Week 12 - Mechanical Design, Machine Design

Assignment

Mechanical Design (part 1 of 2)

Group assignment:

Design a machine that includes mechanism + actuation + automation + application

Build the mechanical parts and operate it manually

Document the group project

Individual assignment:

Document your individual contribution

Machine Design (part 2 of 2)

Group assignment:

Actuate and automate your machine

Document the group project

Individual assignment:

Document your individual contribution

5 axis machine

For our Machine Week, our team looked at different machines and set out to build a 5-axis machine with an open head design. The aim was to allow for different interchangeable tool heads, such as a pick-and-place module or a spindle head, making the machine versatile for various applications.

Group Organisation and My Role

To make the development process more efficient, we divided our team into subgroups focusing on mechanics, electronics, and software.

I was actively involved in the Electronics Team, where we were responsible for designing and producing the custom control board.

Link to the Group page

PCB Design and Production

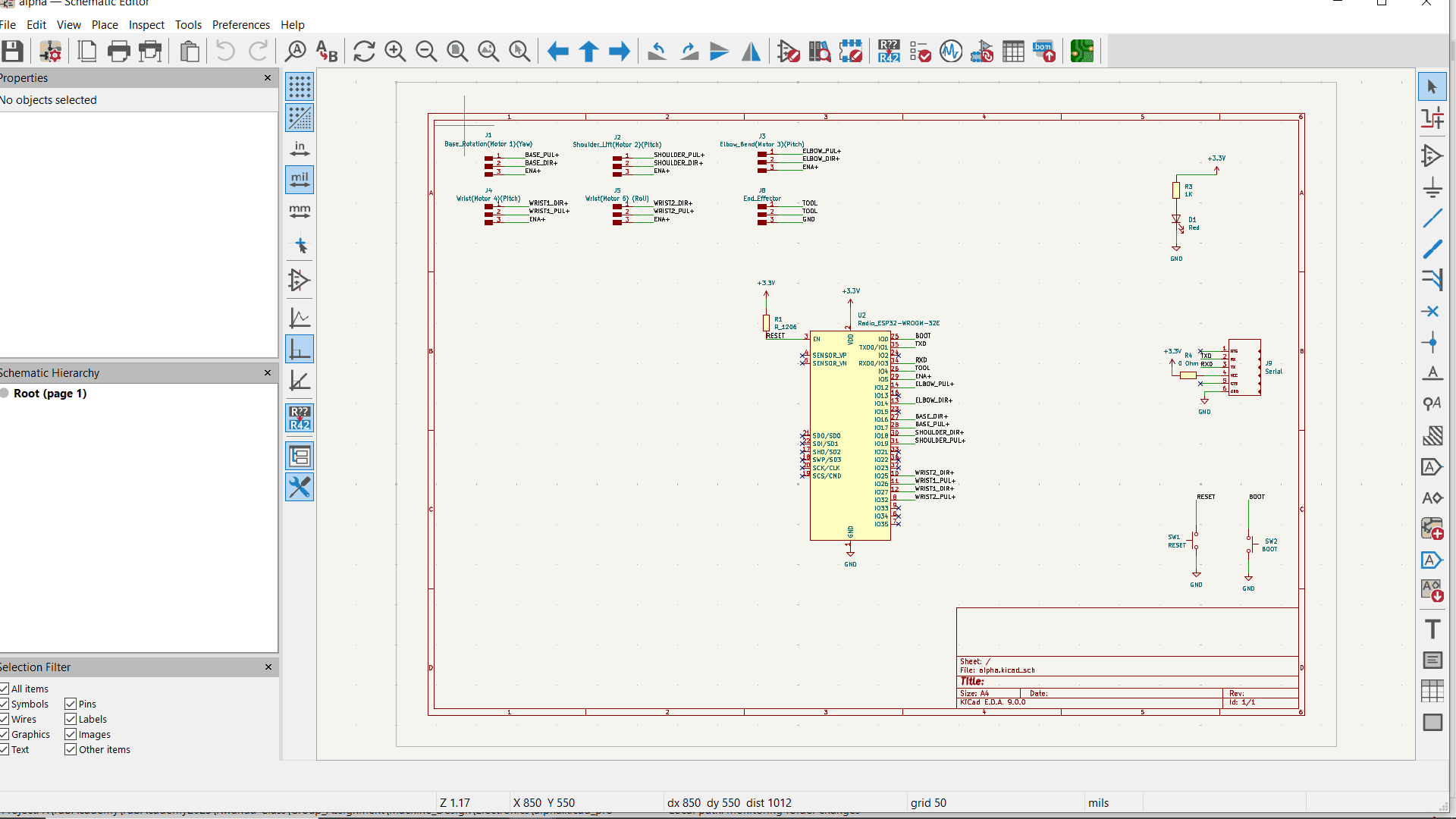

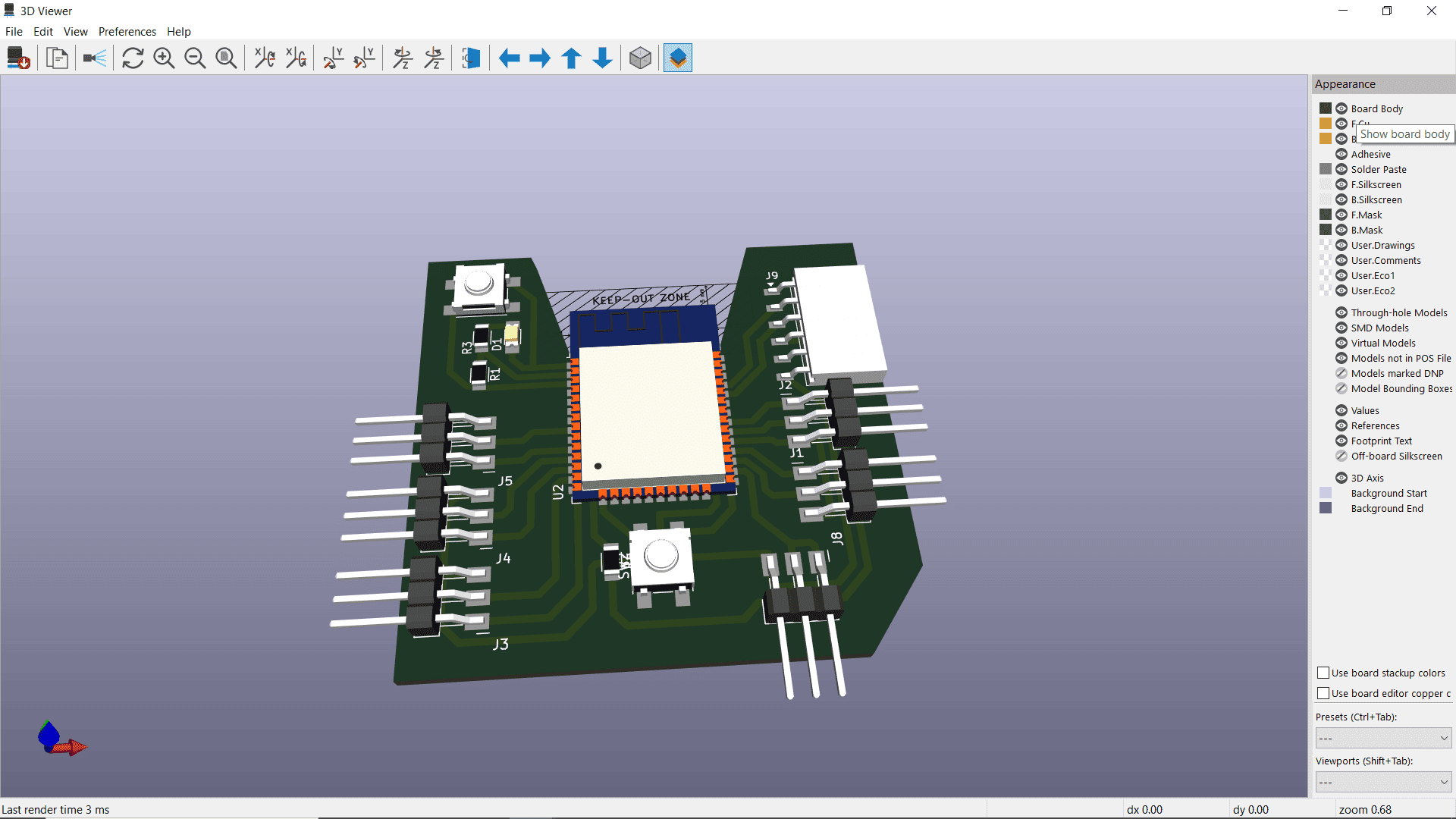

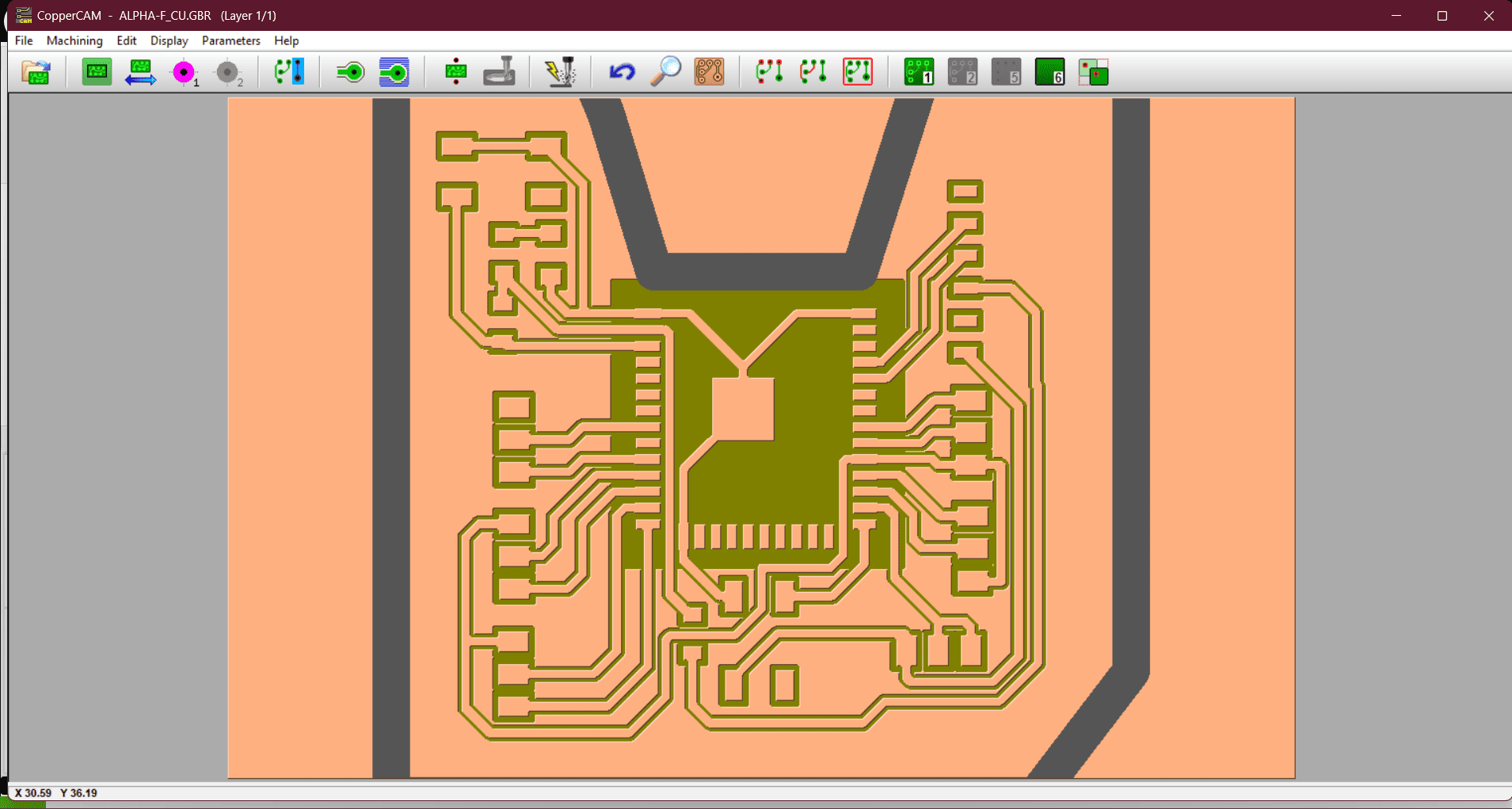

Together with my teammate, we designed a custom PCB using the ESP32-WROOM microcontroller. The board includes:

- Two external push buttons for Reset and Boot.

- Pin headers extended for five stepper motor drivers and one servo motor (for the tool head).

- Serial header for programming the ESP32.

- Power LED to indicate board status.

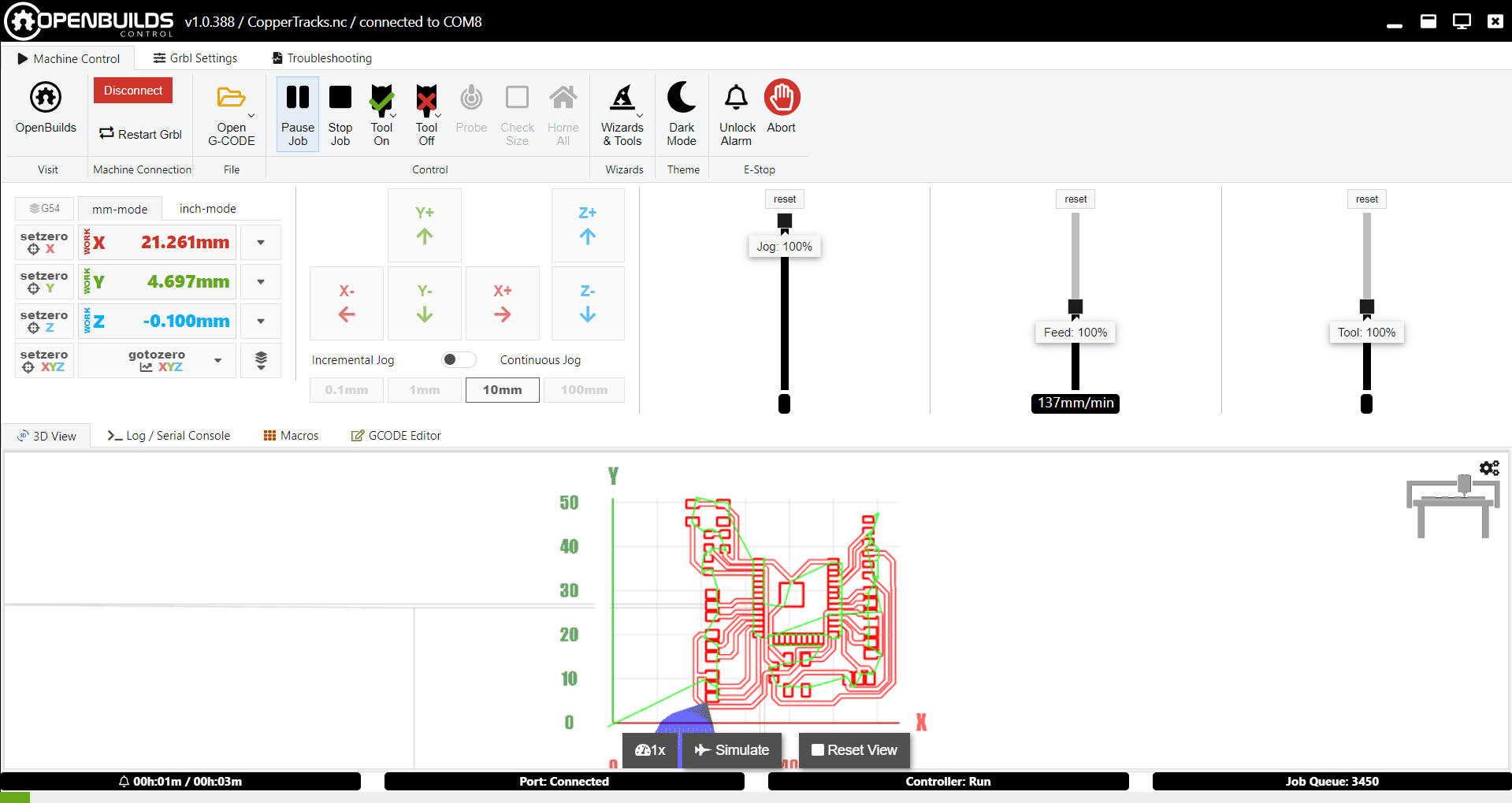

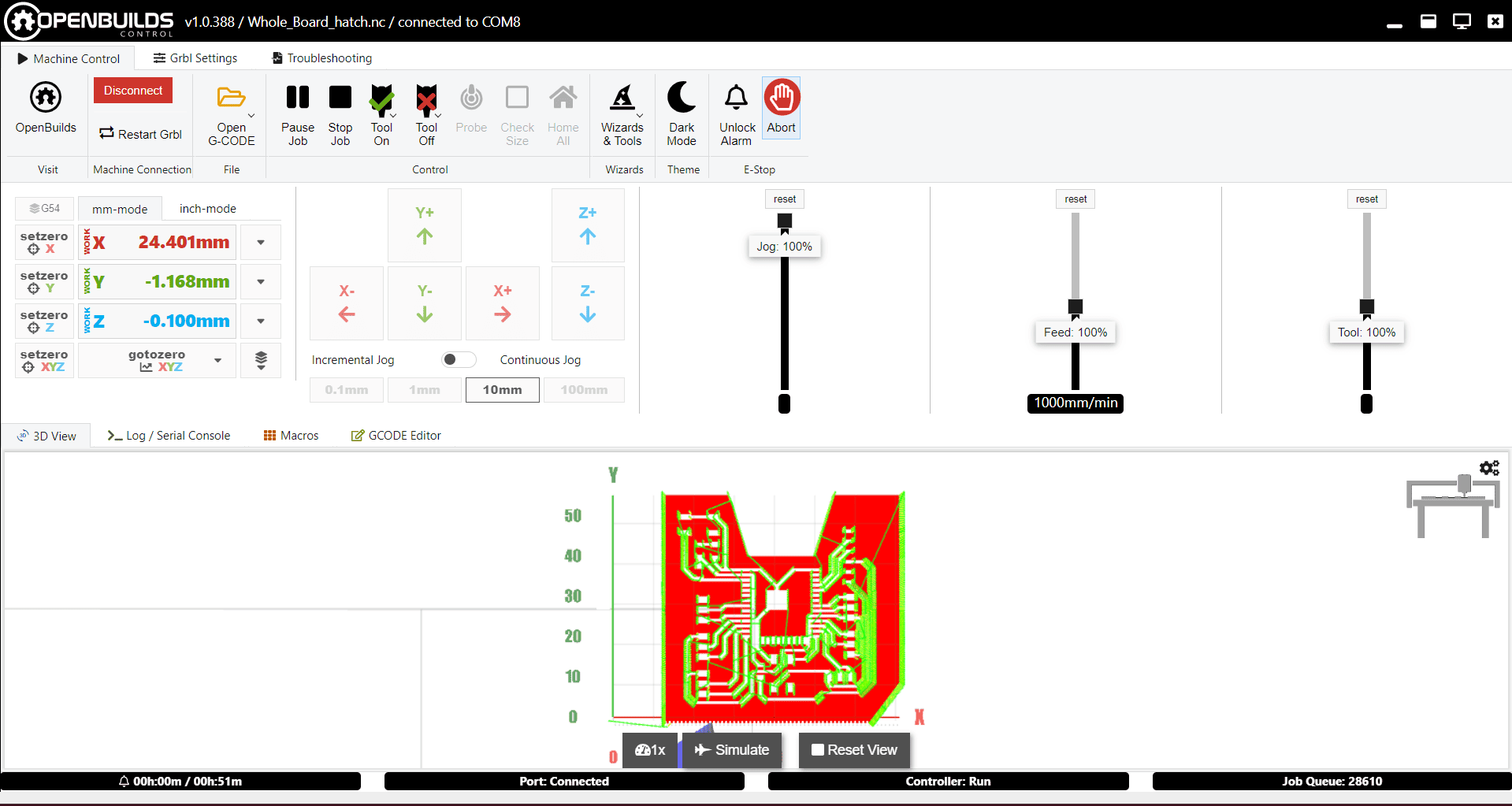

PCB Milling

After completing the design, we exported the files and used ModsProject to generate the required G-code. We milled the PCB using the OpenBuilds CNC machine.

To improve the board's final appearance and to reduce shorting risks, we also cleared the copper from unused regions of the board.

Additional Contribution - 3D Printing

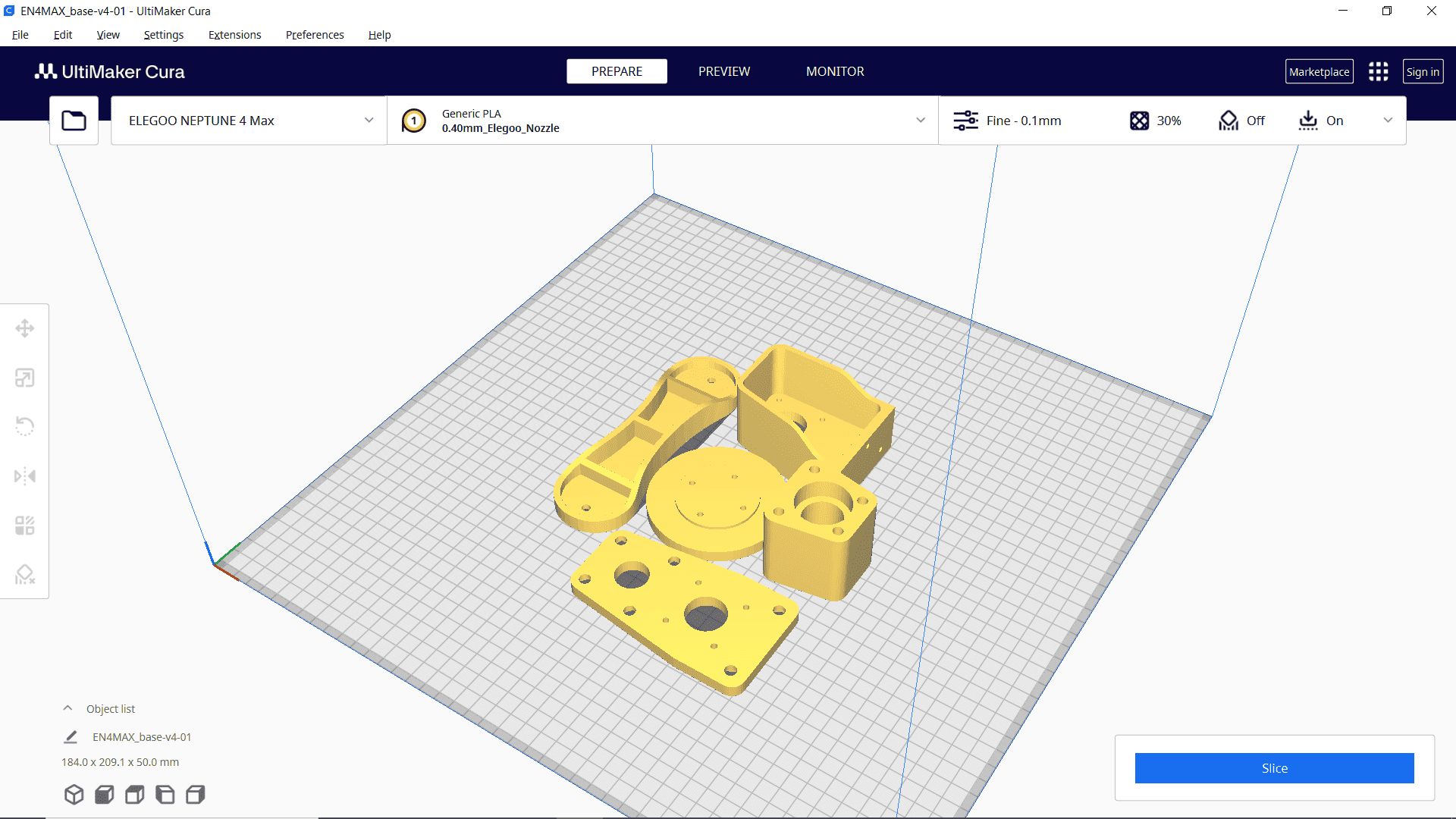

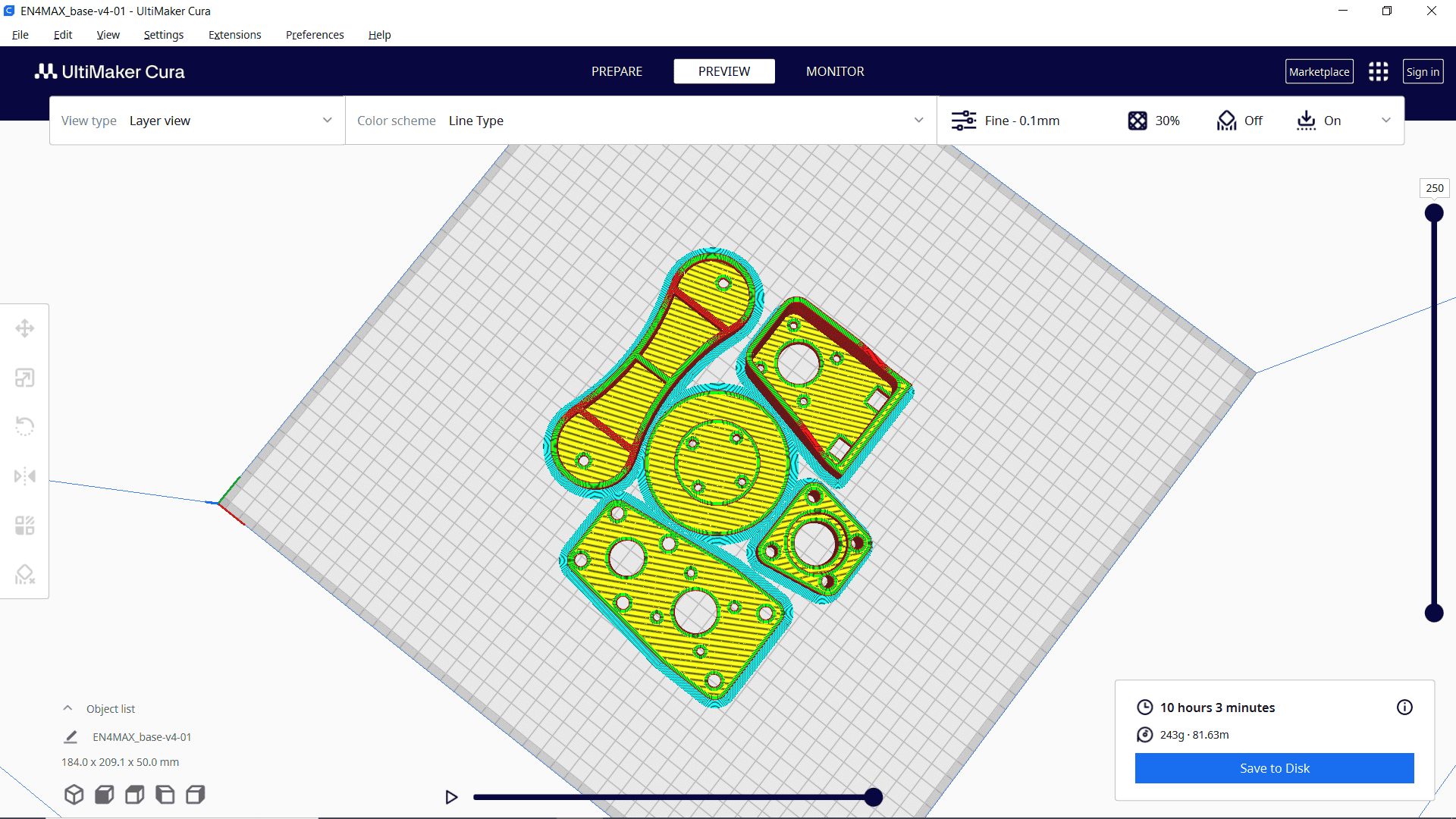

In addition to the electronics work, I also contributed to the mechanical team by preparing the sliced files and printing various machine parts. We used an ELEGOO Neptune printer with PLA filament, which provided sufficient strength and precision for most structural components.