18. Machine week¶

In this part we will build Arduino CNC Foam Cutting Machine. The machine is inspired by the work found here.

This is a team working task and different students will be working on different parts. My part with my colleague Omar is to work on Designing and 3D printing mechanical parts needed for machine to function as well as to hold the structure.

At the beginning we had a team discussion and assigned tasks to sub groups, and we worked in parallel on all machine parts (mechanical, electronics, 3D printing and software). We had three sub groups:

Aziz, Hani: Electronics and software.

Faisal, Hani: Mechanical design.

Batoul, Omar: 3D printing.

When all assigned tasks completed, we all worked as a group to assemble and test the machine, including axes movement, axes calibration, and hot wire calibration. Then we made cutting tests and captured one in the Hero Shoot video.

Group Page¶

Individual Contribution¶

Files to Download to 3D print¶

Gallery¶

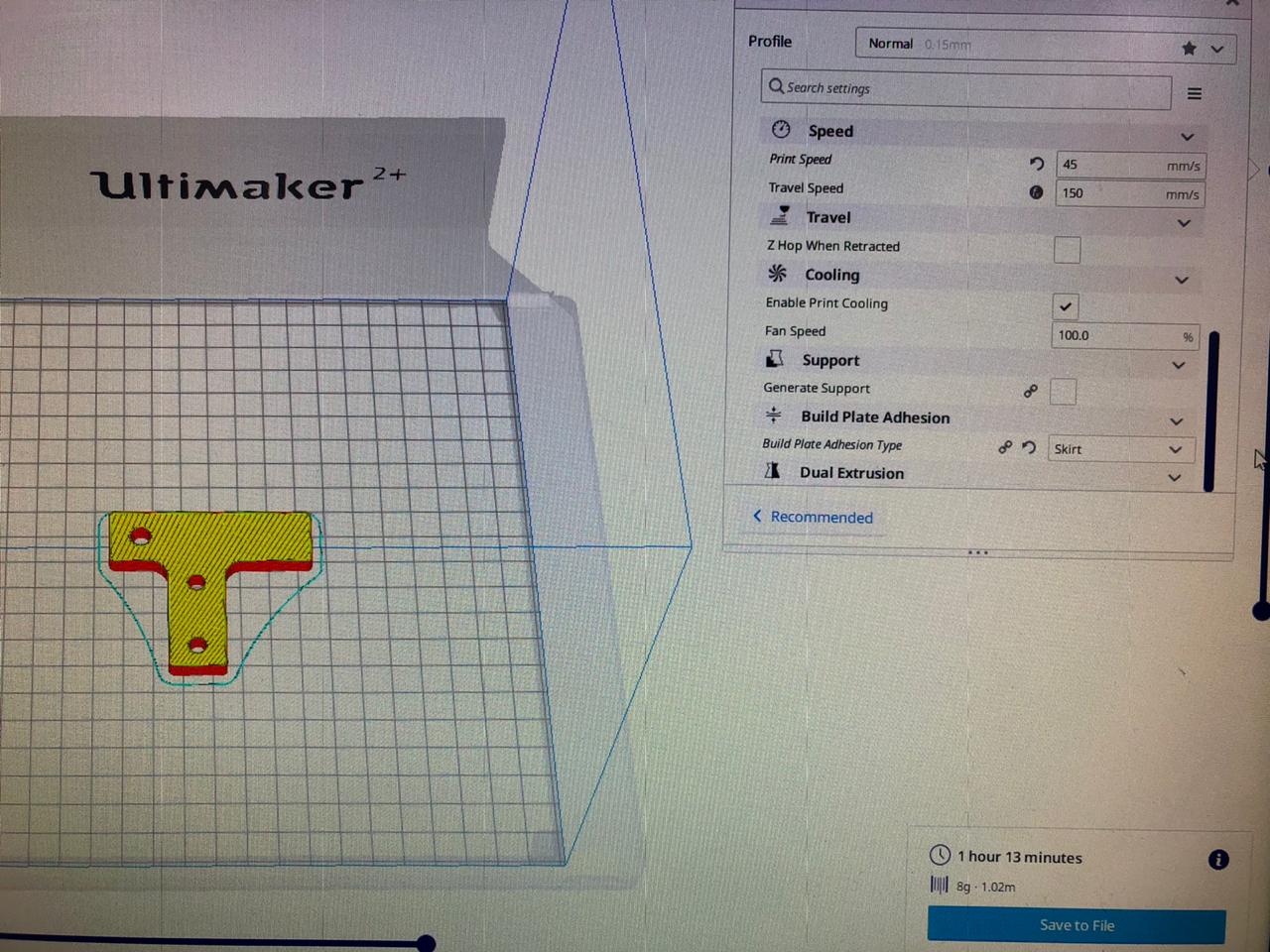

setting the ideal setting for the 3d Printed parts on Cura with layer height .15 wall thickness .7 print speed 45 and travel speed 150

setting the ideal setting for the 3d Printed parts on Cura with layer height .15 wall thickness .7 print speed 45 and travel speed 150

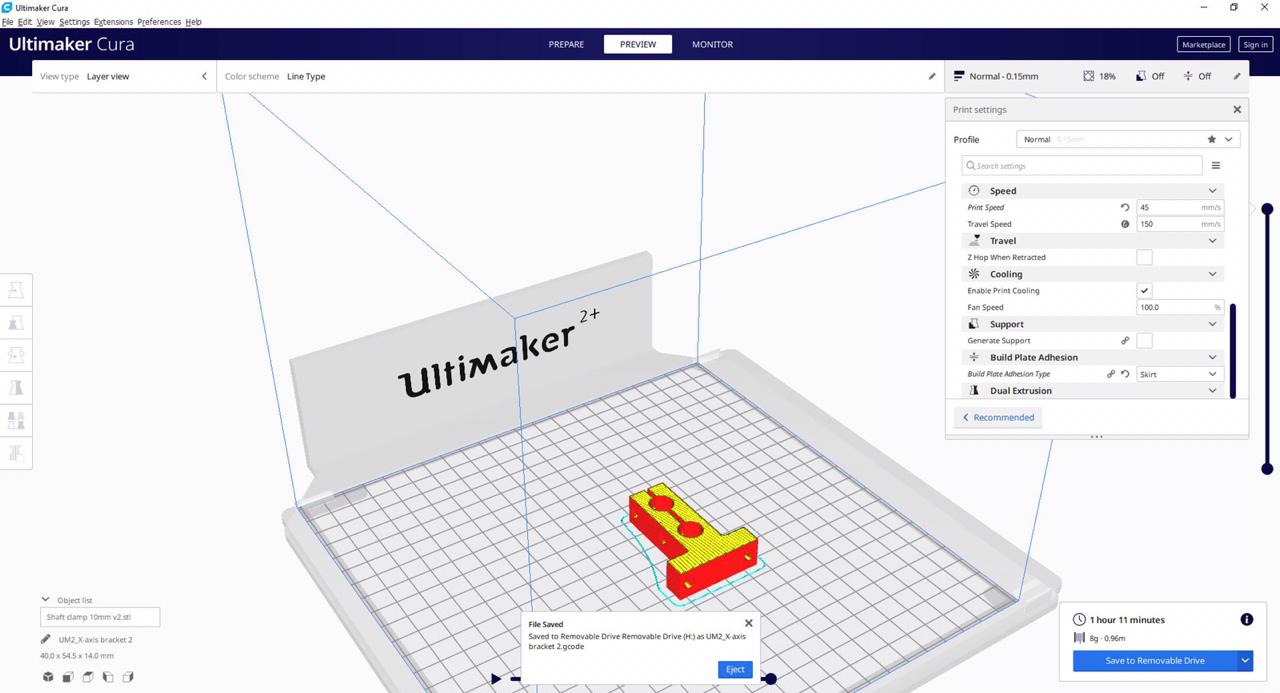

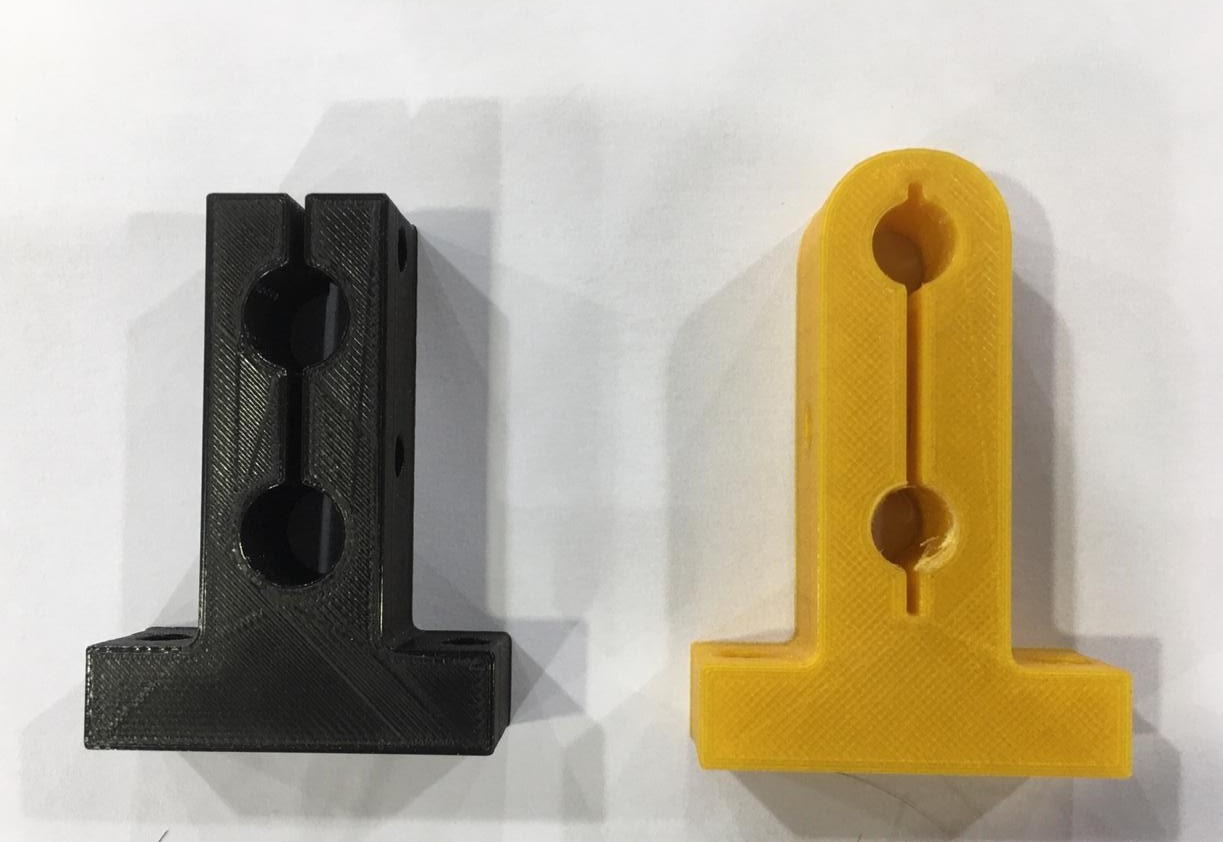

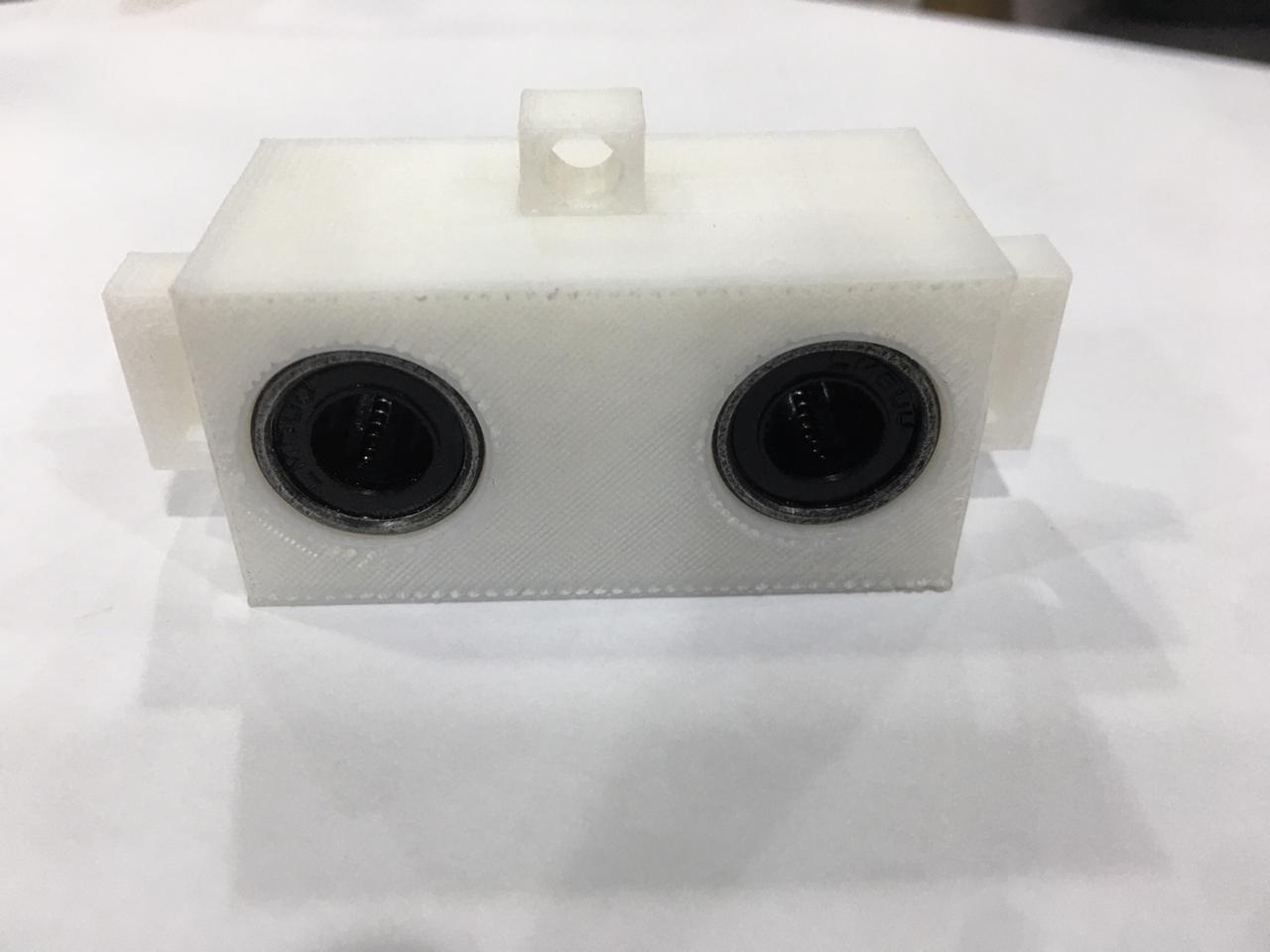

then tried to modify Shaft clamp 10mm to fit the 2 parallel rods ad first prototype and printing it using same settings

then tried to modify Shaft clamp 10mm to fit the 2 parallel rods ad first prototype and printing it using same settings

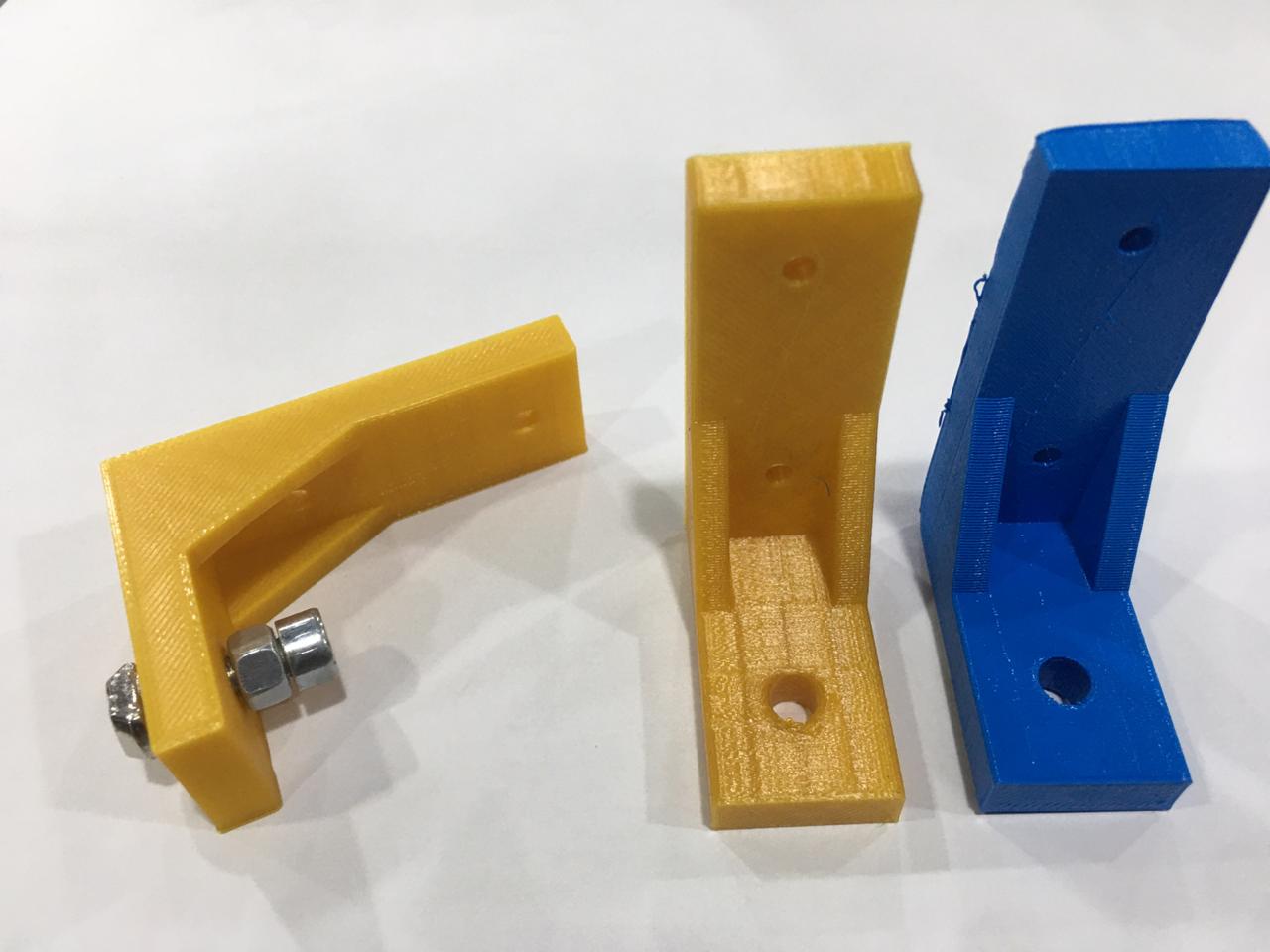

but sadly it was structurally not the best after trying the physical assembly so the design had been modified

but sadly it was structurally not the best after trying the physical assembly so the design had been modified

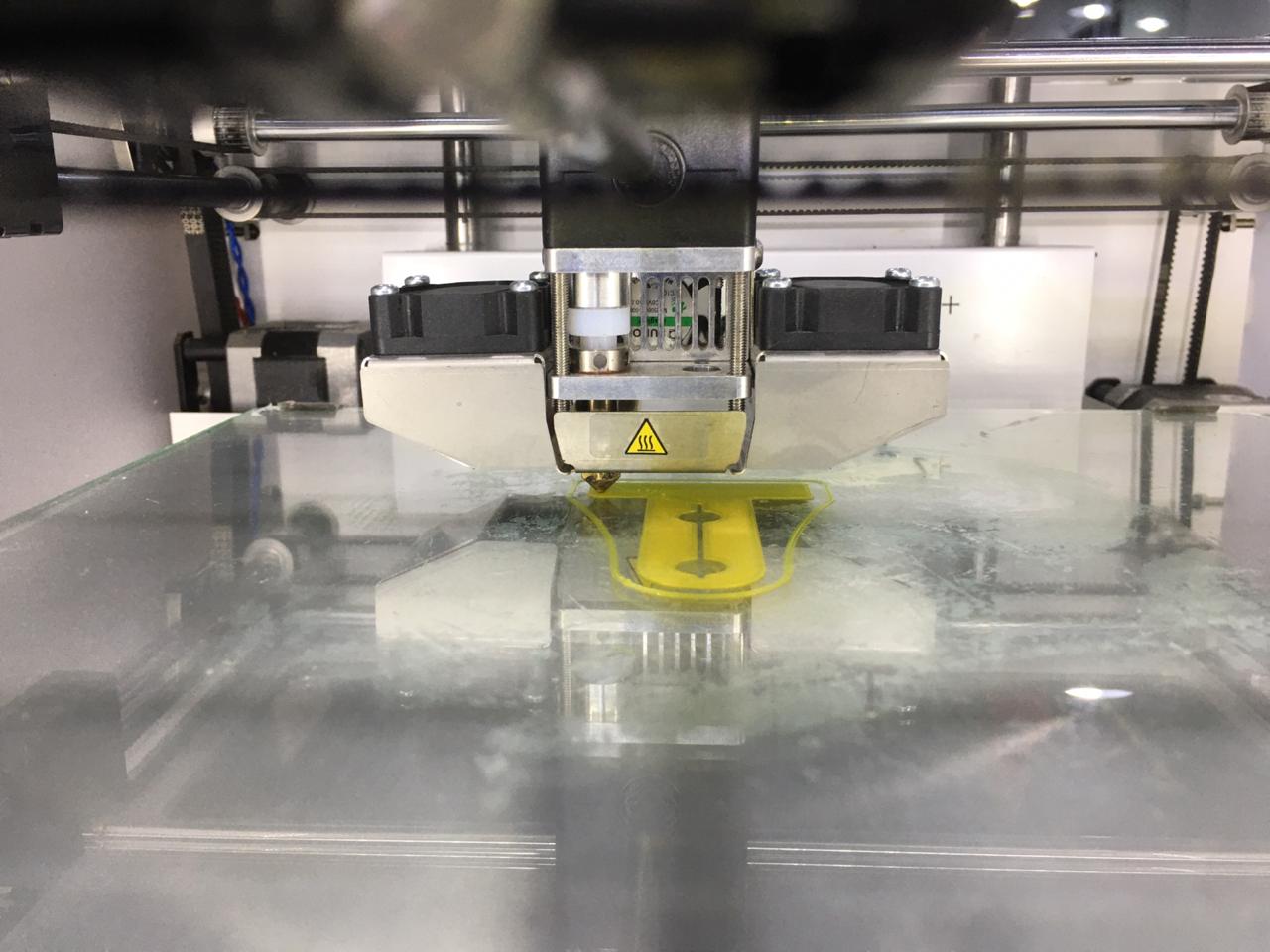

Printing the new design

Printing the new design

comparison between 2 designs

comparison between 2 designs

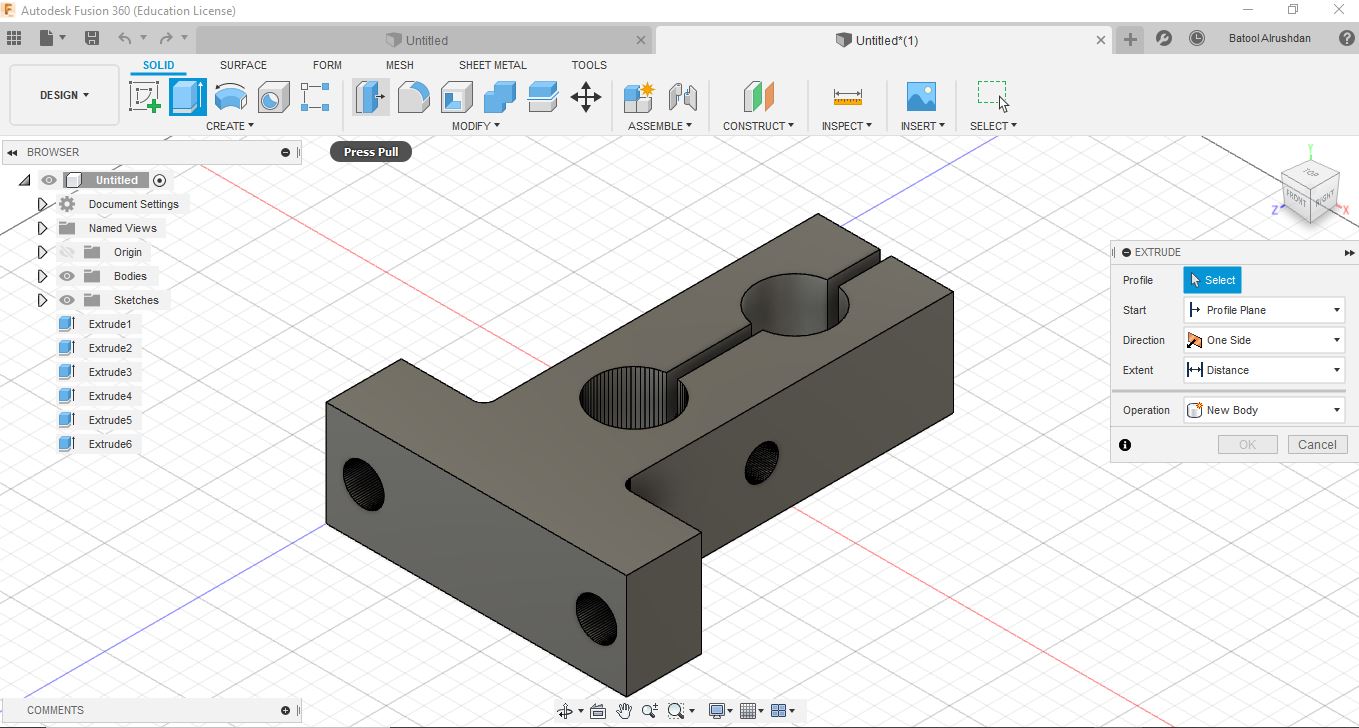

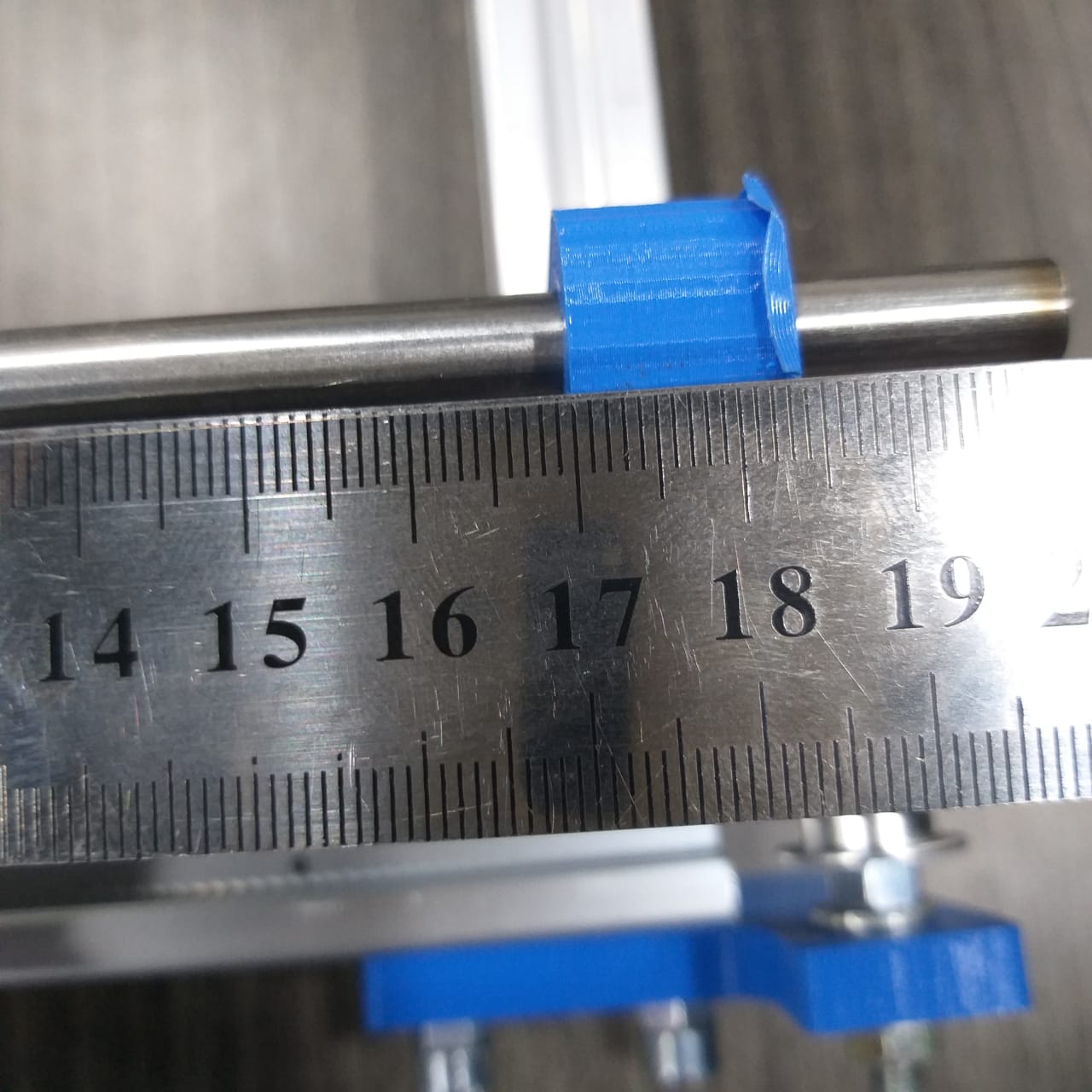

Rechecking on the Shaft clamp modified design and it’s measurement

Rechecking on the Shaft clamp modified design and it’s measurement

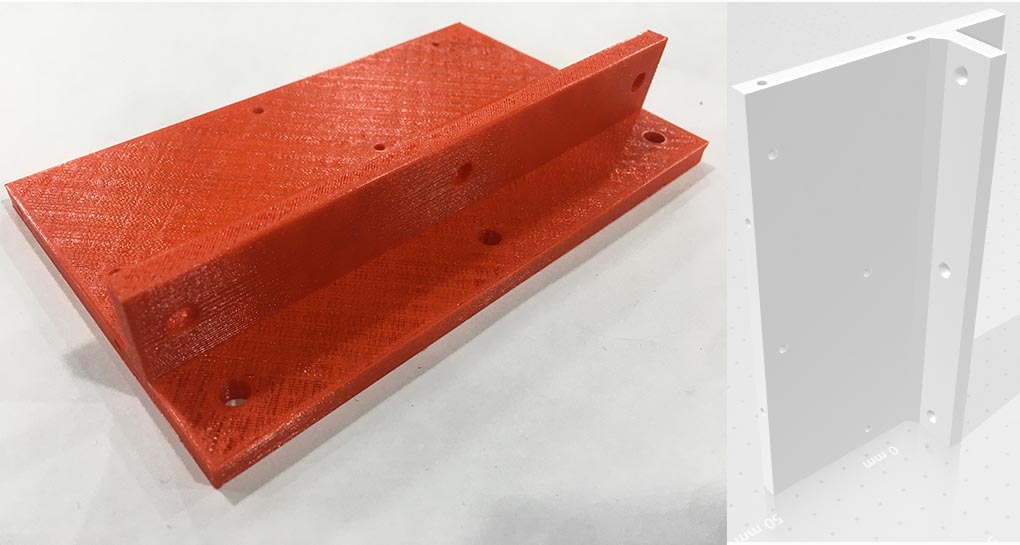

Arduino Case design STL and printed perfect fit from first Time

Arduino Case design STL and printed perfect fit from first Time

checking the fit between 3D printed parts and ordered metallic mechanical parts

checking the fit between 3D printed parts and ordered metallic mechanical parts

Video¶

Micky mouse Trial cutting outline

CNC foam cutting from Batoul Al-Rashdan on Vimeo.

Nike Outline trial by BOR - extra

CNC foam cutting from Batoul Al-Rashdan on Vimeo.