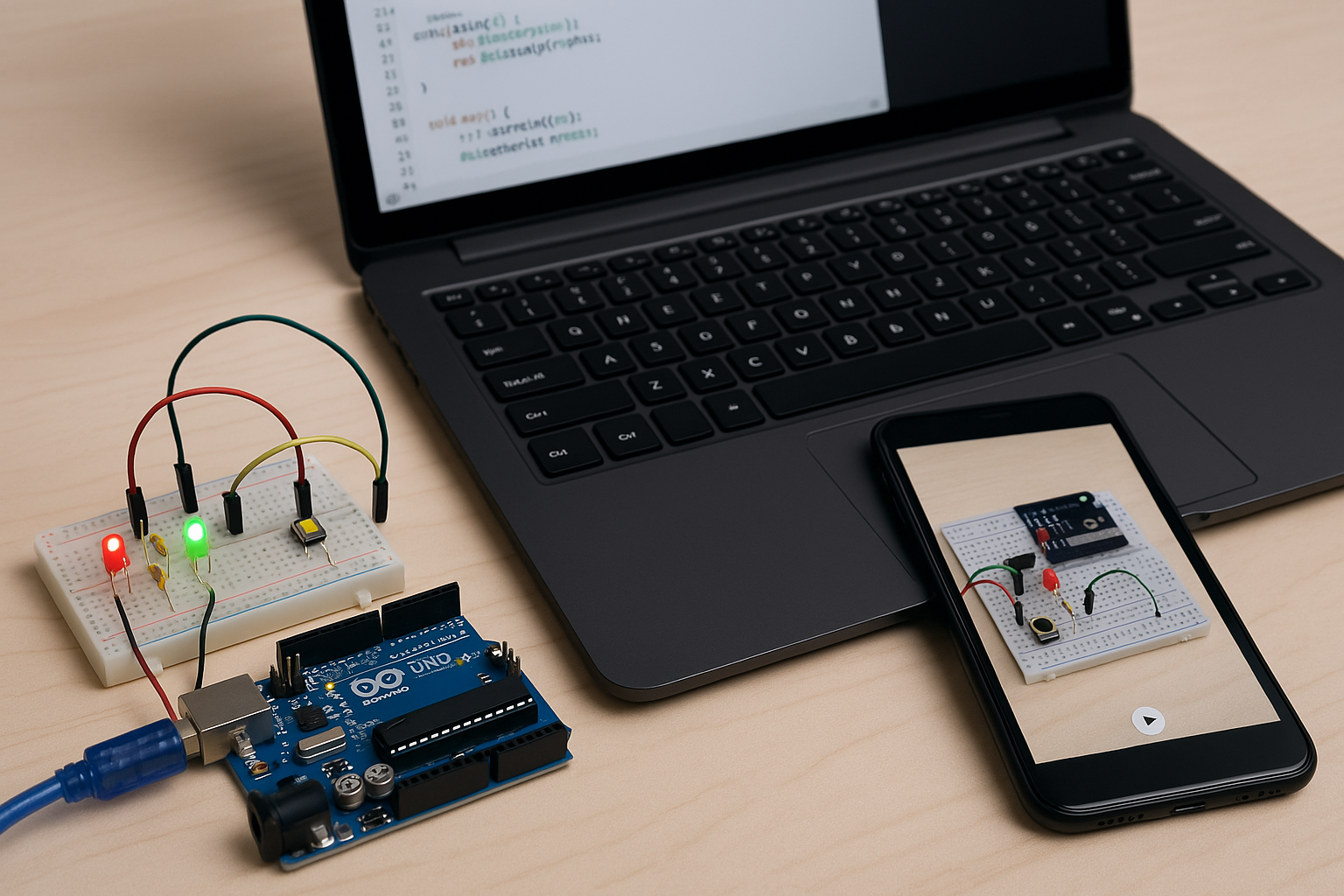

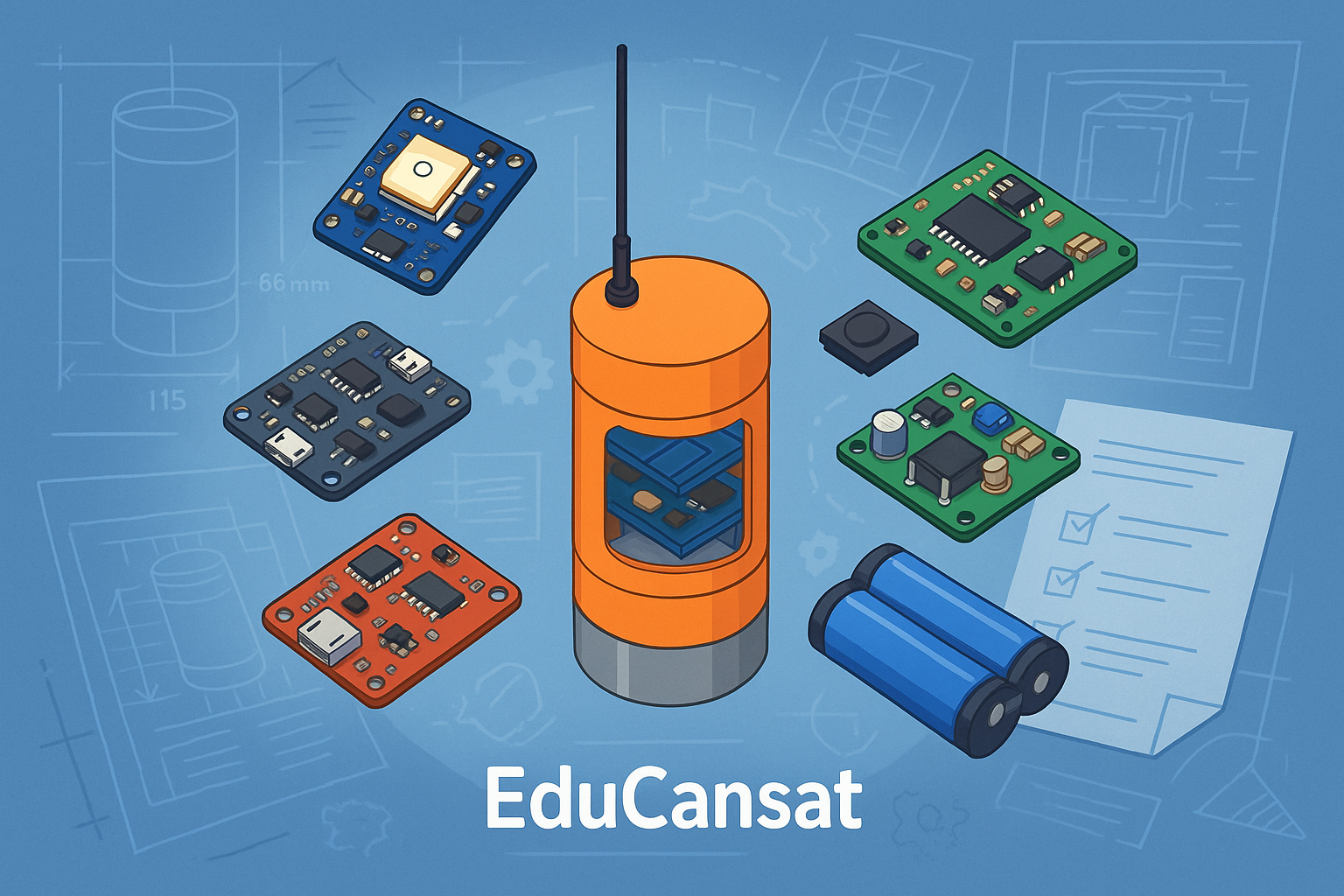

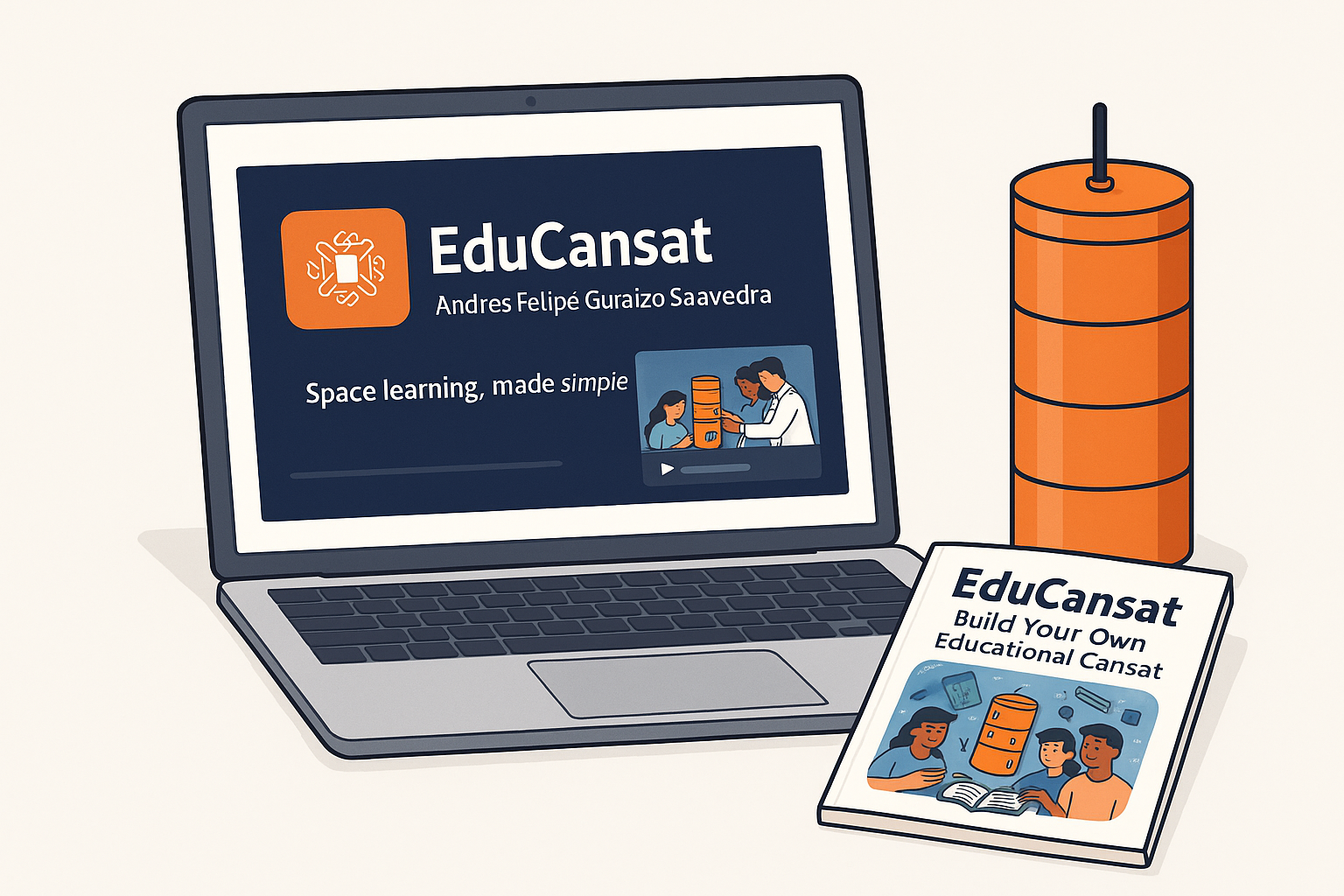

Week 1 Project management:

In the first week, the focus was on setting up the documentation site, configuring version control with Git, and outlining the EDUCANSAT project. This includes an initial sketch, key components, and its intended functionality. The page also details the process of website development and project management.