Week 18

Invention, Intellectual Property, and Income

The Color Sorting Robot is an educational and automation-focused invention designed to identify and sort colored blocks using a robotic arm and conveyor system. It integrates computer vision, real-time processing, and mechanical motion to autonomously detect and place objects based on color.

Plan for Dissemination of Final Project: Color Sorting Robot

To maximize the educational, technical, and social impact of the project, the Color Sorting Robot will be disseminated through the following channels:

]1. Educational Demonstrations and Workshops

Target Audience: School students (Class 6–12), diploma and undergraduate engineering students.

Activity: Organize hands-on demonstrations at Sanjivani Fab Lab, showcasing color detection, robotic sorting, and basic automation principles.

Objective: Promote STEM and robotics awareness among young learners through visual and interactive learning.

2. Integration into Academic Curriculum

Propose inclusion of this project as a lab experiment or capstone module in:

• Mechatronics.

• Embedded Systems.

• Robotics.

• Develop a teacher's guide and student manual explaining hardware setup, coding, and learning outcomes.

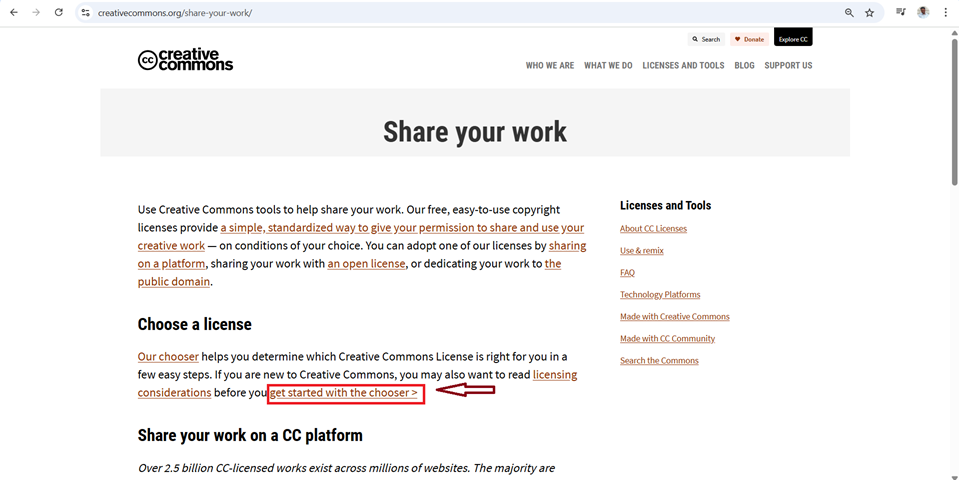

3. Online Platforms and Open-Source Sharing

Share complete project documentation (design files, source code, BOM, instructions) on:

• FabAcademy Archive.

• GitHub Repository.

• Hackster.io / Instructables.

• Include video tutorials demonstrating the working mechanism and assembly process.

4. Technical Conferences and Exhibitions

Present at events such as:

• FAB25 Conference.

• Maker Faire (India or Italy).

• National STEM or Robotics Expos.

• Prepare a poster presentation, working prototype, and distribute flyers with QR code links to documentation.

5. Research and Innovation Cells

• Submit project to the Innovation and Entrepreneurship Development Cell (IEDC) at Sanjivani College for further incubation.

• Explore possibilities for student startups or prototype kits for schools under Atal Tinkering Labs (ATL) scheme.

6. Community Outreach and Social Media

Post updates, progress, and final outcomes on:

• YouTube (project video).

• Instagram / Facebook pages of the Sanjivani Fab Lab.

• College newsletter or blog.

• Encourage feedback and engagement from the online community.

Plan for dissemination

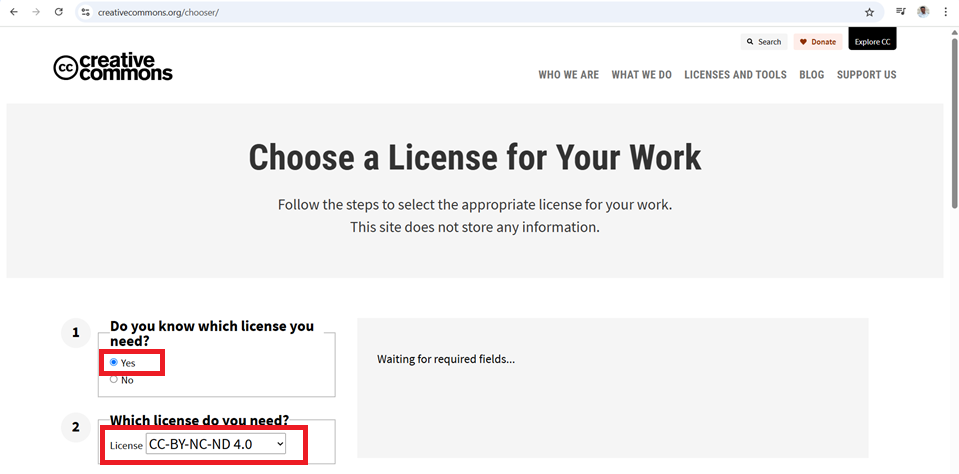

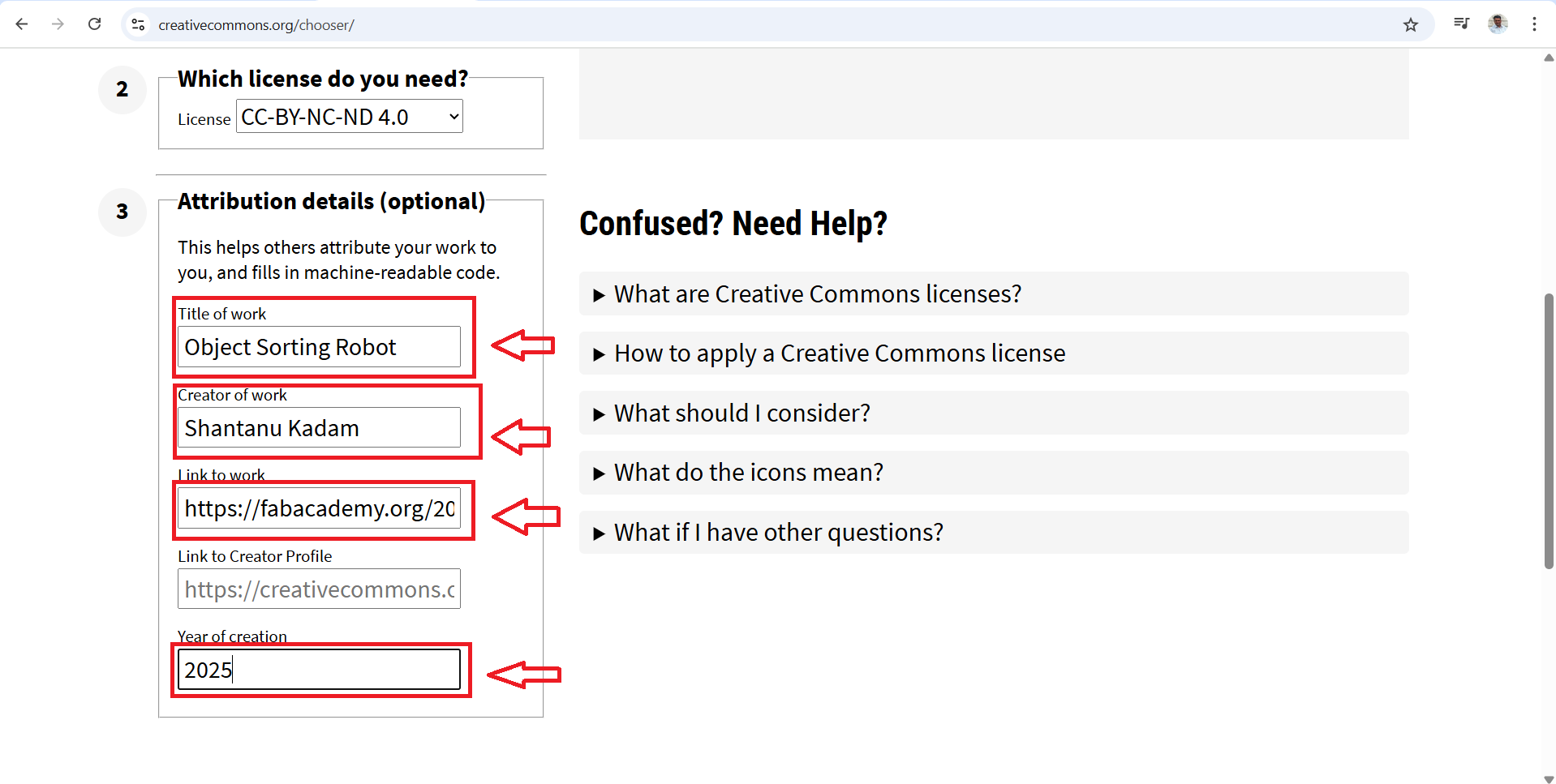

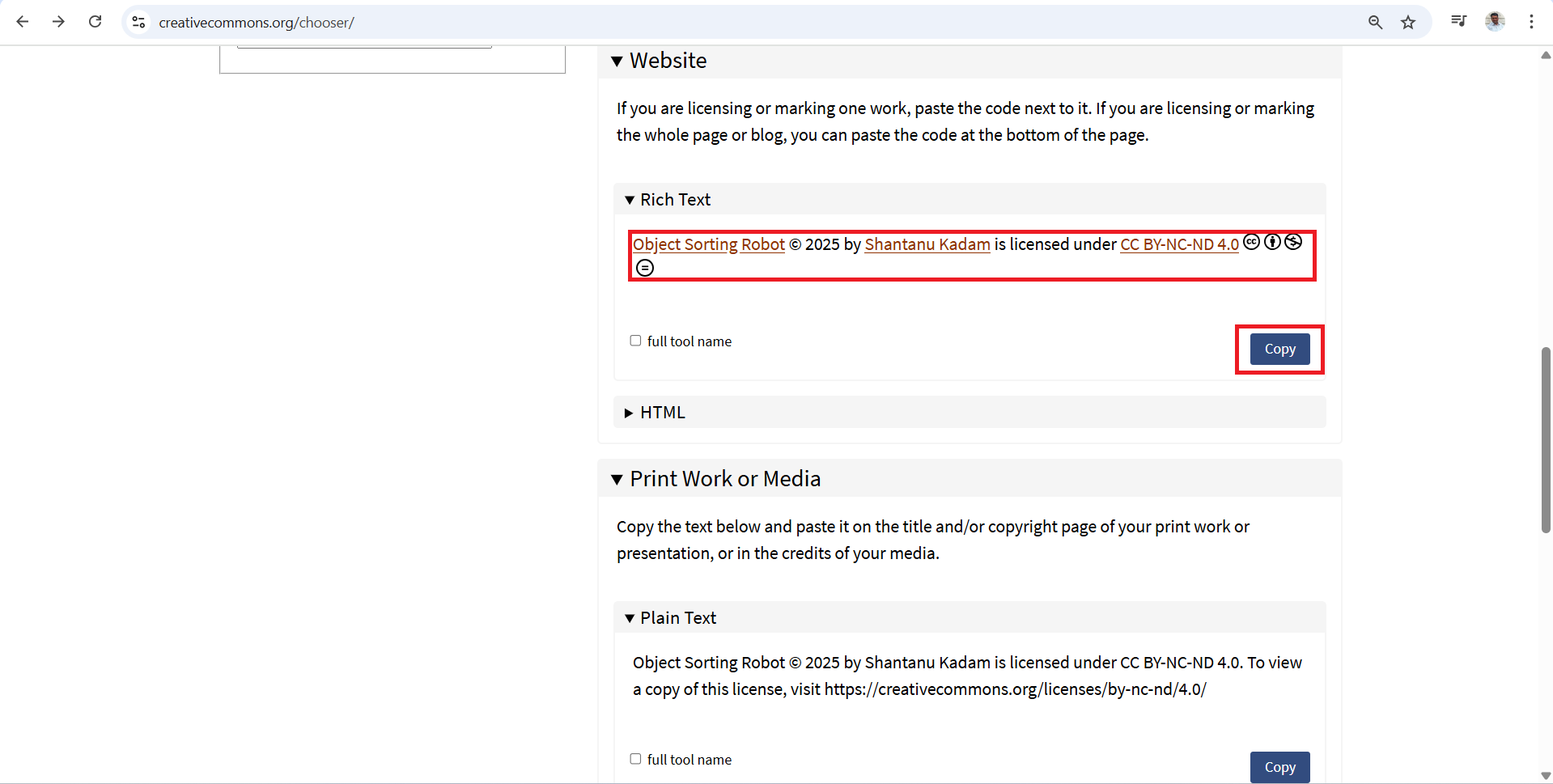

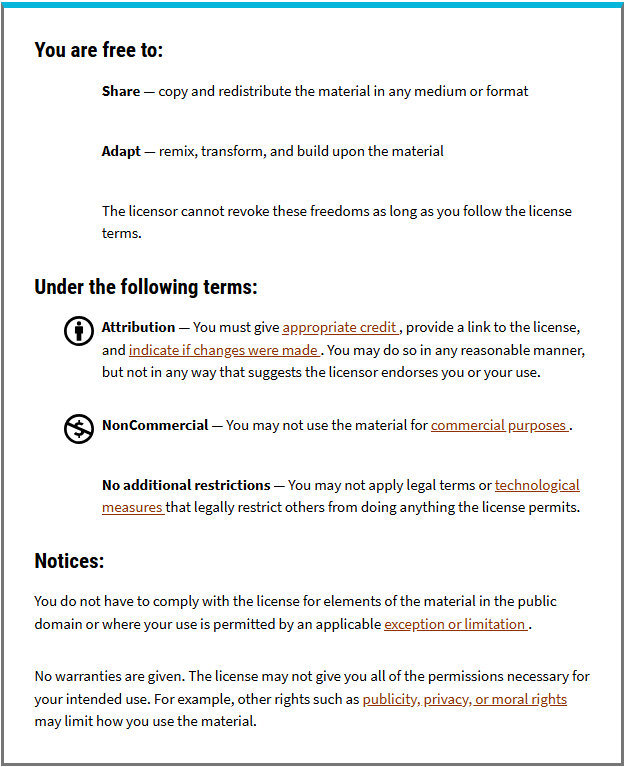

“Color Sorting Robot Project by Dr. Shantanu Kadam is licensed under Creative Commons Attribution-NonCommercial 4.0 International.”

Colour Sorting Robot © 2025 by Dr. Shantanu Kadam is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Future Improvements for the Color Sorting Robot

To enhance the efficiency, functionality, and versatility of the colour sorting robot, several future improvements can be considered:

1. Increased Sorting Speed

Optimize the motor control algorithms and sensor response times to reduce cycle time and increase the overall sorting speed.

2. Multi-Color & Gradient Detection

Upgrade the color sensor or implement advanced image processing using a camera to detect and sort not just primary colors, but also shades, gradients, and mixed colors.

3. Artificial Intelligence Integration

Use machine learning models to classify objects based on color and size patterns, improving accuracy in complex scenarios.

4. IoT & Remote Monitoring

Integrate Wi-Fi or Bluetooth to enable remote monitoring, logging, and control of sorting operations through a mobile app or web dashboard.

5. Voice & Gesture Control

Add voice recognition or gesture-based inputs to allow more interactive control, particularly for educational or demonstration purposes.

6. Adaptive Learning

Implement adaptive learning where the robot can learn from previous sorting decisions and adjust its threshold values automatically for better accuracy.

7. Compact & Modular Design

Redesign the hardware to be more compact and modular, making it easier to transport, maintain, and upgrade individual components.

8. Power Efficiency

Improve power management by using energy-efficient components and implementing sleep modes during idle times to reduce power consumption.

9. Multi-Object Sorting

Enable simultaneous sorting of multiple objects using parallel conveyors or multiple sensor arms to increase throughput.

10. Industrial Application Adaptation

Scale the system for industrial use by integrating conveyor belts, robotic arms, and PLC-based controls for sorting large volumes of colored objects in real-time.

What tasks have been completed, and what tasks remain?

Tasks Completed

In the Color Sorting Robot project, key tasks have been successfully completed, including the selection and integration of electronic components, mechanical structure assembly, color sensor calibration, and the development of code for real-time sorting.

Tasks Remaining

While the core functionality is operational, several tasks remain to refine the project. These include designing and fabricating a final enclosure to protect components and improve visual appeal. Error handling and fault tolerance need to be incorporated for situations like unreadable colors or mechanical misalignment. Power management can be improved by integrating a battery backup or more efficient power supply. Performance optimization, such as increasing the sorting speed and accuracy, is also pending. Lastly, the final documentation, presentation, and a demonstration video need to be completed for project submission and evaluation.

What’s working? What’s not?

What’s Working

The Color Sorting Robot is successfully detecting different colored blocks and sorting them accurately into predefined locations. The color sensor is well-calibrated, and the sorting logic coded into the ESP32-C3 microcontroller functions correctly. The conveyor mechanism is operational and able to move the blocks smoothly. Overall, the integration between hardware and software is functioning well in the controlled test environment.

What’s Not Working

MG995 servo motors used for sorting are not functioning properly, causing occasional misplacement or failure in sorting. The remaining servo motors also require further tuning for consistent performance. Additionally, the project currently lacks a protective enclosure, and there is no implemented error handling for cases like undetected colors or mechanical jams. Power supply stability also needs improvement for long-term and reliable operation.

What Questions Need to Be Resolved?

How can the issue with the malfunctioning MG995 servo motors be resolved to ensure consistent and accurate sorting? What improvements can be made to the power supply system to support stable and uninterrupted operation? How can the sorting speed be increased without compromising accuracy? Additionally, how can the system be made more robust in handling unknown or mixed colors, and what methods can be used to implement effective error detection and correction mechanisms? These questions are critical to improving the overall functionality and readiness of the project for real-world use or demonstration.

What will happen when?

When a colored block is placed on the conveyor belt, the system activates and begins processing. As the conveyor moves the block forward, the color sensor detects the block’s color and sends the data to the ESP32-C3 microcontroller. Based on the identified color, the corresponding MG995 servo motor is triggered to sort the block into the appropriate section. However, due to improper grounding in the electrical connections, some of the servo motors do not operate correctly, leading to misalignment or failure in sorting. Ensuring proper grounding is essential for stable and reliable motor function, and this issue must be resolved to achieve consistent sorting performance.

What have you learned?

I learned how to interface sensors and actuators with a microcontroller (ESP32-C3), write logic for real-time sorting, and design a functional conveyor mechanism. I also understood the importance of accurate calibration, especially for color detection and servo positioning. Additionally, I discovered how crucial proper electrical grounding is for the reliable operation of motors. Troubleshooting hardware issues, managing component compatibility, and optimizing system performance provided deeper insights into real-world engineering challenges. This project strengthened my skills in embedded systems, automation, and project-based problem-solving.

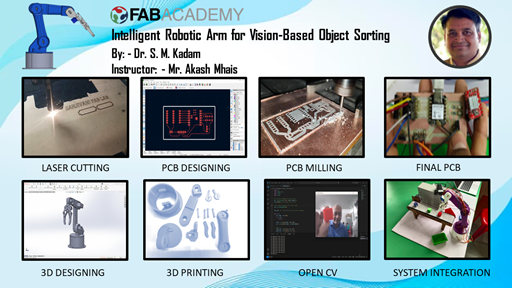

Presentation Drafts:

Here is the draft for my presentation slide:

Here is the draft for my presentation video:

I used the Capcut for the video editing and for the compression I used FFMPEG tool. here is the command for compression of video which I used : ffmpeg -i "source.mp4" -c:v libx264 -b:v 1.5M -c:a aac -b:a 128k "target.mp4"

Object Sorting Robot © 2025 by Shantanu Kadam is licensed under CC BY-NC-ND 4.0