Week 17 - Invention, Intellectual Property, and Income

Intellectual Property

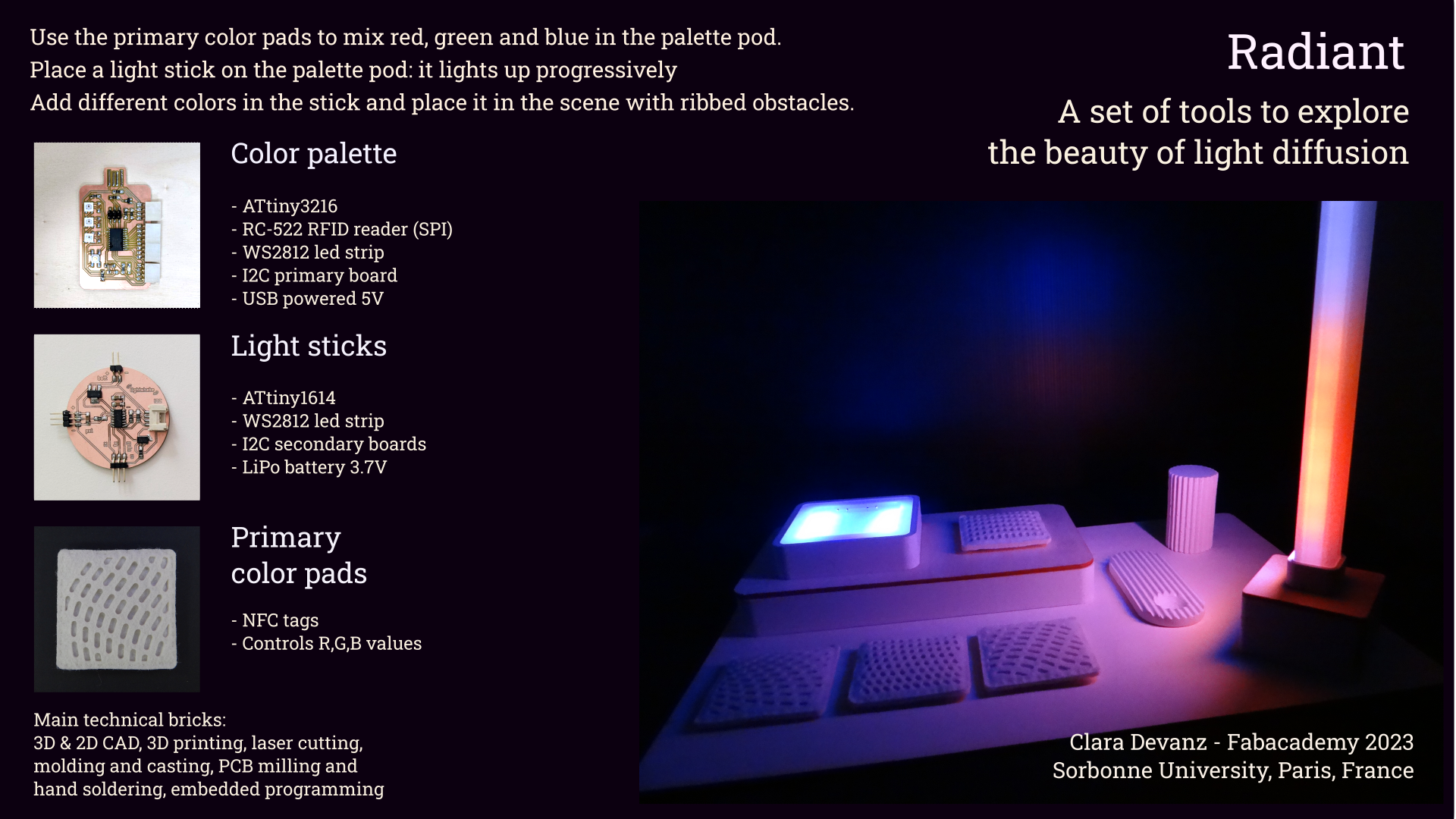

This project is not ment to generate any income. Moreover, it's experimental aspect is very suitable to a collaborative project. Thus, this light art practice itself could evolve along with the spreading of the project, leading to more refined and intuitive gestures, new types of scenes and environments, and a growing database of tools and objects to compose a custom set.

A great license for this diffusion would thus be an opensource copyleft license. Copyleft licenses require users to include the original copyright notice and the license text, and obligate users to make the source code of any modifications or derivative works under the same license as the original.

For Fabacademy, I may choose a more restrictive license to control at the beginning how such a project would be released and spreaded. For example, the creative commons license Attribution-NonCommercial 2.0 France (CC BY-NC 2.0 FR).

Project development

Drafts

One assignment for this week was to create a video and slide drafts for our final presentation.

[EDIT] the temporary video and slide uploaded at that moment has been updated, so here's the final presentation video and slide :

Progress made

This week I worked only on the candle light element.

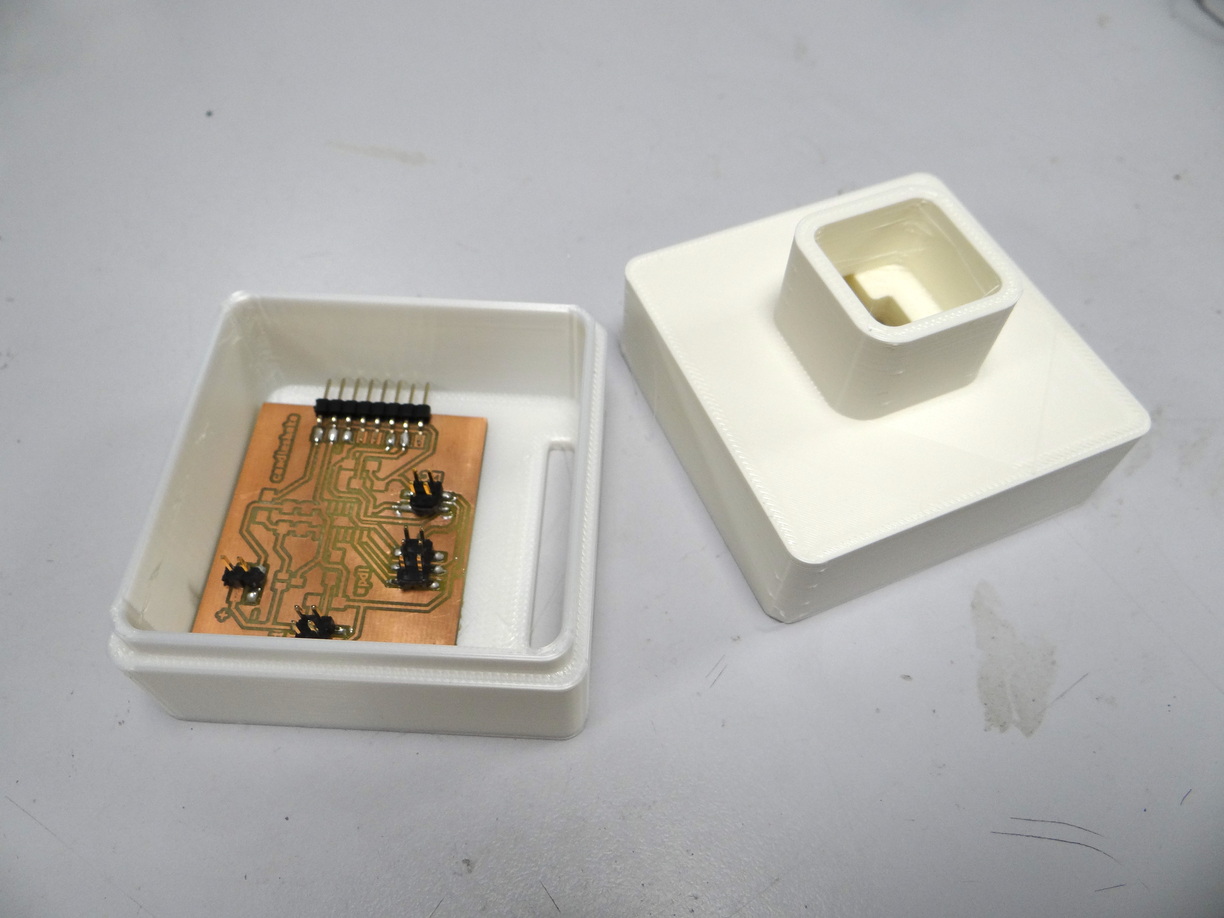

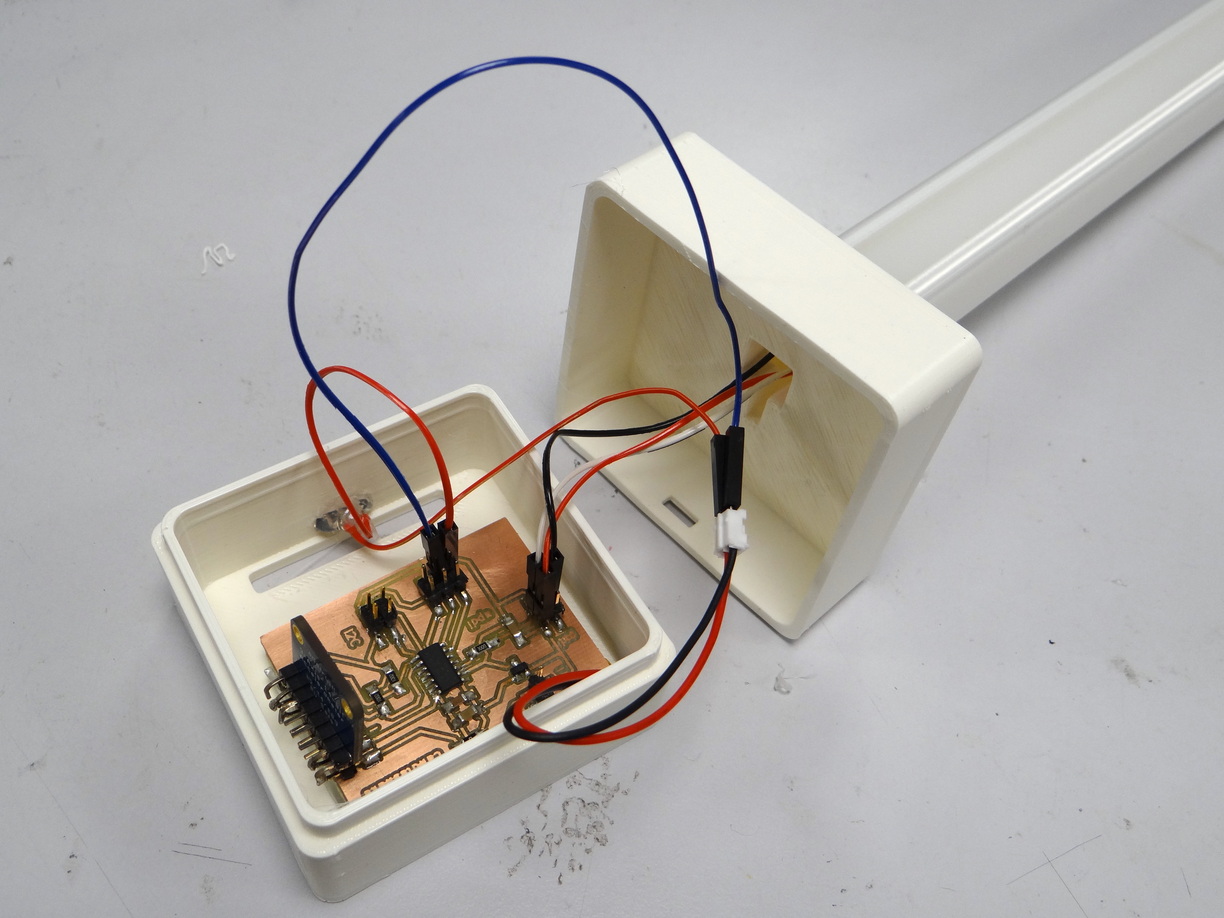

- I tested my PCB casing modelled with Fusion 360 and printed in PLA on Raise 3D Pro 2 machines. I adjusted my designs to obtain a case in two parts, top and bottom. The bottom part contains the PCB and battery. A first hole allow me to place a switch to turn the circuit on and off. A second hole will be used for the contact pads that will connect this circuit to the palette circuit.

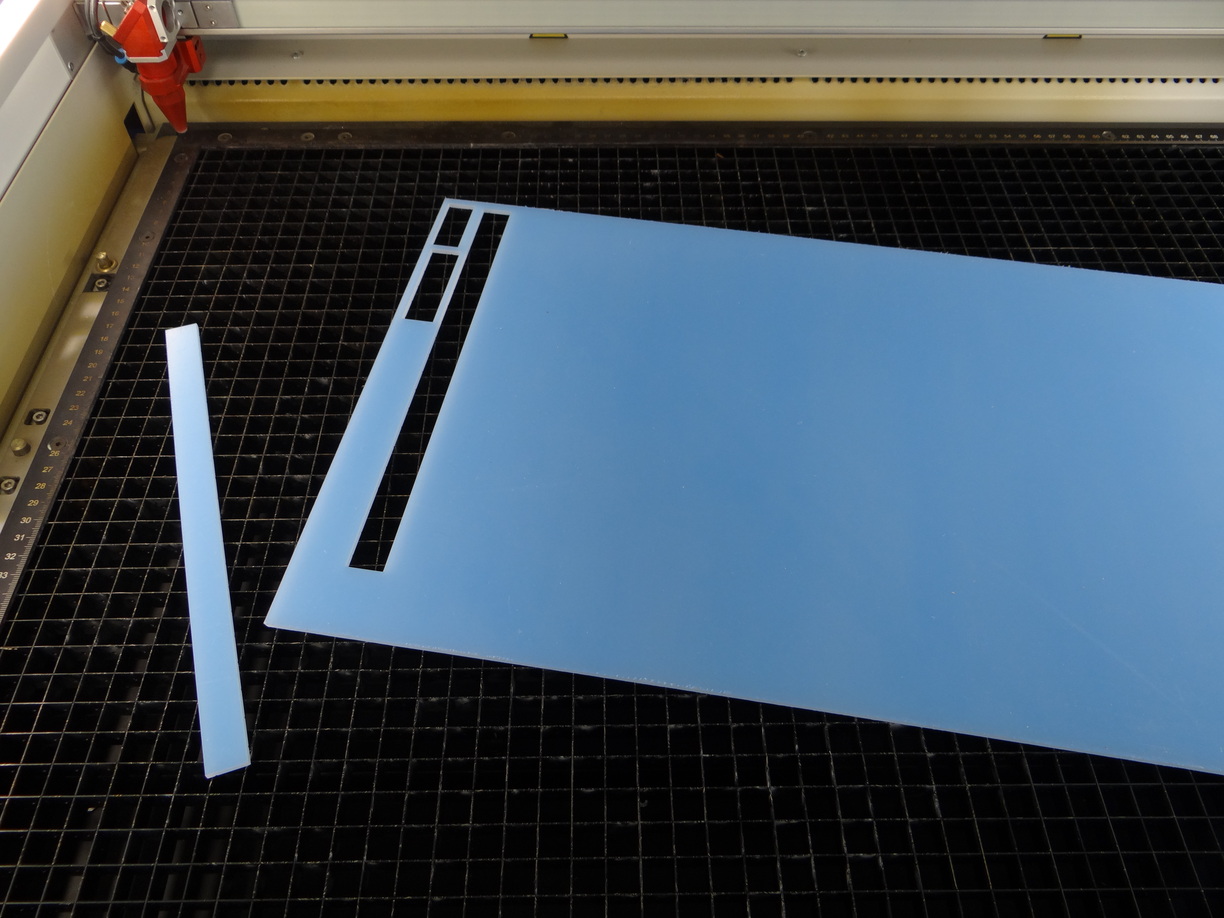

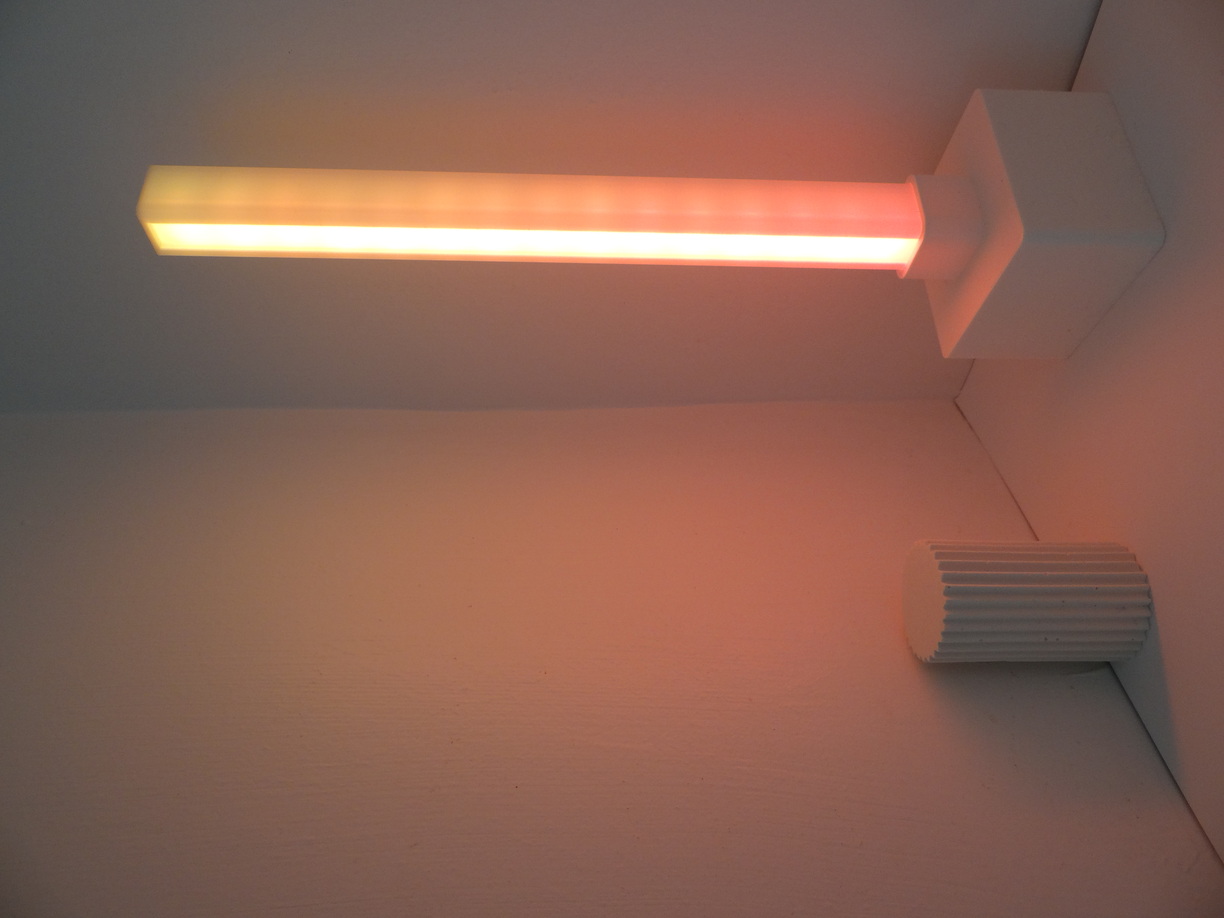

- I did the casing for the neopixel strip, also using Fusion 360. I printed the tube case and lasercut a board of Troglass LED acrylic to diffuse the light.

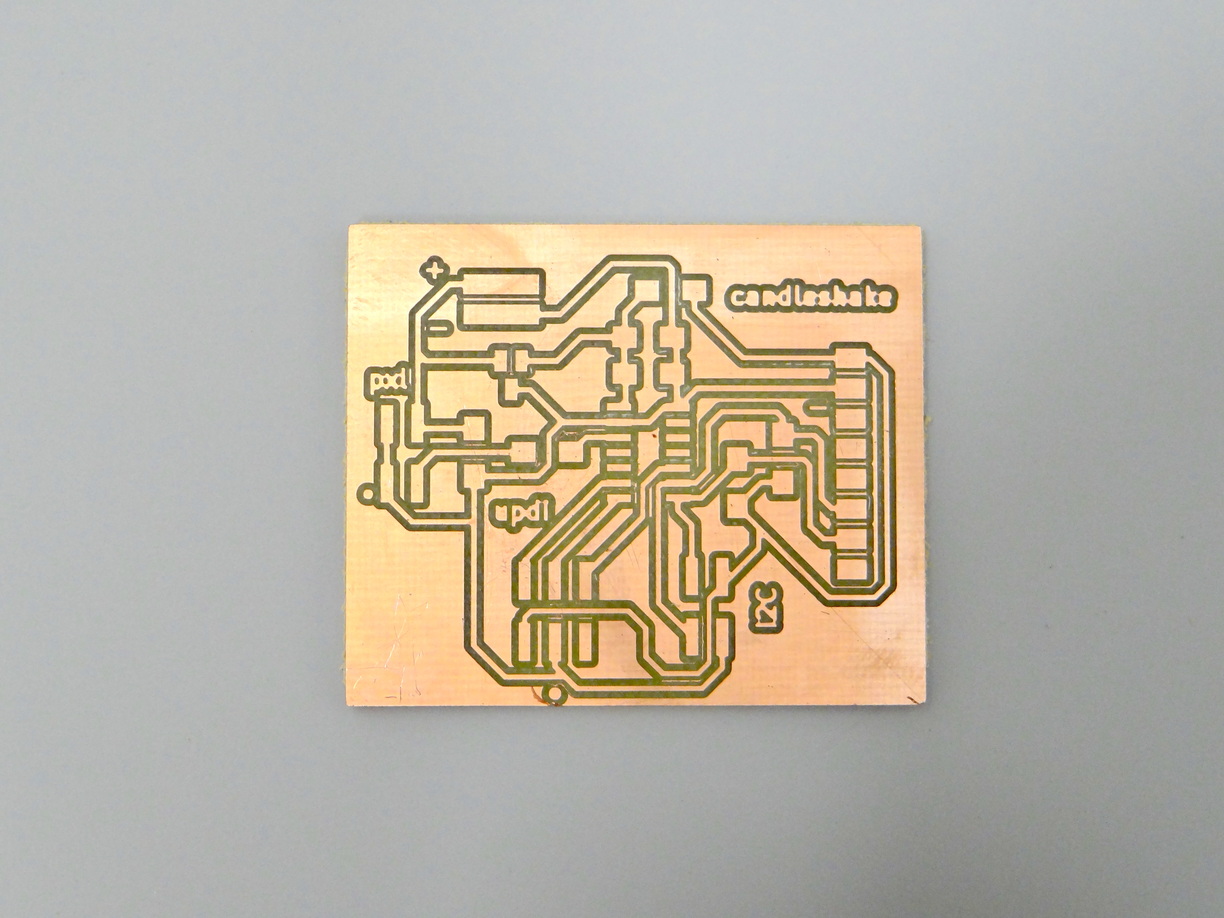

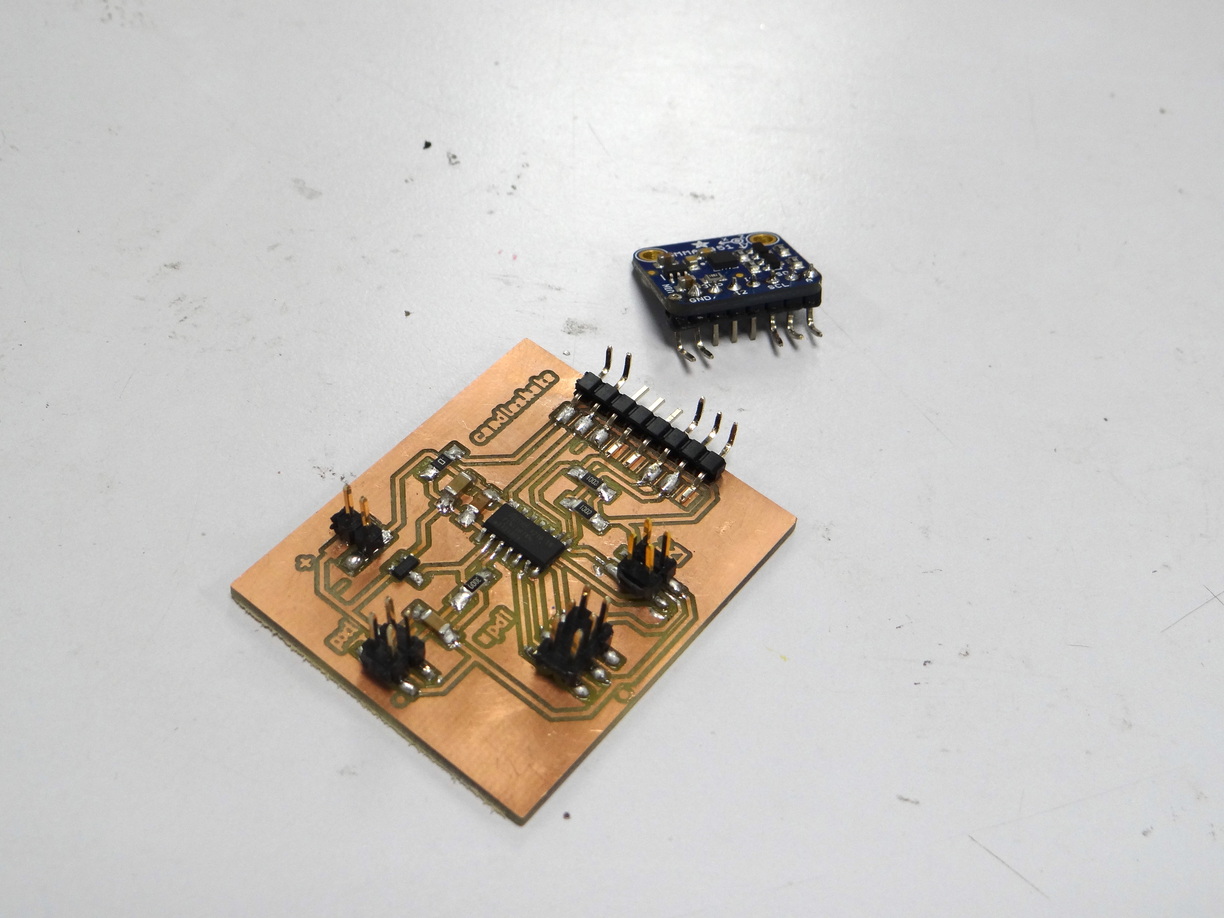

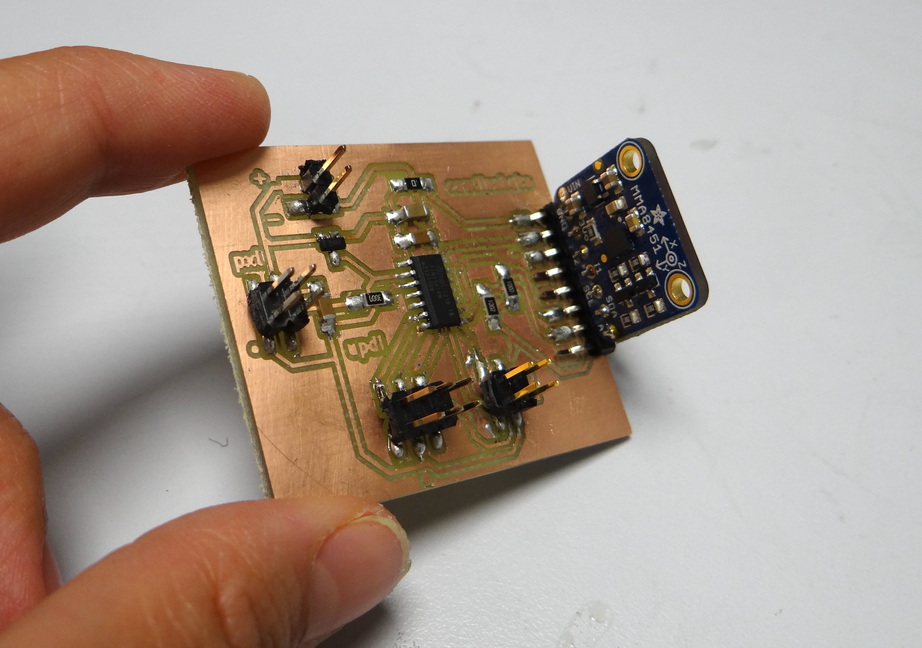

- I redesigned the PCB in Kicad, to have something more compact and with vertical headers. The design is overall very close to the lightshake one, designed and produced during the week Input device (version for an MMA8458 accelerometer breakout board)

- I milled the PCB

- I hand soldered the components. To reduce the volume of the circuit, I had to cut and bend the header pins of the accelerometer breakout board and of my board's pins, then soldered them together.

- I secured everything in the casing and tested: everything works fine!