About¶

Introduction¶

Hi!

I'm Dan Meyer.

a Manufacturing Technologist

who helps

People Optimize Designs for Manufacturing

I live in Chicago.

Chicago from the south at 35th street, Photo By: Dan Meyer

Why I Took Fab Academy¶

I want to improve my range of design and fabrication skills, so I can make things on my own terms, improving my life. I want to teach others to do the same, if they are interested. I want to become fluent in Electronic board design and fabrication, this is a fabrication skill that I do not have.

My Fabrication History¶

Leitelt Bother’s Foundry Workers ~1910

I was born into a family of fabricators. In 1908 my Great Grandfather Charles Leitelt and his brother Edward started Leitelt Bother’s Foundry. Leitelt Bother’s Foundry has been located on the south side of Chicago since 1913 and makes Brass, Bronze, Aluminum, and Almag sand castings. My Great Grandfather Charles Leitelt is the left most man standing with arms crossed in the photo above.

Leitelt Bother’s building ~1945

Around 1990, My Grandfather Ed noticed how interested I was in manufacturing and taught me about sand casting, operating a factory, and how to empower and communicate with foundry workers. When I was 18, and was taking courses in Manufacturing Technology at a local Community College, my Grandfather invited me to work at Leitelt Bother’s Foundry.

Working at Leitelt Bother’s Foundry is where I learned all my traditional heavy manufacturing fabrication skills. This contributed greatly to my lifelong passion of designing and making and teaching others to do the same.

Leitelt Bother’s building 2019

Leitelt Bother’s Foundry is still in operation today and is 5km (3 miles) from the Museum.

U-505 Submarine in the Museum of Science and Industy, Chicago. My family made parts to fight U-Boats, and the also made parts to restore the U-505. During World War II Leitelt Bother’s Foundry made castings for the U.S. Navy to fight the Axis powers, including German U-Boat Submarines. When the U-505 submarine was brought to MSI Chicago, Leitelt Bother’s Foundry duplicated missing and broken parts and made castings to restore the U-505 submarine.

Starting at age 3 my mother started taking me to the MSI, she reports she could not get me out of the green stairwell. I loved operating and watching the mechanisms there.

Academic Education¶

I went to Prairie State College and obtained my Manufacturing Technology A.A.S.

Prairie State College Buildings

While working at Leitelt Bother’s I paid for and obtained my Manufacturing Technology A.A.S. Degree from Prairie State Community College.

Later, while working full time, I spent 7 years in night school at Illinois Institute of Technology earning a B.S. Degree in Manufacturing Technology and Management.

IIT in foreground Chicago in background

There is too much to talk about what happened over the next 30 years. In short, I can tell you that I stayed in Metal Casting for 20 years, I met and learned from many amazing people. I also worked my way up through many high tech factories and became involved the personal fabrication movement.

On the Job Education¶

On the job I earned the titles of:

Welder¶

Dan Tig welding aluminum alloy sand cast grain handling pipes at Leitelt Bros, 1992

Machinist¶

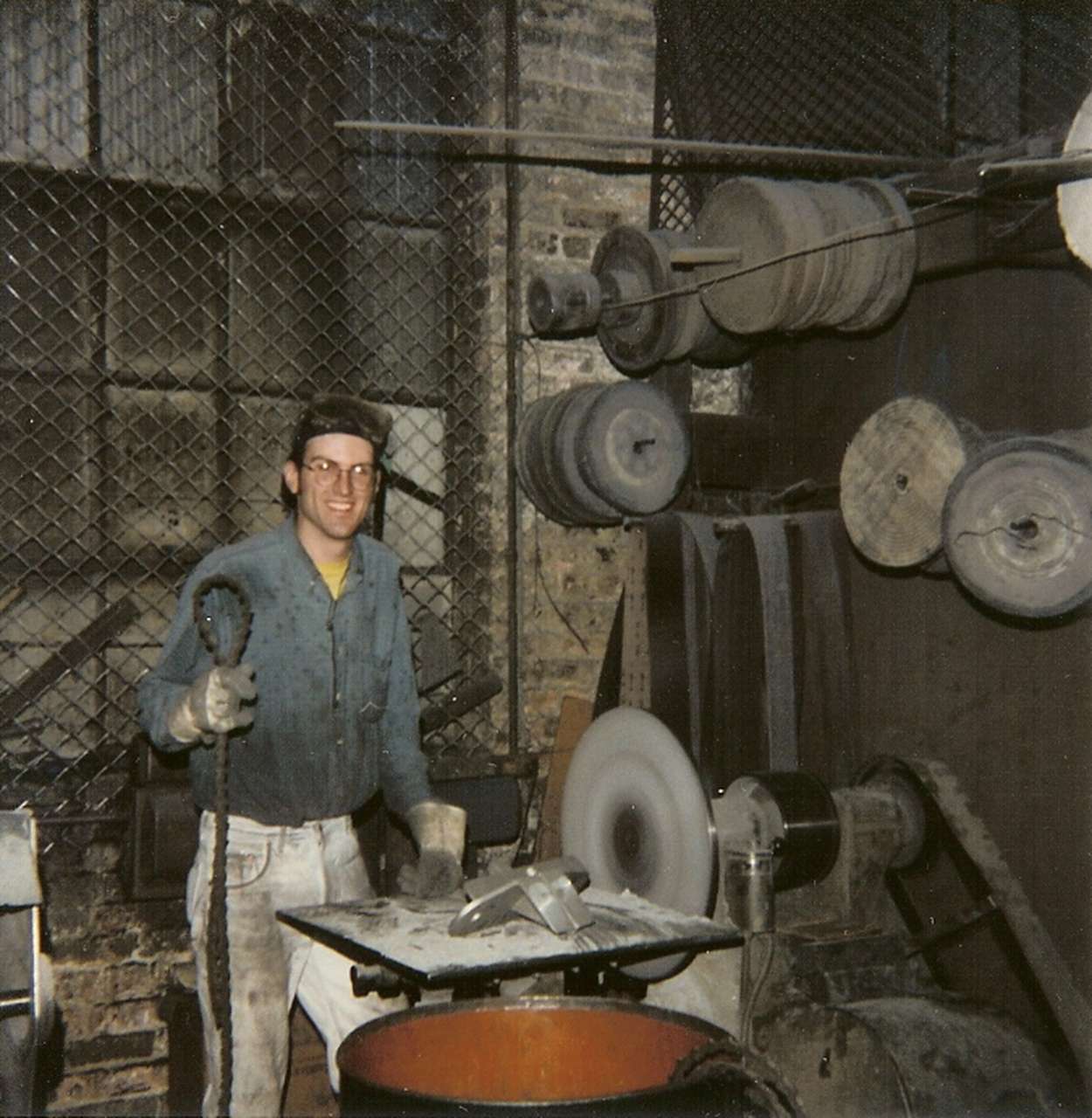

Dan using 1890 Disc Sander from industrial revolution.

Dan using 1890 Disc Sander from industrial revolution.

Showing my sister how a Mazak CNC Machining Center Works, 1993

Roboticist

¶

Motoman robot setup and programmed by Dan Meyer, 2008

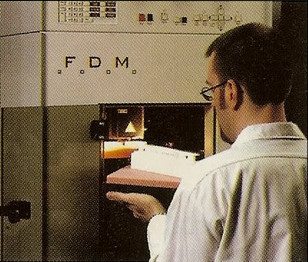

3D Printer Technician

¶

Running Stratasys FDM 2000 3D Printer, 2000

Mold Designer

¶

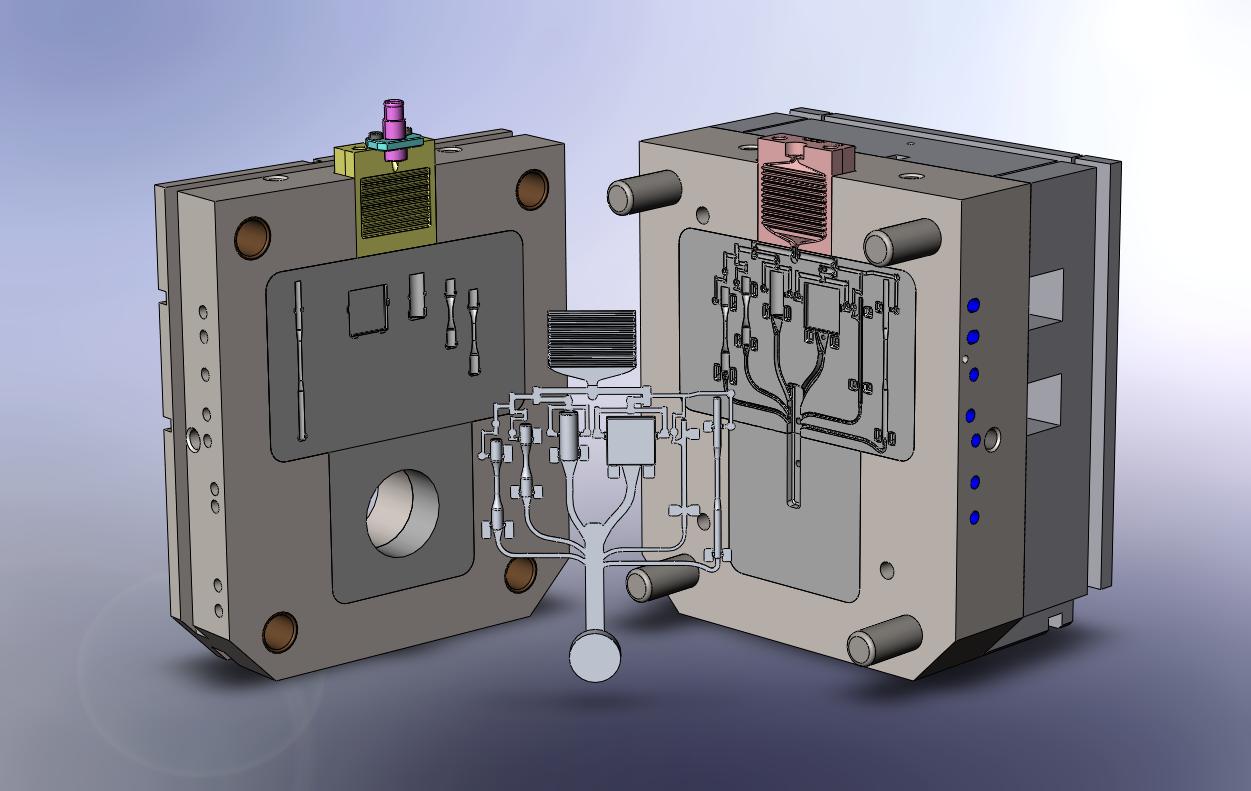

Specimen die for semisolid Mg die casting design by Dan Meyer

Design Engineer

¶

I worked many year as a Design Engineer helping humans convert part and assembly designs to metal casting and other manufacturing processes. I am a world expert in 3D CAD design for the die casting process. I teach people to this day on how to optimize designs for metal casting and other manufacturing processes.

Left: Bearing and motor bracket: Conversion from 16 part stamped assembly to single casting. Right: part converted from a bar stock screw machined part to a zinc die casting using less material and including more features.

Cad feature order for machined die castings, Dan Meyer 2012, from NADCA Design website.

Articulating Flat Panel Display Mount design completed by Dan Meyer in 2006 leading a team of 3 designers in casting design. This design was converted completely from a higher cost sheet metal assembly to a lower cost die casting assembly with more features and less parts count.

Researcher

¶

Voxel simulation of specimen die molten metal filling pattern. Castview voxel software by Ohio State University

Process Engineer¶

Process Engineering Group at Chicago White Metal Casting. Dan on the left and Scott Scheffel right. Dec 16th 1998. Sun Spark Station Computer running Unigraphics on far right. PC on far left is the computer I first ran SolidWorks CAD on.

Book Editor¶

Die Casting Product Design book, major editions and edits by DMeyer 2010

Teacher¶

Dan and students from the Die Casting Machine Operator Training at Premier Die Casting in Avenel NJ. 2010

Instructor Dan and Die Casting Design Seminar attendees at Alcon Labs Irvine CA eye surgery machines division.

Instructor Dan and Die Casting Design Seminar attendees at Alcon Labs Irvine CA eye surgery machines division.

At the North American Die Casting Association, I taught over 20 different courses on Metal Casting Design and Casting Processes around the world.

I also developed new course and created a new website to help people design die castings, called NADCA Design.

Hacker¶

Chicago Maker Summit 1 hosted at MSI Fab Lab, Photo by Anne Pettersen 2012

HyperCAST Rapid Response Manufacturing Team¶

U.S. Department of Defense¶

While Researcher and Design Engineer at the North American Die Casting Association I was on the Rapid Response Manufacturing Team, called HyperCAST, working with and supporting the manufacture of metal castings for the U.S. Department of Defense.

Working on the Rapid Response Manufacturing Team is one of the most exciting things I have done in my entire career. On this team I rapidly developed and deployed castings and tooling. One example was when our team rapidly responded to problems U.S. Army soldiers identified and proposed solutions to in the battle field. The shortest time from a battle field request to manufactured parts back in the battle field was 6 weeks. This specific project for the U.S. Army DEVCOM Armaments Center.

Before the Rapid Response Cast Part Team was put in place it took the DOD years to deploy new parts to the battlefield. I optimized parts for manufacturing, had hard tooling (molds and dies) made, ran test casting off the hard tooling, oversaw and contracted CNC machining, helped specify coatings and finishes and then sent these “recipes” out for quoting in to manufacturers across the U.S. Next I selected a manufacturer to permanently produce parts. Finally I received and distributed feedback, to all involved, from soldiers reporting back from the battlefield on our cast parts. All these processes were completed in as short as 6 weeks.

Portable Mortar Base Casting Design Consulting for DOD. Mold design and flow simulation by Dan Meyer in 2010

The DEVCOM Armaments Center team I worked with now has been integrated into the Army Futures Command. The concepts we tested and proved now are more broadly applied across through the Army Futures Command. The Army Futures Command is one of the best examples of rapid response to soldiers predicted and actual needs for support of combat and direct combat.

I thought NADCA would be the Pinnacle of my career…But then I got a job running the Fab Lab at the Museum of Science and Industry Chicago!

I created an about me section of this website in 2020. I have been updating and re configuring this section multiple times per year. I would like this about me page above to be a succinct intro covering my history and background leading up to what I do currently…below…

My Recent Work History¶

For 10 years I worked at the Museum of Science and Industry in Chicago (MSI), I was the Fab Lab Senior Manager. Currently I work at Chicago Scenic Studios as a IATSE Union Metals Fabricator.

Museum of Science and Industry Chicago¶

I was hired in 2011 to improve the use and performance of the MSI’s Wanger Family Fab Lab. I am often hired as a “fixer” to solve issues with or improve under-performing systems of people, space, and equipment. That’s what a Manufacturing Technologist is trained to do after all.

In 2007 the MSI Fab Lab was funded and installed by a coalition of organizations, MSI, MIT CBA, Argonne National Labs, Illinois Institute of Technology (IIT) and other donors and supporters. However the usage of the space was somewhat constrained with an estimated number of 80-100 users per year. The largest user group was 10 to 20 MSI Science Achievers on Saturdays. The IIT IPRO (inter-professional prototyping course) capstone course, with 20 users per quarter, was another group of users.

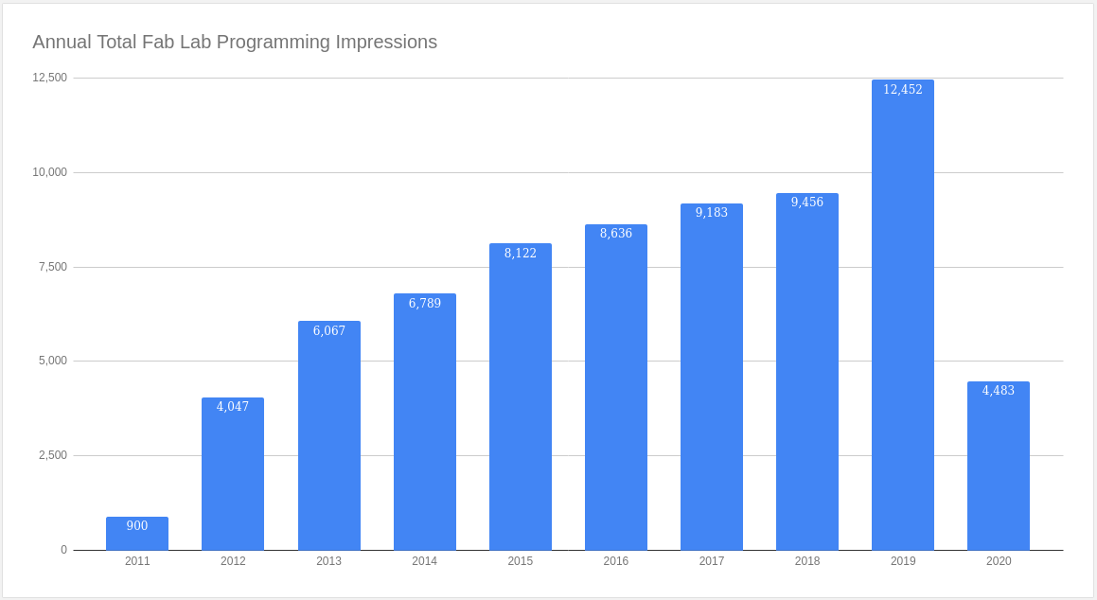

This is somewhat of an over simplification, but in ~2010 the Wanger Family provided seed money to the MSI to be used over 3 years jump start the MSI Fab Lab. Ralph Wanger challenged us to get the Fab Lab up to 10,000 users per year, or his way of saying, get this space utilized better with great programming the MSI is known for.

In early 2011 Rabiah Mayas, Director at time, interviewed and eventually selected me as the first full time Fab Lab Manager at MSI. In the first few months of my employment, Rabiah and I ran workshops with the help of a part time intern Christian McNamara. We also laid the plans and foundations for the future of the MSI Fab Lab. By 2019 we had built the Fab Lab team to 7 full time employees, several dedicated volunteers, and expanded our programming, read on to see the impact of this early work.

Interestingly Rabiah was one of the first examples of what would become to be know as a Fab Lab Champion and I was what would become know as a Fab Lab Guru.

The MSI Fab Lab Team¶

Above: The MSI Chicago Fab Lab Team. Left to Right: Liz, Jen, Patrick, Dan, Eric, Gerard, Kyle

For over a decade I have led this ever changing team that runs the MSI Fab Lab.

In 2011 our Fab Lab had one part time intern, Christian, and myself working full time. Christian and I ran mainly 1hr fab lab laser cut key-chain fob workshops for 10 museum patrons at a time. By 2012 I had over 10 volunteers to help is in our Fab Lab

In 2019 we hit our highest peak with 7 total full time fab lab staff and we had over 10,000 patrons, students and educators design and make something in our Fab Lab.

Bar graph showing 900 visits in 2011 increasing to 12,452 by 2019

Make_X Project Grid¶

At the MSI Chicago, Fab Lab Fab Lab Senior Coordinator Patrick McCarthy, developed a project management system for all our fab lab users, volunteers, and staff.

Animated GIF of the a Analog Belt Board in action showing camper fabrication skill progress in our M-F week long Fab Lab Summer Camp

Our system is called the Make_X Project Grid

- Digital Project Grids Organize Self-Guided Curriculum

- Digital or Analog Belt Boards track student progress

- The system is open source

- We offer 4-6 half day training sessions so you can access, learn about, develop for and share project grid columns.

- Visit Make_X for more info and to register for Project grid training.

- As of 2022 there are over 40 columns of topics in the MSI Core Project Grid

- Over 200 people have contributed to the MSI Core Project Grid

In the Make_X Training we teach you how to develop you own columns and connect columns to your local topics and standards. We also teach you how to manage your own repository that gets pushed to the shared core project grid.

Make_X Project Grid Presentation Overview ask me and I will present this slide deck for you.

Union Metal Fabricator¶

I left the MSI in Feb of 2023 and went to work at Chicago Scenic Studios Inc. (CSSI) as a IATSE Union Metals Fabricator. IATSE is the International Alliance of Theatrical Stage Employees and almost all of the shop floor workers and some of the office folks are memebers of this union. Being part of the union has many benefits, one of which is traveling to entertainment vennues to setup equipment, install museum exhibits and a wide range of theatrical and technical work.

At CSSI I design and fabricate and assemble large and small mechatronic structures for the entertainment industry (Disney etc.). My expertise however is in trouble shooting designs and assemblies and complex manual machining. I work in the Special Projects area, along with another Metals Fabricator and we use a manual Bridgeport mill and Lathe daily to create parts for our own project assemblies and other teams projects. We are called the mad scientist’s of CSSI!

Hacker¶

Above: My first computer, a Epson Equity 2 IBM PC clone.

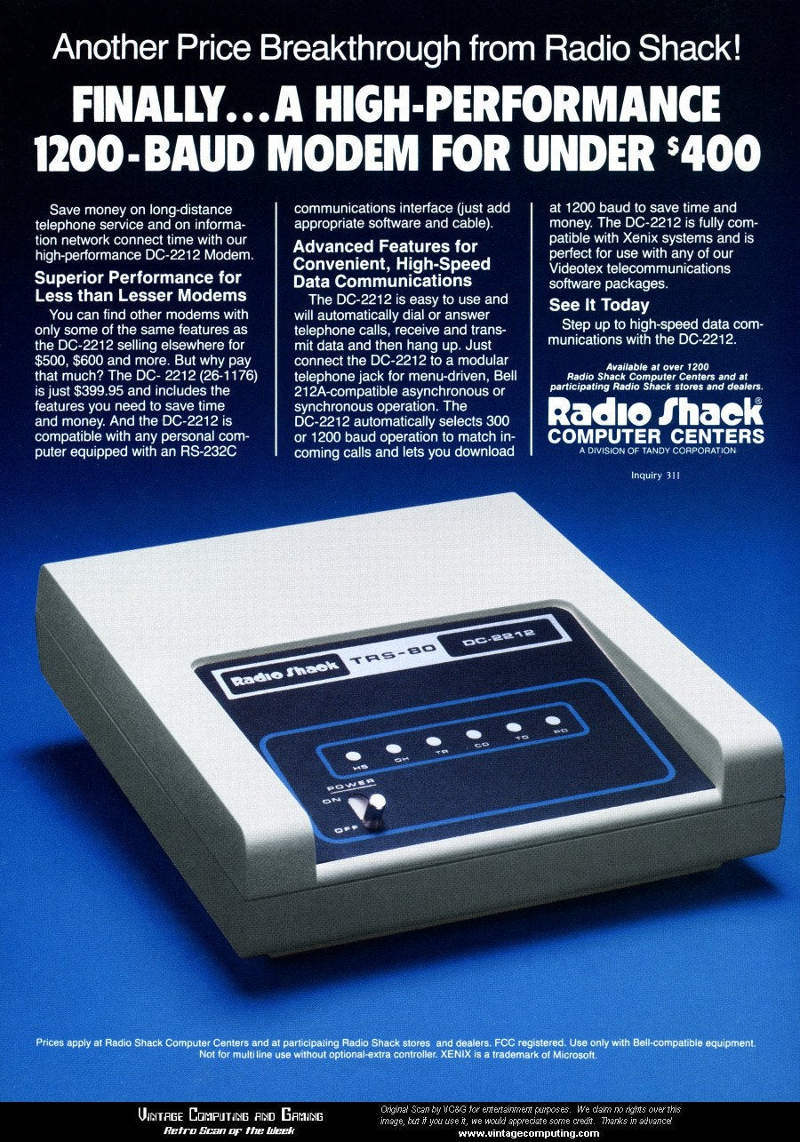

Above: My first modem, which was also the subject of my first hardware hack.

My first hack was to re-wire all 25 pins of the TRS-80 modem with a non-standard pinout, to work with my Epson Equity I+ IBM-PC Clone computer with a standard 25 pin RS-232 serial port. I seem to remember that a technical manual was included with the modem that showed pinouts. Maybe the non-standard serial port was no the PC I had. It’s also possible I was converting the 25 pin ribbon cable to a 9 pin serial port. Maybe the pin-out was in the manual for my PC clone? ahhh memories!

I then proceeded to learn how to control the modem to dial BBS using raw programming commands (from page 29 in the link above).

Through my teen years I learned a ton about computers and hacking techniques, via the Chicago area BBS Network. I also stated meeting other young hackers like my self through that BBS network.

Then the internet came and replaced the BBS world overnight. Or at least it felt that way to me. By 1994 I was in college at Northern Michigan University. There I used a web browser for the first time, and realized that democratization of access to ARPANET was going to change the world. I immediately taught myself HTML Coding and made my first website.

Little did I know that starting around the mid 2000’s that manipulation of information on platforms like twitter, Facebook and other social media platforms would start to control the outcome of elections. This was not the “democratization” I had dreamed of.

However in 2010 I joined a hacker space in Chicago Pumping Station: One and found a new clan of Hackers and people that I connected with on a level that I had never experiences before. Joining a hacker space felt like to me, the moment Neo Enters the Matrix for the first time. I took the red pill…

Morpheus: “You take the blue pill, the story ends, you wake up in your bed and believe whatever you want to believe. You take the red pill, you stay in wonderland, and I show you how deep the rabbit hole goes.”

… and I found out how deep the rabbit hole went, it was endless, and it was a wonderland of sharing, learning and friendship that just kept going. And yes there was a bit of drama as well, but that’s to be expected.

MiG Aircraft Builds¶

At South Side Hackerspace: Chicago I lead a group called the Multi-Rotor Interest Group (MiG). We help each other build and fly various types of radio controlled aircraft. We CNC cut most of our foam RC aircraft we build, fly, crash and repair.

Above: MiG in action during a HTC foam RC aircraft build.

Industrial Music Scene¶

From 1988 onward I have been a part of the Industrial Music Scene, and frequent the Chicago based haunts and clubs that play Industrial Music. The Scene has changed over the year and new generation of EBM / EDM fans carry that torch forward.

More Info¶

For more info about me and my family and life experiences please see my Projects

References¶

History: Leitelt Brothers Foundry Website, About

HyperCAST: NADCA HyperCAST Project Foundry Magazine