Final Project

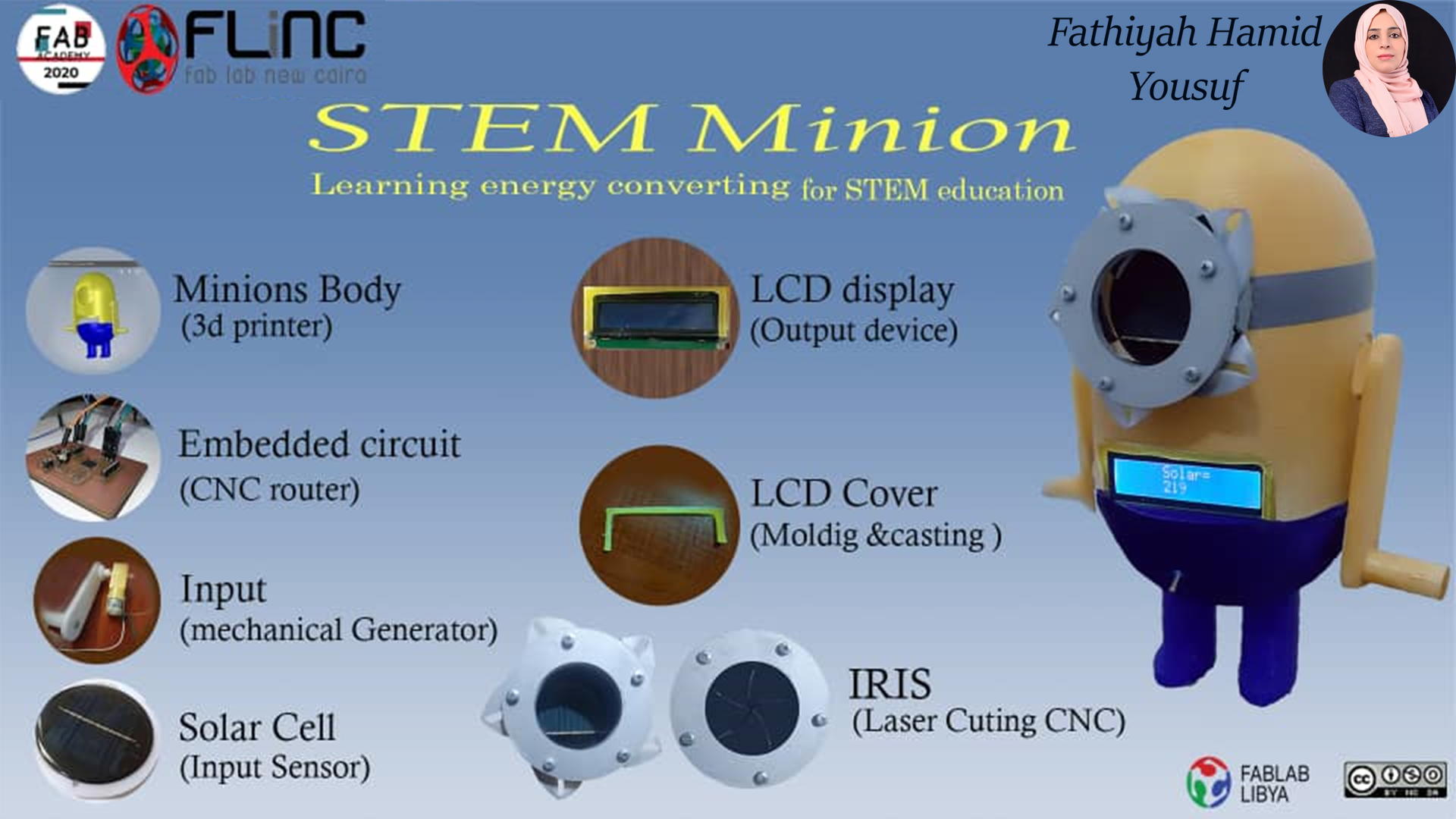

STEM Minimon

Children face some difficulty in science and technology and link it to daily life to show the importance of studying these sciences.

This difficulty can be overcome by using technology to simplify these sciences and create models that are close to reality

Science and Mathematics are everywhere in the world around us By exposing students to STEM and giving them opportunities to explore STEM-related concepts, they will develop a passion for it and hopefully pursue a job in a STEM field .

As I am an engineer, tutor and mother too, I would like to give my children a "Stem Minion", which is the name I gave to my project to learn and have fun with science.

"STEM Minion" robot demonstrates the energy convertion concept with play and fun, This robot illustrate two types of energy:

1- Solar energy: Using solar cells placed in the robot's "Minimon" eye, the iris opening mechanism was used to control the amount of light that passes to the solar cell. When the iris is opened, the intensity of the solar energy that passes to the solar cell increases likewise when it is closed, the energy decreases. This change in power will displayed on the LCD

2- Mechnical Energy by using dc Motor that located in robot arm, this motor will genrate electricity by turn armature shuft, the variation of electricity genration will appear at LCD.

1- Solidworks to design and simulate the robot.

2- 3D printer to build the "STEM Minimon" body by using Ultimaker Cura to genrate 3d printer Gcode.

3- Eagle software to desig the PCB.

4- "Mods" to generate Gcode for router.

5- Inkscape to draw the IRIS.

6- RD works to genrate laser code.

7- Laser CNC cuter to cut the IRIS.

8- Molding and casting technic to make LCD cover

9- Arduino IDE to program the Atmega328.

10- In this case solar cell and dc motor genrator are using as inputs but LCD is an output.

* 3D Design

In this part I've design by Solid Works that describes in Computer Aided Design

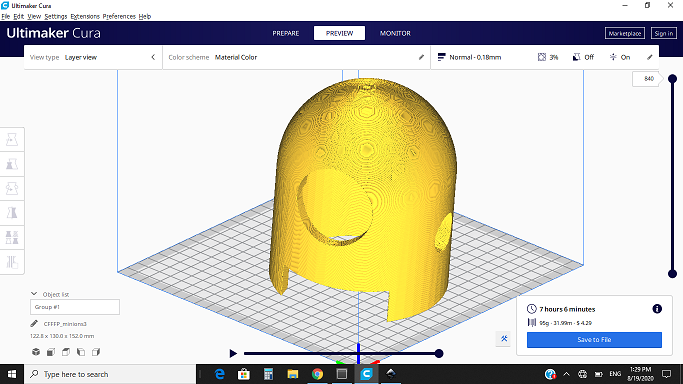

* 3D Printer

I've used Anet A8 printer with Normal quality which has these paremeter :Layer height 0.15 Wall thickness 0.8 Wall line count 3 Top Layers 6 Bottom Thicness 0.8 Bottom layer 6 Infill density 5% Infill pattern Grid Printing temp 200 C Build plat temp 60 C printing speed 60mm/s PLA material

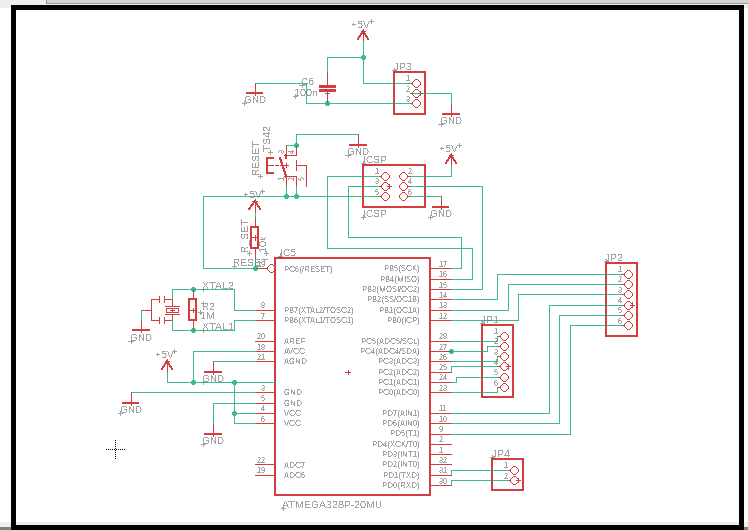

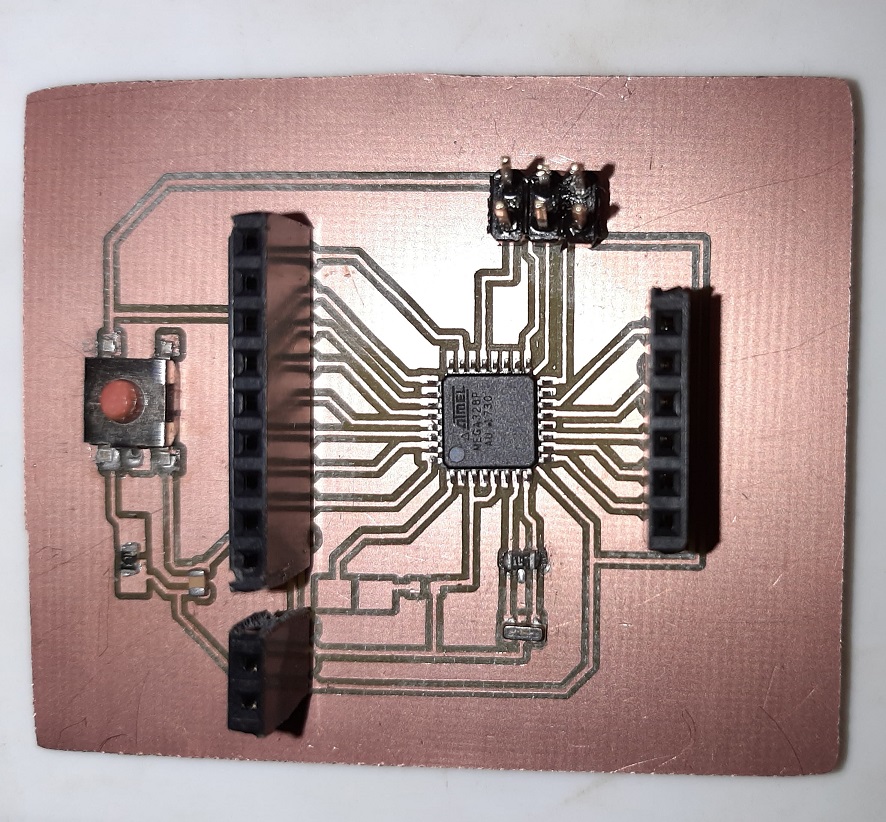

* Electronics Design

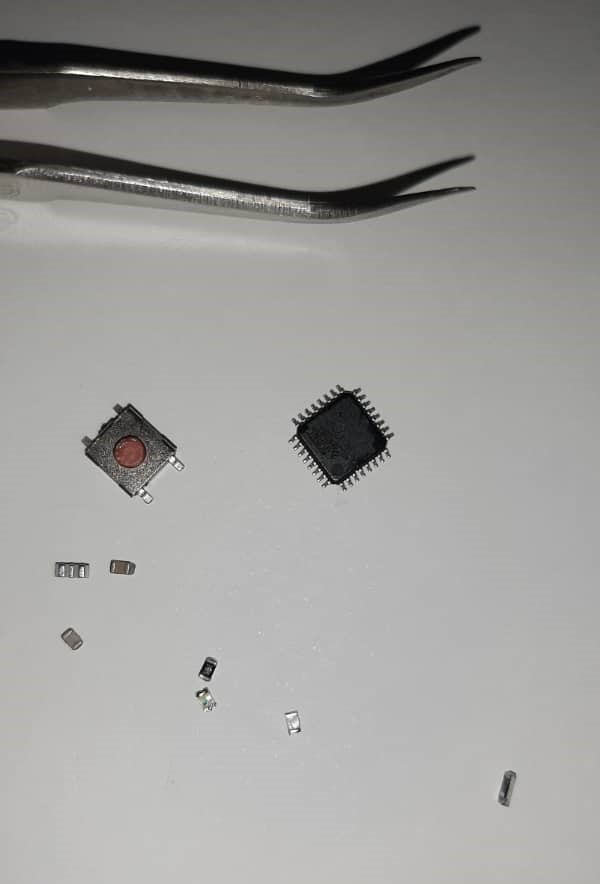

As COVID19 affect, all shipping companies canceled shipping operations to us, and I was in the process of receiving a shipment of electronics from DigKey that I will need for my project and to carry out the tasks of these weeks.

However, I decided to address these limitations and find alternatives, That made me taking apart an Arduino Board by desoldering to get components, so that I could re-solder them in my own board

Finally I have my SMD components, I have resold these components to my board

Using Eagle software to design my board, In Electronics Design Week

* 2D design

I've used "Corel Draw" to draw 2D of the '"iris part" that I've cut by laser cutting and putting it in minimons Eye.

-First I've draw three circls then use "Virtual Sigment delete tools" then cut unwanted lines to get desired shap

- I drew 4 circles centered with intersection, and pentagon, then drew 5 circles, distribute them to the corner of pentagon after that delete it

* Assembly & Test

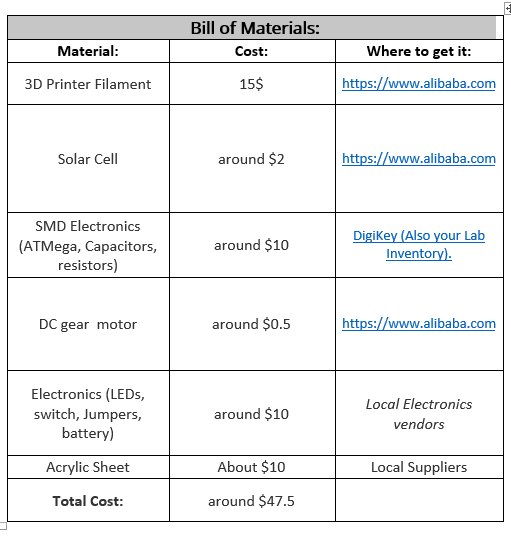

* Bill of Material

- Total budget can be estemited around 60$ here a Bill of Material

* Acknowledgment

I wish to express my sincere appreciation to my instructors, MAY EL-DARDIRY and Khaled Youssef both of them convincingly guided and encouraged me to be professional and do the right thing even when the road got tough.

I would like to pay my special regards to my colleagues Ishaq, Mansour, Shakankery, Rowa, whom I had the honor to study with.

I wish to express my deepest gratitude to My husband "Ahmed alshwahdy" , for his enduring love, for believing in me long after I'd lost belief in myself, and for sharing my wish to reach my goal.

I am indebted with great love of My children Rawah , yahya , roa'a during this long journey with full of work.

I would like to pay my regards to all fablab libya team whose kept me going on week by week , this work would not have been possible without their support especially “Abdelfatah bushnaf”

* Files