Final Project - Bionic Hand

1. Project Description

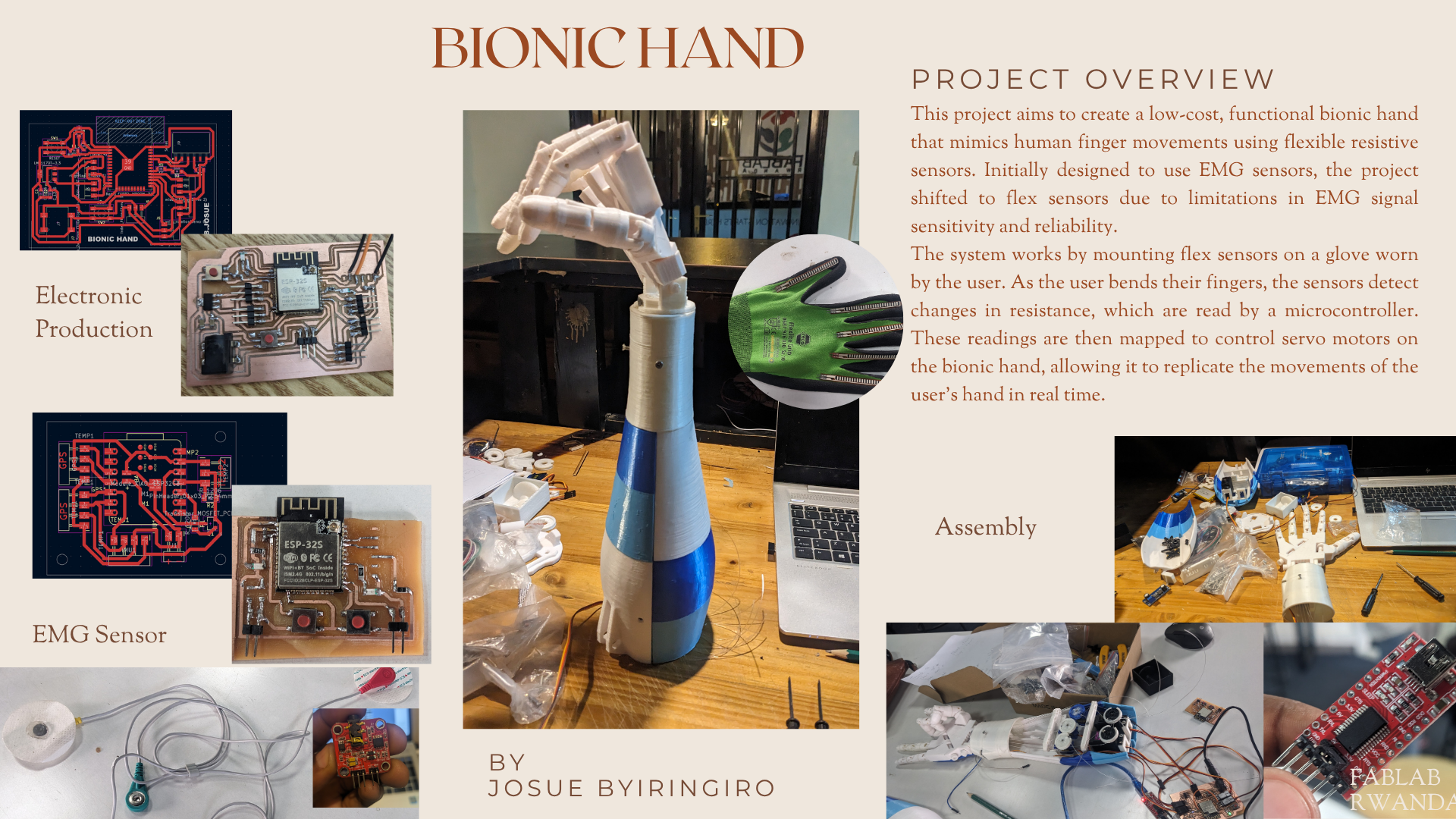

This project is a 3D-printed, muscle-controlled bionic hand designed to assist individuals with upper-limb disabilities or amputations.

It features five independently actuated fingers and a rotating and tilting wrist, controlled wirelessly via muscle movements.

Originally designed to use EMG (electromyography) sensors, the system was adapted after the initial EMG sensors failed due to poor signal quality.

A custom glove embedded with flexible resistive sensors was created as a temporary yet functional control solution.

The glove detects finger or forearm movement based on resistance change and controls the bionic hand wirelessly.

2. Motivation

In Rwanda, access to affordable, functional prosthetics remains a serious challenge, especially in underserved communities.

High costs, limited availability, and dependence on imported technologies leave many individuals with limb loss without effective support.

This project is driven by the desire to build local, low-cost assistive solutions for Rwandans using digital fabrication and open-source tools.

By creating a bionic hand that is:

- 3D printable

- Built from accessible materials

- Controlled using simple electronics

3. System Overview

The system is divided into two main modules:

- Hand Unit

- Sensor Module (Glove)

3D-Printed Bionic Hand

Controlled by an ESP32 microcontroller.

Contains 5 servo motors that controls the fingers

Uses fishing line tendons to actuate movement.

A wearable glove with five flexible resistive sensors, one for each finger.

Detects bending or muscle movement.

Controlled by a Xiao ESP32-3C microcontroller that reads sensor values and transmits commands wirelessly to the hand unit.

4. How It Works

The user wears the glove and moves their fingers.

Each flexible sensor changes resistance depending on motion.

The glove Xiao ESP32-3C processes these changes and sends a wireless command to the hand ESP32 microcontroller.

The bionic hand receives the signals and moves the appropriate servo(s).

Servos pull nylon tendons to flex each finger.

5. Components

| Category | Material | Purpose |

|---|---|---|

| Microcontroller | ESP32-WROOM module | Central controller for both sensor unit and hand unit, handling signal processing and servo control |

| Actuators | Servo motors (7x) | Five for finger movement, two for wrist rotation and tilt |

| Power | 5V power Supply + LiPo battery | Portable power sources for both the hand and the wearable sensor module |

| Mechanical | Plastic cord (nylon or fishing line) | Acts as tendon to transmit servo pulling force to finger joints |

| Structure | Filament (PLA) | Used to 3D print the hand structure, finger segments, wrist components, and enclosures |

| Resistors | Flexible Resistors | Used to track the finger movements |

| Enclosure | Gloves | To help fix flexible resistors well aligned to fingers |

6. Design and Fabrication

Hand

Initially it was an open source design from

InMoov I modified in Solidworks with my changes

The whole body was 3D printed.

3D Printing

Printed in PLA filament using Elegoo Neptune 4 max Printer

Print settings: 0.2mm layer height, 30% infill, -0.16 horizontal Expansion(That is when parts fit each other in my case)

Finger components were printed separately and assembled post-printing

Electronics and Wiring

Designed 2 PCBs for the hand and glove units

ESP32-S microcontroller for the hand unit

Xiao ESP32-3C microcontroller for the hang glove unit

Flex sensors read as analog inputs of the fingers.

Servo motors handles finger movements acording to signal provided

5V Power adapter for the hand unit.

3.7V rechargeable battery for the Glove unit

Sensor Glove

- Flex sensors sewn along finger lengths of a bought glove

- Wires soldered and routed to the PCB circuit board with an ESP32 microcontroller attached on the wrist strap.

7. Testing and Results

- Motion control tested by comparing finger bend in glove to hand movement.

- Communication between glove and hand was stable and responsive.

8. Final Assembly and Packaging

- All servo motors are mounted inside a 3D-printed housing together with its microcontroller

- Tendons run internally through channels to each finger.

- The glove is compact and worn comfortably over the hand.

9. Future Plans

- Reintegrate EMG sensors once a better-quality set is available.

- Redesign hand for a more human-like appearance.

- Add touch sensing and feedback to improve control.

- Improve power management and add on/off switch.

- Partner with Rwandan prosthetic labs and organisations to test real-world application.

10. License

My project work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International (CC BY-SA 4.0) license.

Read More about the license

11. Slide and Video Presentation

Presentation Slide

Presentation Video

12. Files

3D Hand Design: STL files

Hand PCB: KiCad Design

Glove PCB: KiCad Design

Hand codes: Arduino Codes

Glove codes: Arduino Sketch