10. Mechanical Design And Machine Design

Hero shot

Shaker_In_Action from DENIS Sylvain on Vimeo.

Assignment

Problem

The fablab has acquired a UV printer. There’s a slight problem: the cartridges have to be shaken every day. You have to shake them all for about 1 minute, but above all, don’t make a mistake when you put them back in place.

Idea

Create a machine that can shake the cartridges so that we’re not stuck with this task.

Link to our Group week 10 page

Planning

We worked all together, with our instructor, on the design and functioning of this shaker.

Sylvain came with this idea that would help in the FabLab and searched for the codes to make it work.

As Elodie was better than me in 3D design and works already with Fusion360 for her own projects, she took the biggest drawing part of the machine and I did the small and easy parts, like the attachements, to get used to the Freecad program and learn with baby-steps how to draw in 3 dimensions.

We chose to work this way because we could only meet 1 day all together to do the project as we all have a job aside the Fab Academy.

So working each of us on our own part and bringing everything together this one day helped us a lot to finish it quickly.

That way we could all focus on how to change to code that Sylvain found to work with our purpose and also adjust the design of the machine that Elodie made.

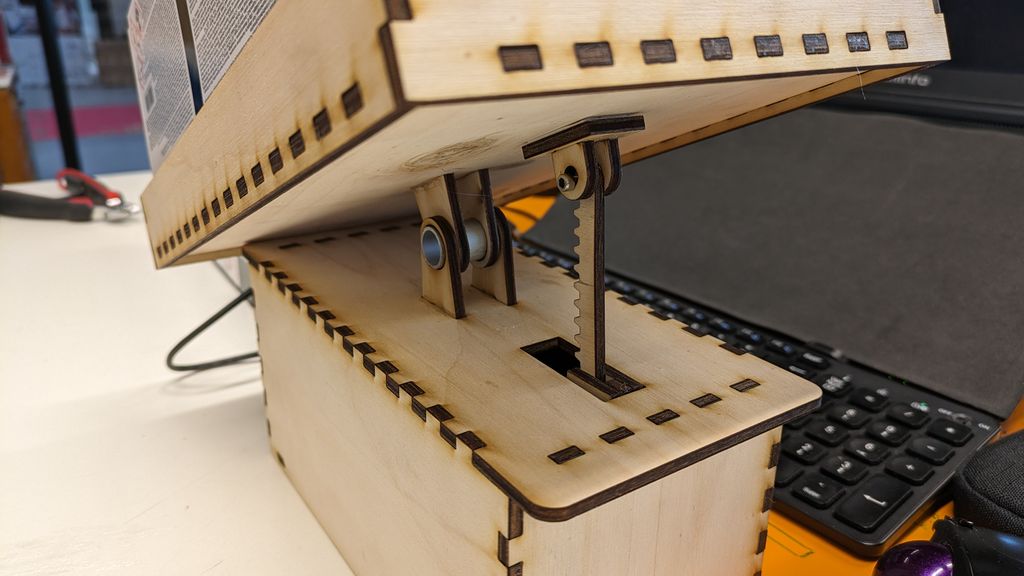

That's also why we did the biggest parts in wood using the laser cutter (only a few minutes to get done) rather than 3D print it. Faster to adjust if something is wrong.

I still did 3D printed the attachement part as it was a small piece to do and so that we would have some 3D print for the assignment.

My part of the job

As I told above, I took the "easy" 3D modelling part because I'm really struggling with this kind of design and the programs to use for it (but I also helped in working on the machine design, solving the issues, taking the pictures/videos, printing in 3D and documenting everything).

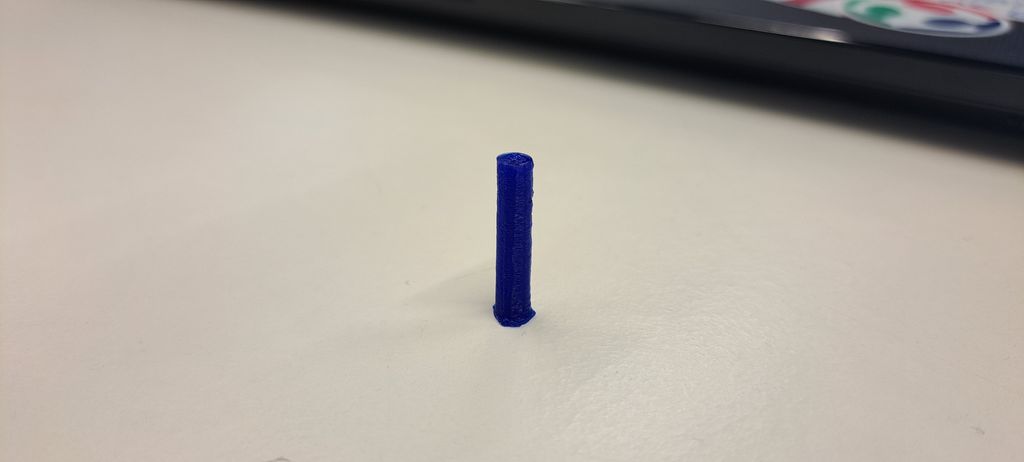

We needed a small piece to help stabilize the "arm" that would move to shake the cartridges.

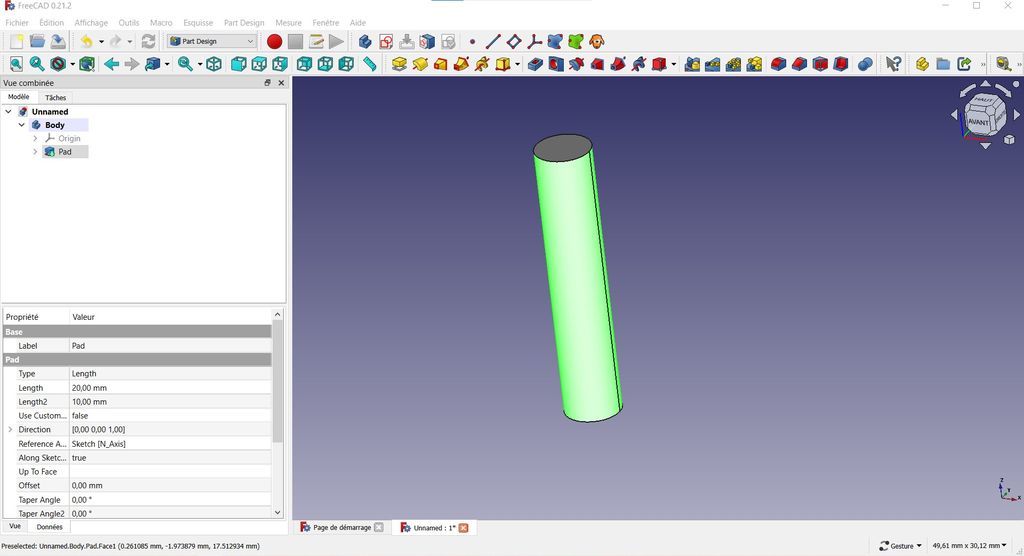

So I designed a little rod in Freecad by extruding (at the right dimensions) a circle.

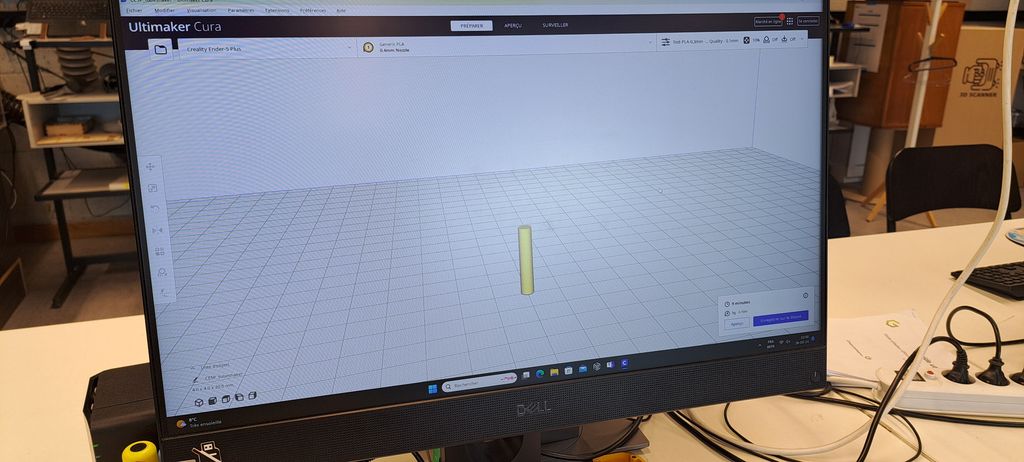

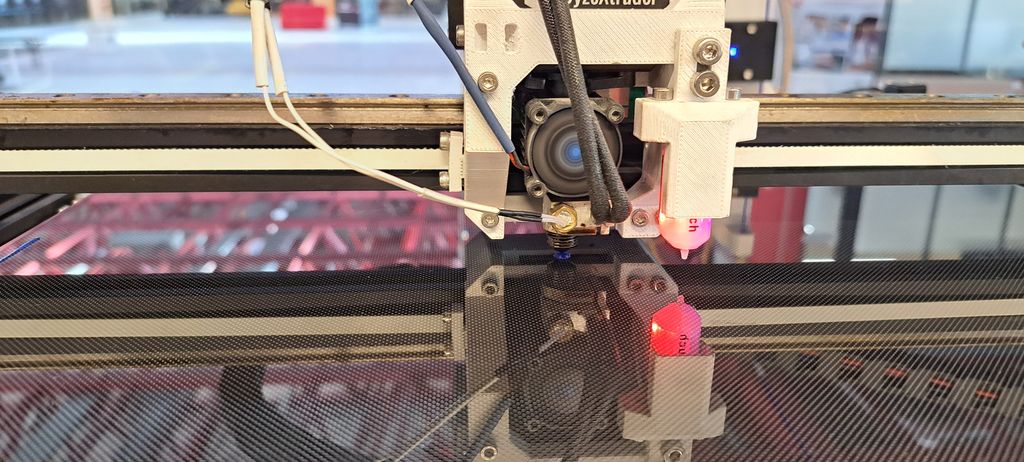

I then exported the .stl file and launched the 3D print with Cura on one of our Ender printer.

Unfortunately, this little rod wasn't strong enough to get the arm stabilized so we used a metallic nut with washers instead which was way better !

But hey ! I made it and found my way in the program after only... several hours ! ^^' (I'm not made for this !)

Resources