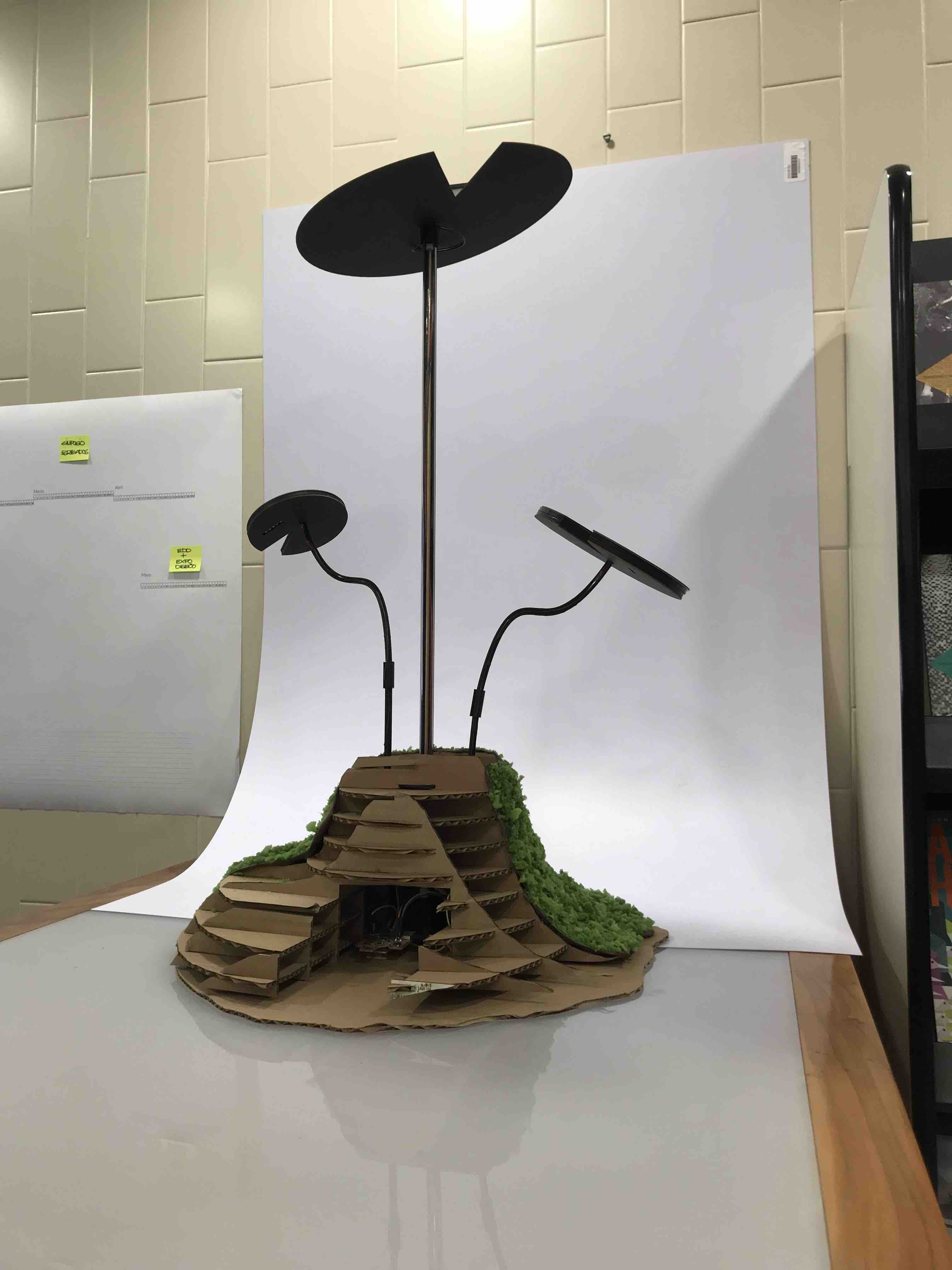

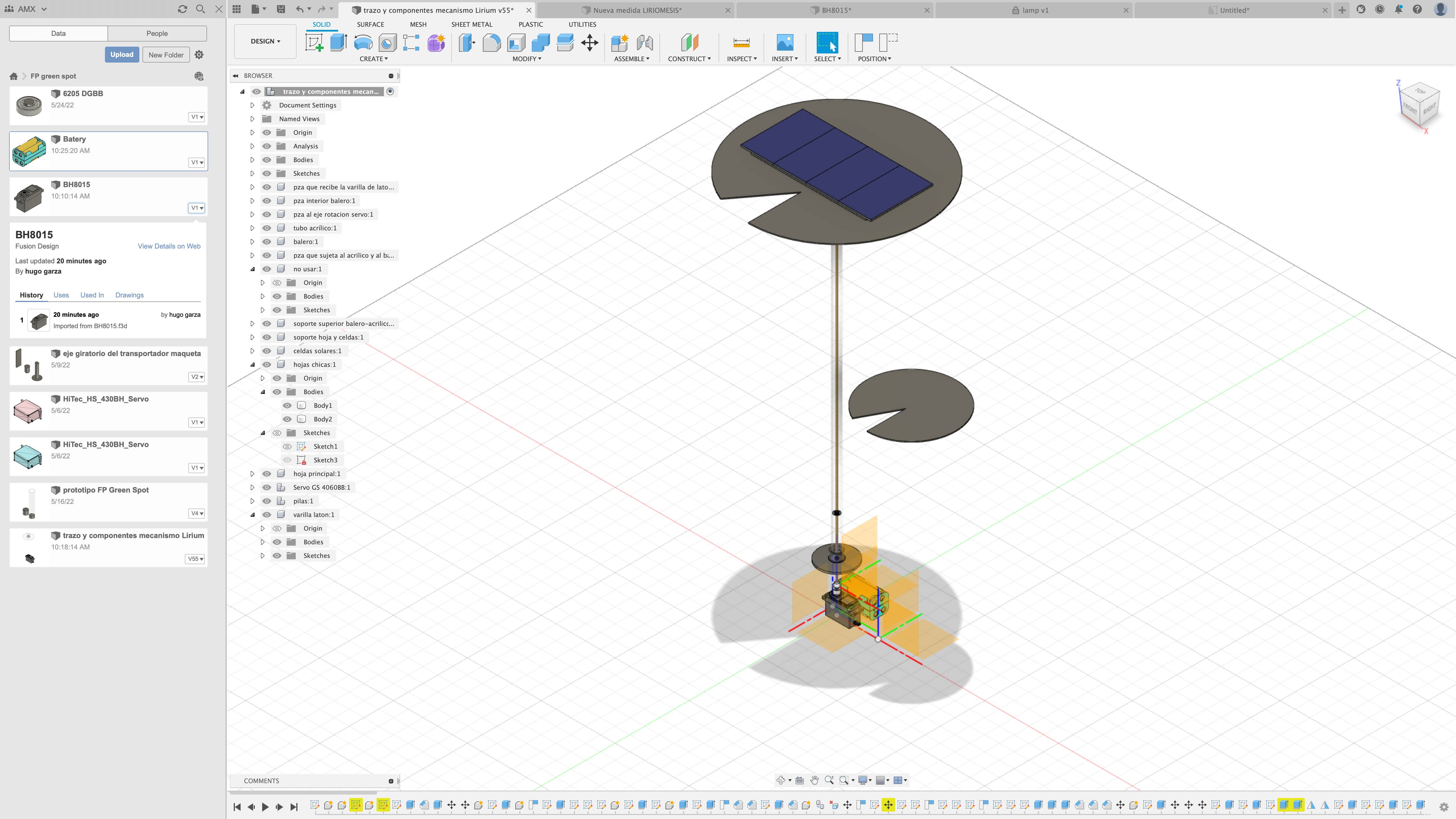

Hero shot.

First, the Social

Responsibility committee launch de "Green Campus" iniciative and I

decide that I want to present a project to the authorities. The

inspiration for my project begun when i saw a public luminary

outside the University Campus that had Solar Panels, then I just

remember that our students love to rest over the grass of the

Campus, then I remember one exhibition that held in Mexico City a

few years ago that I helped to mount in the Museo Mexicano de

Diseño that the Trienalle di Milano brought, and some of the

objects exhibit there resemble this big flowers like in Alice in

Wonderland and for last I remember a project that one former

student design like 2 years ago in my class, the objective was to

use Biomimesis to design some decorative or functional object and

she, Paulina Russ design this Lirium like little lamp to use it in

a bed side table and then I think this project could look awsome

in a bigger scale, really bigger scale like some 6 or 7 meters

tall. This proyect is about giving our students a place to rest,

to study, to talk, to re-connect with nature, with each other, to

have a conversation without devices, an old-fashion conversation

an "analog" one, so I talk to Paulina about this project and she

agree to participate with her original design.

So, I start to design

the new form , function and the electronics to accomplish the

requeriments that was to build a mockup to show it to the

authorities in the frame of this "green campus" iniciative in

collaboration with Paulina that help me to design the lower base

of this new big Lirium.

DESIGN of the green spot

a place to re-connect

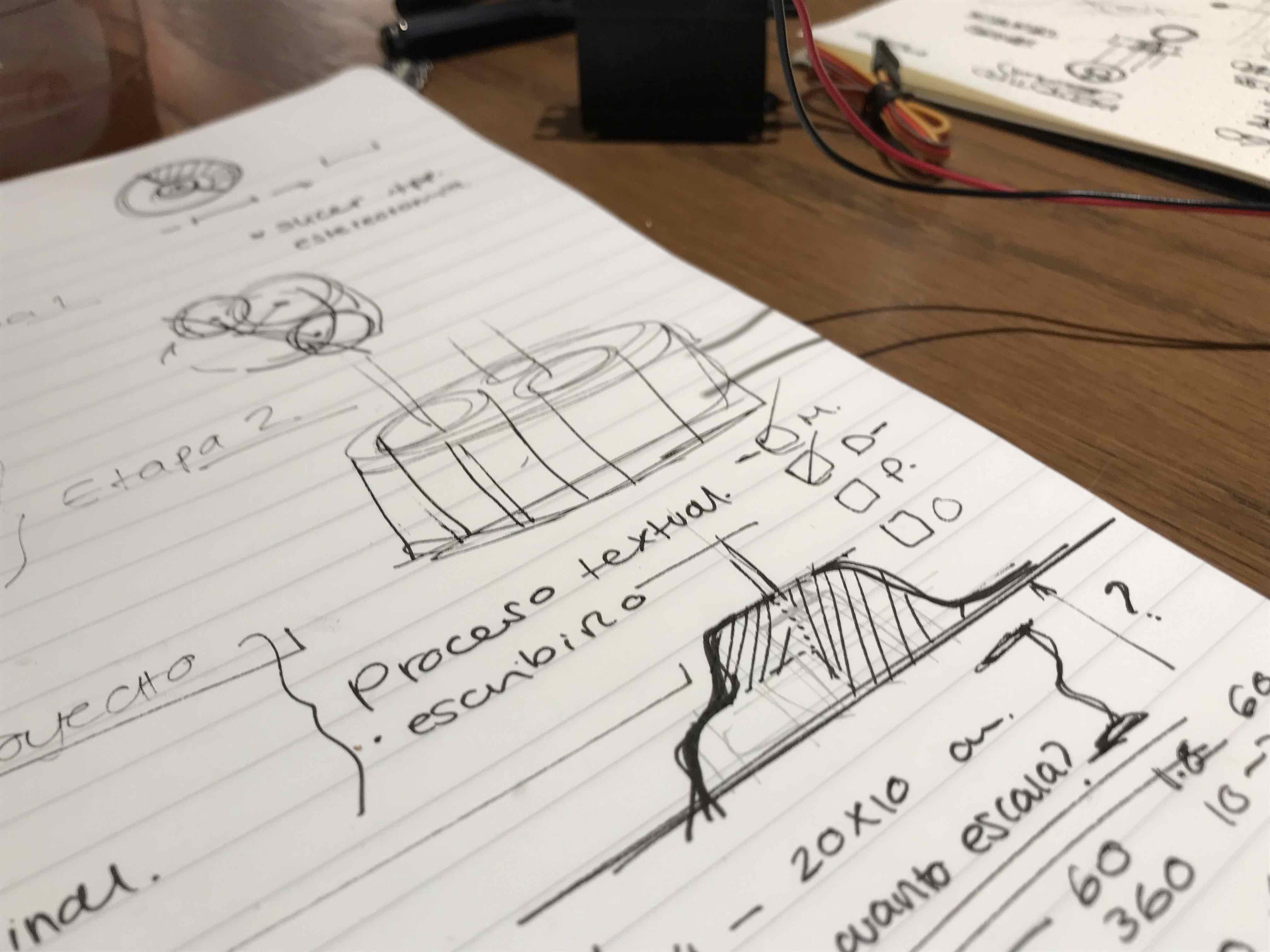

Here are some

sketches and notes regarding the redesign and activities to do.

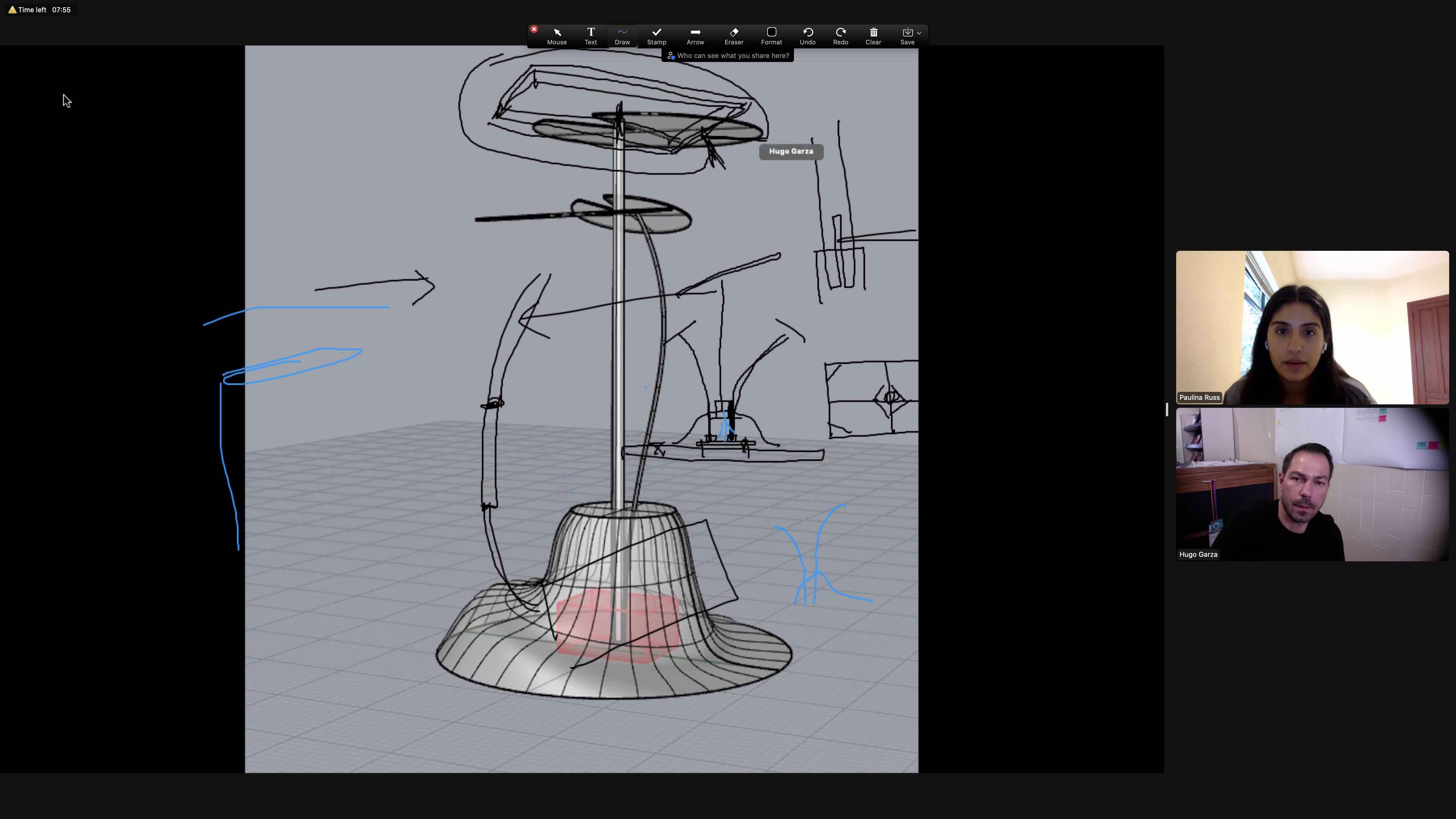

She is Paulina. Here we

are sketching the new components of the green spot over a 3d image

so she can redesign the base and I can continue with the design of

the new components.

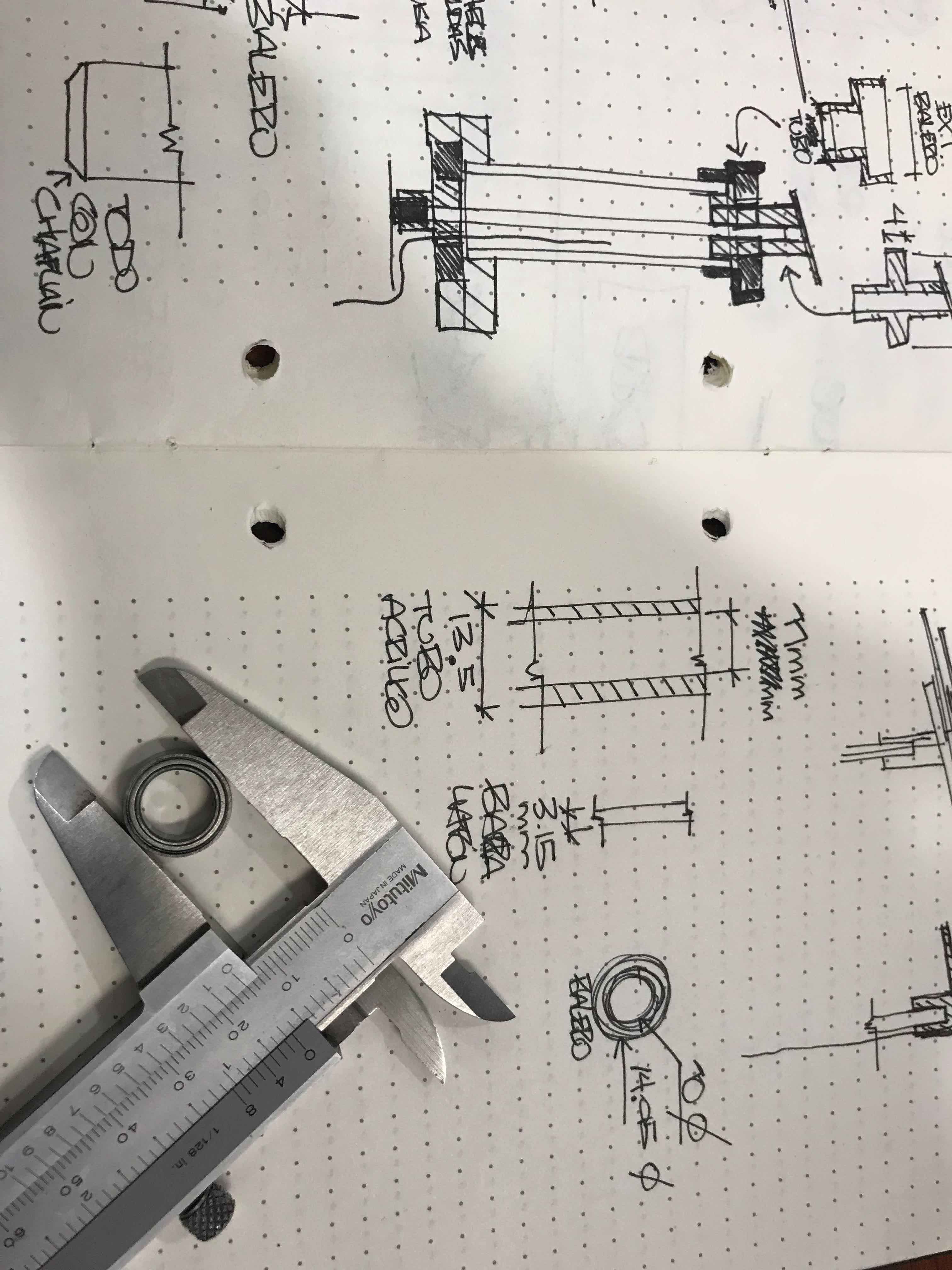

Measuring the

bearings so I can start filling the Parametrycs in fusion360

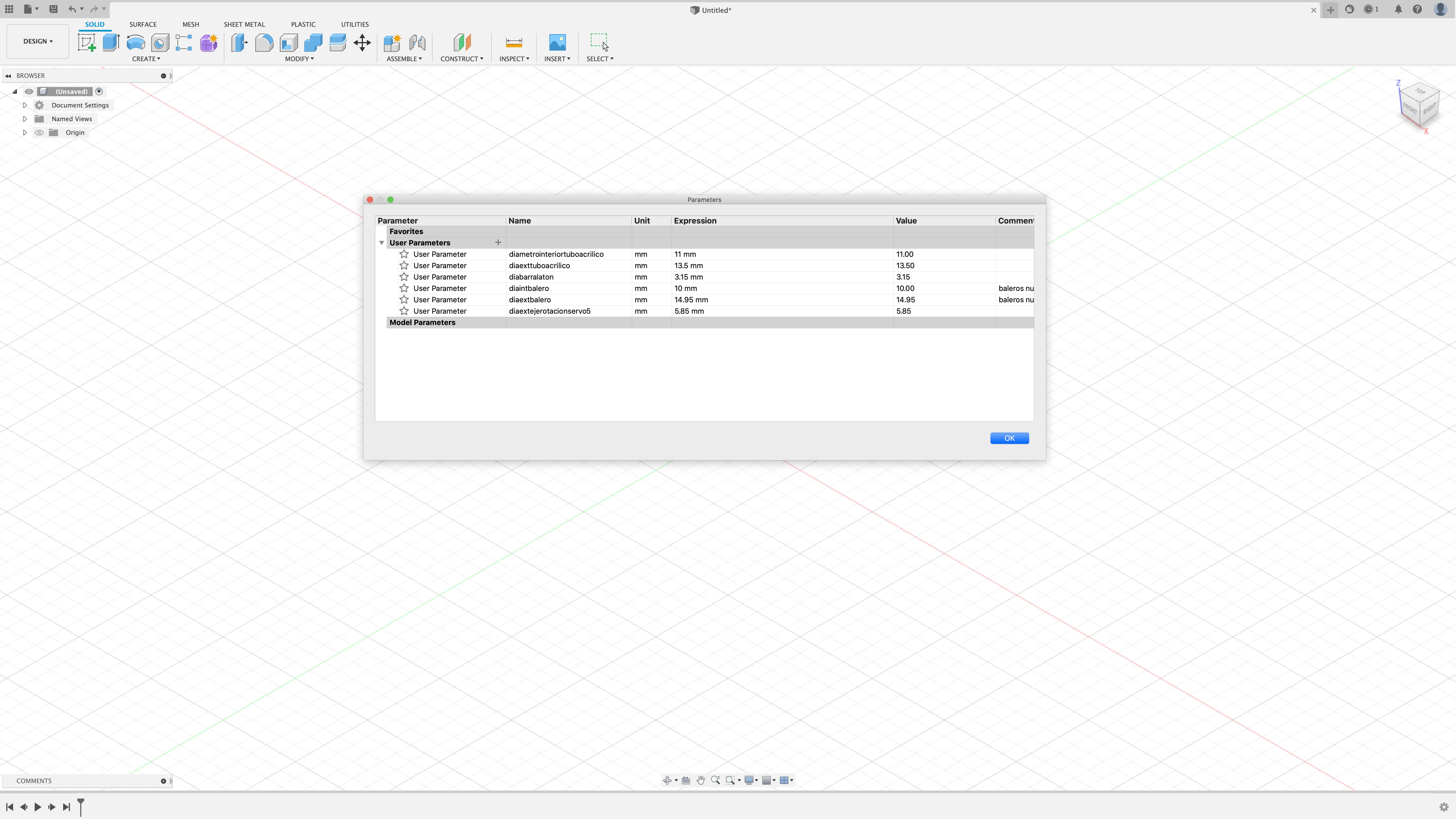

This is the

Parameters window, her you can add or change your own data, like

NAME (name your parameter) UNIT (mm, cm inch,etc) EXPRESSION (the

dimension like 11, 12 or 34) VALUE (is the same that you use

in EXPRESSION).

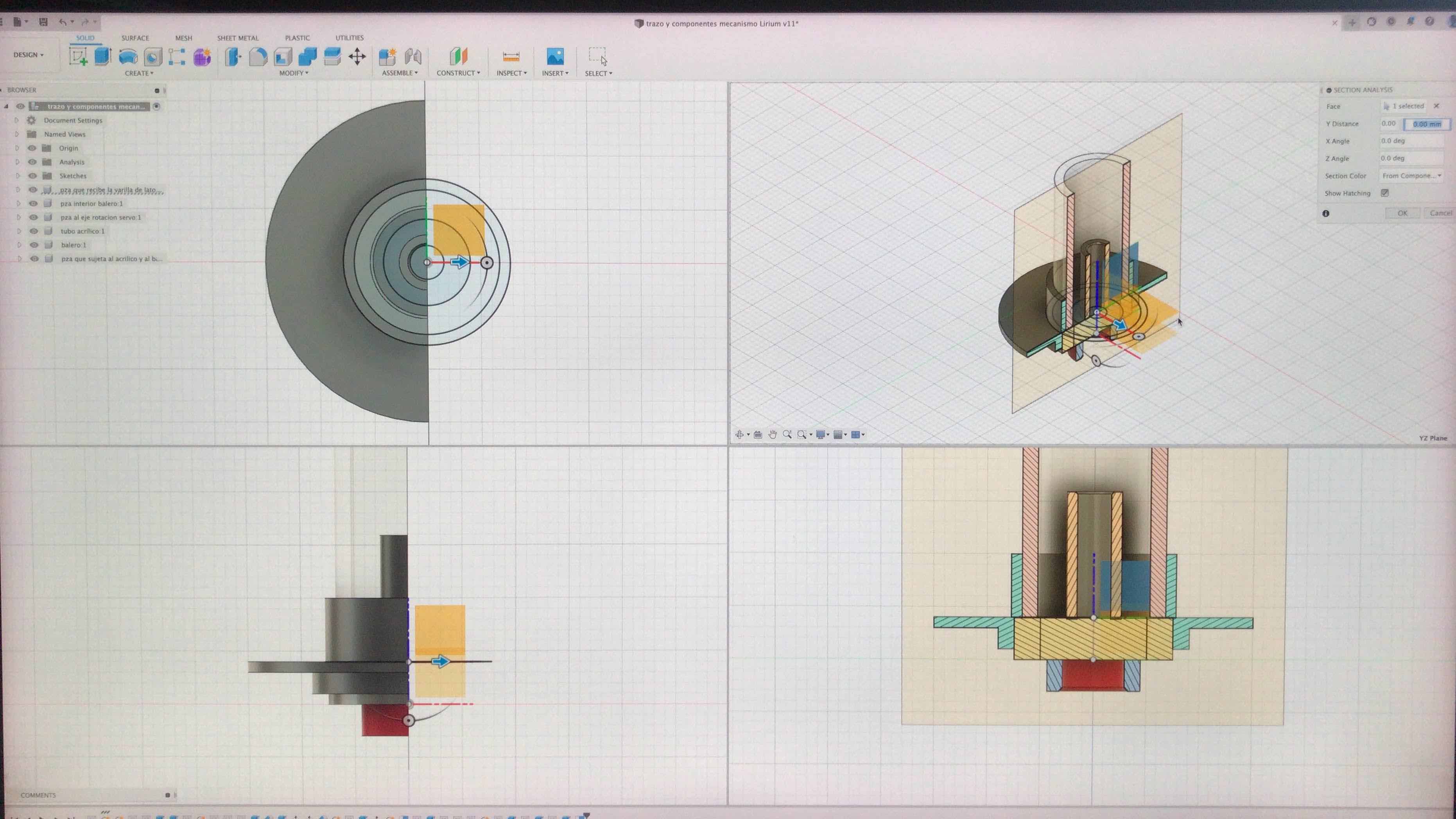

A section view of

the bottom support of the rotation axis, with the bearing, the

brass rod and the acrylic pipe. To design this I use the

parameters mentioned above, if I need to change a component, or

put some tolerances I don´t have to redraw nothing, just change

the EXPRESSION value of the parameters I already use.

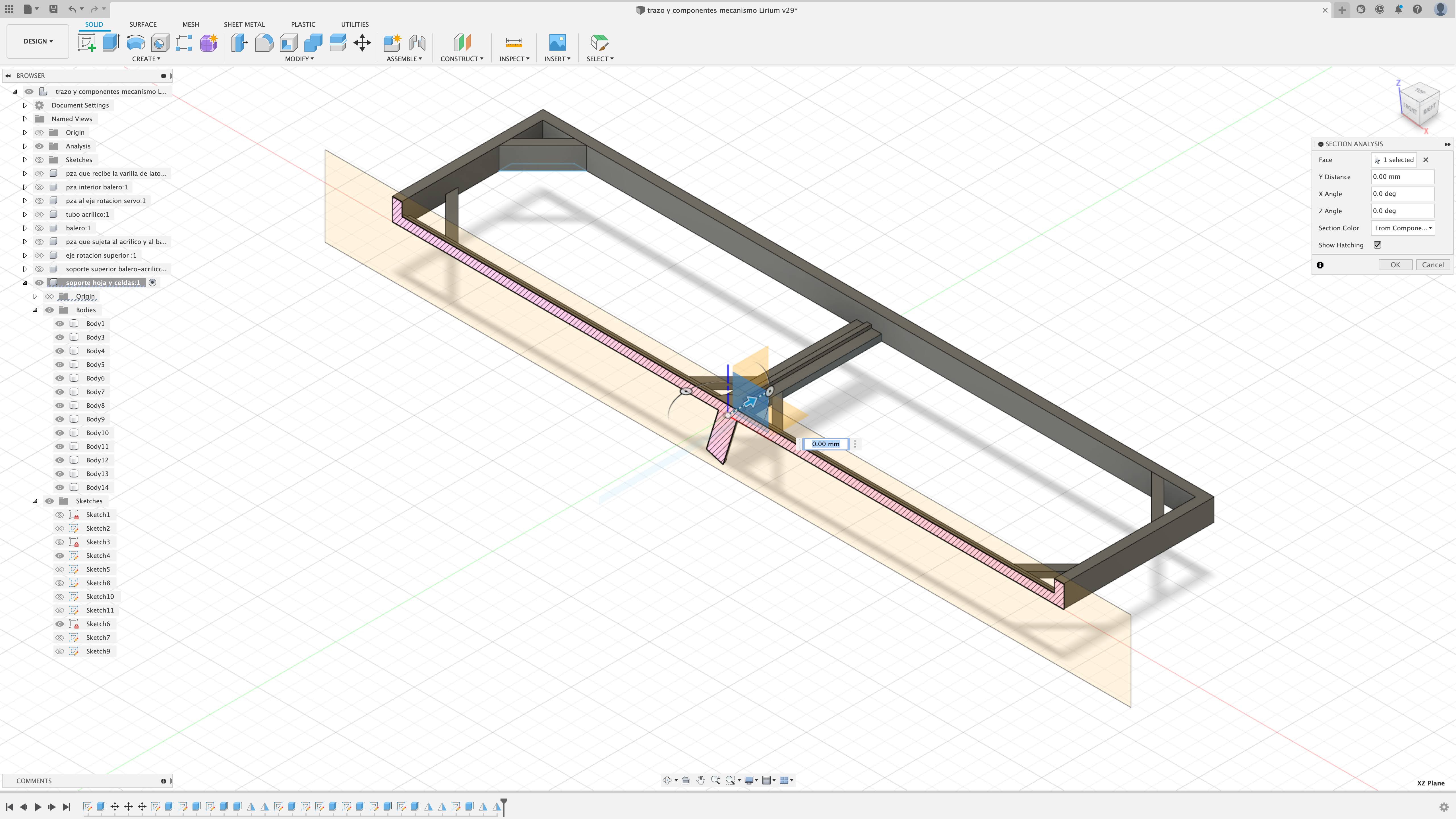

A section view of

the solar cell support that will be 3D printed.

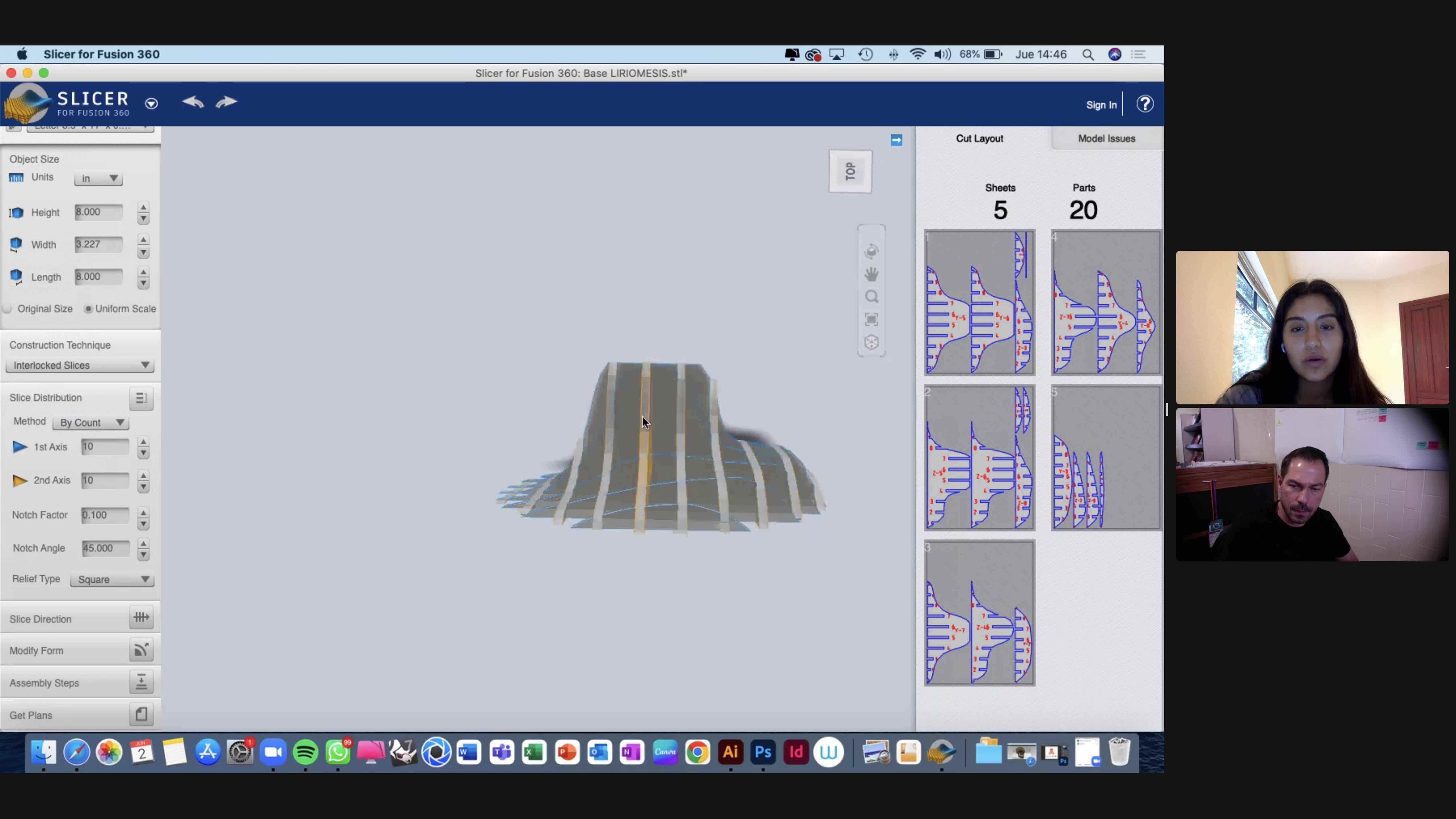

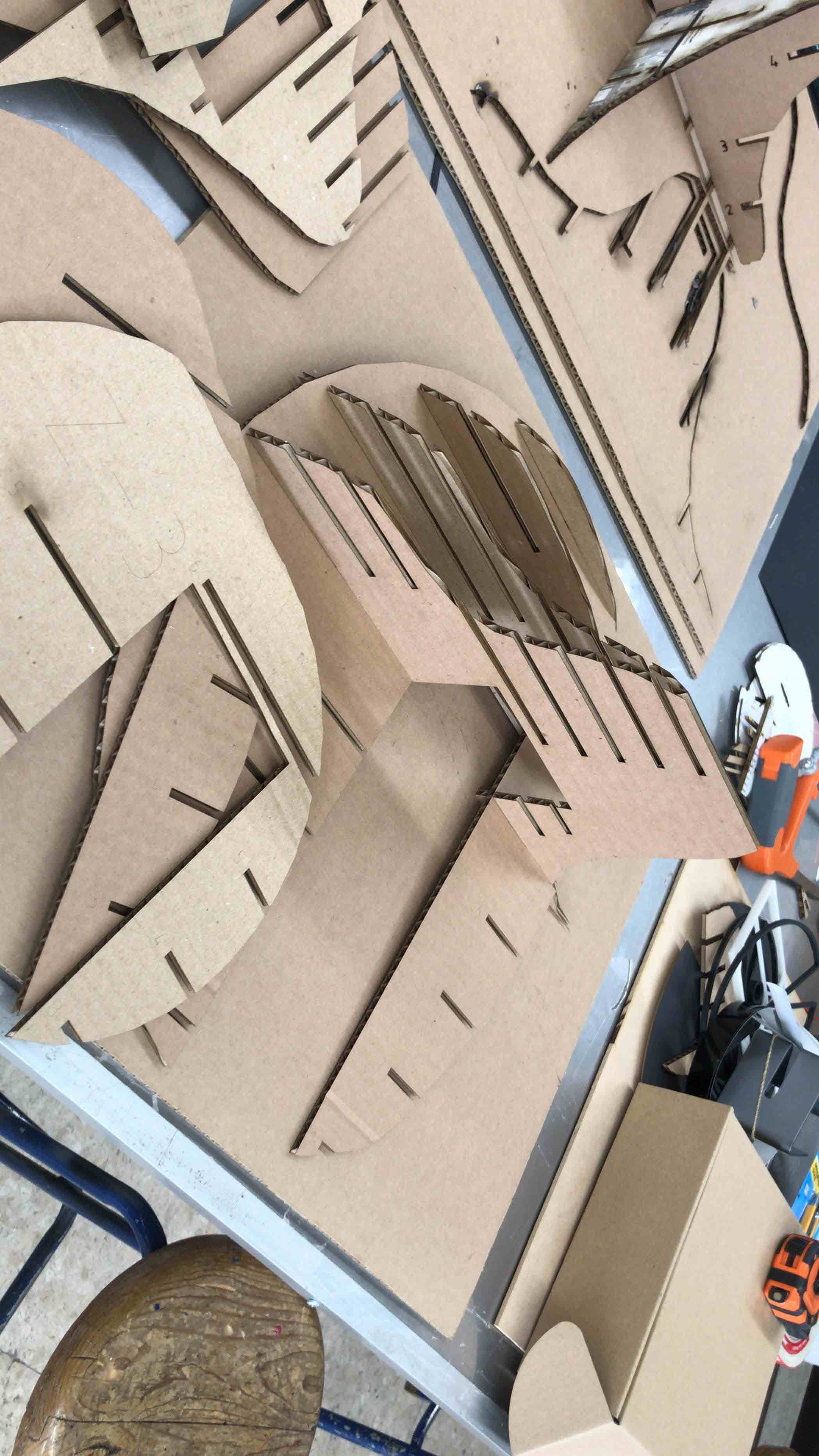

Cheking the base

3D model in Slicer, this software convert your 3D models into

different forms of construction techniques, in this case we

use the Interlocked Slices because I want to make it with

corrugated cardboard.

I want to fit

this components into the base, so here I made some drawings

in the image to show it to Paulina so I can explain better

my idea and wich components to fit in.

A drawing

direct into the slicer image to indicate where I need the

space to fit those components.

investigation

a place to re-connect

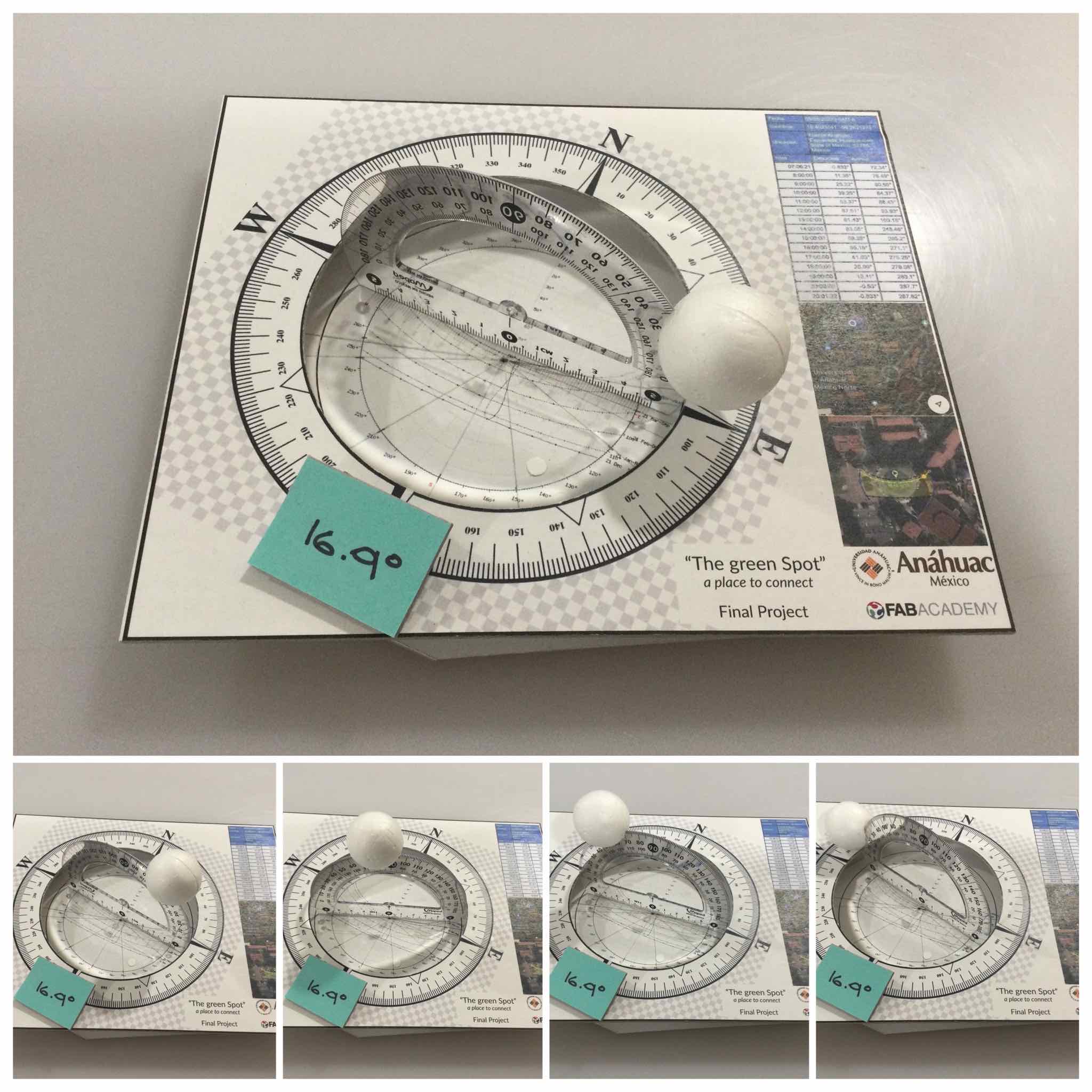

position of the

sun

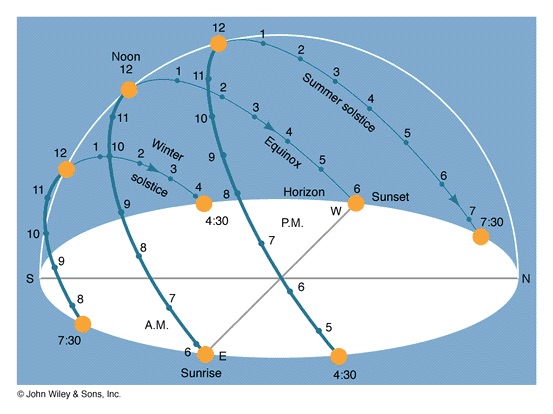

Path of the sun

here in the Universidad Anáhuac México

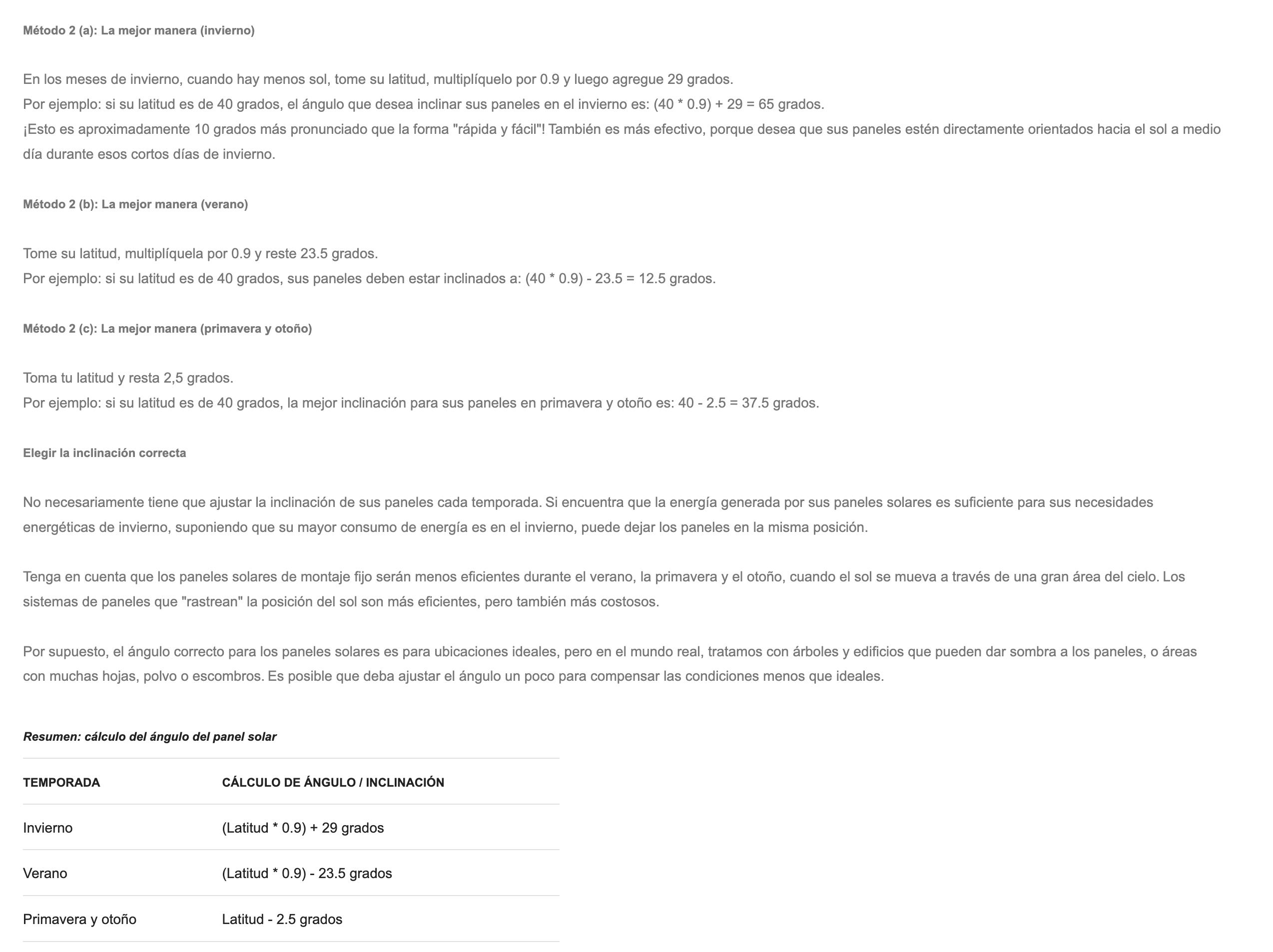

Different methods

to choose the right angle to set up your solar panels

path of the sun

in summer and during winter

the incline I

choose for my panels is 16.9º

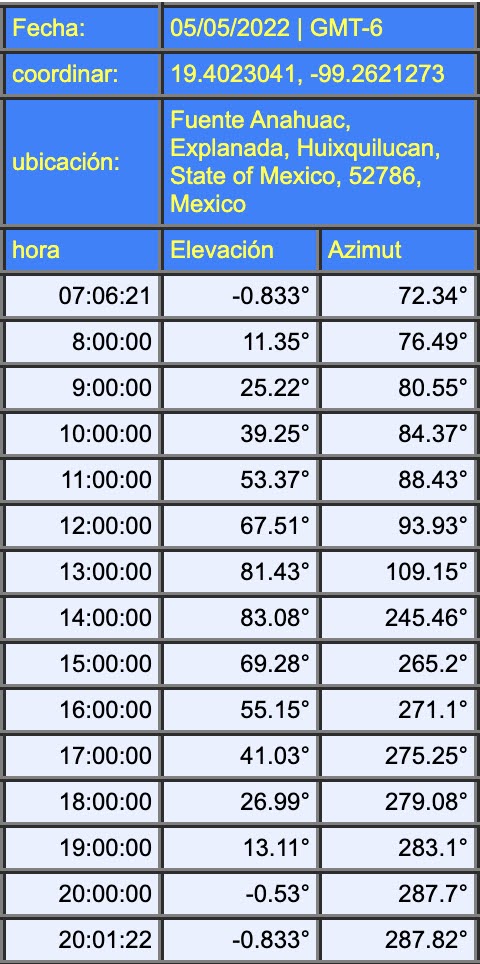

this is a table

with the altitude and azimuth of the sun in its path right

above the University

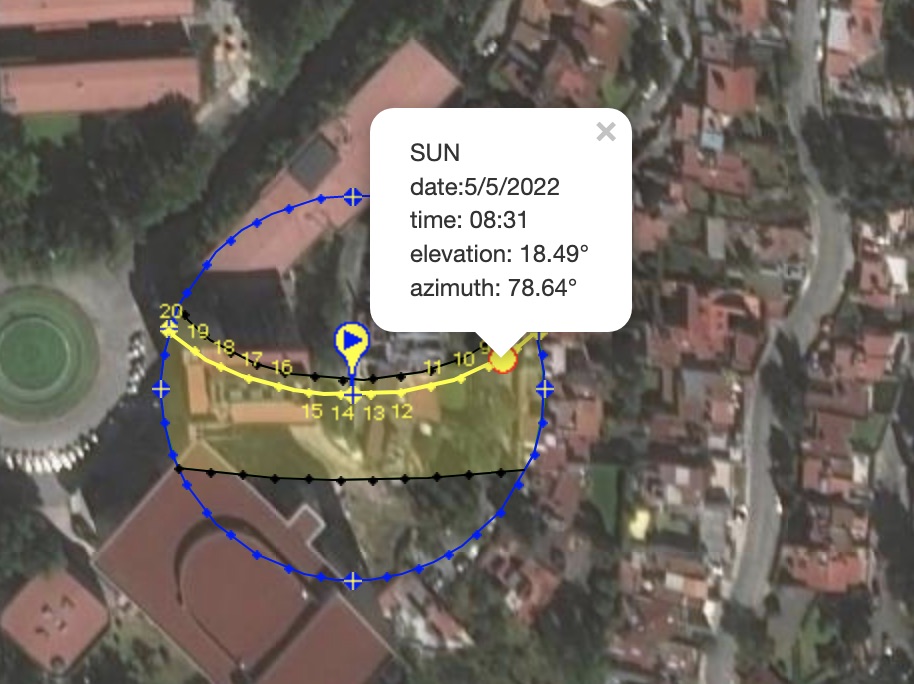

I made this to

visualize the path of the sun mention in the above table, with

this I be able to define the position of the solar cells and

time spending in that position during the day, the next day,

at 6:30 AM they return to the initial position

IHere we can see

the recomended high of the leds and angle of light of public

luminairies

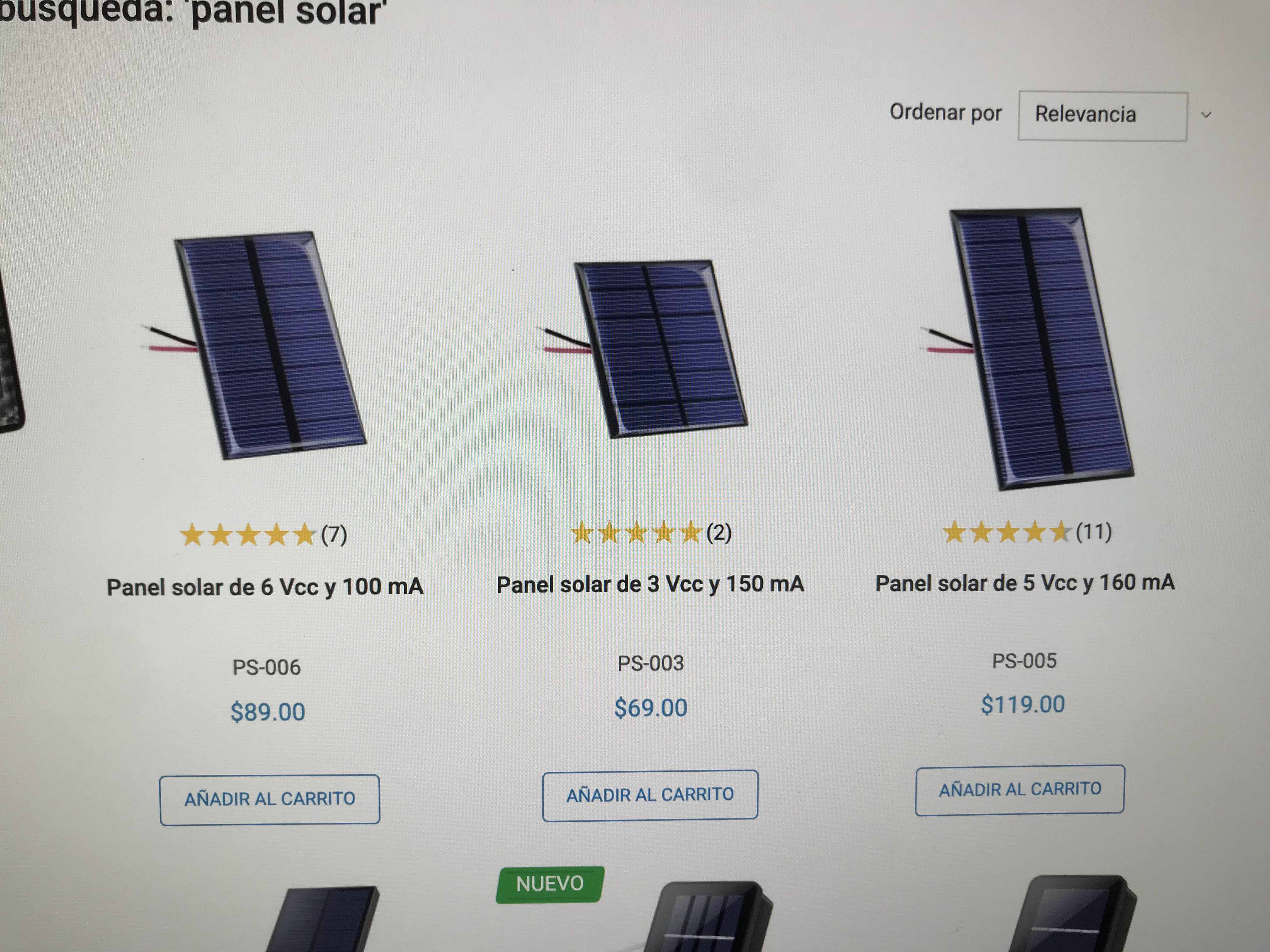

I choose the 5vcc

and 160mA for the project, because of the batteies and the

servo

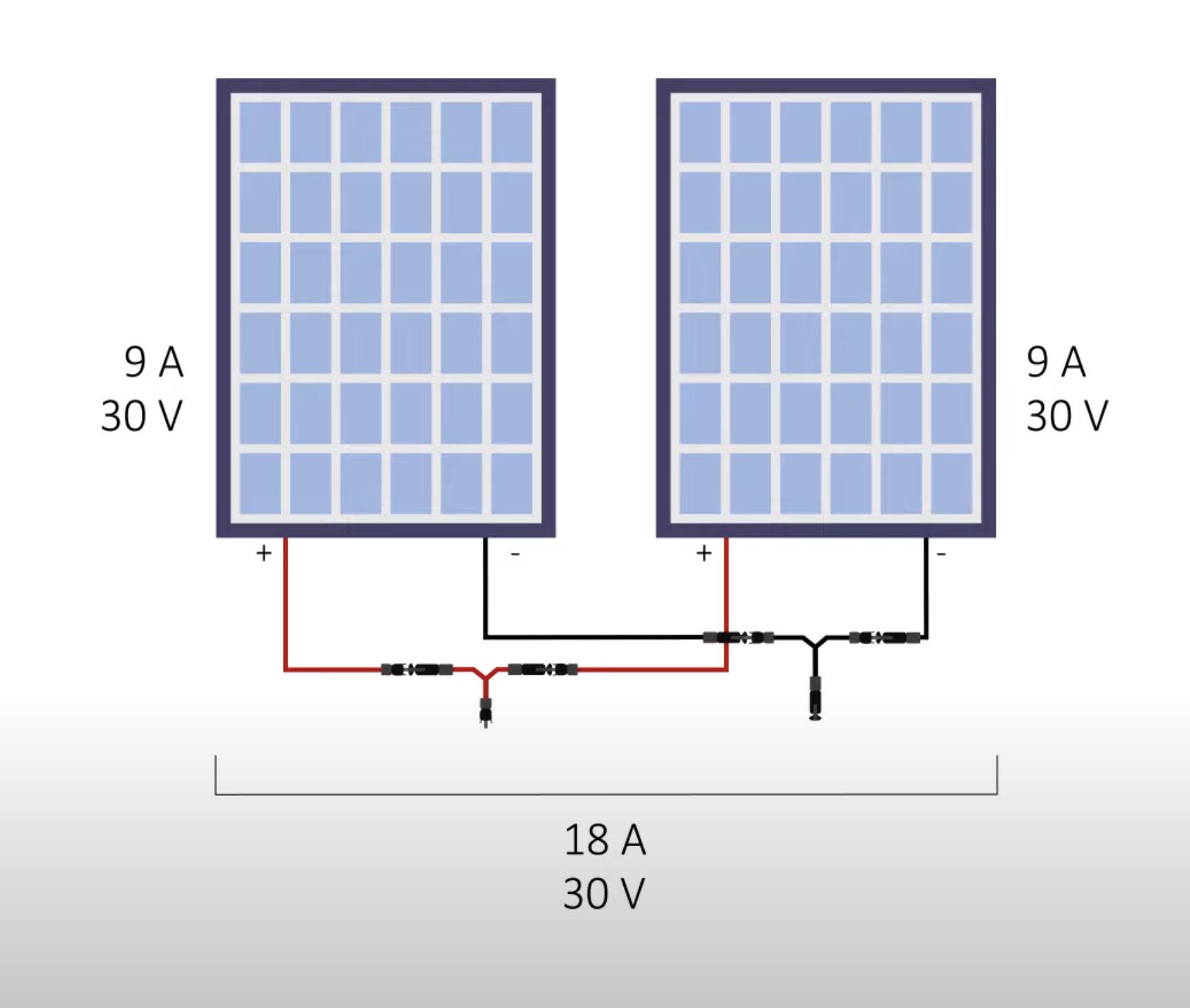

The connection of

the solar panels should be in paralel to maintain the Voltage

of 5V but sum de Amp, in this case 160x4=640mA

production

a place to re-connect

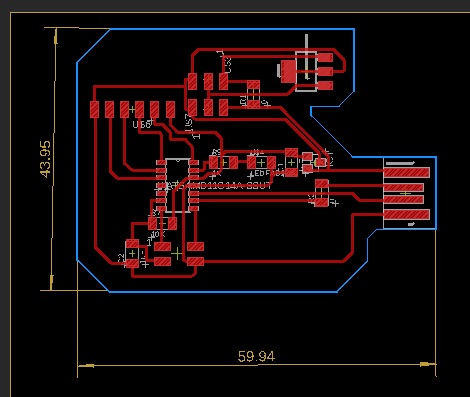

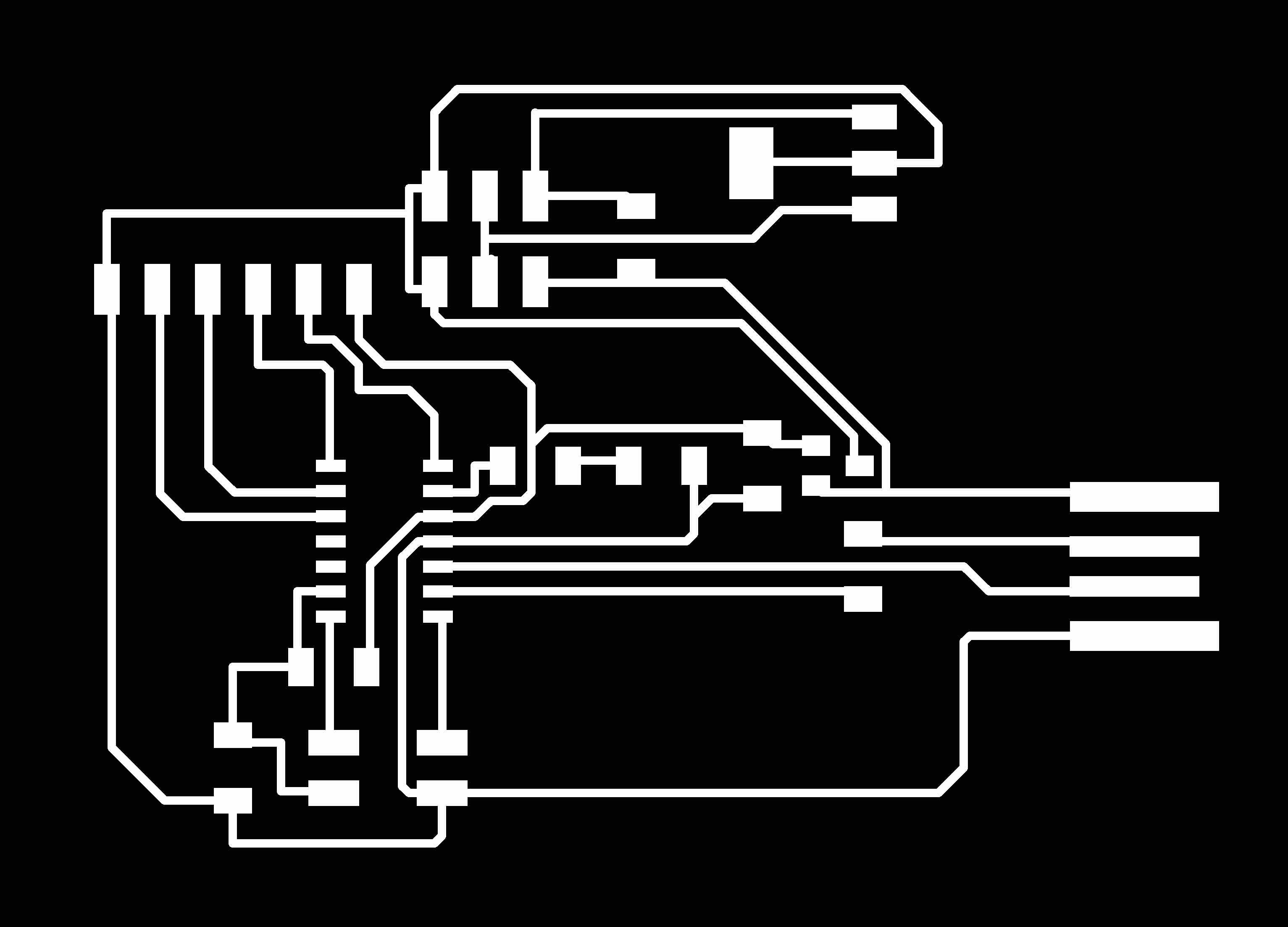

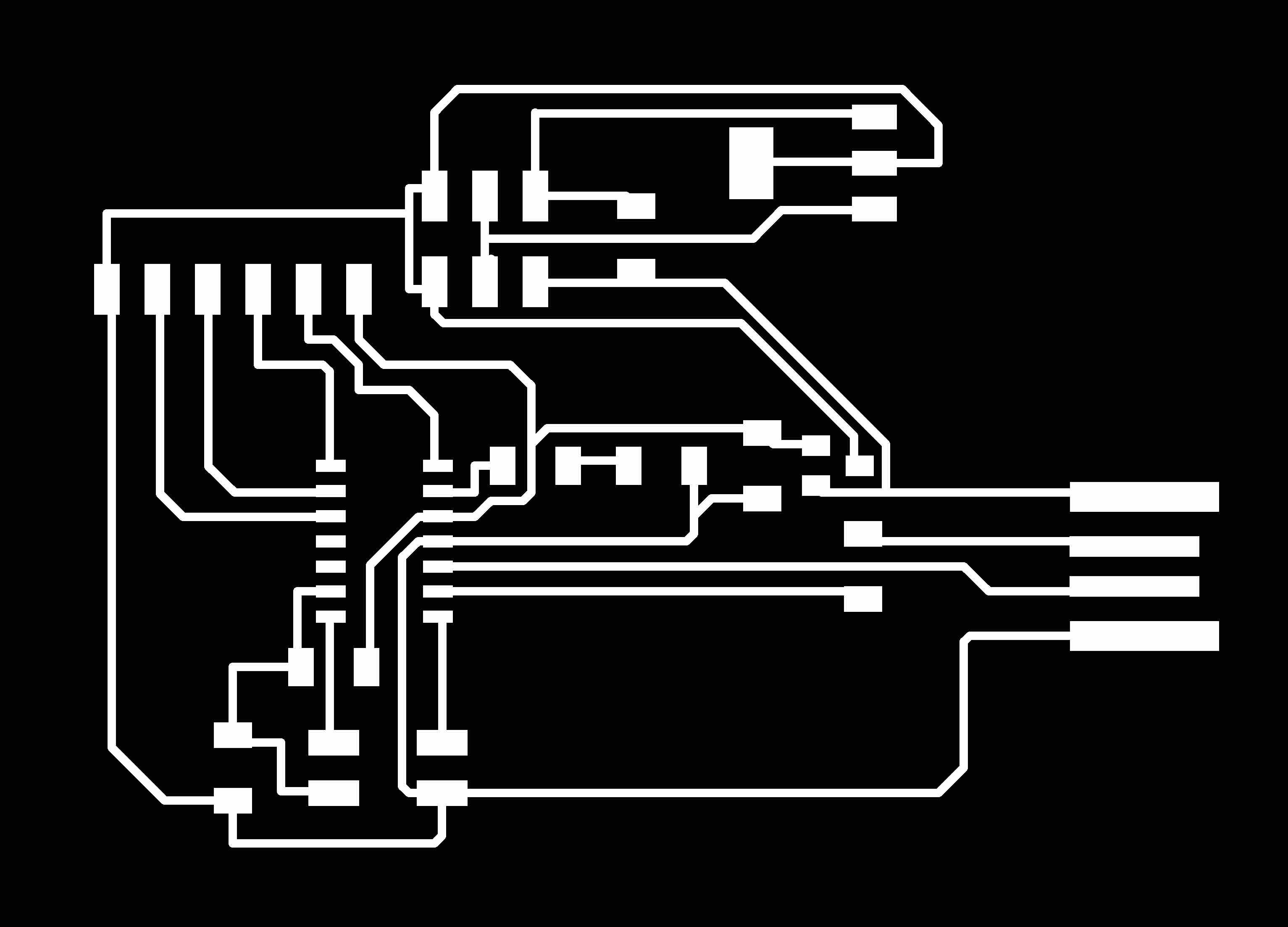

Image of the PCB

with components and traces ready to export it to a PNG image

My redesign of the

SAMDINO, the Hugodino, this PCB its the one who´s going to

control my project

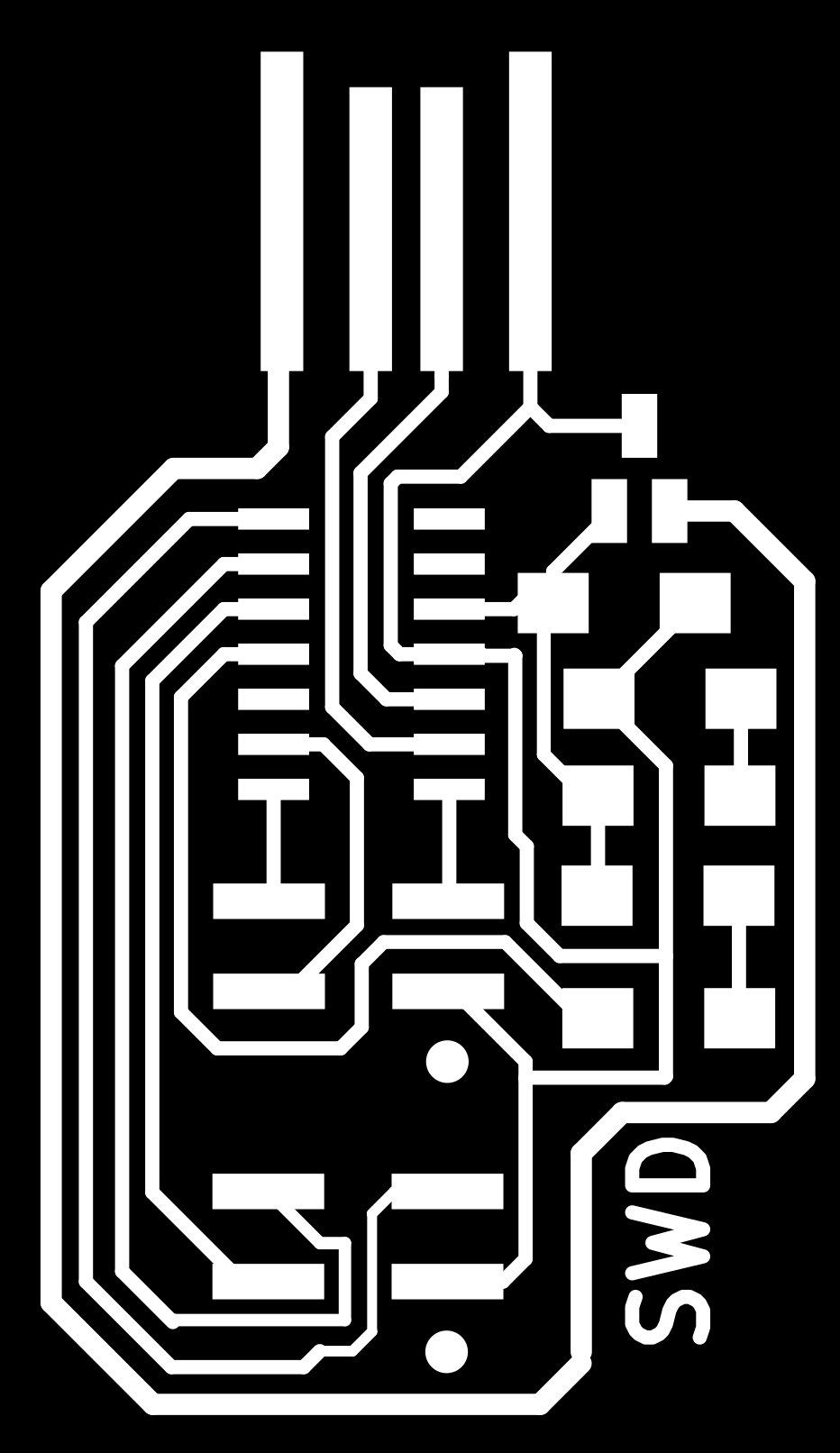

PNG image of my SWD

PCB

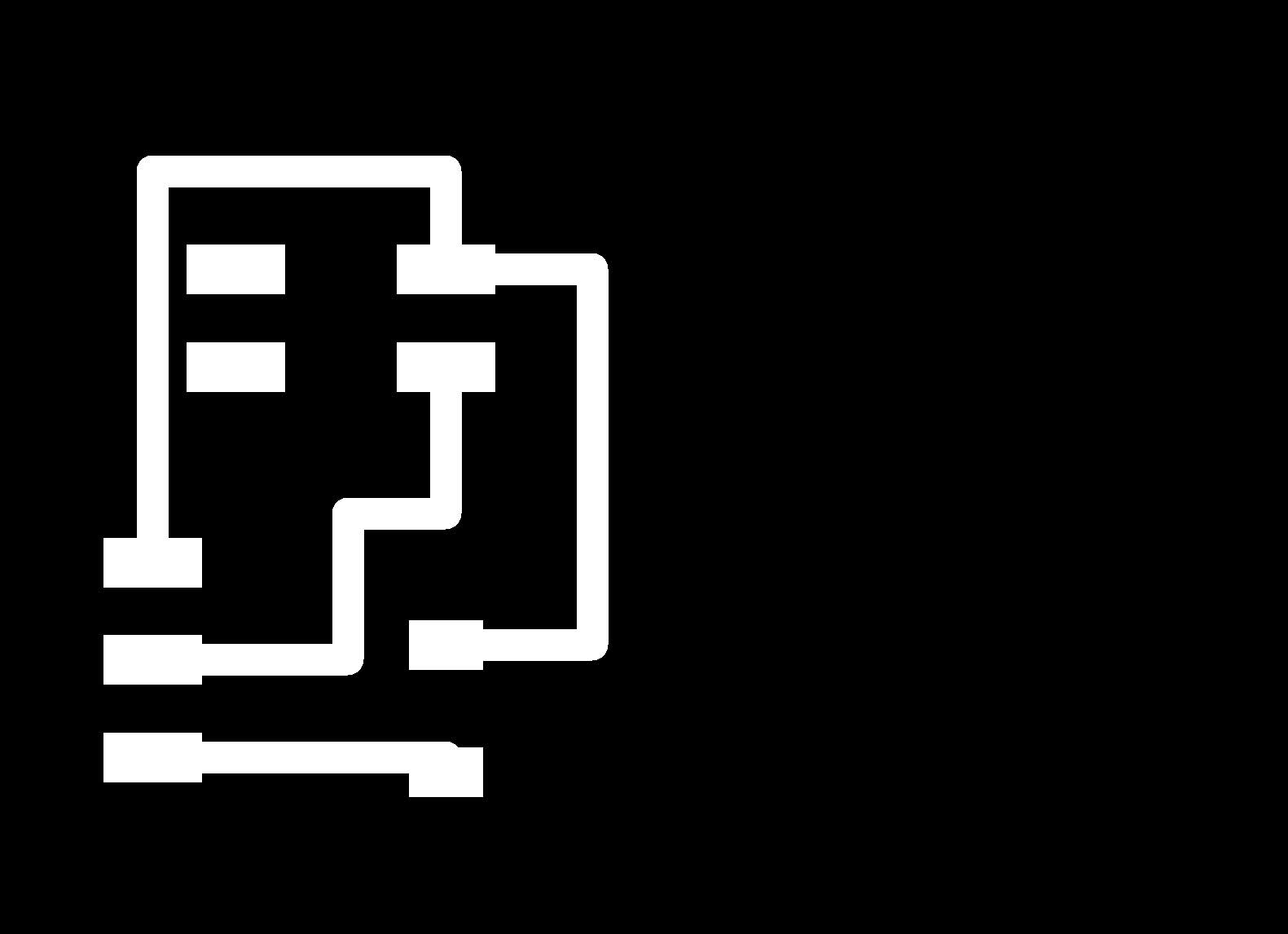

PNG image of my LDR

PCB

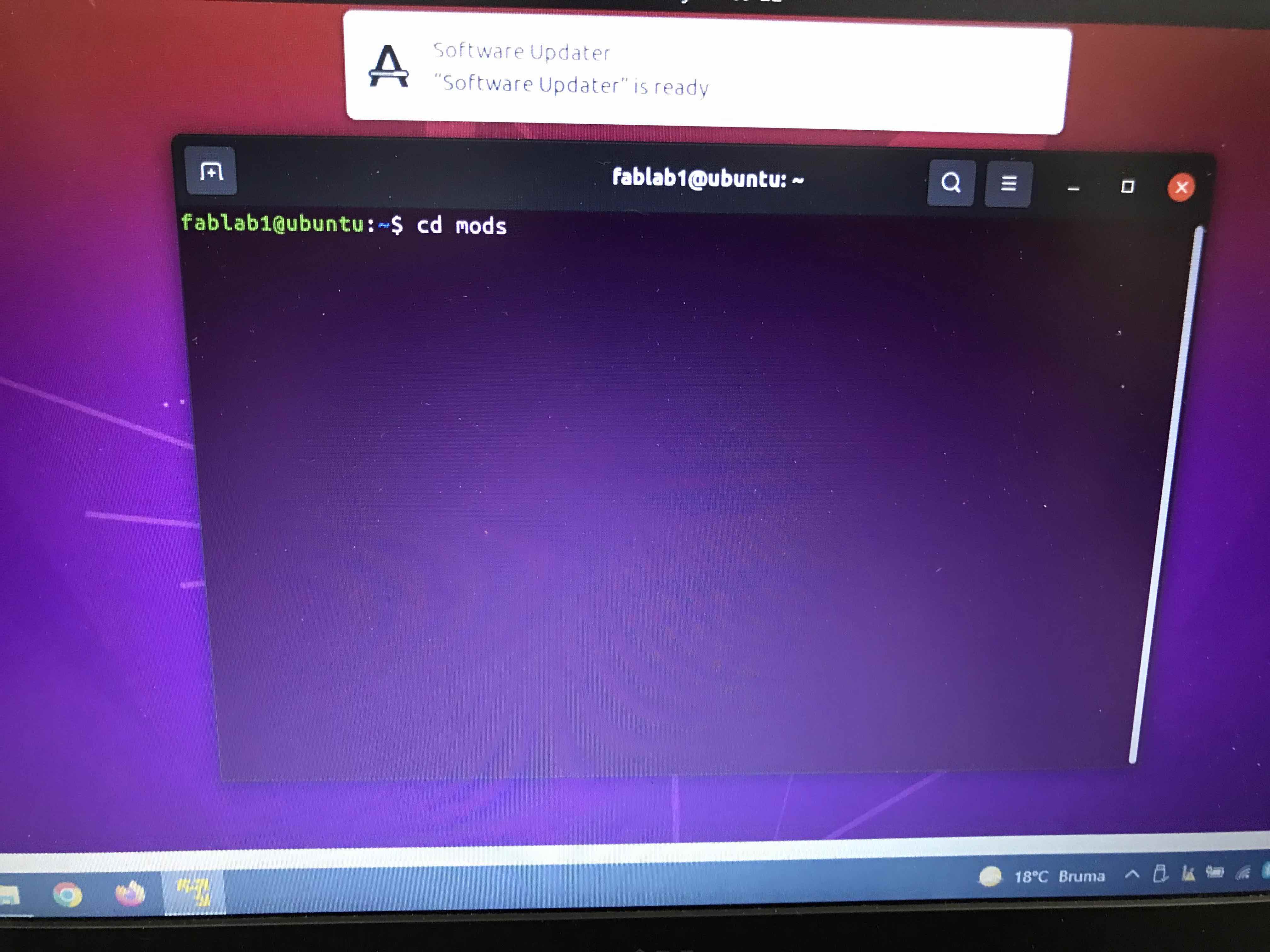

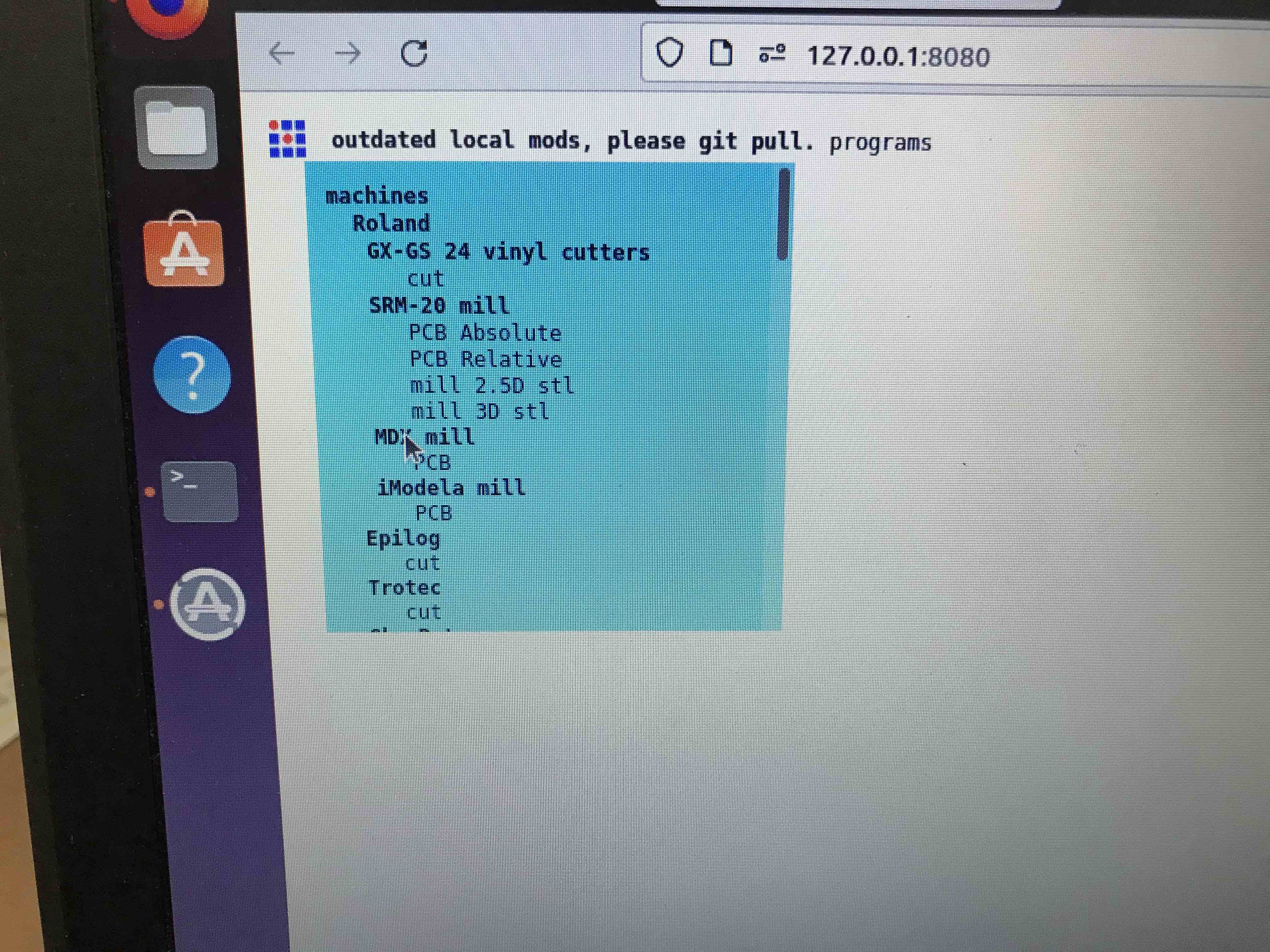

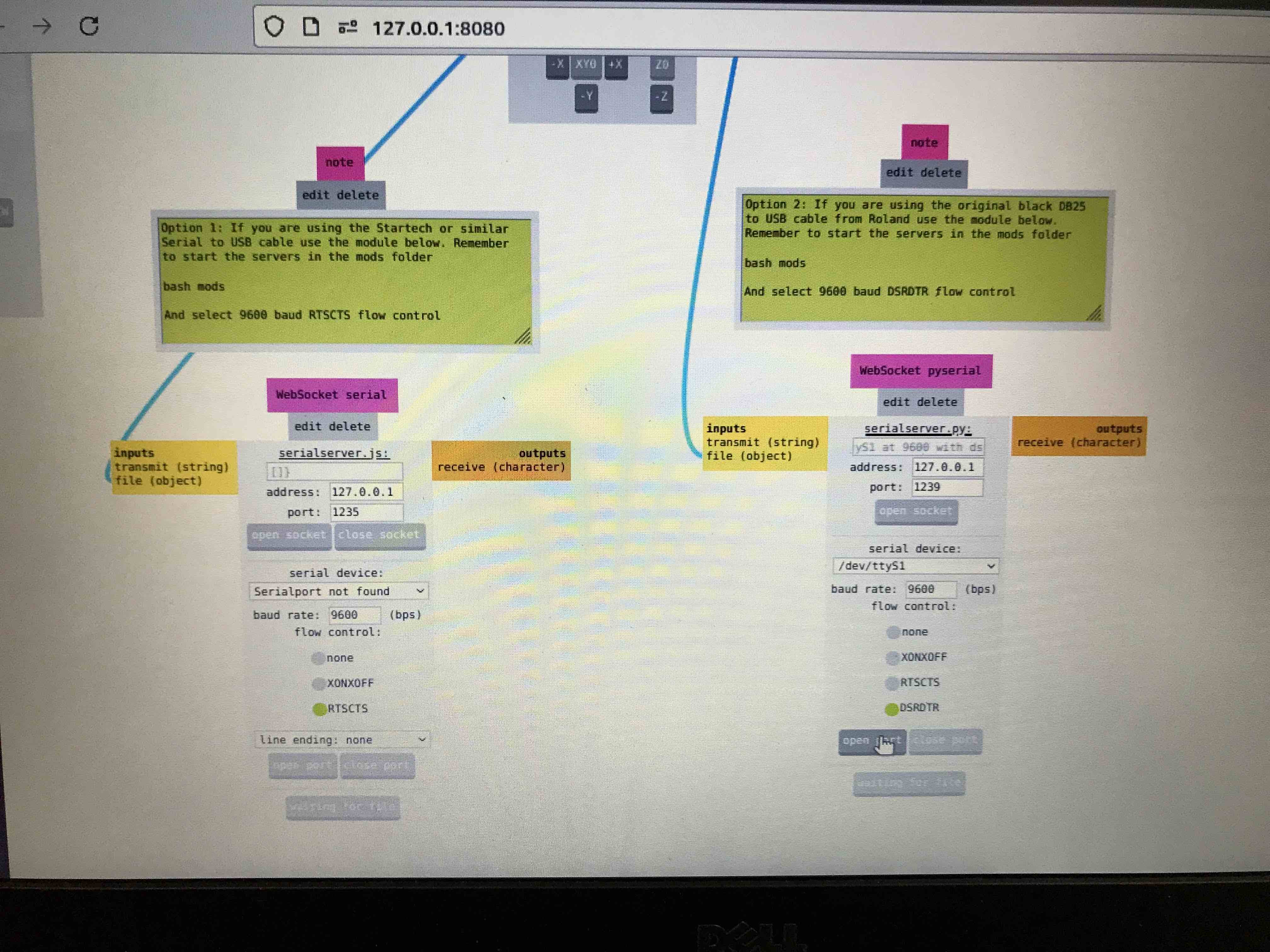

Opening UBUNTU to

open MODS

Opening MODS

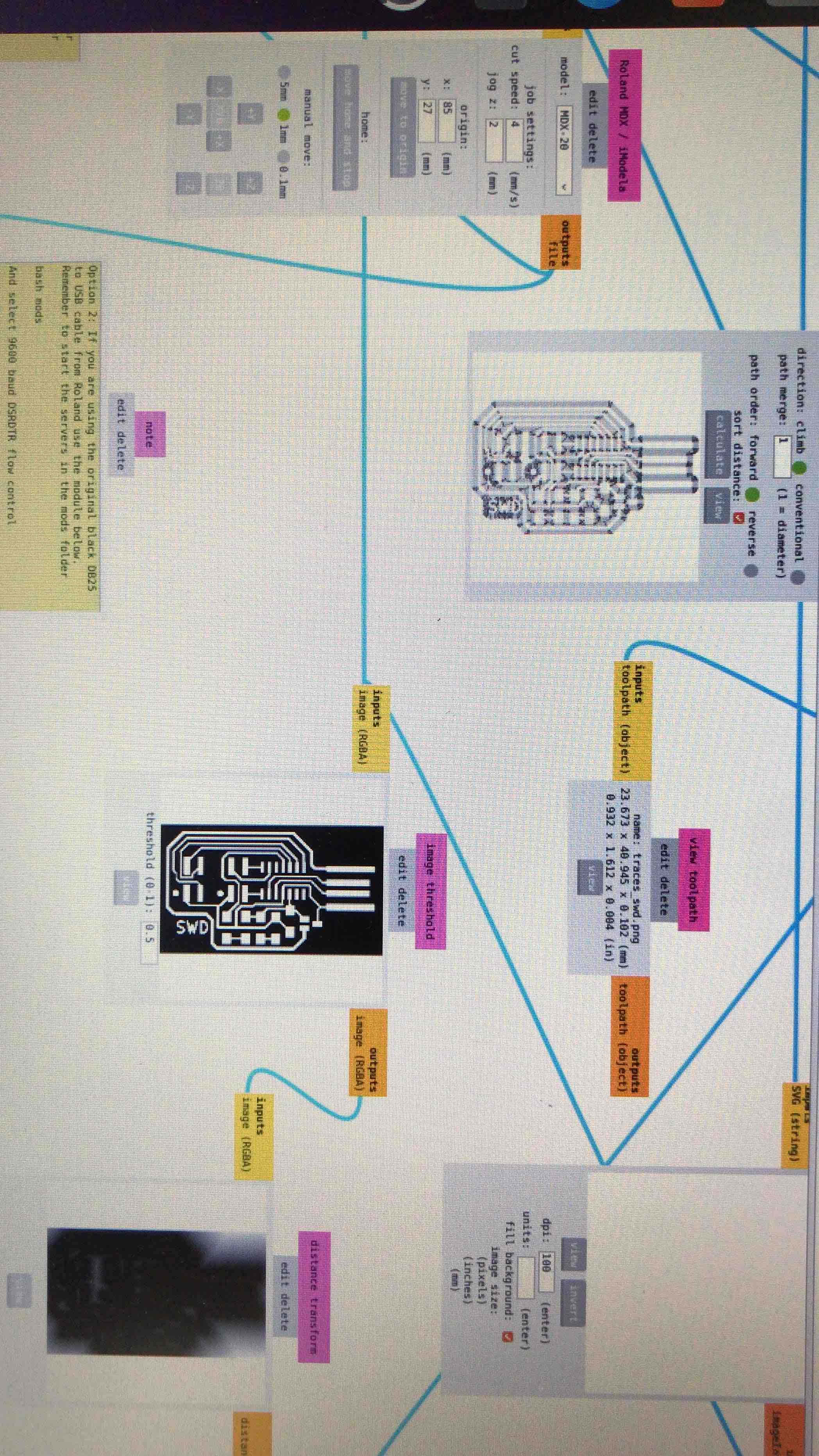

The PNG image of my

PCB, always import a PNG image of the PCB and of the outline if

need it

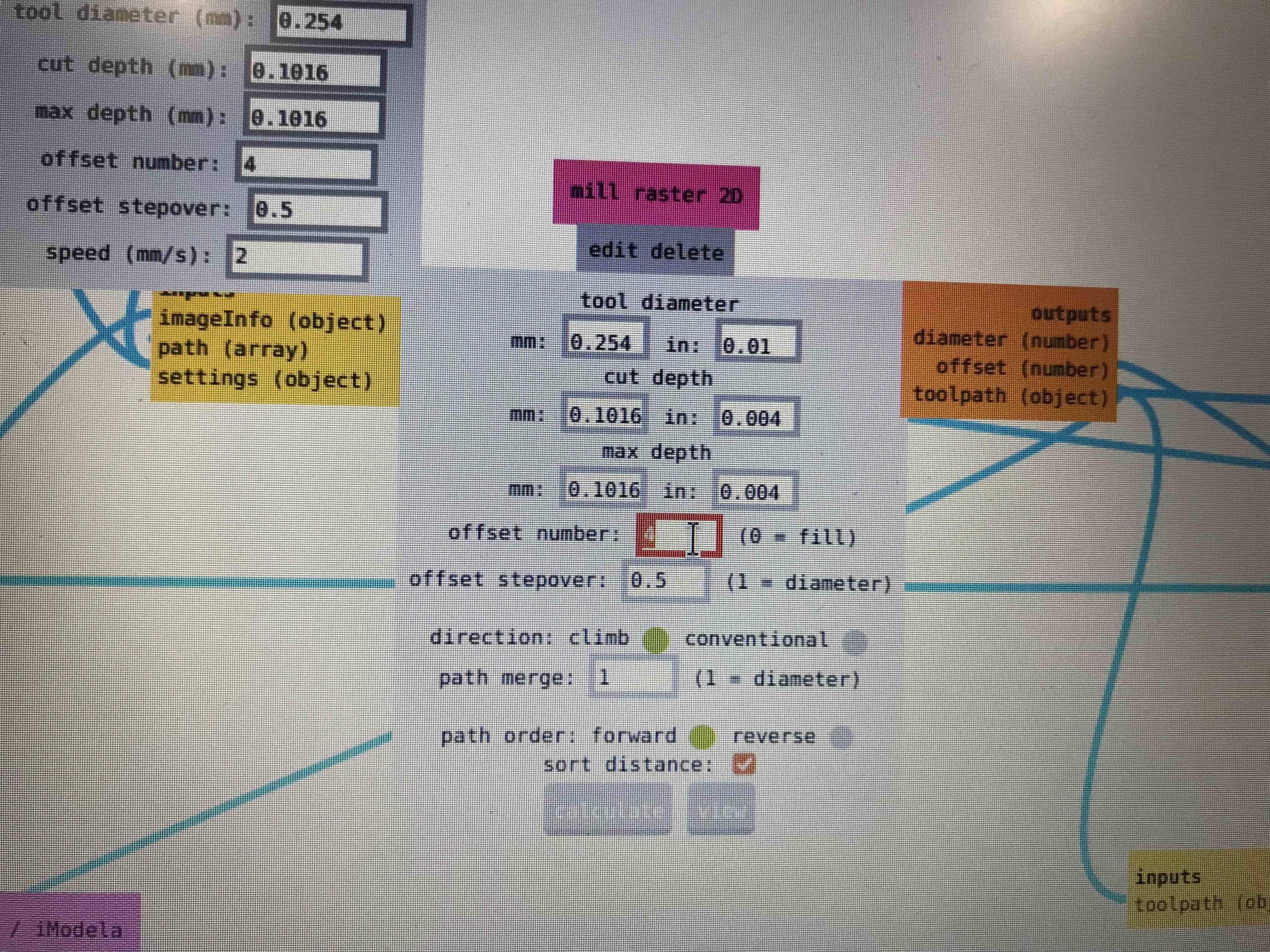

Here I´m about to

change the offset so I obtain better clearance between traces

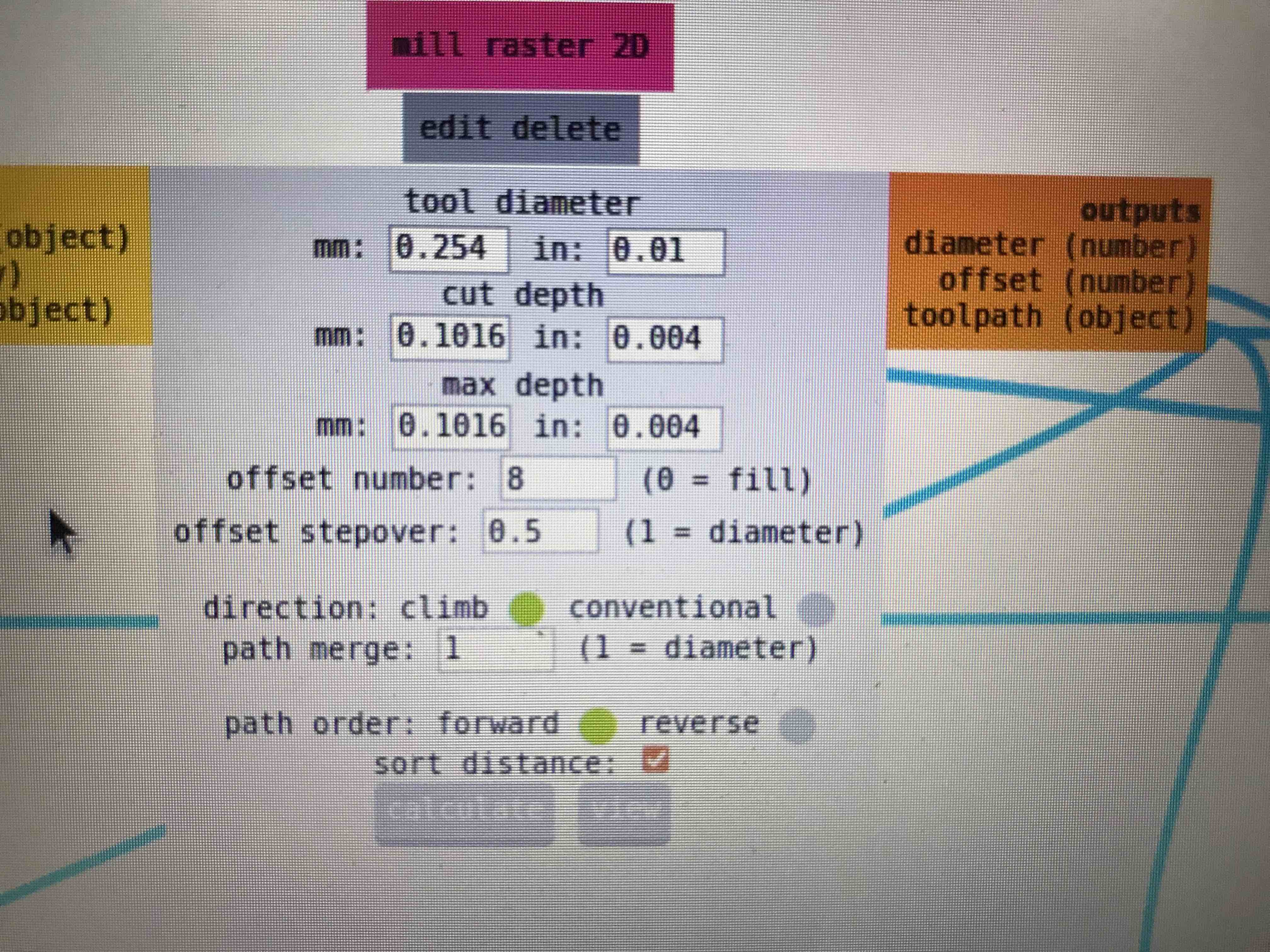

Setting the offset

on 8

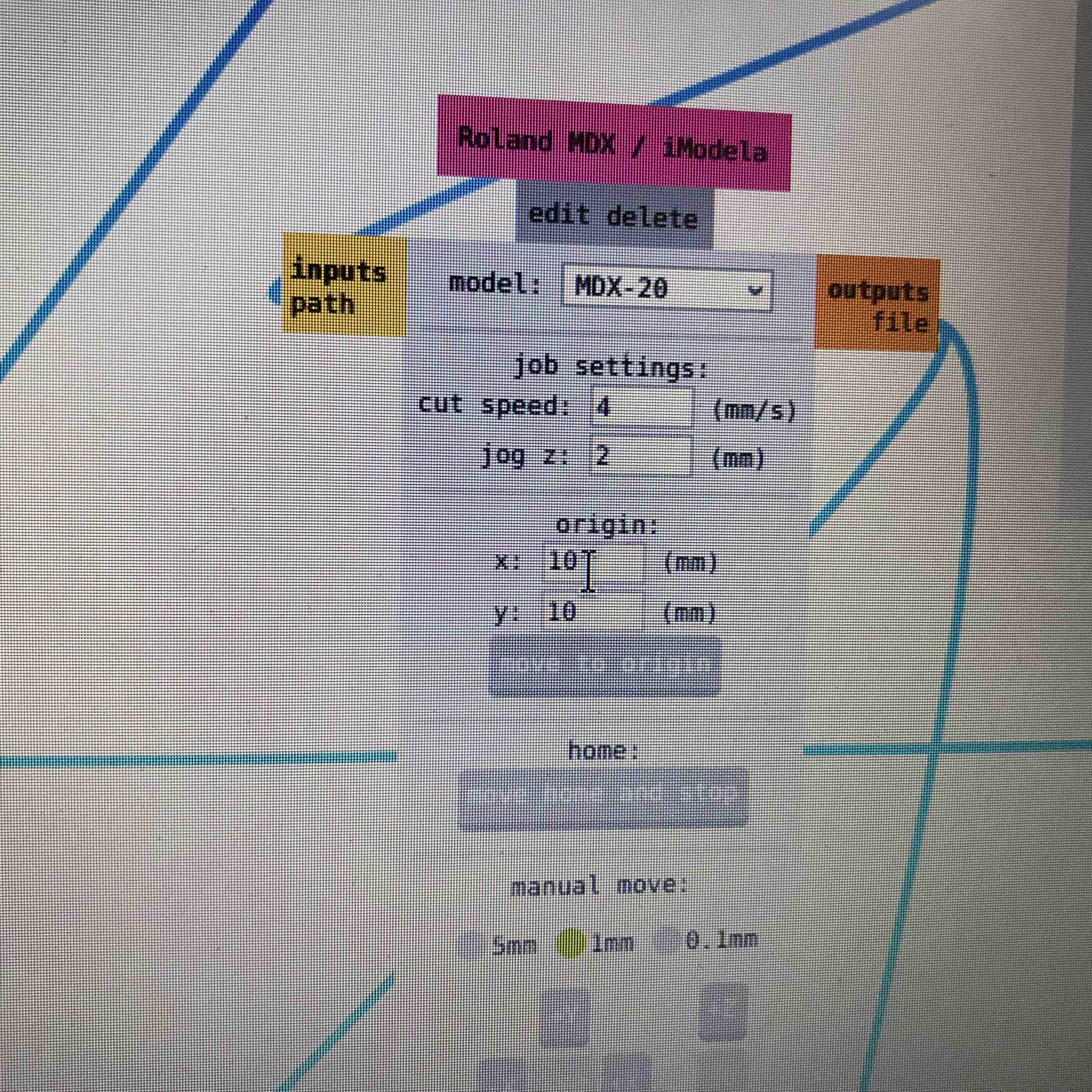

Setting the origin

to start milling

Settings on MODS

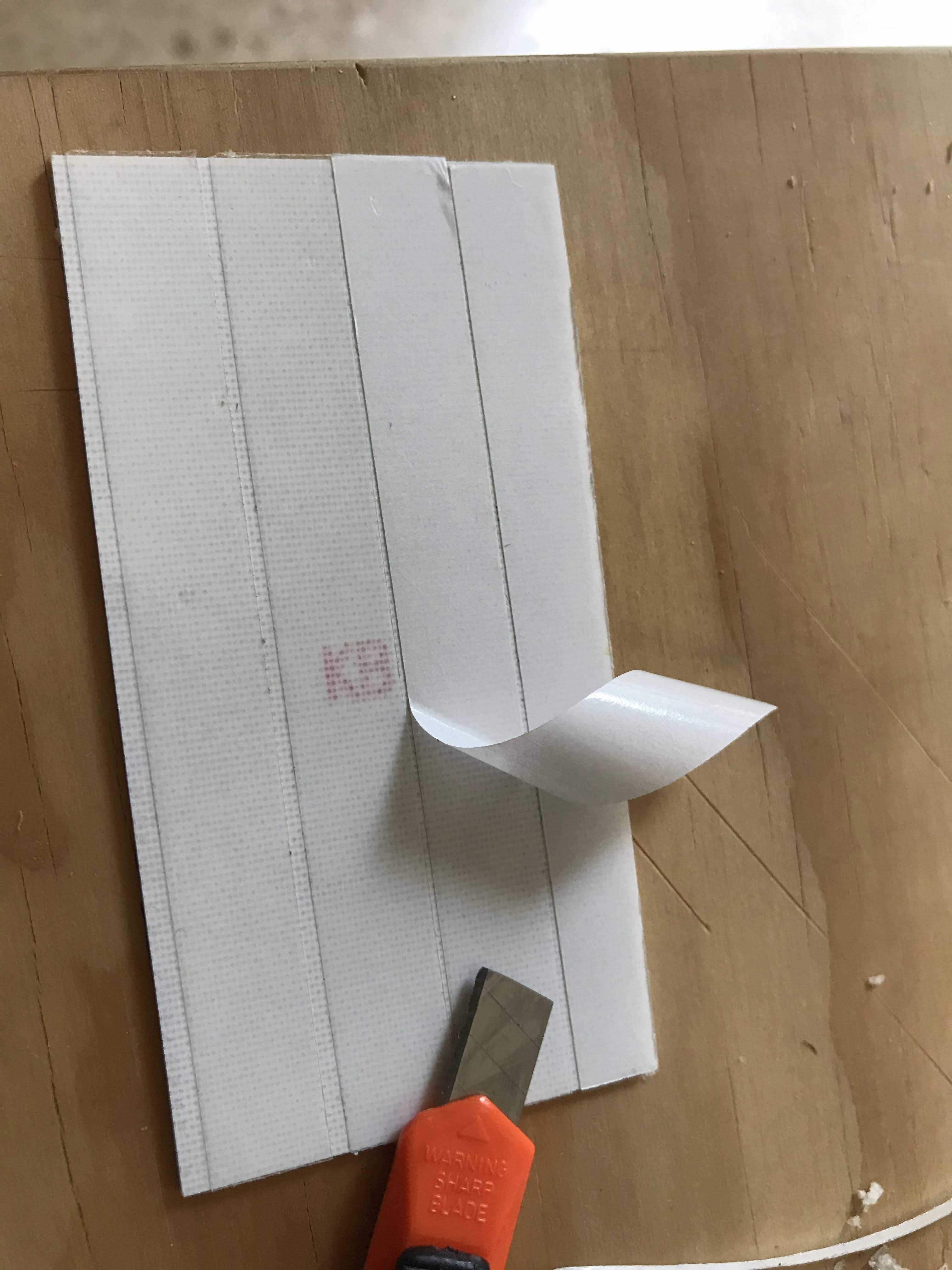

Putting some double

adhesive masking to the coper plate to stick it to the sacrifice

bed

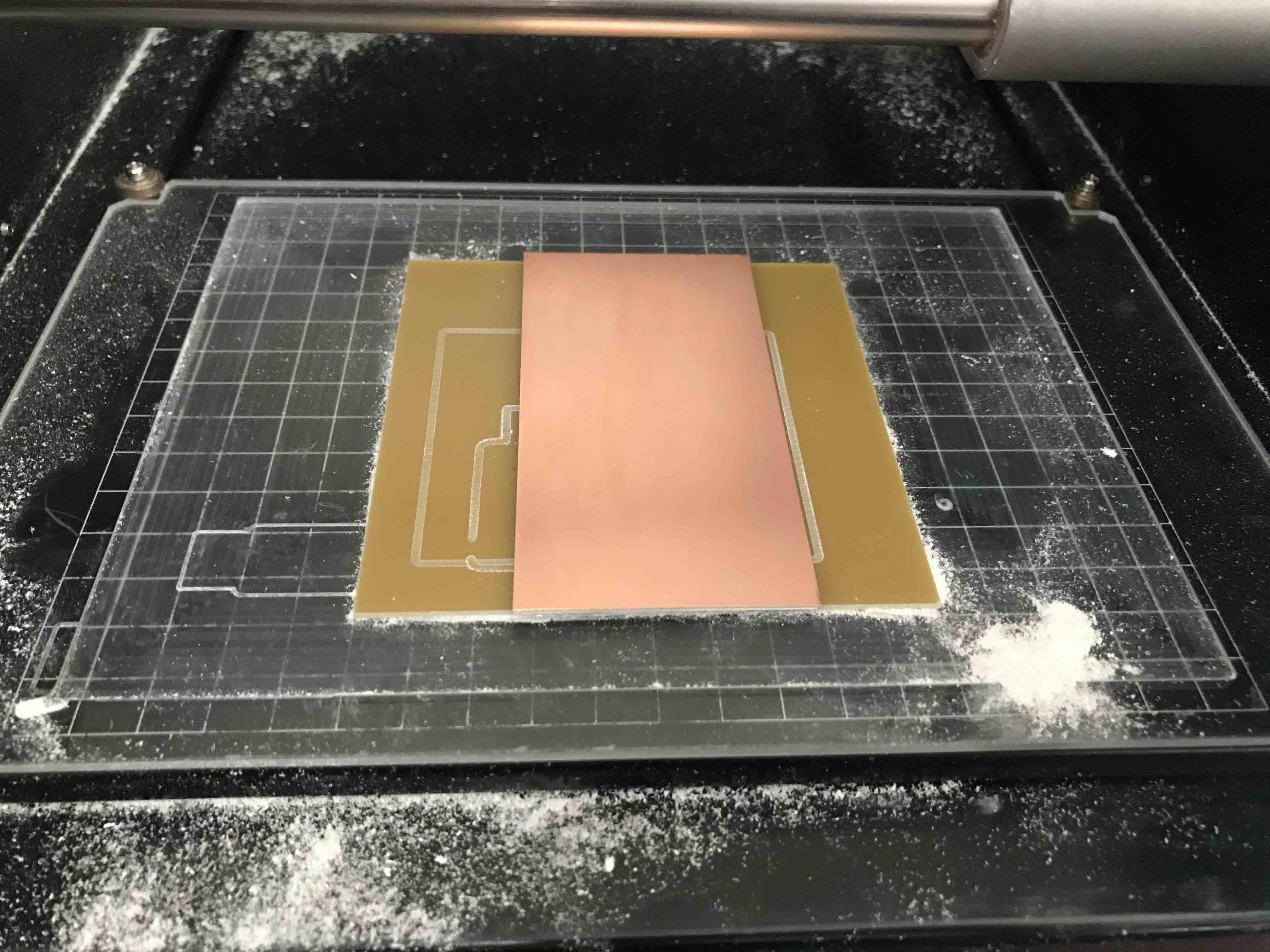

The copper plate

stick to the sacrifice bed

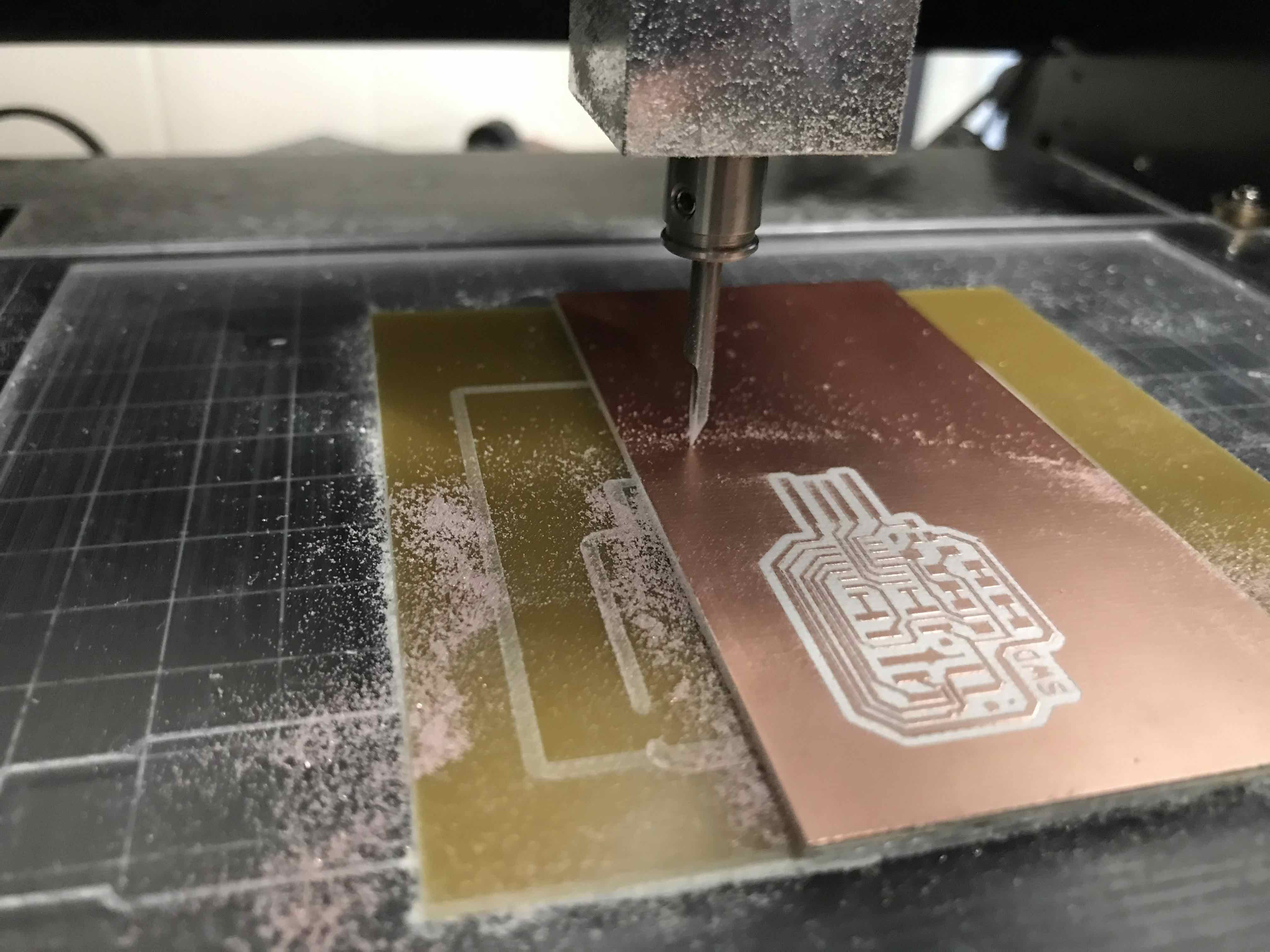

The MODELA just

finish milling my SWD

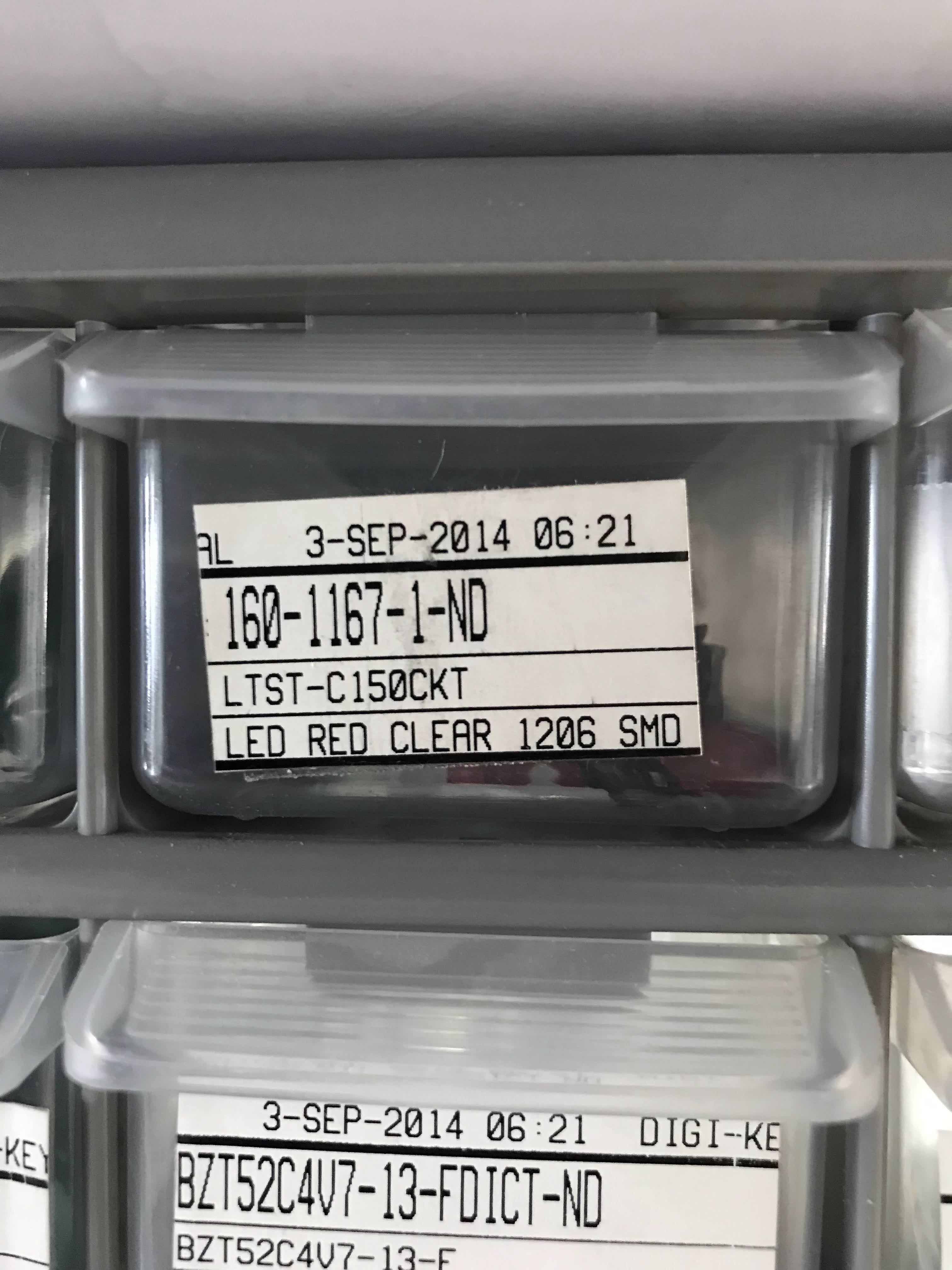

All the components

that our PCBs need are here in little boxes

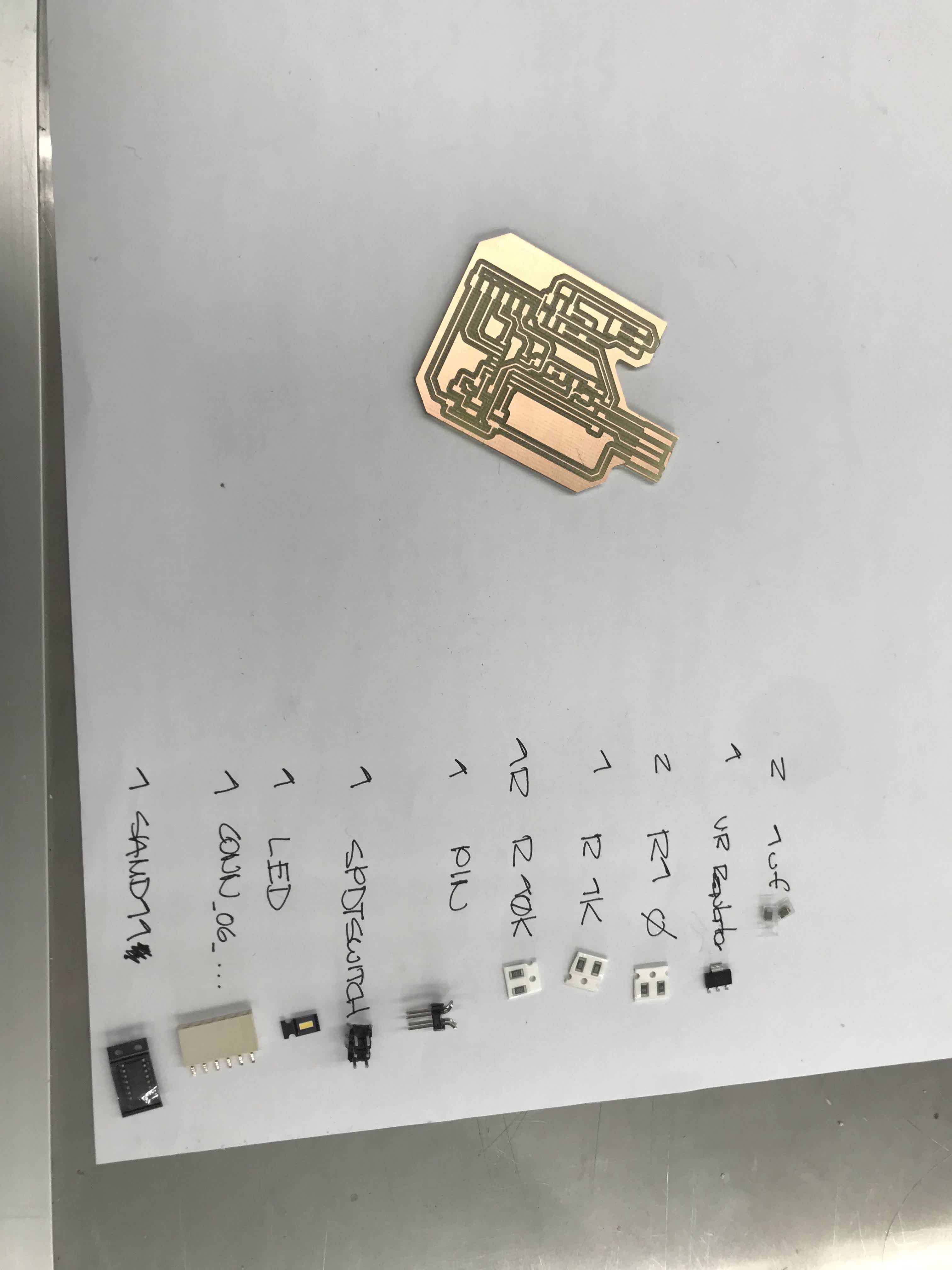

This PCB is for the

LDR and those are the components I need to put on it

The list of the

components I will weld at my Hugodino board

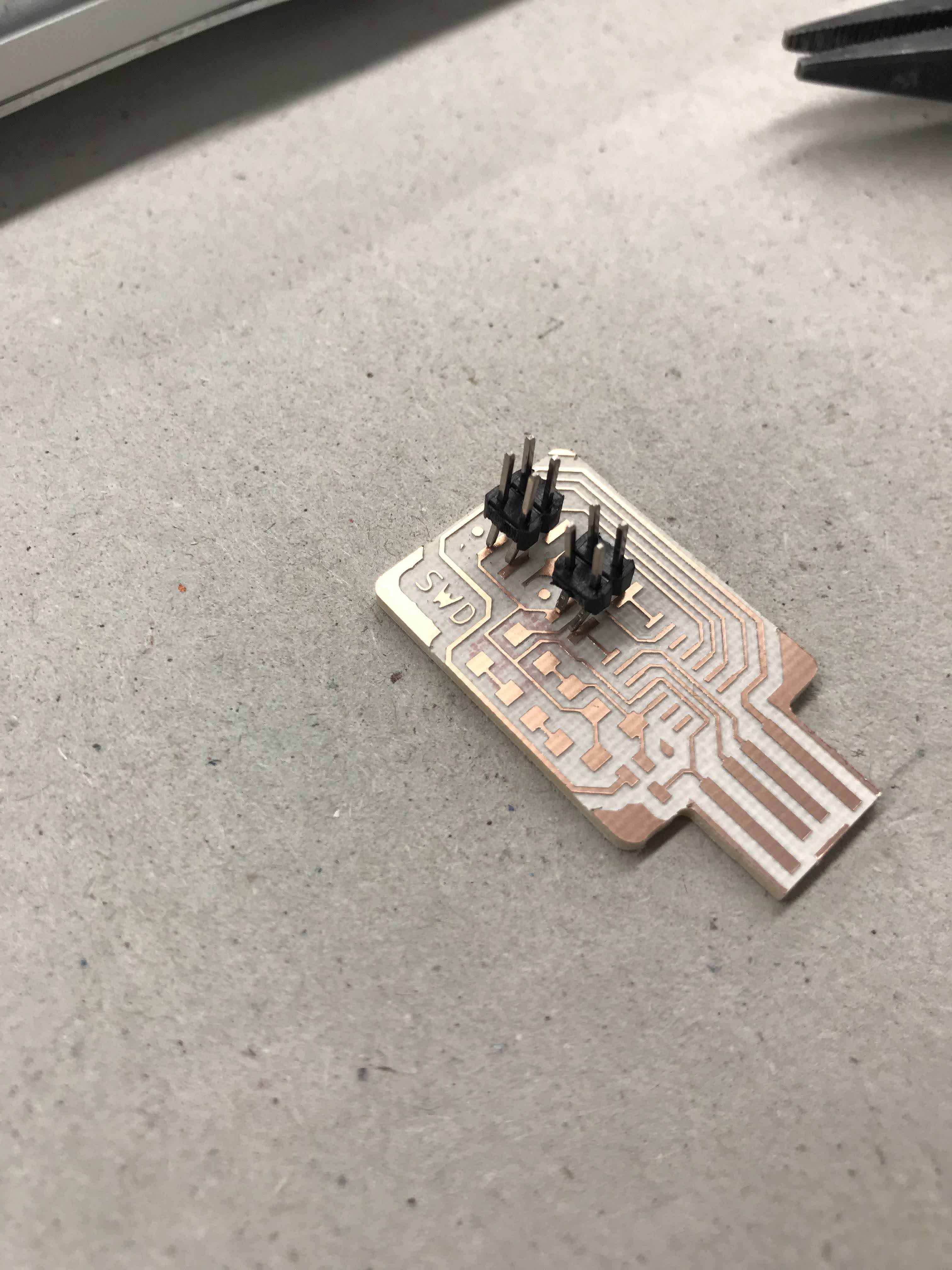

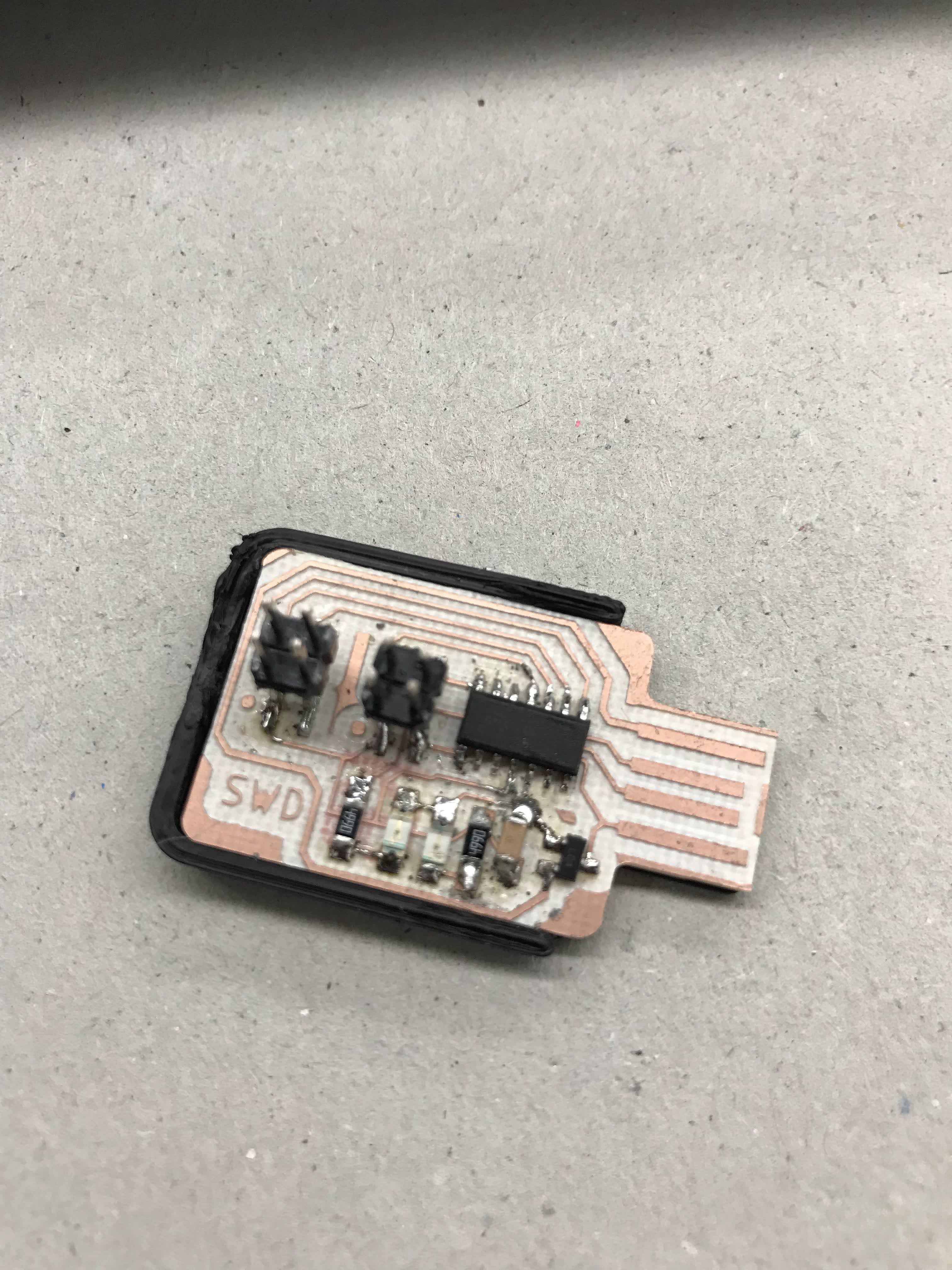

My SWD board

previously to start welding the components

A shot of the SWD

finish, with this I will program my Hugodino board

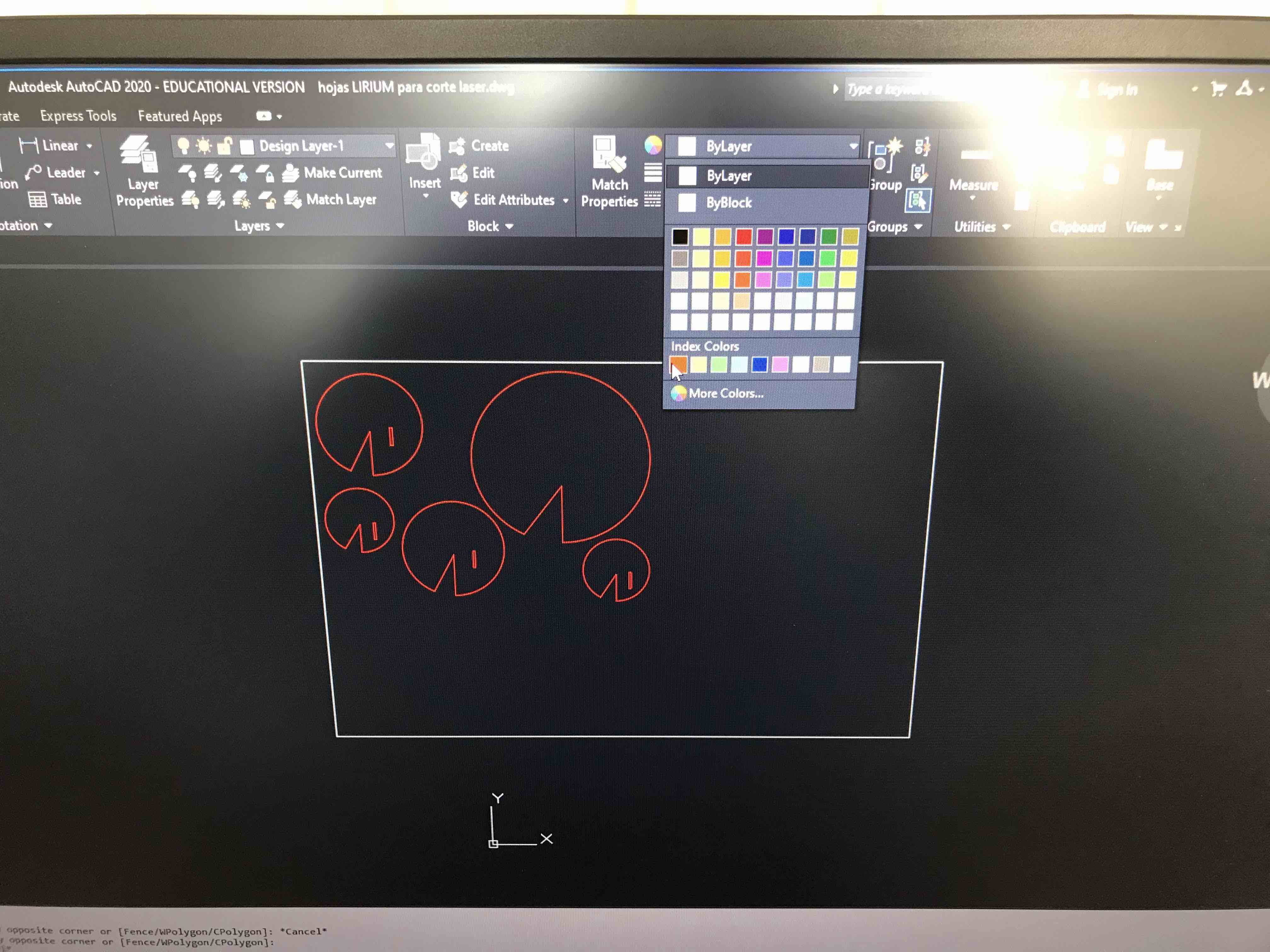

The leafs covers in

Autocad, this drawing is in a DWG format. Here I´m choosing the

color of the layer so the laser machine knows if it is a cut or

just engrave.

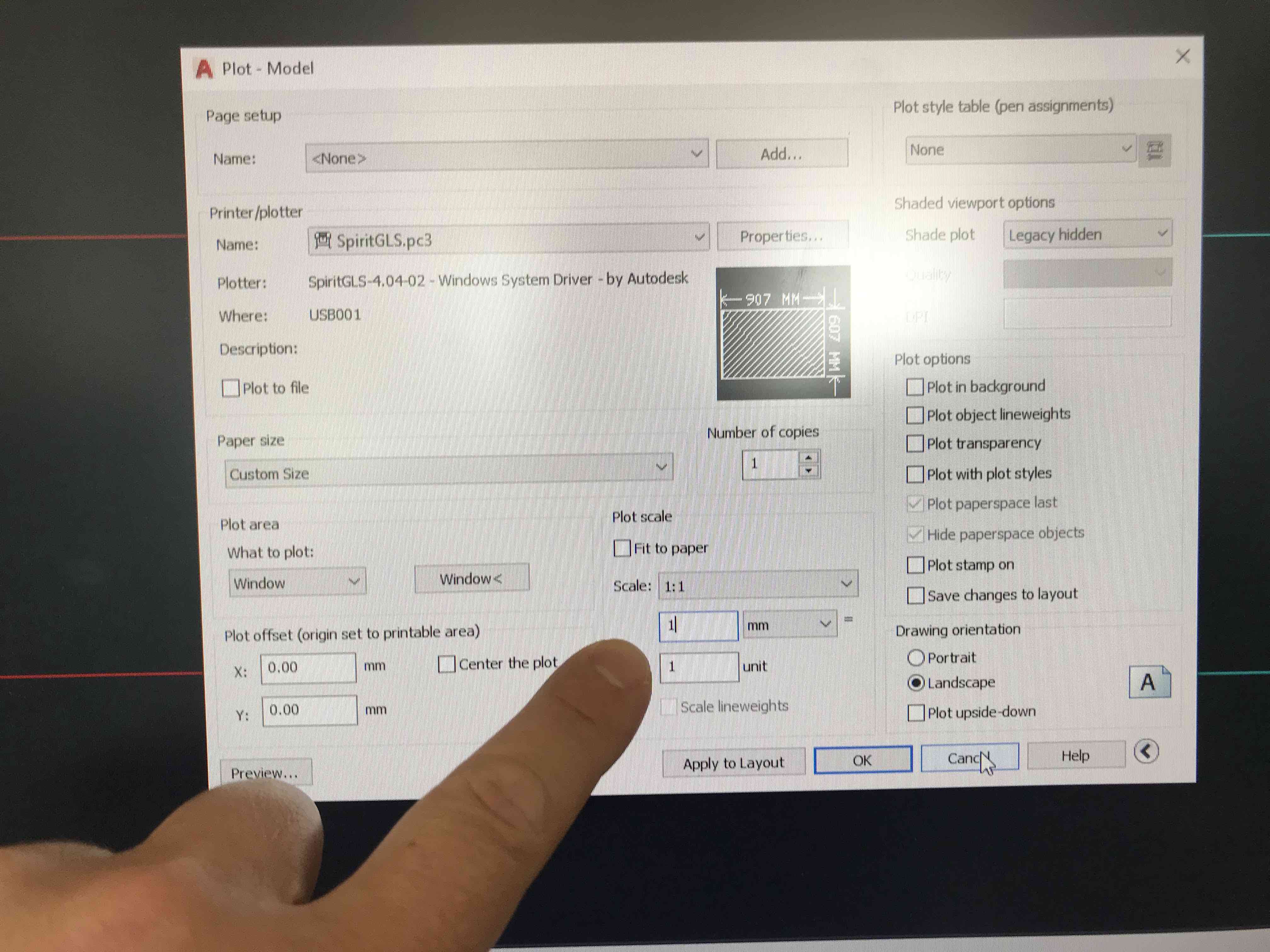

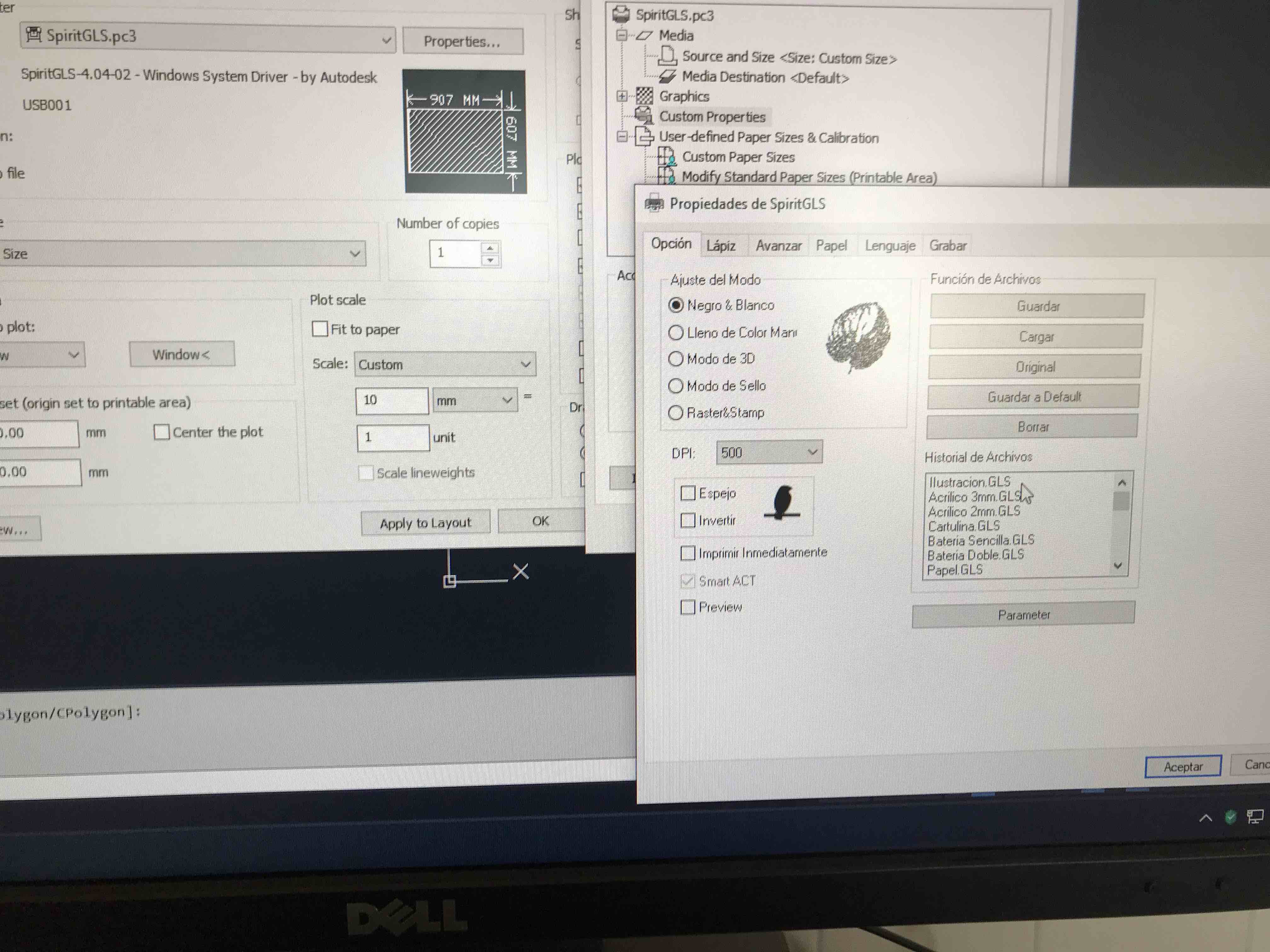

This is the setting

panel of the laser machine, here we put the size, the proporties

and the scale

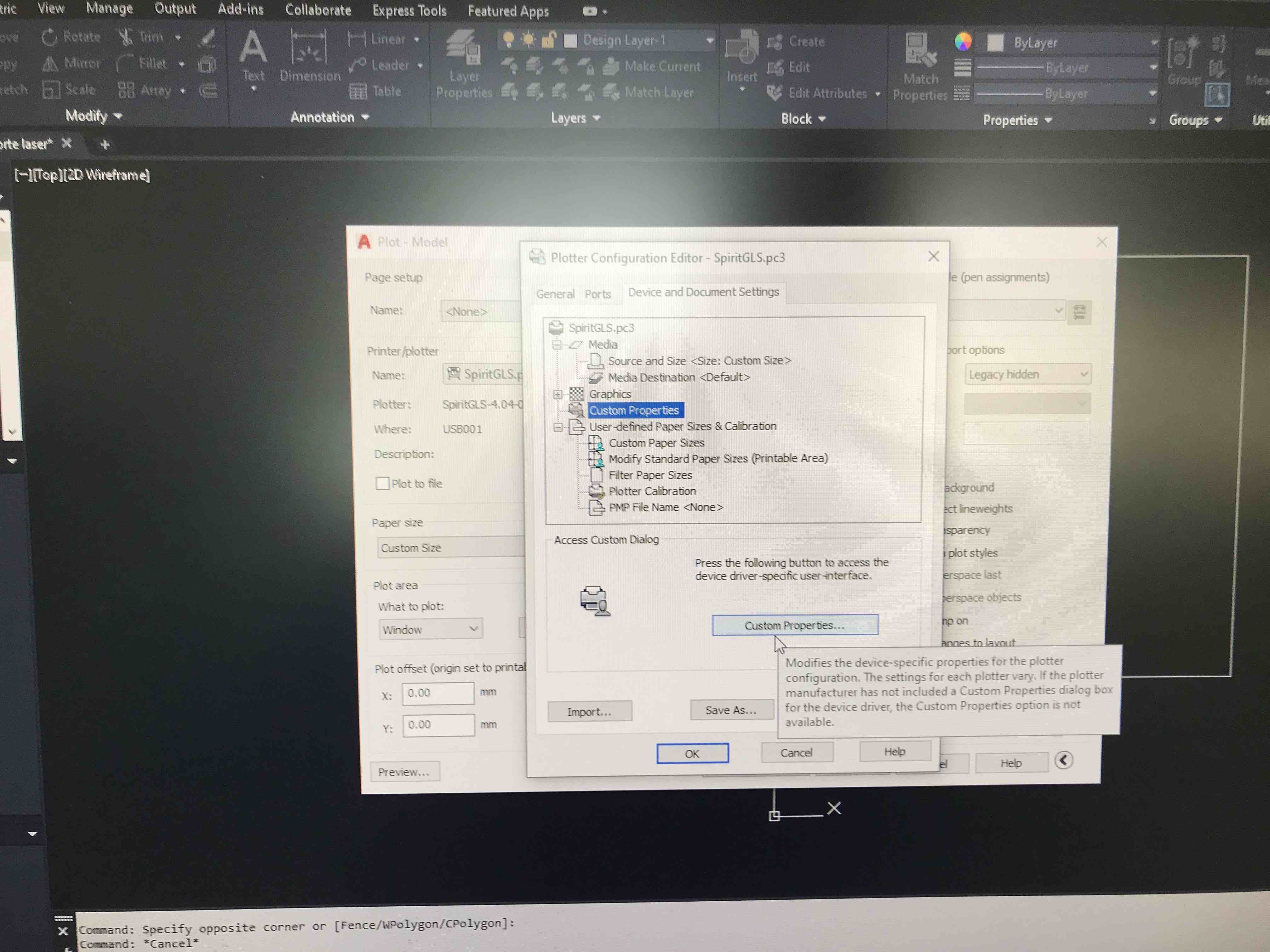

The custom

properties initial panel

Here I´m going to

select the material that I´m about to cut, in this case is

"cartulina ilustración" or ilustration board.

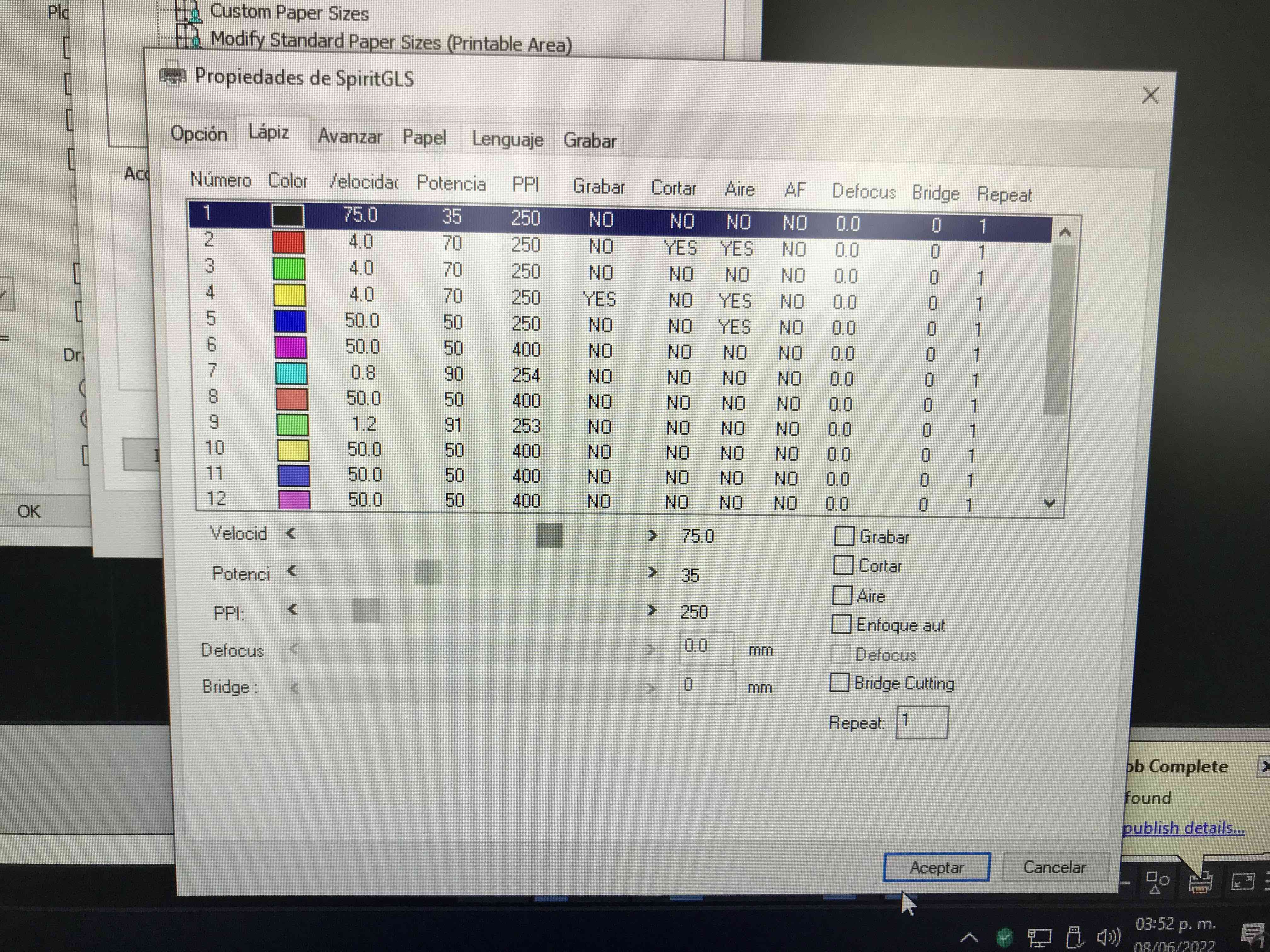

This must match the

layer color I choose in order to cut or engrave, in this case

the red color will cut with a 75mm speed and a 35 of power

settings

Laser machine

display, here we can see the name of the archive display and we

can select different functions like level up or down the

material in order to had the right separation between the laser

nozzle and the material.

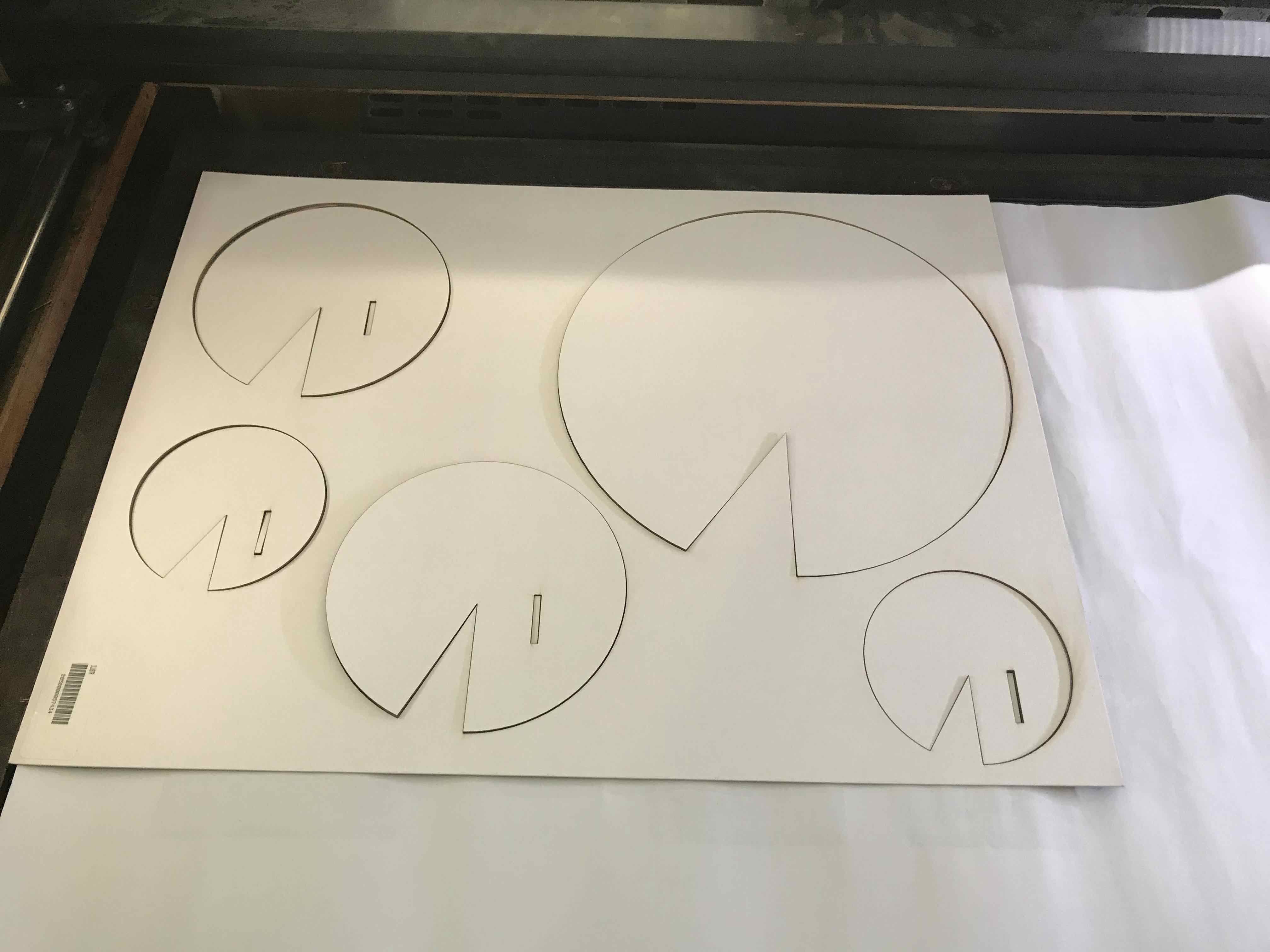

My pieces already

cut, it is recomend to put some paper below the cardboard to

protect the downside face of our pieces.

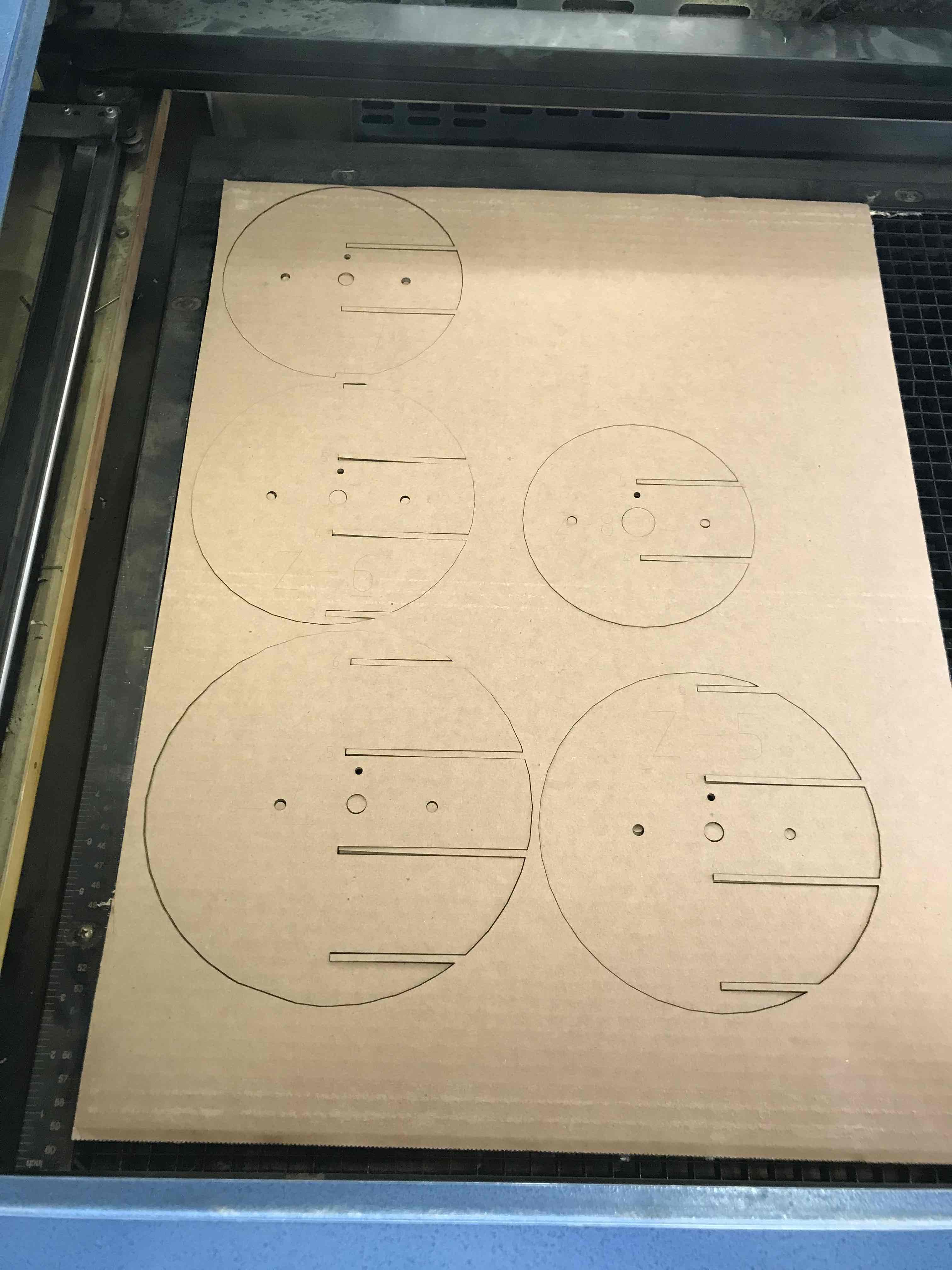

Some of the base pieces

that also were cut in the laser machine

the "Z" pieces that

fit in the base, al the pieces has a "code" number so you know

in wich place they fit.

More cardboard

pieces

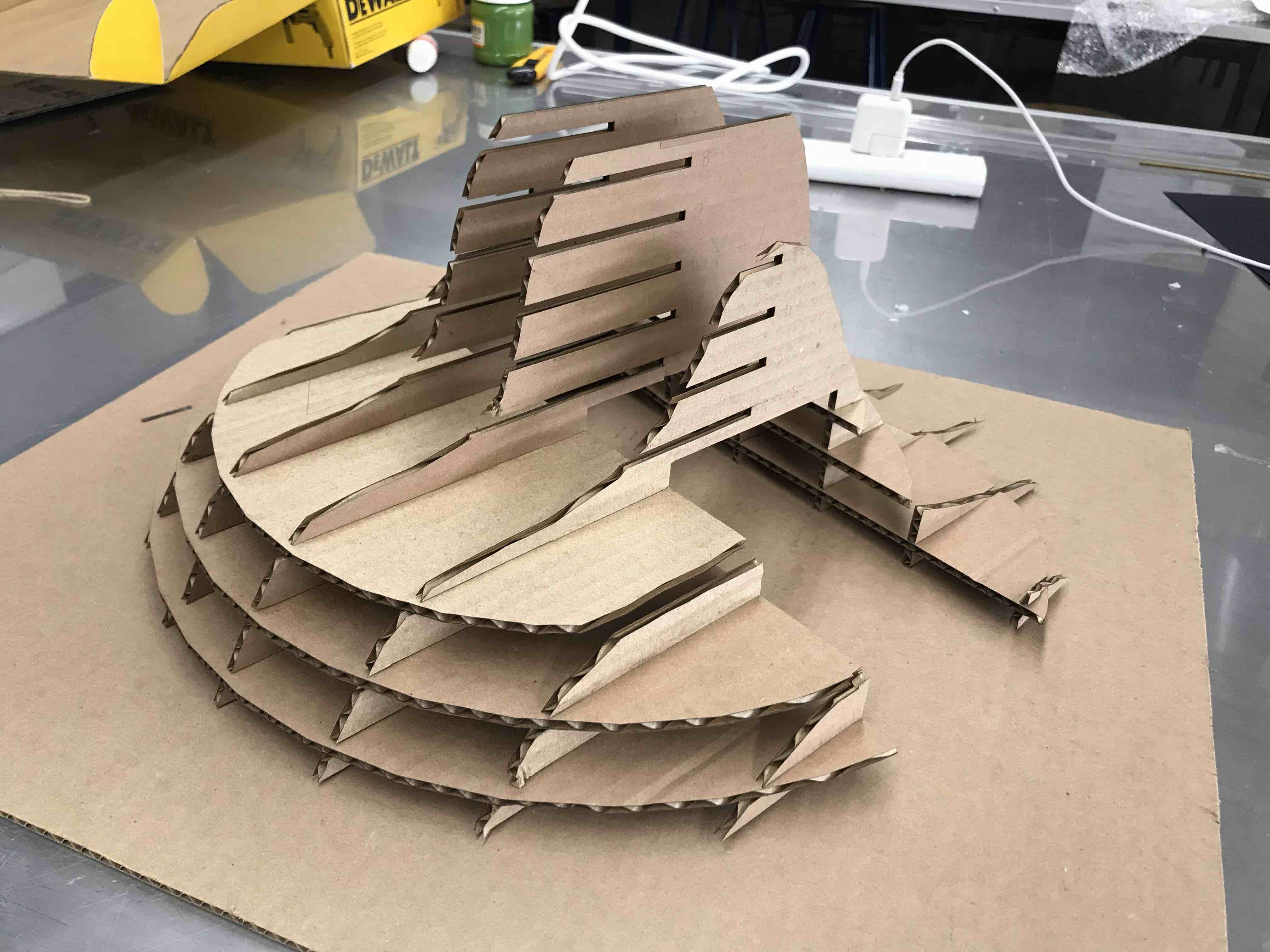

Te base almost

finish with the cardboard pieces

All the pieces

of double corrugated cardboard that forms the base in

place

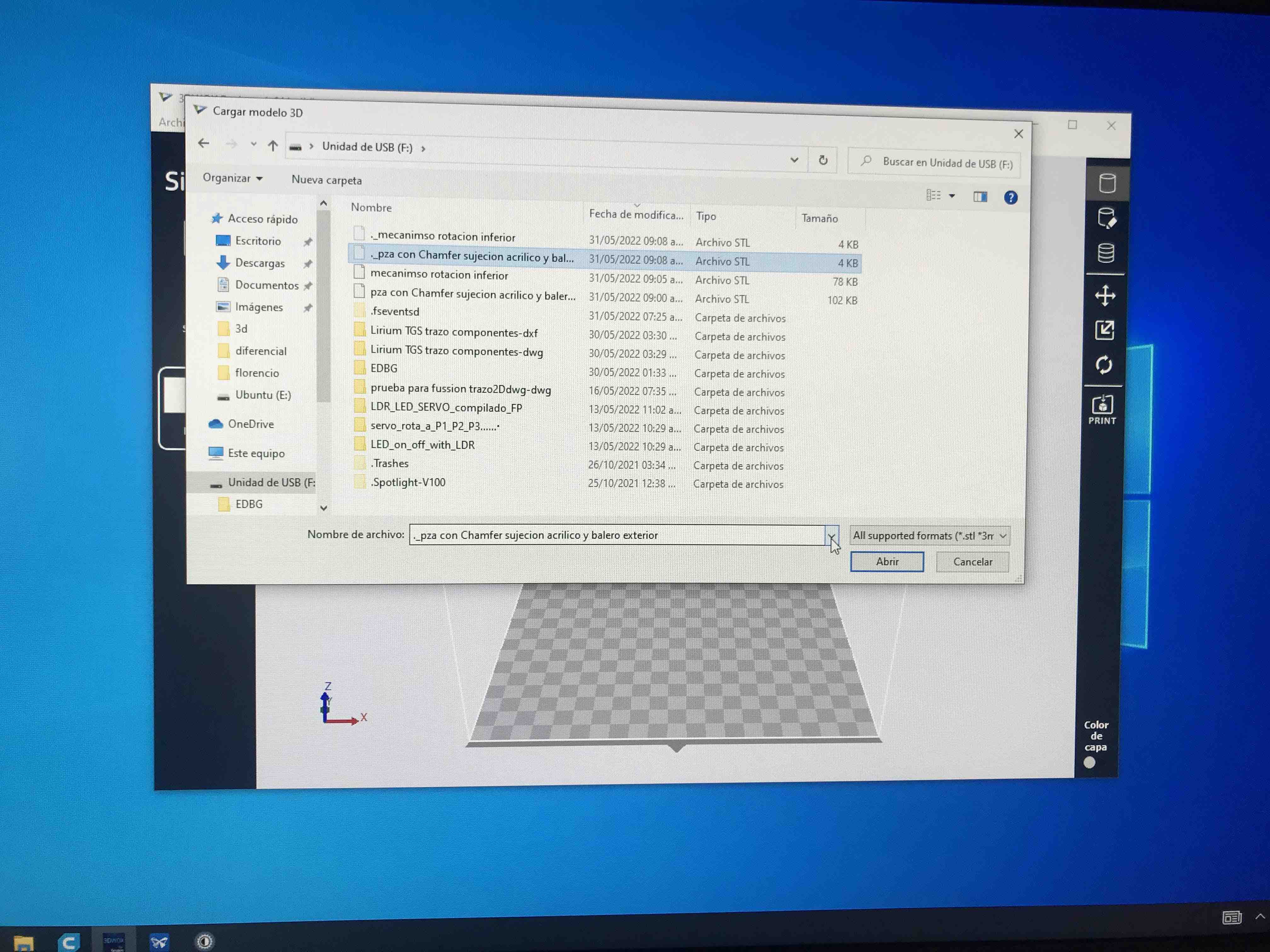

once you have your

object ready to print, export it in .STL format, so you can

import it to the 3D printing machine software without problem.

Sample of one

object imported.

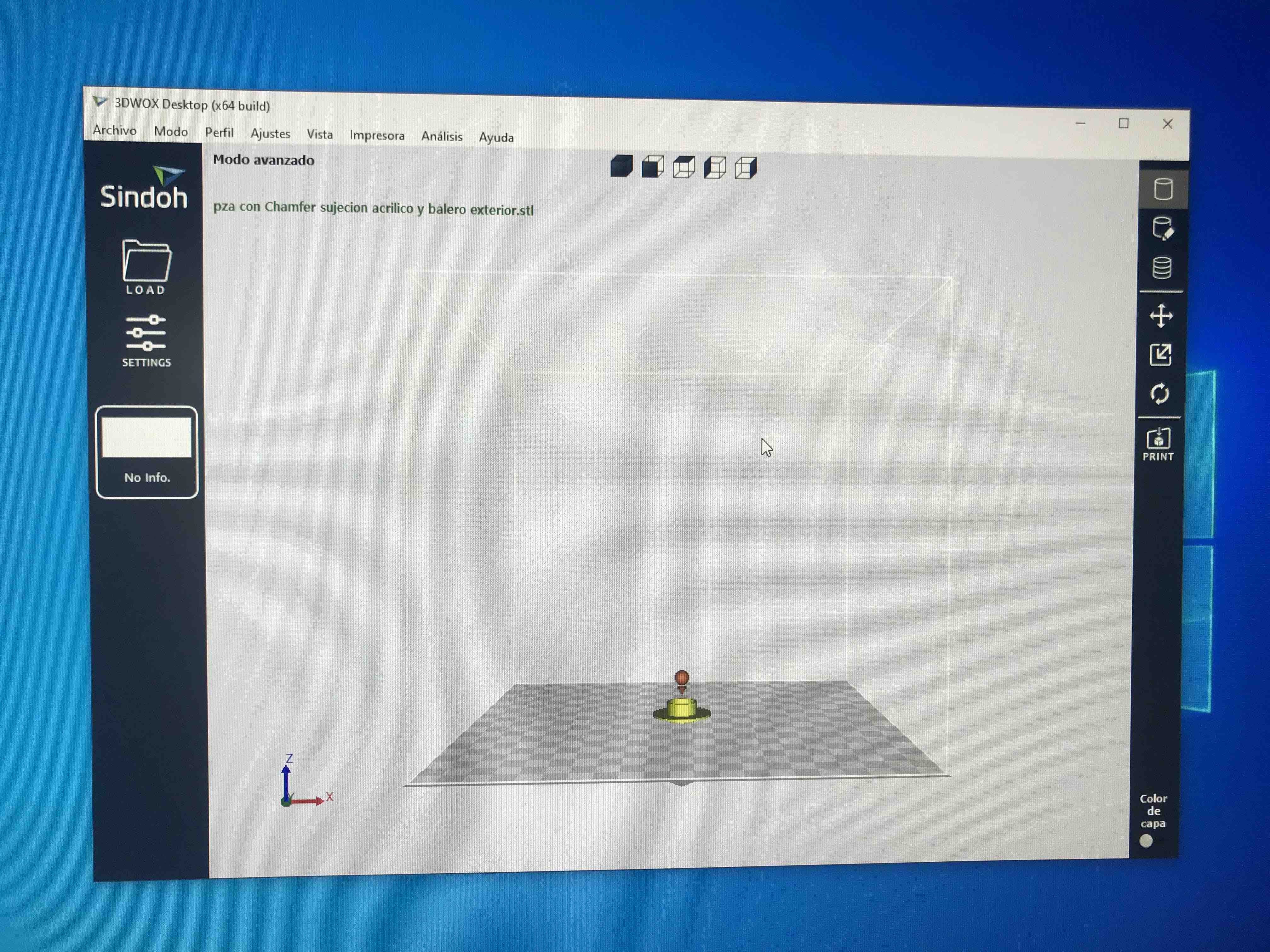

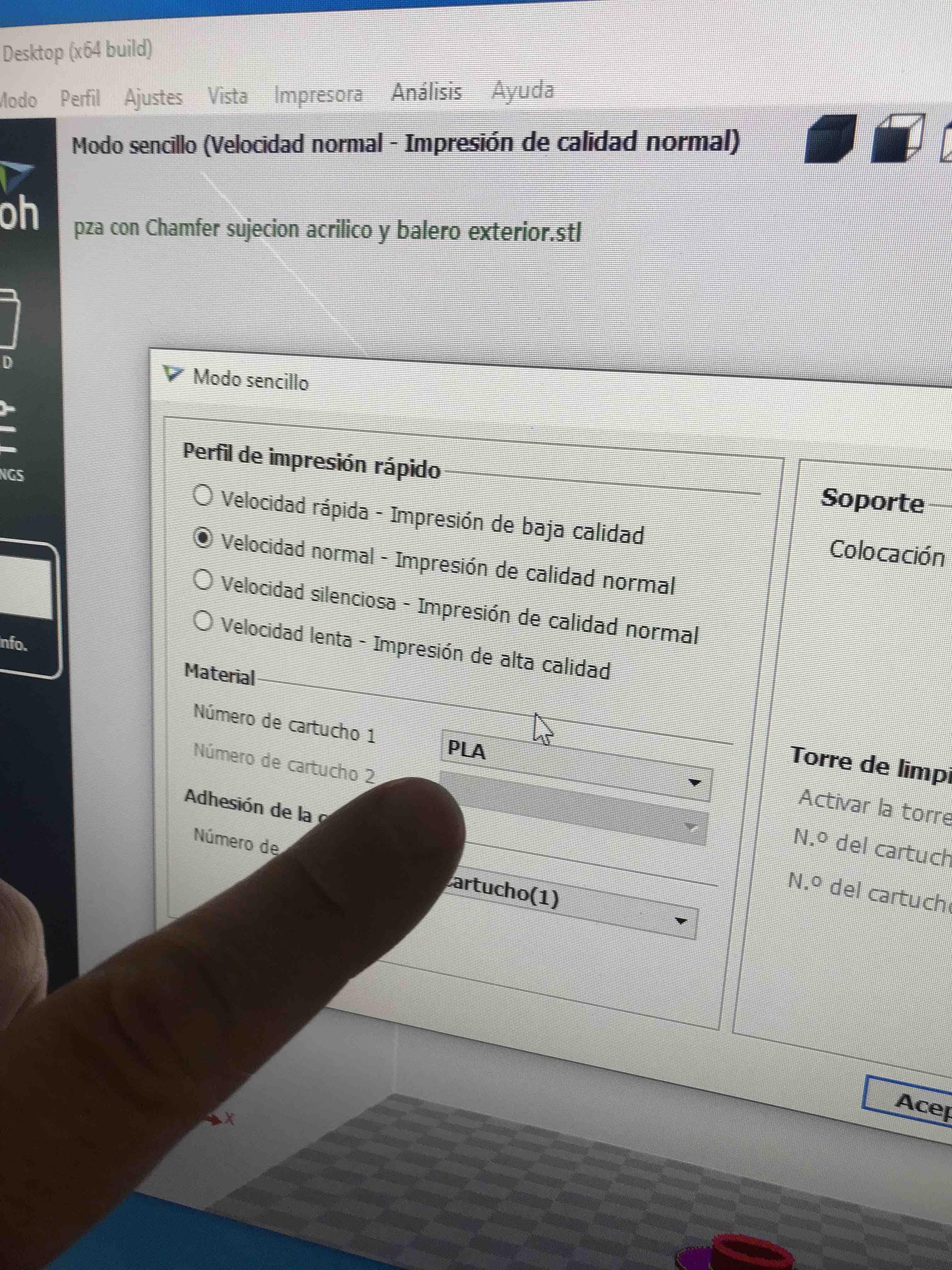

When in Advance

settings, first, be sure to choose the right material, in this

case could be ABS or PLA, then you can set up the support, the

layer thickness, the speed in general or for the outside or

inside face of your object.

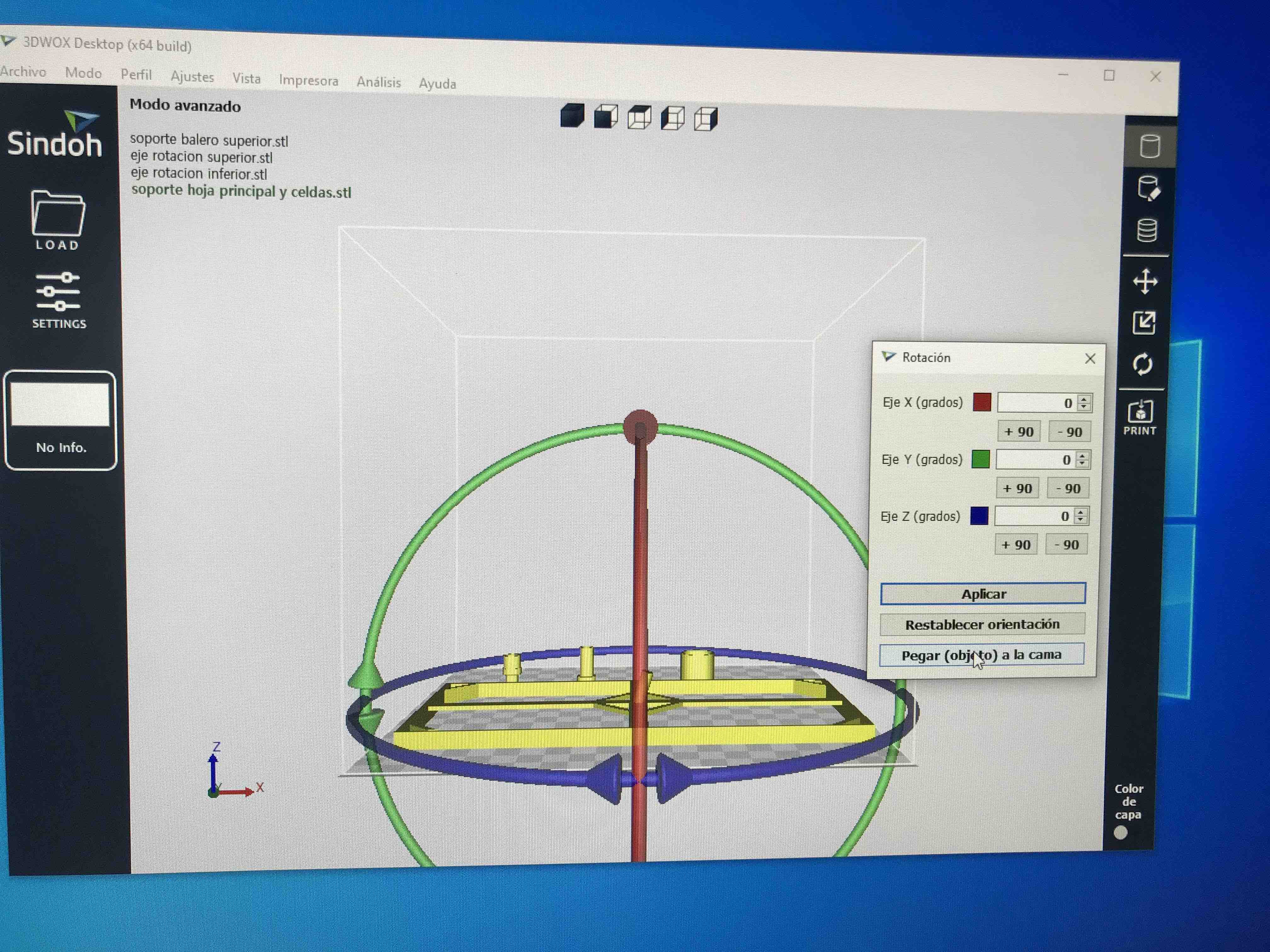

If you need to

rotate the object into a better position to fit better the print

process you can do it with the rotation menu in X, Y or Z Axis

and you can dcecide the angle need it and then you can click the

Stick object to bed to be sure it is in the right position.

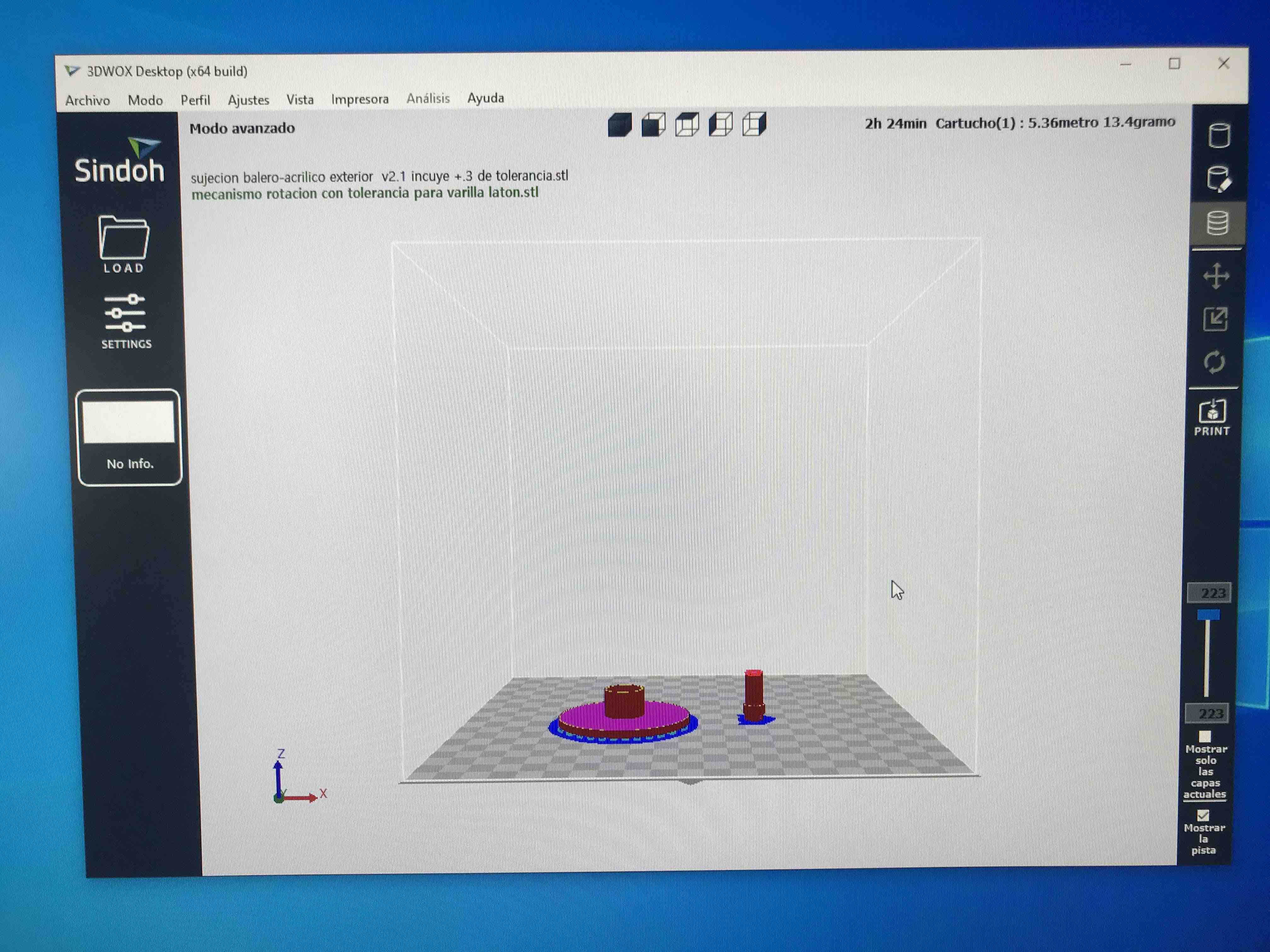

The Gcode is

already export and in this screen you can se the printing layers

with the slide that you can find at the right of the screen, the

one who has the 223 number, you can go up or down.

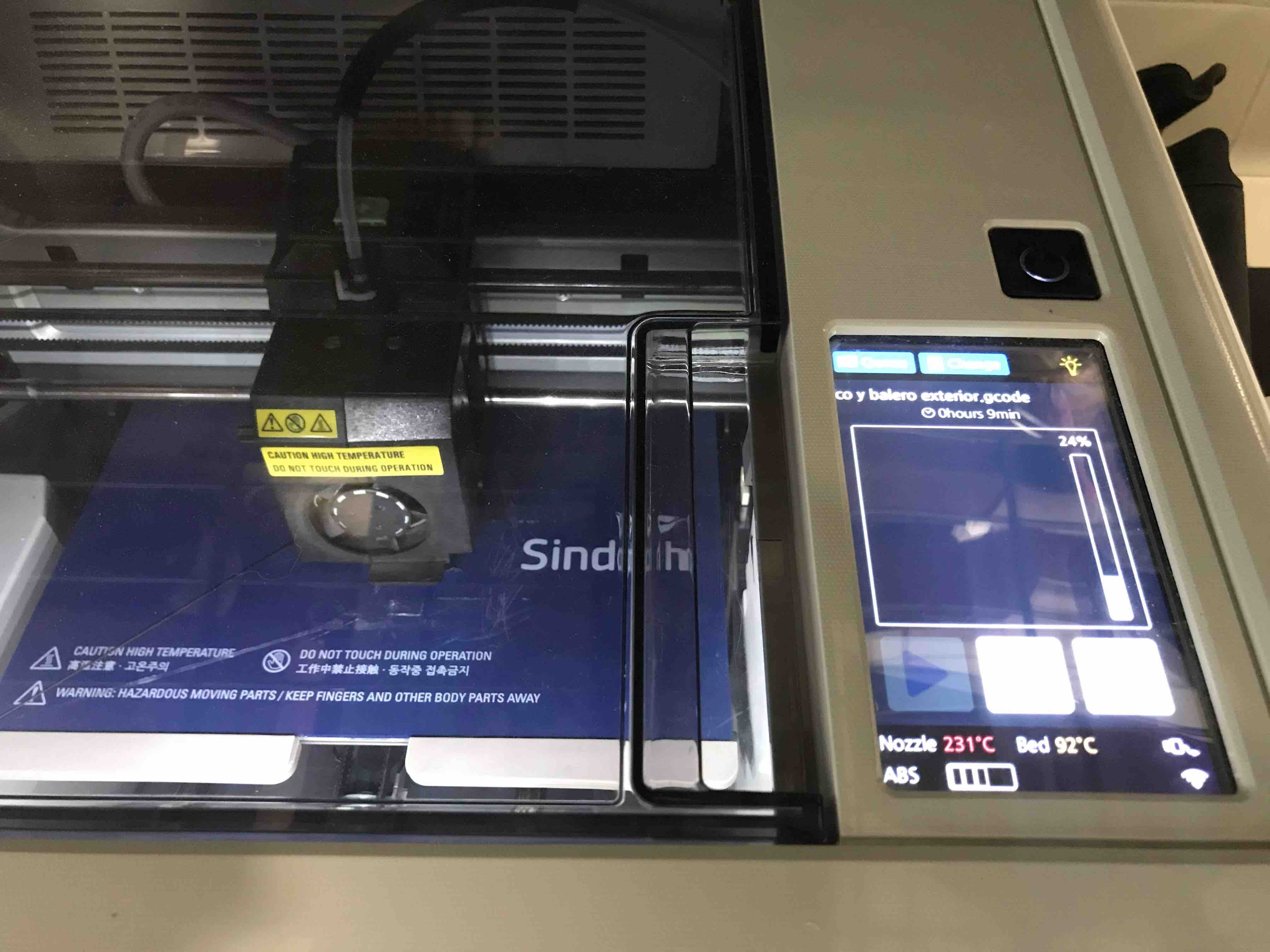

Here you can see

that is printing the support that atache the object to the bed

of the machine, over this will start to print your final piece

Once printing just

wait and from time to time just check if everything is fine.

Cardboard leafs and

the perimeters printed in 3D some in ABS and others in PLA. I

did this to check settings, printing time, texture and quality.

The axis of

rotation and the solar cells support printed in 3D

electronics

a place to re-connect

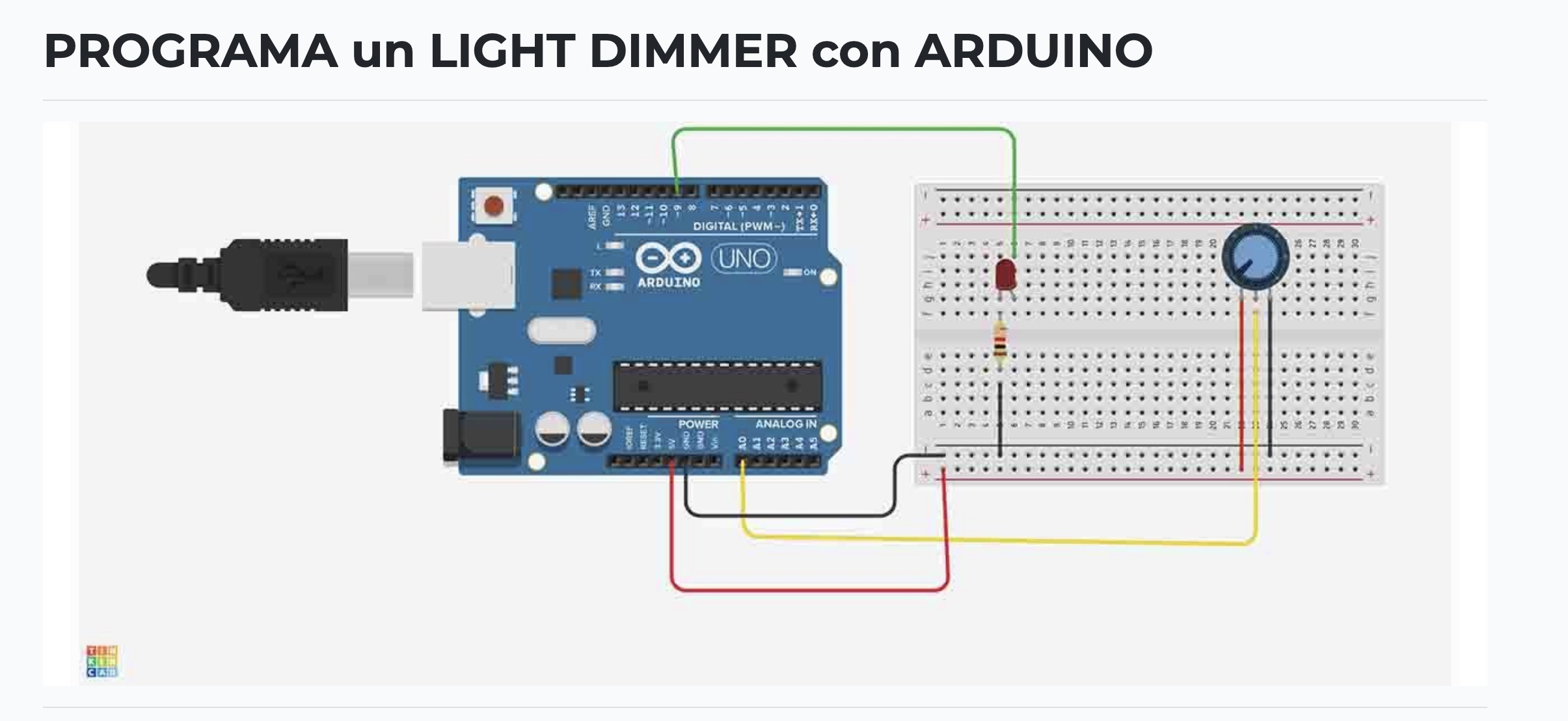

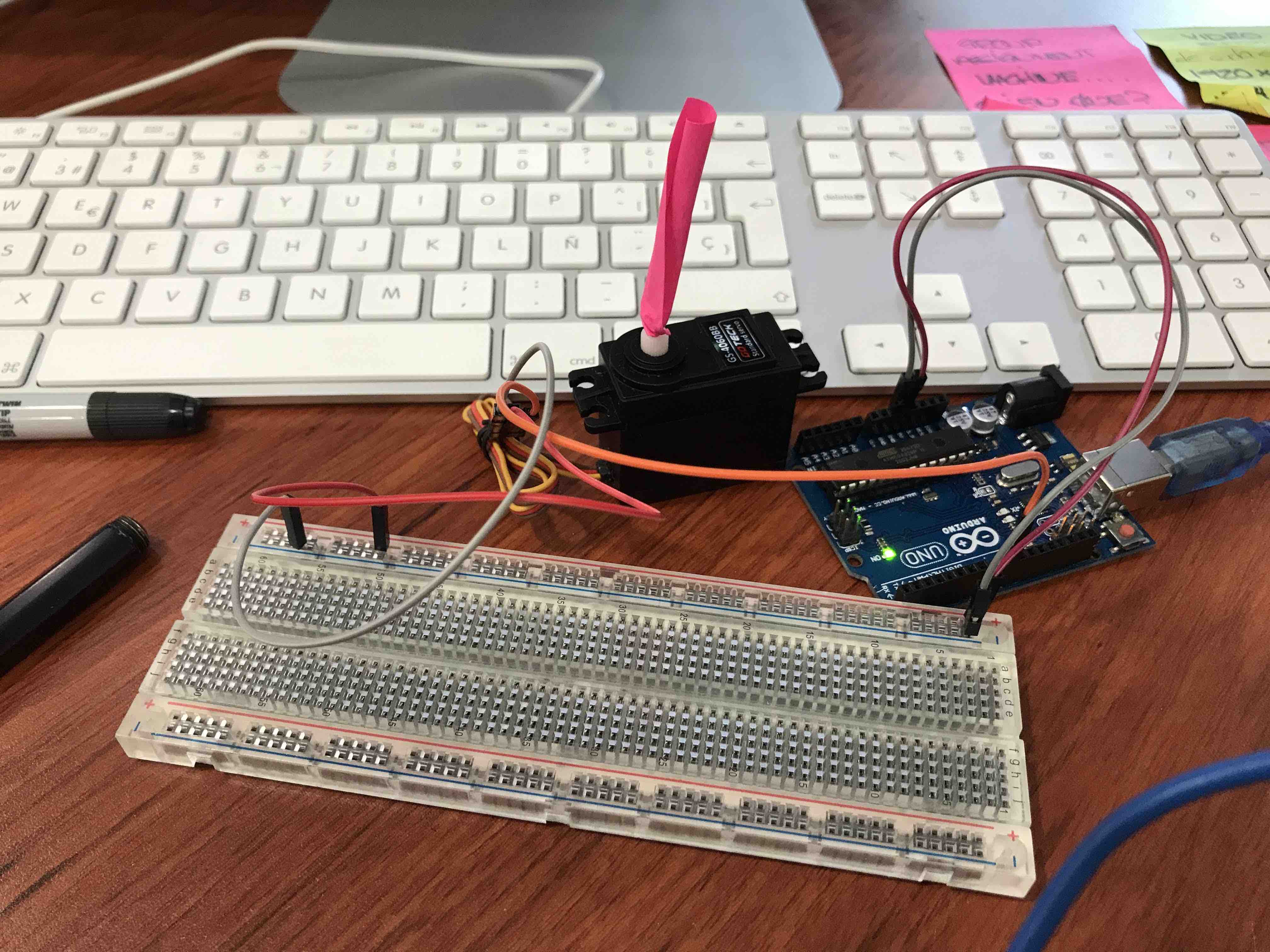

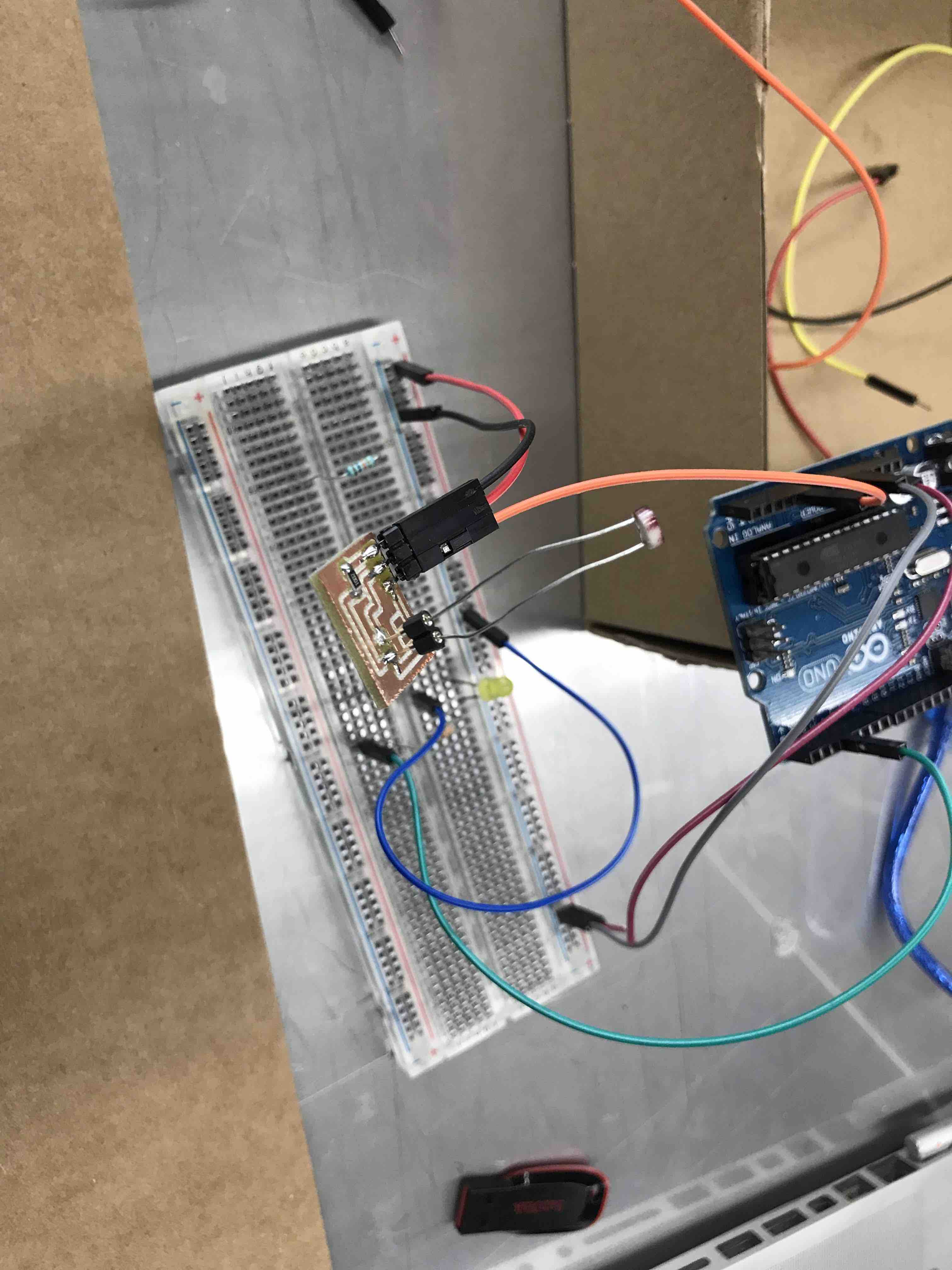

first Ilook for the

schematics of Arduino for the Servo and the LEDS with LDR to start

to do some programming and test the variables of the code

first Ilook for the schematics of Arduino for the Servo and the LEDS with LDR to start to do some programming and test the variables of the code

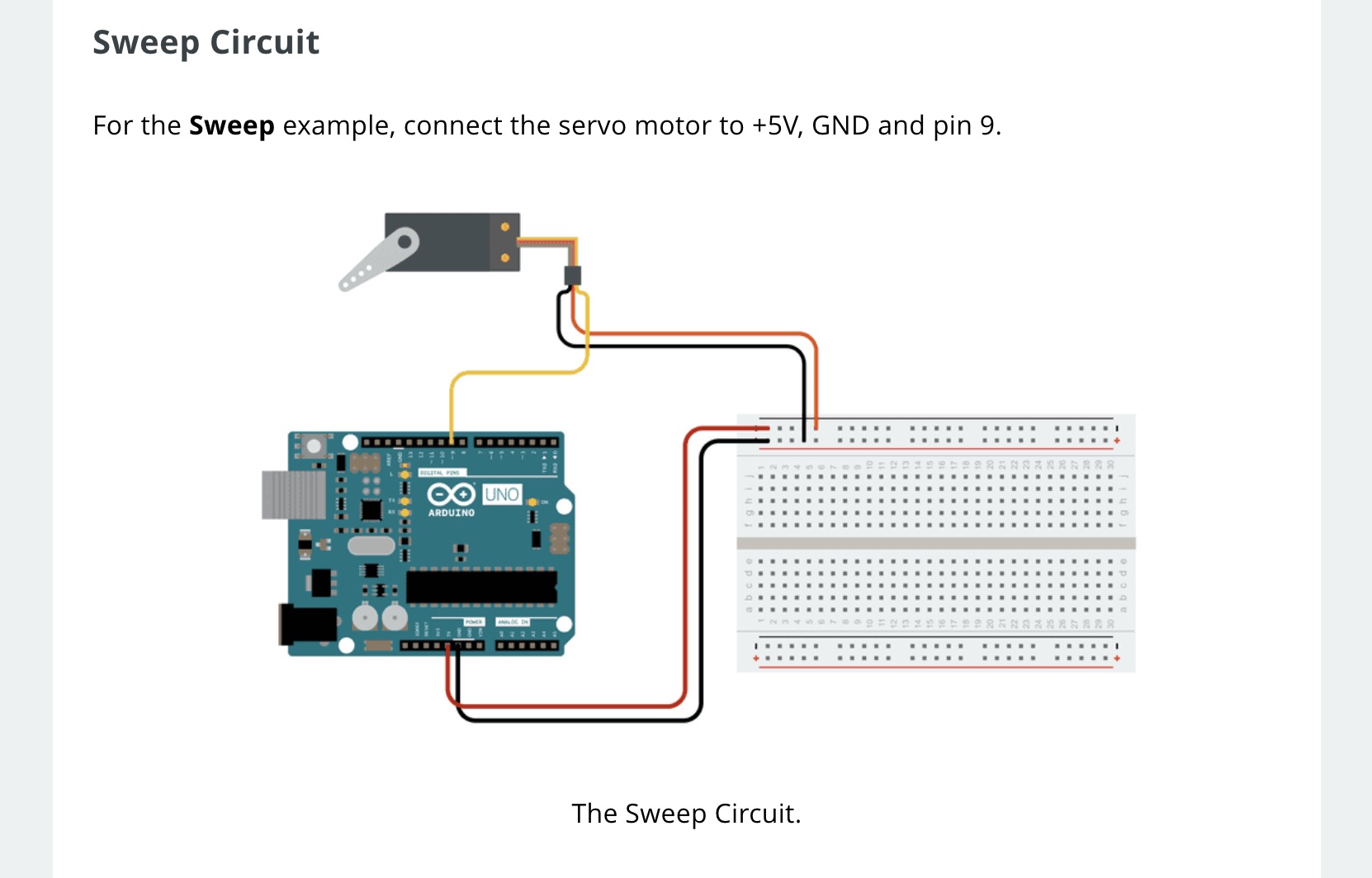

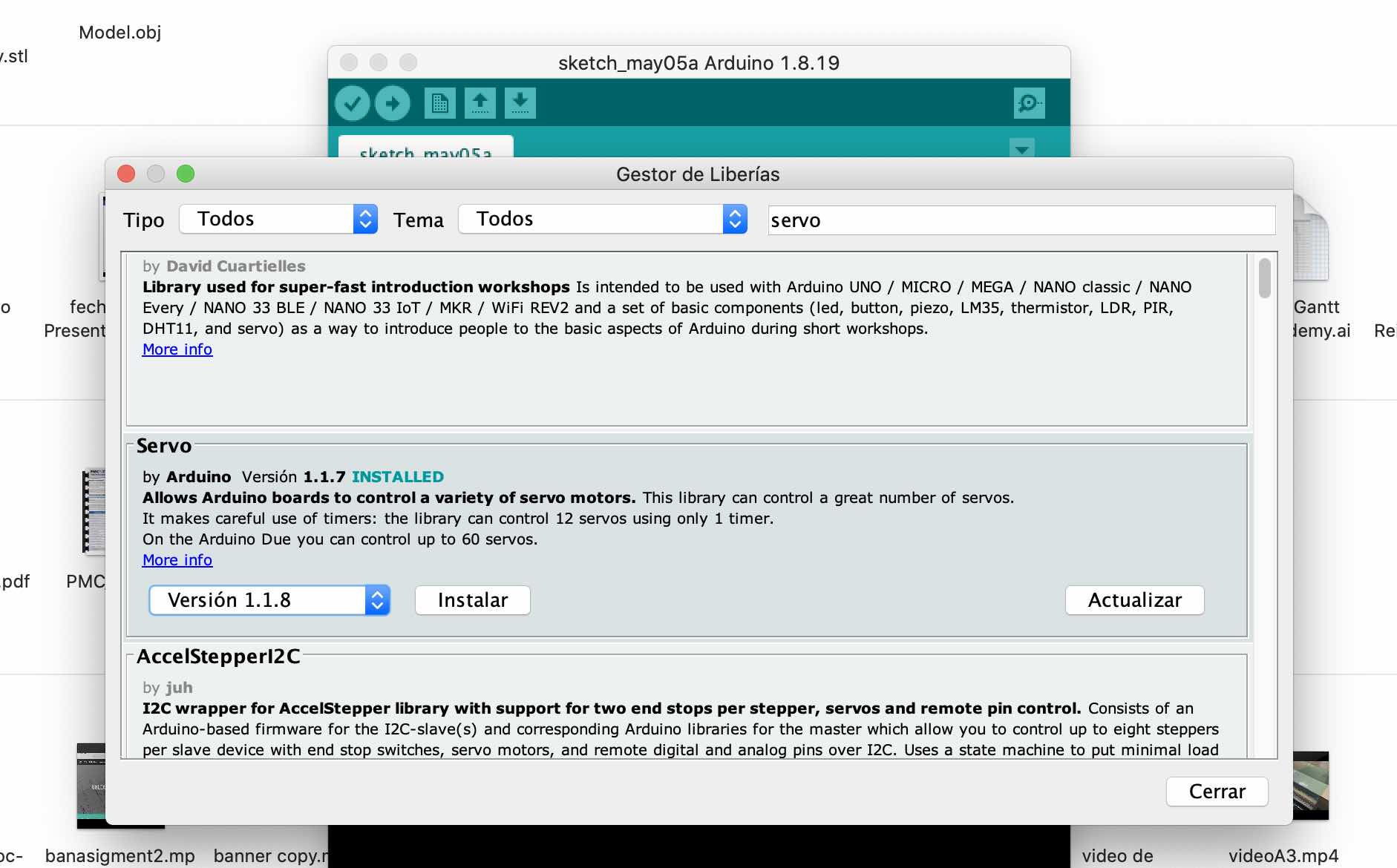

Then I look and

install the libraries missing for the servo

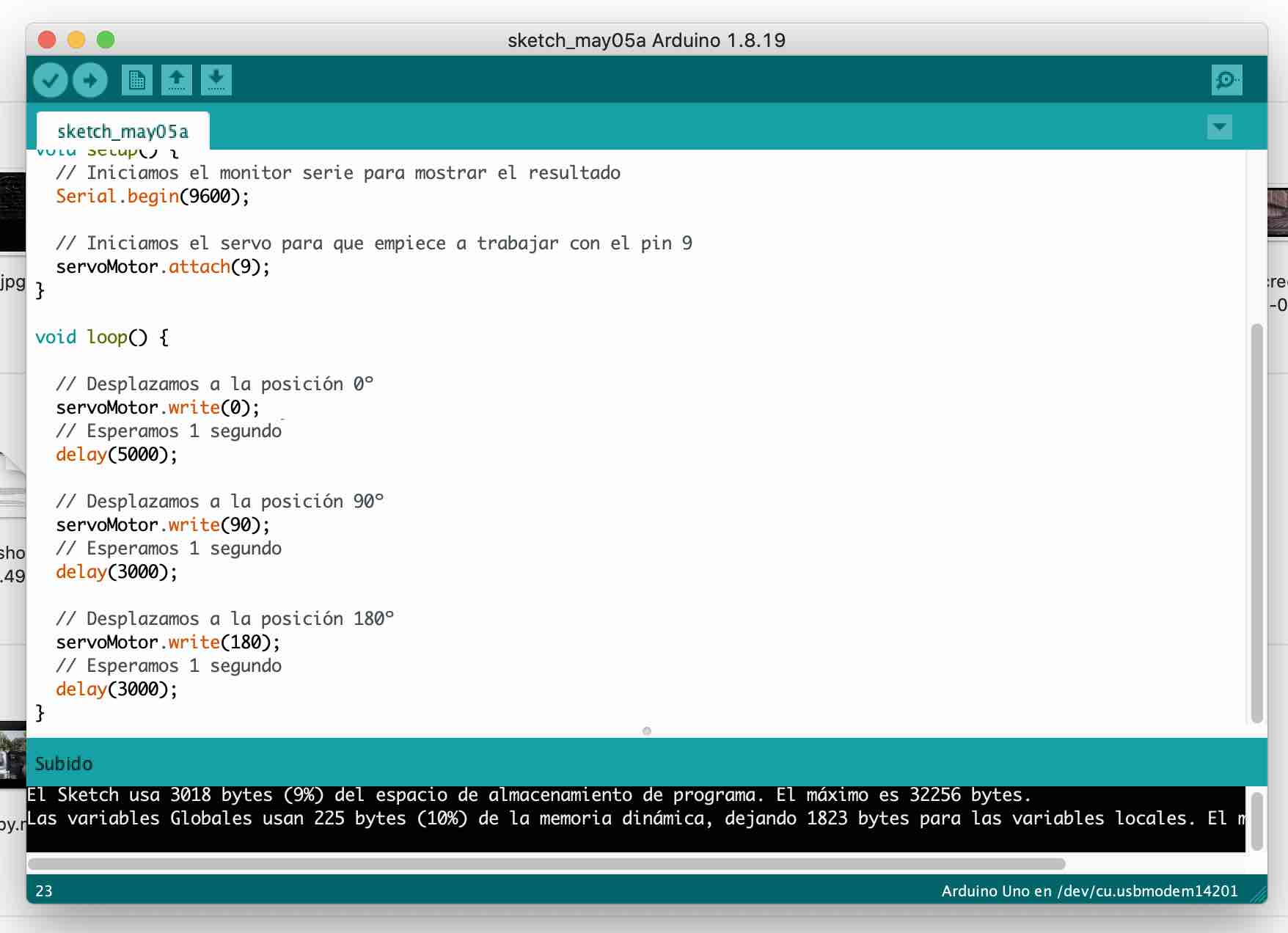

Here´s a code that

moves a Servo motor in different degrees, thats just what I need

for my project.

And works well, it

was easy

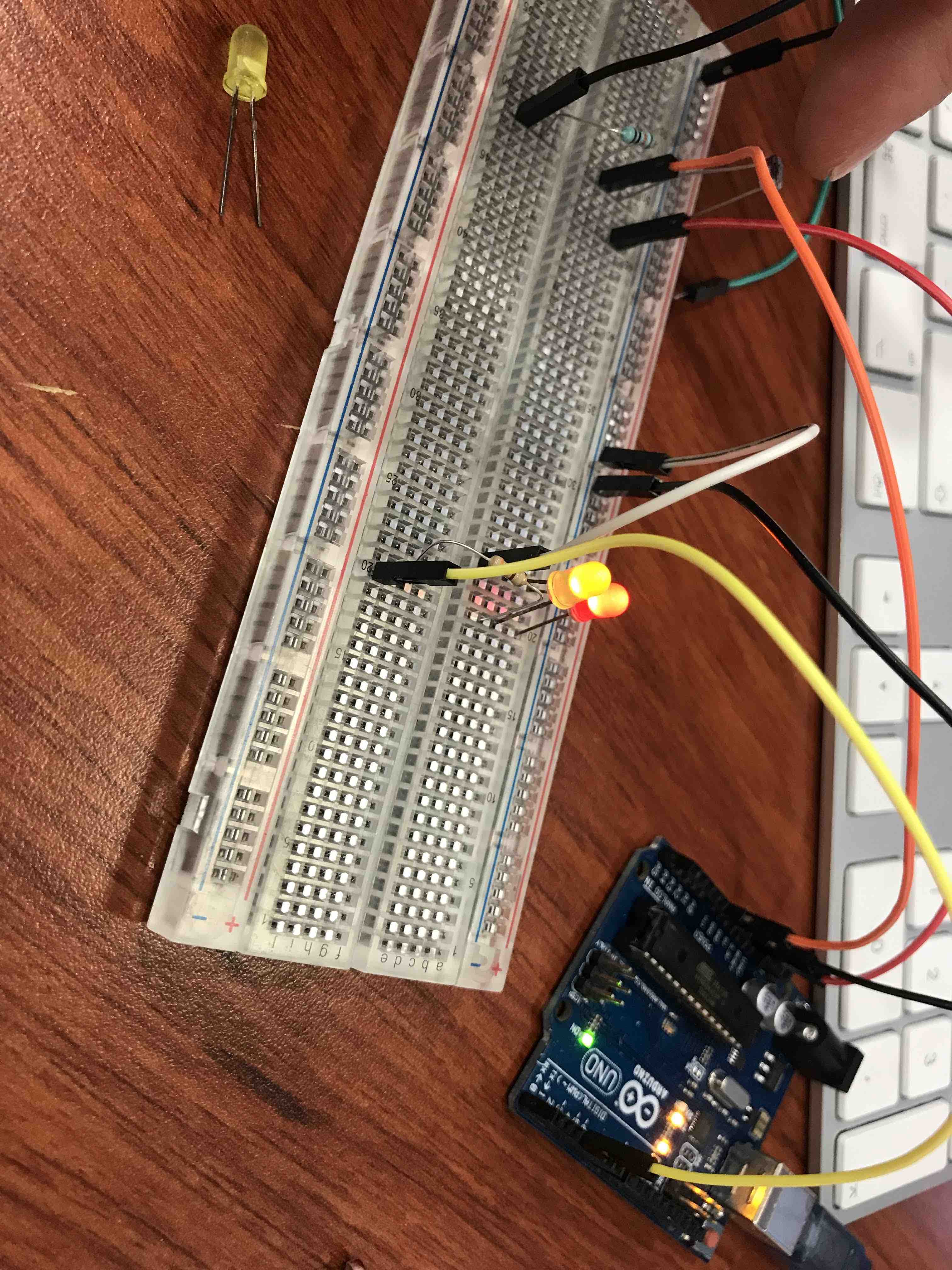

Here I´m testing leds

ON/OFF with an LDR

Then I redesign the

SAMDINO to fit my requeriments so I can replace the arduino with

it and start programming a new code

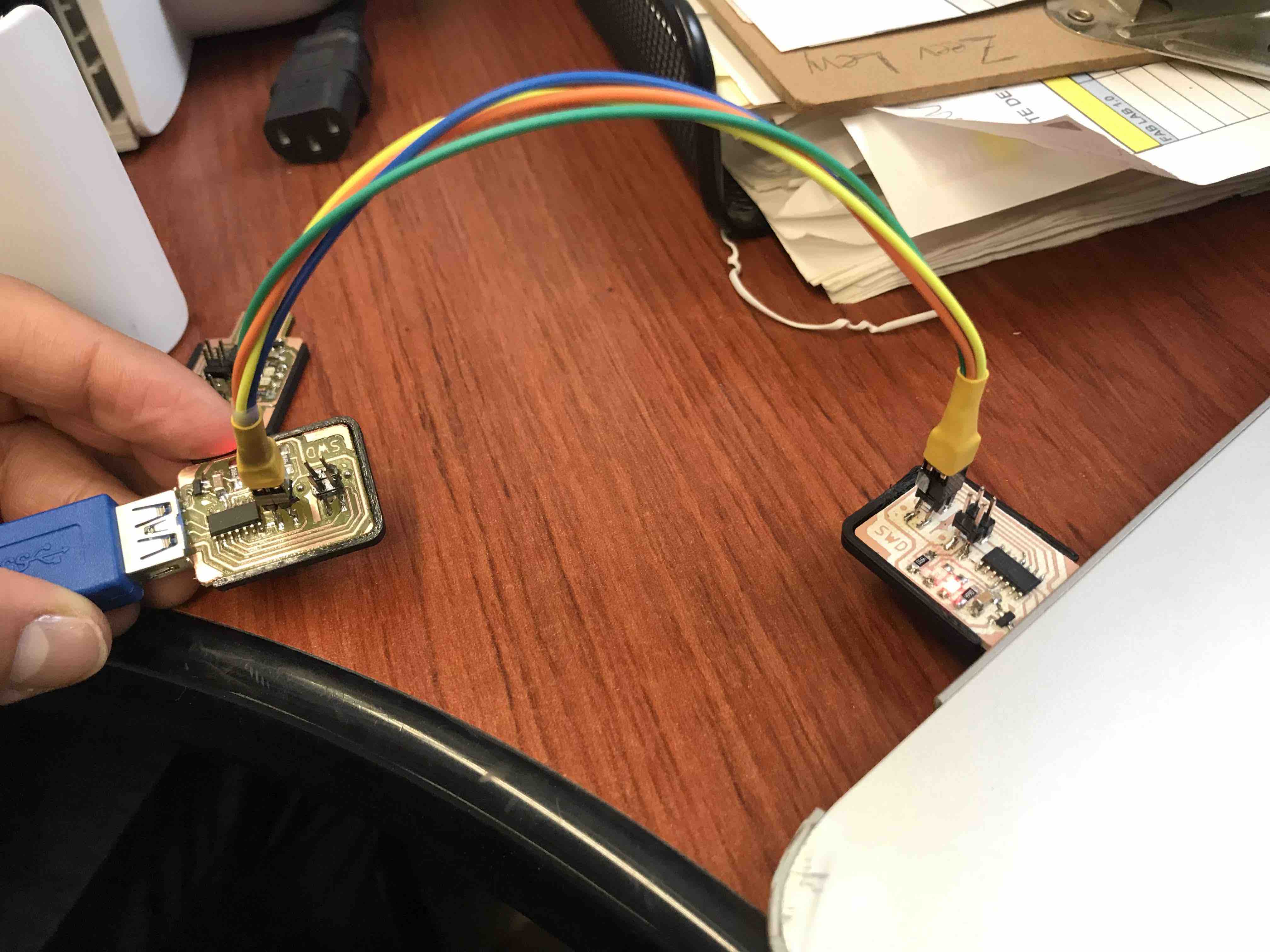

First I had to

connect my SWD to "life" so I can program my PCB Hugodino with

this

Here are the hugodino

board and the SWD, the connection was ok

Everything goes well.

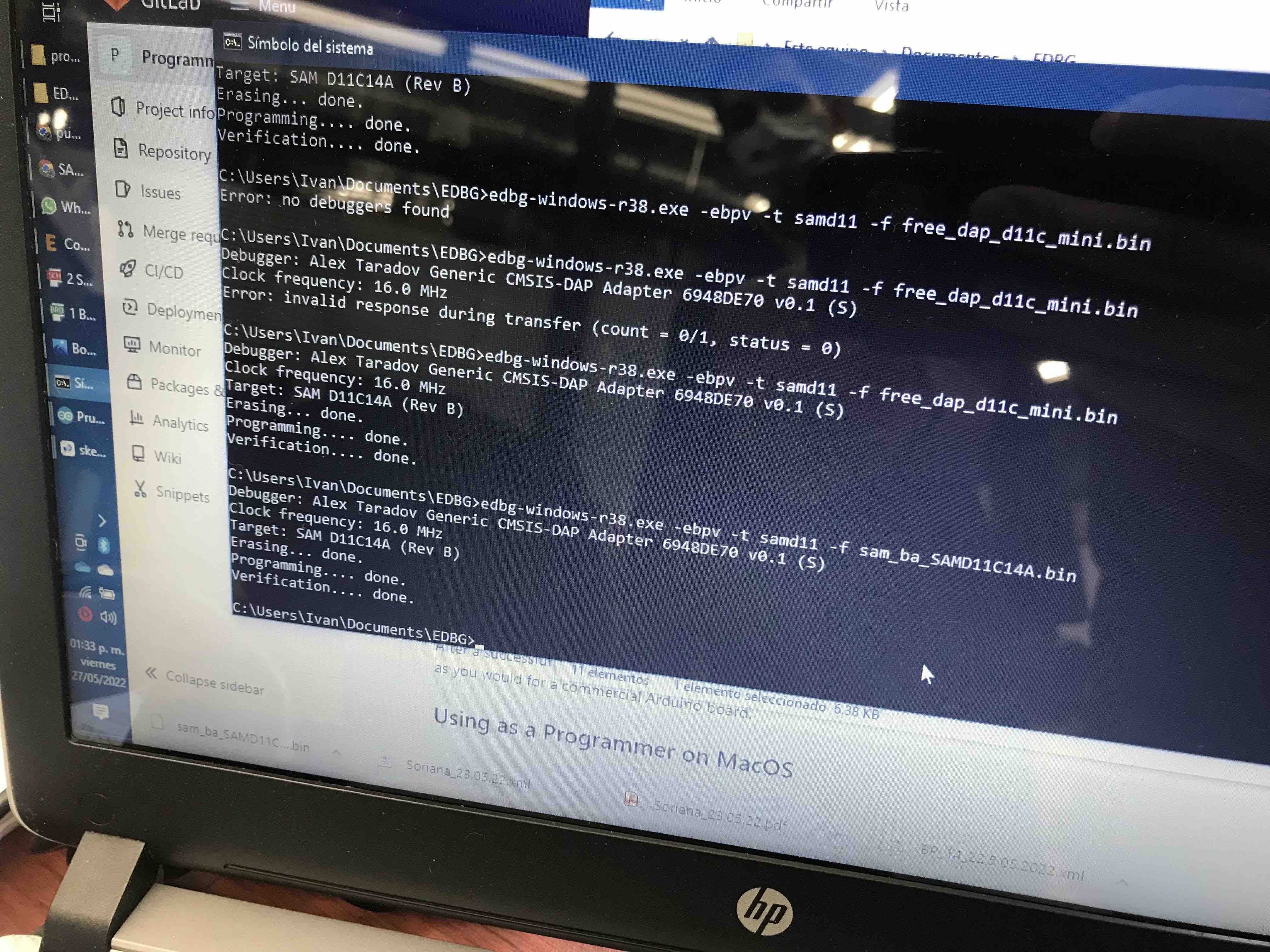

Here we use the EDBG to "turn on" the hugodino board using the WSD

PCB

The led of my PCB is

on indicating we are good

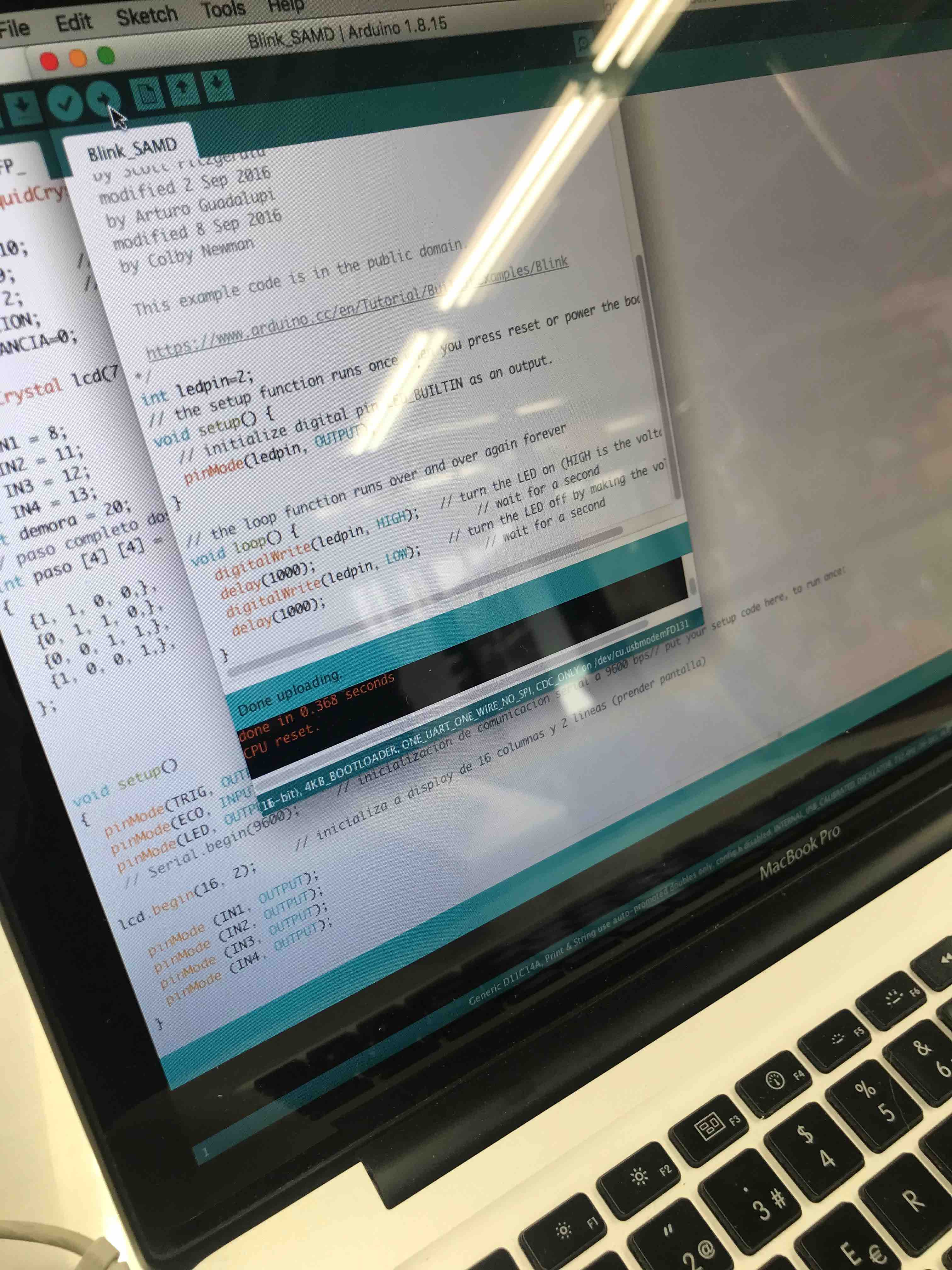

Mhere the code for

the SAMDINO that makes the LED blink, in the future I´m going to

use the SAMDINO code to design my own codes to fit my requirements

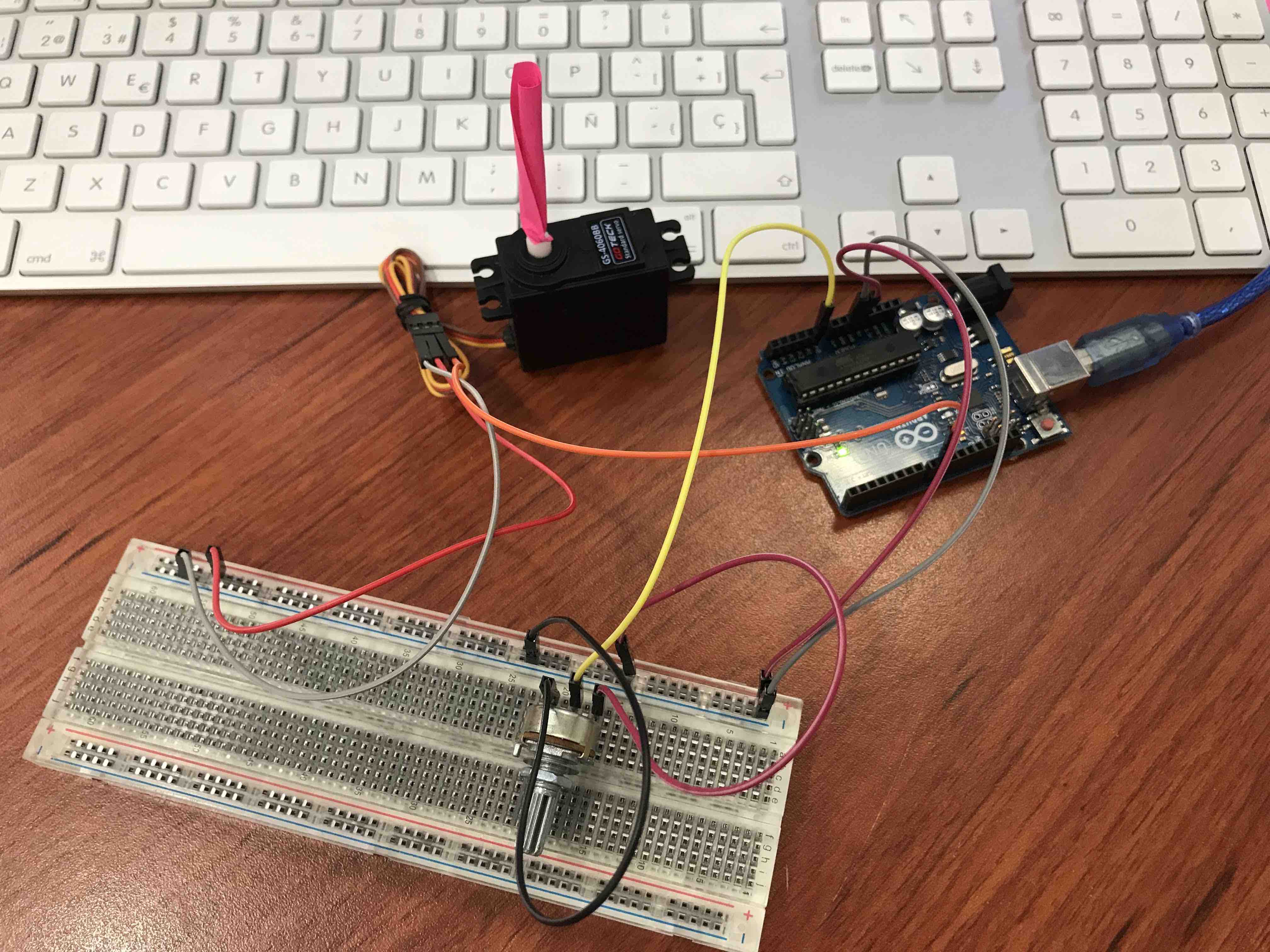

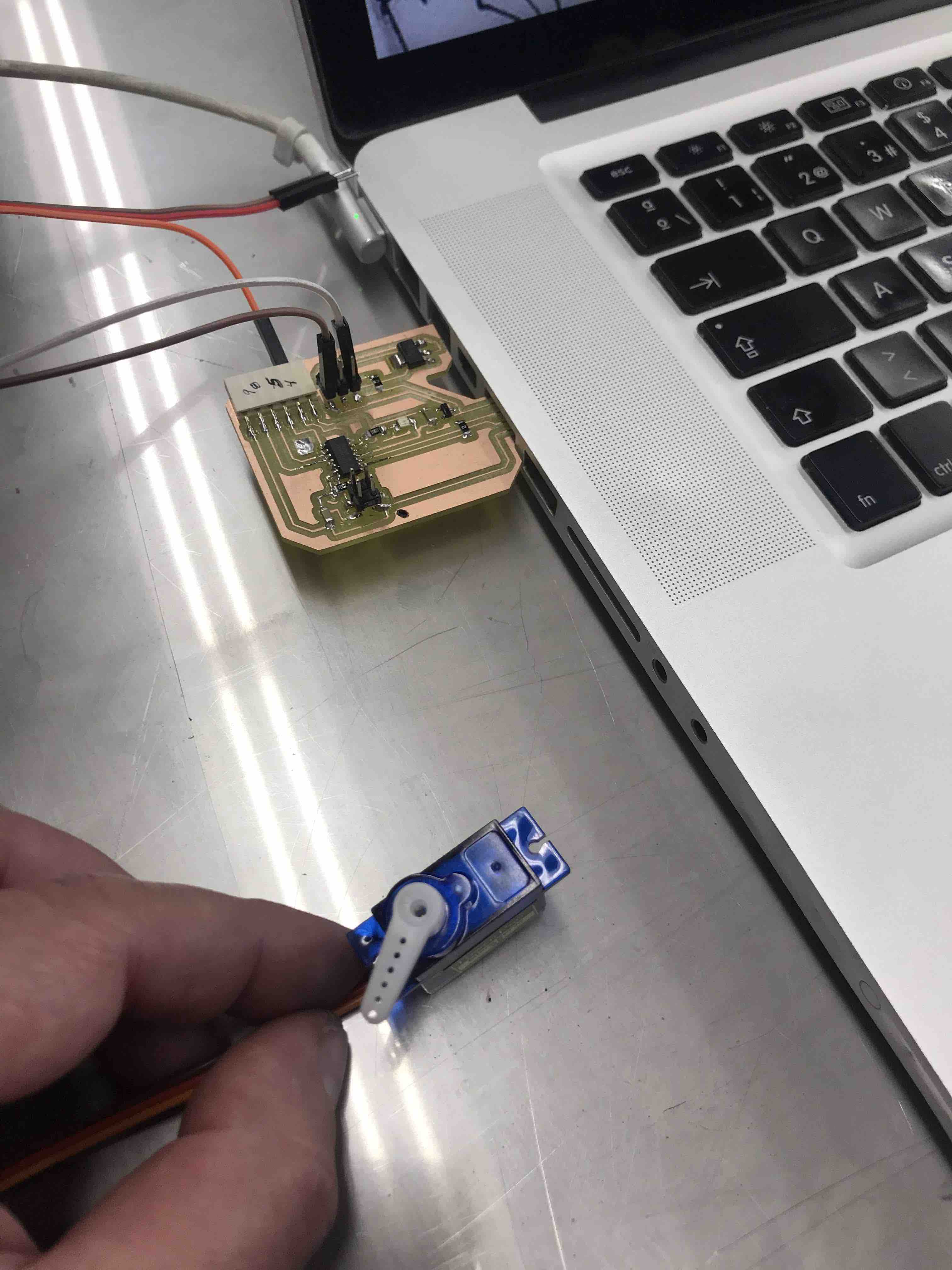

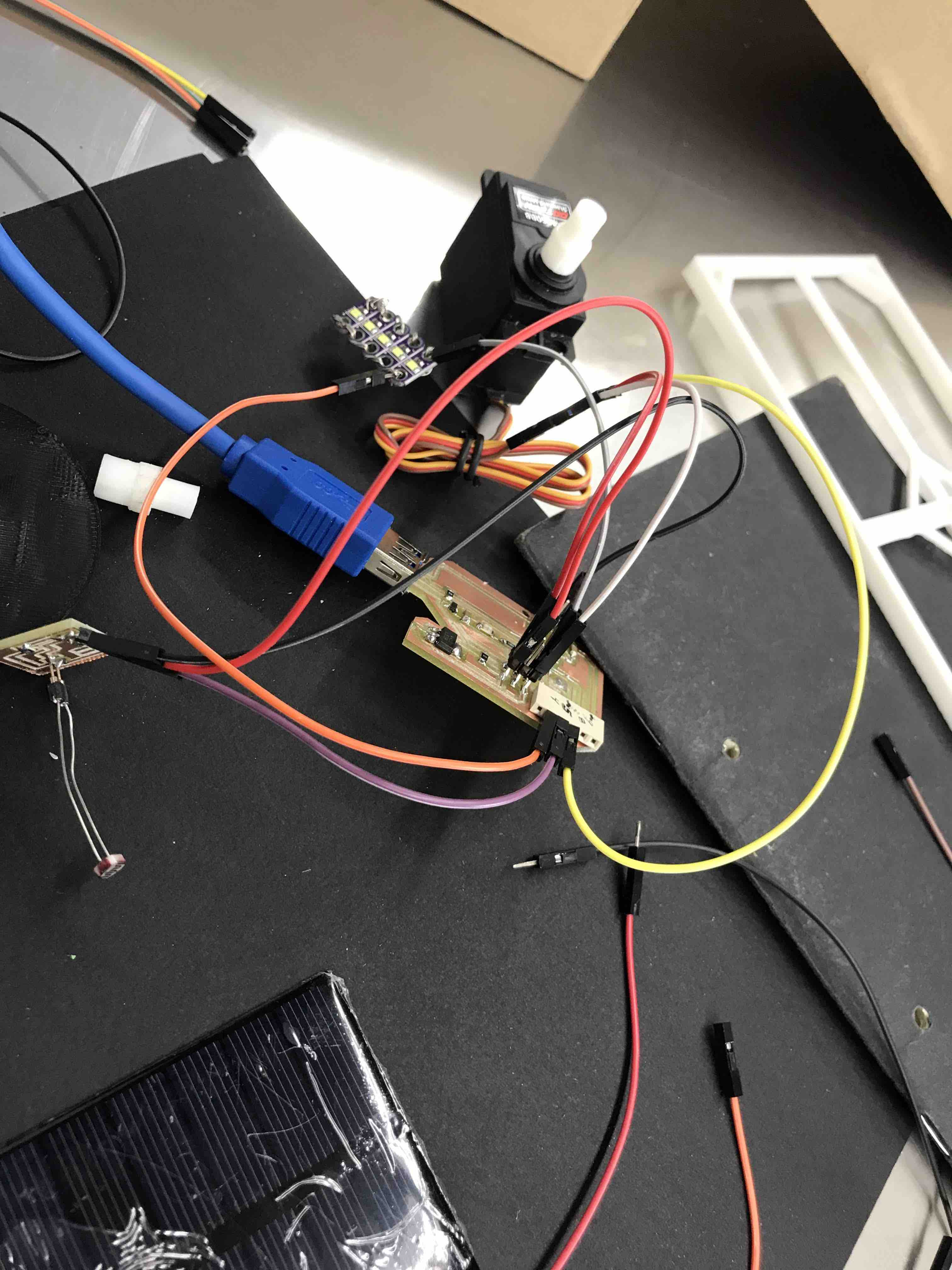

The servo is moving,

thats really fine

Testing the LDR PCB

with a breadboard to see it it works before use it directly with

my board.

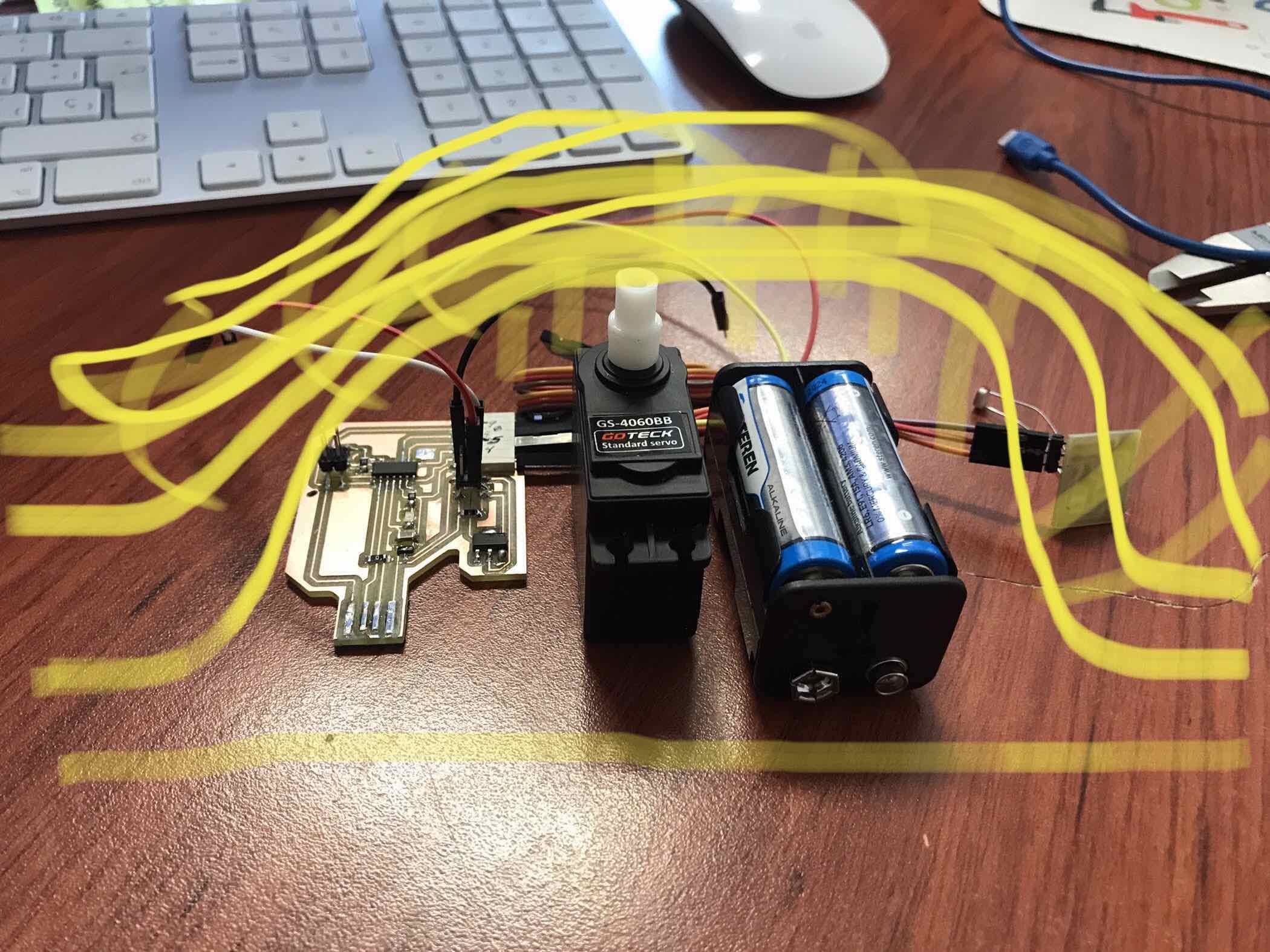

an image of the first

2 PCBs I did for my project

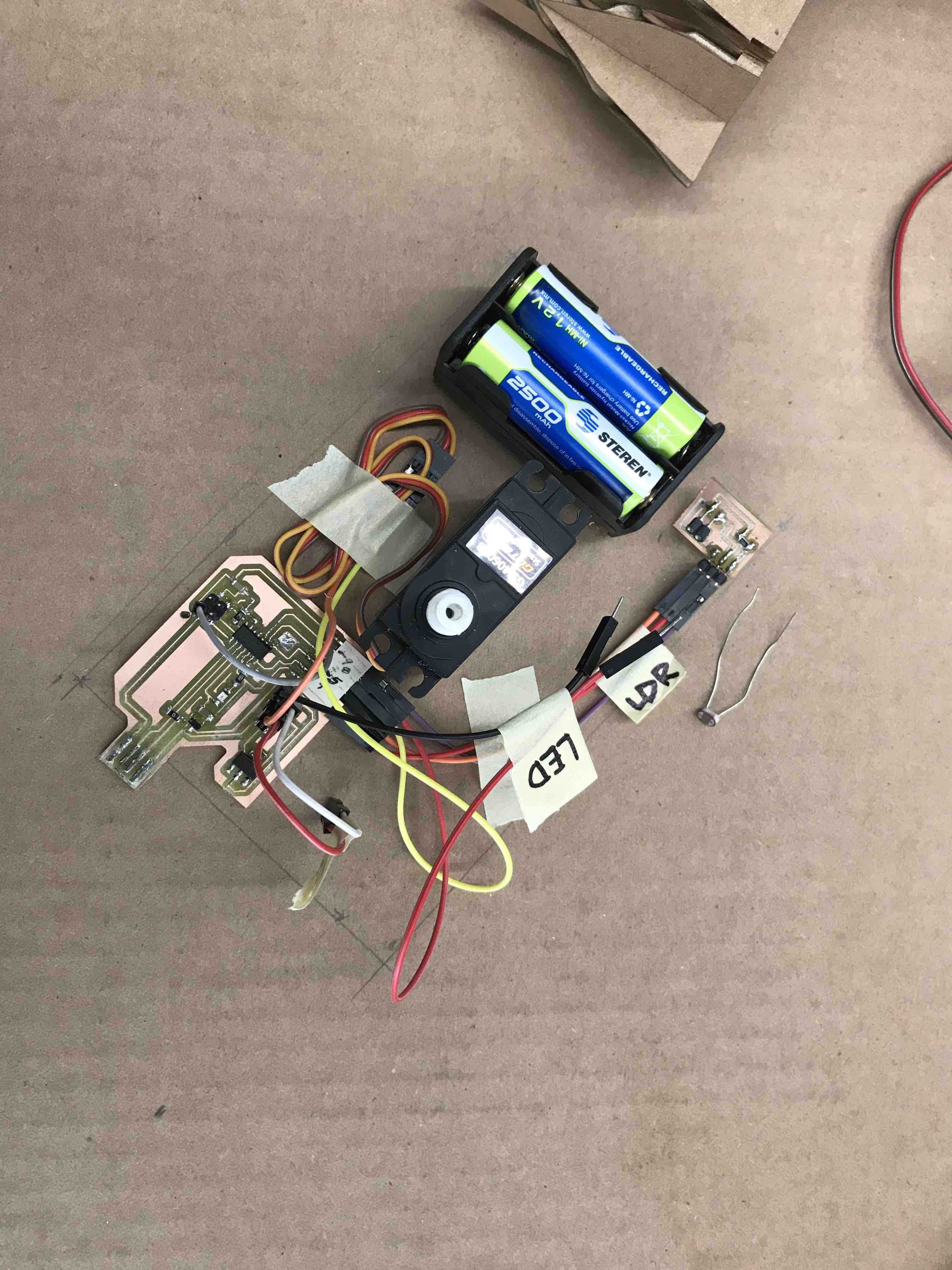

I put some masking

tape to identify wich cable is for what component-connection

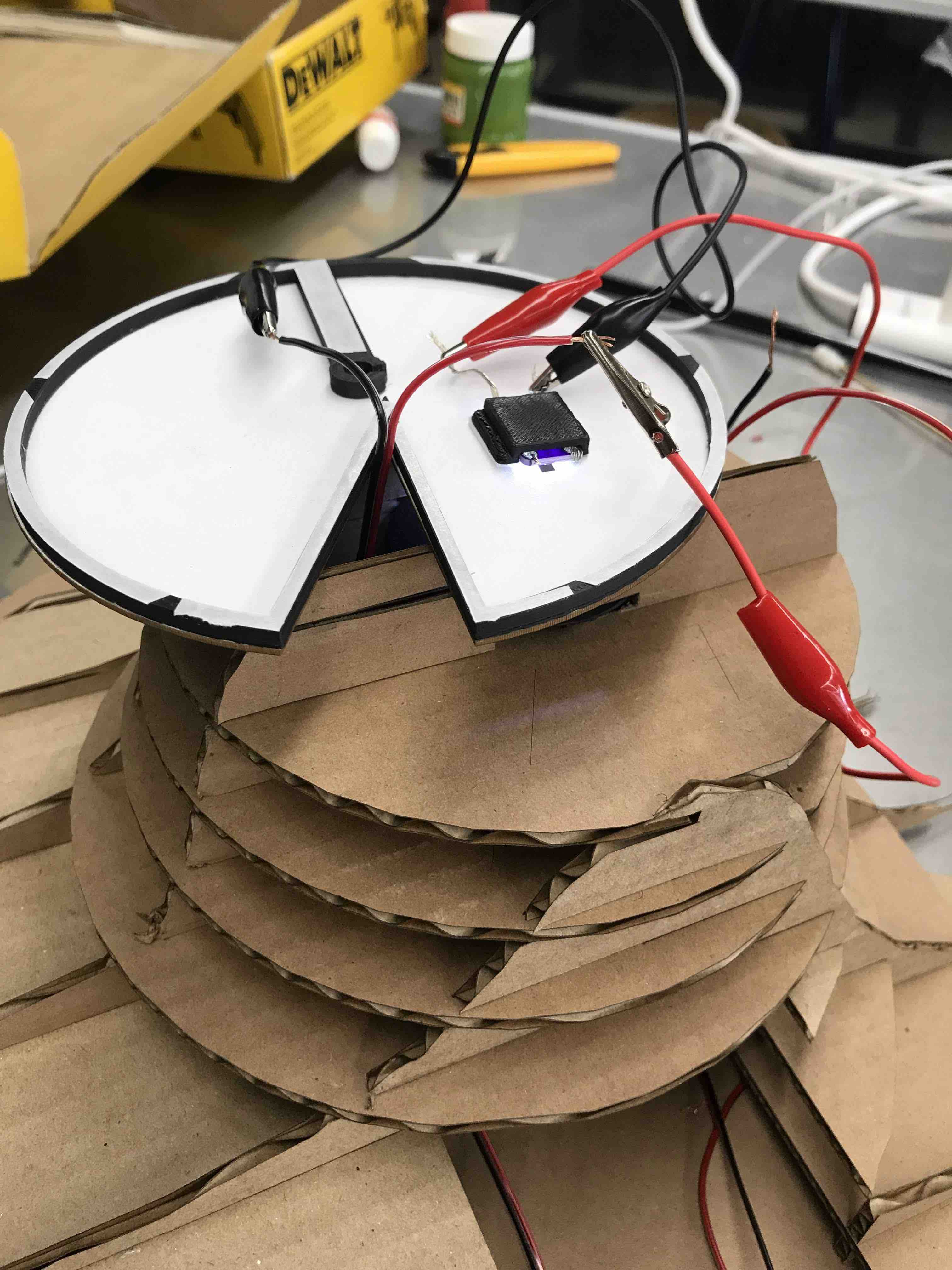

Remember the space i

need to be done in the base in the design phase? here it is, and

the servo, batteries, PCB etc will fit inside the base.

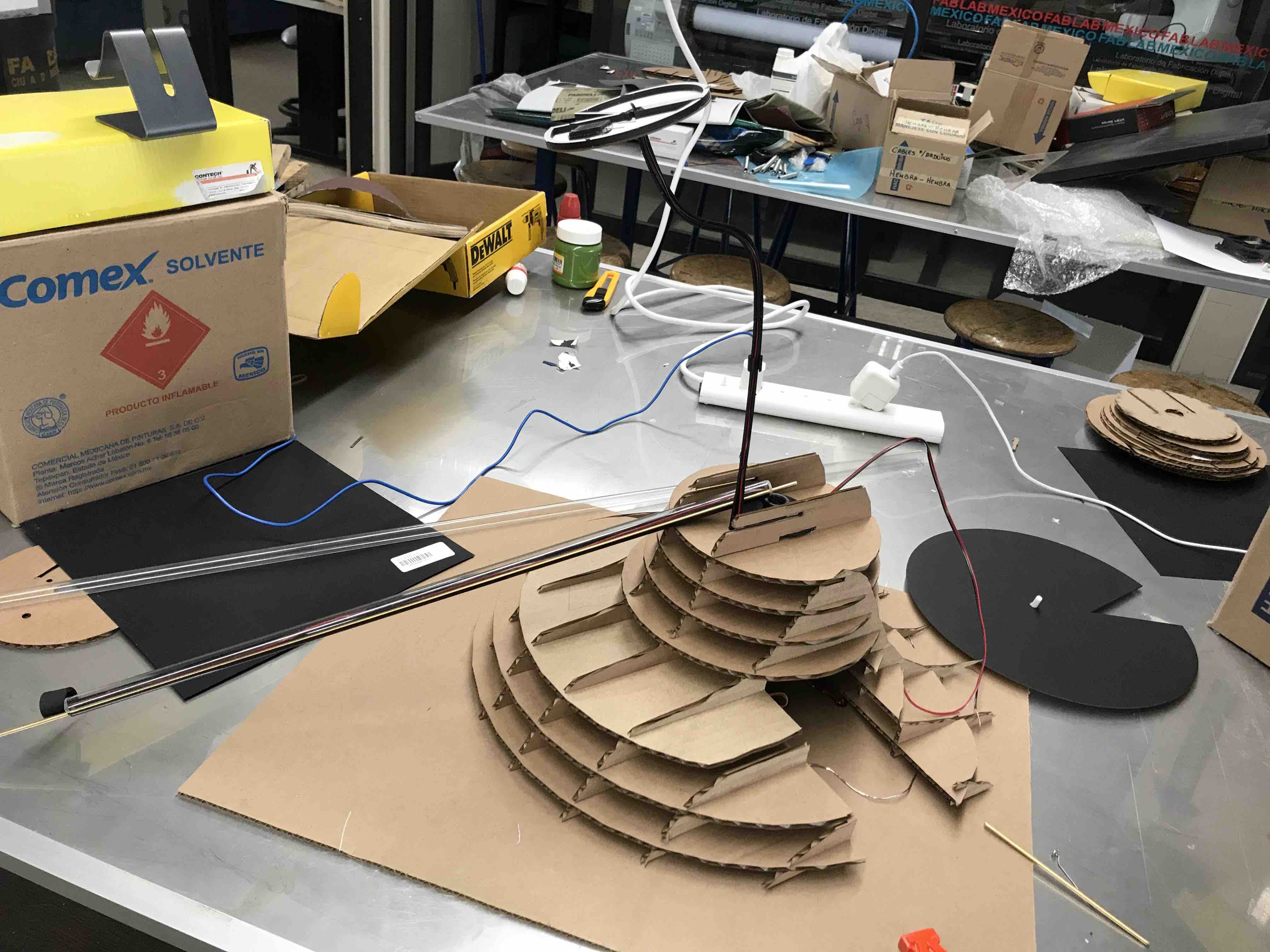

ASSEMBLe

a place to re-connect

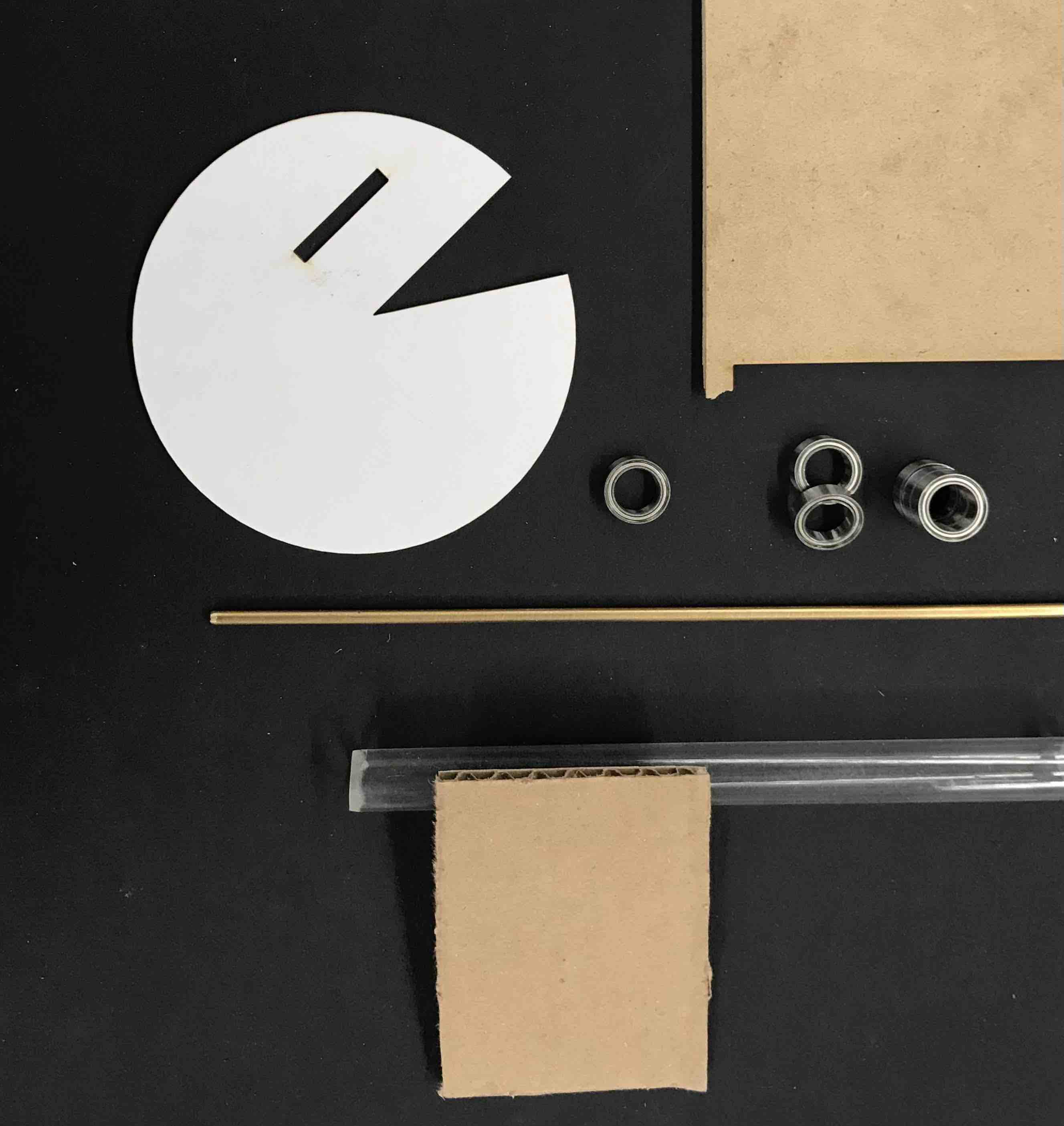

different materials to

be used in the prototype: corrugated cardboard, bearings, acrylic

pipe, cardboard and a brass rod.

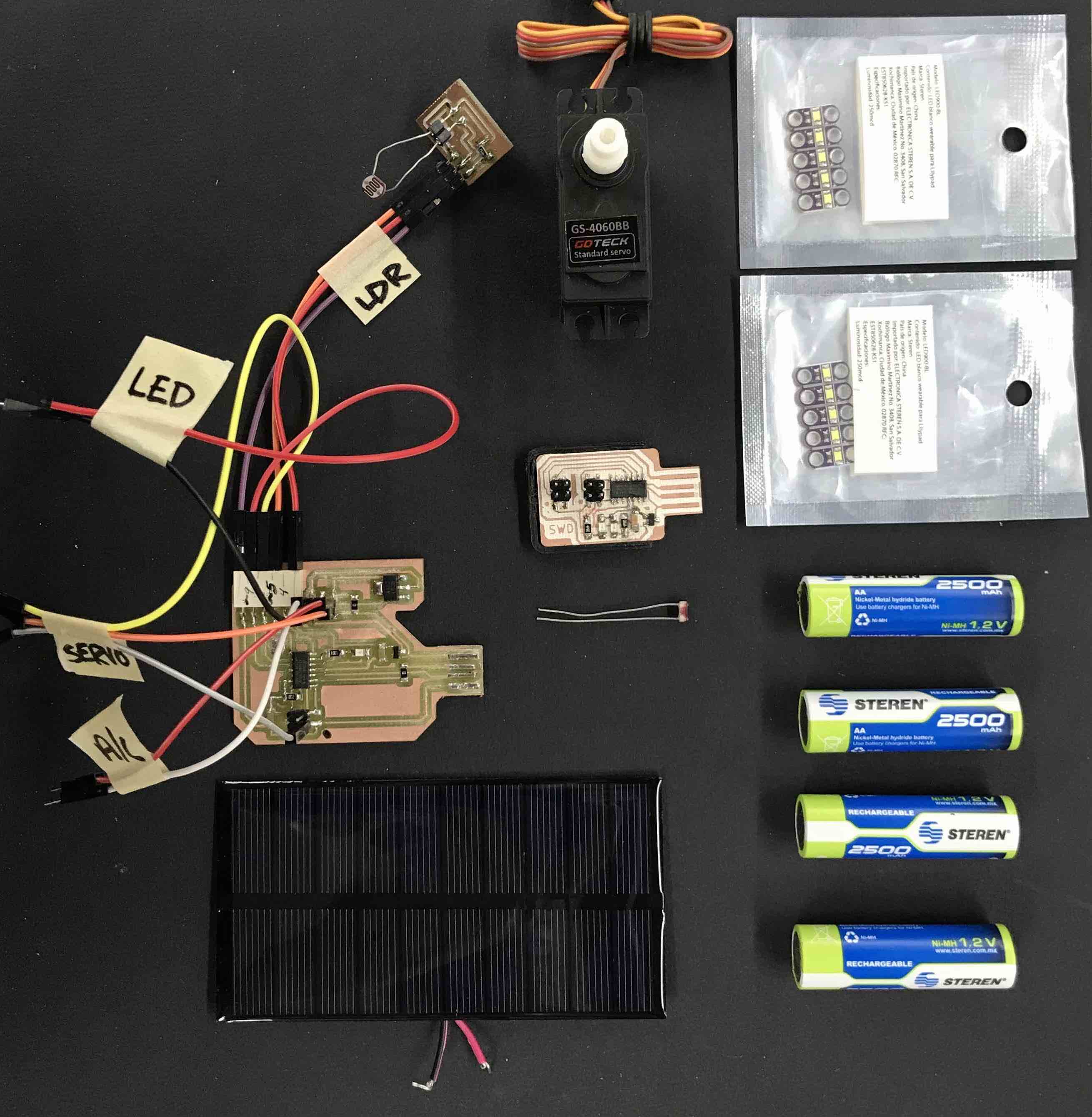

3D printed components

Electronics components

some 3d printed

objects; solar cell support, axis of rotation.

Cardboard and 3d

printed pieces that will form the leafs

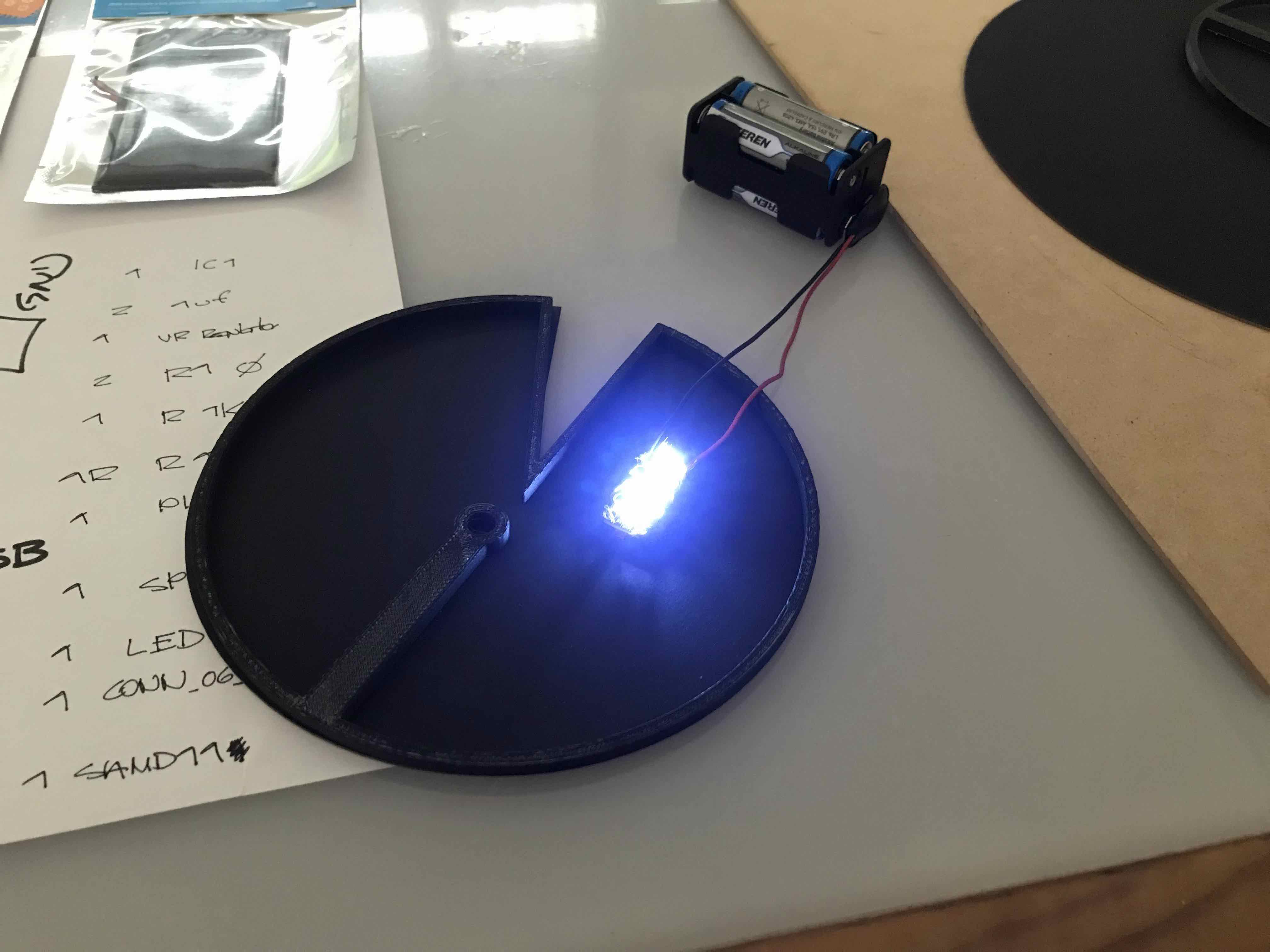

testing LEDs in the

leaf

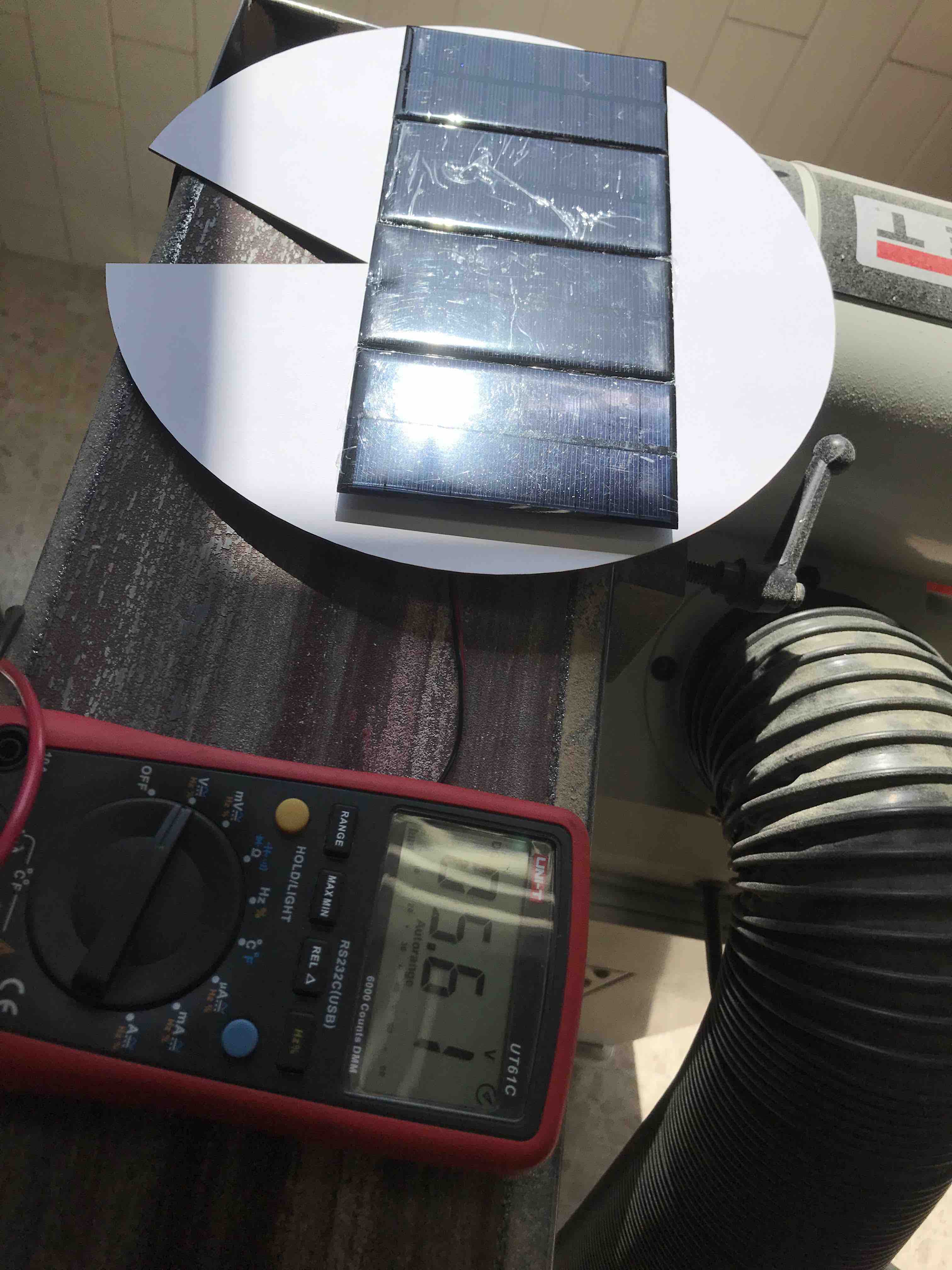

Checking the voltage,

then I charge the rechargeable batteries with the solar cells, I

made an exercise of half an hour and the batteries went from 5.0 to

5.286

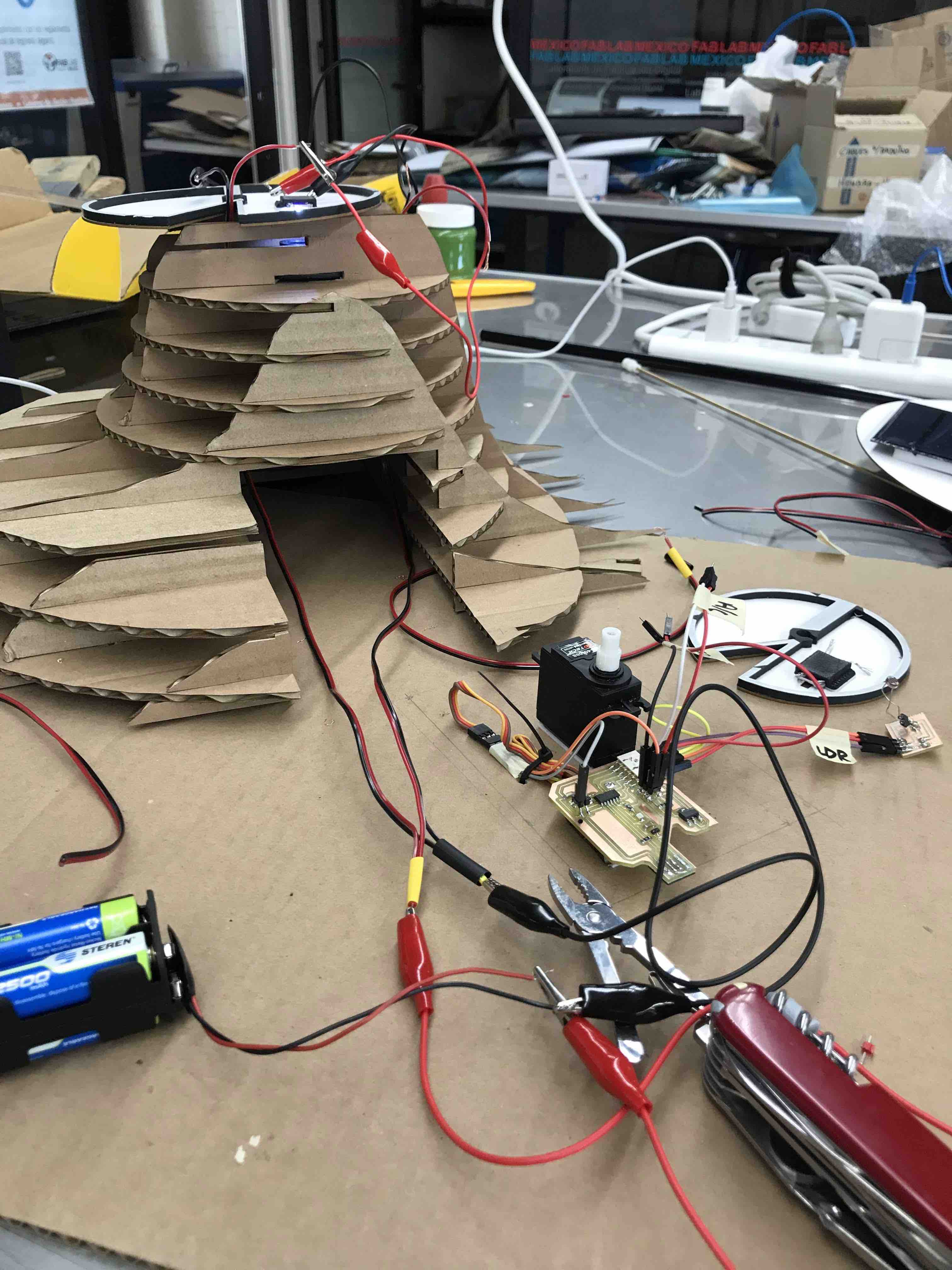

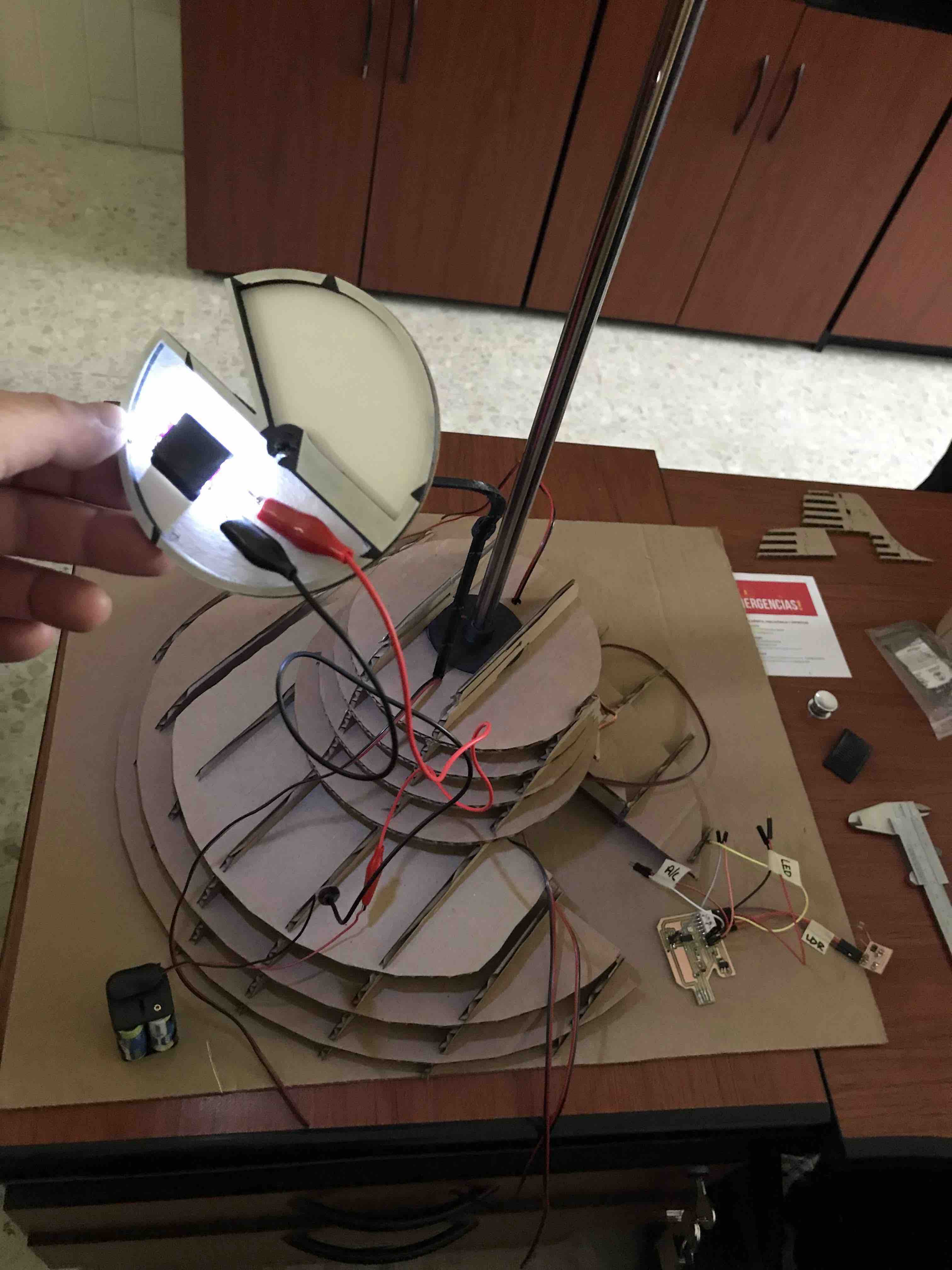

The PCBs, servo almost

done and the base has all the upper components fit

connecting the LEDS in

their place and checking electrical connections

Checking the Voltage of

the solar panels

fitting the secondary

leafs supports that guide the cables from the base to the LEDs

Checking the LDR and

the LEDS function

Assemble of the central

mechanism that connect the principal leaf with the servo so can turn

the solar cells toward the sun

prototype

a place to re-connect