This week's group assignment focused on designing and building a five-axis robot arm with interchangeable tools at the end effector. The robot arm is intended to perform tasks such as milling and isolation routing. The project was divided into teams, each responsible for specific aspects: circuit design, mechanical design, firmware development, and interface design. This collaborative effort aimed to integrate these components into a functional and versatile robotic system.

we decide to make 3 groups

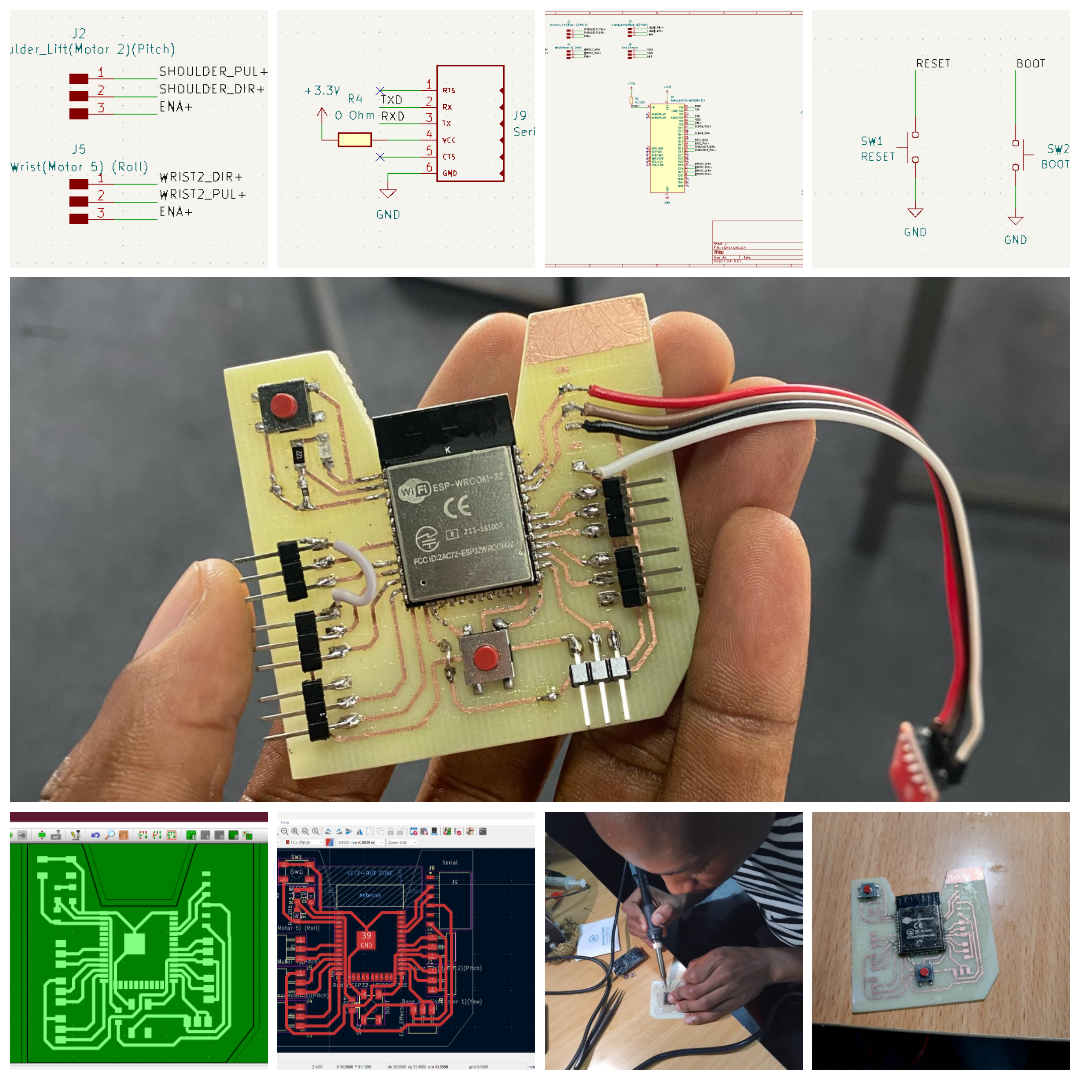

In this group, we focused on designing and printing the printed circuit board (PCB) for our machine. The PCB serves as the central control unit, integrating various components such as microcontrollers, sensors, and actuators. We utilized software tools to create the schematic and layout of the PCB, ensuring proper connections and functionality.

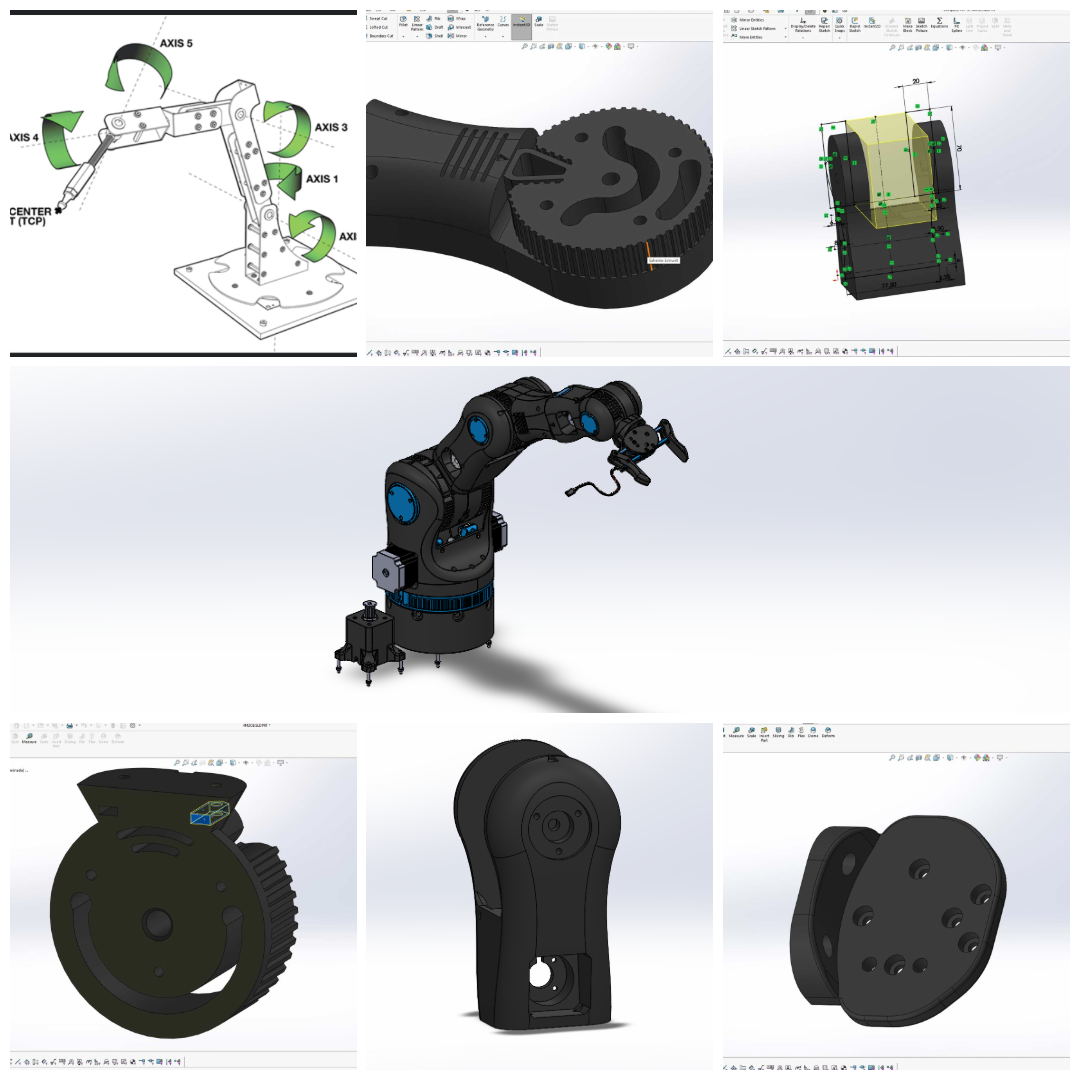

During the design and assembly phase, we faced a major challenge with structural overload. Initially, the combined weight of the 3D-printed parts and NEMA 17 stepper motors caused stress and instability at the arm’s joints. To solve this, we reinforced the weak sections in our designs and redistributed the weight for better balance. Through several iterations and team collaboration, we achieved a stable and functional mechanical prototype.

To accelerate our progress, we adapted an open-source design from BCN3D Moveo, modifying the parts to fit our specific requirements.

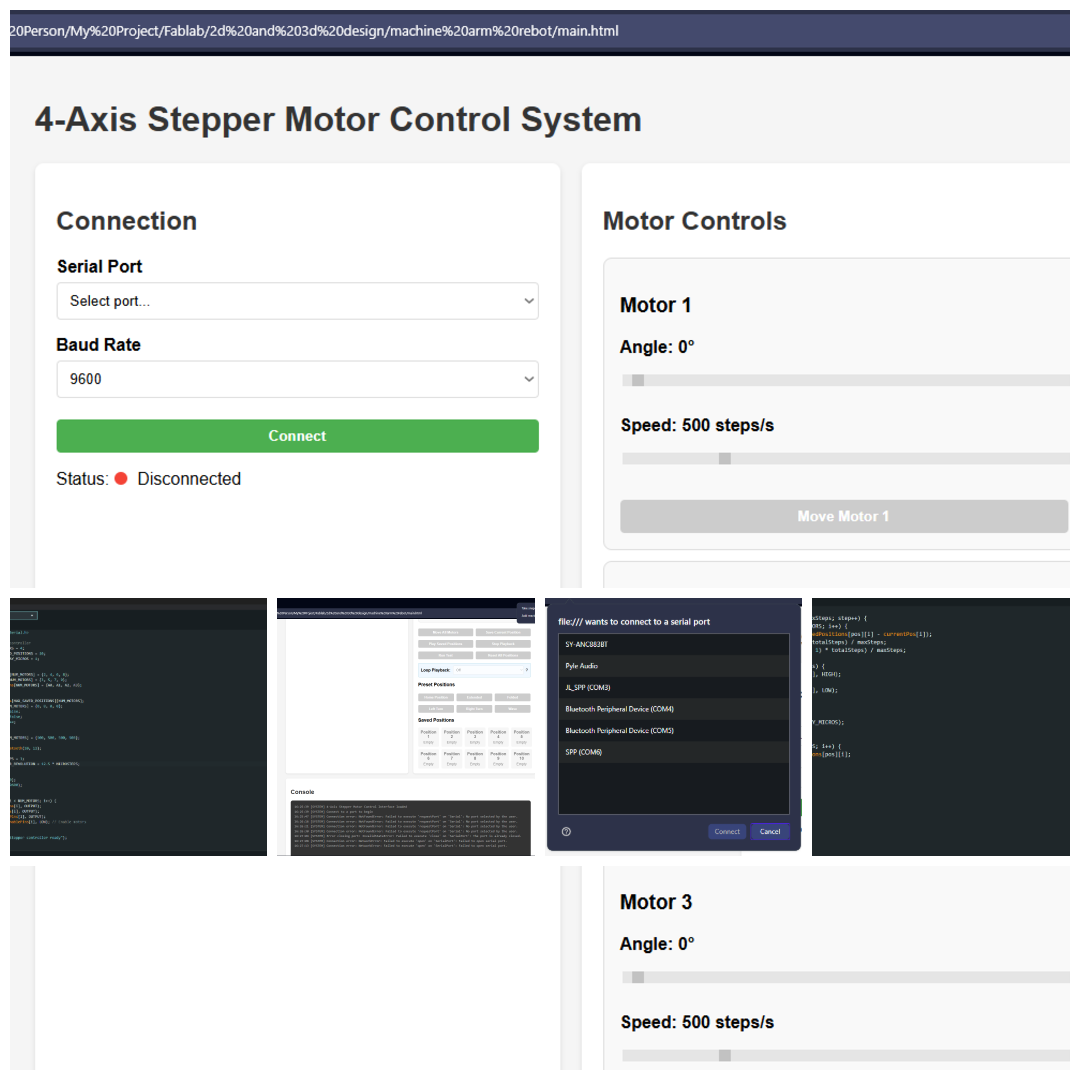

In this group, we focused on developing the firmware and interface for the machine. The firmware was programmed to control the stepper motors, allowing for precise movement and positioning of the machine. We utilized libraries and frameworks to facilitate communication between the microcontroller and the motors. The interface was designed to provide a user-friendly experience, enabling easy control and monitoring of the machine's operations.

In conclusion, the group assignment on machine design provided valuable insights into the collaborative process of creating a functional robotic system. Each team member contributed their expertise, resulting in a well-integrated machine capable of performing complex tasks. The challenges faced during the design and assembly phases were overcome through teamwork and innovation, leading to a successful project outcome.

We learned the importance of effective communication and collaboration in achieving a common goal. The project not only enhanced our technical skills in circuit design, mechanical engineering, and firmware development but also fostered a sense of camaraderie among team members. Overall, this assignment has prepared us for future challenges in the field of robotics and machine design.

We are grateful for the opportunity to work on this project and look forward to applying the knowledge and skills gained in future endeavors. The experience has been both educational and rewarding, and we are excited to continue exploring the possibilities of machine design and robotics.