System Integration is the process of connecting various subsystems or components into one cohesive system that functions as a unified whole. It involves both hardware and software integration, ensuring that different modules—such as sensors, controllers, actuators, and user interfaces—communicate effectively and work seamlessly together. In product development or robotics, system integration includes aligning electronics, mechanical structures, power management, and programming to achieve the desired operation. It helps reduce complexity, improve performance, and allows efficient control and monitoring. Successful system integration ensures that the overall system meets functional, safety, and usability requirements.

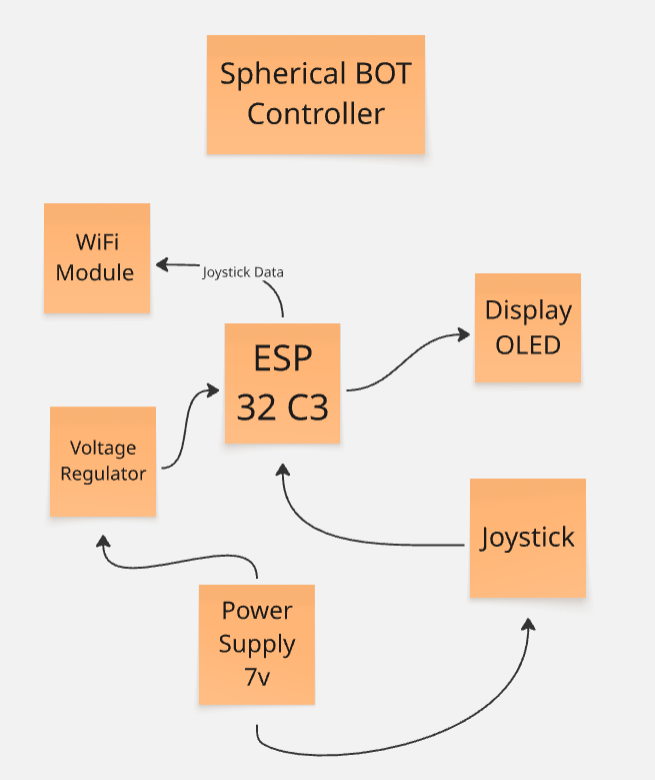

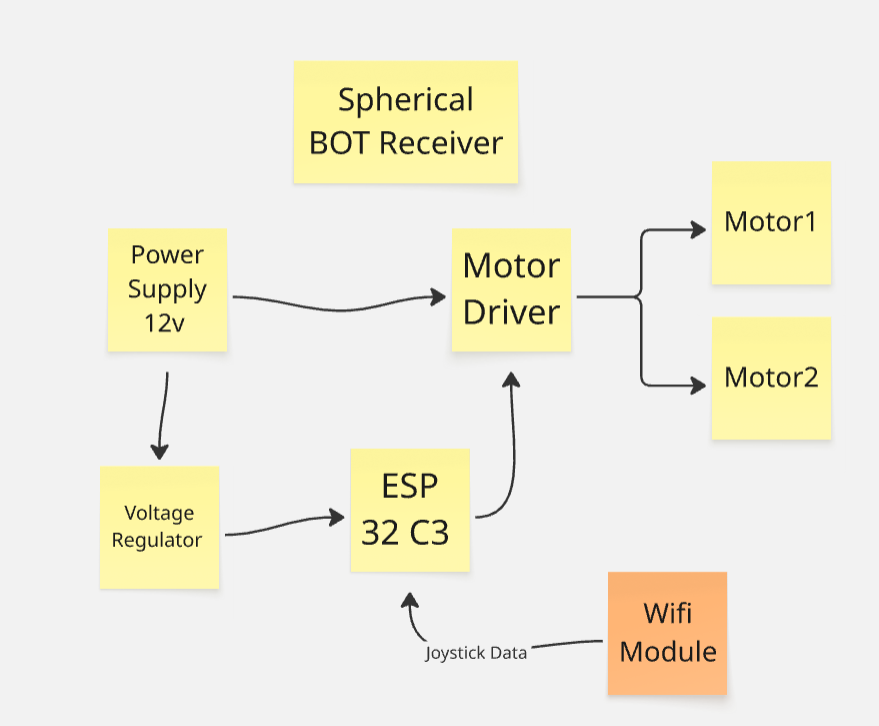

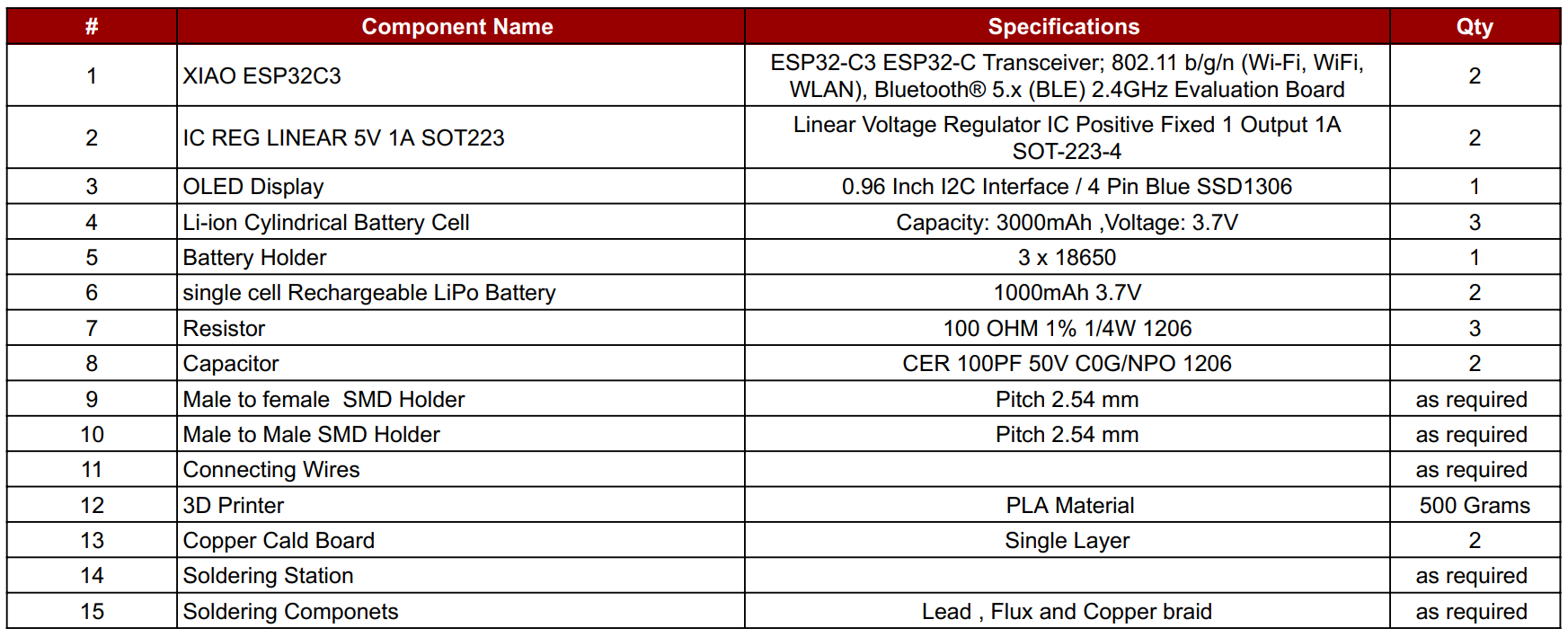

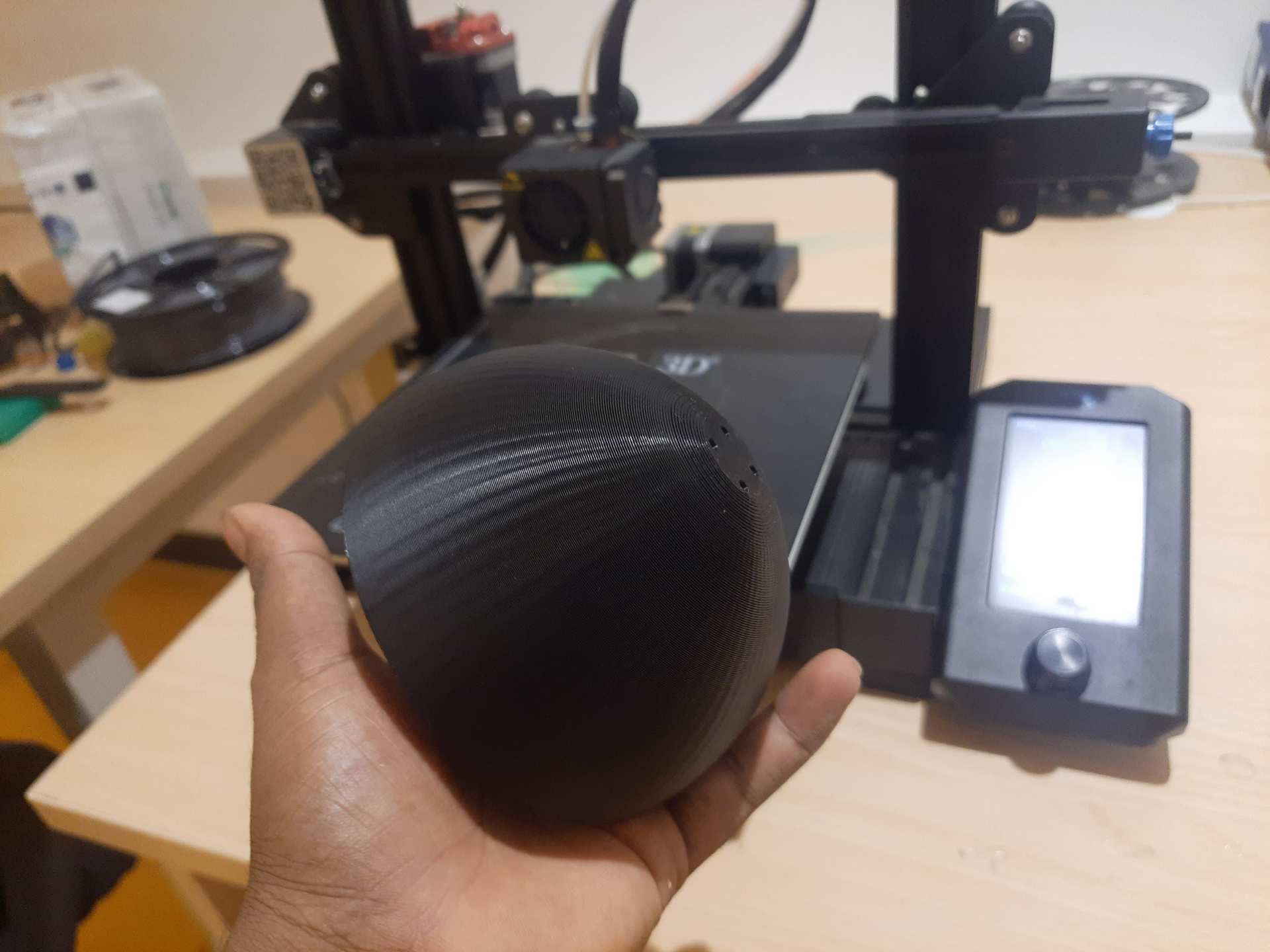

The Special Spherical Bot project involves designing a compact mobile robot with wireless control using a custom ESP32-C3-based controller. The mechanical structure is fully 3D printed with mounts for motors, PCBs, and internal components. Custom PCBs were developed—one for the bot with a Raspberry Pi Pico and TB6612FNG motor driver, and another for the controller integrating an analog joystick and Li-ion battery. Wireless communication is handled via ESP-NOW or BLE. Software enables responsive movement using PWM control based on joystick input. The system was tested for integration, power consumption, and wireless performance, ensuring reliable, real-time operation in field conditions.

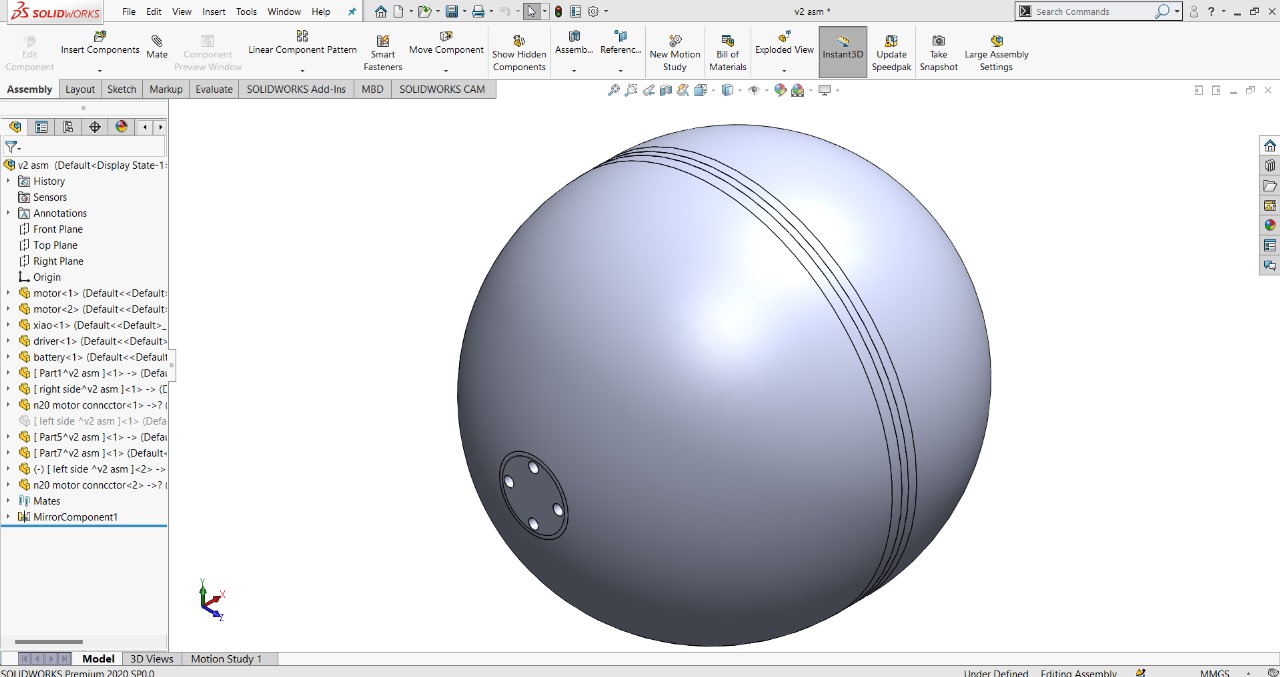

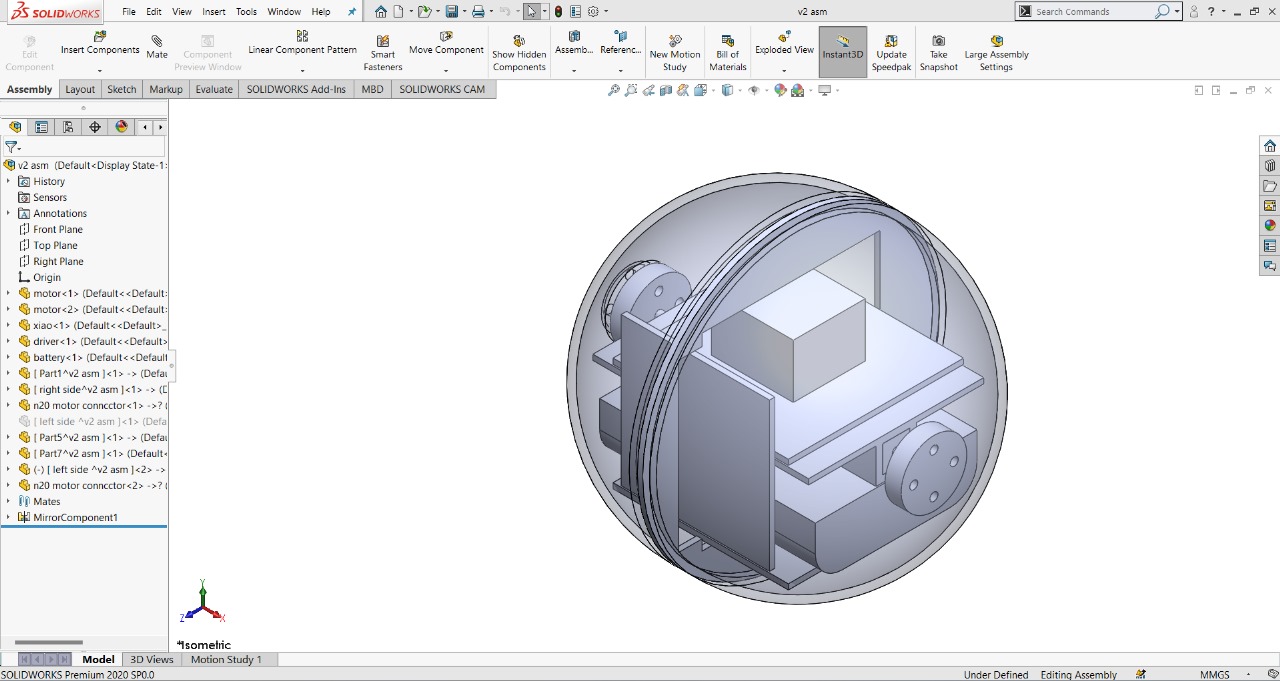

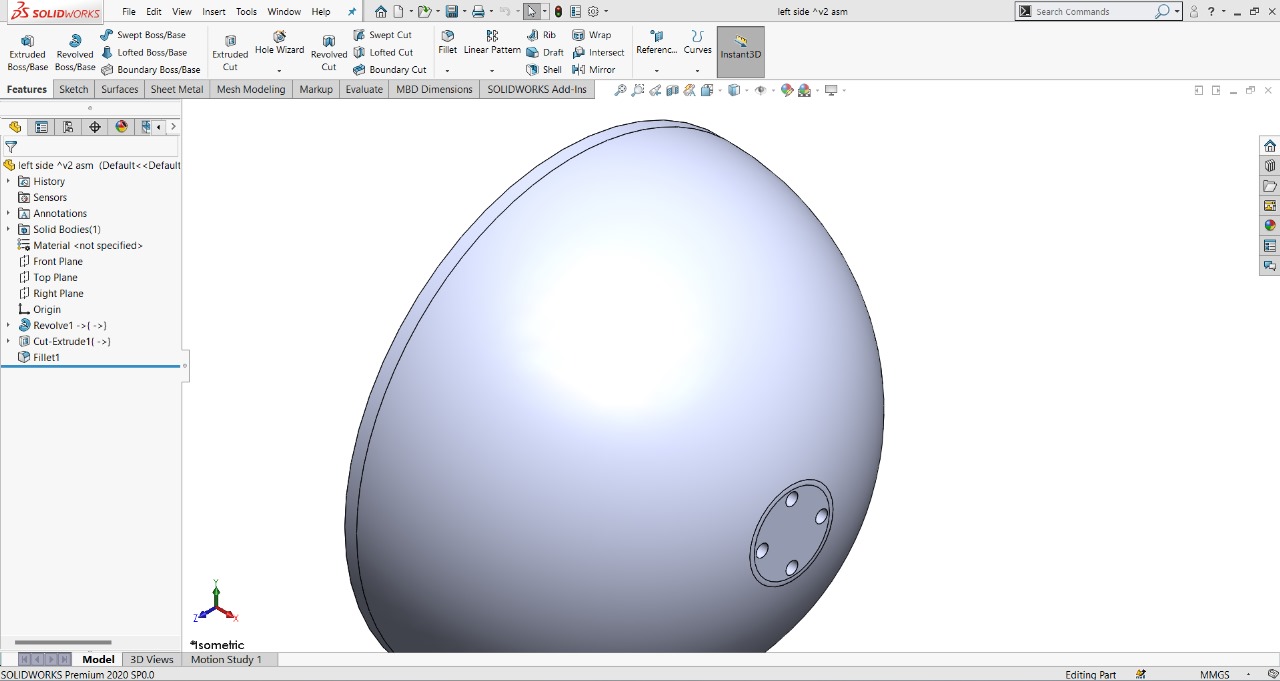

I designed a spherical bot in SolidWorks, integrating N20 motors and a battery holder within a compact, balanced structure. The model includes motor mounts, internal supports, and precise dimensions for proper assembly. All components were virtually tested for fit and function, and the complete design files are included in the original folder.

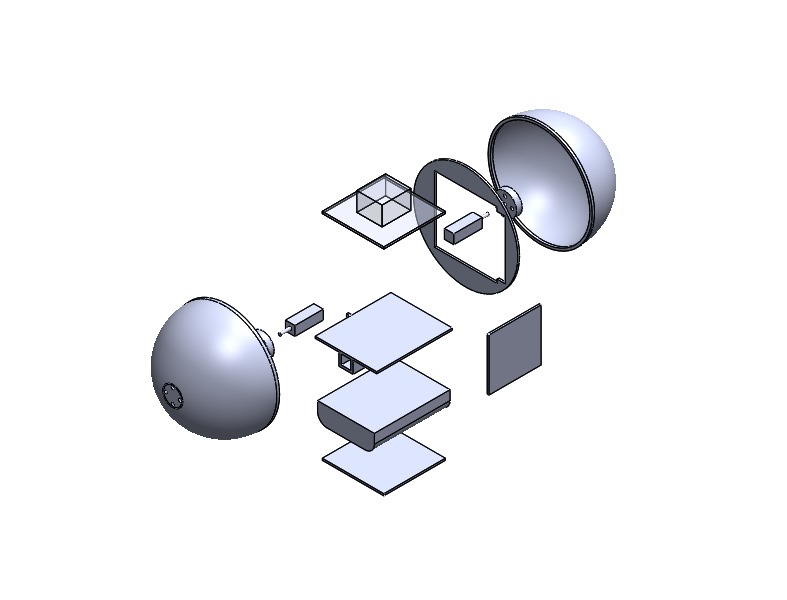

Here is the exploded view of the spherical bot, showcasing all individual components and their assembly order. It clearly illustrates how the N20 motors, battery holder, internal supports, and outer shell fit together. This view helps in understanding the design structure and simplifies the assembly process during physical construction.

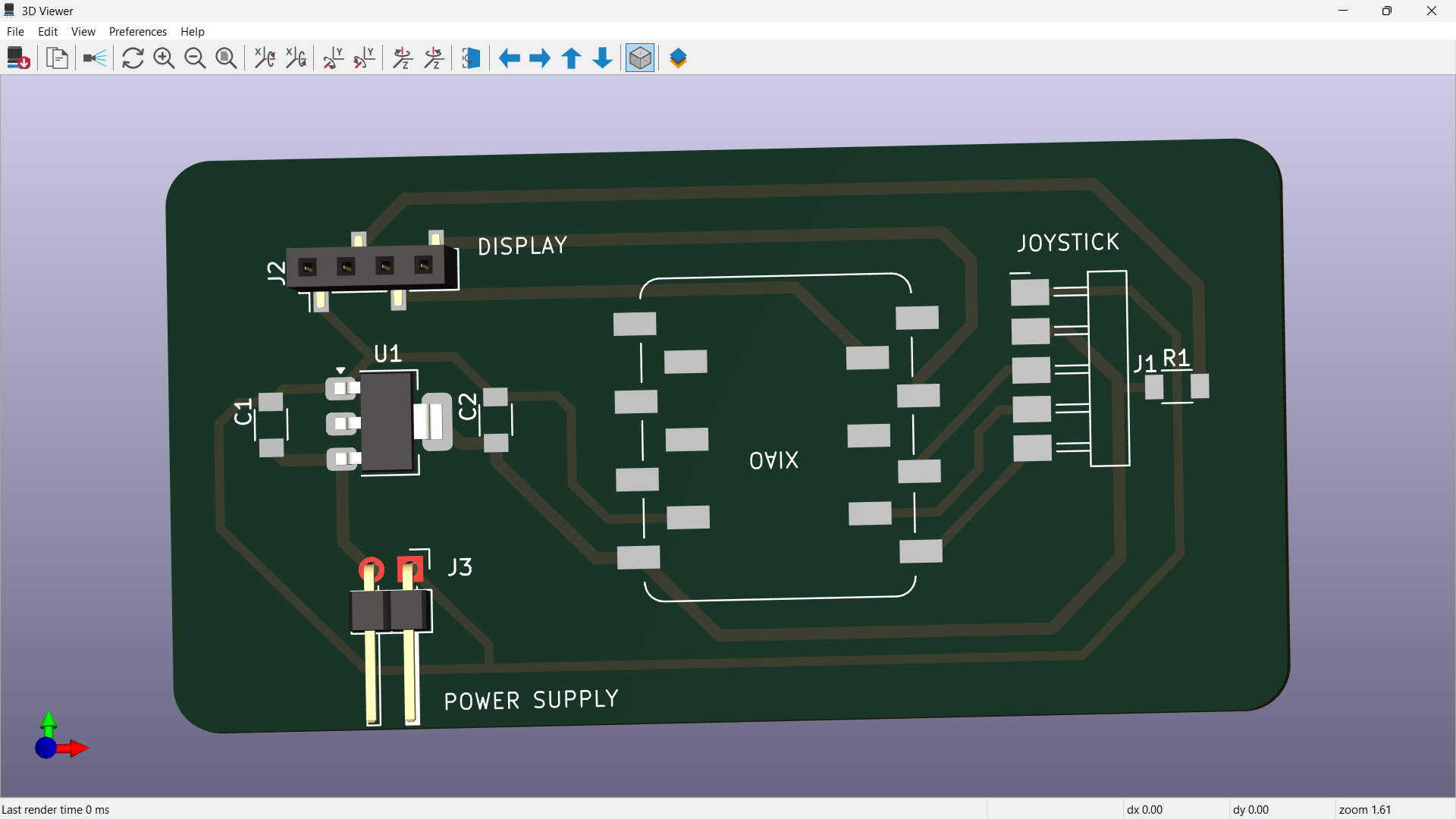

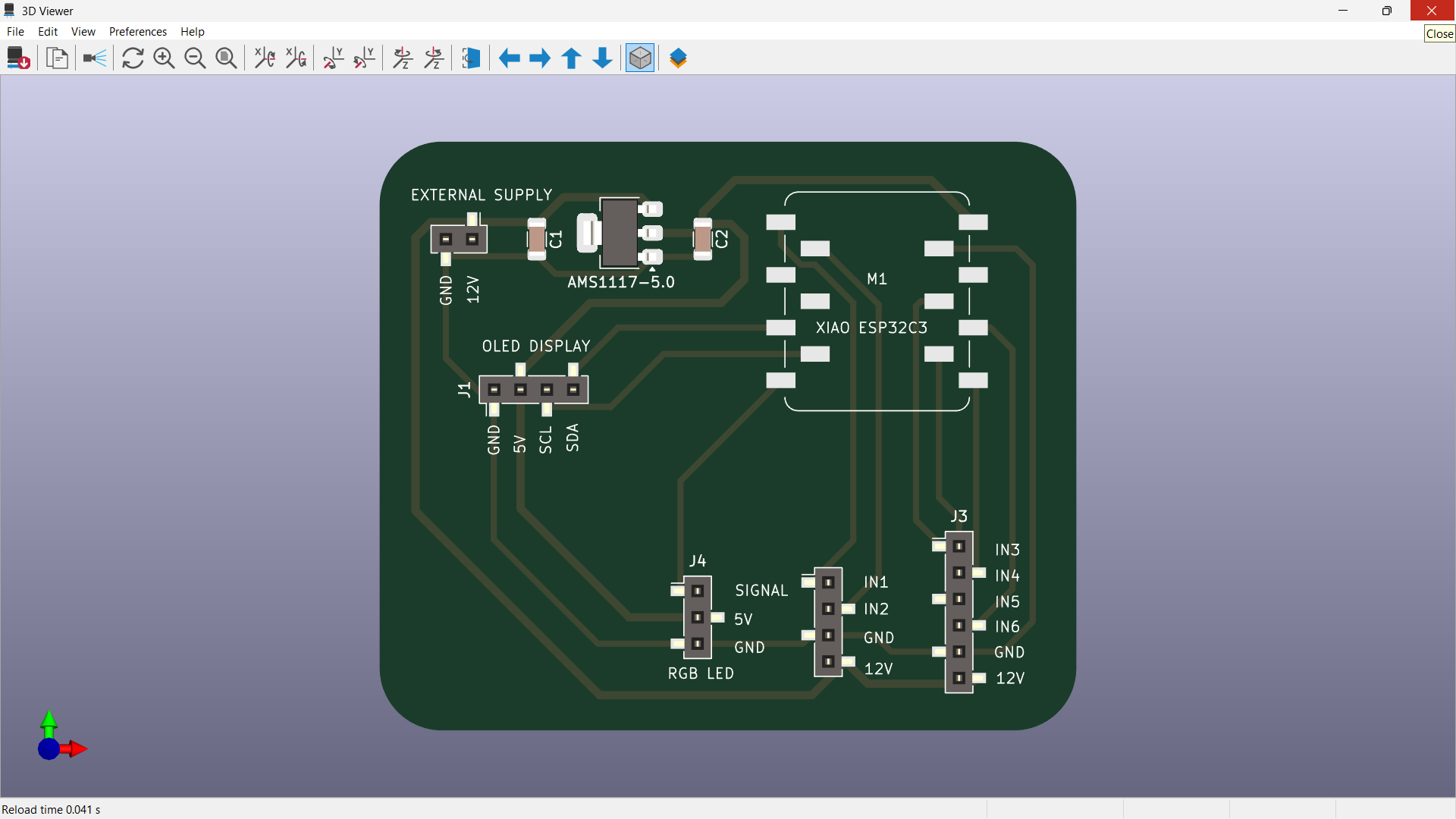

The electronics design and production were completed during the Electronics Design Week and Electronics Production Week. In the design phase, I created custom schematics and PCB layouts using EDA software. During the production week, I milled, soldered, and tested the board to ensure functionality. All design and fabrication files are included.

Link for Electronic Design week

Link for Electronic Production week