'Concentration becomes a virtue when you are working with a needle.'

African Proverbs

Electronic Production

It is on days like this that I wish I was Inspector Gadget. Well, no can't do. I have to give my best to achieve the best. So the agenda of the week is to learn how to use a PCB milling machine, and fabricate a microcontroller programmer from scratch. Yes, this includes soldering and other dirty works that are not conducive for a lazy man!

Before we proceed further, I will give a little explanation about Electronics and PCB. This will ensure that we are on the same page when we get to the section of the assignment.

PCB means - Printed Circuit Board. mechanically supports and electrically connects electrical or electronic components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it Reference.

Characteristics

There are different characteristics of PCBs. These are detailed in the section below:

Through-hole Technology: This mounts electronic components by leads inserted through holes on one side of the board and soldered onto copper traces on the other side. Boards may be single-sided, with an unplated component side, or more compact double-sided boards, with components soldered on both sides. Horizontal installation of through-hole parts with two axial leads (such as resistors, capacitors, and diodes) is done by bending the leads 90 degrees in the same direction, inserting the part in the board (often bending leads located on the back of the board in opposite directions to improve the part's mechanical strength), soldering the leads, and trimming off the ends. Leads may be soldered either manually or by a wave soldering machine Reference.

Surface-mount Technology: is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical components mounted in this manner is referred to as a surface-mount device (SMD) Reference. With SMT, components became much smaller and component placement on both sides of the board became more common than with through-hole mounting, allowing much smaller PCB assemblies with much higher circuit densities. Surface mounting lends itself well to a high degree of automation, reducing labor costs and greatly increasing production rates Reference

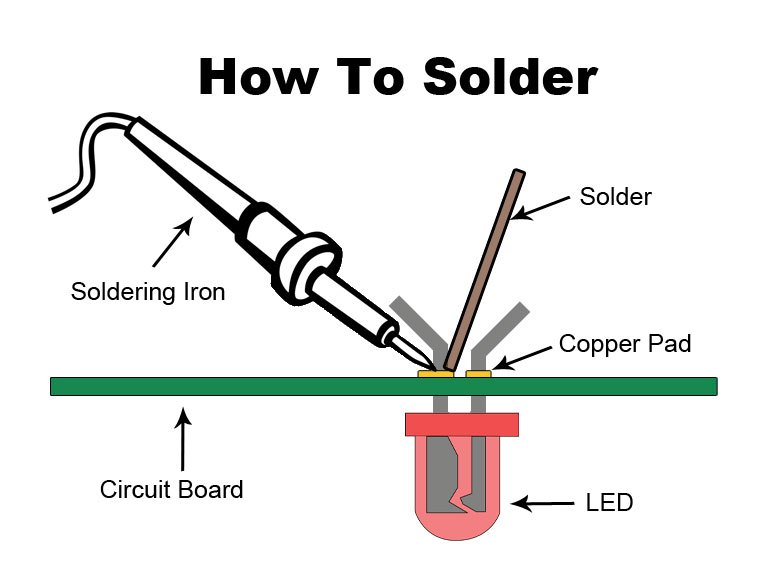

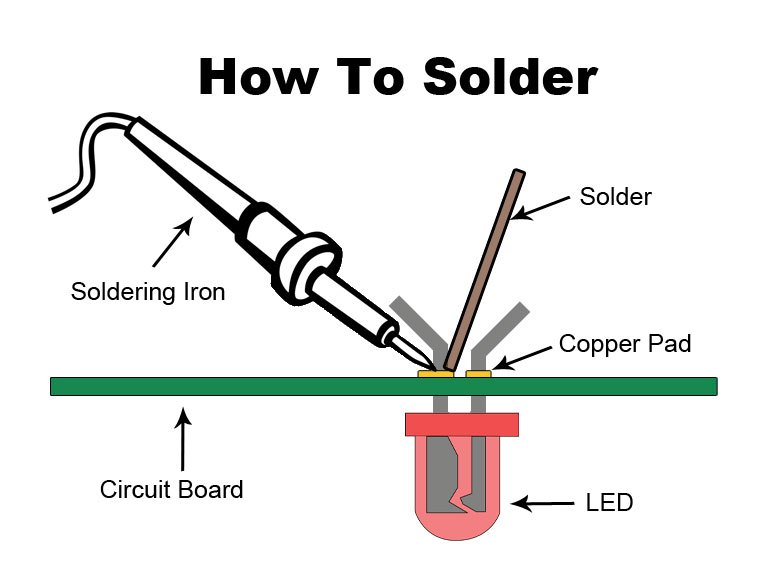

How To Solder

To survive in the electronic world, as well as accomplish you goal of being a person endowed with the knowledge on 'How to Make Almost Anything', the knowledge of soldering should be one of the critical skills in your arsenal.

To solder, you will need the following tools, some are mandatory, while the others are optional:

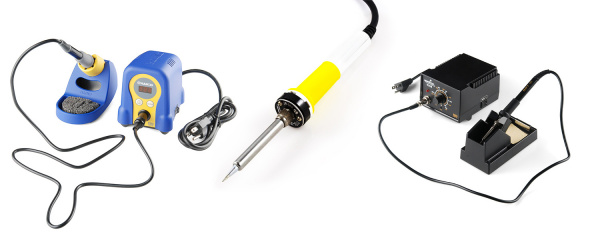

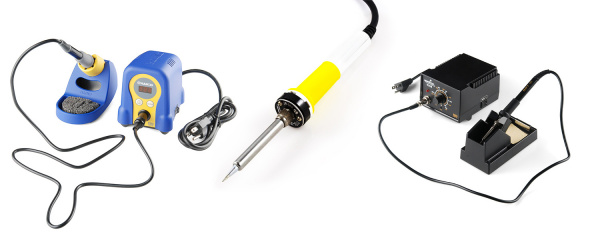

1. Soldering Iron: this is the most important tool in the world of soldering. Soldering irons are most often used for installation, repairs, and limited production work in electronics assembly.

FYI. You should also use the right soldering tips!

2. Solder: This is another critical component used to join the electronic component to the fabricated board. The traditional solders are composed of two metals, that is tin and lead. This melts at a high temperature.

3. Brass Sponge: This helps the solder from oxidizing, this is done by cleaning the tip of the soldering iron in the sponge to wipe off the impurities that causes oxidization.

4. Solder Vacuum: This is a great tool for removing solder left behind in through-holes when delsodering components. It is also known as a 'Solder Sucker'.

Third Hand: This is also known as 'Third Arm', it is used to help hold the PCBs, wires, and components in place during soldering.

And other tools such as Flush Cutters, Diagonal cutters, Needle Nose Pliers, and snippers.

To enhance your practical experience in soldering, please visit Here.

To view the assignment, click Assignment or simply go to the assignments sections below.