Applications And Implications

Individual Assignment

This assignment has the following objectives:

What will it do?

The purpose of the Shed Net automation project at Vigyan Ashram, Pune, is to automate the opening and closing of polyhouse Shadenet by using Phototransistor to monitor ambient light levels. Depending on the intensity of the light, the system activates motors to adjust the Shadenet for capsicum plants.This automated process ensures consistent light exposure, reduces the need for manual intervention, lowers labor costs, and enhances the efficiency of the cultivation environment.

What will you design?

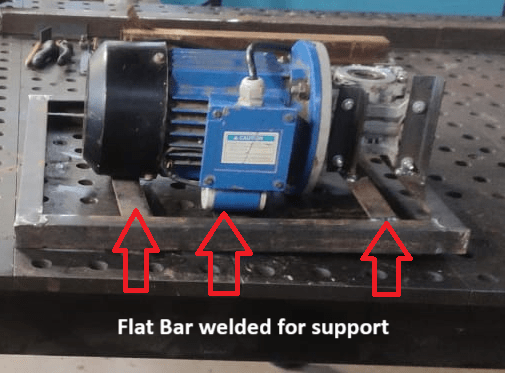

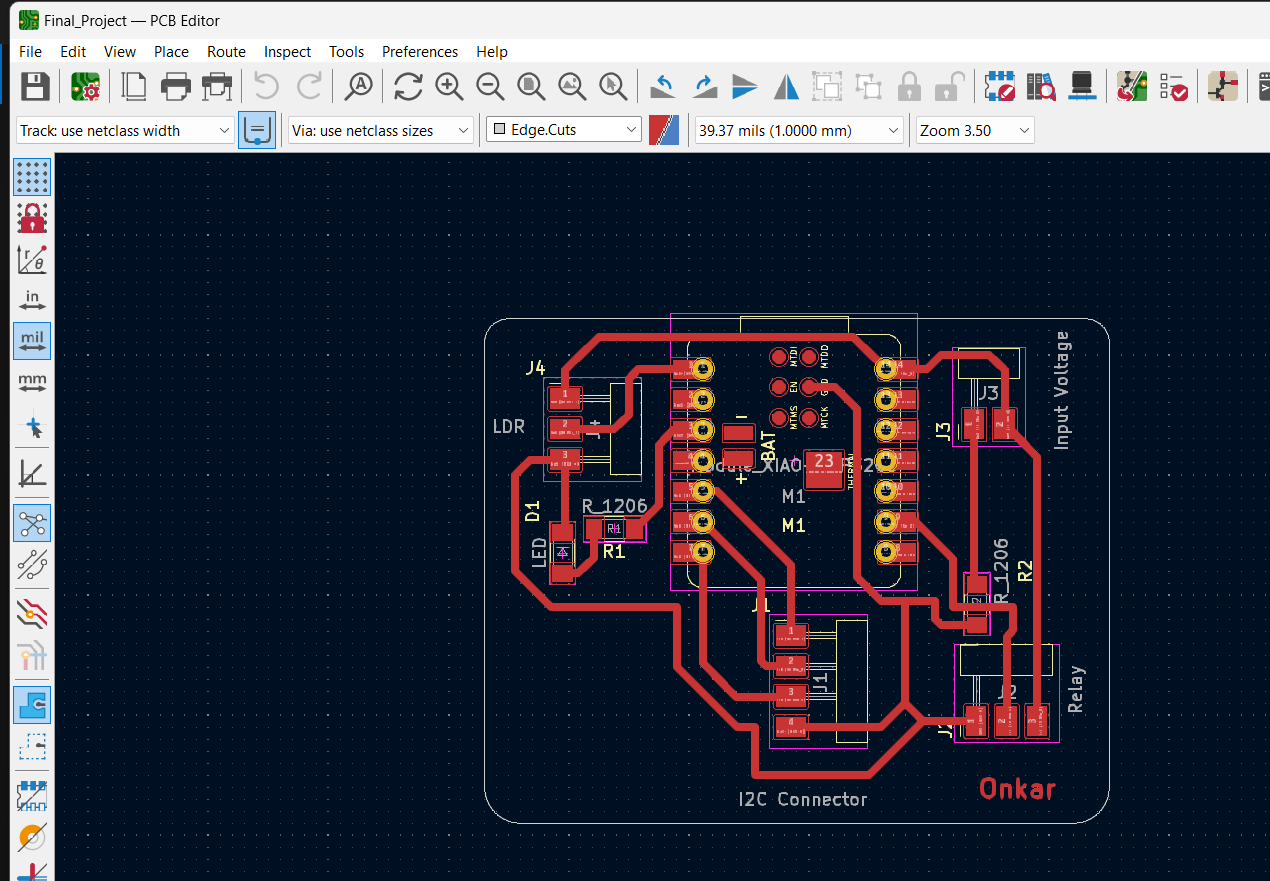

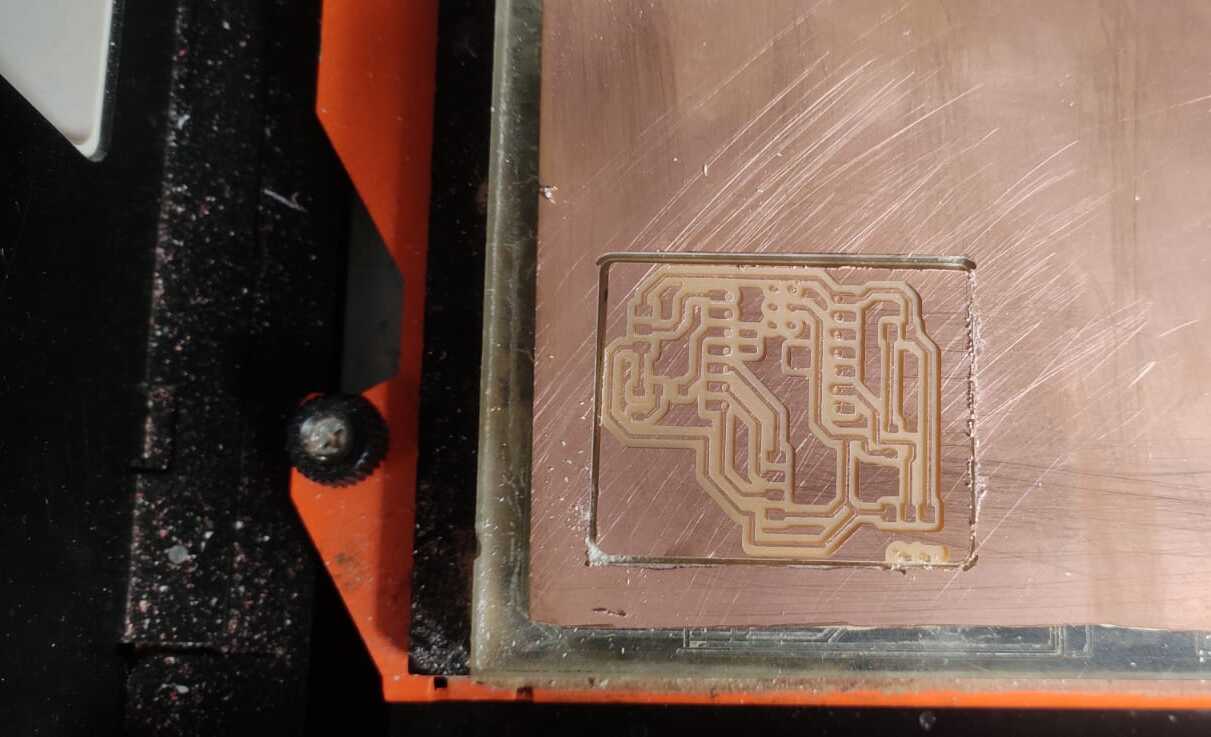

For this project, I began by configuring the induction motor to rotate in reverse and attached it to the shaft where the Shadenet are mounted. I also performed some fabrication work to ensure the motor was firmly secured. Next, I designed a microcontroller board incorporating a Phototransistor and a relay to manage shadenet movement based on light intensity. Finally, I connected the microcontroller board to the relay and motor, linked the setup to the main power supply using wires, and 3D-printed a housing to encase the board and circuit.

What materials and components will be used?

For this project, I required various electronic and electrical components, as well as some fabrication work, including 3D-printed parts, as detailed in the BOM list.

Bill of Material

| Item | Description | Price |

|---|---|---|

| Single Phase Induction Motor with Gear box | 1 Nos | Rs 5700 |

| Relay | 2 nos | Rs 450 |

| Phototransistor | 1 nos | Rs 78 |

| 3 core wire | 50 ft | Rs 836 |

| Switch Button | 1 Nos | Rs 21 |

| MS Angle 25×25×5 | 20 ft. | Rs 650 |

| MS flat Plate 30×5 mm | 4 ft. | Rs 150 |

| MS Square Tube 25×25×2 | 6 ft. | Rs 230 |

| 5V Adapter | 1 Nos | Rs 189 |

| PCB Copper Clad | 5cm×7cm | Rs 20 |

| Microcontroller | XIAO ESP32 C3 | Rs 450 |

| Nut and bolt | 8 nos | Rs 40 |

| Washer | 16 Nos | Rs 20 |

| Metal Sheet | 2 X 2 ft | Rs 180 |

Where will they come from?

Electronic components, including the ESP32C3 microcontroller, connectors, Phototransistor, relay, and copper-clad PCB, were acquired from the Fab Lab, ordered through an online platform. Hardware items such as the switch Button, 3-core wire, and plug pins were sourced from a local supplier. The motor, already in our workshop inventory, had been previously purchased from a local vendor.

How much did they cost?

The cost of all components is listed in the table above. Please refer to it for details.

What parts and systems will be made?

Established connections for a single-phase induction motor to rotate in both clockwise and counterclockwise directions.

Design and Fabricate a motor support stand.

Controller board, an integrated circuit designed to regulate the movement of the Shadenet by utilizing an Phototransistor and relay.

3D printed Box for electronics circuit.

Fabrication of Motor Stands

PCB Design and Milling

What processes will be used?

Milling to create a slot for the keyway

Welding to fabricate the motor stand

PCB milling to produce a microcontroller board

Electronic design and programming

Utilizing welding and cutting equipment to construct a table

3D printing to build an electronics enclosure

Laser cutting to make a nameplate

Plasma cutting to create a cover for the motor

What questions need to be answered?

What kind of motor is utilized to operate the opening and closing of the Shadenet?

What power options are available for the system?

What light intensity thresholds initiate the opening or closing of the curtain?

What sensors and electronic components are used for automating the Shadenet?

How does the system alert users to any faults or maintenance requirements?

How will it be evaluated?

Phototransistor Performance: How accurately the Phototransistor detects light levels and triggers the shadenet mechanism.

Speed of Operation: The speed at which the curtains open and close in response to light changes.

Environmental Changes: How well the system addresses specific challenges in the polyhouse environment, such as uneven light distribution.

User Experience: The simplicity with which users can engage with the system, whether it’s through a manual switch, a remote, or a mobile application.

Installation and Maintenance: How easy the system is to install and maintain, including replacing or repairing components