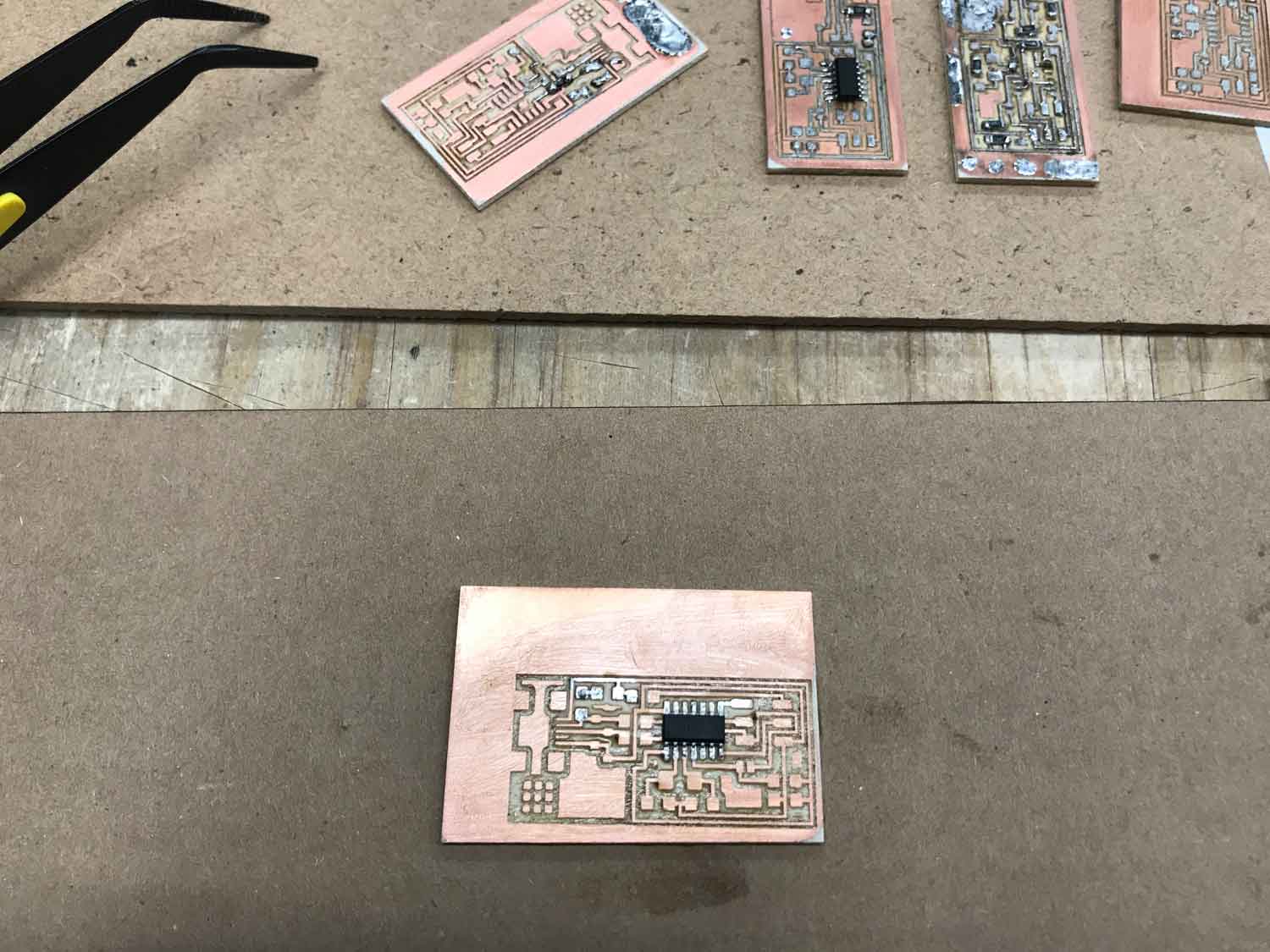

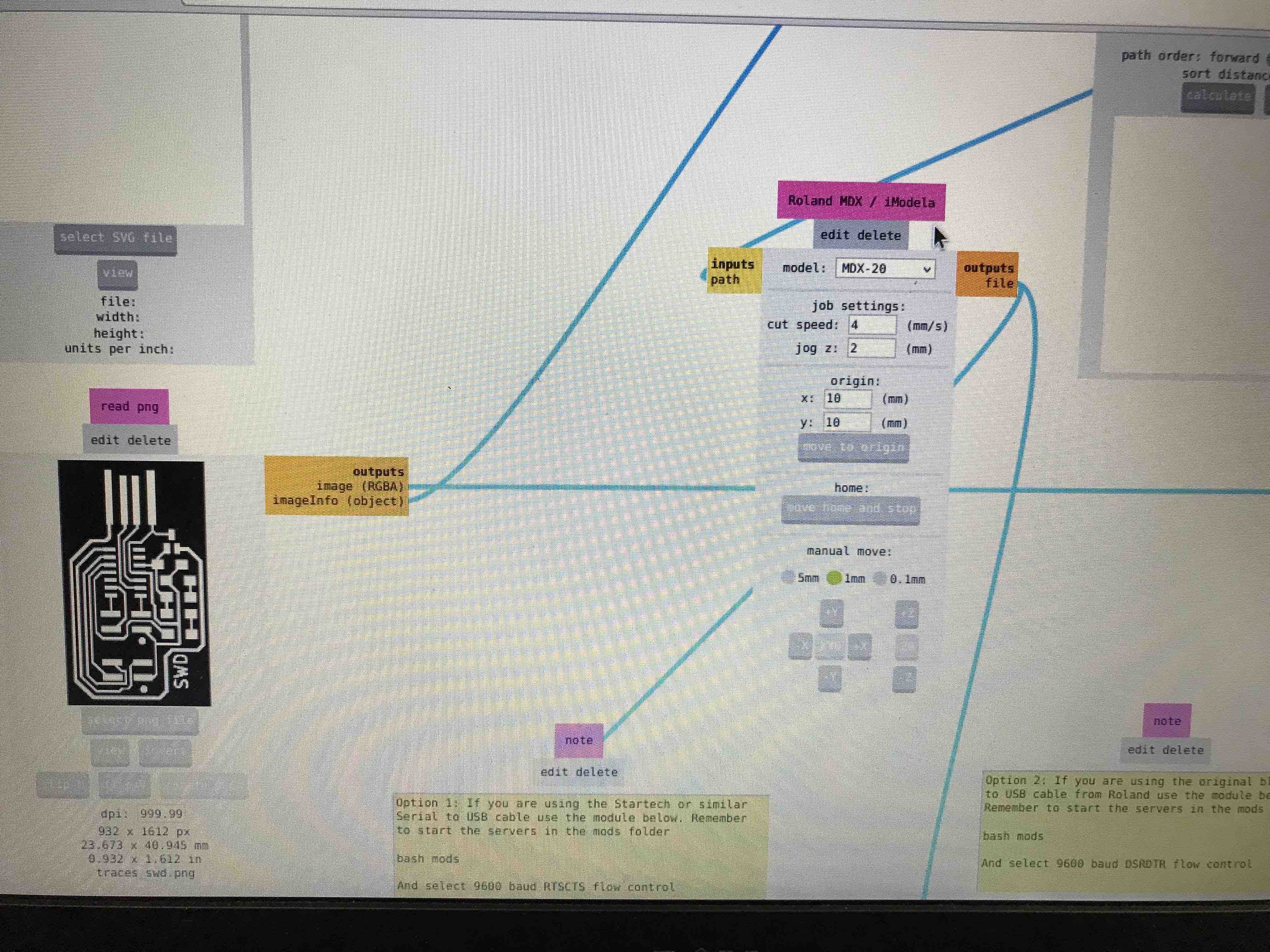

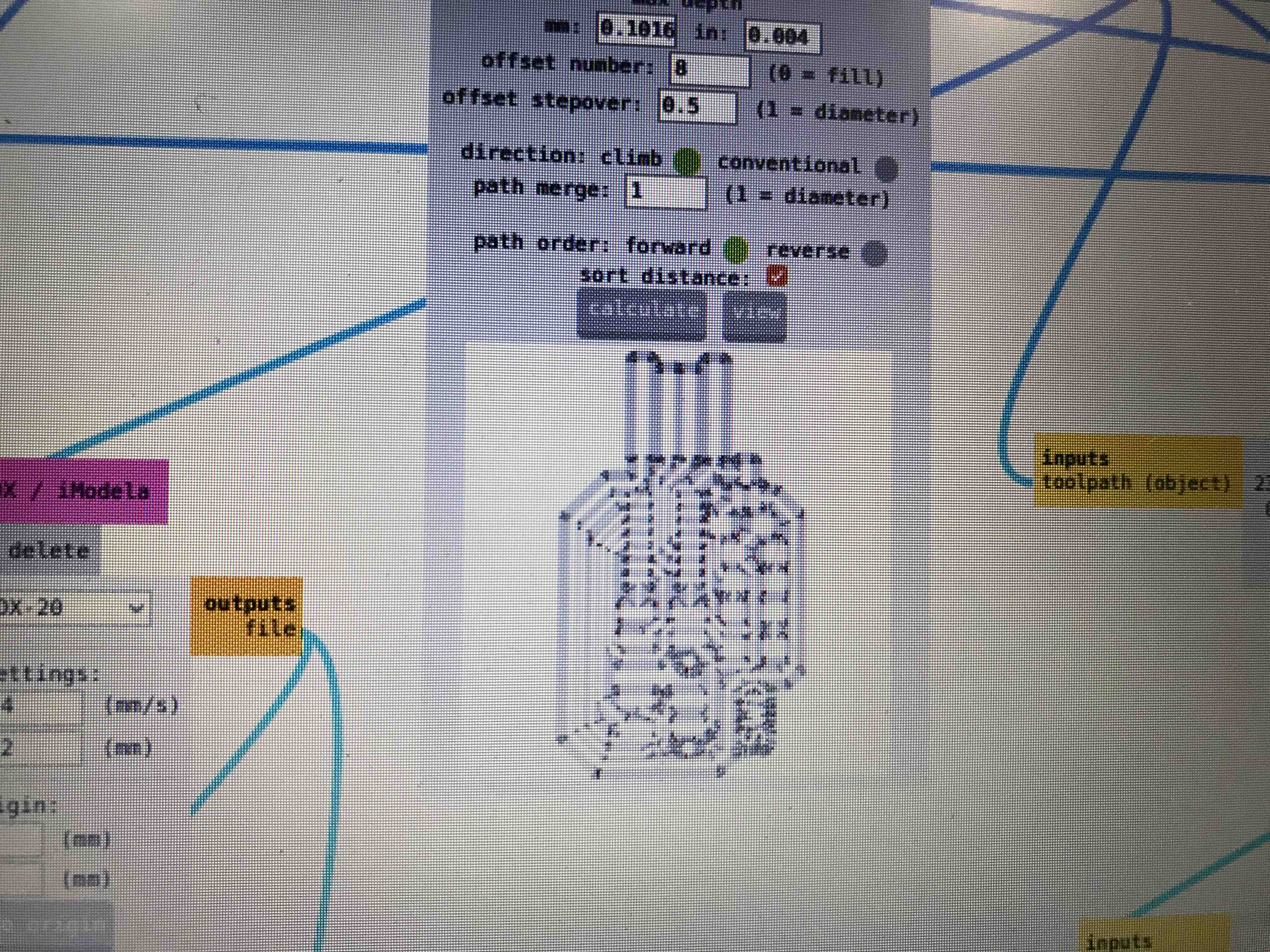

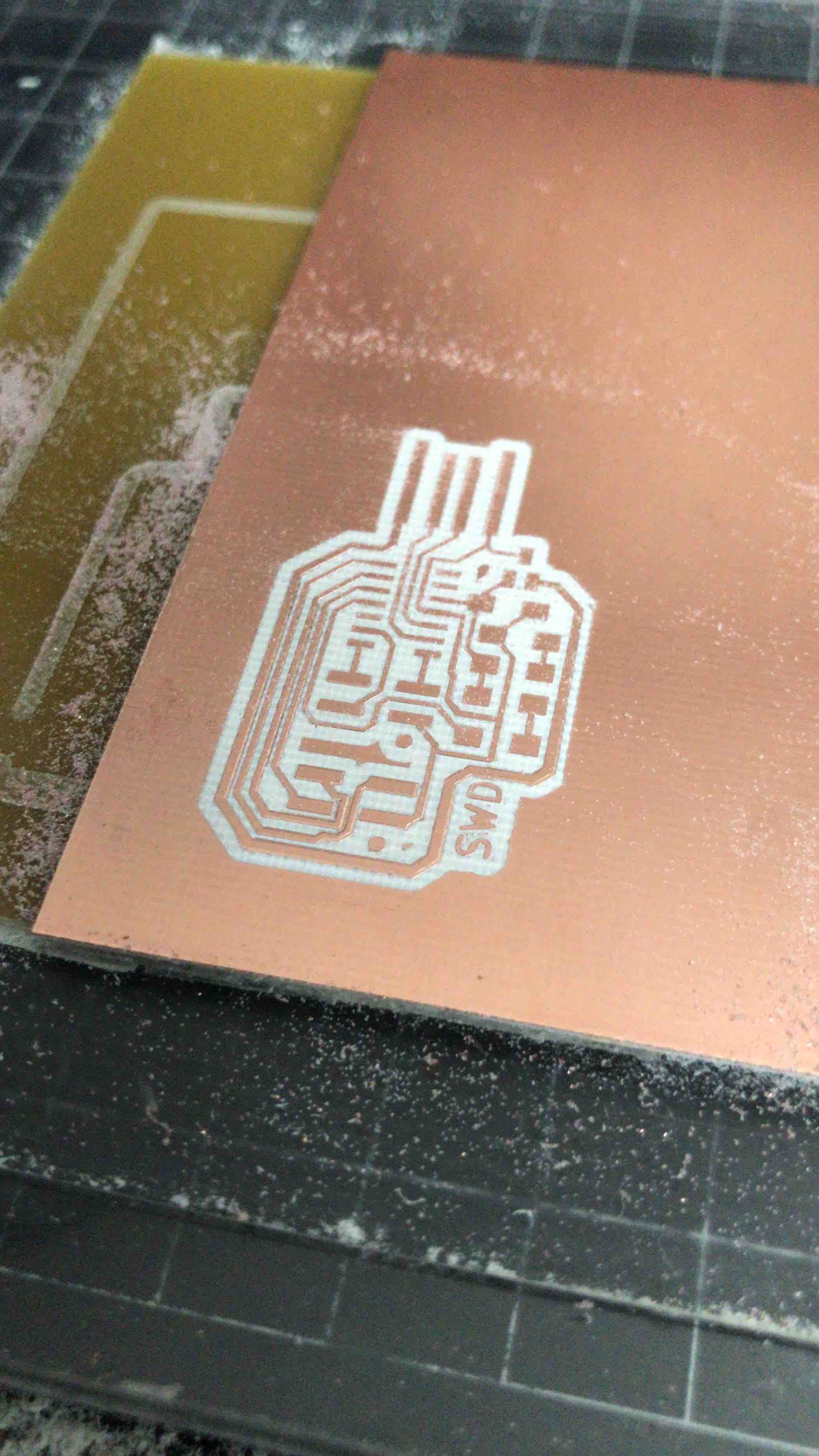

electronics production

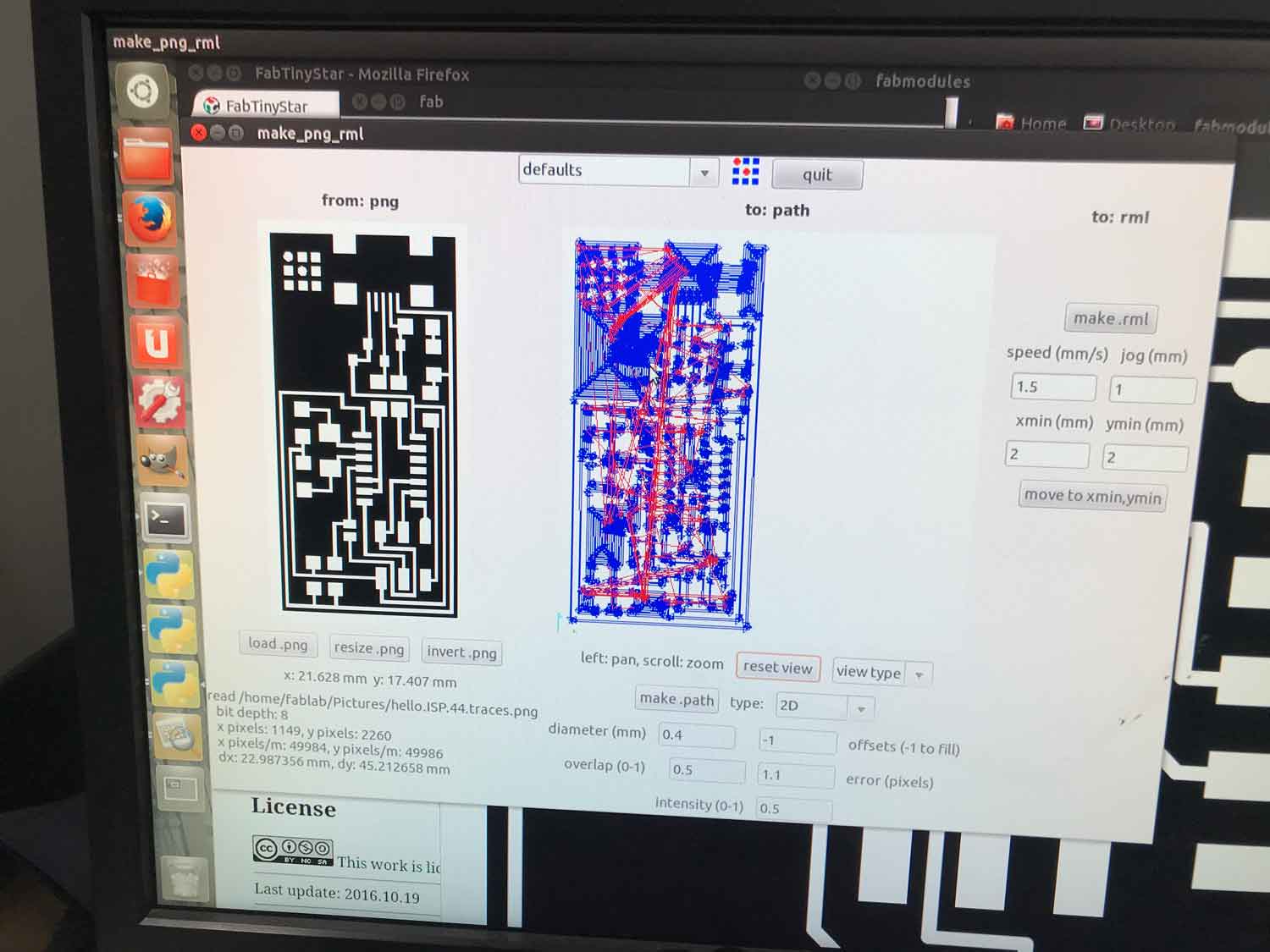

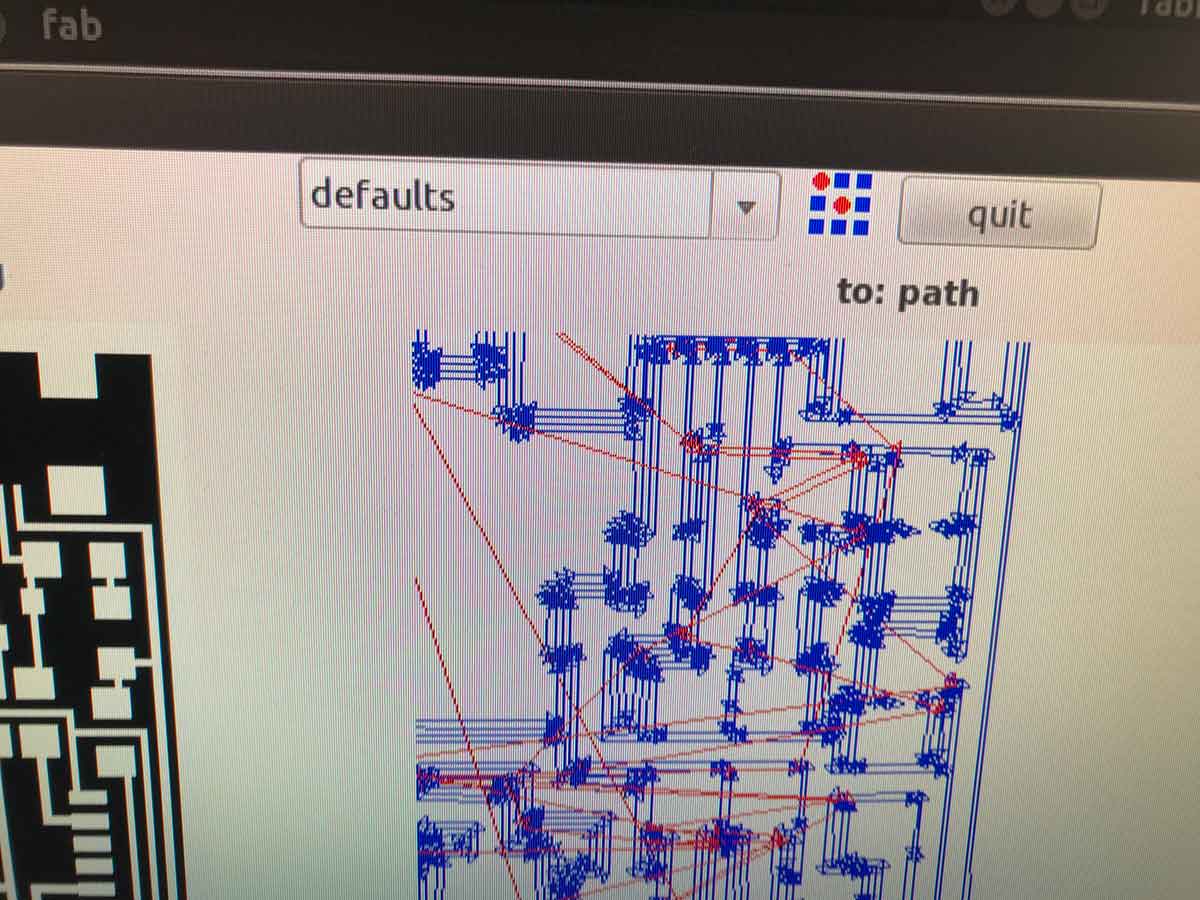

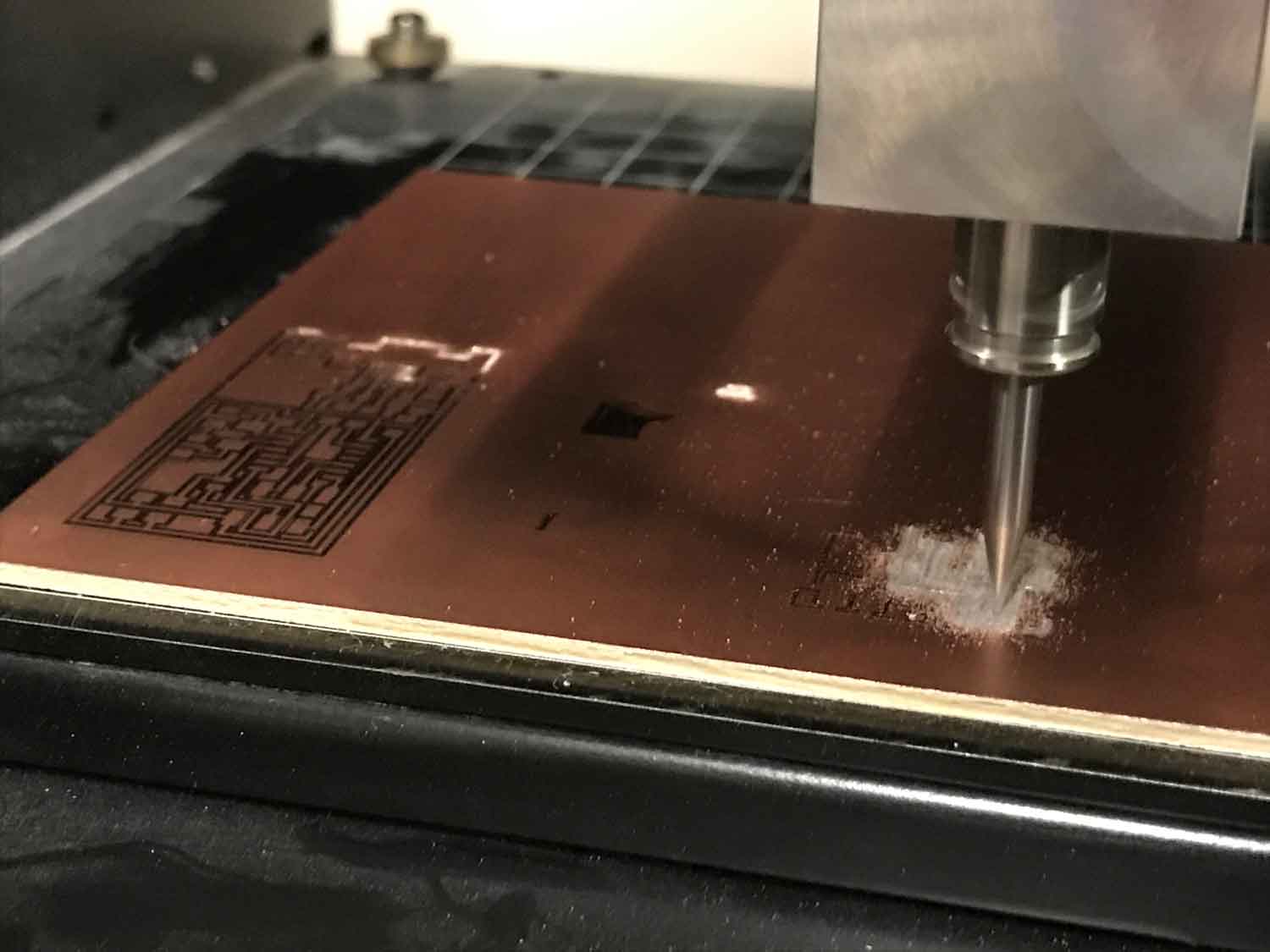

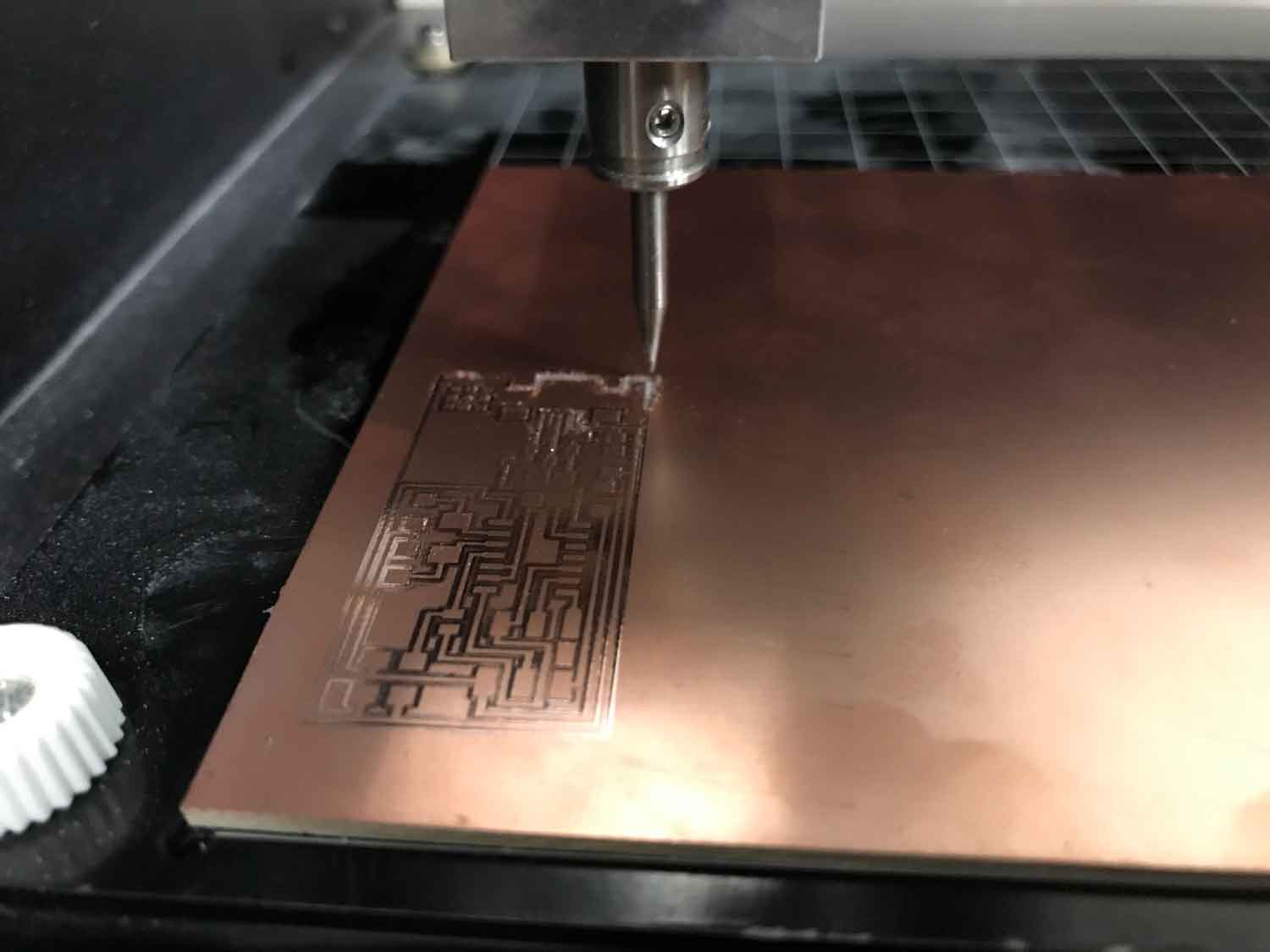

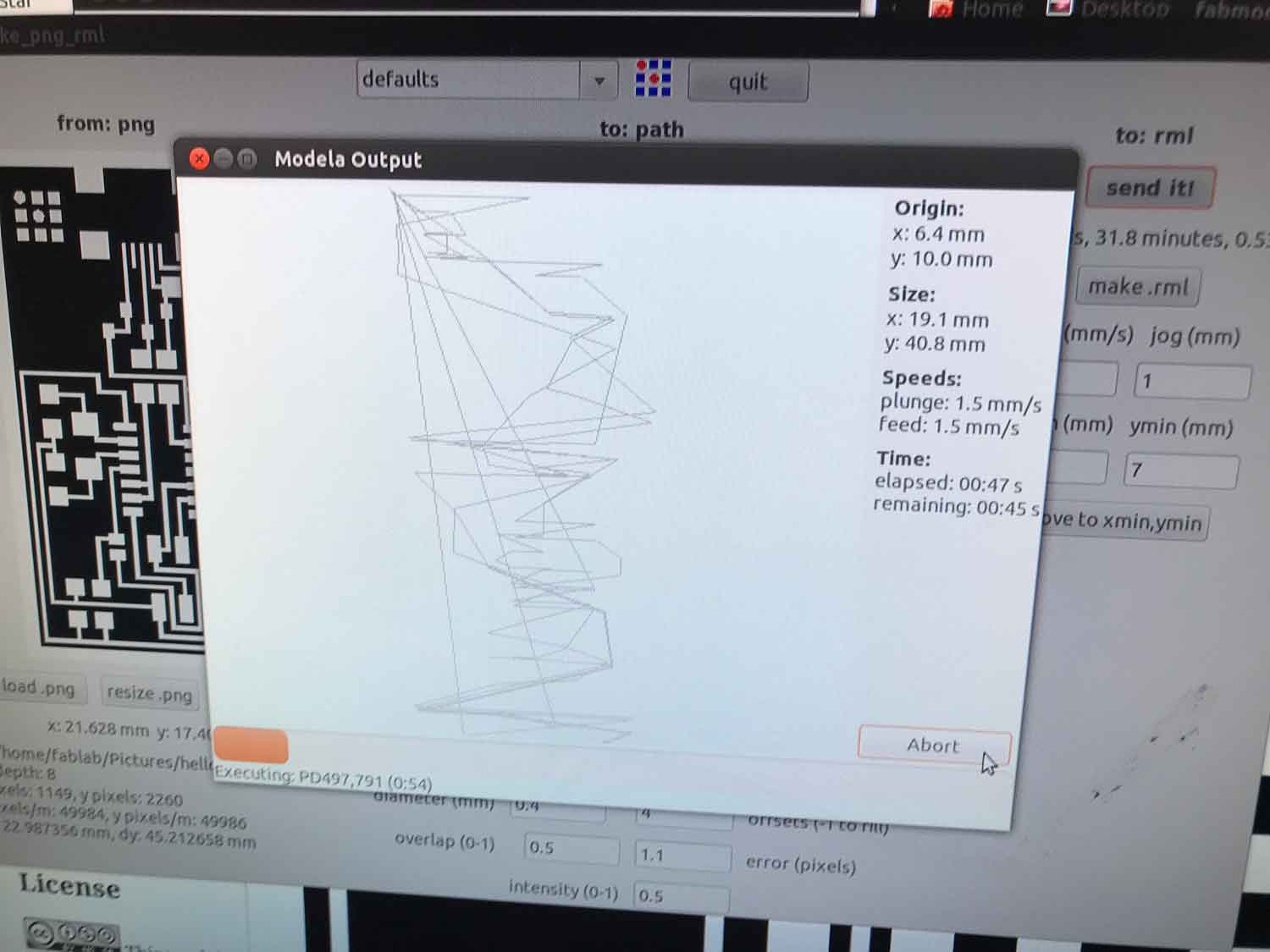

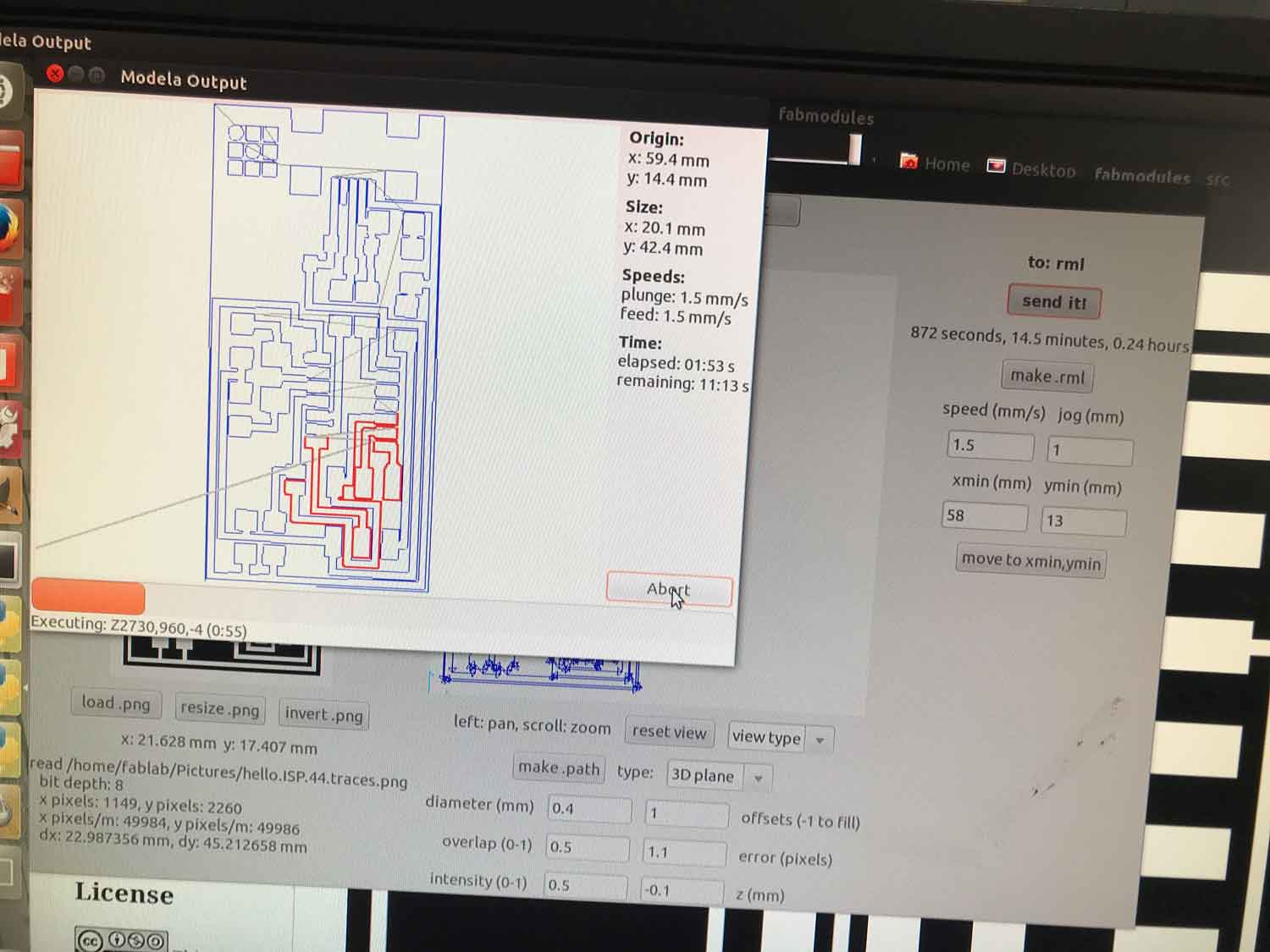

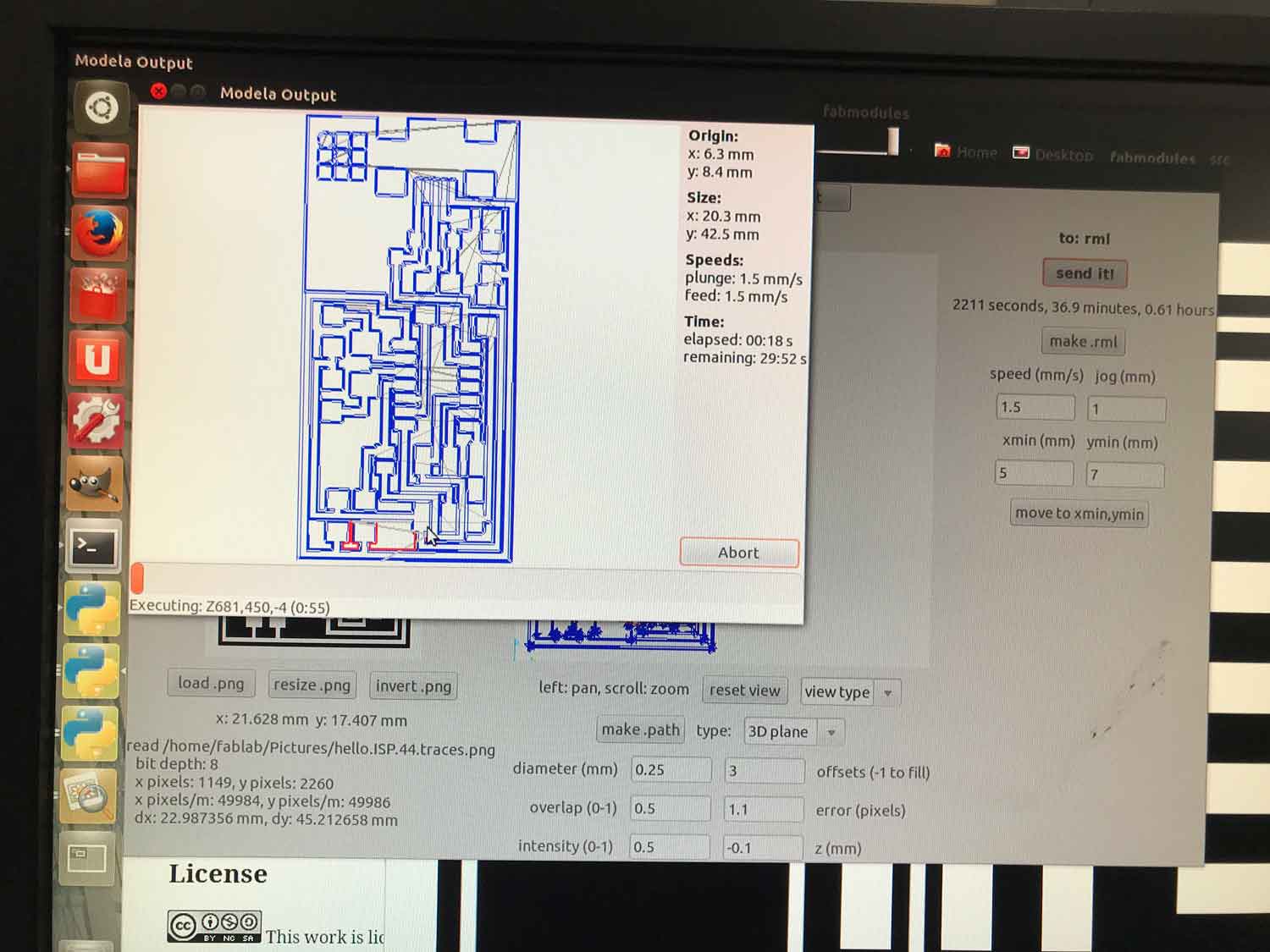

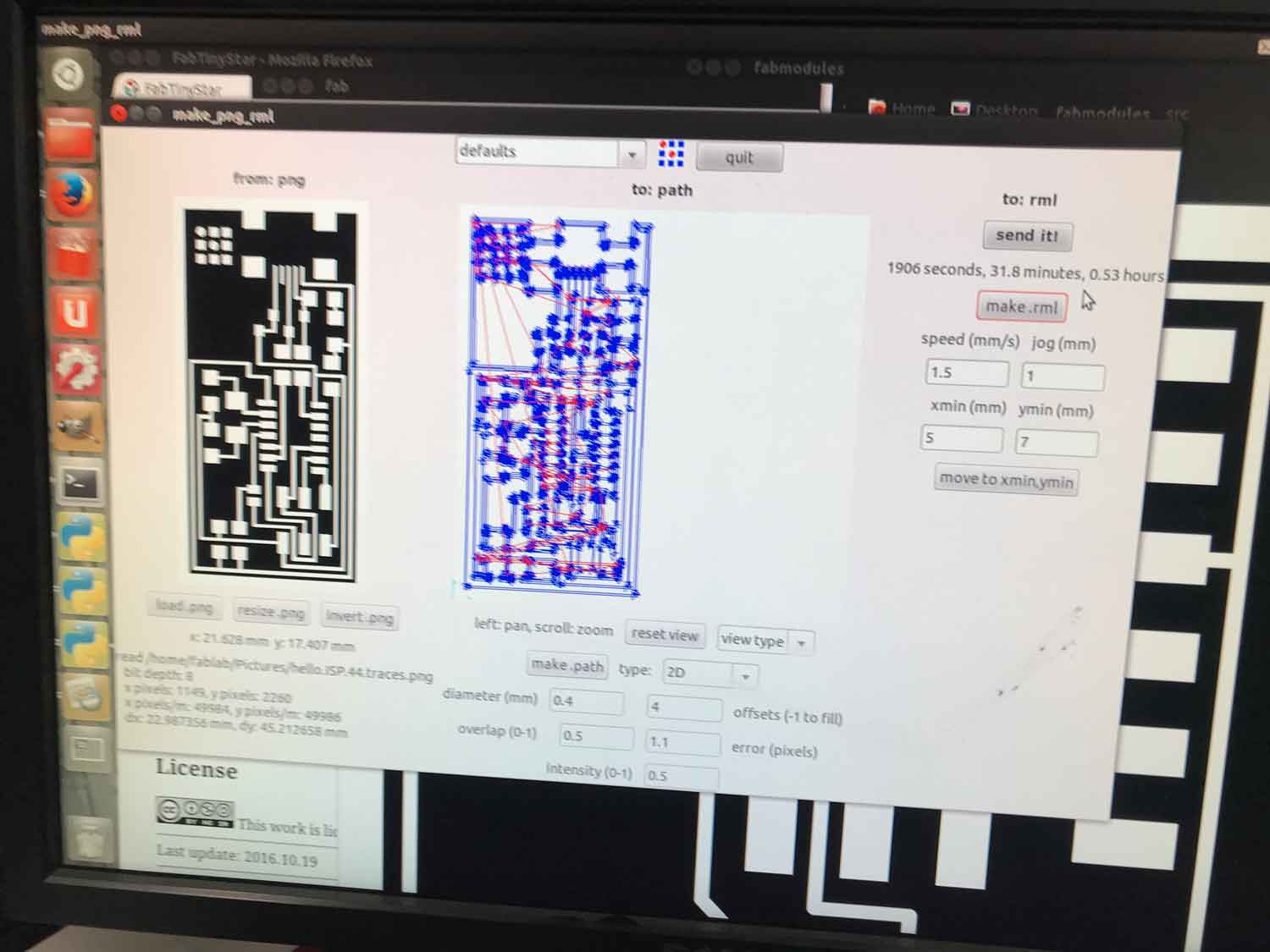

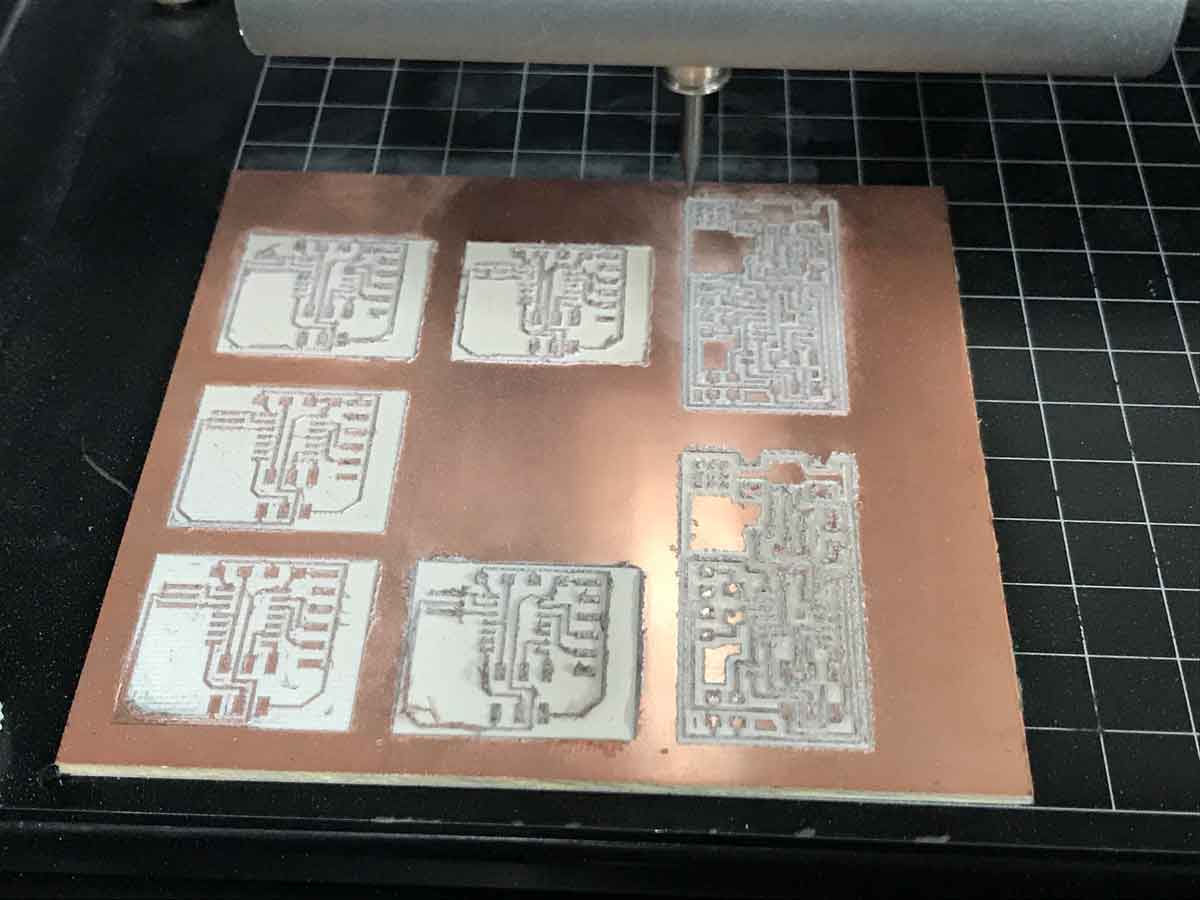

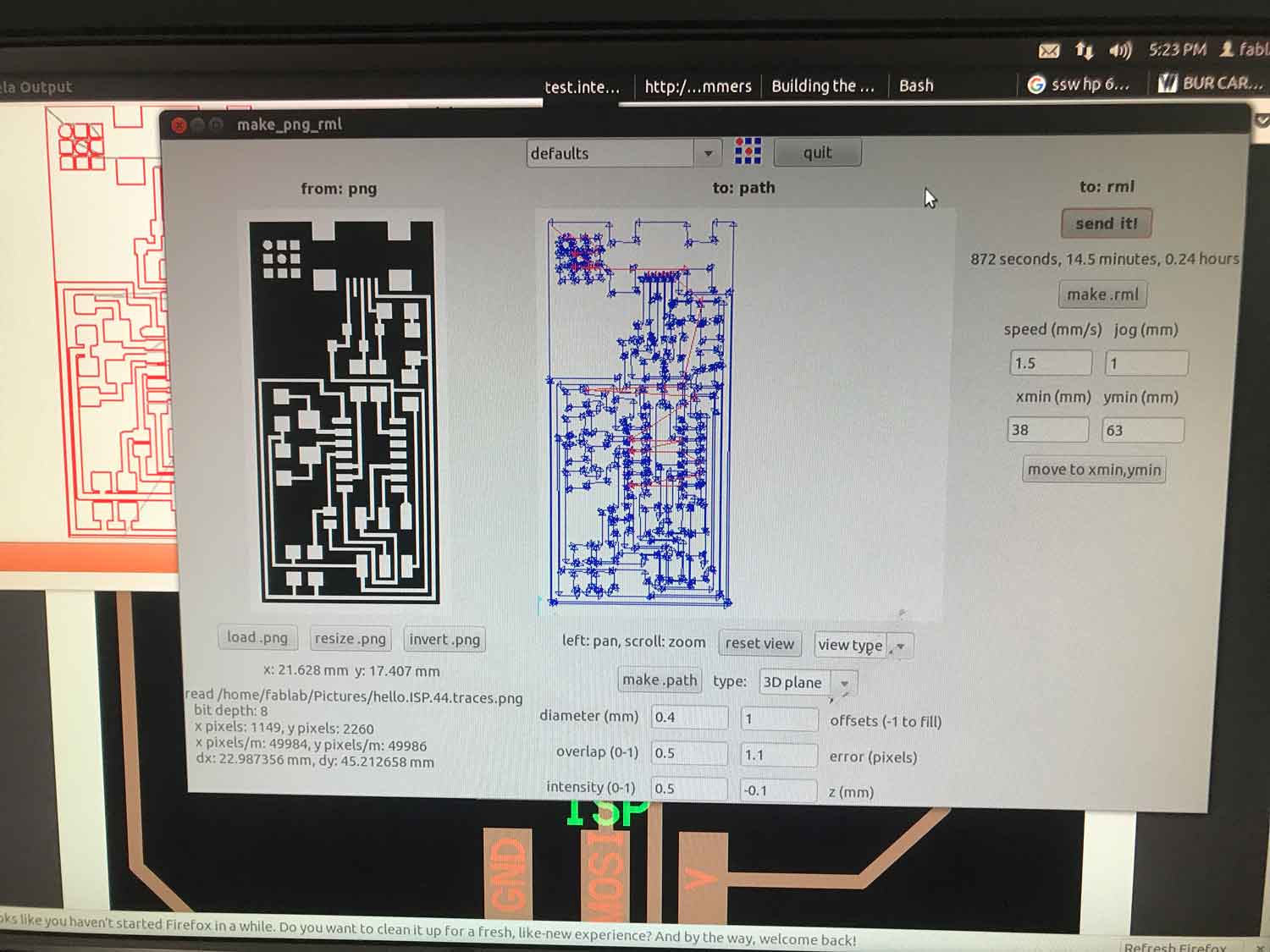

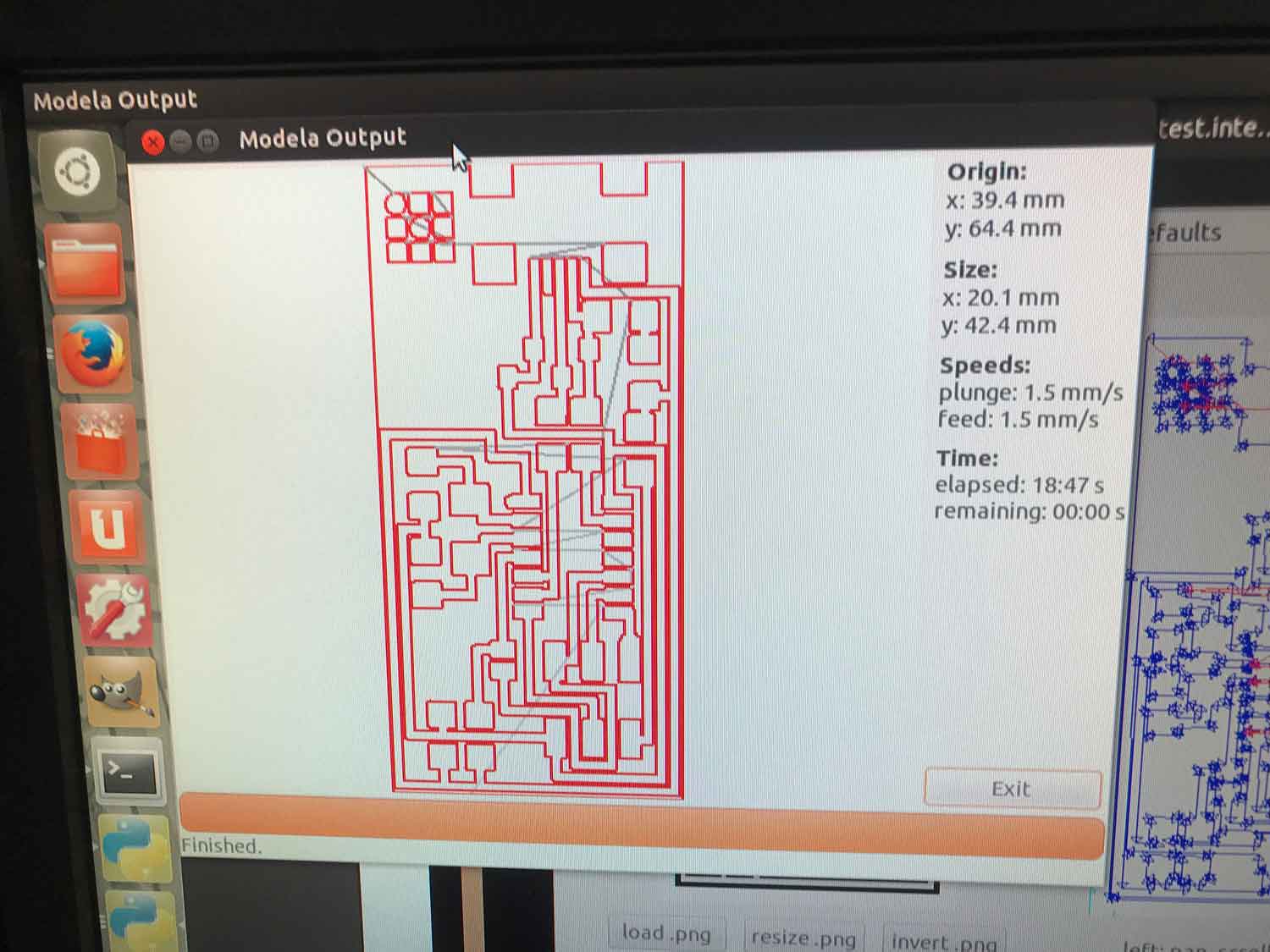

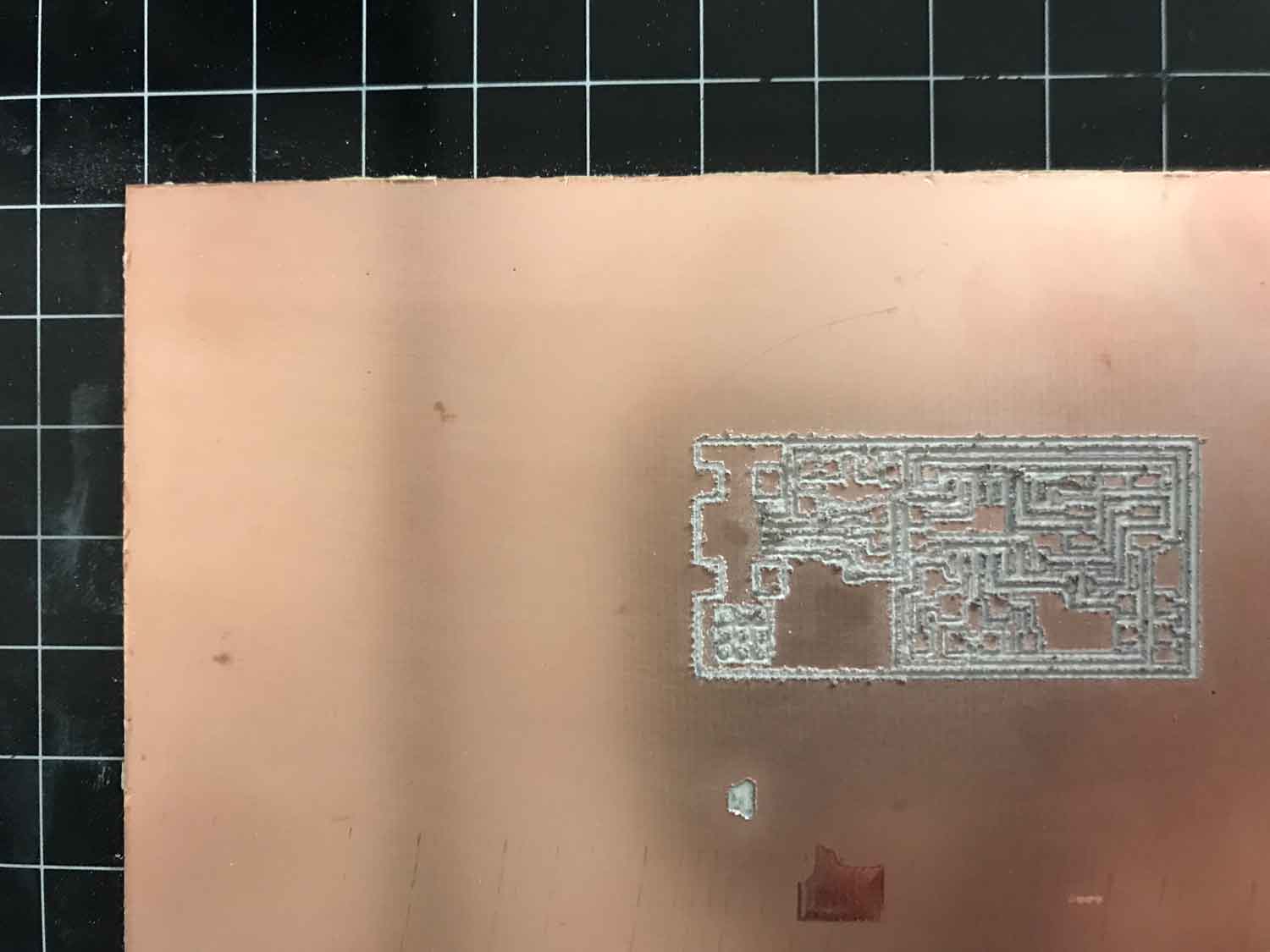

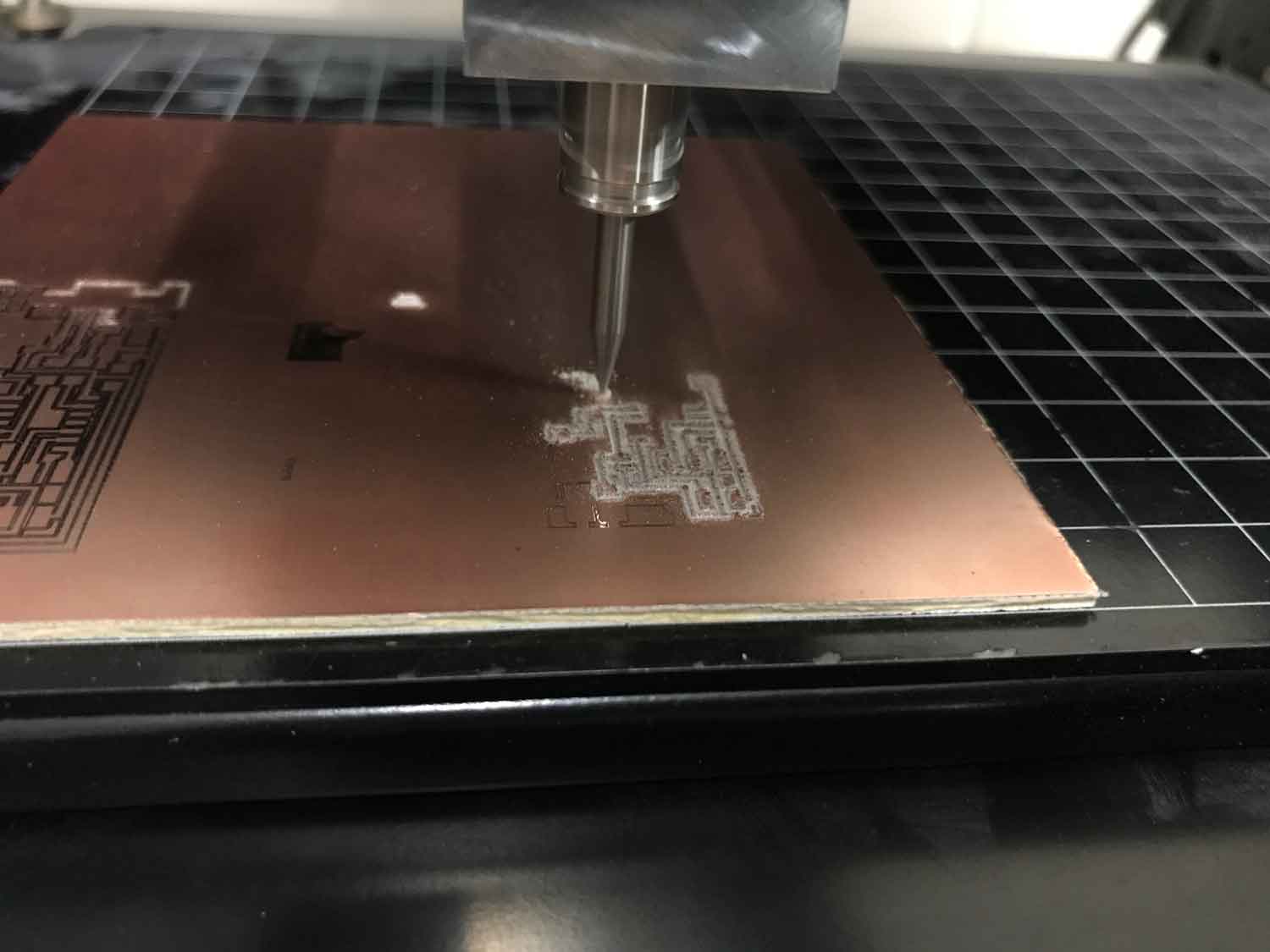

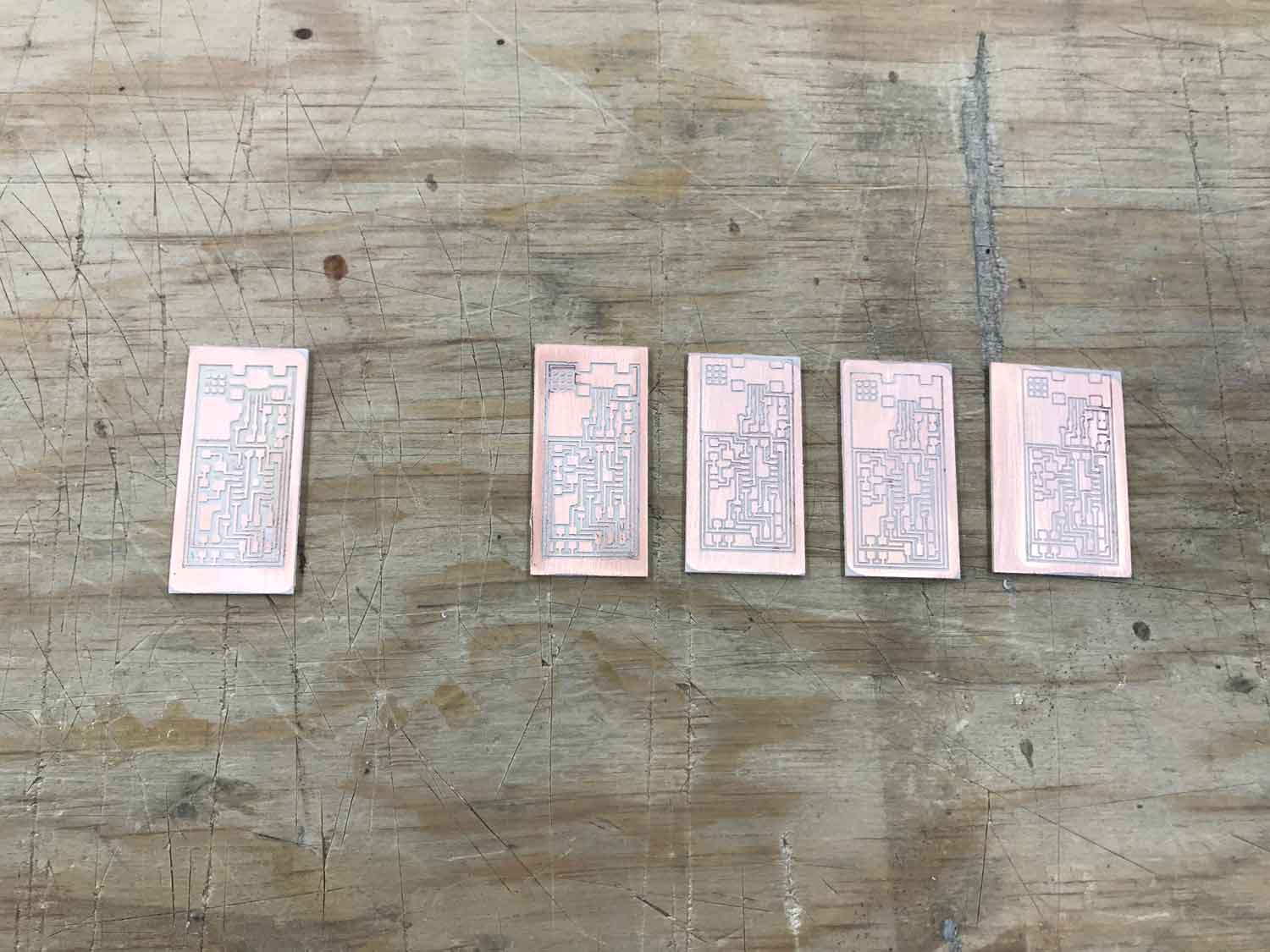

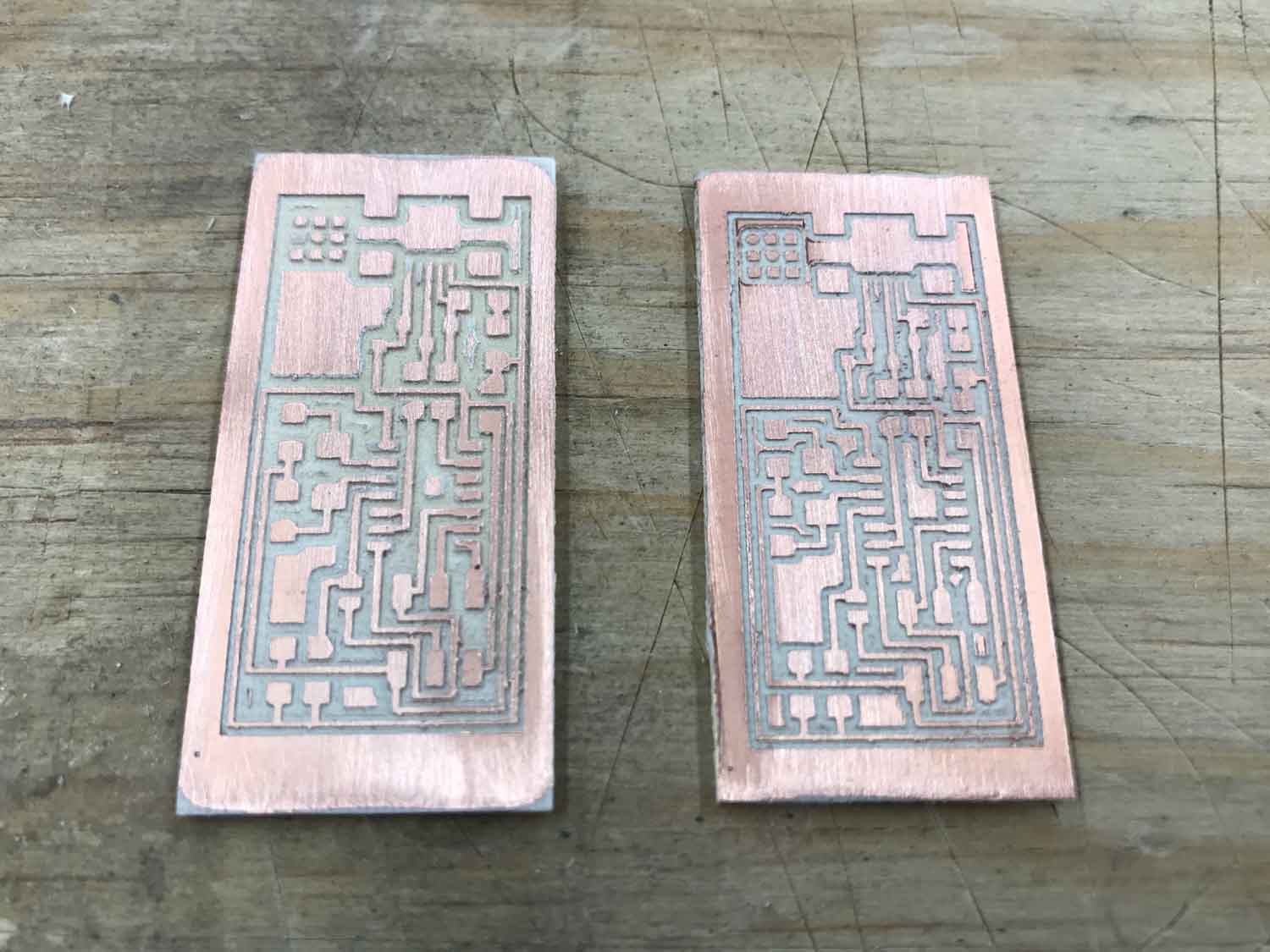

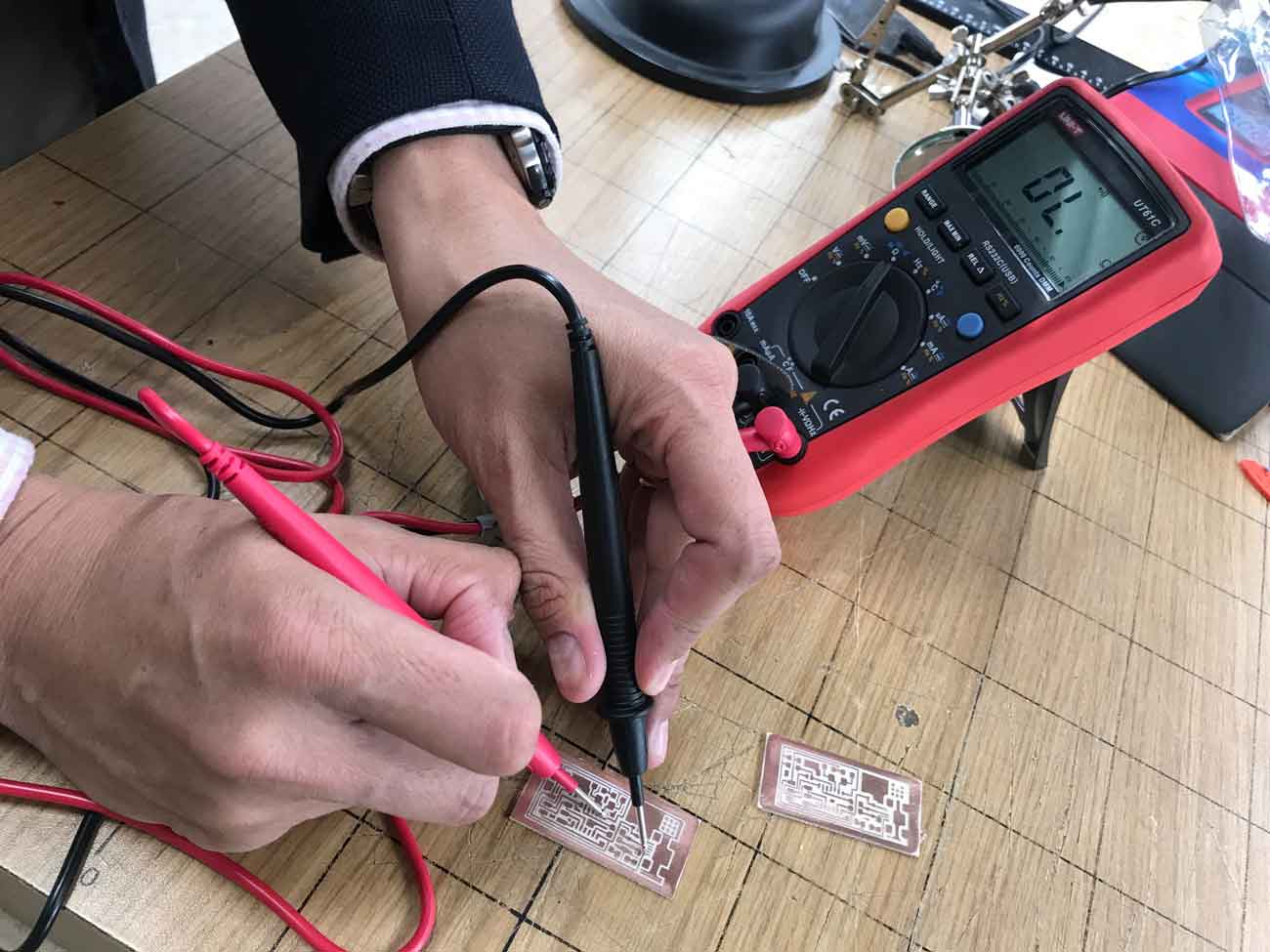

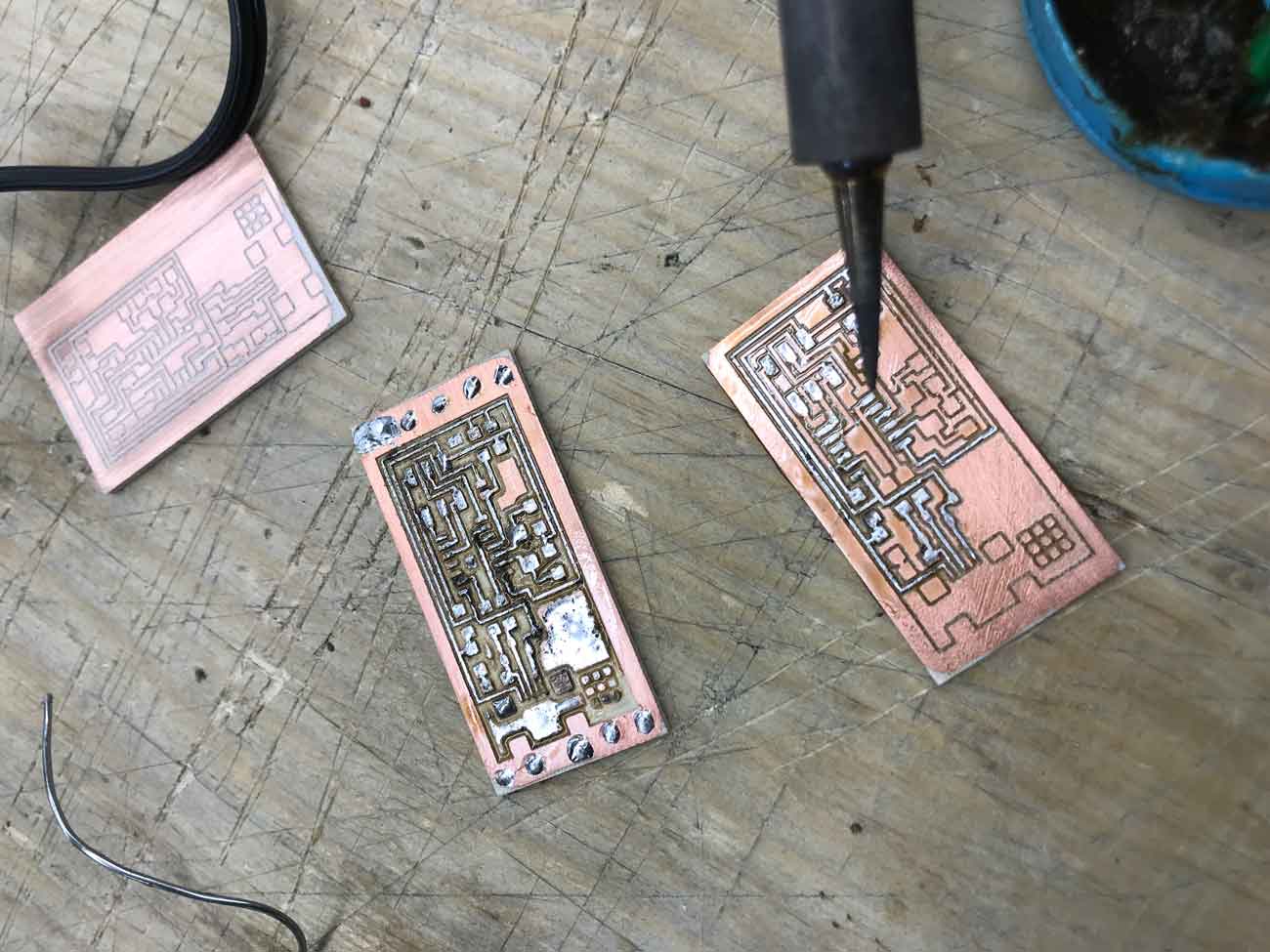

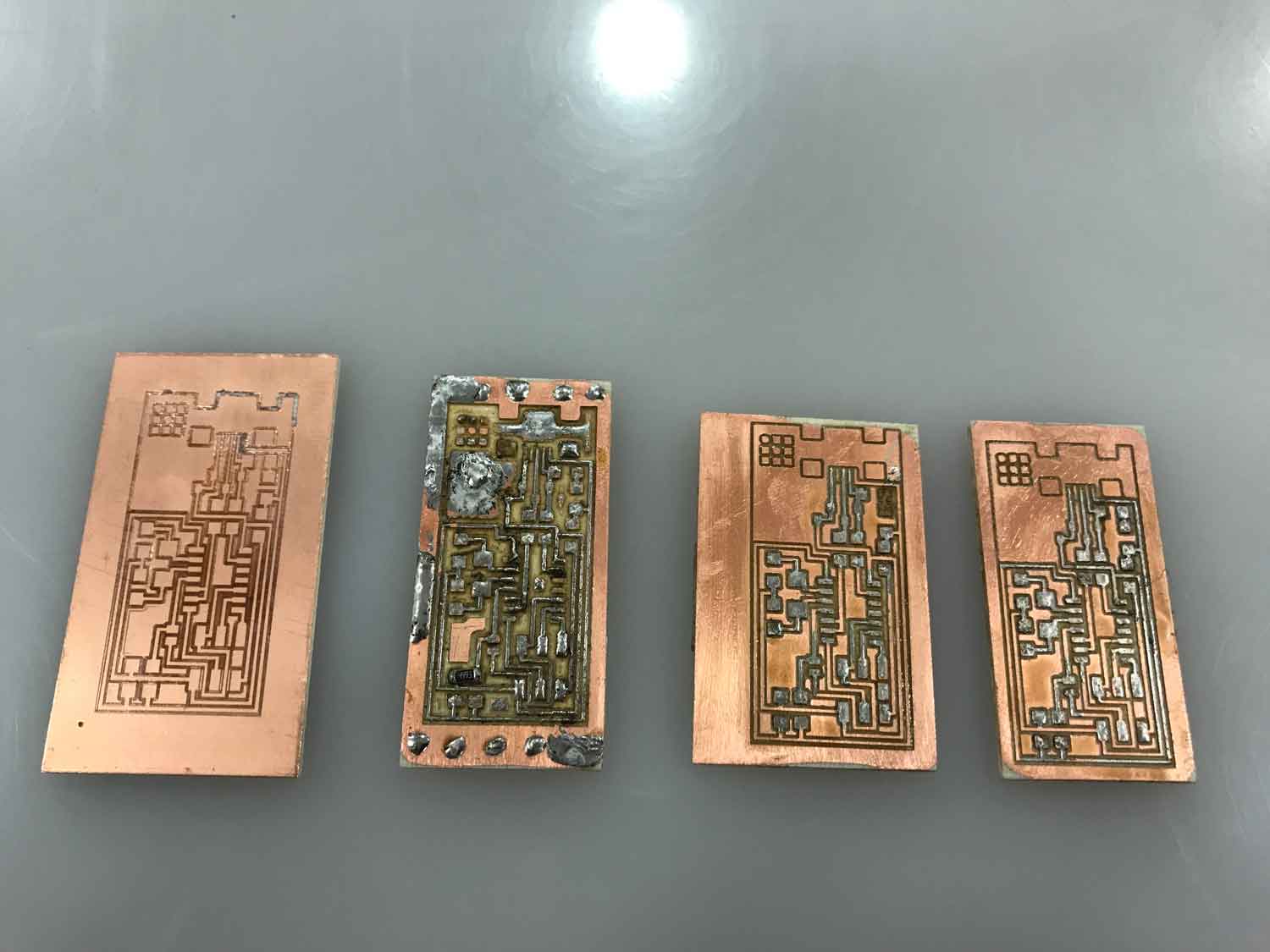

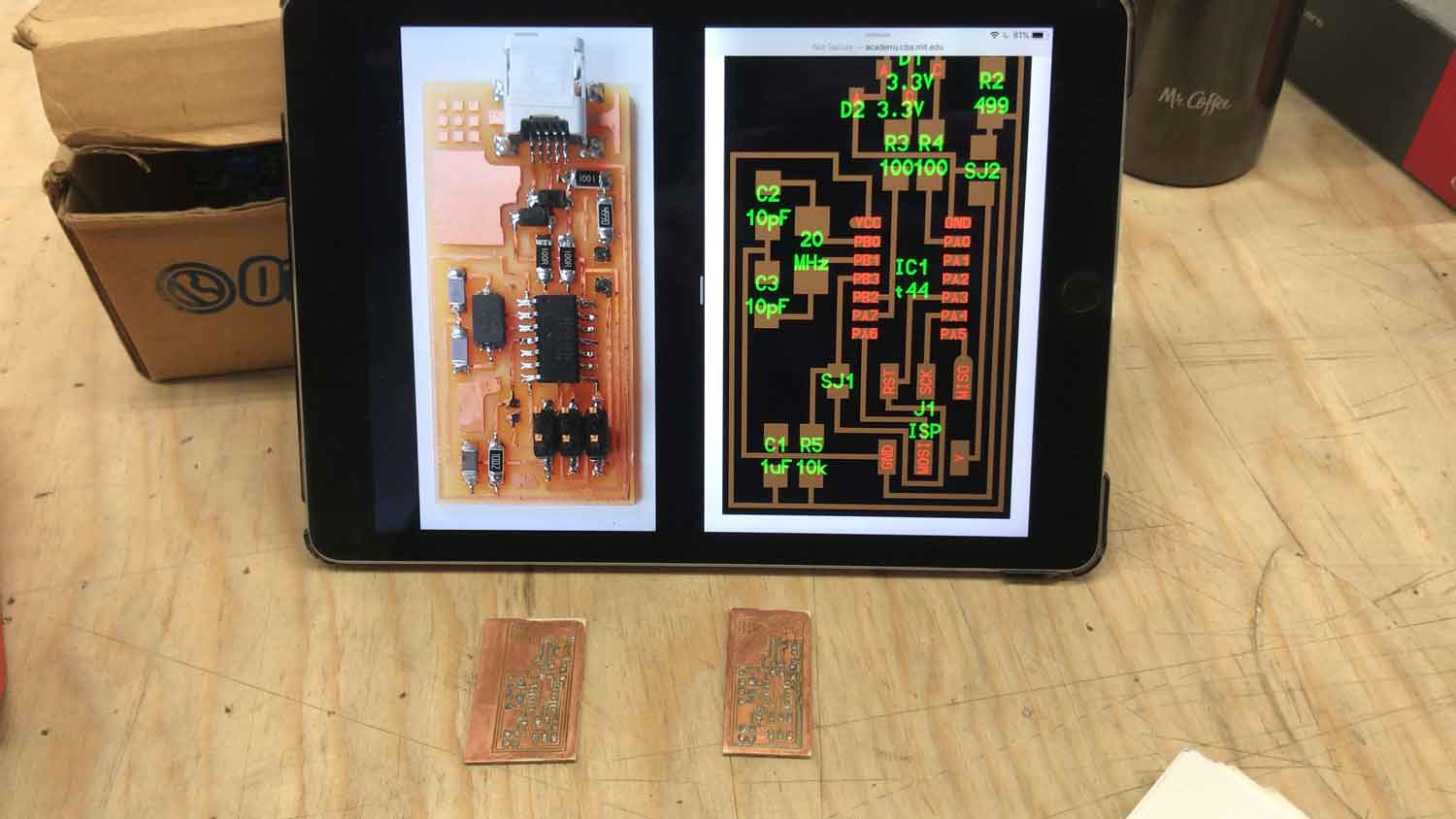

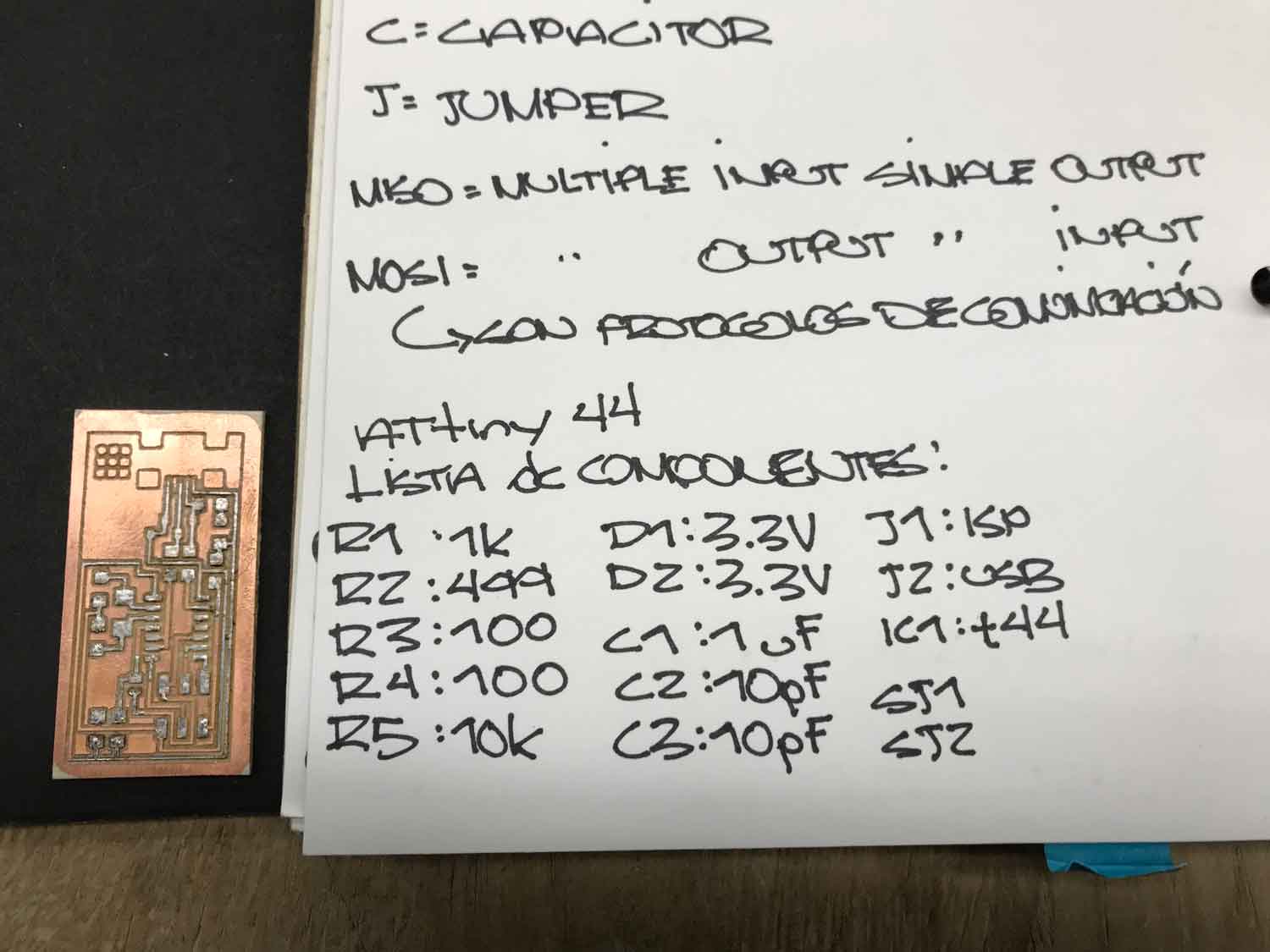

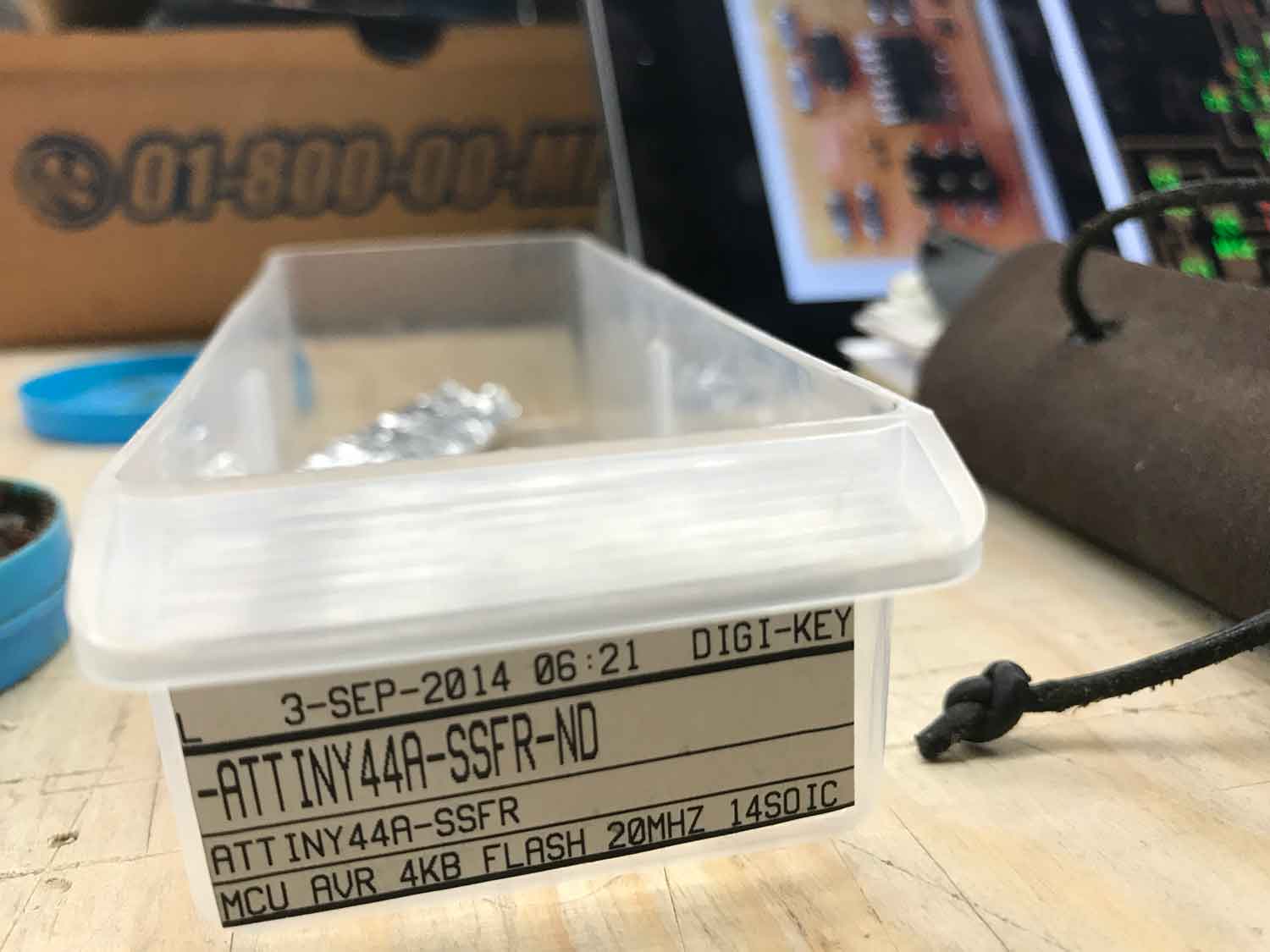

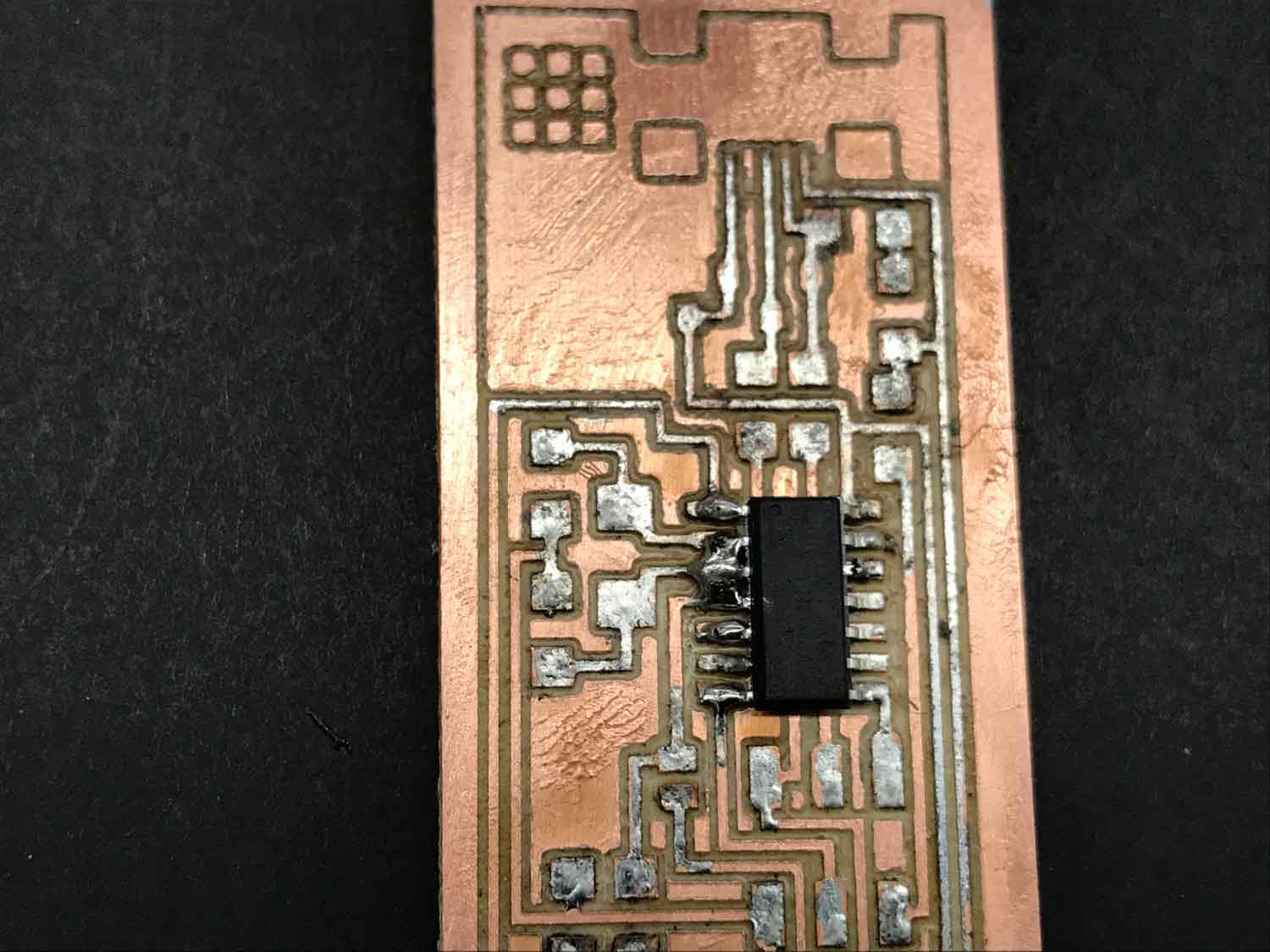

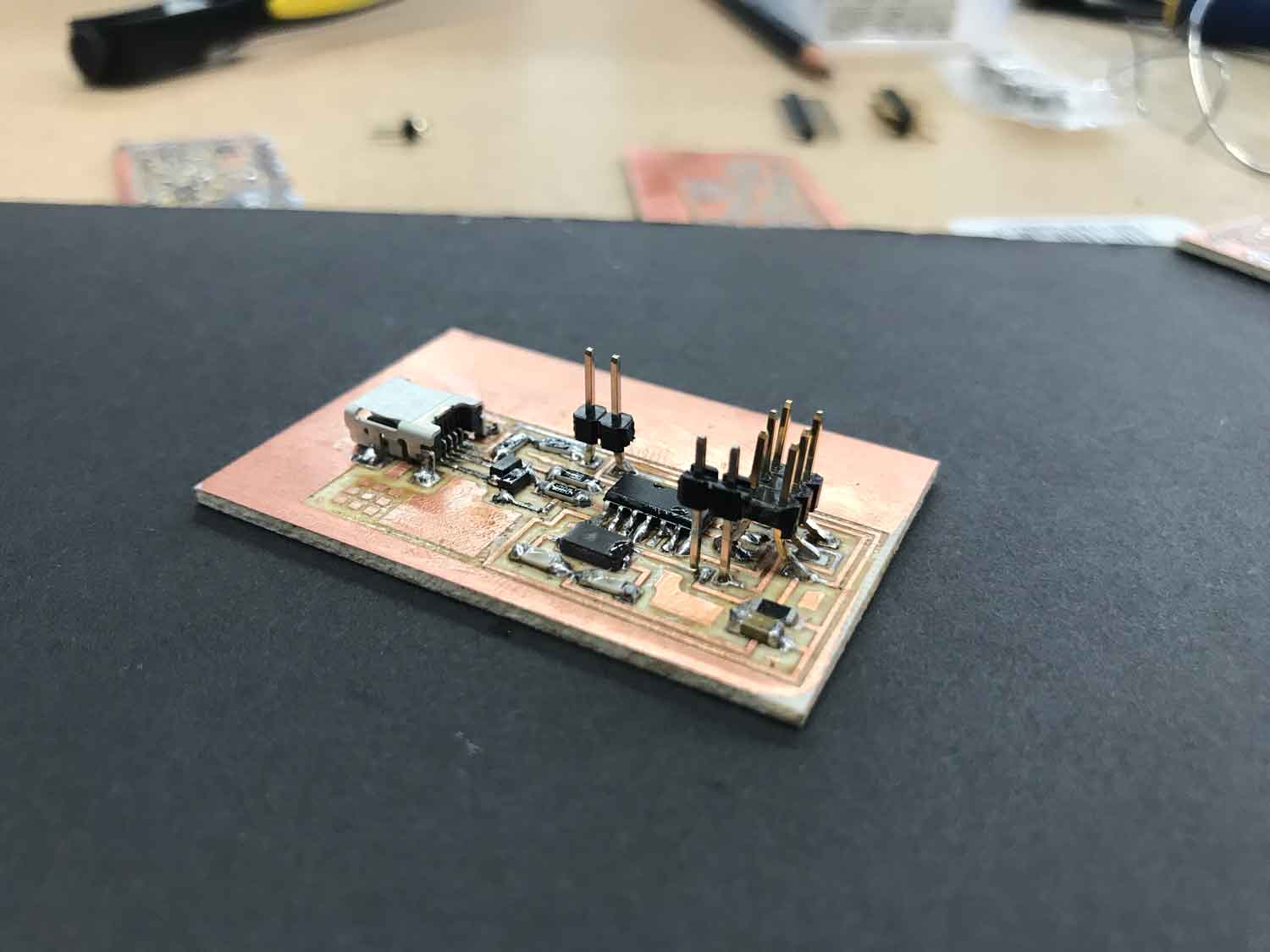

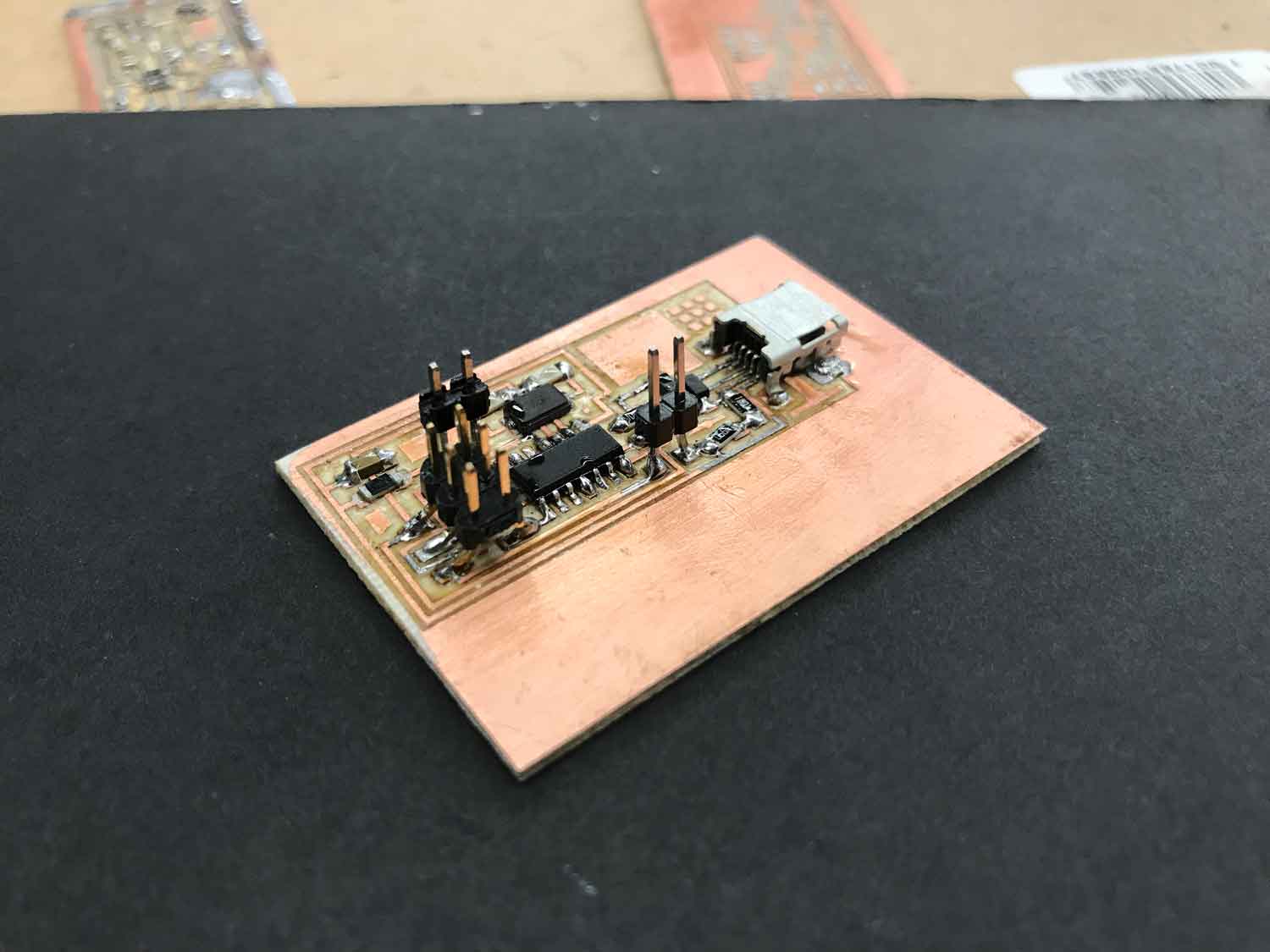

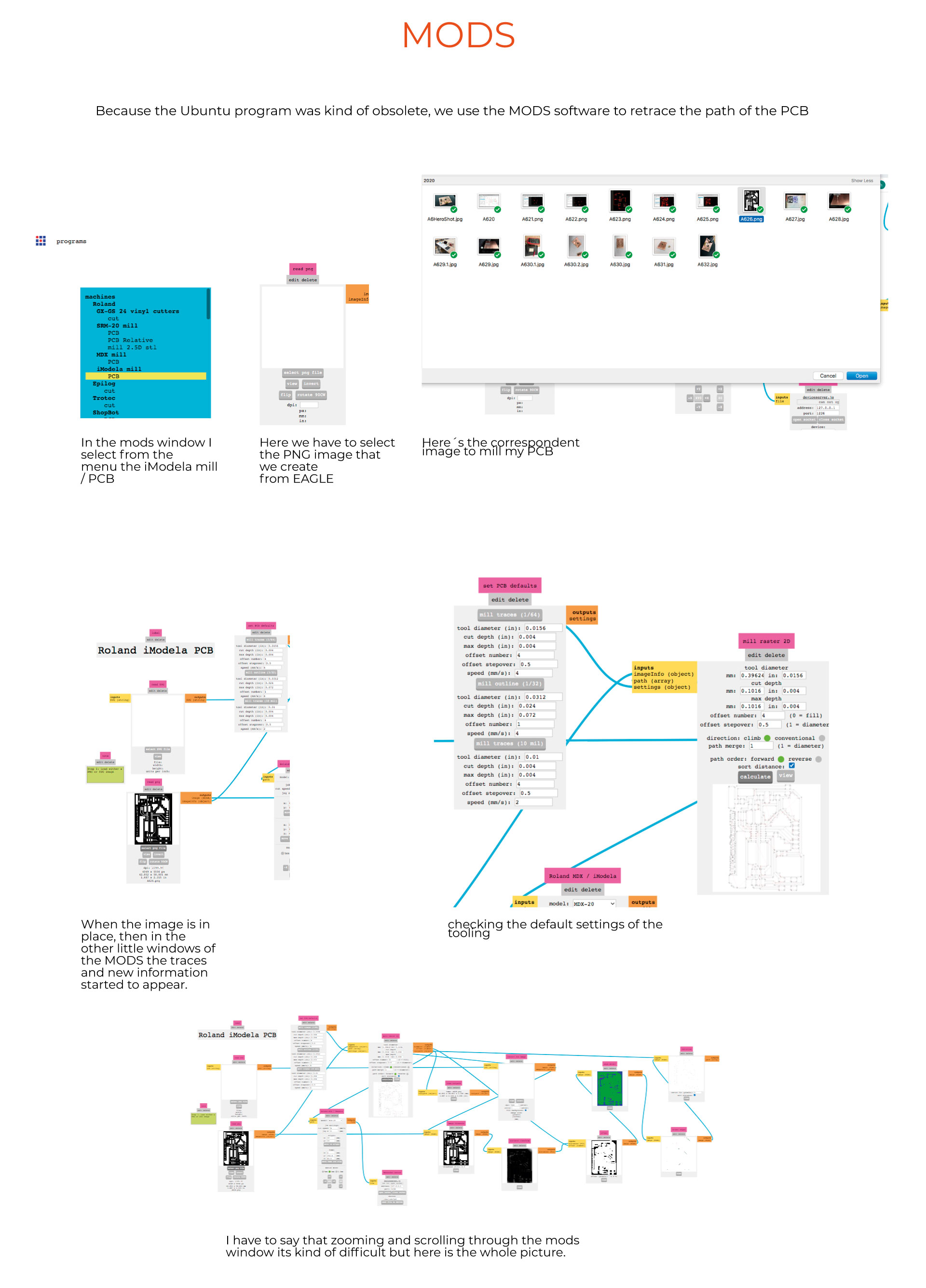

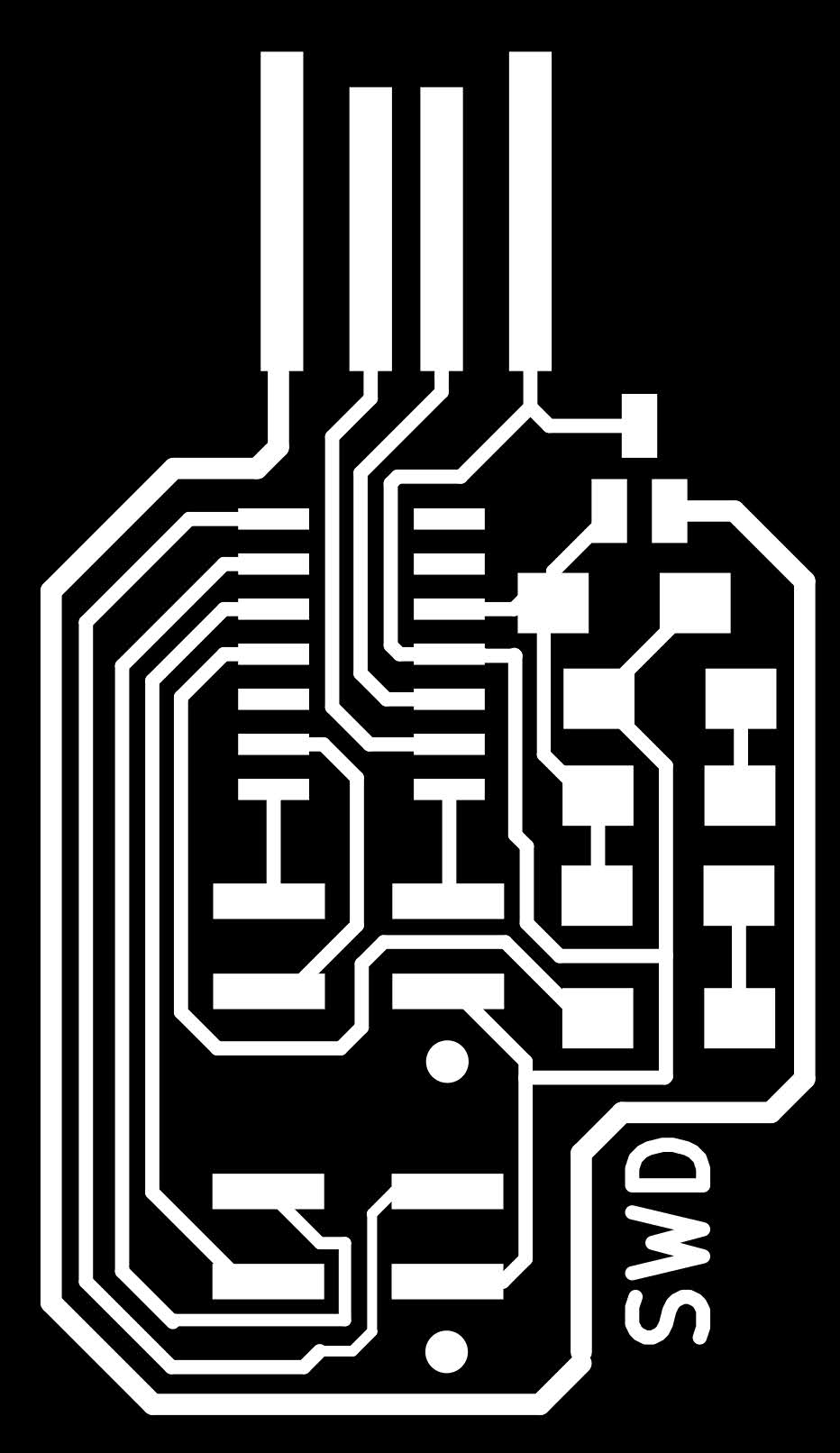

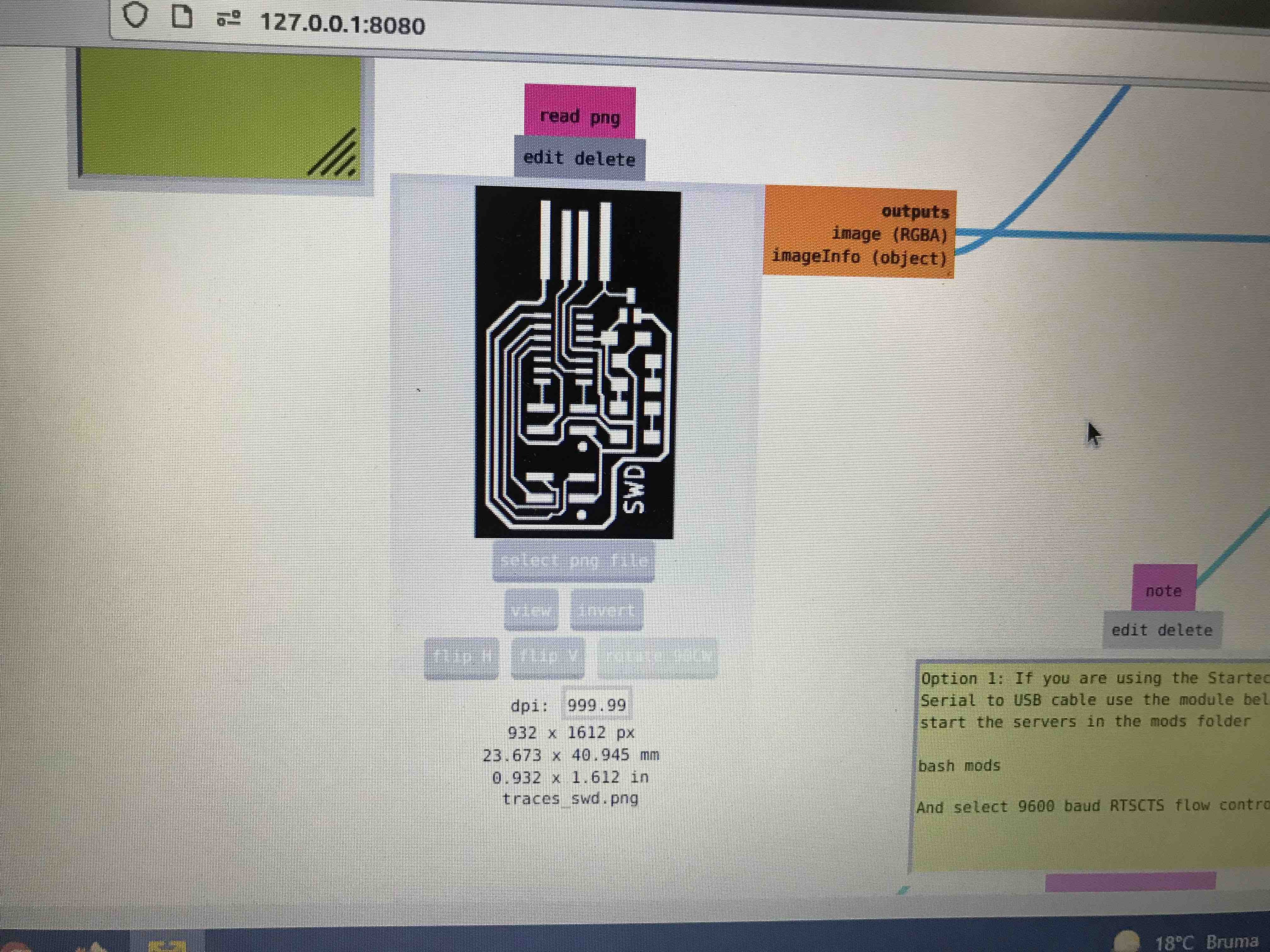

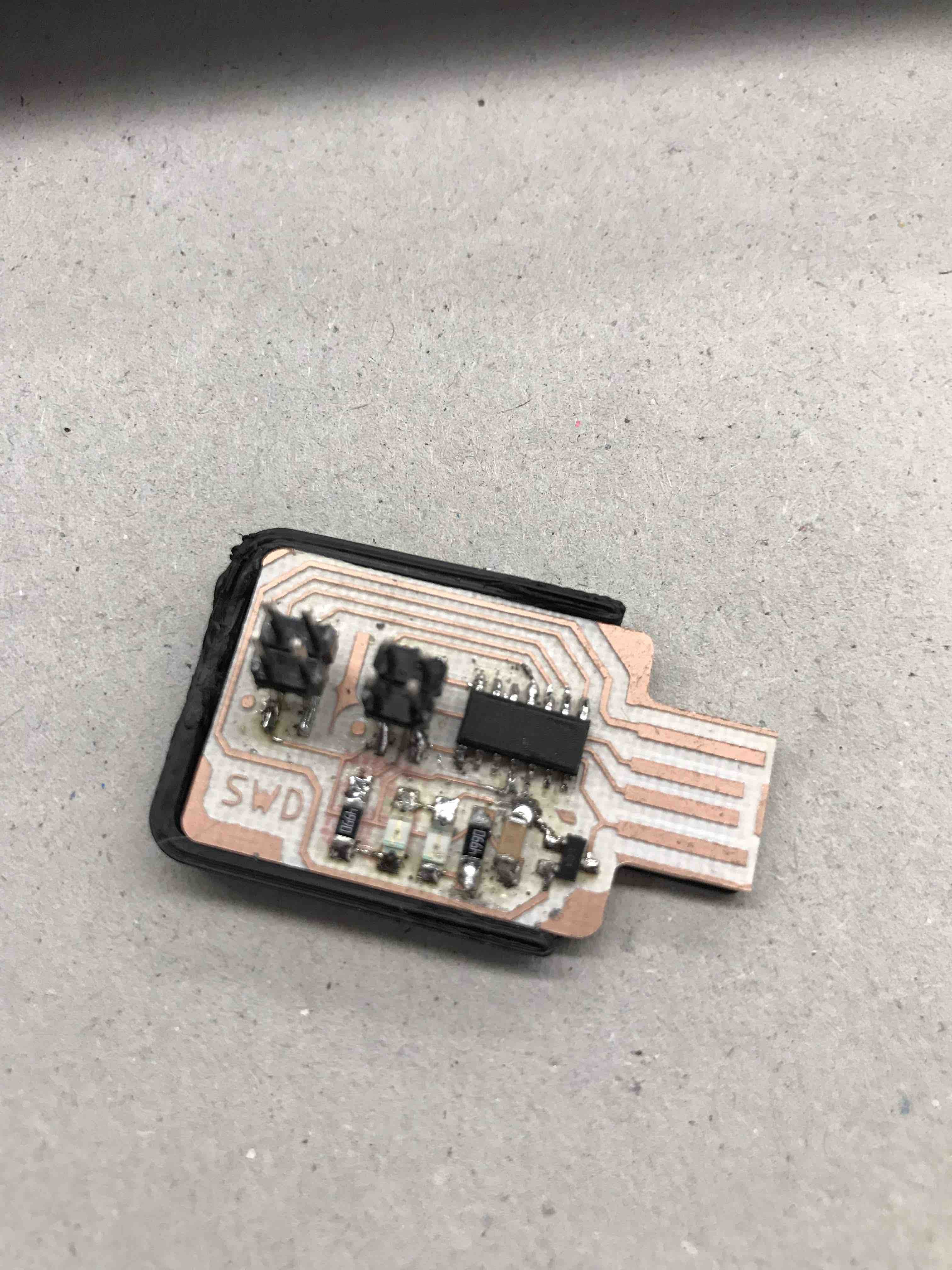

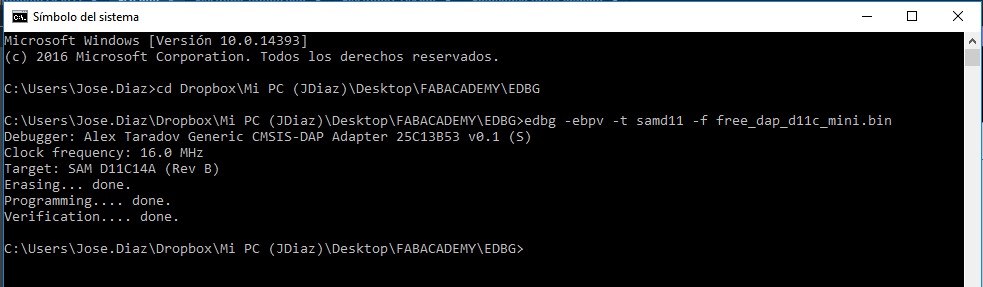

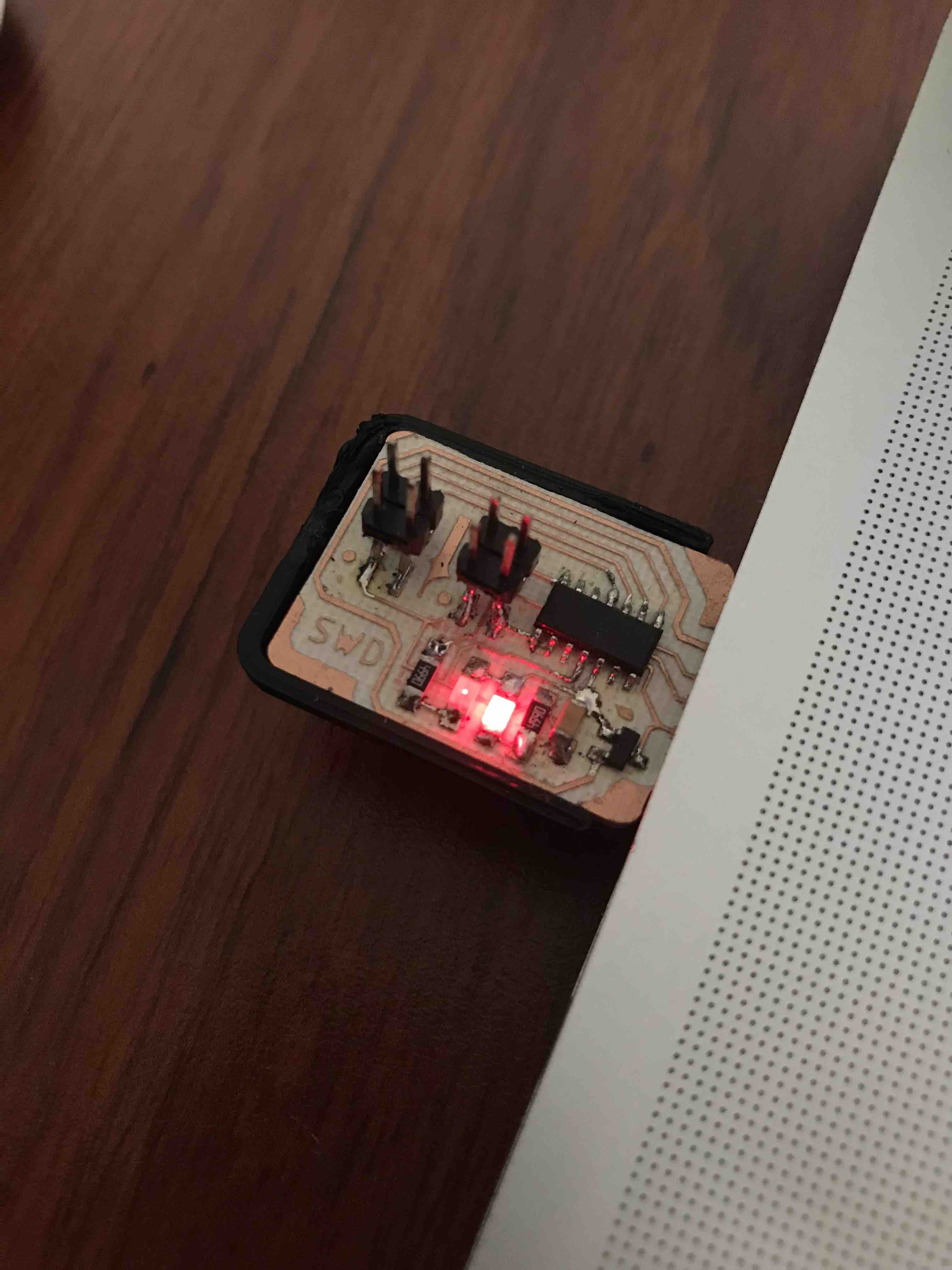

make an in-circuit programmer by milling and stuffing the PCB, test it, then optionally try otherPCB processes.

.

make an in-circuit programmer by milling and stuffing the PCB, test it, then optionally try otherPCB processes.

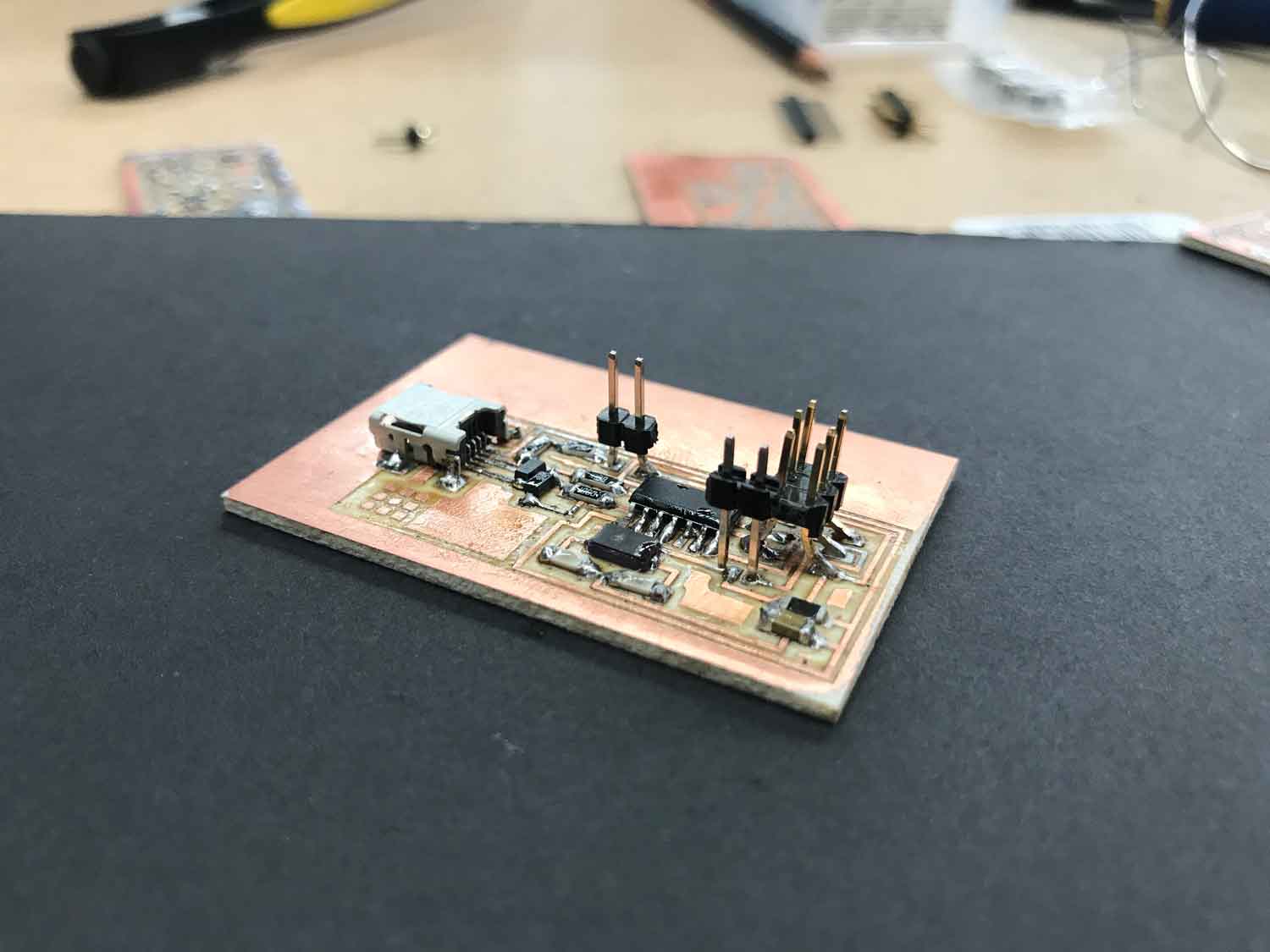

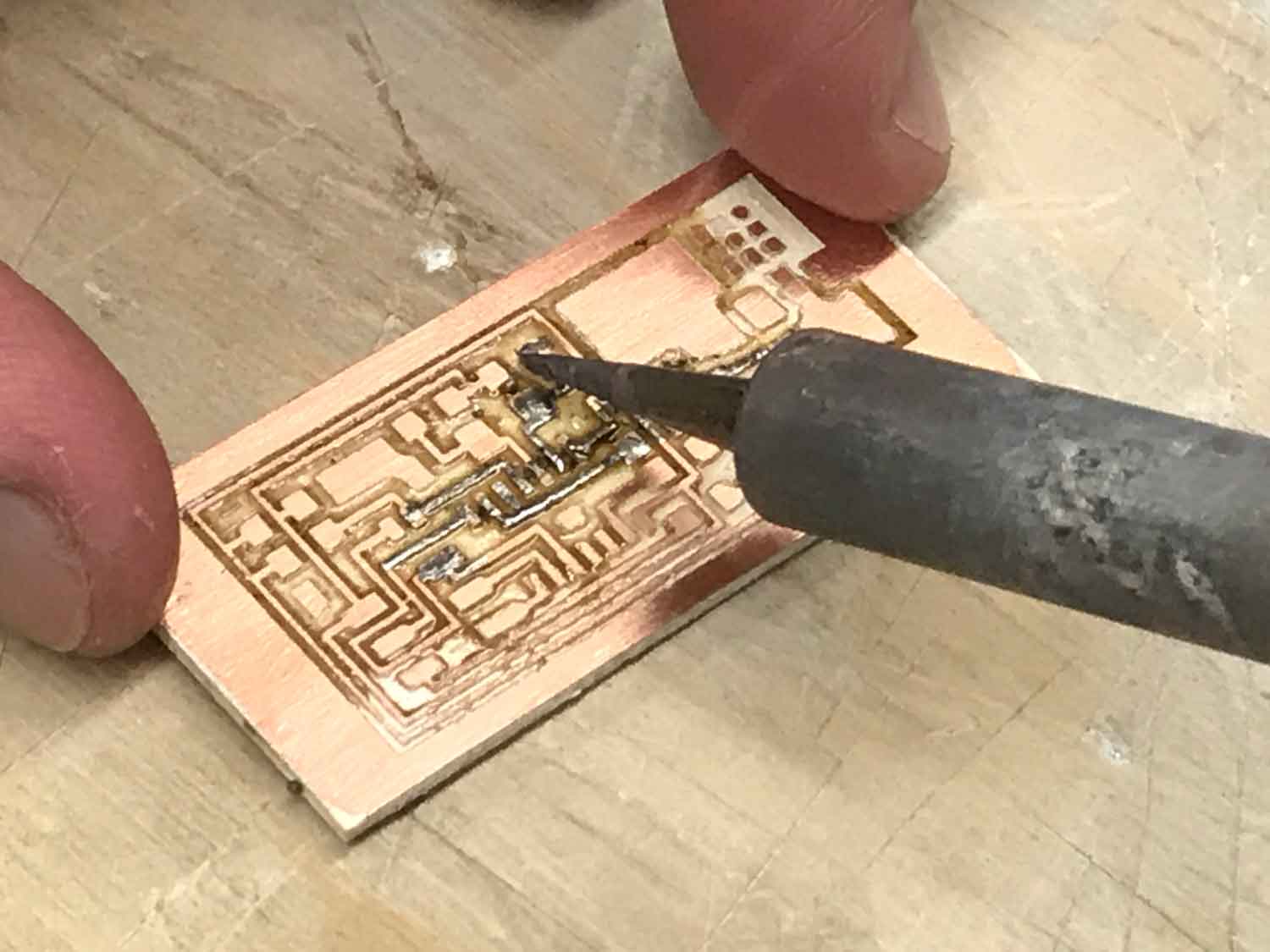

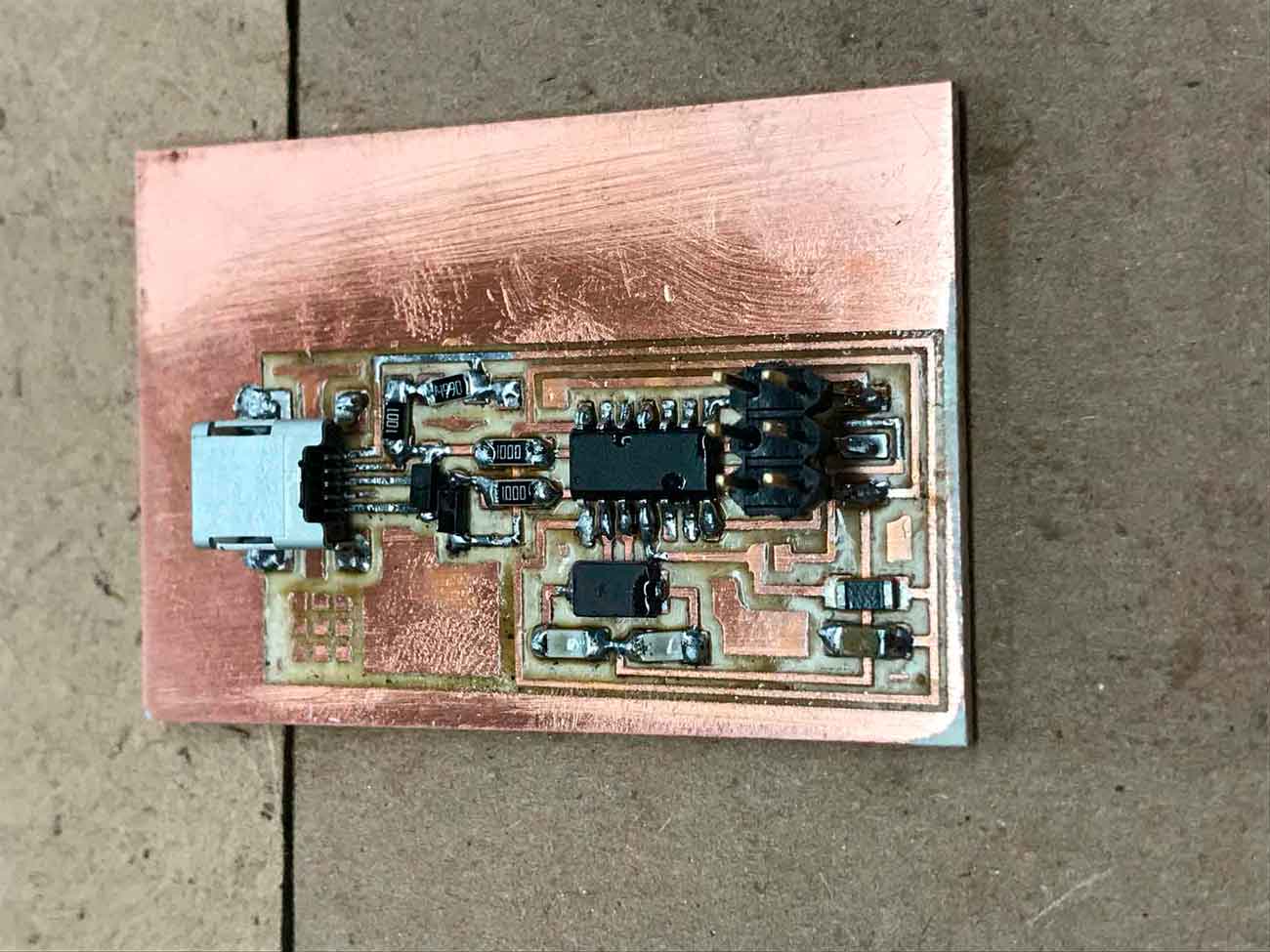

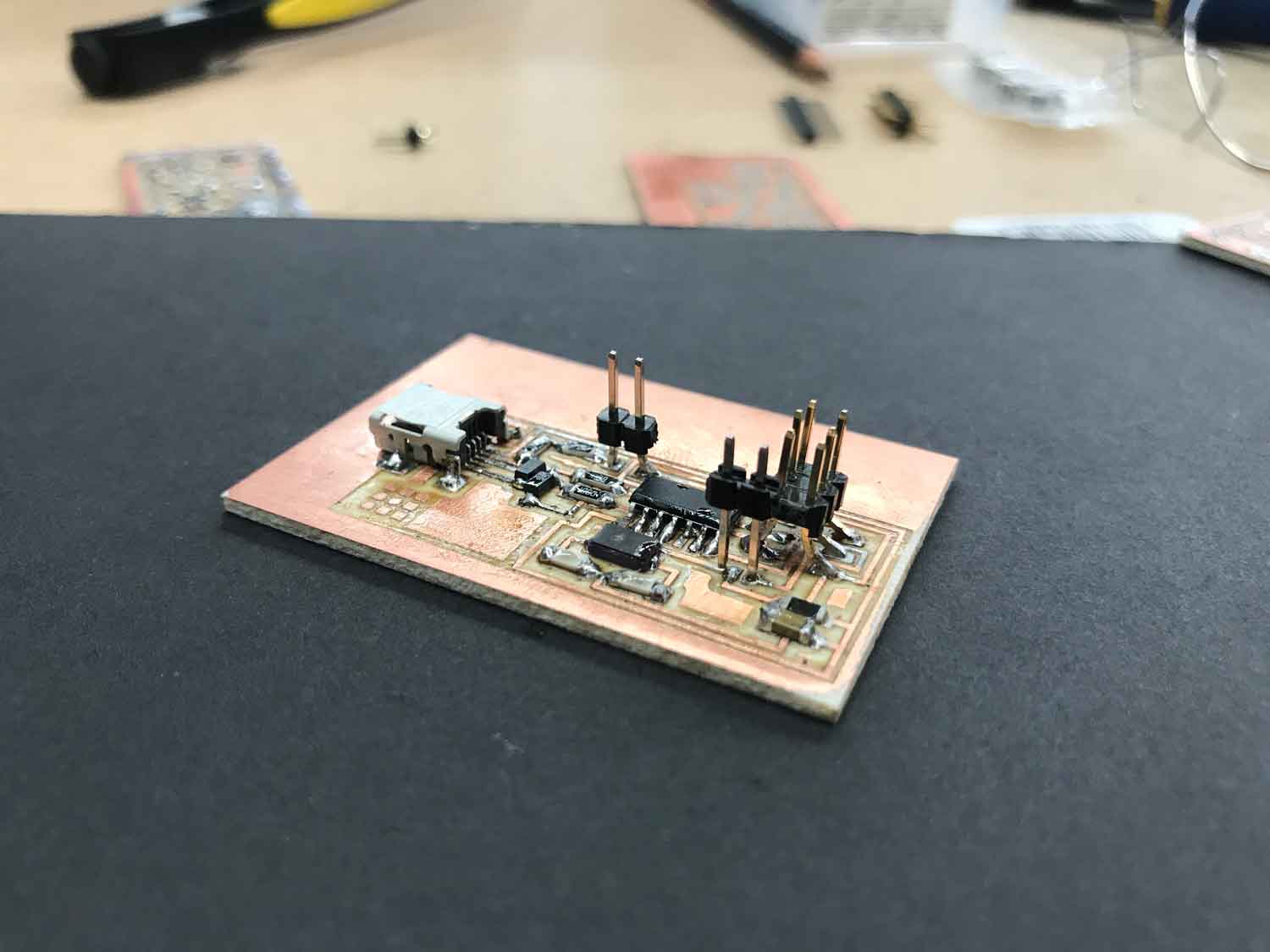

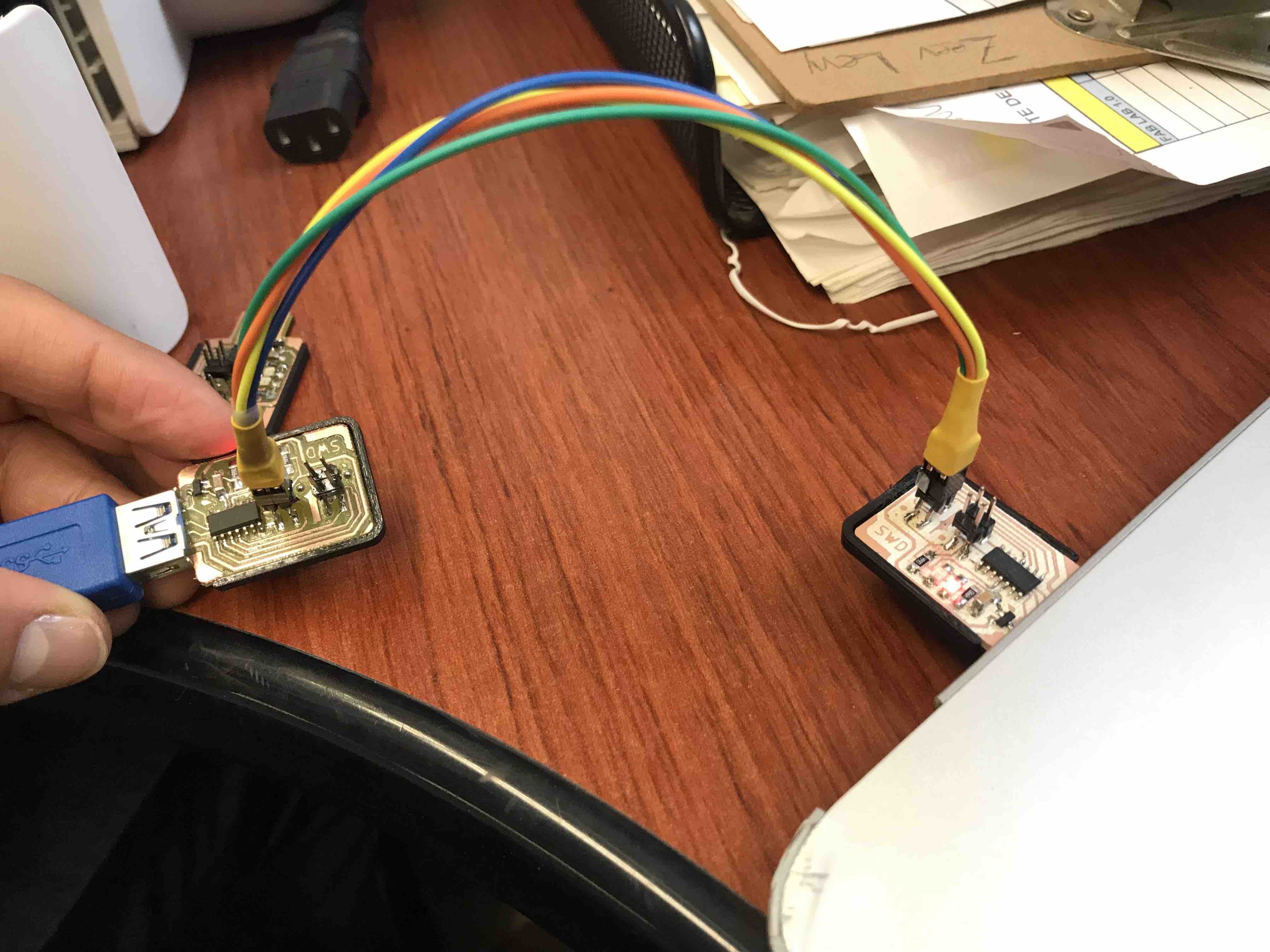

Preparing everything to start welding the components.

and the link to the group assignment is: FabLabCDMX.

a place to re-connect