Computer Cutting Control

Group Assigment

Laser cutter's characterization:

My colleagues in "FabLab New Cairo" are test their CNC Machine I've follow their steps but with FabLab Libya's machine

Fablibya libya machine specifications:

AOL Lacer cutting machine (Jinan AOL CNC Equipment company) laser Tube: RECI CO2 Laser Tube 100W Size: 130cm X 90cm Software: RDWorks Graphic format: AI, BMP, Dst, DXF, Dwg, LAS,PLT

I've tested the Lacer cutting machine in different parameter ( speed and power - kerf -Joint clearance)

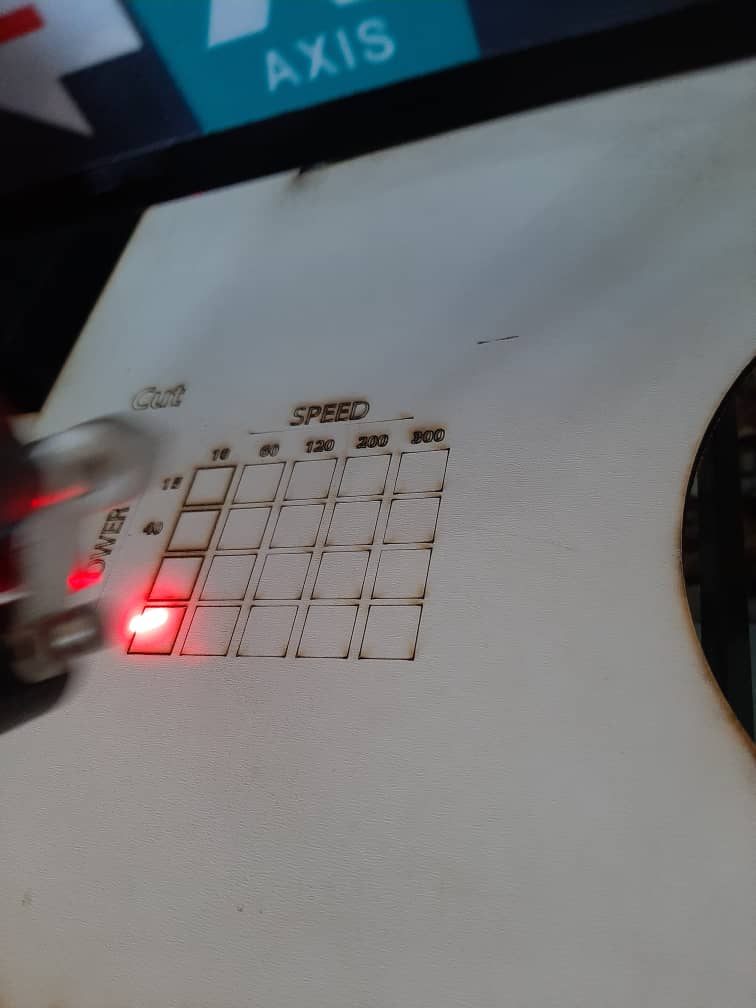

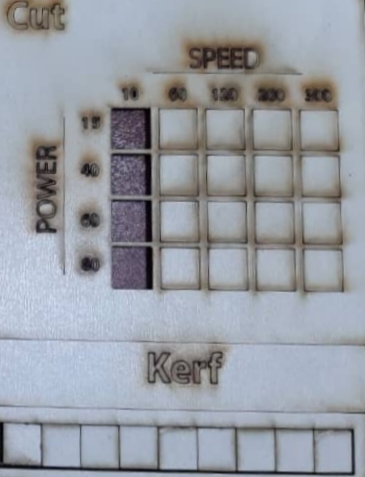

* Power, Speed test:

I have drawn multiple squares I give them different power and speed with MDF 3mm then I get this result of cutting in figure below.

In first time we have an issue :Non squares are cut cause the lens of laser machine is out of focus (we recently have changed machine's place, which made the lenses move a little bit ) after some research I have read this "steps"

and follow them , finally the machine works good :) the result in figure below

* Kerf test

Kerf refers to the space that is opened up when the laser passes through a material. Kerf is determined by material properties and thickness.

calculate the laser cutter kerf:

1- Draw the 9 square, which gives 10 lines. 2- Measure the total kerf 3- Total kerf= width of total 9 squares (before cutting) – width of total 9 squares (after cutting). 4- Divid total kerf / 10

I have tested MDF 3.0mm then I found the total kerf = 1.3mm ; That means our kerf machine is = (0.13 mm)

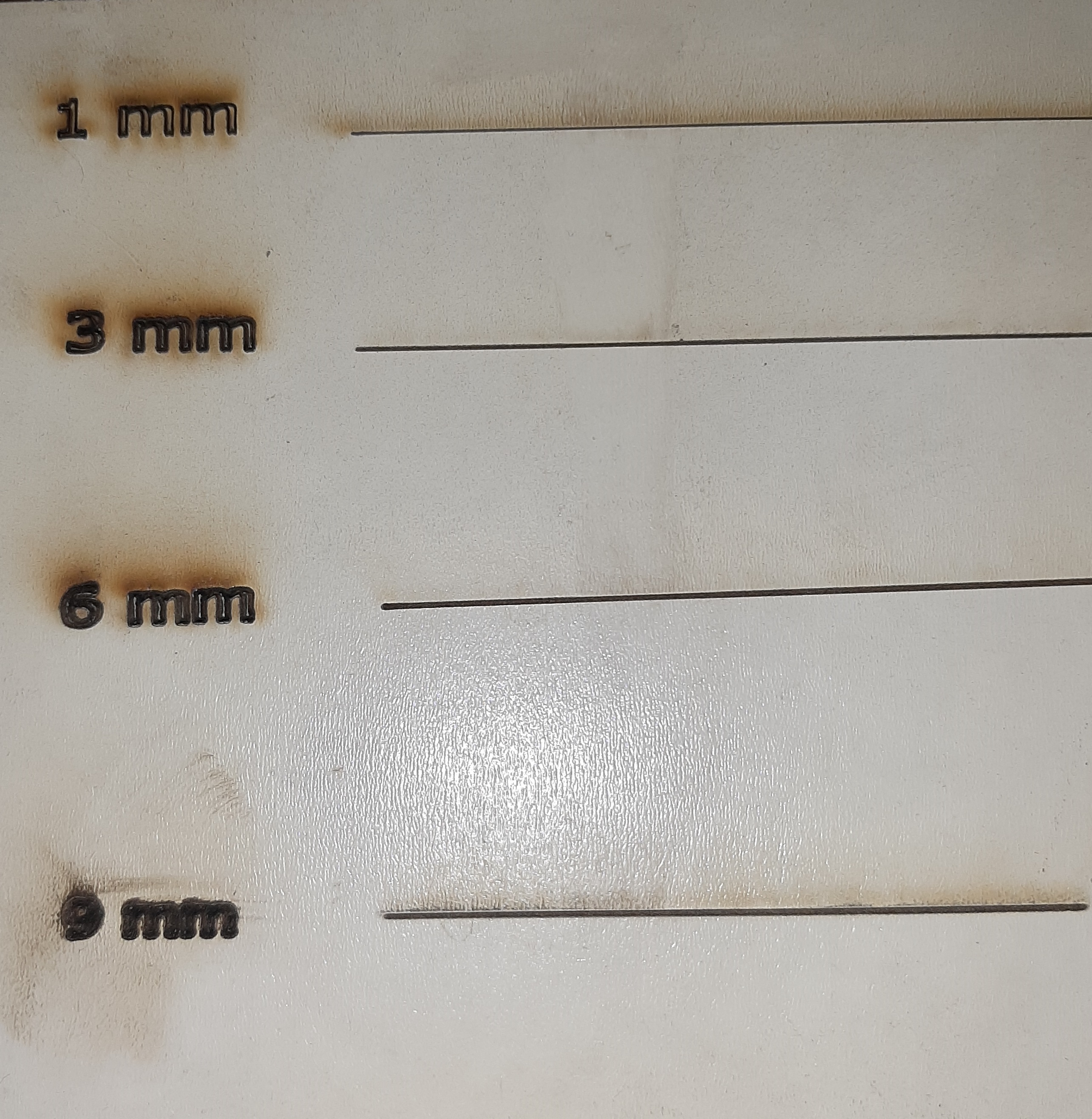

* Focus test

I this test I have draw 4 lines and change the distance of laser according to (1mm, 3mm, 6mm, 9mm) the figure below can show the result , I found (1mm ) is better because it more sharp and intensive

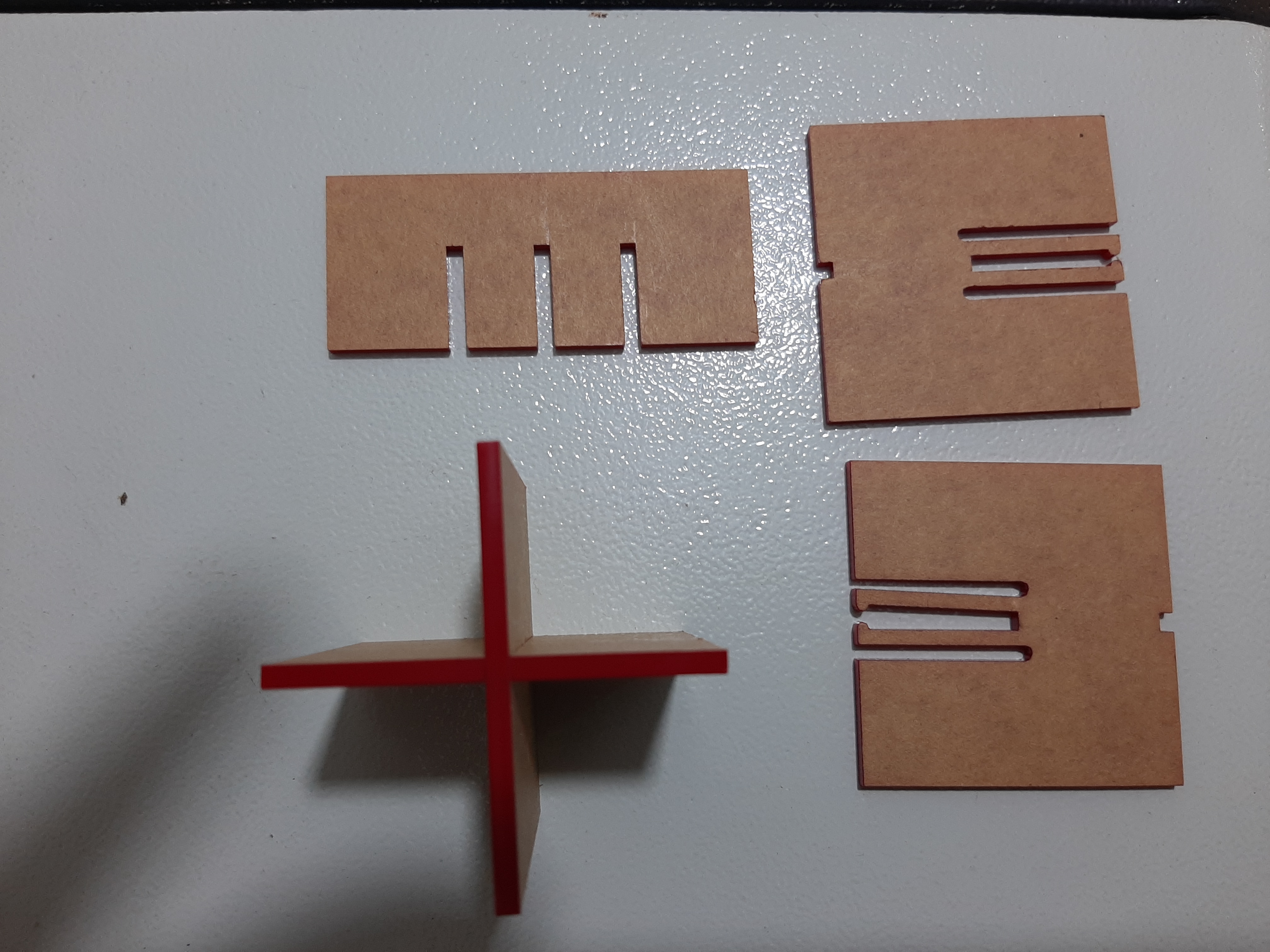

* Joint clearance test

Individual Assigment

The goal is computer-controlled cutting using two different machines:• Vinyl Cutter

• Laser Cutter

Vinyl Cutter

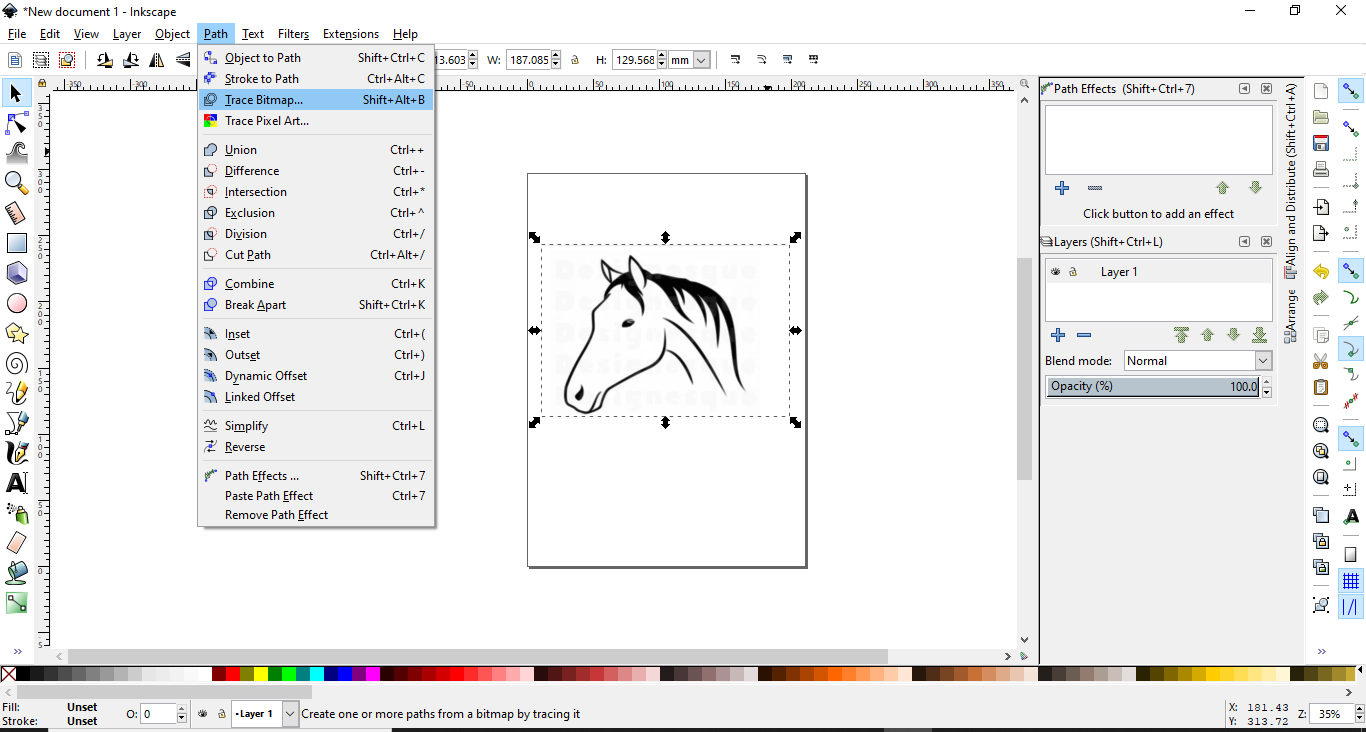

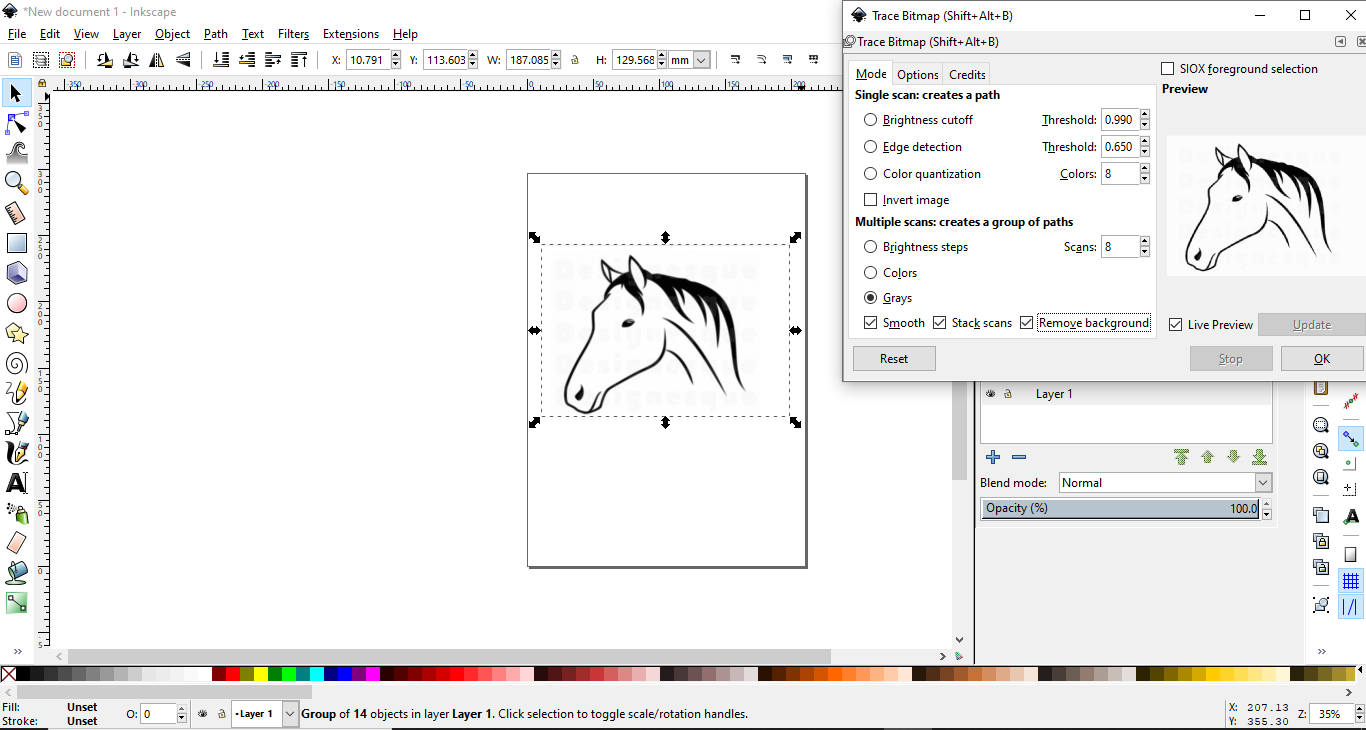

A vinyl cutter is a type of computer-controlled machine. Small vinyl cutters look like a desktop printer. Like a printer controls a nozzle, the computer controls the movement of a sharp blade over the surface of the material. You can create an image with Open Office Draw, or Gimp. Other programs can work fine.Your image should be black and white with no gray for best results. I have download black and white (horse image)with high quality

* open it with Inkscape software.

*select the image and click on path menu --> Trace Bitmap

* I Have write "FabLab Libya" as a text and import our logo

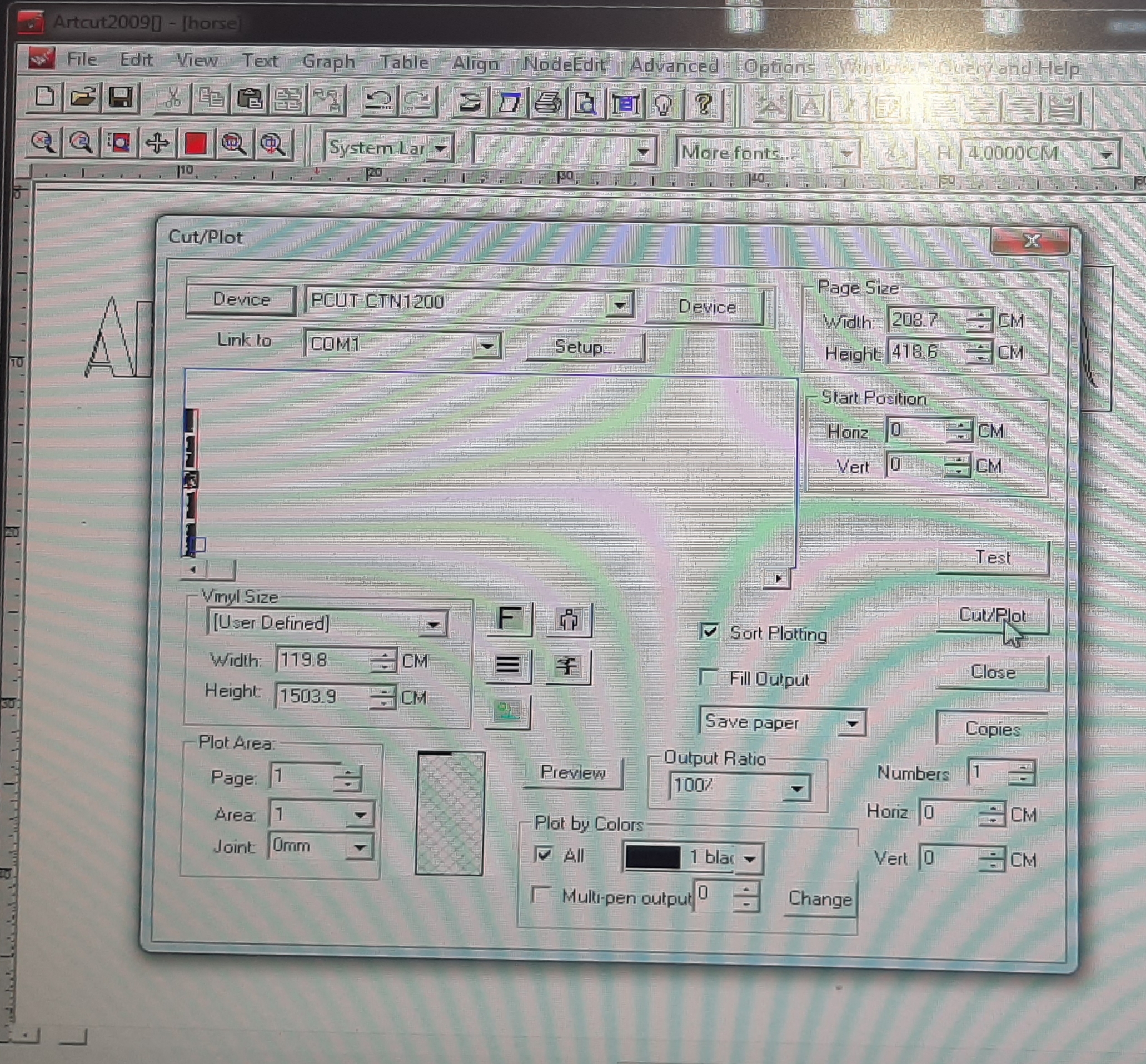

* Save these files as .PLT

• Cutting procedures

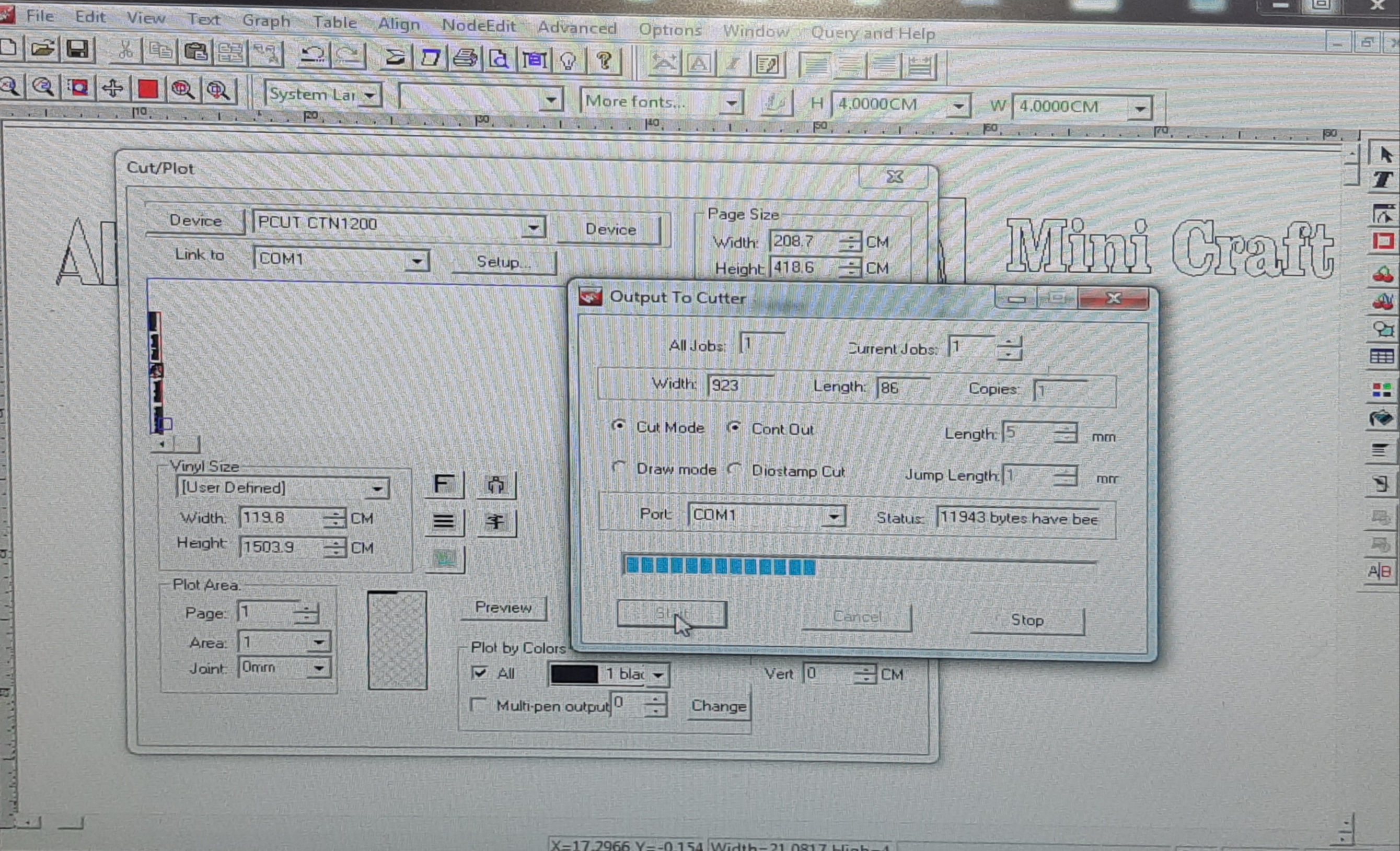

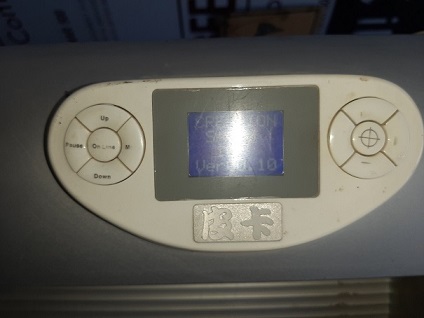

I've used Creation CTN1200 Cutting Plotter 1200 Vinyl which have specifications

Model Number : CT1200 Voltage : 110/220/240 Cache Capacity : 1MB Paper Feed Width : 1300MM Cutter Pressure : 100G Cutting Width : 1200MM Cutting Speed : 100mm/s Driver : Stepper Motor Cutting Length : 2meters Repeat Cutting : supportive Size : 1200 vinyl cutter

Now, I have to open the vinly software.

Here is My first sticker

Laser Cutter

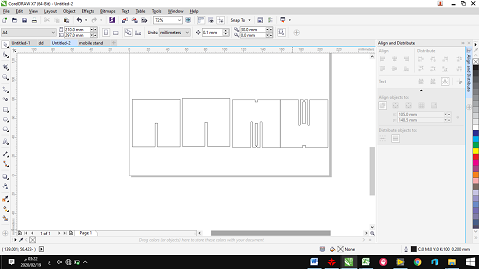

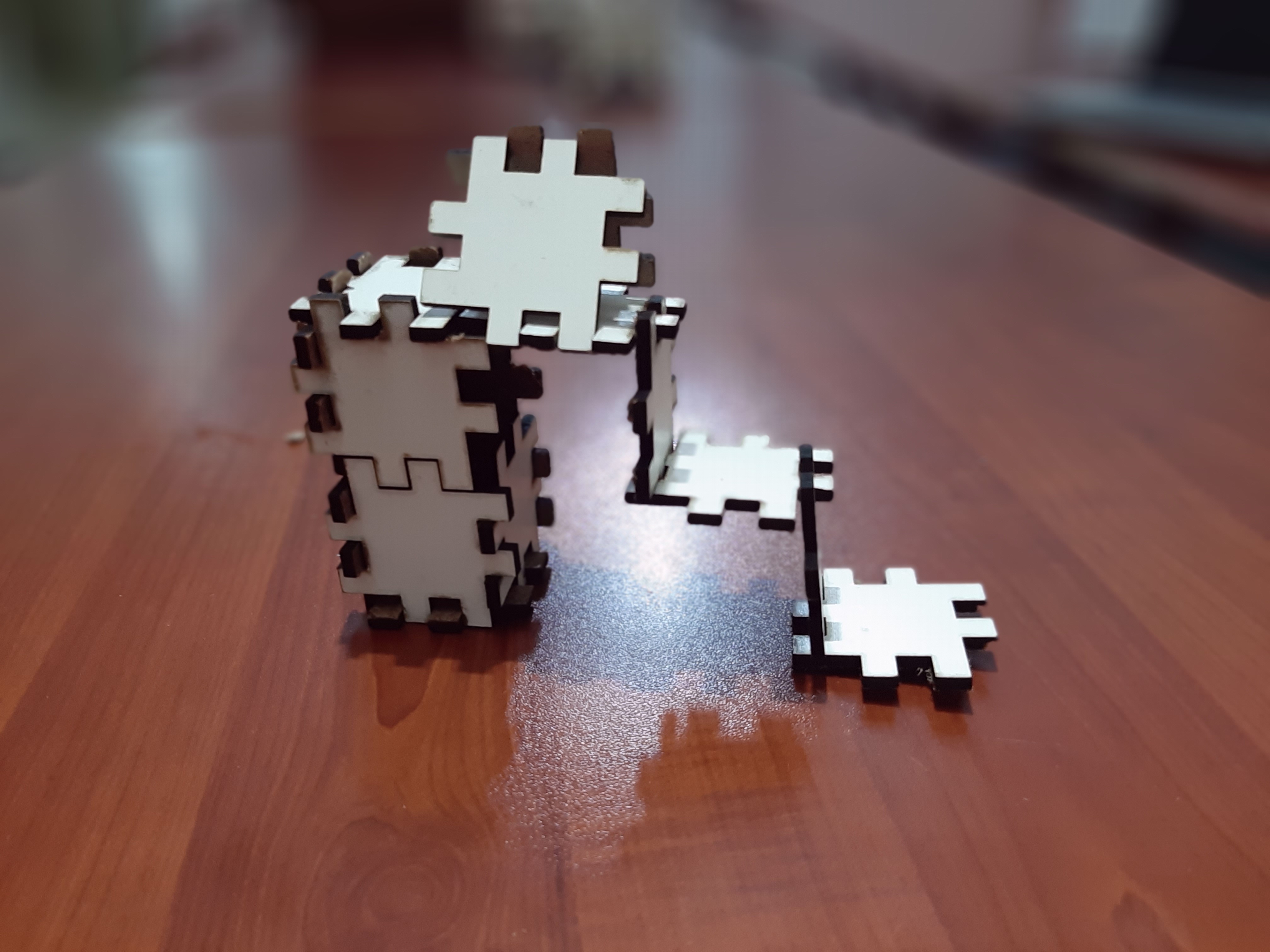

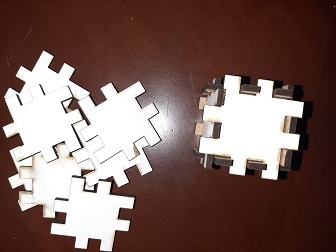

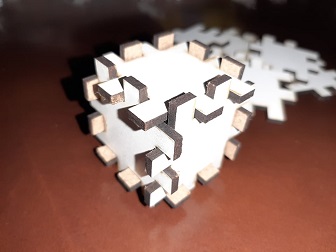

The main mission of this project is design and build toys assembled cubes, and test different joint,and I have design and build mobile stand

Parametrical Design:

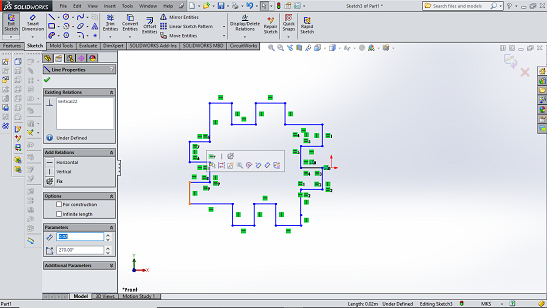

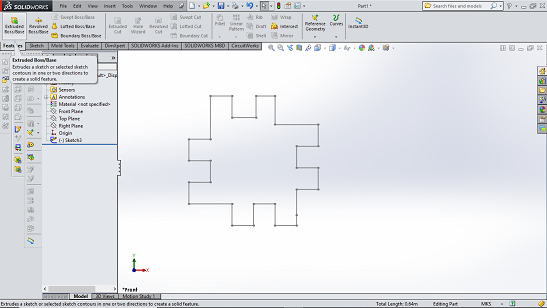

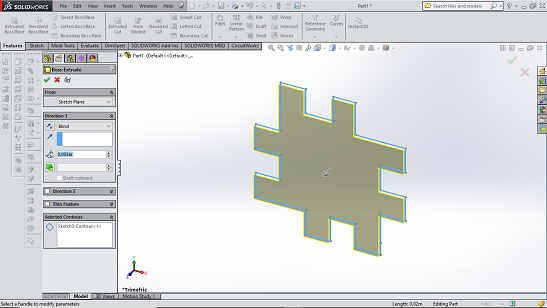

I've tested solid work as paramtrical design it very easy with two feature (smart dimention - equal =) I start draw lines from sketch, line by line unitl complete all design , after that I've select all lines and choose equal, with smart dimention change every short line with 8mm and long lines with 16mm

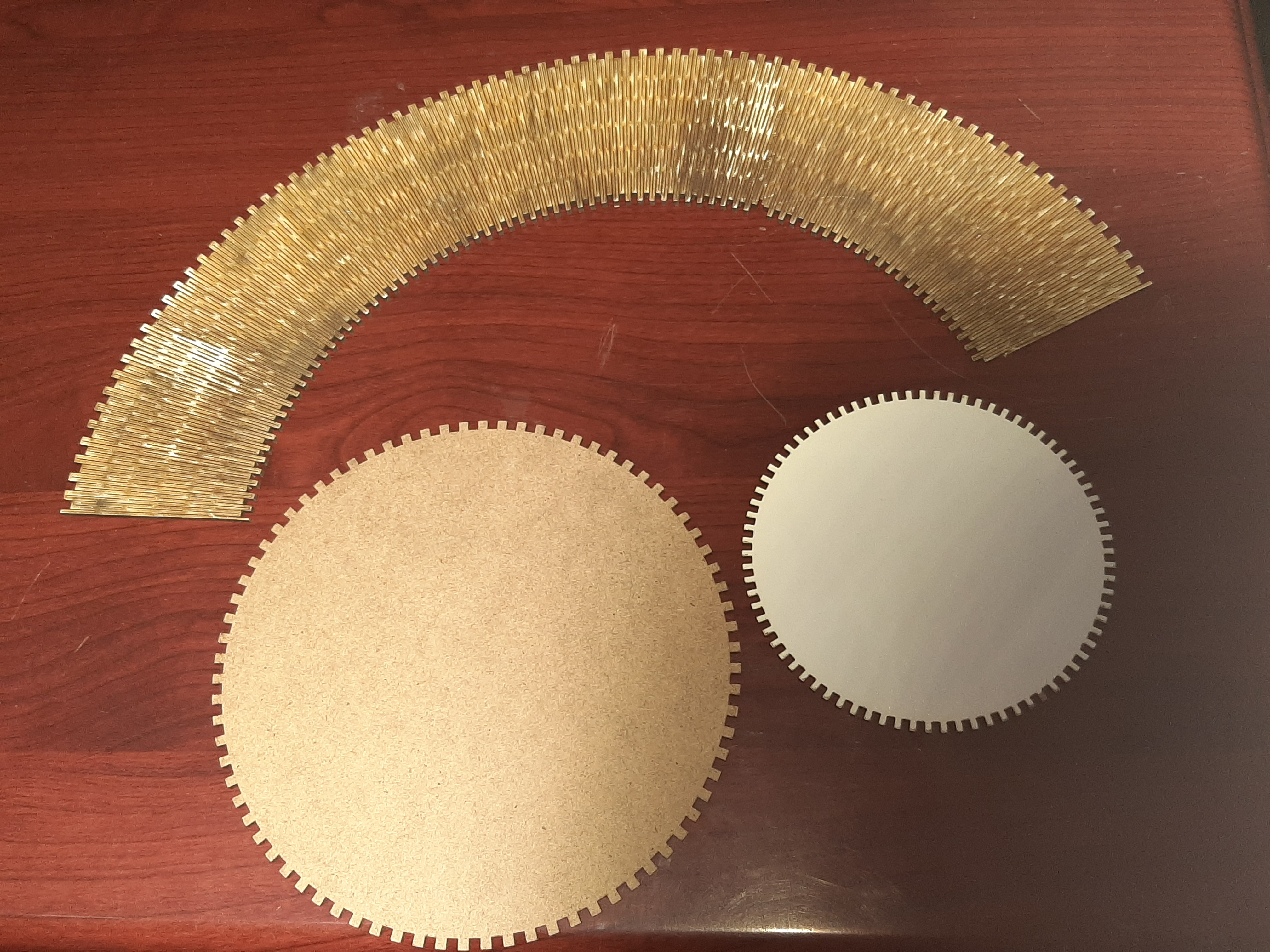

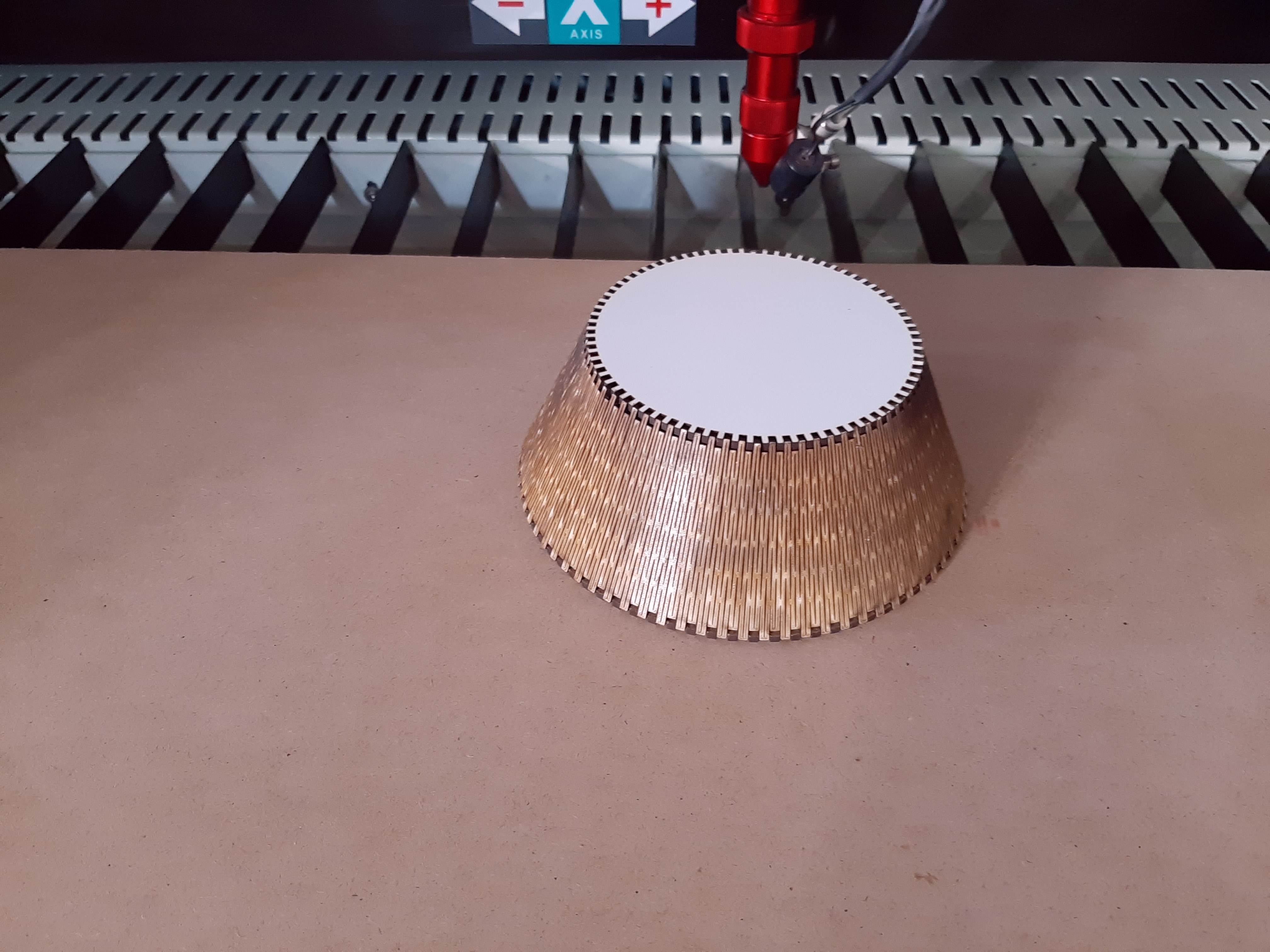

Conical Box maker:

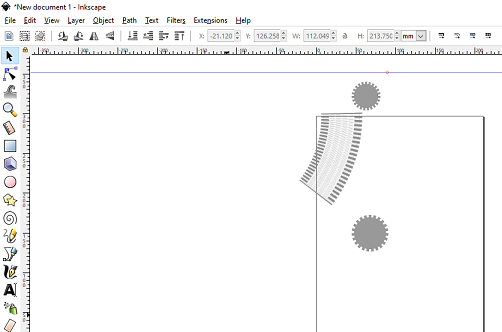

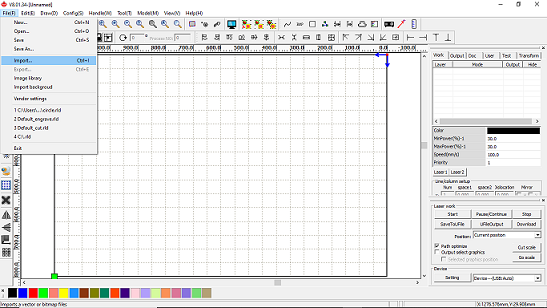

I want to make a flex structure that why I interest to Make a conical box, making conical box with inkscap is very easy and wonderful :) you need to download Conical box generator extenstion

1-To install an extension, download and unpack the archive file. 2-Copy the files into the directory listed at Edit > Preferences > System: User extensions. 3-After a restart of Inkscape, the new extension will be available 4-Reopen inkscape from Extension tool bar >> FabLab >>Conical box Maker 5-follow these steps in figures below.

Files: