- Confirm that your final project incorporates 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, embedded microcontroller interfacing and programming, answering the following questions:

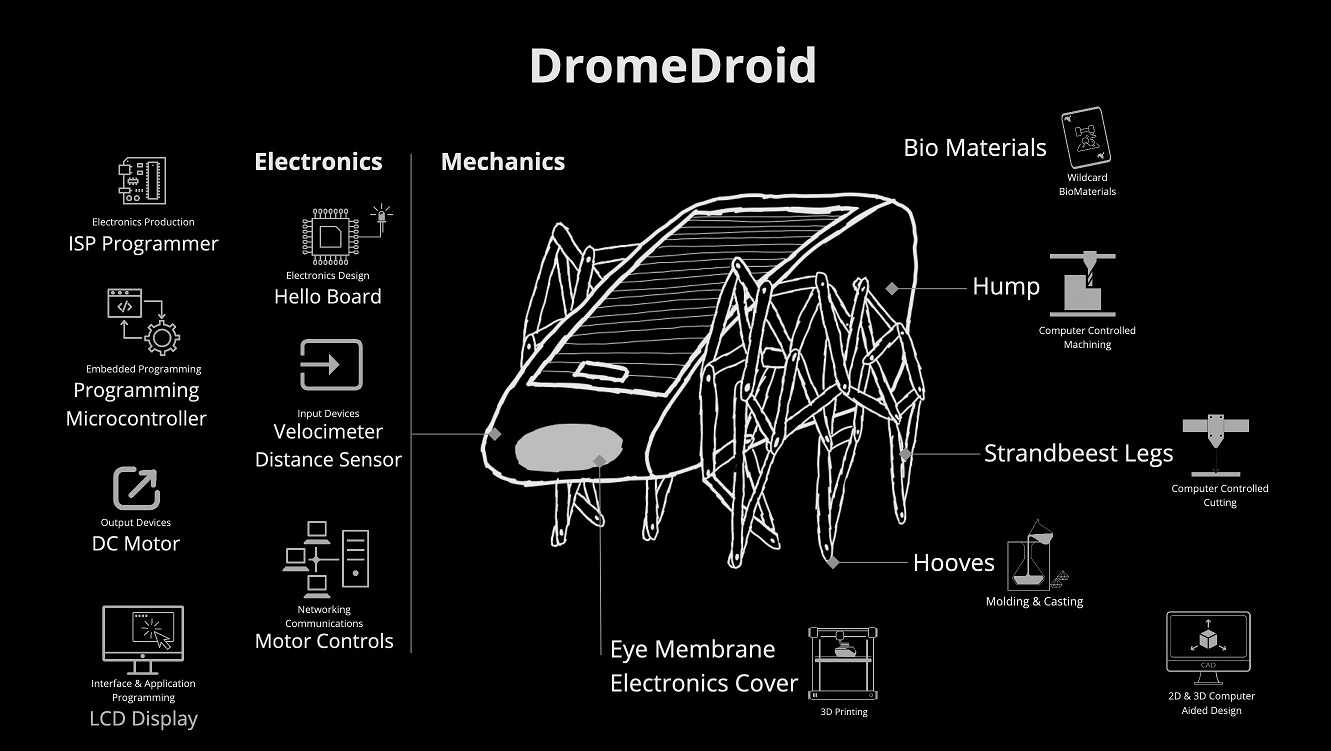

The DromeDroid aims to be an explorer's companion. It will be able to follow at a constant distance using a series of time-of-flight sensors while carrying vital supplies. As its eventual purpose is to work on a different planet, perhaps Mars, where a dog does not survive, it can offer companionship as well, filling a role similar to the aforementioned dog.

The inspiration for the body of the Dromedroid, especially the legs, are from the Strandbeest project. This is an invention by Theo Jansen from the Netherlands. The Strobot is the inspiration for its electronics. It uses the same time of flight sensor but in my case the output device, the motor, rotates the strandbeest mechanical legs instead of wheels.

I want to design a robotic companion that uses Strandbeest legs to move around. The Strandbeest legs would give it a more life-like character. It will be able to figure out how far an object is, through light, in order to calculate distance from an object and then move according to the program's commands to stay at a constant distance from the person it follows. It will include a generous compartment to hold items and a separate sub-compartment with the electronics. I also want it to have a nice organic curved shape and to be built out of a biodegradable material such as wood.

The DromeDroid's scope of work has been broken up into modules where I make sure that the final project incorporates additive and subtractive fabrication, electronics design and production, embedded programming and interfacing, all the different skills learnt in FabAcademy. The project's plan is described in the graphic above.

I want to use wood for the main body, specifically 4 mm lightweight plywood. I also want to 3DPrint some parts, such as the gears and axles for my legs out of PLA. For my electronics I will etch a PCB board, that connects up to three VL53L1X time of flight sensors and a L298N commercial motor driver. They connect to the two geared DC motors.

Given my geographical location, where none of the materials can be locally sourced, all of the materials and components I will be using in my final project will be imported from a variety of international sources.

Electronics

(2) Gear Motors 3 to 9V $13.00

(1) L298N Motor Driver $6.00

(1) Rechargeable Li-Ion Battery $70.00

(1) AAA Battery holder $1.50

(2) AAA Batteries $5.00

(2) Gear Motors 3-9V $13.00

(1) ATtiny 3216 $1.70

(1) Red LED SMD $0.20

(1) 470 Resistor SMD $0.10

(3) 4.99k Resistor SMD $0.10

(1) 0 Resistor SMD $0.10

(1) 1uF Capacitor SMD $0.15

(20) Male to Female Header Cables $2.00

(5) Connector Header SMD 4pos 2.54mm $3.50

(20) In line Male Header $2.00

Body Coponents

4mm Plywood $8.00

PLA Filament $6.00

Screws and Socket Screws $25.00

Metal Rods $20.00

Shipping

(2) Shipping Fees $240.00

I will laser cut the wooden parts and design them myself. I will also 3DPrint custom pieces, designed in Fusion360. I will also use an etching process for my PCB and I will design it using KiCAD.

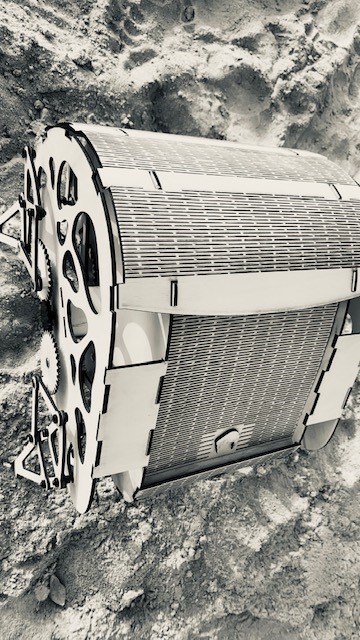

I will use a laser cutter to cut the wooden parts and want to use a ‘living hinge’ technique which allows wood to be bent way beyond conventional methods. I also will press fit the wooden pieces. I will be etching myself a PCB, which will be designed in KiCAD. I will solder the parts on the PCB. I want to use a 3DPrinter to make some custom parts such as the gears which need special spacing.

- How do I receive input from a Time of Flight sensor?

- How do I control a DC motor?

- How can I move Strandbeest mechanical legs while minimizing friction?

- How can I manage my time well?

- What batteries do I use?

- How do I keep my electronics in place?

- How do I make a project that does not look cobbled together?

I have three goals for my companion, each of varying difficulty.

1. Move a Strandbeest leg with a motor depending on its relative distance to an object.

This is the central part of the electronics and very important to be able to move. This is the practical side of the project.

2. Achieve a nice, finished look, with all the electronics hidden away, including a practical storage area.

This is the aesthetic and functional aspect of the project. I want it to look nice and smooth, so that it feels as a finished.

3. Have the whole self-contained robot walk on the ground, moving at least 1 meter.

This is the final product idea. If I can have the robot move a meter or more on the ground or for a propolonged amount of time responding to the sensors on "air" I would consider it a successful project!