Computer Controlled Cutting

This week Assignment is on Conputer Controlled Cutting. This week includes both Individual and group assignment aimed to understand about how cutting machines work. We are going to check and verify the relationship between power, speed, and how accurately the machines cut materials. We've been working with two main machines: the SIL CO2 Laser Cutter, which is great for big cutting jobs. And the Graphtec CE60000-60 Plus, perfect for precise vinyl cutting. This is Individual assignment. I made a design in coreldraw and cut it into the vinyl Cutter. Using these machines effectively requires knowing their ins and outs, so we're exploring their functionality thoroughly.

Group Assignment

Do your lab's safety training.

Characterize your lasercutter's focus, power, speed, rate,

kerf, joint clearance and types

In group assignment we have done testing for leser cut. For this we have design squares and write speed and power proportionally and according that we gived the speed and power for machine same we have done for scanning, This way we have tested the requirement of correct speed and power for machine.

Find my group assignment link here... Click Here

Individual Assignment

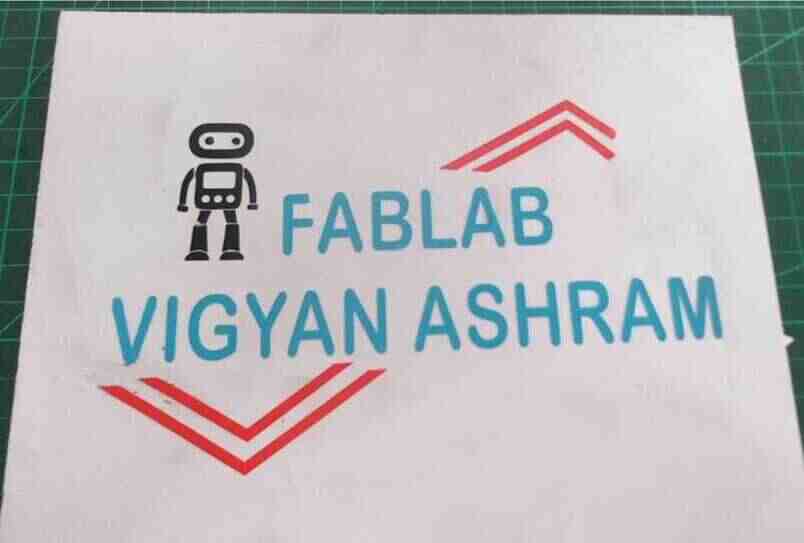

Vinyl Cutter

A vinyl cutter is a perfect introductory tool for creating signs, offering a straightforward process. It functions by precisely cutting patterns and letters from computer-designed vector files onto a vinyl roll. This vinyl is loaded into the cutter and connected to the computer using a USB or serial cable. The Vinyl Cutter at Fablab Vigyan Ashram is a Graphtec CE6000-60 Plus model.

The Graphtec CE60000-60 is a device used for cutting designs from vinyl material. It's commonly used for making signs, stickers,

and decals. Think of it like a printer, but instead of printing, it cuts shapes and letters out of vinyl sheets based on digital

designs. You can design your creations on a computer and transfer them to the vinyl cutter for precise cutting.This machine is

favored by businesses, artists, hobbyists, schools, and institutes seeking to produce custom vinyl graphics for a variety of

applications.

It's known for its accuracy, speed, and versatility in handling different types of vinyl materials.

The CE6000 series of cutting plotters offers high performance at a low cost.It includes capabilities such as sensing registration marks

and cutting perforations, making it ideal for creating labels or packaging prototypes. The Graphtec CE6000 Plus Series comes with floor stands except

for the 15" CE-6000-60 model, which has a rear media roll rack, the Cutting Master Plug-in, and Graphtec's Automatic Registration Mark

Sensor system included as standard.

Reliable Cutting Quality

Intuitive Operation

Improved Software

Graphtec ARMS

Contour Cut Pre-Printed Graphics

450g Force

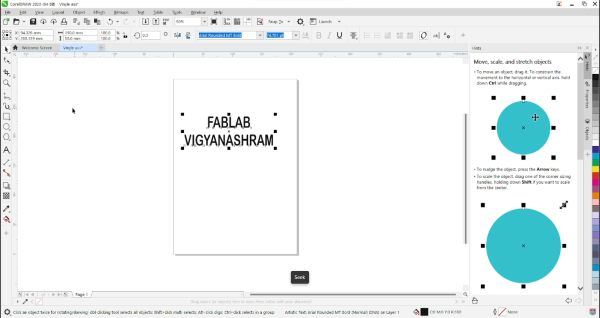

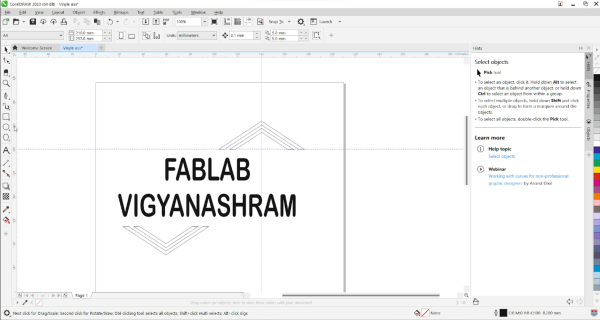

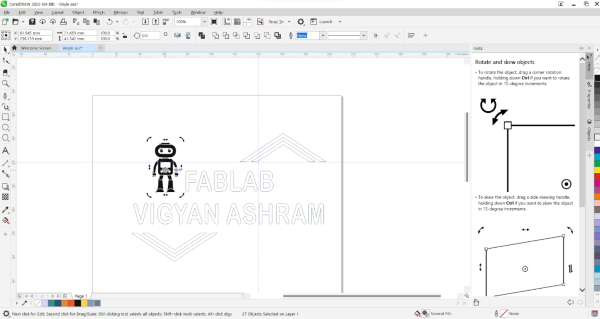

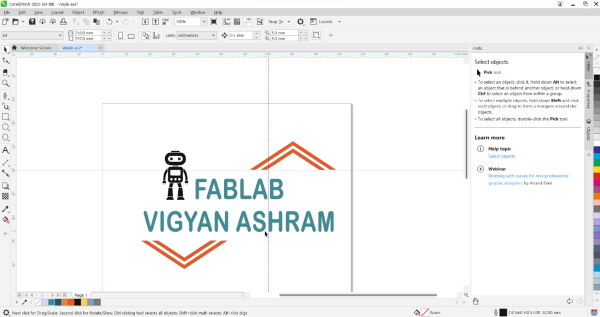

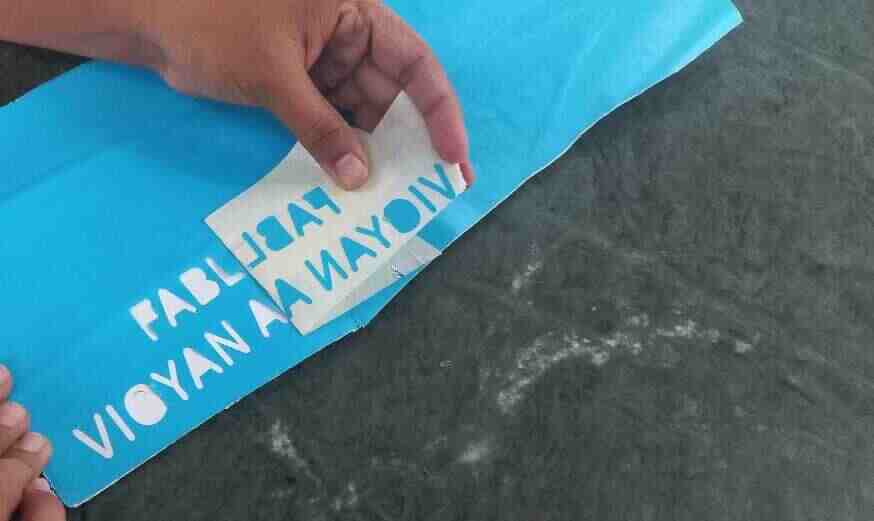

First I made design for sticker in CorelDraw.

With Graphtec Cutting Plotters, we get different accessories, but one of the most important is the cutting blade. It's like the tool that does the cutting work for different materials. There are three main types:

About Cutting Blades:-

30 deg blade is very thin material.

45 deg blade is Used for general vinyl cutter.

60 deg blade used for thick material like OFC sheet, copper sheet, mirror sheet.etc

Process to operate vinyl Cutter:

Step 1:

Switch on the machine and wait for it to initialize the settings, then push down the lever at the back to insert and load the vinyl paper.

During loading, ensure the color vinyl paper is facing upwards and the peel-off white paper is facing downwards.

Step2:

First, load the material correctly, then pull the lever to secure the paper on bed. Next, use the Arrow Keys on the control panel to move the Cutting Head and choose the starting point on the cutting area.

Step3:

using the cut command and remove the vinyl paper upon completion.

Leser Cutter

The SIL CO2 Laser Cutter is a handy machine used a lot in making things. It works by using a powerful laser beam to cut through different materials very precisely. You can use it for cutting wood, plastic, fabric, and selective non metallic material. People use it in many industries like making signs, creating prototypes, and designing jewelry. One of the cool things about it is that it can make really detailed designs. Certainly! Here’s a rephrased version: It operates using computer software, allowing you to design your desired cuts and control how the machine executes them.. But it's important to be careful when using it because lasers can be dangerous. You need to follow safety rules and make sure to take care of the machine by cleaning and checking it regularly. Overall, the SIL CO2 Laser Cutter is a useful tool for making things accurately in different fields.

SIL Laser Engraving Machine Specifications

| Feature | Description |

|---|---|

| Applications | |

| Manufacture | Optional Features: Rotary Attachment, Auto-Tracing Camera for Images, Dual Laser Heads, Quad Laser Heads, and Honeycomb Platform. |

| Laser Types |

|

| Control System | DSP based stand-alone control system for offline work with 32 MB file space & easy-to-use printer driver software. Can print directly from AutoCAD, CorelDRAW, Photoshop, etc. Features include printing real pictures, deep engraving, gradient engravings. |

| Plotting Unit | High-speed belt drive plotting unit with precise micro-stepping drives. |

| Working Table Sizes |

|

Paramatric Design

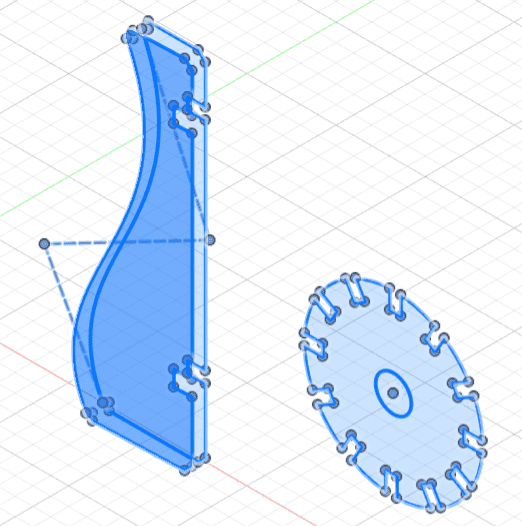

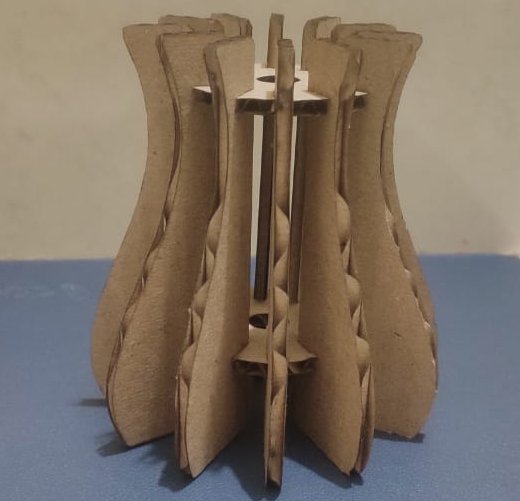

I want to design a flowerpot so I first open the fusion design software.

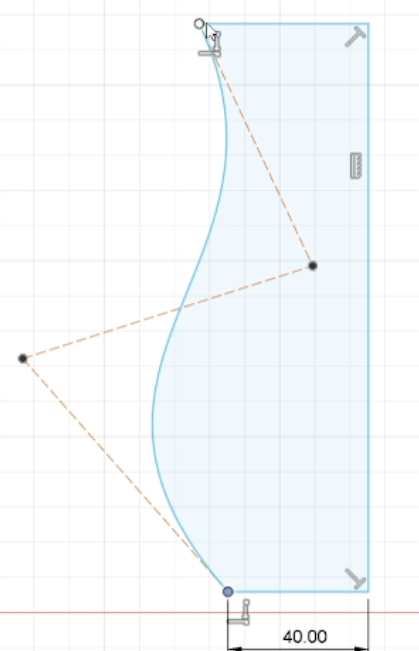

Then I made 2d design.

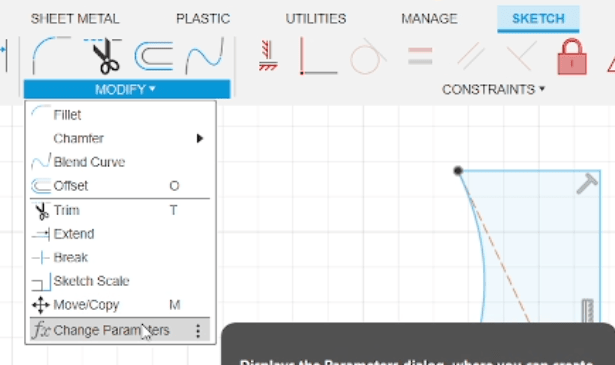

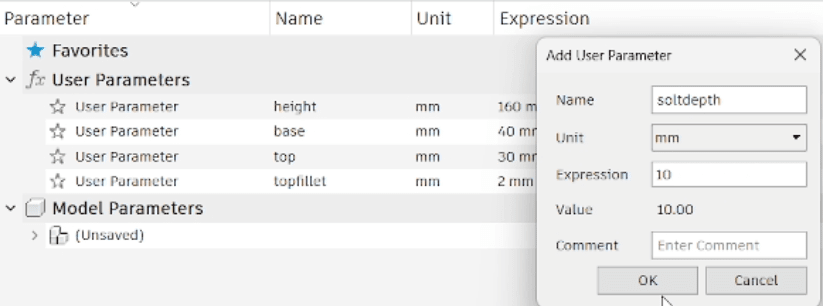

Then I go to change parameter for paramatric.

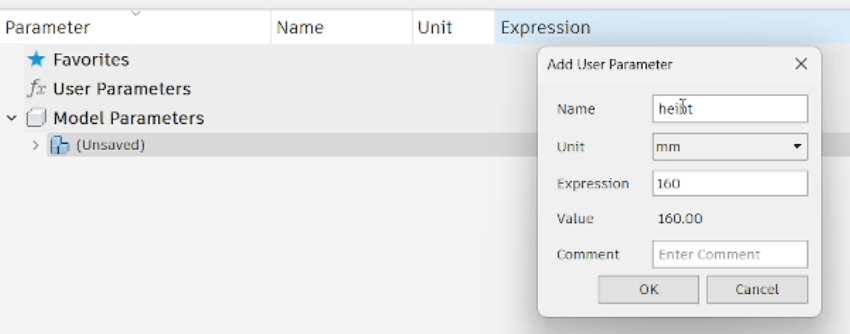

I set parameter for height.

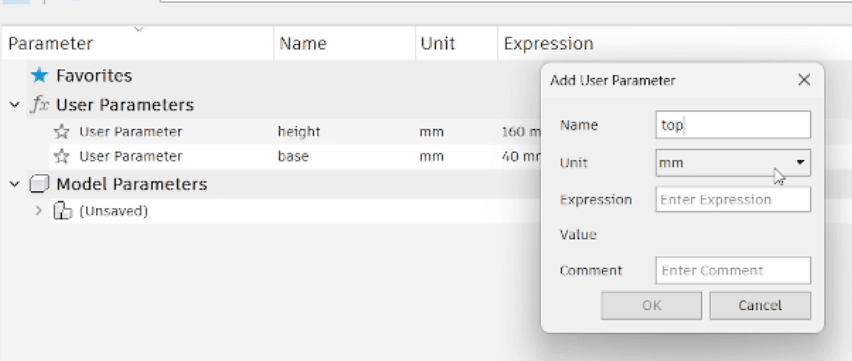

Then added parameter for top

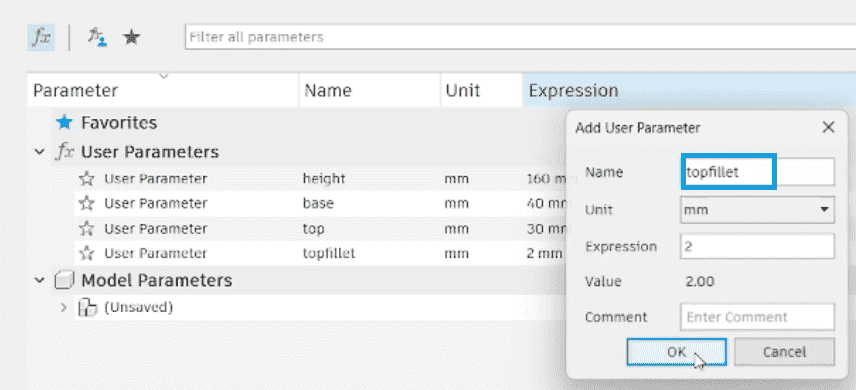

Selected the parameter for fillet.

Then I design slot and done paramatric for that dimension also.

I have done Paramatric design for object as below.

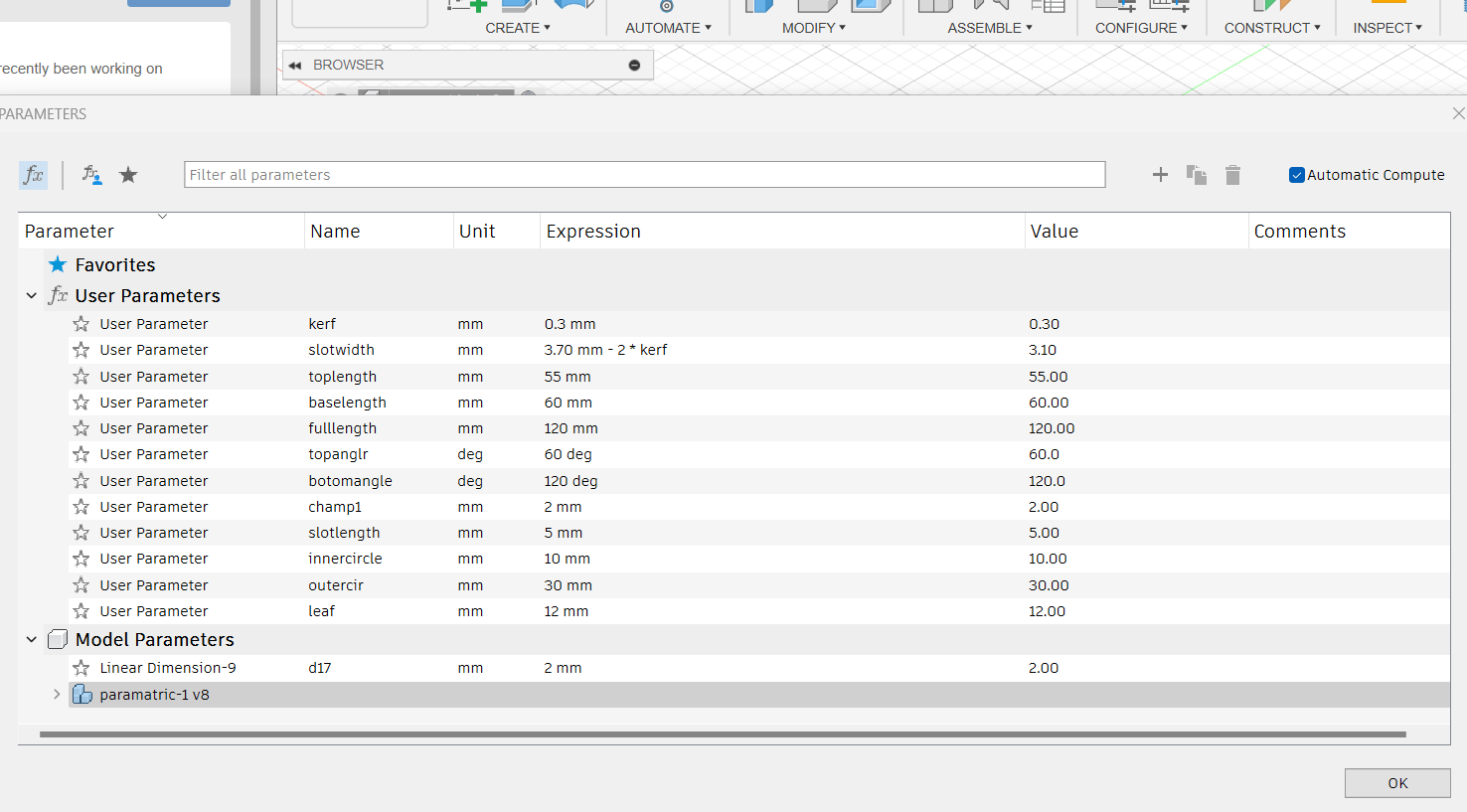

I also added and modified other dimensions for maramatric. After done with our group design we are able to understand about kerf so I done kerf calculation while designing. By considering this kerf I have design object like flowerpot.

Leser Cut

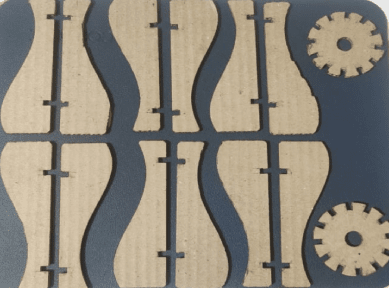

After design I save that file in dxf file format for rdworks software. Here I given the culour code for cut file and also selected speed and power for cutting. All procedure for operation of leser machine is available on Group Link

Then I done with the cutting my design..

This is my final object I have made during this assignment.

Key Learning

During this assignment I learn about paramatric design.

Also learn about the kerf calculation for our lab's leser cutting machine.

Understand the process of operation and safety for leser machine.

Also aware and operate vinyle machine by designing sticker in CorelDraw.