'A hunter with only one arrow does not shoot carelessly.'

African Proverbs

Computer-controlled Cutting

Objectives

The objective of this week's lesson is to understand the basics of parametric design. As well as to show that I can use both the Vinyl cutter and the Laser cutter machine to express my creativity.

This will be detailed in the assignment section. To see the assignment, please Click Here.

In this week, a particular word stands out. Some might be already used to this word, but I am just getting a hang of it now. The special word is 'Kerf'!. So what is Kerf? In the paragraph below, I will provide a Textbook definition of Kerf (Copy and Paste Edition).

According to ESAB Knowledge Center, Kerf = Width. They further defined it as the width of material that is removed by a cutting process. From this definition, it is apparent that 'Kerf' is not just particular to laser cutting, but all cutting process.

In addition, according to Wiktionary, Kerf could mean any one of the following:

Why Kerf width is Important

When cutting parts on a CNC plasma or laser machine, you want to produce accurate cut parts, with final dimensions as close as possible to the programmed shape. So if you program a 6” by 6” square, and the plasma arc removes 0.200” of material, as it cuts, then the resulting part is going to be 5.8” by 5.8”. So the actual tool path has to be compensated by 0.100” to the side of the programmed path, all the way around the part.

The illustration below depicts the typical Kerf width of four different cutting processes (that is, Plasma cutter, Oxy-fuel, Waterjet, and Laser). Amongst all these processes, processes like waterjet and laser, remove a smaller amount of kerf, which is one of the reasons they can be more precise.

About the machines

What is a Vinyl Cutter and how does it work?

A Vinyl cutter is a computer controlled machine that is mostly used to trace out patterns and unique designs from Vinyls and other materials. Out of all the machines in a FabLab, from my knowledge, I think the Vinyl cutter is probably the cheapest.

The Vinyl cutter reqires a computer to function. Hence, the reason it is called a Vinyl cutter. The machine has a blade, which must be kept sharp all the time to aid effective cutting and a happy user. The cutter is capable of moving the blade on an X and Y axis over the material, cutting it into the shape designed by the user.

It can be used to cut nice stickers for laptops, doors and other uses. It can also be used to cut designs for T-Shirt manufacturing. After reading this text, I am thinking of working on 'Open Vinyl' as my final project instead of 'Fab Mode'.

What is a Laser Cutter and how does it work?

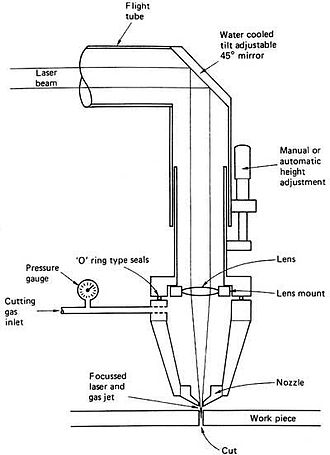

LASER stands for 'Light Amplification by Stimulated Emission of Radiation' *Genius*. I must confess that I did not know that Laser itself is a synonym until Neil Gershenfeld bursted my bubbles (Arigato Neil!). So a laser cutter is a computer numerically controlled machine that slices materials with laser. The laser is generated from some laser beams such as CO2 (this is the most common) and YAG laser beams. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated ( Reference). The focused laser beam is directed at the material, which then melts, burns, or vaporizes away the unwanted part, leaving an edge with a high-quality surface finish. Depending on your spending power, there are lasers that can cut almost anything. Moreover, there are few more details to know about a laser cutter, these will be presented in the assignment section.

At Openlab Hamburg, we have a Trotec Speedy 100. This machine can cut and engrave on Acrylic, Laminates, Leathers, Papers, Plastics, Textiles, and Woods. It can also only engrave on Glass and Stones (So leave no stones unturned). The product parameters of the machine are given below:

.PSSHHHHHHHH! TOP SECRET! - We also have the biggest open source laser cutter ( Laser Duo), which is embedded with both a CO2 and YAG laser beam. The machine was designed and developed by Daniele Ingrassia (Only God knows where he finds the time to do all these crazy inventions). The machine is way cheaper and bigger than our commercial laser cutter (Yes! Size does matter!). However, we are unable to use it since it did not pass the safety standard set in my University. Despite this disappointment, I was proud to be solely responsible for the crazy tasks inbuilding this great machine.

If you noticed that I did not indicate the type of Vinyl cutter we have at our lab. That was deliberate because we do not have one.

Parametric Design

Before proceeding into this week's task. I quickly did an online check to learn more about parametric designs. Out of the numerous video presentations out there, I found these Youtube link1 and Youtube link2 very helpful. So you can also view the link.

According to (Wikipedia), Parametric design is a process based on algorithmic thinking that enables the expression of parameters and rules that, together, define, encode and clarify the relationship between design intent and design response. Parametric design is a paradigm in design where the relationship between elements is used to manipulate and inform the design of complex geometries and structures. The term parametric originates from mathematics (parametric equation) and refers to the use of certain parameters or variables that can be edited to manipulate or alter the end result of an equation or system. While today the term is used in reference to computational design systems, there are precedents for these modern systems in the works of architects such as Antoni Gaudí, who used analog models to explore design space.

Parametric modeling systems can be divided into two main types:

To find more details about my parametric design journey, please go to Week 3 Assignment .