3.Computer-Controlled-Cutting

This week we learned about parametric design and its application to computer-controlled cutting, principally in laser cutting and vinyl cutting.

What is Parametric Design?

Parametric design is an algorithm-based methodology that uses parameters, rules, and constraints to define relationships among elements. CADs like SolidWorks, Fusion 360, and Onshape follow this workflow. This will allow us to change a variable or dimension and automatically change the design without breaking the model’s logic, letting us explore and iterate through several design variations/versions.

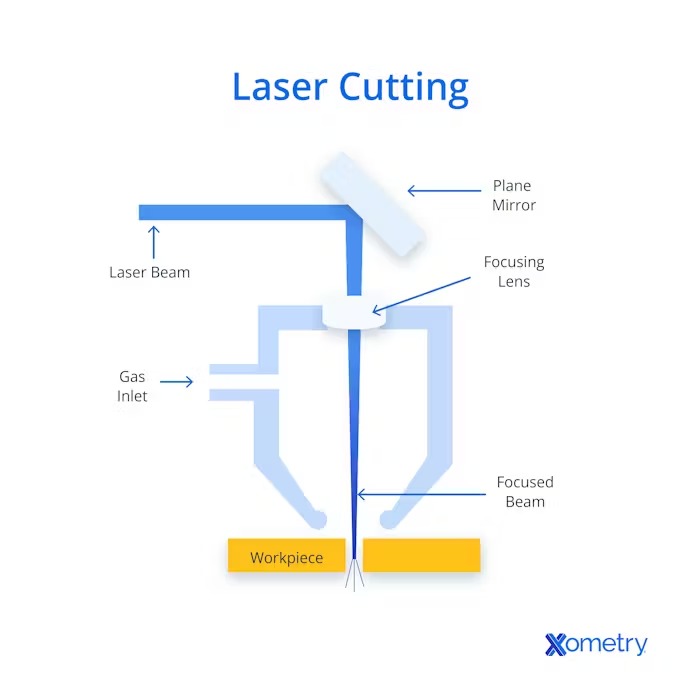

Laser Cutting

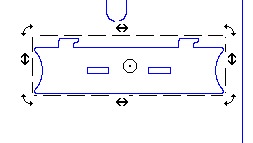

Laser cutting is a thermal, non-contact process that uses a high-powered, focused laser beam. It is normally used to engrave and cut different kinds of materials, like metal, plastic, or wood. It works thanks to a CNC (Computer Numerical Control) software, which indicates the digital pattern the laser beam must follow, while the beam traces the path, a coaxial gas jet (oxygen or nitrogen) blows away burnt material, leaving clean, finished edges. In this image, we can see the principal components of the laser cutters in general.

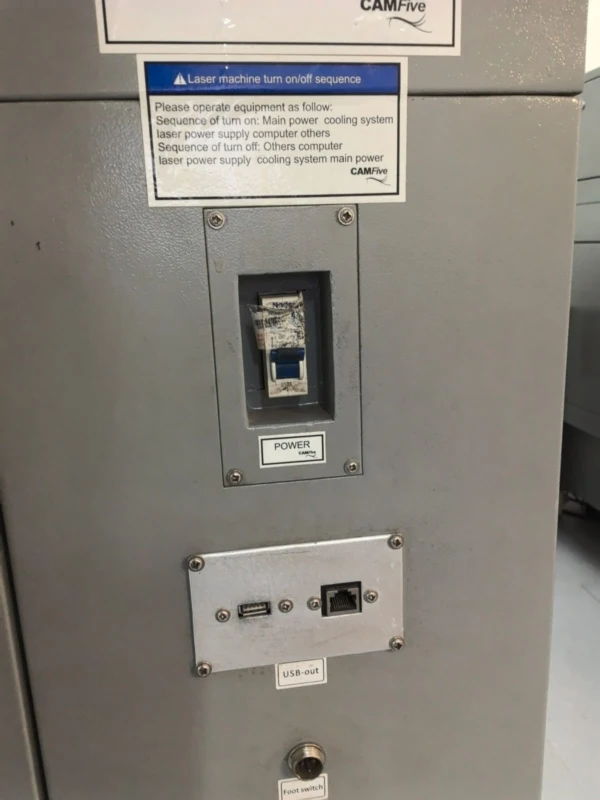

At Fab Lab Puebla, we have 3 different laser cutters from CAM Five: The CFL-CMA1200, CFL-CMA1080K, and CFL-CMA 1309T. You can learn more about them and laser cutting in the group assignment.

Check that the machine chiller is on; it helps to maintain a safe workplace by regulating the machine regulator. Then we need to turn on the automatic voltage regulator. After that, we need to turn on the machine switch and release the safety button. Then we insert the key, turn on the laser, and move it to max

Machine Setup (Laser)

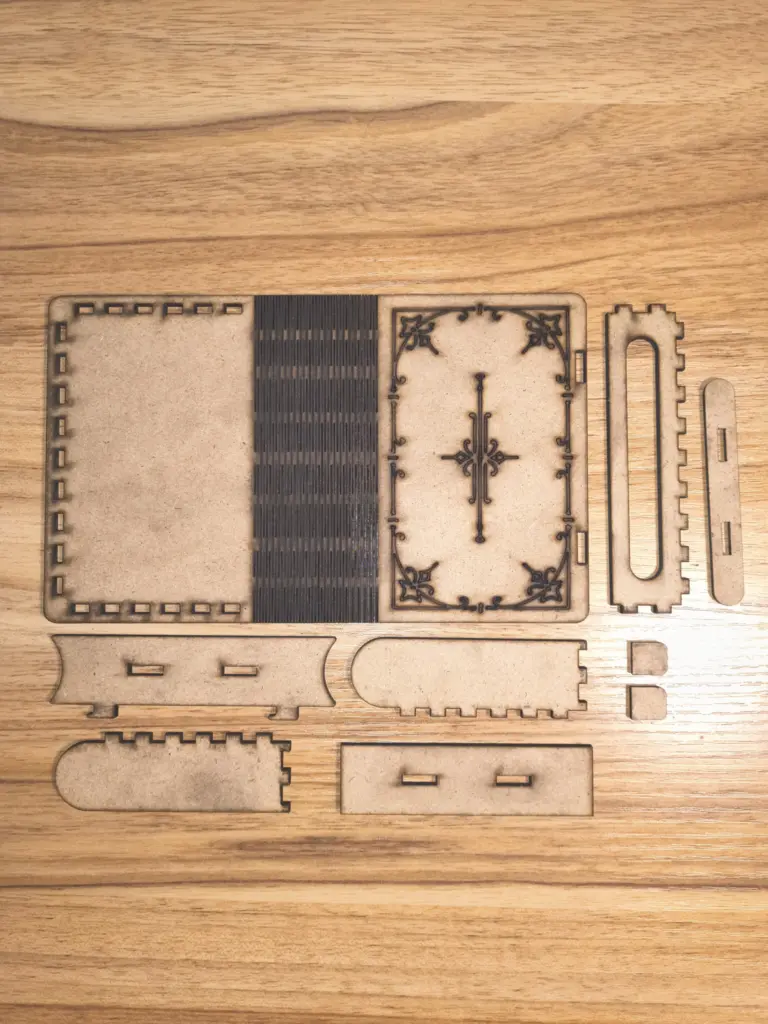

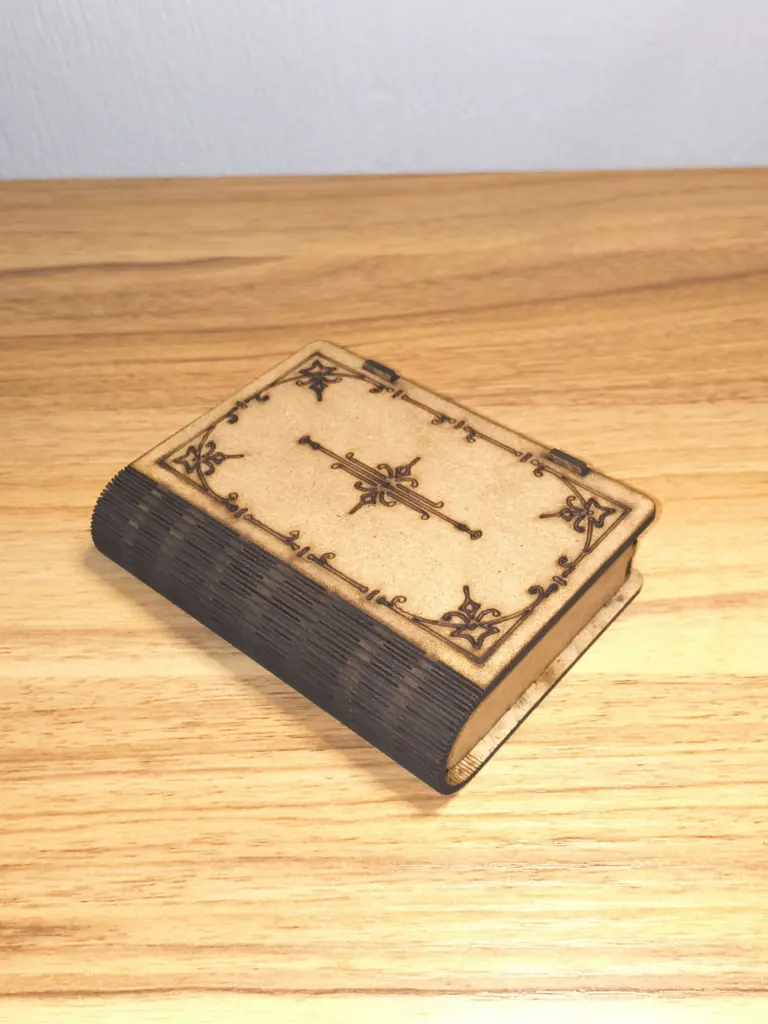

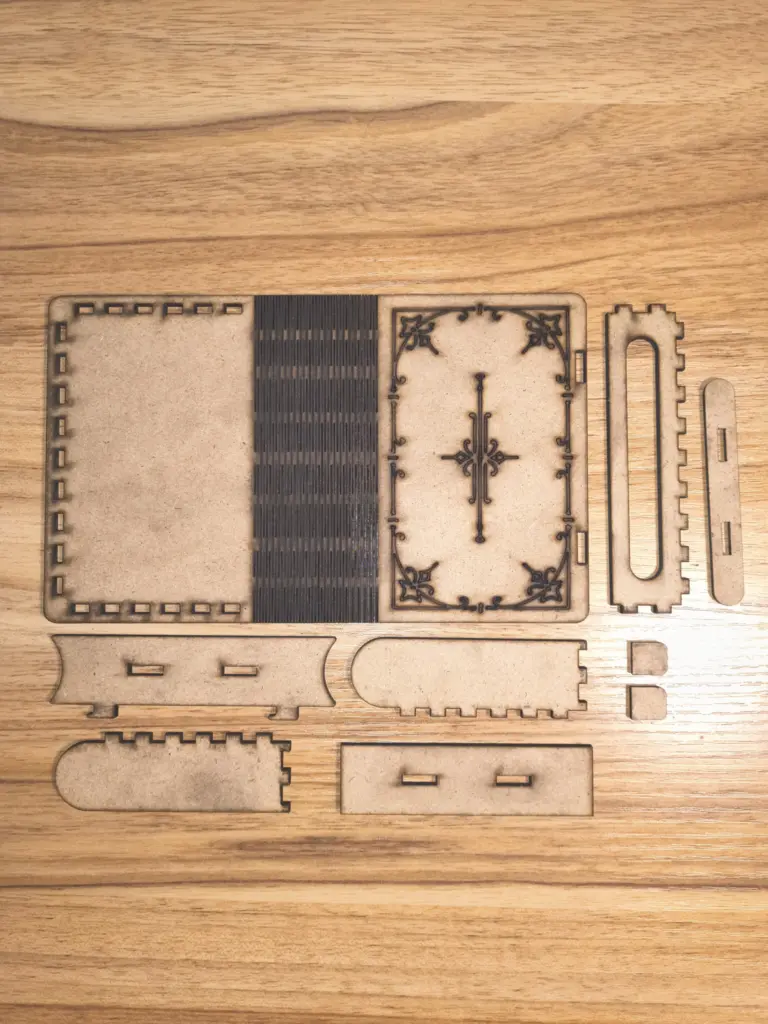

Parametric Kit – Card Game Box

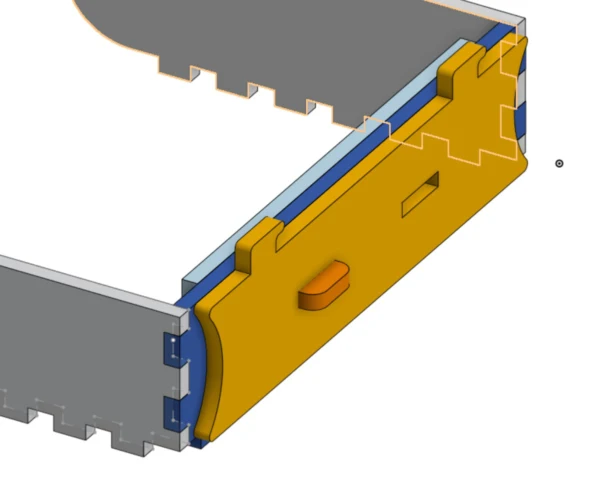

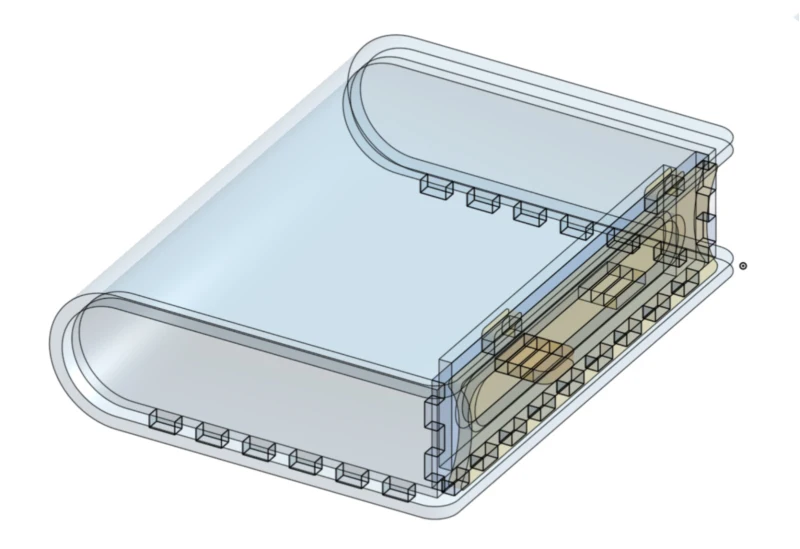

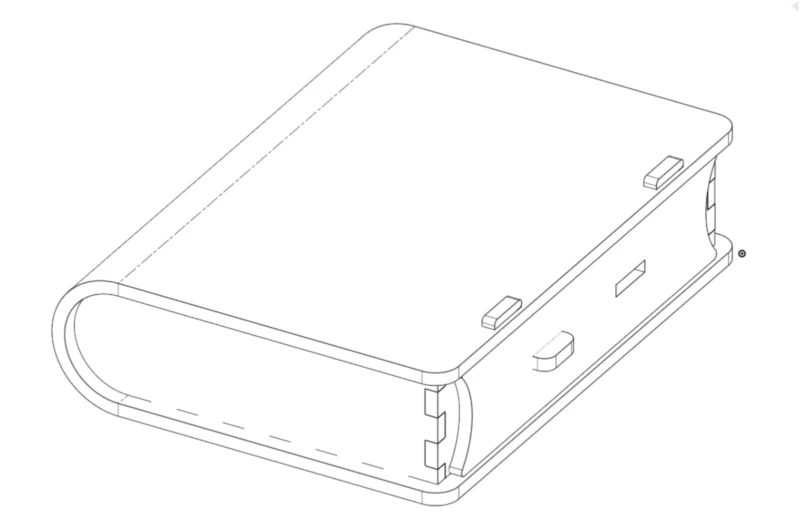

For this exercise (parametric kit), I designed a box for card games in Onshape because it's on the cloud, and my computer can't run SolidWorks properly. This box uses a flexible hinge, finger joints, and a sliding locking mechanism based on “Flexible book boxes” I found on the internet and Pinterest.

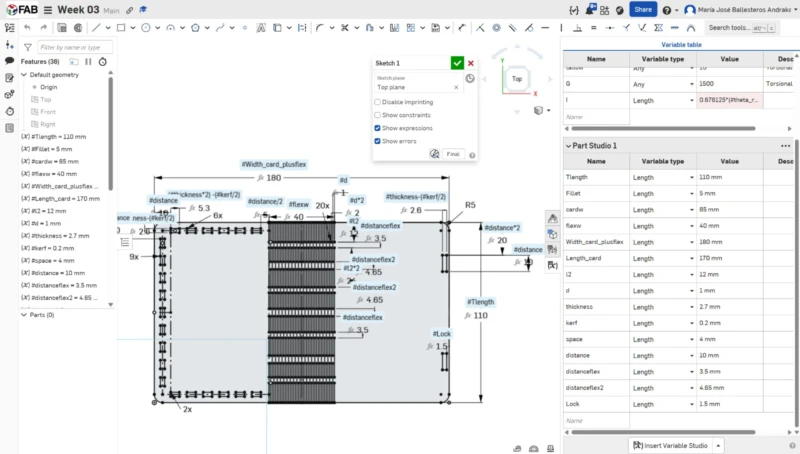

Shape Design Process

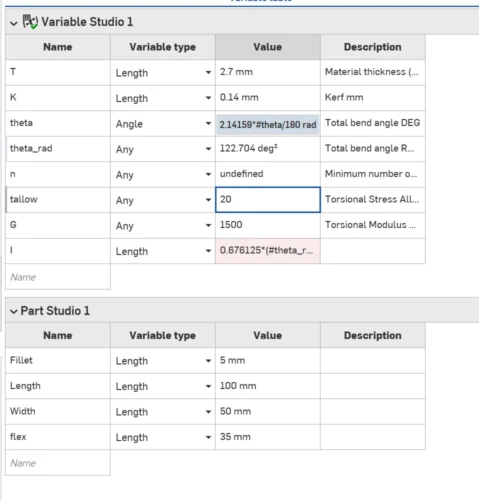

First, I created a new Document named Week 03 and created a sketch on the Top Plane. In this sketch, I drew a rectangle (that will represent the book paste), and I used the fillet tool to round the vertices. Since this moment, I started using “equations” or variables. To do so, first, I used the command (d) to dimension the length or width, and instead of writing the exact number, I wrote (#). This will create a variable of the name we want and give a certain dimension (the one we indicated), which can be changed and will update the design without breaking the constraints.

Then I drew the lines for the living/flexible hinge. To be honest, I tried creating a table variable just like our assessors in SolidWorks, but two variables ended up being undefined due to “error regenerating” and I couldn't solve it. So I did it at heart, my first attempt was a failure, because there was too much space and didn't allow a 180 bending. I did a quick laser cut try and my piece snapped. So I searched on the internet, and encountered a youtube video with flexible hinge samples and their radio bending. I saw that a 1mm distance was perfect for what I needed, so I updated my pattern. To do my pattern first, I drew a line that touched the edge, followed by another line that is double the length of the previous one with a small distance. In total, the line section ends with 4 lines. Then I did a linear pattern.

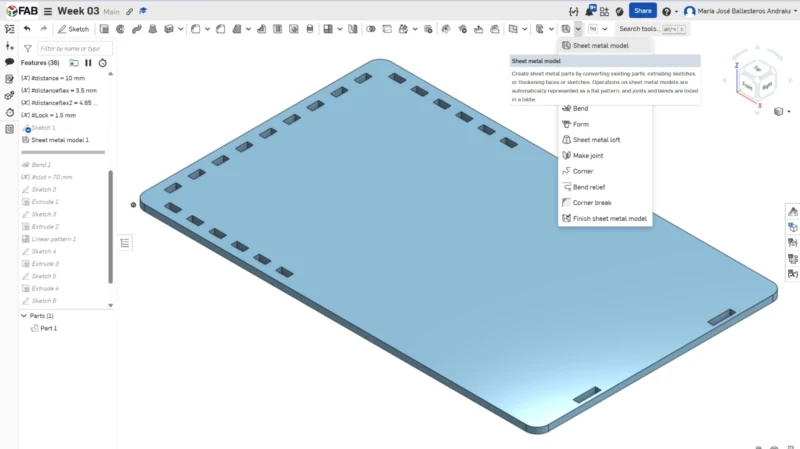

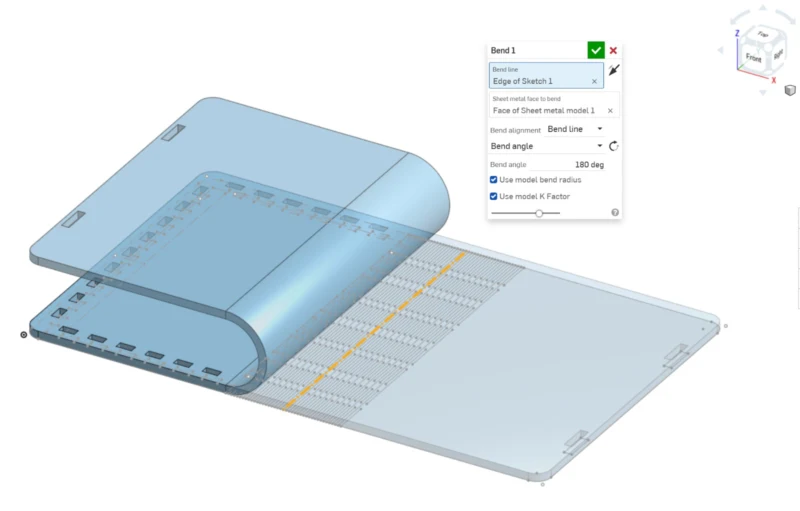

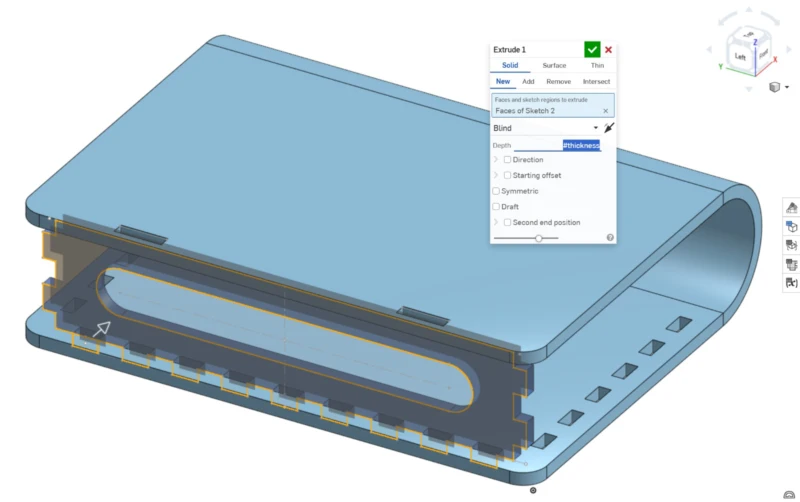

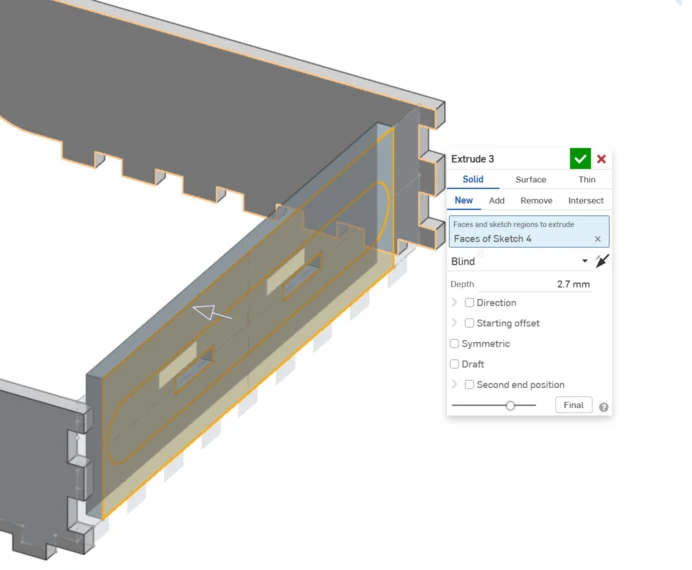

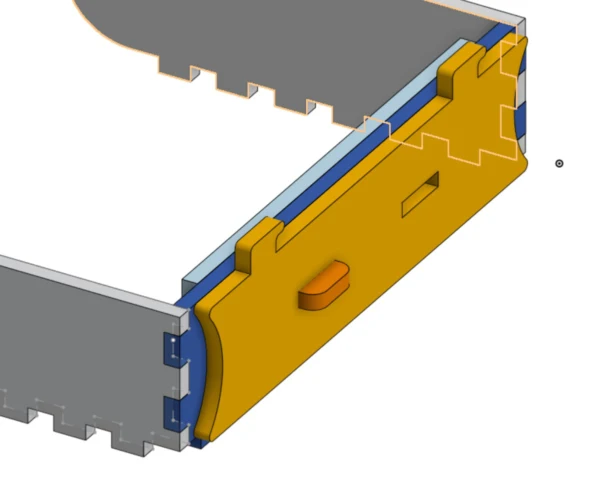

Because the sketch is an extended version of the book case it is difficult for me to visualize if what I'm doing is correct, so I tend to model it as its final look, and use the principal planes to model (top, right, and front), and model using the previous piece form. In this case, because my sketch bends, instead of using the normal extrude tool, I used the “Sheet metal model” that allows me several operations from a “sheet or plane” even though my design is not metal-made. Some operations we can do are: Flange, Hem, Tab, etc. In this case, I used “bend” and used the center line of my flex hinge pattern as the bend line.

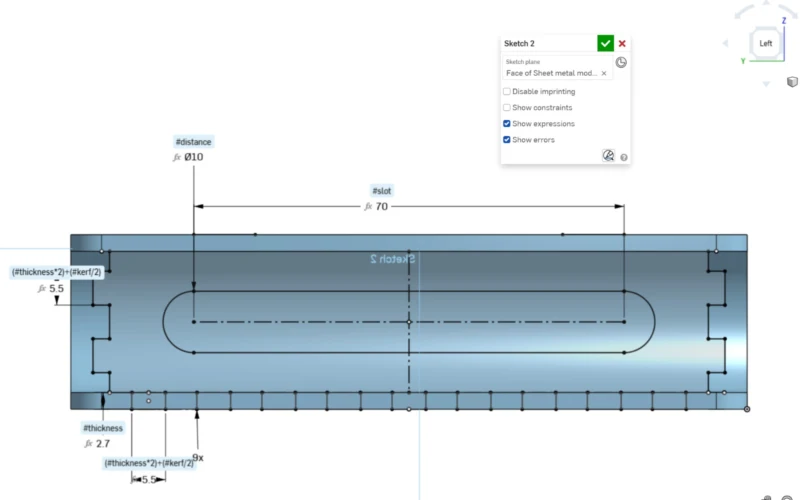

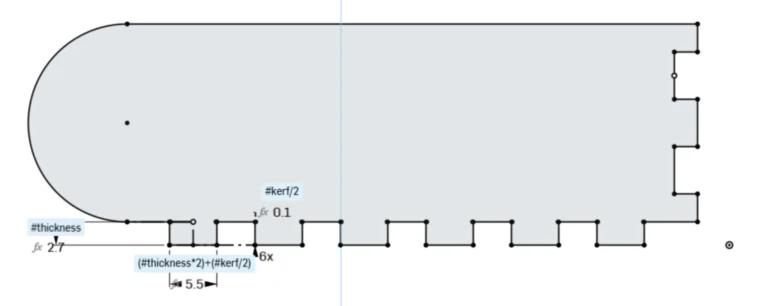

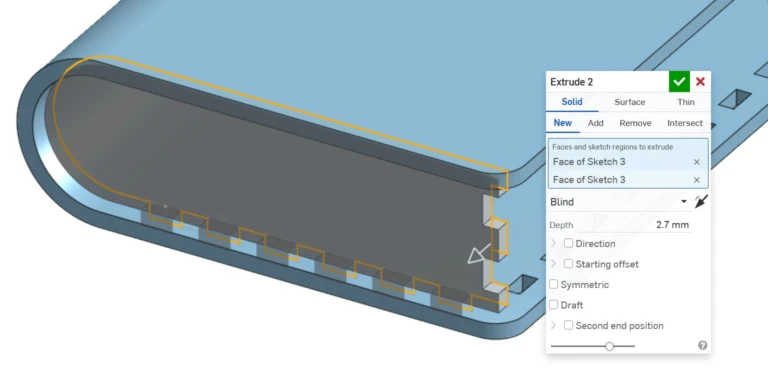

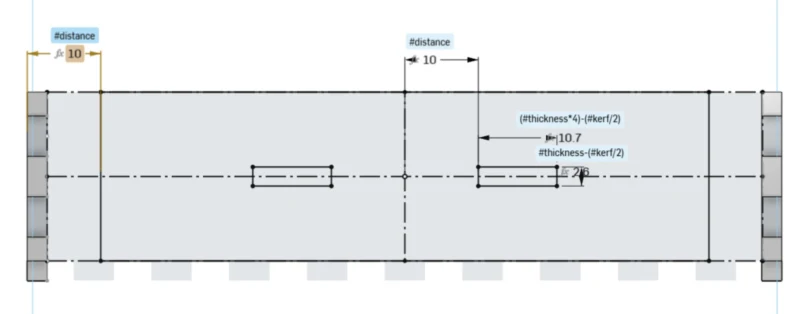

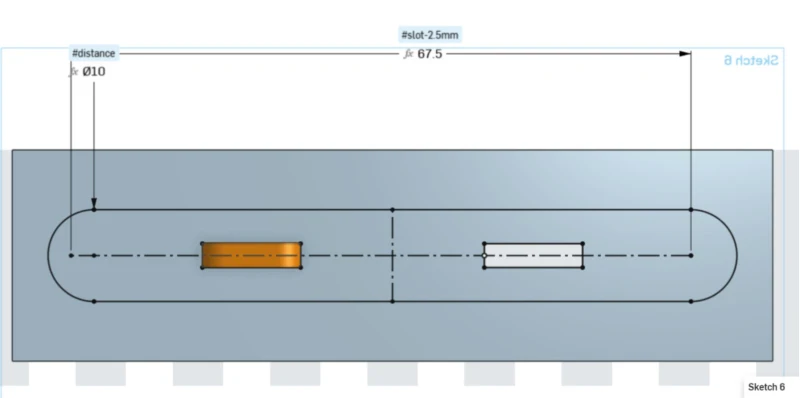

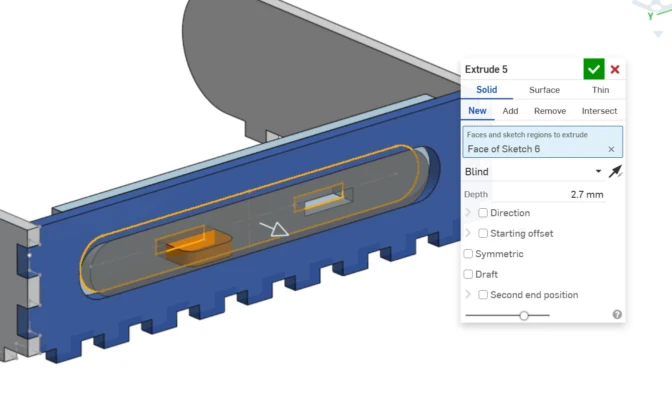

With this, I took the parallel distance between the book's internal faces as a reference to the “front” size of the book. First, I wrote the command (u) to open the “Use” tool and reference the finger holes of the book paste, then I drew a rectangle with the height of the material thickness and the length was (thickness*2)+(#kerf/2). After it, I did a pattern and drew a larger rectangle the size of the piece, then with (m) or “trim” I removed the extra lines. Then I drew a slot that will be the guide to the sliding mechanism. Finally, I extruded the piece.

Kerf and Precision

Kerf refers to the material removed by the laser beam. Measuring kerf is essential for accurate fitting and assembly. To measure it, we drew a rectangle with lines, cut it, and measured the gap. We divided the result by the number of lines we drew in this case 10. So we got 1.38 mm/10= 0.138 mm of kerf (you can see more about it on the group assignment)

- Male joints: add half kerf to each side

- Female joints: subtract half kerf from each side

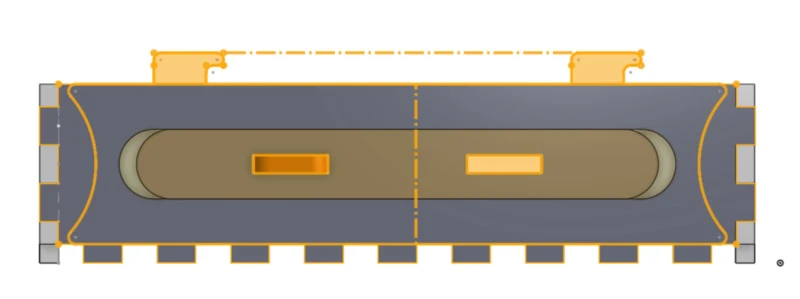

Pieces and Sliding Mechanism

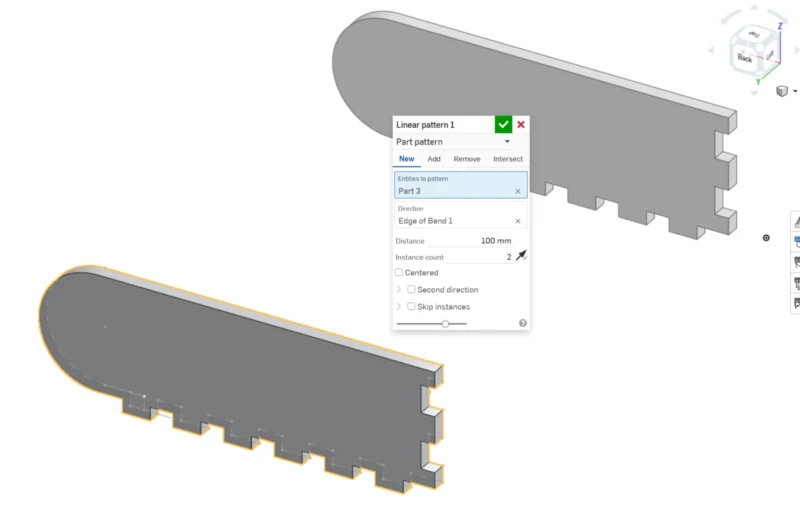

For the following pieces, I followed the same logic, drew the rectangles for the joints based on the previous pieces, and assigned the general size of the piece. Either adding or subtracting some distance and using previous variables. For the side that is repeated I used the 3d tool linear pattern and assigned the length of the piece. This step can be omitted if you do not want the 3 models with all the pieces and just want the individual ones.

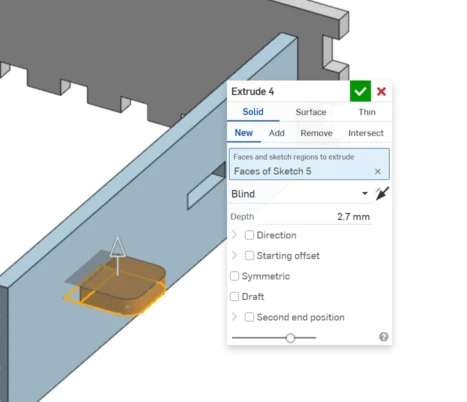

The sliding mechanism has 5 pieces: a base to attach the sliding slot and the sliding bolt latch, plus the slot guide, and 2 connecting pieces.

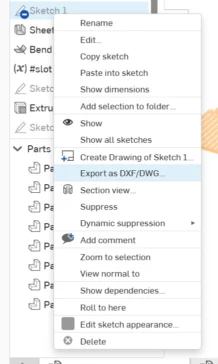

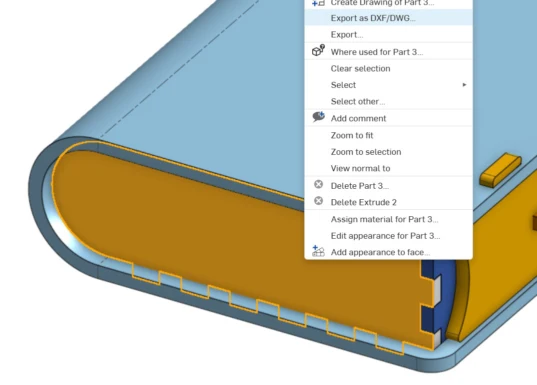

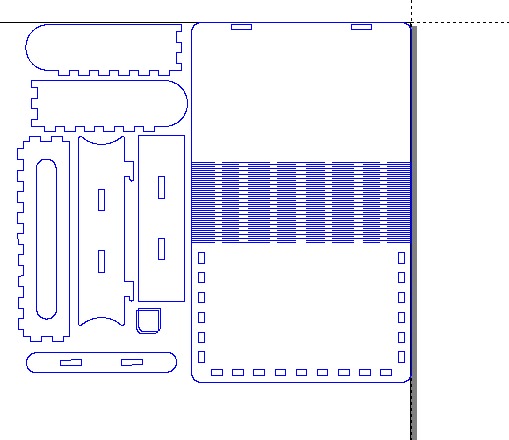

Exporting Files

After I finished all my pieces, I exported the first sketch DXF, followed up with the parts DXF. You can either export the sketches or right-click the wanted face of your part and select export DXF. To export, we need DXF format (Drawing Exchange Format- a vectorial file) with the 2000 version (the one our machines work with) in millimeters.

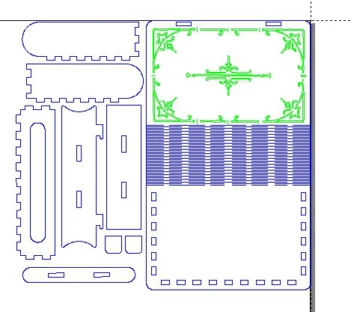

Another extra step is creating a drawing to locate all the pieces, sketches and export one DXF but in my case, I exported them as separate files (in case I just need to change one piece), and I accommodate manually as I want in Smart Carve.

Laser Cutting Workflow

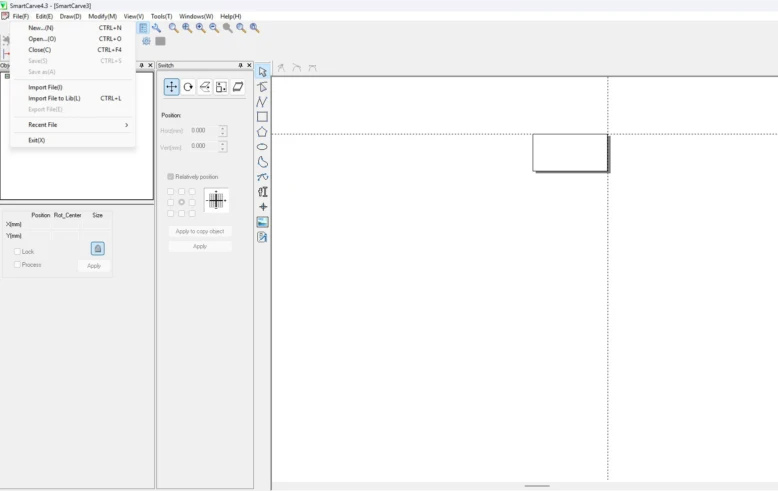

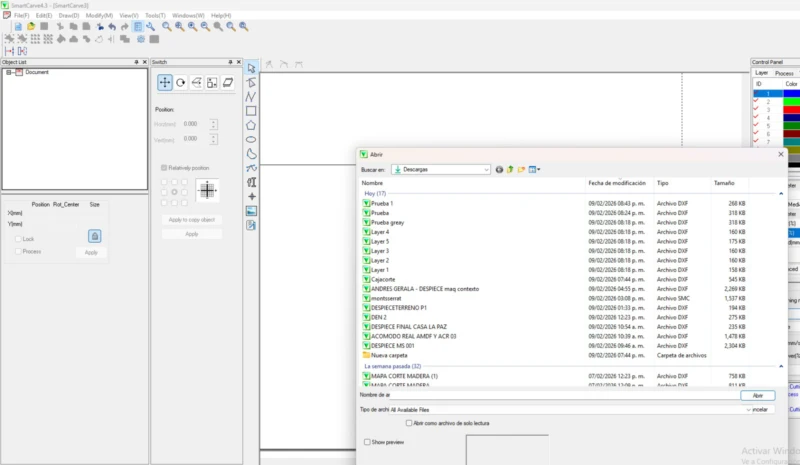

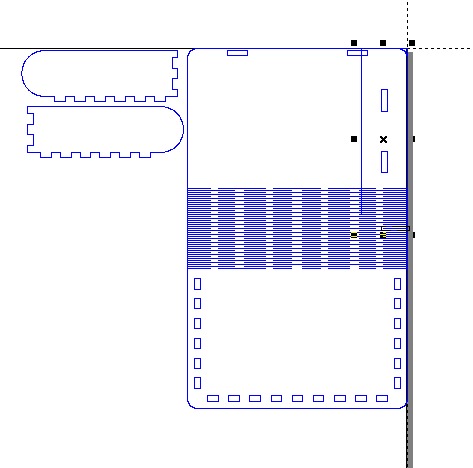

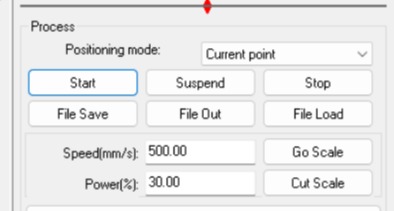

To laser cut, we need to import our files to Smart Cave software. To use the program, we need to insert a USB security dongle, which works as a key to open the program. If we do not insert it, we can't use the program. Once opened, the workplace interface, we select the menu option and click on the import file. Then we select our file. If we have several files, we must repeat this process one by one.The program will ask you in what work units you want to import it, select millimeters

With different files, the pieces will appear on the origin in the orientation you exported them, so you will need to arrange them according to your material workspace. In my case, I needed to move and rotate some of them. You can change between move and rotation with one right click.

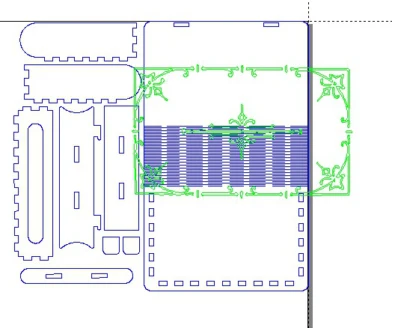

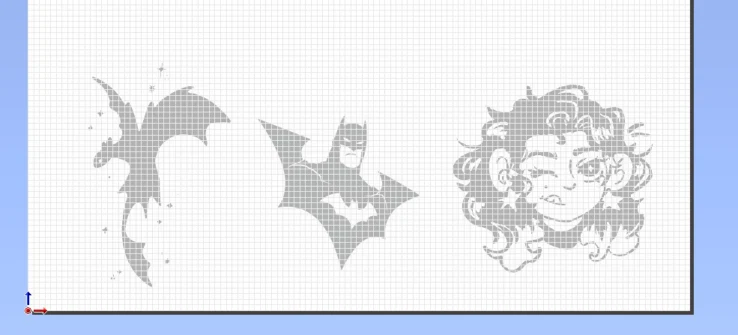

I also added a pattern to engrave it. I tried to add it directly on Onsape but it moved almost all my sketches. So I decided to add it on Smart Cave. To do it, I use the image trace tool to vectorize a pattern I liked on Affinity, just like in week 02.

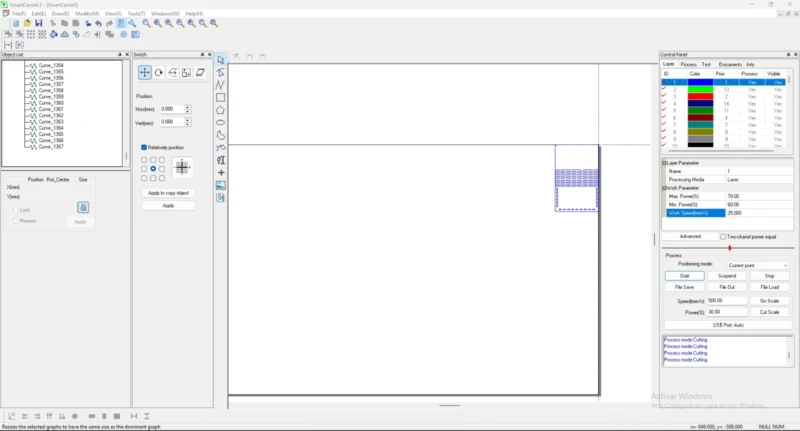

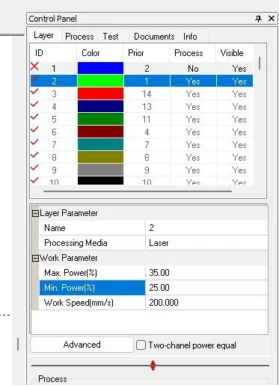

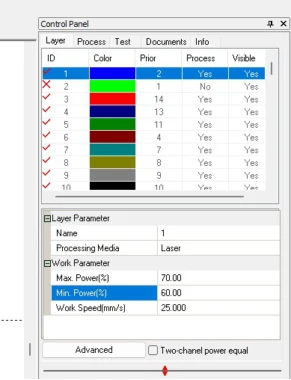

Once I have the accommodation like I wanted it, I selected the pattern group and changed it to a different ID process in the control panel, with that I can adjust the parameters (Max %, Min%, and work speed) depending if it's a cut or engraving process.

To engrave, I represented it with the green ID, changed its priority to #1 (so it engraves before cutting), and established the parameters of 35 25 200

To cut, I used the blue ID with the following parameters: 70 60 25.

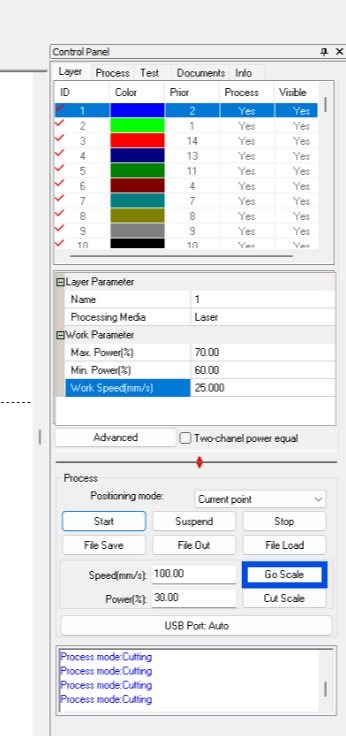

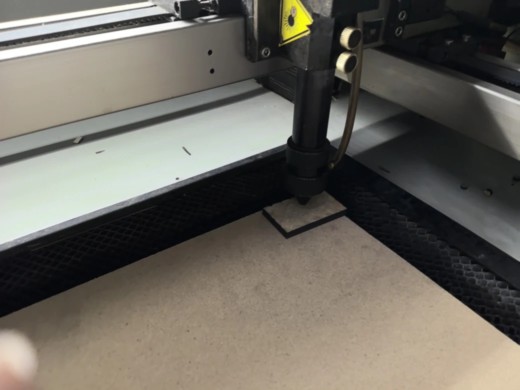

Before sending the cut file, we need to ensure our cutter machine is ready. For it I used the CFL-CMA1080K, so we first check the cooler, then turn on the automatic voltage regulator, then we turn on the machine on the left, then we liberate the safety switch and activate the machine panel with the key. Then we turn on the laserbutton and put it to its max. Normally, the origin is on the top right corner, but we can set up a new origin with the row on the panel control and then pressing the origin button after we have the desired position.

8 images

Now returning to Smart carve. We select Go Scale to see the working area of our file. If it's correct, we can send it at the start. You can also choose to process or not the different Id’s. For this exercise, first I tested a general parameter for engraving it, so I selected the blue ID (cut must not be processed), so the machine will only read the engraving and I can save time if it doesn't work.

However, I liked it so, when it finished I repeated the process, disabled the green Id (engrave) and enabled the blue one, to perform the cut. Because the machine remembers the origin and I didn't change it, both processes share the same starting point and don't affect my design.

Technical Issues

Sometimes the material doesn't cut completely, and it can be for different reasons:

- Warped material affecting cut depth: your material is warped, so it will have different distances to the nozzle, please select one with low warping.

- Nozzle misalignment: your nozzle can be uncalibrated (too close or too far from the material). The ideal distances are 5mm, and for that, we have a small rectangle of mdf with that thickness.

- Incorrect power parameters: here parameter tests will help, sometimes with a second pass if the parameters are close enough to what is needed can solve the problem; if not,you need to change them.

- Material thickness variation: The same parameters can have different results on different mdf qualities. For example, on the second material burn is cleaner, but the thickness is also different. So you need to adjust your original file, change the thickness variable, and export again, and do the smart cave process.

Vinyl Cutting

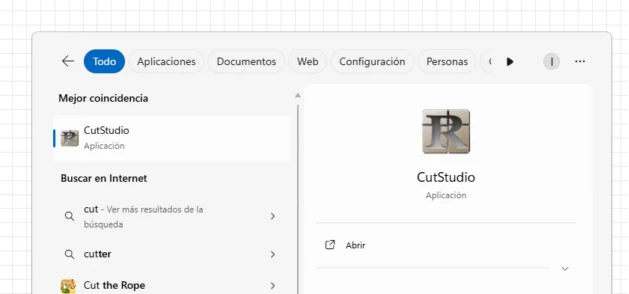

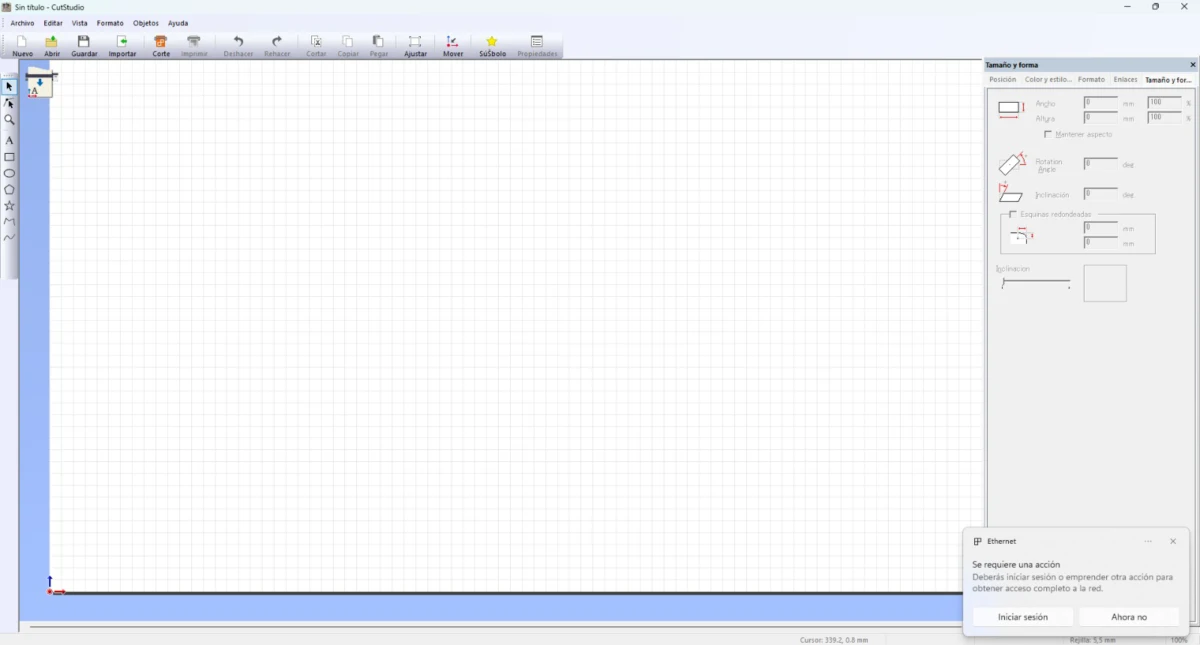

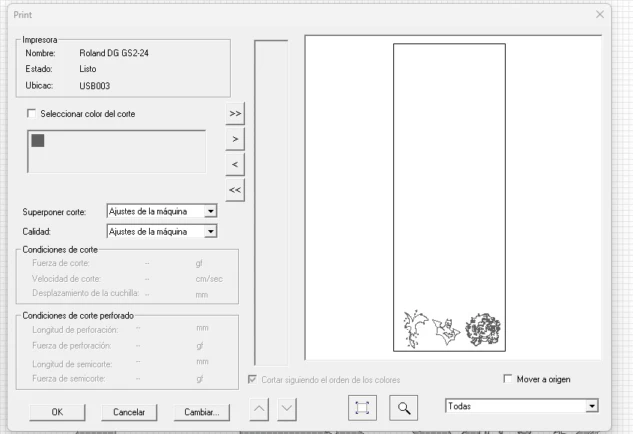

Vinyl cut follows the same CNC logic as the laser cut, but instead of using a focused beam, it uses a knife. For this exercise, I used the VersaSTUDIO GS2-24 from Roland and the Cut Studio Software.

Importing Files

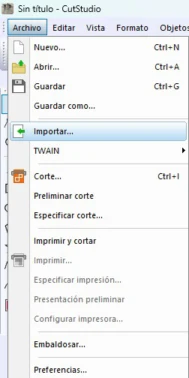

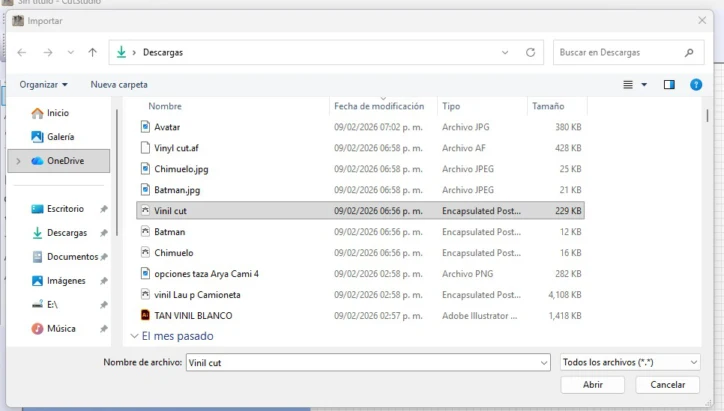

First, we need to import our file; the recommended formats are EPS (Encapsulated PostScript) or JPEG (for outline extraction).

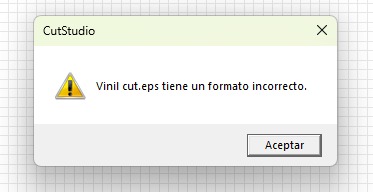

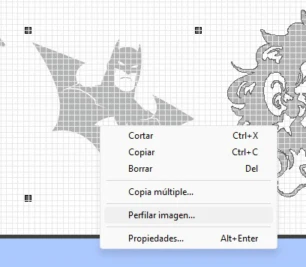

While I tried importing an EPS (it automatically outlines the cut), Cut Studio sent me a warning saying it was in the incorrect format. I have previously worked on Illustrator files as EPS and didn't have a problem. However this time I exported them from Affinity, and even if I changed the export settings, the result was the same, so I imported them as images (JPEG).

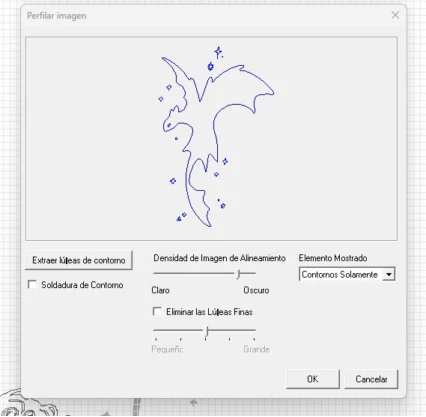

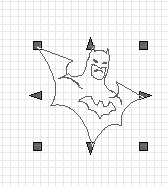

Creating the Outline

For JPEG files, select the image, right click and choose “perfilar imagen” (outline image). This opens a window where you can choose the final result (image + outline or just the outline). After that, the image size can be adjusted using the size and form window. For this exercise, I used the total material area and repeated my designs in a smaller scale.

Preparing the Cut

Once the design is ready, go to File and press Cut. A preview window appears showing the pattern and workspace layout. If everything looks correct, press OK.

Machine Setup (Vinil)

The cutter must be ready before sending the file. First turn it on and load the material. In this case we used a full vinyl roll because there were no scraps. The roll must be secured using the clampers. To secure them, pull the handle; otherwise the material may move and create cutting errors.

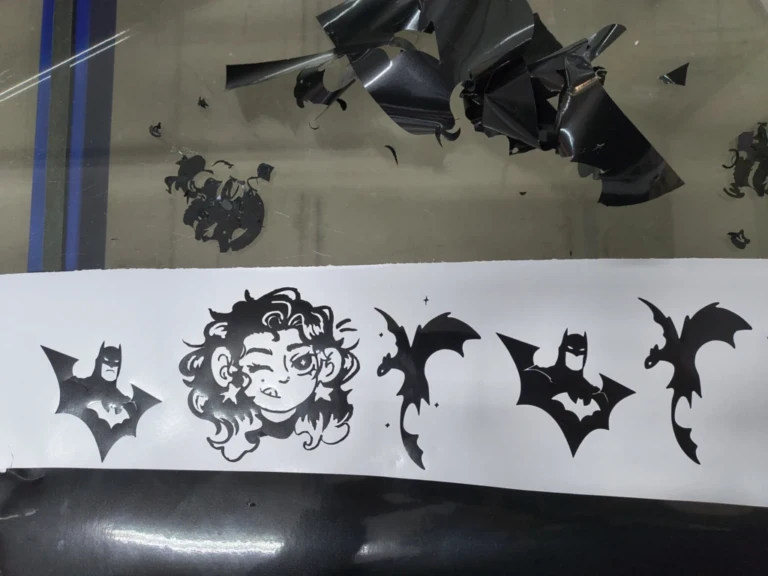

Cutting Process

For this exercise, pen force and origins were already configured, so we didn't change them. After loading the roll, the machine was ready and the file was sent to cut. Once finished, the piece was removed using a cutter.

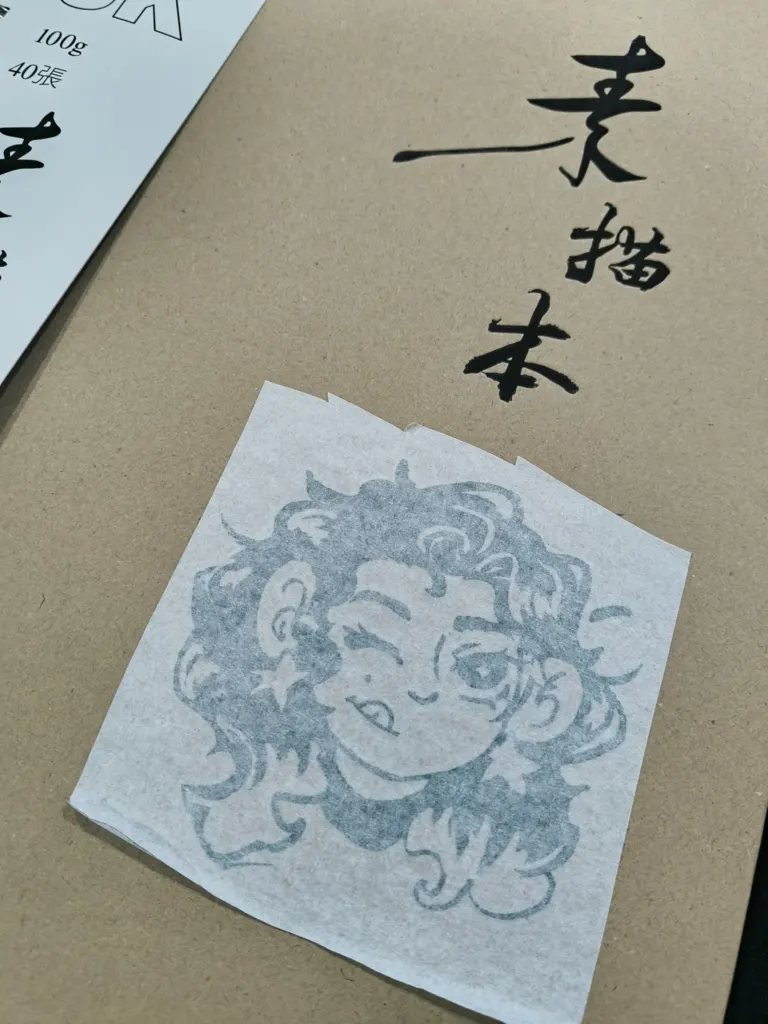

Weeding

After cutting, the excess vinyl must be removed. I used the tip of a cutter, although weeding tweezers or hooks work better for detailed designs.

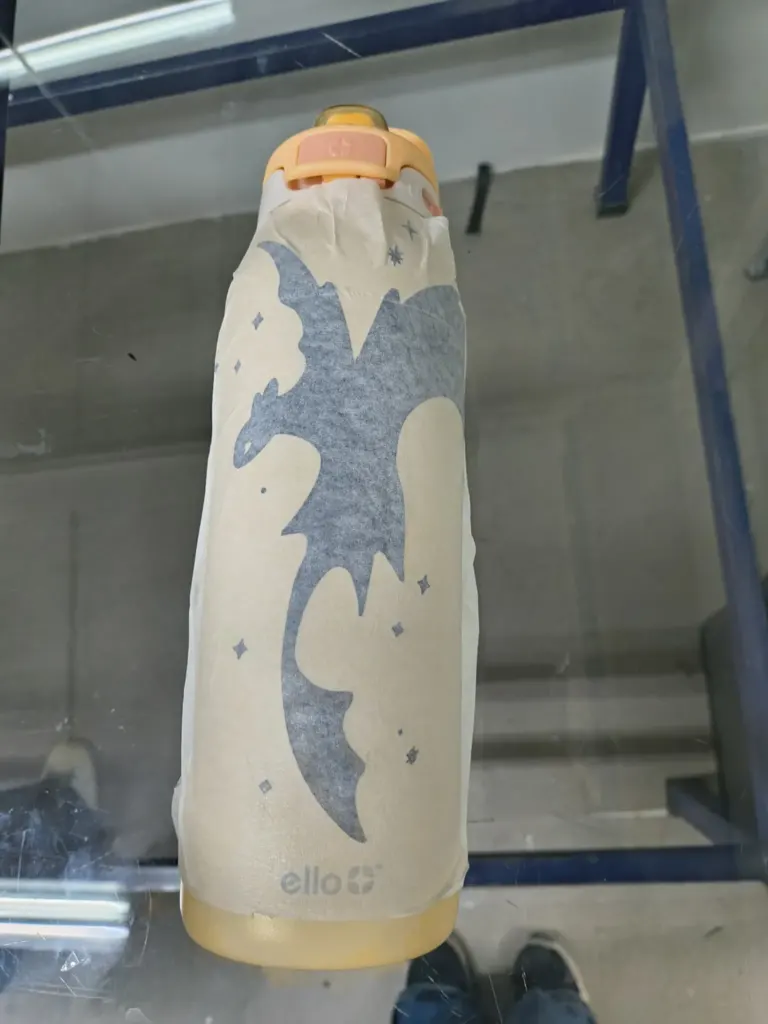

Transfer Paper Application

Once cleaned, transfer paper is applied. It works similarly to masking tape. I had some issues because it was extremely sticky and tore easily, which caused wrinkles. With help from a classmate, I focused on pressing the design with a card while the transfer paper was rolled evenly.

Final Application

The design is now ready to be applied. Choose a clean surface, remove dust or grease, place the design, press with a card, remove the transfer paper, and the vinyl application is complete.

Files

Box FilesVinil