1. Principles and Practice¶

Assignment: Plan and sketch a potential final project

My Other Idea’s¶

My first idea was to work with my colleague (Alaric Pan) on designing a smart chess board created by DIY Machines. I’ve been an avid chess player since middle school, so this idea was perfect. We envisioned having LED that could tell every possible move of each piece, and when the player inputted a invalid move, the board would light up. Though these features would only copy DIY Machines design, so we were going to include a CNC claw that would move each piece. After talking with my instructor Mr. Dubick and Dr. Taylor, I was told that we couldn’t work together.

It was unfortunate because we already had a working prototype that we worked on for the first semester of our engineering class. I had a tough time coming up with a second idea, but Mr. Dubick helped me decide on wireless LED’s. It was a cool idea, but I was never interested in it and there was already a YouTube video on how to make it.

My Final Project¶

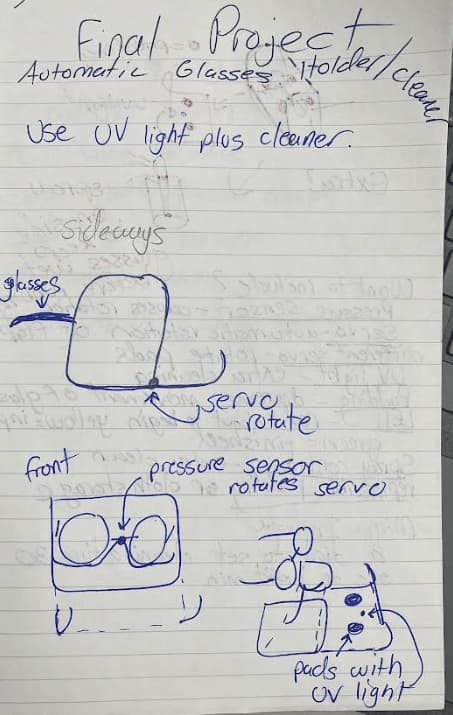

A couple days before Fab Academy started, I came up with an idea, automatic glasses cleaners. I have worn glasses for the past 2 years and one problem I’ve always noticed that they can never stay clean. Whether it’s the lenses or the frames, glasses accumulate bacteria, and this problem isn’t always addressed. I occasionally clean the lenses, but I rarely touch the frames. I searched the internet for a completed product and I found one by LensHD. As I did more research on glasses and how to clean them, I found that there are two ways

- Manually clean them with a cloth and spray

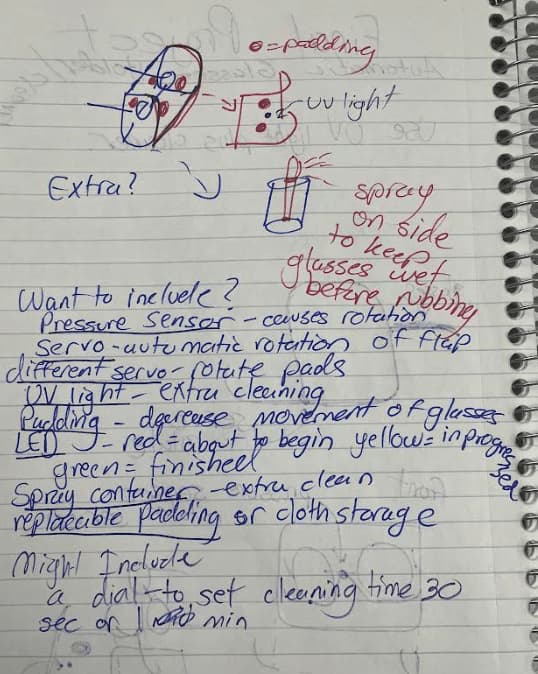

- Use UV light to get rid of the bacteria (similar to how they clean bacteria off phones) I wanted to include both for my final project. This way, I have clear lenses and clean frames. Additionally, with the pandemic there is a need for more sanitary head wear. Dr. Taylor and I talked about components I could add, and we came up with this list

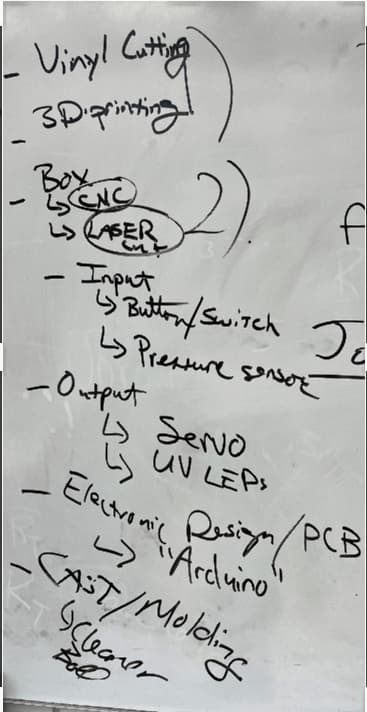

This is a more readable version of what we brainstormed

| Skill | Application for Machine |

|---|---|

| Vinyl Cutting | Sticker for button that activates the machine |

| 3D Printing | The area where the rotating pad servos rest and attach to |

| CNC | Creating the box out of wood using either tabs or just gluing them |

| Input | Button and switch that activate the machine, pressure sensor (pending) |

| Output | Servo that rotate the pads, stepper motor that lower the top part, UV light, LED |

| Electronics Design and PCB | Arduino |

| Casting and Molding | Holder that stores disinfectant spray for the lenses |

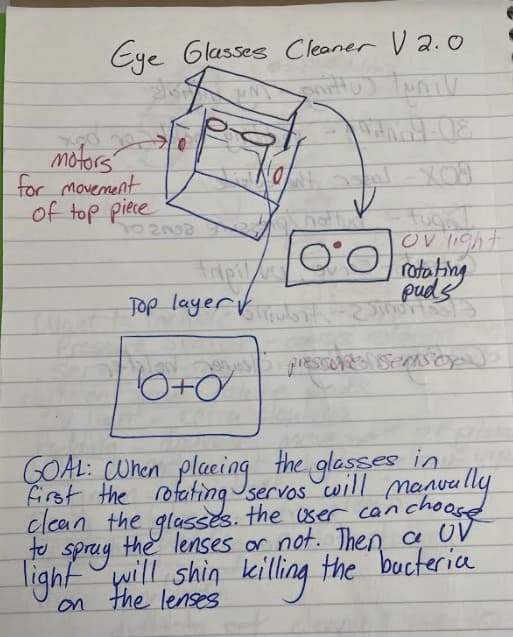

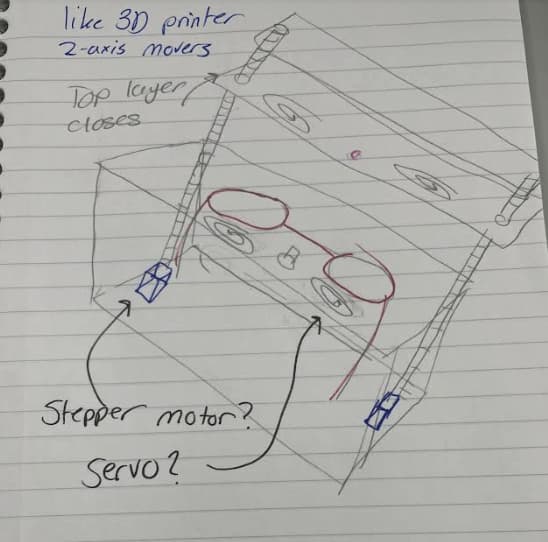

When first designing, I wanted to take LensHD’s design and automate it by having servos rotate that flap then, the pads rotate immediately after the compartment closed. The UV light would turn on after the servos cleaned the lenses. However I realized that in LensHD’s design had the frames sticking out from the back and the UV would shine through (which could be harmful) and all of the frames wouldn’t be cleaned. My design needed 4 requirements

- Encapsulate the whole pair of glasses so the UV light can clean the frames

- Cover the UV light so the user isn’t exposed to it

- Have rotating pads on the front and back of the lenses

- Have a pressure sensor on the bridge of the glasses

Sketches and Ideas of Machine¶

Version 1.0¶

Version 2.0¶

What I Learned¶

I learned how to brainstorm ideas for a potential final project and point out certian flaws in my prototype design. I learned how to reaserch specific topics and encoporate those ideas into my final project.