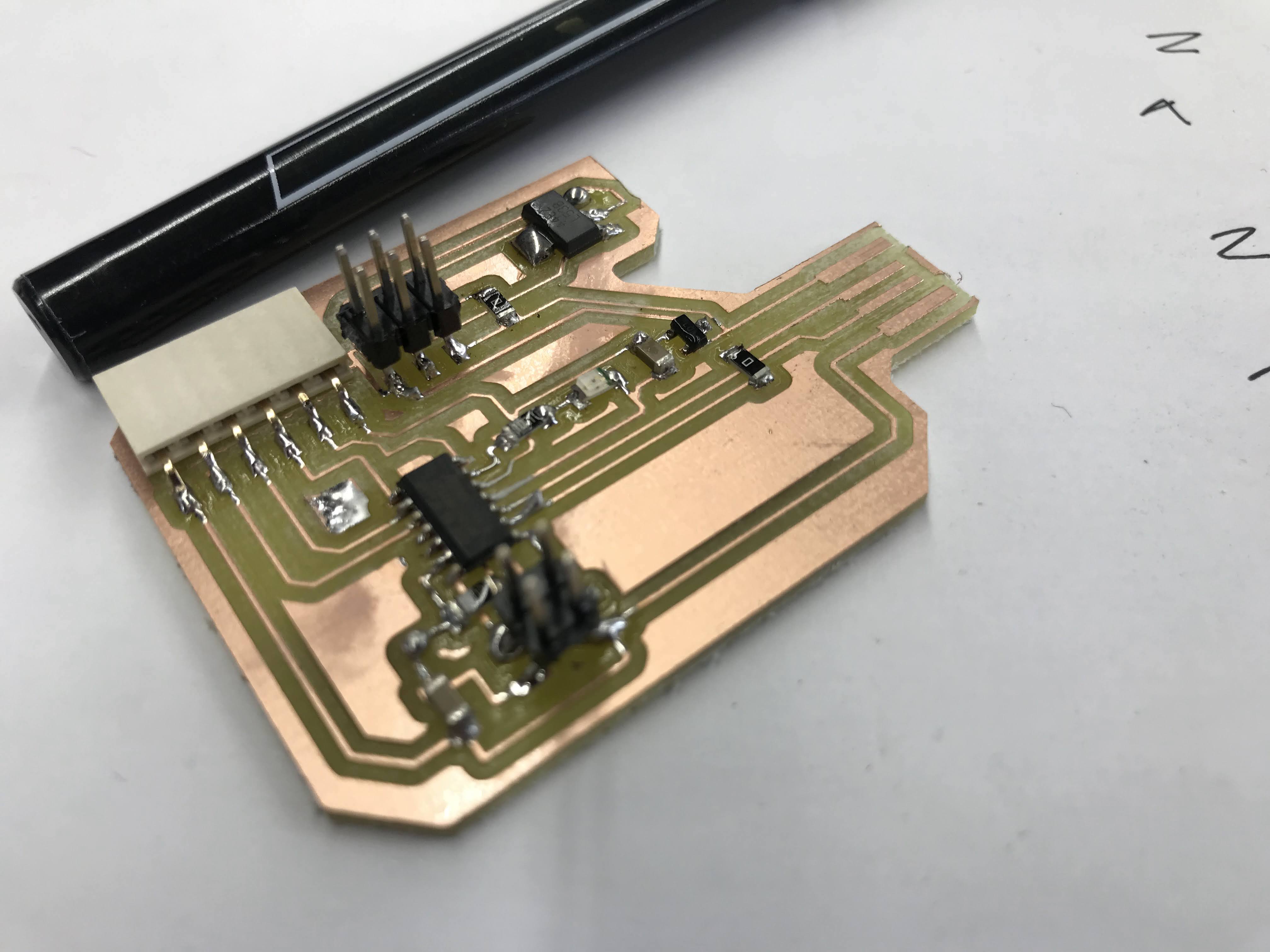

My PCB and the

components I need to weld it

For this

assignment I want to blink the PCB led to check comms, then

the servo rotate and the led will go ON and OFF (HIGH and

LOW)

the servo only

rotates from 0 to 180º VS a step motor that rotates 360º but

for assignment purposes I will use the servo, so, in this

tst code first the red led will turn ON and OFF, then the

servo moves into 3 different positions and then the wearable

LED (lamp) will turn ON, OFF and ON again

Here is the

code and a video

int

led = 2;

int servo = 8;

int angle;

int pwm;

int lamp = 5;

void setup()

{

pinMode(servo, OUTPUT);

pinMode(led, OUTPUT);

pinMode(lamp, OUTPUT);

}

void loop ()

{

//Probe PCB board function

digitalWrite(led,HIGH);

delay(1000);

digitalWrite(led, LOW);

delay(1000);

//Move servomotor

servoPulse(servo, 15);

delay(1000);

servoPulse(servo, 120);

delay(2000);

servoPulse(servo, 180);

delay(4000);

//turn On & turn off lamp

digitalWrite(lamp, HIGH);

delay(500);

digitalWrite(lamp, LOW);

delay(1500);

digitalWrite(lamp, HIGH);

delay(500);

}

void servoPulse (int servo, int angle)

{

pwm = (angle*11) + 500; // Convert angle to microseconds

digitalWrite(servo, HIGH);

delayMicroseconds(pwm);

digitalWrite(servo, LOW);

delay(50); // Refresh cycle of servo

}

int servo = 8;

int angle;

int pwm;

int lamp = 5;

void setup()

{

pinMode(servo, OUTPUT);

pinMode(led, OUTPUT);

pinMode(lamp, OUTPUT);

}

void loop ()

{

//Probe PCB board function

digitalWrite(led,HIGH);

delay(1000);

digitalWrite(led, LOW);

delay(1000);

//Move servomotor

servoPulse(servo, 15);

delay(1000);

servoPulse(servo, 120);

delay(2000);

servoPulse(servo, 180);

delay(4000);

//turn On & turn off lamp

digitalWrite(lamp, HIGH);

delay(500);

digitalWrite(lamp, LOW);

delay(1500);

digitalWrite(lamp, HIGH);

delay(500);

}

void servoPulse (int servo, int angle)

{

pwm = (angle*11) + 500; // Convert angle to microseconds

digitalWrite(servo, HIGH);

delayMicroseconds(pwm);

digitalWrite(servo, LOW);

delay(50); // Refresh cycle of servo

}

PRODUCT DISPLAY

for our students

projects