Week 17

Applications and Implications

I have developed a Color Sorting Robot as part of my project work. For demonstration purposes, I fabricated 2 cm × 2 cm color blocks using PLC material in various colors. These blocks are loaded onto a conveyor belt system.

The robot is programmed to detect the color of each block as it moves along the conveyor. Upon identification, the robot picks up the block and sorts it into predefined bins or areas based on its color. This automation process showcases the robot’s ability to perform real-time color detection, classification, and accurate mechanical sorting.

The system simulates industrial automation techniques used in manufacturing and recycling industries, with a focus on speed, precision, and reliability.

What will it do?

The Color Sorting Robot will automatically identify and sort color blocks placed on a moving conveyor. As each block passes through the system, the robot detects its color using a camera, then picks up the block and places it into a predefined location assigned for that specific color. This process repeats continuously, allowing automated, accurate, and efficient color-based sorting of materials without human intervention.

Who’s done what beforehand?

Before developing this project, I conducted a review of existing color sorting systems used in industrial automation, recycling plants, and food processing lines. These systems commonly use color sensors, conveyor mechanisms, and robotic arms controlled by microcontrollers or PLCs (Programmable Logic Controllers) to sort items based on color.

Several earlier projects and research have demonstrated similar concepts using:

• TCS3200/TCS34725 color sensors for real-time color detection.

• Arduino, Raspberry Pi, or PLCs as controllers for automation logic.

• Servo motors or robotic arms for mechanical sorting.

• Conveyor belts to simulate a production line.

I studied these implementations to understand sensor integration, object handling mechanisms, and the logic used for sorting. Building on these ideas, I designed and implemented a customized version using 2 cm × 2 cm PLC material blocks, a conveyor setup, and a robotic sorting arm tailored for academic demonstration and small-scale automation.

What sources will you use?

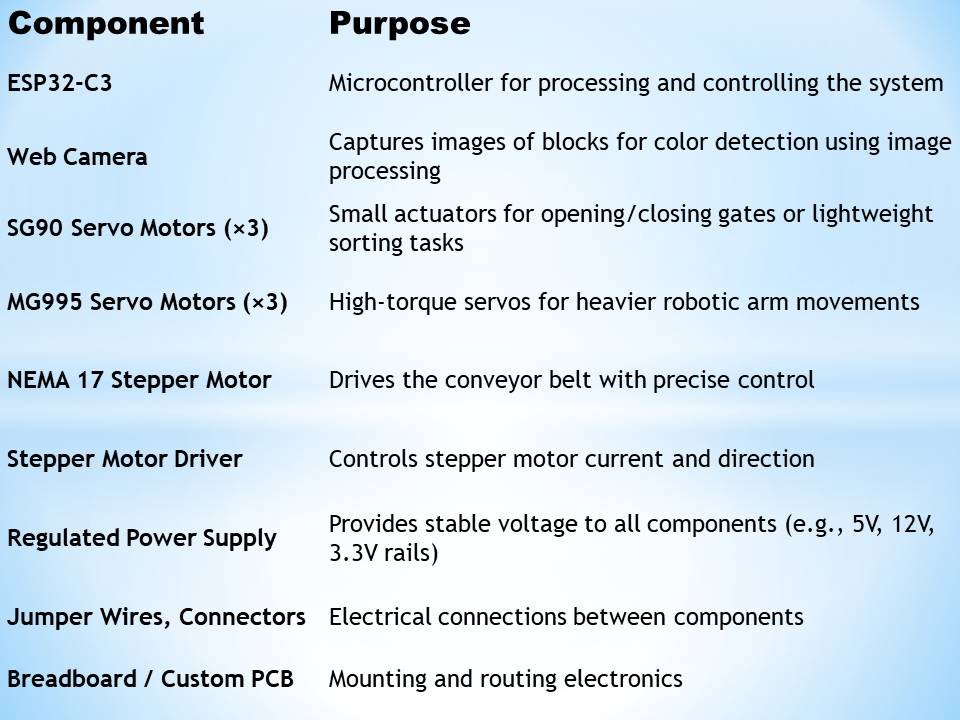

To build the Color Sorting Robot, I will use the following hardware components and supporting resources:

Hardware Components:

1. Web Camera (USB or ESP32-compatible):

• Used as a vision system to capture live images of the colored blocks for detection and classification.

• Source: Repurposed from lab equipment or purchased from electronics vendors.

2. SG90 Servo Motors:

• Compact servos for lightweight motion control, ideal for operating sorting mechanisms or gates.

• Source: Online platforms like Robu.in or Amazon, or from existing lab inventory.

3. MG995 Servo Motors:

• High-torque servo motors for handling heavier mechanical actions like robotic arms.

• Source: Electronics marketplaces or reused from previous robotics projects.

4. ESP32-C3 Microcontroller:

• Acts as the main control unit for interfacing with the camera, servos, and other peripherals.

• Source: Ordered from trusted suppliers like Robu.in or sourced from Fab Lab inventory.

5. NEMA 17 Stepper Motor:

• Used to drive the conveyor belt, offering precise speed and position control.

• Source: Purchased online or obtained from old CNC/CAM equipment.

5. Regulated Power Supply:

• Supplies stable voltage and current to the stepper motor, servos, and ESP32-C3.

• Source: Lab power supply or a dedicated power adapter module (e.g., 12V 5A SMPS).

Supporting Resources:

• Datasheets and Manuals for all components (available online from manufacturer websites).

• ESP32-C3 Documentation from Espressif’s official site for programming and pin configuration.

• Open-source libraries and sample code from GitHub and Arduino IDE for controlling servos, stepper motors, and camera image processing.

• Online tutorials (YouTube, Instructables) and technical forums (Stack Overflow, Arduino Forum) for integration guidance and troubleshooting.

• Academic references and Fab Academy documentation for structured methodology and system design.

What will you design?

I will design a vision-based robotic color sorting system that automatically identifies and sorts objects based on their color using image processing and robotic actuation. The key systems and components I will design include:

1. Vision-Based Color Detection System:

• A software module using a webcam to capture real-time images of the moving blocks.

• Image processing (e.g., using OpenCV with ESP32-C3 or a companion PC) to detect the dominant color of each 2×2 cm PLC block.

• Region of Interest (ROI) logic to isolate and analyze each block precisely.

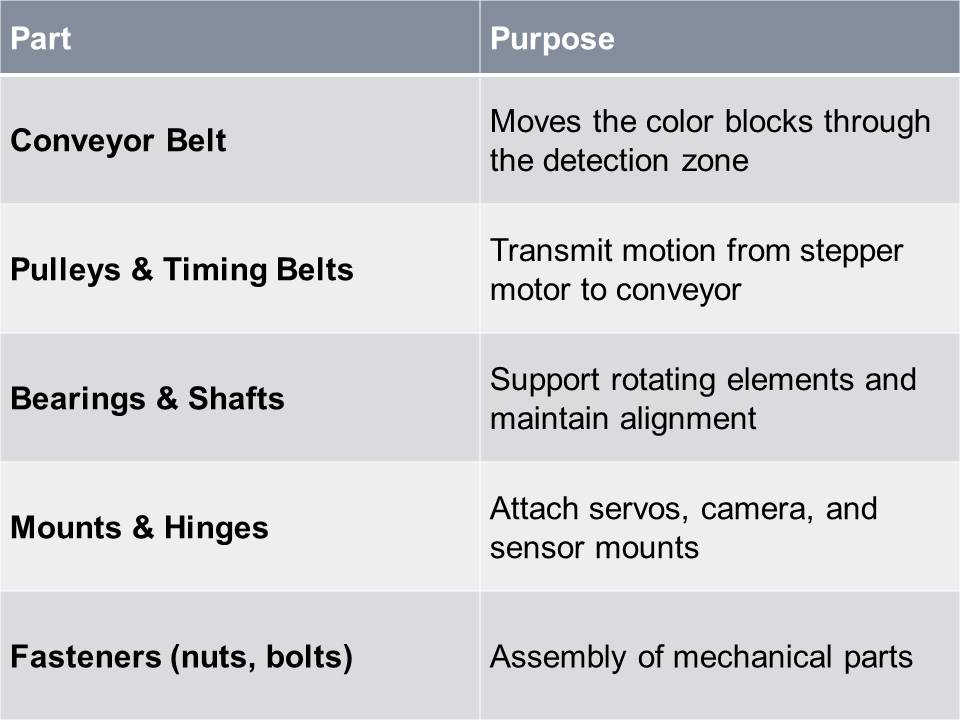

2. Mechanical Structure:

• A custom conveyor belt frame to carry color blocks through the detection zone.

• Design and alignment of the stepper motor (NEMA 17) with pulley and belt systems for stable linear motion.

3. Robotic Sorting Mechanism:

A servo-based robotic arm or pusher system that sorts blocks into predefined bins based on color classification.

• SG90 servos for precise, light actuation.

• MG995 servos for heavier-duty operations like arm lifting and block placement.

4. Control and Integration Circuit:

A centralized control system based on the ESP32-C3, handling:

• Input from the vision system or sensor module.

• Output signals to servos and stepper motor drivers.

• Power distribution and regulated operation of all components.

5. Embedded Software and Control Logic:

Firmware for ESP32-C3 to manage:

• Communication with the camera module or PC.

• Decision-making based on image input.

• Control signals to actuators based on detected color.

6. Power Management:

A regulated power system design to safely supply different voltage levels to:

• ESP32-C3 (3.3V or 5V).

• Servo motors (typically 5–6V).

• Stepper motor (12V via driver module)

What materials and components will be used?

The Color Sorting Robot will be built using a combination of electronic components, mechanical parts, and structural materials. Below is the detailed list:

1. Electronic Components:

2. Mechanical Components:

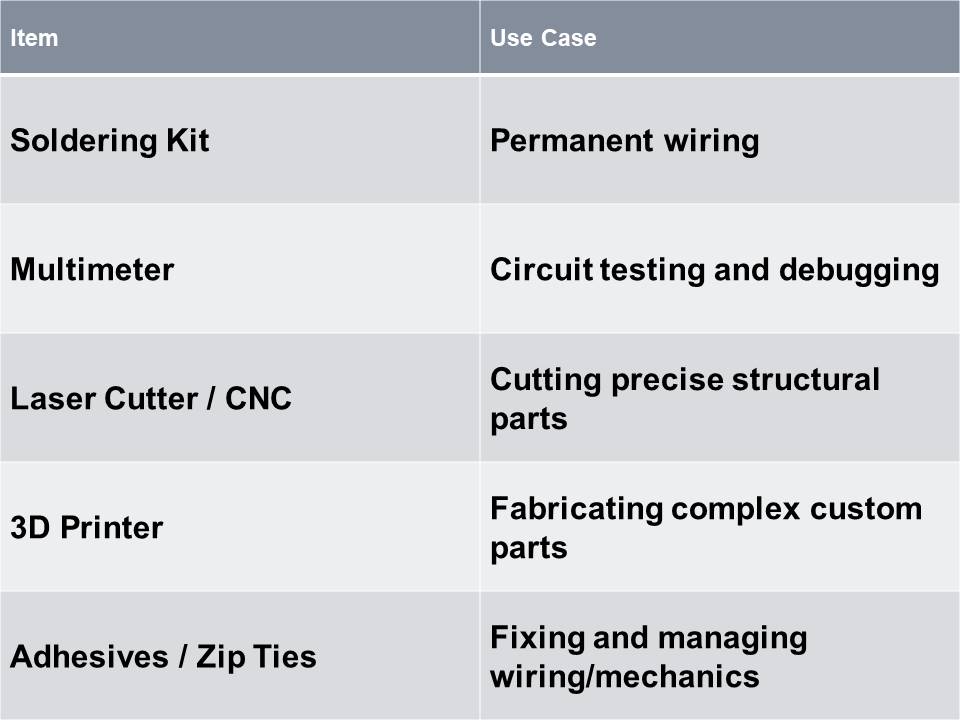

3. Optional Tools & Supplies:

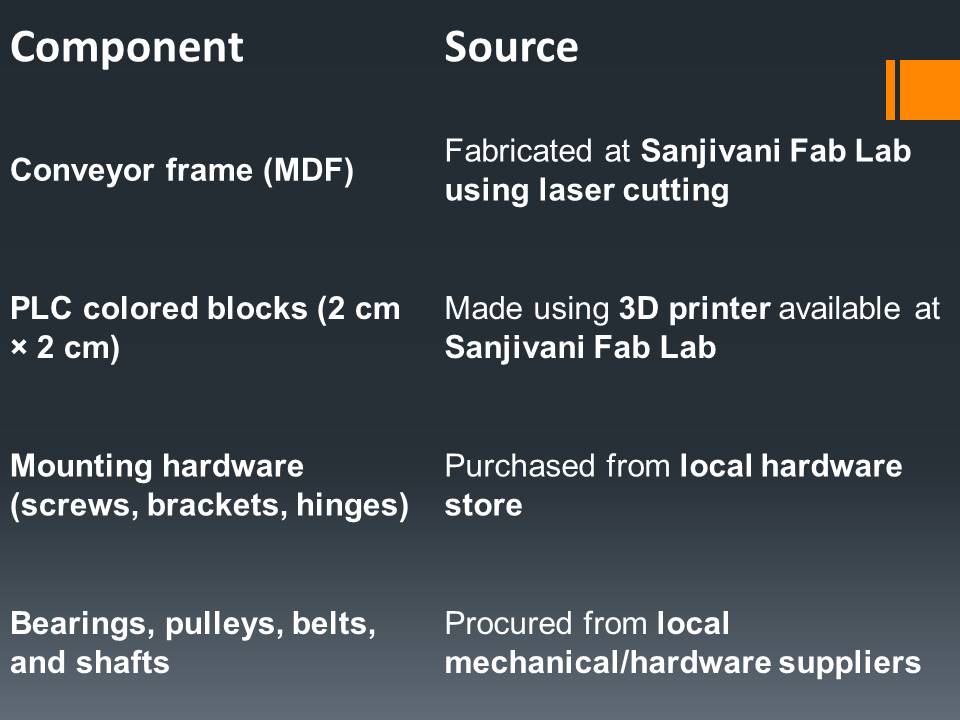

Where will they come from?

All components and materials required for the Color Sorting Robot will be sourced as follows:

Electronic Components

(All provided by Sanjivani Fab Lab)

ESP32-C3 microcontroller

Web camera

SG90 servo motors (×3)

MG995 servo motors (×3)

NEMA 17 stepper motor

Regulated power supply

Wires, connectors, jumper cables, breadboard/PCB

Mechanical and Structural Components

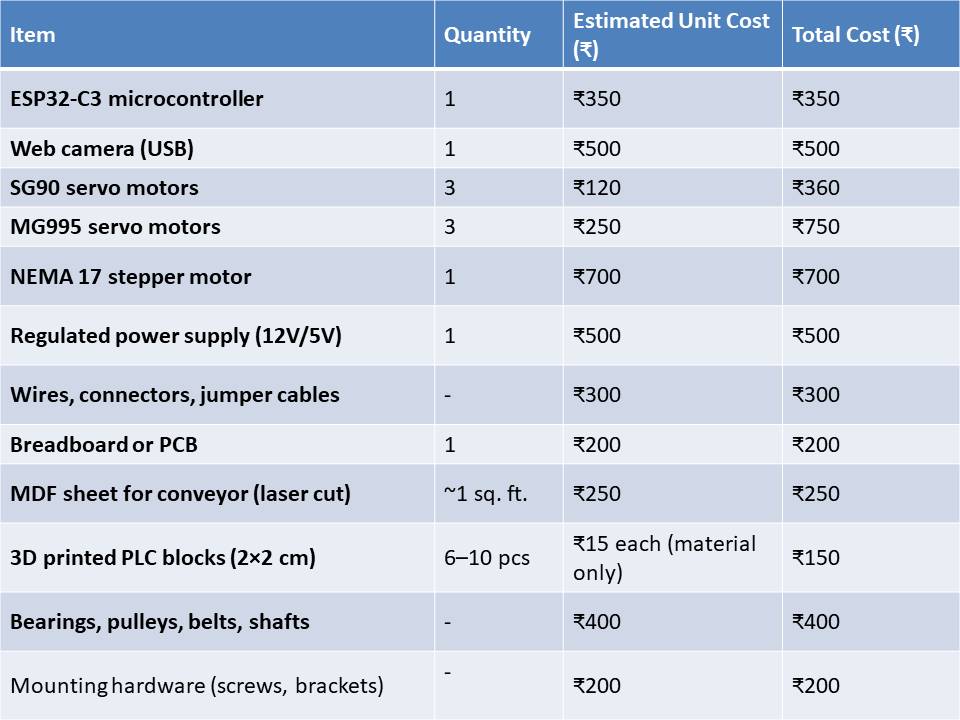

How much will they cost?

This cost estimate assumes that fabrication (laser cutting, 3D printing, soldering) is done in-house at Sanjivani Fab Lab, so only material costs are considered.

What parts and systems will be made?

The Color Sorting Robot will include both hardware assemblies and software systems developed during the project. These are:

Mechanical Parts to be Made:

1. Conveyor Belt Frame:

• Made from MDF and laser-cut at Sanjivani Fab Lab.

• Supports the motion of the colored blocks through the detection zone.

2. 3D Printed Color Blocks:

• Small 2 cm × 2 cm PLC plastic blocks, each with a different color, for sorting.

• Created using 3D printers.

3. Mounting Structures:

• Servo holders, camera stands, and electronic component brackets.

• Fabricated using MDF or 3D printing.

Electromechanical Systems to be Built:

1. Conveyor Drive System:

• Uses a NEMA 17 stepper motor, pulleys, and belts.

• Moves blocks in front of the vision system.

2. Color Sorting Mechanism:

• Robotic arm or gate system using SG90 and MG995 servo motors.

• Activated based on detected block color to sort into specific bins.

3. Power Distribution System:

• Supplies required voltages (e.g., 5V, 12V) to all motors and microcontroller.

• Includes regulated power supply and wiring layout.

Software & Control Systems to be Developed:

1. Image Processing and Color Detection:

• Code to process images from the web camera and classify block colors using RGB or HSV values.

• Possibly developed using OpenCV (on PC or integrated with ESP32-C3, if feasible).

2. Embedded Control Code:

Program for ESP32-C3 to:

• Read data from image processing system.

• Control stepper motor speed/direction.

• Trigger servo motors based on color classification.

3. System Integration and Logic:

• Coordination between image capture, detection, movement, and sorting.

• Implemented as a finite state machine or sequential logic.

What processes will be used?

Process Used:

1. PCB Milling

Used to fabricate the custom PCB for interfacing the ESP32-C3 microcontroller with servos, stepper motor driver, and power connections.

2. Laser Cutting

Employed for cutting MDF sheets to make the conveyor frame, support structure, and motor mounts.

3. 3D Printing

Used to manufacture:

• 2 cm × 2 cm colored PLC blocks.

• The entire robotic arm assembly including links and gripper.

• Servo brackets and structural connectors.

What questions need to be answered?

• How accurately can the system detect and differentiate colors using the camera and image processing?

• How precise is the robotic arm’s movement during the sorting operation?

• Is the synchronization between conveyor motion, color detection, and sorting mechanism well-timed?

• Can the conveyor system run smoothly with the NEMA 17 stepper motor setup?

• Are the servo motors (SG90 & MG995) strong enough for the robotic arm’s movement?

• Is the power supply adequate for all components running simultaneously?

• Can the ESP32-C3 handle real-time control of motors based on color input?

• How will the logic be implemented – state machine, interrupt-based, or polling?

• What is the accuracy rate of correct sorting after multiple trials?

• What improvements can be made to increase speed or reduce sorting errors?

How will it be evaluated?

The following contains the minimum criteria for a successful final project:

1. Ease of Use:

The robot can be easily assembled and operated by users with basic knowledge, using the provided documentation, wiring guides, and setup instructions.

2. Educational Value:

The project enhances understanding of color detection, mechanical automation, and control systems. Users demonstrate improved knowledge of embedded systems, servo/stepper motor control, and basic image processing concepts through demonstrations or assessments.

3. Component Durability:

All components (servo motors, stepper motor, PCB, 3D printed parts, and conveyor) must withstand repeated operation without failure or degradation in performance.

4. Cost Efficiency:

The overall cost of the robot is optimized using in-house fabrication (3D printing, laser cutting, PCB milling), and remains significantly lower than commercial sorting or training robots with similar functionality.

5. Visual Appeal:

The robot has a clean, compact design with well-assembled structural parts. The use of colorful blocks and labeled sections makes it visually engaging and suitable for demonstration or educational purposes.

6. Interactive Learning:

The robot responds interactively to different block colors, triggering accurate sorting actions in real time. Users can clearly observe the role of each component—camera, microcontroller, motors, and sorting arm.

7. Safety:

All components are safely enclosed; the mechanical parts are free of sharp edges, and the electronics are powered via a regulated supply. The system is safe for handling and observation by students aged 12 and above.