13. Input devices¶

Assignment¶

individual assignment¶

measure something: add a sensor to a microcontroller board that you have designed¶

and read it¶

group assignment¶

probe an input device’s analog levels¶

and digital signals¶

My Assignment Plan¶

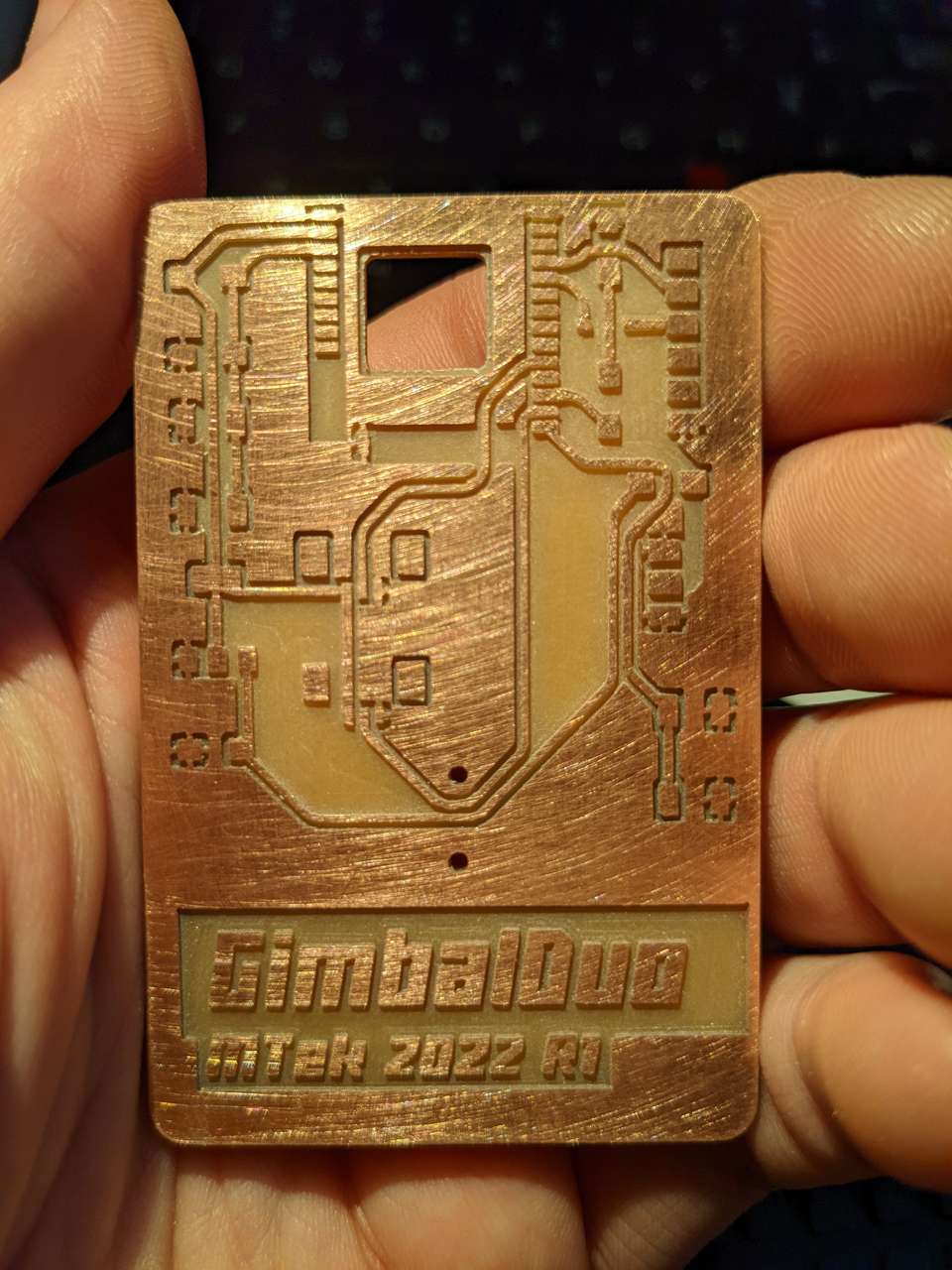

I will make a ESP 32 board that reads both a potentiometer and a hall effect sensor mounted in the same geometry RC control sticks. I will then measure and compare these two inputs. Maybe I will graph the output so the resultant smoothness can be compared. ~~I may make my ESP32 chip un-plugable from my board (buying pins and headers to do this costs more than an entire ESP-32 Chip, not cost effective).~~

- Design ESP-32 based board with 4 gimbal inputs.

- Design one sub-board that duplicates or improves gimbal performance using Texas Instruments DRV5055A3Q1 can run at 3.3 or 5vdc (Q1 series has higher temp range)

TX12 and TX16 RC Transmitters¶

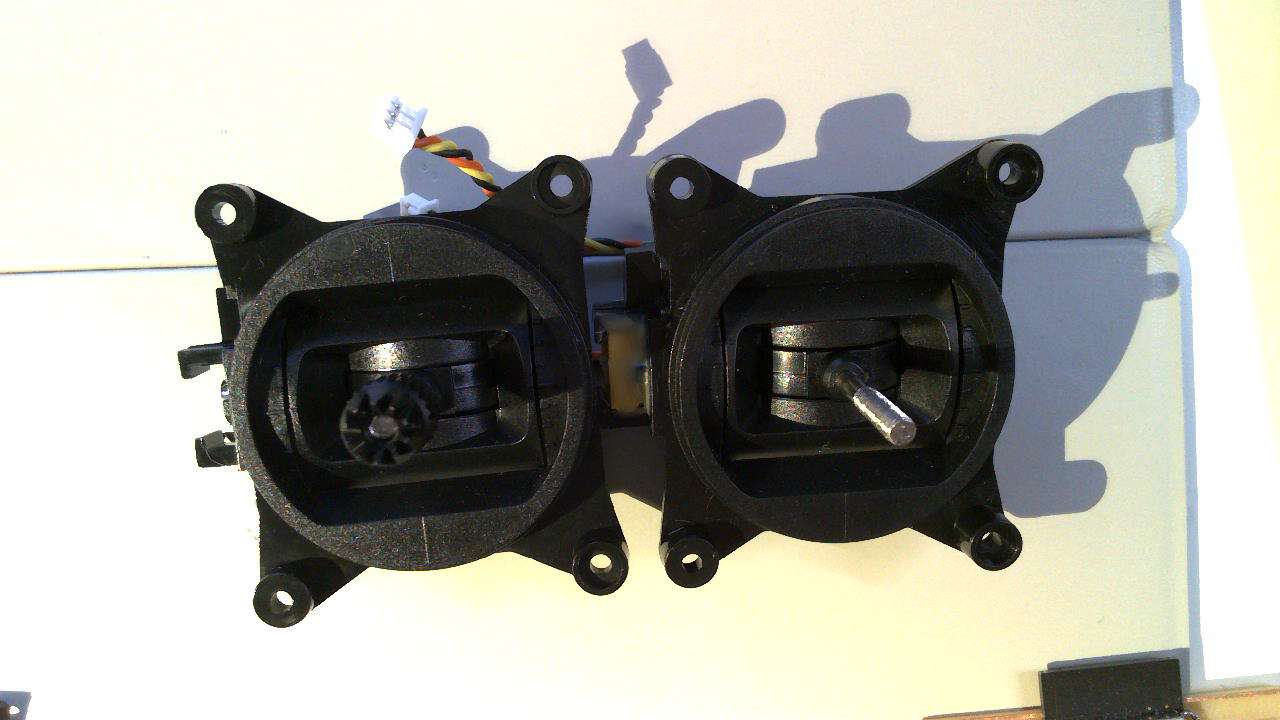

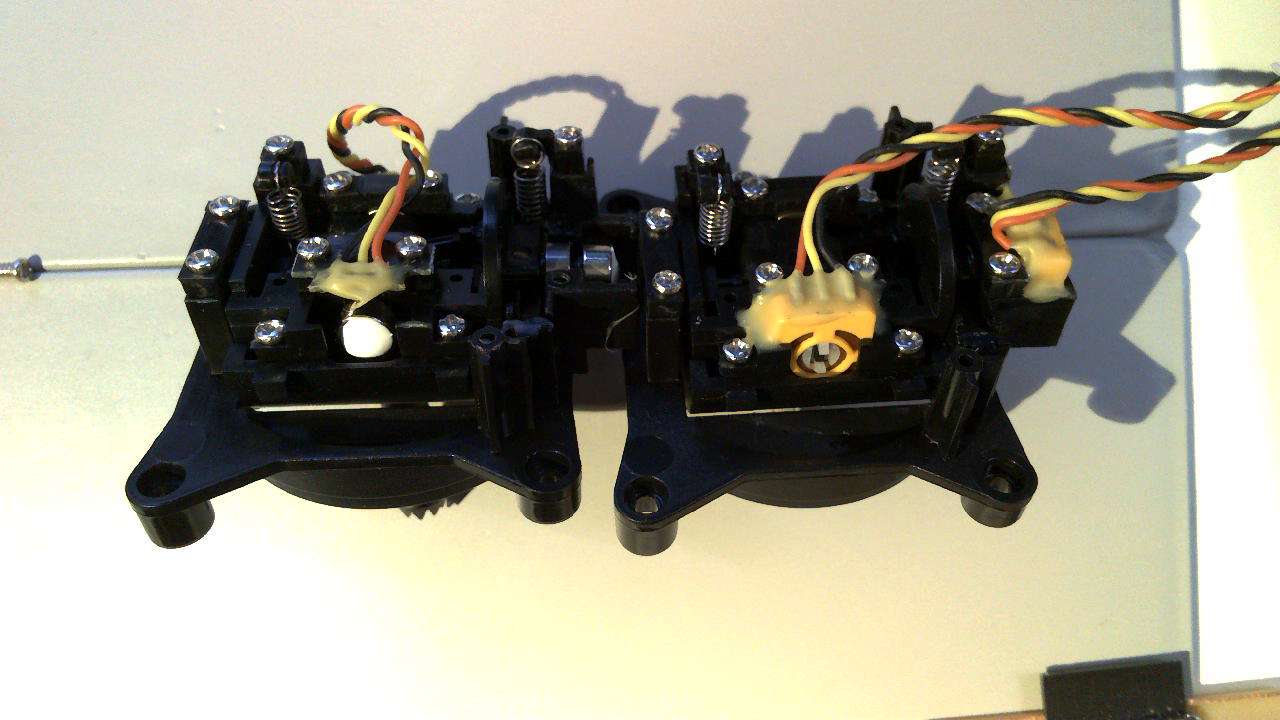

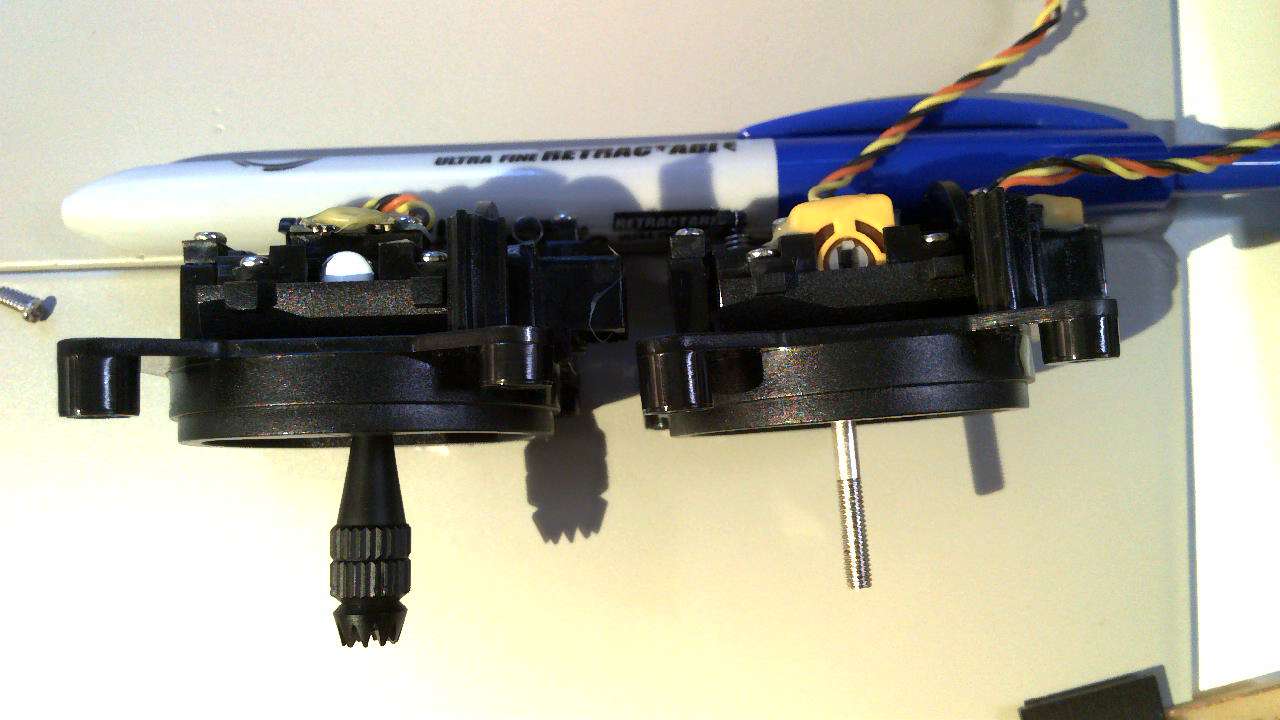

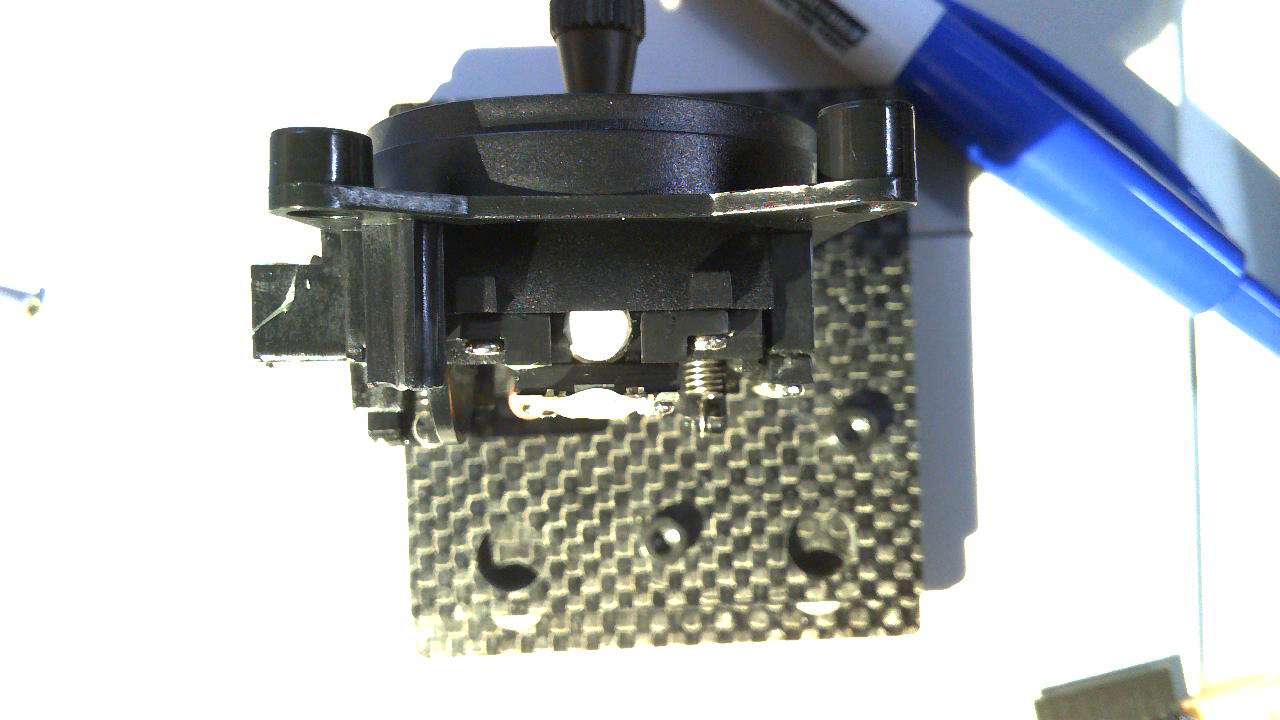

I have some spare Jumper Brand Hall and Pot Gimbals in my workshop, here is what they look like:

Images above show the differences between the hall (left) and potentiometer (right) gimbal sensors.

Images above show the differences between the hall (left) and potentiometer (right) gimbal sensors.

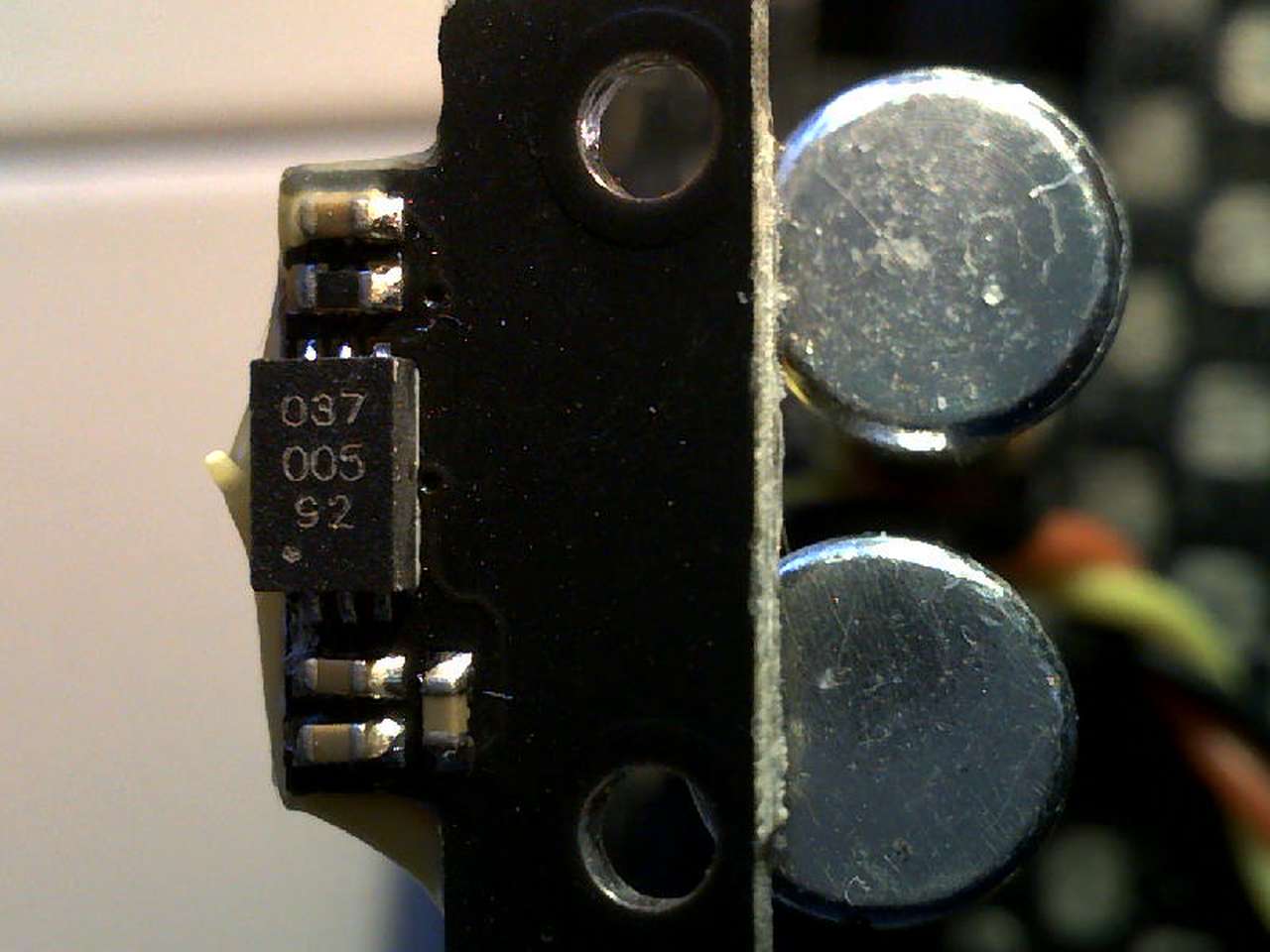

Unscrewing the hall effect sensor board from the gimbals revealed a chip marked 03700592. It ends up this chip is most likely a Allegro A1392SEHLT-T with a 2.50 mV/G Sensitivity.

Unscrewing the hall effect sensor board from the gimbals revealed a chip marked 03700592. It ends up this chip is most likely a Allegro A1392SEHLT-T with a 2.50 mV/G Sensitivity.

I searched for this number and no results came up. However a search for the common chips used in RC controls did result in lots of information.

It seems that the Allegro A1388LLHLX-2-T hall effect IC is widely used as the hall sensor in most modern hall effect gimbals as of 2022. See links below:

OfficalEdgeTXDiscussionThread “They use the same Allegro A1392 hall effect IC, as e.g. the original RadioMaster hall gimbals (V1 to V4 and also AG01).” The AG01 is a $60 a piece gimbal that is highly regarded as one of the best gimbals on the market. so it seems a Allegro A1392 is an upgrade over the A1388 chip.

This RC Groups discussion has details on the exact gimbal sensors I have. Here I summarize the important notes from this discussion:

- The 100k resistor forms a potential divider with the input resistance of the Vref pin of the 1391 chip that reduces Vref to 250/(250+100)x3.3 = 2.36V

- The minimum allowable Vref on the datasheet is 2.5V

- There is a footnote on the specifications relating to Vref that says :”Degradation in device accuracy will occur with applied voltages of less than 2.5 V”

- The input resistance of the Vref pin decreases with temperature, further lowering Vref as temperature increases

- The change in output with temperature is far less stable at Vref=2.5 to 3V than it is at 3 to 3.5V (see relevant graph below) - goodness knows how it behaves at 2.3V!

- A tiny correction to @Mister_G report above - the datasheet of Allegro A1392 (page 3) says, MINIMUM 250 kOhm, thus the value and the deviation from positive supply rail on Vref pin can be a bit less than the worst case value listed here in the calculations.

RadioMaster TX12 HALL gimbal¶

Pinouts¶

Jumper Hall Effect Gimbal Info and Pin outs see Post #6

This photo shows the typical wire color meaning, but always check your wires to be sure.Source

This photo shows the typical wire color meaning, but always check your wires to be sure.Source

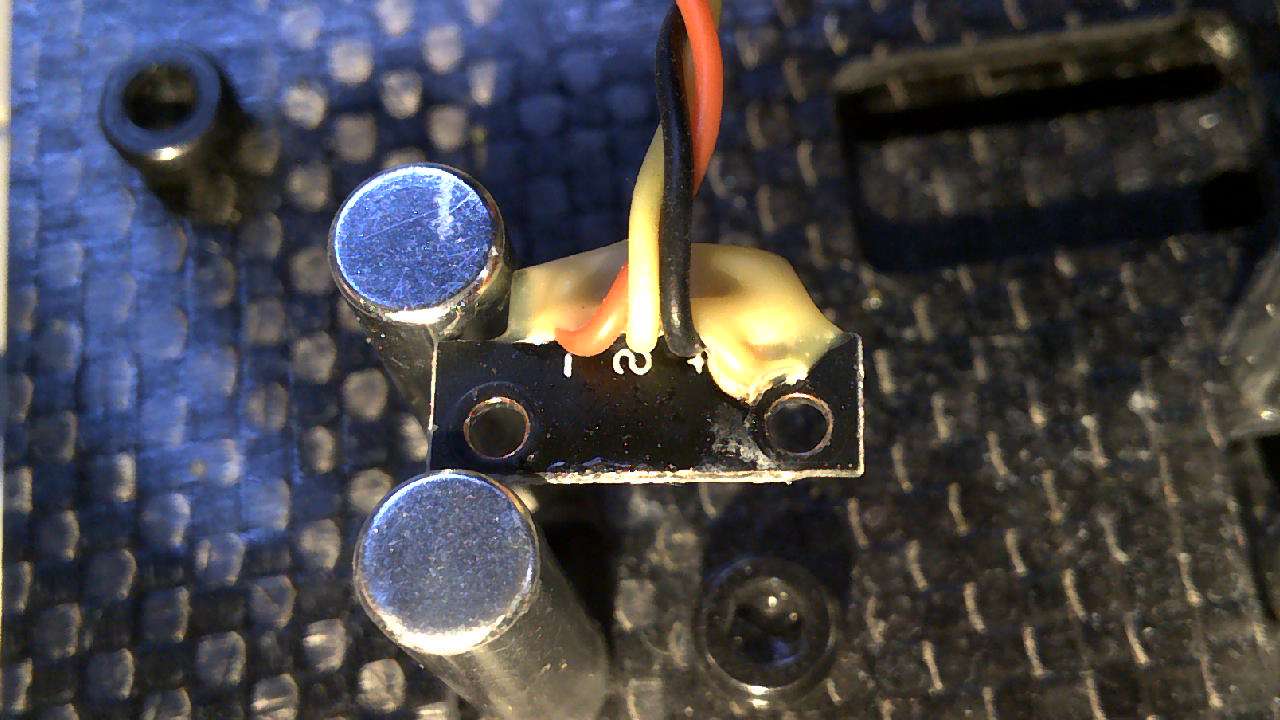

On the back of my hall sensor board I can see the -,S,+ markings.

On the back of my hall sensor board I can see the -,S,+ markings.

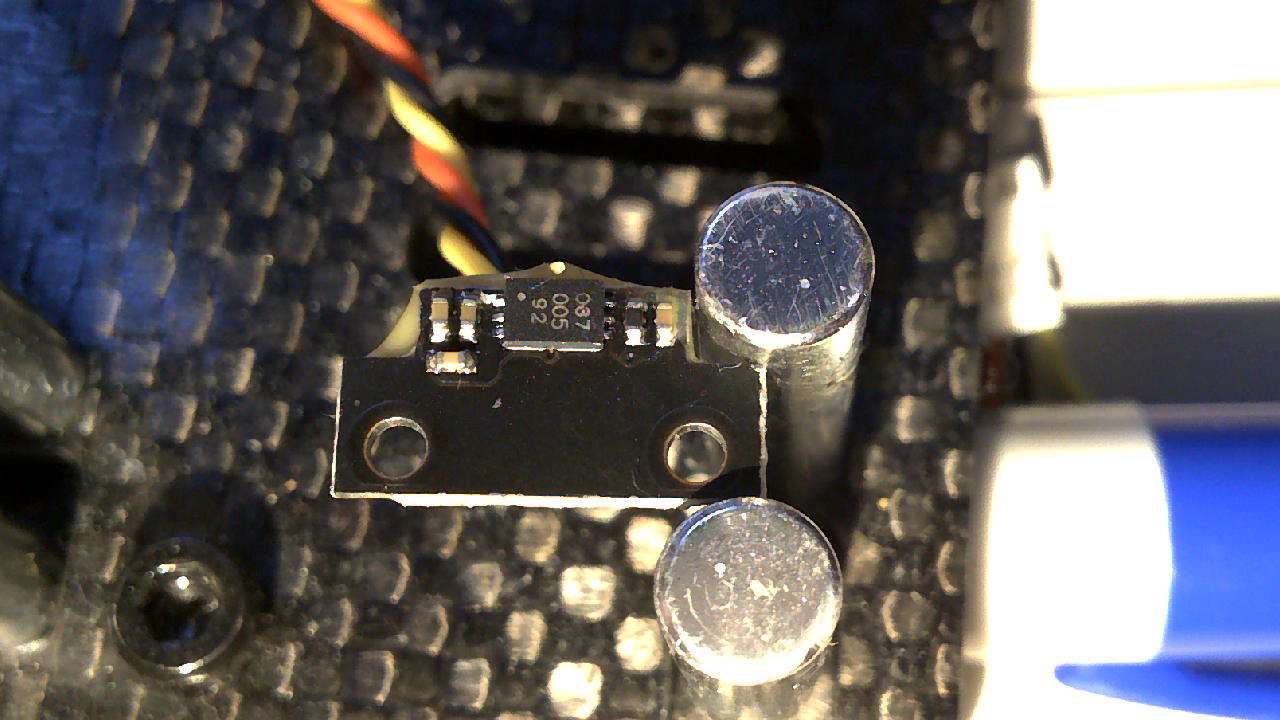

This shot shows the traces on the front side of the board and the vias leading to the wires on the back side.

This shot shows the traces on the front side of the board and the vias leading to the wires on the back side.

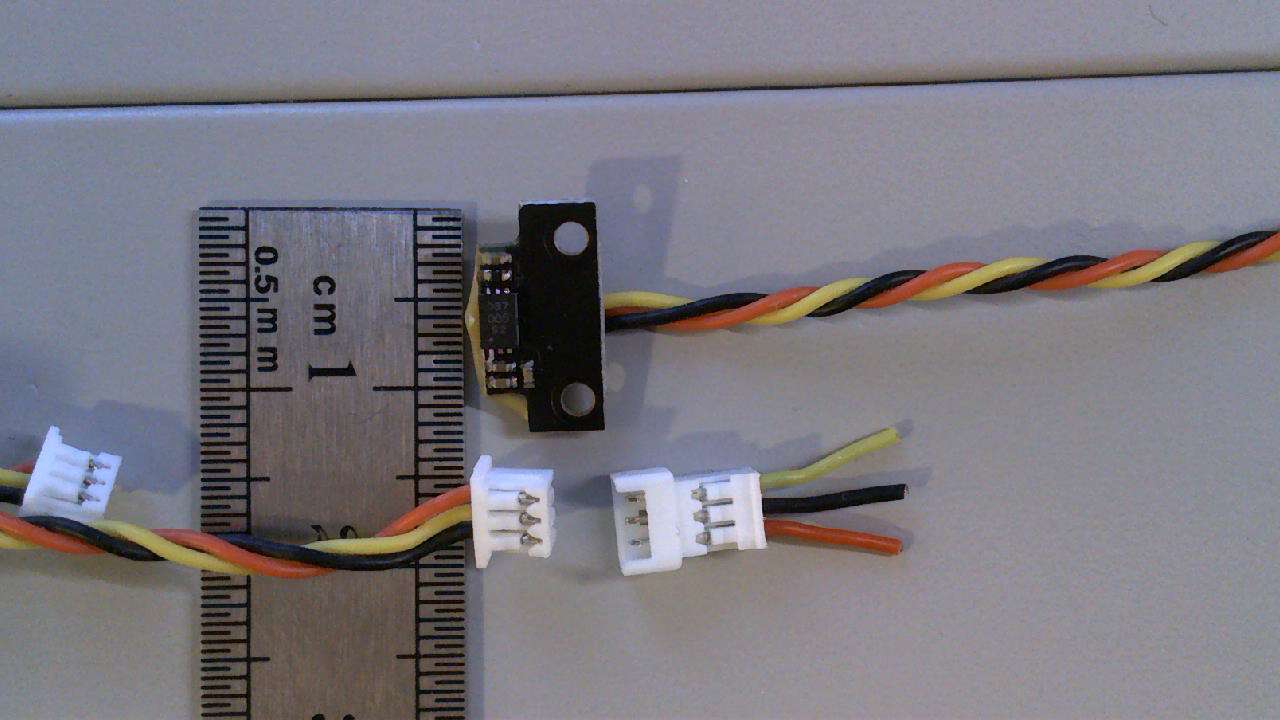

Here are the connectors used & their sizes.

Here are the connectors used & their sizes.

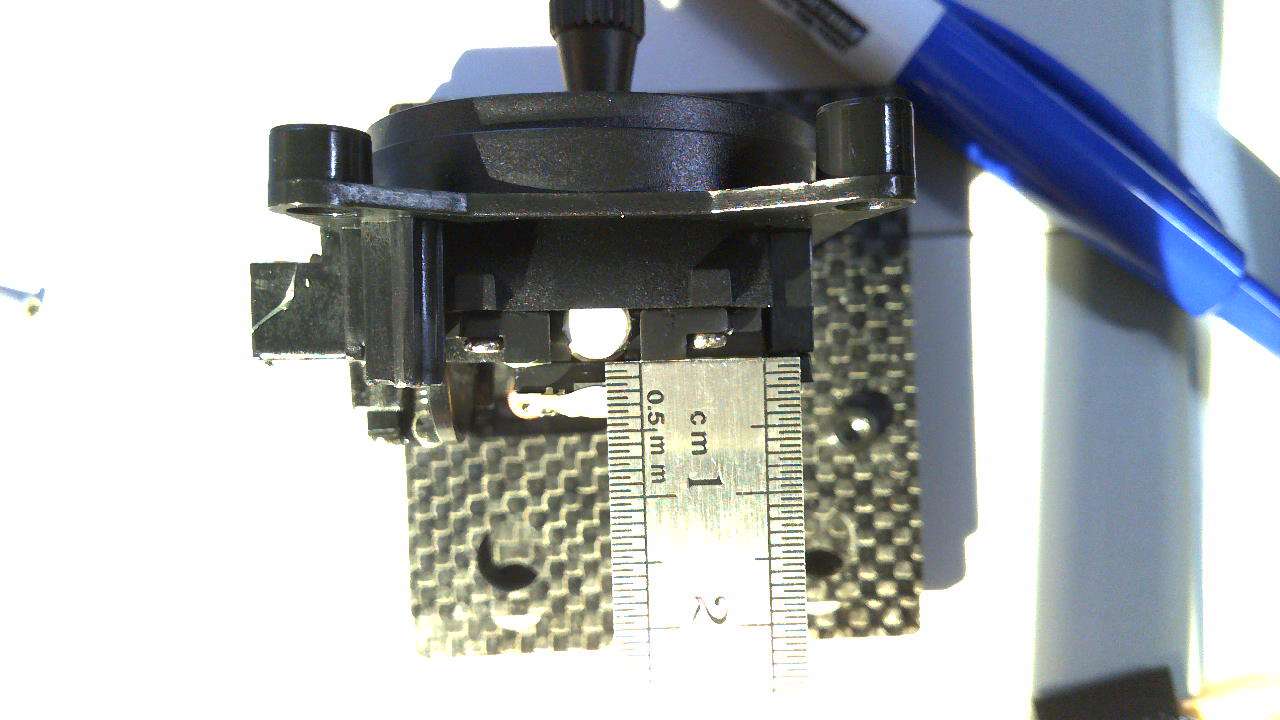

Gap between hall sensor and magnet

Gap between hall sensor and magnet

Gap measurement ~1.0mm

Gap measurement ~1.0mm

TI Hall Effect sensors¶

I found the datasheets for TI Linear Hall-effect sensors to be much easier to understand. However, the sensitivity measurements were completely different making it difficult to figure out if TI hall effect sensors could replace allegro sensors in my application.

Of most interest to me was that lots of RC folks complain about temperature drift on their hall effect gimbals. The TI DRV5055 Hall Effect Sensor datasheet says: “Compensation For Magnet Temperature Drift for A1/A2/A3/A4 Versions and None for Z1/Z2/Z3/Z4 Versions” The A version seem like they may solve this issue!

Best Hall Sensors Radio Control Gimbals¶

- Texas Instruments DRV5055-Q1 can run at 3.3 or 5VDC (device features magnet temperature compensation to counteract how magnets drift for linear performance across a wide – 40°C to +150°C temperature range)

- Texas Instruments DRV5055A3 can run at 3.3 or 5VDC (features magnet temperature compensation to counteract how magnets drift for linear performance across a wide – 40°C to 125°C temperature range)

- Allegro A1388 sensor takes 4.5 to 5.50 v in and outputs analog of 0 - 5vdc (or slightly narrower)

Note: That Allegro & Texas Instruments define the sensitivity of their hall sensors with different values. However there is an easy base 10 conversion to translate: How can I measure my exposure to magnetic fields from electrical sources? “The strength of the magnetic field is expressed in units of Tesla (T) or microtesla (µT). Another unit, which is commonly used is the Gauss (G) or milligauss (mG), where 1 G is equivalent to 10-4 T (or 1 mG = 0.1µT).”

- TI A3 series sensitivity: 25 mV/mT

- Allegro A1388 LLHLX-2-T series sensitivity: 2.5 mV/G = 25 mV/mT

Older 3VD RC transmitters¶

I would like to convert my of old work out potentiometer gimbals on our Turnigy 9x transmitters to Hall Effect sensor based gimbals. However the 9x runs on 5vdc. We are in luck because there are two good 3.3VDC hall sensor options above.

A nice guide that explains how a hall effect gimbal would work on a 9x radio is Conversion of a Turnigy 9X to Hall effect sensors

Connectors¶

The connectors on all my radio control gimbals are all 1.25mm pitch 1x3 position. These are Molex picoblade connectors and I purchased surface mount headers for my custom board from DigiKey.

The connector pinout is standardized, but be aware the wire colors used may not be the same on all gimbals. Most gimbals are setup Red - Yellow signal and Black +. As you can see the colors may not match standards.

Board design¶

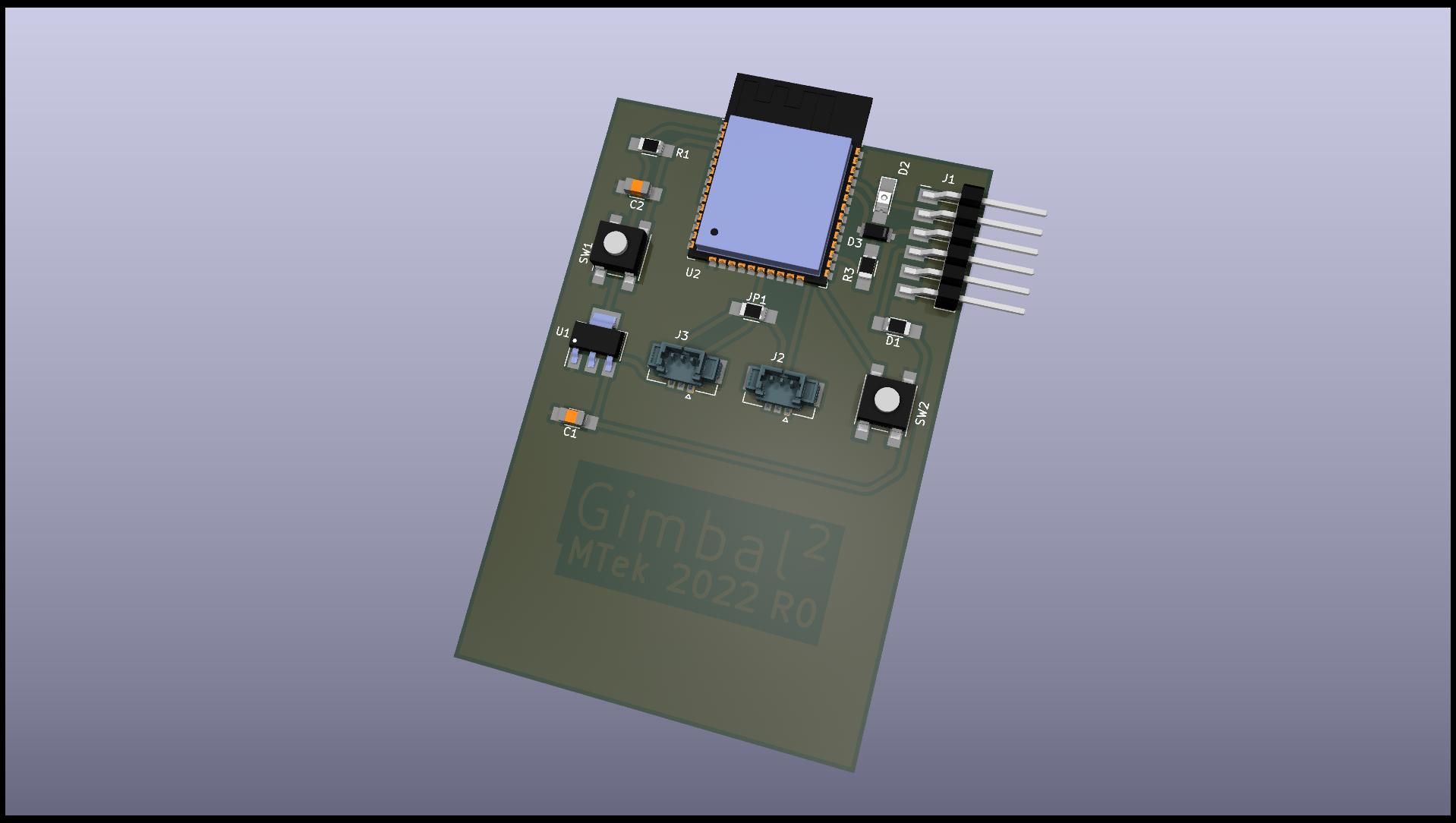

3D View¶

Above: Rev 1 KiCad 3D Board view. The board is double sided with the back side being ground. Note the two holes for Rivet vias.

Rivet Vias¶

I realized I was spending more time trying to route traces then it would take to learn how to use vias and a double sided board with ground on the backside. So I searched the Fab Academy Repo and found this great page: PCB_Rivets

The company Bungard makes the rivets we sue in Fab Academy and the data for them is quite simple and located at: Through-hole rivets. This site says “a drilling diameter that is 0.1mm larger than the outer diameter is required.” So i used the online Tables Generator to make a quick markdown table of the two sizes of rivets on the Fab Inventory, including drill diameters (⌀):

| ID | OD +/- 0.03 mm | Drill ⌀ | Shaft L +/- 0.10 mm | Head ⌀ +/- 0.15mm | wall d +/- 10% |

|---|---|---|---|---|---|

| 0.6mm | 0.8mm | 0.9mm | 2.2mm | 1.3mm | 0.1mm |

| 1.0mm | 1.4mm | 1.5mm | 2.5mm | 2.2mm | 0.2mm |

In the USA you can buy Favorit Rivets from VPCinc.com The size I used was the 1.0mm Inner diameter. Lets see how much each Rivet costs:

| Order Code | Description | Price per 1k | Price Each |

|---|---|---|---|

| 700-028-2 | Favorit RIVETS 1.0mm ID | $52.50 | 0.525¢ |

I’m using 3 vias, so total cost is $1.58

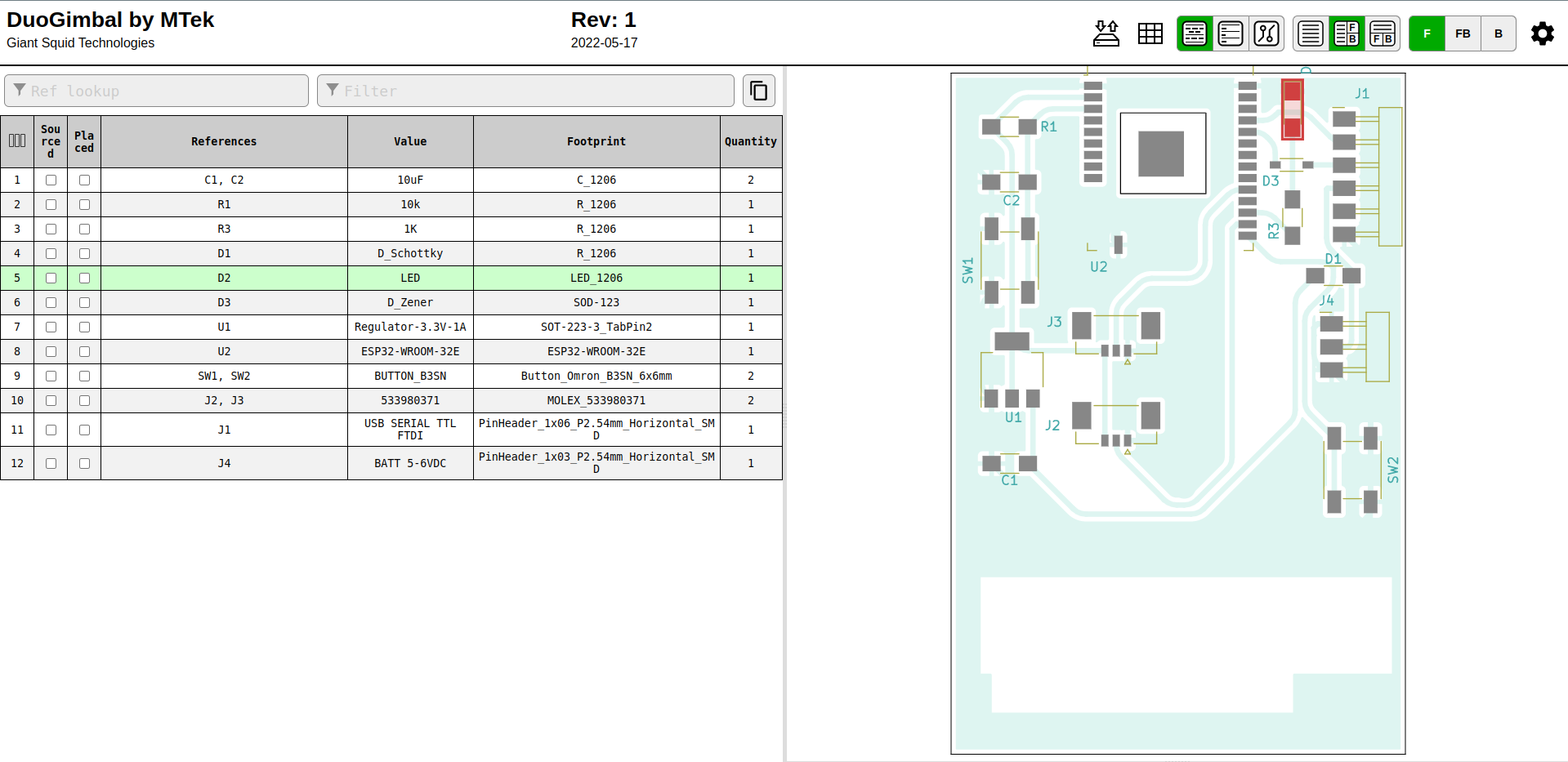

BOM¶

| Index | Item | QTY | Supplier | Mfg P/N | Cost Ea | Ext Cost | Link | Note |

|---|---|---|---|---|---|---|---|---|

| 1 | CAP CER 10UF 35V X6S 1206 | 2 | Digikey | GRT31CC8YA106ME01L | 0.47 | $0.94 | https://www.digikey.com/en/products/detail/murata-electronics/GRT31CC8YA106ME01L/5416847 | |

| 2 | RES 10K OHM 1% 1/4W 1206 | 1 | Digikey | RC1206FR-0710KL | 0.1 | $0.10 | https://www.digikey.com/en/products/detail/yageo/RC1206FR-0710KL/728483 | |

| 3 | RES 1K OHM 1% 1/4W 1206 | 1 | Digikey | RC1206FR-071KL | 0.1 | $0.10 | https://www.digikey.com/en/products/detail/yageo/RC1206FR-071KL/728387 | |

| 4 | DIODE SCHOTTKY 100V 150MA SOD123 | 1 | Digikey | BAT46ZFILM | 0.46 | $0.46 | https://www.digikey.com/en/products/detail/stmicroelectronics/BAT46ZFILM/1207026 | |

| 5 | LED RED CLEAR 2SMD | 1 | Digikey | XZMDK60W | 0.39 | $0.39 | https://www.digikey.com/en/products/detail/sunled/XZMDK60W/4902037 | |

| 6 | DIODE ZENER 3.3V 500MW SOD123 | 1 | Digikey | BZT52C3V3-7-F | 0.23 | $0.23 | https://www.digikey.com/en/products/detail/diodes-incorporated/BZT52C3V3-7-F/717734 | |

| 7 | IC REG LINEAR 3.3V 1A SOT223 | 1 | Digikey | ZLDO1117G33TA | 0.51 | $0.51 | https://www.digikey.com/en/products/detail/diodes-incorporated/ZLDO1117G33TA/2095592 | |

| 8 | ESP32-WROOM-32D microcontroller unit | 1 | Digikey | ESP32-WROOM-32D | 4.08 | $4.08 | https://www.digikey.com/en/products/detail/espressif-systems/ESP32-WROOM-32D-4MB/9381716 | |

| 9 | SWITCH TACTILE SPST-NO 0.05A 24V | 2 | Digikey | B3SN-3112P | 1.07 | $2.14 | https://www.digikey.com/en/products/detail/omron-electronics-inc-emc-div/B3SN-3112P/27856 | |

| 10 | RES 0 OHM JUMPER 1/4W 1206 | 1 | Digikey | RC1206FR-070RL | 0.10 | $0.10 | https://www.digikey.com/en/products/detail/yageo/RC1206FR-070RL/5698945 | |

| 11 | CONN HEADER SMD 3POS 1.25MM | 2 | Digikey | 533980371 | 0.75 | $1.50 | https://www.digikey.com/en/products/detail/molex/0533980371/699067 | |

| 12 | CONN HEADER SMD R/A 36POS 2.54MM | 1 | Digikey | GBC36SGSN-M89 | 0.1175 | $0.12 | https://www.digikey.com/en/products/detail/sullins-connector-solutions/GBC36SGSN-M89/862355 | |

| 13 | CONN HEADER SMD R/A 36POS 2.54MM | 1 | Digikey | GBC36SGSN-M89 | 0.1175 | $0.12 | https://www.digikey.com/en/products/detail/sullins-connector-solutions/GBC36SGSN-M89/862355 | |

| 14 | FR1 Board 2x3 Single Sided | 1 | Carbide 3D | 2x3 SS | 1.00 | $1.00 | https://shop.carbide3d.com/products/fr1-copper-clad?variant=41237063046 | |

| 15 | Favorit RIVETS 1.0mm ID | 2 | VPC | 700-028-2 | 0.525 | $1.05 | https://www.vpcinc.com/Category/Favorit-Through-Hole-Rivets-104.cfm | |

| Total | $12.85 |

Interactive BOM¶

Above: Click image to access the HTML Interactive Bill of Materials (iBOM) generated by KiCad.

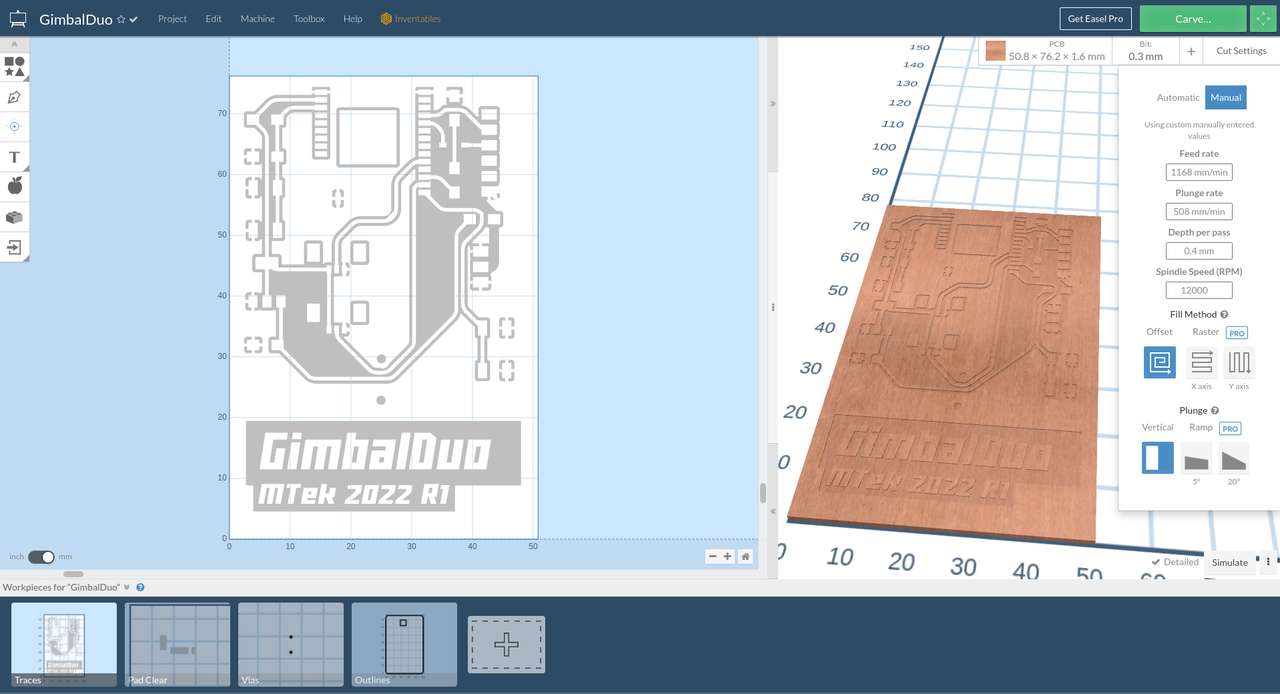

CAM¶

See Easel CAM parameters above.

You can access my Easel GimbalDou CAM data and with the specified tooling you could duplicate my board on a x-carve mill. With minor setup changes you can use easel to mill this board on any GRBL compatible CNC machine.

See Easel CAM parameters above.

You can access my Easel GimbalDou CAM data and with the specified tooling you could duplicate my board on a x-carve mill. With minor setup changes you can use easel to mill this board on any GRBL compatible CNC machine.

Milling¶

I milled my board on the small x-carve 300 x 300 mm CNC Mill.

I milled my board on the small x-carve 300 x 300 mm CNC Mill.

Stuffing¶

Stuffing isn’t just for Turkey’s!

I used the interactive bom and a new tool I found in KiCad called “Net Inspector” that allows you to highlight individual nets, for trouble shooting.

programming¶

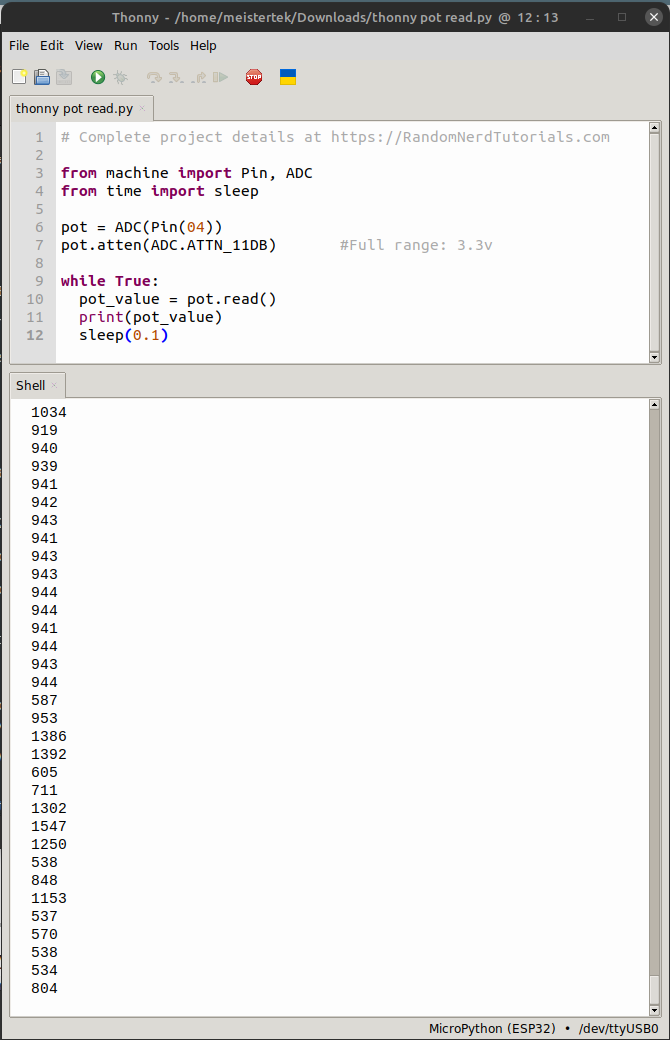

I used Sara and Rui Santos’ excellent guides at Random Nerd Tutorials to learn about reading analog values from the potentiometer sensor gimbals:

measure something and read it¶

I have used some excellent esp32 pin guides in the past, but the one at randomnerdtutorials is the best I’ve seen so far! ESP32 Pinout Reference: Which GPIO pins should you use?

ESP32 ADC – Read Analog Values with Arduino IDE

I decide it was time to try a different coding language: MicroPython.

I found this tutorial on MicroPython useful: ESP32/ESP8266 Analog Readings with MicroPython

To work with MicroPython I tried out Thonny IDE. I used the Linux Mint Software Manager to install Thonny. I tried uPyCraft as well but it was difficult to install so I stopped and moved ahead with Thonny.

I also needed to install python 3, esptool and stuptools, but when I went to my linux mint software manager both were already installed, probably from installing expresif dev software in previous assignments.

Next the guide said to run the esptool command, i typed the following into terminal:

python -m esptool

A bunch of expected text resulted showing that esptool was working:

esptool.py v4.1…

Next I plugged in my ESP32 GimbalDou board and flashed it with the MircoPython firmware:

The guide said:

If you are putting MicroPython on your board for the first time then you should first erase the entire flash using:

esptool.py --chip esp32 --port /dev/ttyUSB0 erase_flash

From then on program the firmware starting at address 0x1000:

esptool.py --chip esp32 --port /dev/ttyUSB0 --baud 460800 write_flash -z 0x1000 esp32-xxlatestrelease.bin

replace the “esp32-xxlatestrelease.bin” with the latest release .bin file downloaded on the the bottom of the page above, or use the file linked in the files section of this page. Remember that you need to reset your esp32 board to be programmed by pressing and holding the prog button and then pressing and releasing the reset button, then releasing the prog button.

during the command above the following was displayed:

esptool.py v4.1

Serial port /dev/ttyUSB0

Connecting......

Chip is ESP32-D0WD (revision 1)

Features: WiFi, BT, Dual Core, 240MHz, VRef calibration in efuse, Coding Scheme None

Crystal is 40MHz

MAC: ac:67:b2:d5:85:10

Uploading stub...

Running stub...

Stub running...

Erasing flash (this may take a while)...

Chip erase completed successfully in 16.9s

Hard resetting via RTS pin...

Next I ran the command to install the latest micropython firmware to the esp32:

esptool.py --chip esp32 --port /dev/ttyUSB0 --baud 460800 write_flash -z 0x1000 esp32-20220618-v1.19.1.bin

during the flash command above the following was displayed:

esptool.py v4.1

Serial port /dev/ttyUSB0

Connecting.....

Chip is ESP32-D0WD (revision 1)

Features: WiFi, BT, Dual Core, 240MHz, VRef calibration in efuse, Coding Scheme None

Crystal is 40MHz

MAC: ac:67:b2:d5:85:10

Uploading stub...

Running stub...

Stub running...

Changing baud rate to 460800

Changed.

Configuring flash size...

Flash will be erased from 0x00001000 to 0x0017efff...

Compressed 1560976 bytes to 1029132...

Wrote 1560976 bytes (1029132 compressed) at 0x00001000 in 25.2 seconds (effective 495.6 kbit/s)...

Hash of data verified.

Leaving...

Hard resetting via RTS pin...

Next I had to find what port my ESP32 was connected to, using the arduino ide I went to tools, port and found that my port was /dev/ttyUSB0 Not sure why this is needed, I moved onto the next task.

Next I ran the MicroPython script replacing the given pin with the GimbalDuo GPIO 04 which is simply pot = ADC(Pin(04)) in MicroPython.

# Complete project details at https://RandomNerdTutorials.com

from machine import Pin, ADC

from time import sleep

pot = ADC(Pin(04))

pot.atten(ADC.ATTN_11DB) #Full range: 3.3v

while True:

pot_value = pot.read()

print(pot_value)

sleep(0.1)

I cut and pasted the code into Thonny IDE. Next in Thonny I selected “Run” “select interpreter” and then selected: “MicroPython (ESP32)”” and Port: “”…()/dev/ttyUSB0)…”” hmm that’s why they wanted me to get the port above!

Next I pressed the reset button on the GimbalDou board while it was plugged into the usb port. This triggered the Shell window to respond with confirmation:

rst:0x1 (POWERON_RESET),boot:0x12 (SPI_FAST_FLASH_BOOT)

configsip: 0, SPIWP:0xee

clk_drv:0x00,q_drv:0x00,d_drv:0x00,cs0_drv:0x00,hd_drv:0x00,wp_drv:0x00

mode:DIO, clock div:2

load:0x3fff0030,len:4540

ho 0 tail 12 room 4

load:0x40078000,len:12344

ho 0 tail 12 room 4

load:0x40080400,len:4124

entry 0x40080680

MicroPython v1.19.1 on 2022-06-18; ESP32 module with ESP32

Type "help()" for more information.

Next I clicked the play button and got:

>>> %Run -c $EDITOR_CONTENT

0

274

283

281

288

286

281

282

279

282

288

286

288

286

283

286

284

283

285

284

285

287

285

286

286

288

283

285

286

287

284

285

277

Troubleshooting¶

something was wrong :( maybe my pot wires were messed up? I tried the run the program again, but this time I touched the circuit board traces near the pot. This would introduce my finger as a variable resistor or potentiometer to the circuit and the following was displayed:

>>> %Run -c $EDITOR_CONTENT

372

426

2254

3617

3338

2286

1872

1787

1750

1746

1804

1755

1719

1710

1696

1680

1682

1707

1847

2357

2873

1939

1648

1788

1714

1703

1655

1648

1677

1677

1607

1597

1567

1652

1713

1811

1839

1680

0

1109

395

289

283

284

279

281

282

283

288

278

276

279

279

279

282

282

279

285

282

285

285

282

────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────────

MicroPython v1.19.1 on 2022-06-18; ESP32 module with ESP32

Type "help()" for more information.

>>>

Cool! the new numbers above corresponded to a light and heavy touch of the traces with my fingers. Next I changed the wiring on my pots.

Then I ran the code again moving the gimbal. This time I got nothing but zeros. I checked the board for shorts and found one going from signal to ground. I de-soldered the connector for the gimbal (potentiometer) and found that a ground pour was shorting to the signal contact of the connector. I removed the section of ground pour that was causing the short and then re-soldered the connector and ran the MicroPython code again…

And got this via the Thonny IDE Shell while moving the gimbal:

2206

2207

2205

2203

2208

2203

1636

1275

1412

2220

2739

3955

4041

3029

2346

1388

528

529

944

2893

4095

4095

3711

2777

1695

927

526

523

511

509

510

525

524

528

528

528

528

516

510

530

527

522

519

507

517

526

1162

2652

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

4095

3745

2703

1649

688

518

506

499

499

499

496

496

496

496

496

496

496

496

496

496

496

496

496

509

1035

2295

3264

4095

4095

4095

4095

4095

4095

4095

4095

3723

2367

1157

505

505

505

503

501

499

499

497

497

539

1728

3439

4095

4095

2205

2206

2207

2207

2204

2208

2206

2206

2206

2208

2208

2207

2208

2203

2206

2206

Holy Frack! it works! Time to take a video

Hero Video¶

Above: Video of Thonny IDE MicroPython code for potentiometer gimbal input showing changing values with 11db of signal Attenuation via Thonny Shell

Above: View of Thonny IDE in use running the MicroPython code below.

Above: View of Thonny IDE in use running the MicroPython code below.

code¶

MicroPython Code “esp32ReadAnalog.py” with comments explaining my understanding of the code.

# Complete project details at https://RandomNerdTutorials.com

# modified by Dan "MTek" Meyer 2022-Jul-31 Sun 9:44pm

from machine import Pin, ADC #ADC=analog digital conversion

from time import sleep

pot = ADC(Pin(04)) #pick your boards GPIO pin

pot.atten(ADC.ATTN_11DB) #Full range: 3.3v with x db signal attenuation

while True: #while loop forever?

pot_value = pot.read() #read the pot value

print(pot_value) #print pot value to shell

sleep(0.1) #pause x.x seconds between reads

Notes for future projects¶

Single stick RC aircraft control¶

I have always wanted to design and make a single stick RC aircraft control, well it looks like this is quite possible for me to do. Single stick RC controls date back to 60’s and 70’s. A single stick gimbal adds a twist knob on the end of the stick for rudder control.

It turns out our friends in the RC construction vehicles finally drove radio control manufactures to re-visit the single stick control. This link shows a tear down of the brand new gimbal extender that fits on the end of traditional gimbal sticks! FrSky 3-Axis CNC Gimbal Extender with Magnetic Hall Effect Sensor for MC12 Gimbal post #27 shows mechanical disassembly and post #31 shows a close up of the hall sensor.